Abstract

Cadmium sulfide (CdS) nanoparticles, monopods and tripods nanostructures have been synthesized by pulsed laser ablation in methanol at various laser fluences without using surfactant. The effect of laser fluence on the optical, structural, morphological, and electrical properties of CdS nanoparticles were investigated by using UV–Vis spectroscopy, X-ray diffraction (XRD), scanning electron microscopy, atomic force microscopy, and Hall measurement. XRD patterns show that synthesised CdS nanoparticles are nanocrystalline and have hexagonal wurtzite structure. The direct optical energy gap of CdS was found to be within the range of (2.5–2.8) eV depending on the laser fluence. The electrical investigation showed that the synthesised CdS nanoparticles were n-type with mobility increased with laser fluence.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Semiconductor nanoparticles or quantum dots have recently drawn attention due to their unique physical and chemical properties. Cadmium sulfide (CdS) is a technologically useful material due to its wide band gap of 2.42 eV which makes it useful in wide range applications such as; light emitting diodes, single electro and field effect transistors [1] photosensors [2] window materials [3], solar cells [4]. CdS nanoparticles have been extensively investigated due to their strong confinement effects which resulted in remarkable variation in their optoelectronic properties with size [5]. This point could be utilized to enhance the characteristics of CdS nanoparticles used in optoelectronic devices. It has been reported that preparation of colloids nanoparticles in aqueous and non aqueous media has good control over the size, shape and size distribution through the selection of appropriate preparation conditions (controlling the nucleation and growth of nanocrystals) [5–7]. Many techniques were adopted to synthesis CdS nanoparticles e.g. wet chemical, solvothermal, microwave irradiation, sol–gel, double-hydrophophilic block copolymers, chemical growth and laser ablation in liquids [8–15]. Laser ablation of nanoparticles in liquid has attracted great interest due to its simplicity, no needs for surfactant and good control on size and shape of synthesized nanoparticles [16]. In this technique, many parameters can affect the characteristics of synthesised nanoparticles such as laser fluence, laser wavelength, pulse duration, and colloid solution type. Gong et al. have used Ti: Sapphire femtosecond laser pulses to synthesize high stability colloids CdS nanoparticles in water with size ranging from 2 to 8.6 nm [17]. In this study, we report the formation of CdS nanoparticles by Nd:YAG laser ablation of CdS target in methanol without using any surfactant. Besides; the effect of laser fluence on the nanoparticles characteristics was demonstrated and compared with reported results.

2 Experiment

Nd: YAG laser (type HUAFEI) operating at 1064 nm and 7 ns pulse duration was used together with 11 cm positive lens to ablate 99.99 % purity, 1.5 cm diameter CdS pellet. The pellet was placed at the bottom of a glass vessel; containing 5 mL of absolute methanol without the addition of any surface active substances. The ablation process was performed at normal pressure and in open air with laser energy of (100–500) mJ per pulse and 15 min ablation time.The energy of laser pulse was measured using Joule meter and calibrated to take into account the methanol attenuation. The laser beam diameter on the surface CdS pellet was measured by an optical microscope and found to be 2.37 mm. X-ray diffractometer (XRD-6000, Shimadzu) was used to investigate the structure and crystalinity of nanoparticles. Scanning electron microscope SEM (T-scan Vega III Czech) was employed to study the structure of nanoparticles. Atomic force microscope AFM (AA 3000 scanning probe microscope) was employed to study the morphology of nanoparticles. The absorption of the colloidal nanoparticles solution was measured by using UV–Vis double beam spectrophotometer (CECIL, C. 7200, France). Hall measurements were carried out using Ecoia, HMS-3000 system (van der pauw configuration) to estimate the conductivity and mobility of CdS.

3 Results and discussion

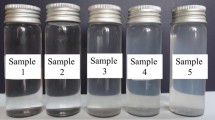

The color of fresh suspension of CdS colloidal was found to depend on the laser fluence. For CdSe NPs synthesised at low laser fluence the color was light yellow, which changed to dark yellow after increasing the laser fluence as shown in Fig. 1. This could have resulted by the variation of CdS particle size with ablation laser fluence [17].

Figure 2 displays the absorption spectra of CdS nanoparticles prepared at various laser fluences (1.76, 2.12 and 2.52) J/cm2. Figure 2 also shows that the absorption decreases from 300 to 500 nm with a remarkable peak at 470 m for CdS nanoparticles formed with 1.76 and 2.12 J/cm2 and at 500 nm for those prepared with 2.52 J/cm2. The appearance of these peaks could be due to the quantum size effect. The intensity and width of these plasmon peaks were found to be laser fluence dependent. Sedimentation of CdS after several days of ablation was observed; particularly for those synthesised at high laser fluence and this result agrees with that reported by Anikin et al. [16].

Based on absorption data, close to the fundamental absorption edge, the value of absorption coefficient α can be calculated from the following equation

where t is the thickness and T is the transmittance. The energy gap E g of CdS nanoparticles was estimated using Tauc’s relationship [18]

where A is constant and hv is the photon energy. The optical energy gap of CdS nanoparticles was determined from the plot of (αhv)2 versus hv; where the intercept of the straight line with the hv axis gives the band gap.The values of direct optical energy gap were found to be (2.5, 2.73 and 2.8) eV corresponding to laser fluences of 2.52, 2.12 and 1.76 J/cm2, respectively (see Fig. 3). These values are larger than CdS nanoparticles prepared by copper laser ablation in ethanol and acetone [17]. The increase in the value of energy gap of 0.4 eV (blue shift) for sample prepared at 1.76 J/cm2 comparing to bulk CdS energy gap 2.4 eV is due to quantum size effect [19]. The energy gap of synthesised CdS nanoparticles decreased at high laser fluence; suggesting the production of smaller CdS particles at lower laser fluence [15, 17]. The XRD patterns given in Fig. 4 confirmed that the synthesised product have pure hexagonal CdS nanocrystals according to JCPDF card no. 77-2306. Diffraction planes of (100), (002), (101), (110) and (103) corresponding to diffraction angles 2θ = 25°, 26.5°, 28.4°, 44.3°, and 48.7°, respectively were observed in the XRD pattern. The c/a ratio for all CdS nanoparticles samples was found to be larger than 1.

The crystallite size (D) was calculated using the Scherrer’s formula [20]

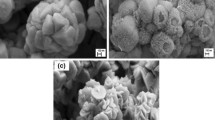

where λ is the x-ray wavelength of CuKα source (0.154056 nm), θ is the Bragg’s angle and β is the full width at half maximum (FWHM) of the diffraction peak in radians. The average hexagonal crystallite size was calculated. The values of D obtained from Scherrer’s formula are 13, 18 and 40 nm for laser fluence of 1.76, 2.12 and 2.52 J/cm2, respectively. Figure 5 shows SEM image of multi-arm nanostructured CdS prepared at various laser fluences. It is clearly seen that the morphology depends on laser fluence. A mixture of spherical nanoparticles, monopod rods, bipod rods, and tripod rods were observed (denoted by arrows). For CdS nanoparticles synthesized with 1.76 J/cm2, the average particle size was about 40 nm and agglomerated particles were noticed; as shown in Fig. 5a. When the laser fluence increased from 1.76 to 2.25 J/cm2, the nanoparticles were converted into multi-arm micro and nanostructures with arms of approximately (2.8–5.5) μm in length and (80–400) nm in diameter (Fig. 5c). The formation of these structures pointing to superior optical and electronic of nanostructured CdS [13]. Up to best of our knowledge, no such structures have been reported for nanostructured CdS prepared by laser ablation in liquid. The surface morphology of the synthesised CdS nanoparticles was investigated by using AFM analysis. Figure 6 shows 3D AFM image of CdS nanoparticles prepared at different laser fluences. The surface of the substrate is well covered with CdS nanoparticles; distributed uniformly on the surface. It is obvious from this figure that the nanoparticles prepared at 1.76 J/cm2 laser fluence (Fig. 6a) have small ordered particles with semi-spherical shape with the existence of some monopod rods. The average particle size estimated with the aid of software was about 75 nm. The value of particle size is higher than that calculated from XRD analysis. This is because XRD depends on the size-defect free volume, while AFM directly visualizes the grain without taking into account the degree of crystal defects [21].The formation of larger particles can be attributed to aggregation of small particles [22]. Higher laser fluence resulted in the formation of elongated particles indicating the presence of multi-armed structures (denoted by circle on image of Fig. 6c). The root mean square of surface roughness of CdS particles was 0.8, 1.35 and 1.5 nm for laser fluence of 1.76, 2.25 and 2.5 J/cm2, respectively.

The room temperature dark I–V characteristics of Al/CdS nanoparticles layer contact prepared with 1.76 J/cm2 without any post annealing is given in Fig. 7. It clearly shows an ohmic contact over the whole applied voltage range. Hall effect measurements which were conducted for CdS at room temperature,these measurements confirmed the n-type conductivity of the synthesised CdS nanoparticles. The increase of CdS conductivity with laser fluence (Fig. 8) is ascribed to the decrease of sulphur to cadmium ratio (formation of excess interstitial cadmium ion or sulphur vacancies-represented as donor) [23] and due to the increase of Hall mobility. Hall measurement revealed that the electron mobility of CdS increased from 5 to 28 cm2/V.s as the laser fluences increased from 1.76 to 2.5 J/cm2.This increment comes from the formation of large CdS particles at higher laser fluence and this result is consistent with SEM and XRD results and due to reduction of the structural defects.

4 Conclusion

One step synthesis of multi-pod rods and nanoparticles CdS was demonstrated and analysed by using nanosecond laser ablation of CdS target in methanol without using any surfactant. XRD and SEM investigations reveale that the nanoparticles are single-phase hexagonal structure of CdS with morphology and size controlled by laser fluence. Multi-armed CdS structures bipod rods and tripod rods were formed at high laser fluence. At laser fluence lower than 2.25 J/cm2, blue shift was observed due to quantum size effect. Depending on laser fluence, SEM observation confirmed the existence of highly agglomerated 25–90 nm CdS particles.

References

C. Rao, P. Thomas, G. Kulkarni, Nanocrystals: Synthesis, Properties and Applications (Springer, Berlin, 2007), p. 9

L. Marzān, P. Kamat, Nanoscale Materials (Kluwer, London, 2003), p. 5

L.E. Brus, J. Chem. Phys. 80, 4030 (1984)

T.D. Dzhafarov, F. Ongul, S. Aydin Yuksel, Vaccum 84, 310 (2009)

J. Uchil, M. Pattabi, J. New Mater. Electrochem. Syst. 8, 109 (2005)

A. Korgel, G. Monbouquette, J. Phys. Chem. 100, 3463 (1996)

S. Ramesh, V. Nsrayanan, Chem. Sci. Trans. 2, 192 (2013)

J. Barman, J.P. Borah, K.C. Sarma, Optoelectron. Adv. Mater. Rapid Commun. 2, 770 (2008)

M. Pattabi, B. Amma, K. Manzoor, Mater. Res. Bull. 42, 828 (2007)

V. Singh, P. Chauhan, J. Phys. Chem. Solids 70, 1074 (2009)

Y. Wada, H. Kuramoto, J.T. Tikamura, T. Sakata, H. Mori, S. Yanagida, J. Mater. Chem. 11, 1936 (2001)

N. Hullavarad, S. Hullavarad, Photonics Nanostruct. 5, 156 (2007)

C. Haibin, L. Xuemei, C. Guangda, Z. Weiwei, Y. Zhang, J. Zhong, X. Junjian, L. Yan, Cryst. Growth Des. 5, 1801 (2005)

S. Khajuria, S. Sanotra, J. Ladol, H. Sheikh, J. Mater. Sci. Mater. Electron. 26, 7073 (2015)

S. Wageh, M. Maize, J. Mater. Sci. Mater. Electron. 25, 4830 (2014)

K. Anikin, N. Melnik, A. Simakin, G. Shafeev, V. Voronov, A. Vitukhnovsky, Chem. Phys. Lett. 366, 357 (2002)

W. Gong, Z. Zheng, J. Zheng, X. Hu, W. Gao, J. Appl. Phys. 102, 64304 (2007)

J. Tauc, Mater. Res. Bull. 3, 37 (1968)

R.A. Ismail, Micro Nano Lett. 11, 951 (2011)

P. Scherrer, Gött. Nachrichten Gesell. 2, 98 (1918)

F. Somma, M. Nikl, K. Nitsch, C. Giampaolo, A. Phani, S. Santucci, Superficies y 9, 62 (1999)

Ahmed N. Abd, Nadir F. Habubi, Raid A. Ismail, J. Mater. Sci. Mater. Electron. 25, 3190 (2014)

H. Khallaf, O.I. Oladeji, G. Chai, L. Chow, Thin Solid Films 516, 7306 (2008)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abd, A.N., Ismail, R.A. & Habubi, N.F. Characterization of CdS nanoparticles prepared by laser ablation in methanol. J Mater Sci: Mater Electron 26, 9853–9858 (2015). https://doi.org/10.1007/s10854-015-3660-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-3660-5