Abstract

This letter describes a new organic (1-bromoadamantane) ultrathin film as gate dielectric, which was successfully deposited by sol–gel spin-coating process on a flexible polyimide substrate at room temperature. The metal–insulator-metal (MIM) device with organic (1-bromoadamantane) ultrathin (10 nm) film as gate dielectric layer operated at gate voltage of 5.0 V, showing a low leakage current density (5.63 × 10−10 A cm−2 at 5 V) and good capacitance (2.01 fF μm−2 at 1 MHz). The chemical structure of the 1-bromoadamantane layer was investigated by Fourier transform infrared spectrometer. The excellent leakage current density and better capacitance, probably due to the presence of polar, non-polar, low-polar groups, and bromine atoms in ultrathin film. Practical properties of the film in MIM capacitor such as dielectric constant as well as bending result of leakage current density and breakdown voltage have been better related to such fundamental adhesion nature over flexible substrate. This permits estimation of the properties of new dielectric in thin film form and short lists of the best materials for low loss and good capacitance flexible capacitors could be drawn up in future.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

There has been increasing interest in the development of electronic circuits on flexible substrates to meet the growing demand for low-cost, large-area, flexible and lightweight devices, such as roll-up displays, e-papers, connectors, and keyboards. Organic/polymer materials [1, 2] have attracted a lot of attention for building large-area, mechanically flexible electronic devices. These materials are widely pursued since they offer numerous advantages for easy-processing (e.g., spin-coating, printing, evaporation), good compatibility with a variety of substrates including flexible substrates, and great opportunity for structural modifications. Apart from the above, low dielectric constant (low-k) materials are known to decrease lower cross-talk noise, power dissipation, and, when incorporated in device systems, can dramatically decrease resistance–capacitance (RC) delays [3]. As shown in the International Technology Roadmap for Semiconductors (ITRS) guidelines, interlayer metal insulating materials need to have dielectric constants <2.4 to effectively isolate devices having sizes <100 nm [4]. Thus, much attention has been given to the research and development of new materials with low-k [5]. There is also a strong desire on the part of microelectronic industry to develop advanced, large-scale new materials that can meet the growing demand for miniaturization, high-speed performance, and flexibility. But researchers have had little success in making new low-k ultrathin films on flexible substrates at 25 °C.

Recently, numerous technologies have been developed for the preparation of thin film or crystal embedded thin film devices [6–8]. Among various methods to prepare semiconductor or insulator films, atomic layer deposition (ALD), physical vapor deposition (PVD), and chemical vapor deposition (CVD) appear to be the most useful new technologies [9–11]. However, above methods require ultrahigh vacuum condition and expensive tools. The sol–gel spin-coating method is a very efficient approach toward crack-free and smooth ceramic films in prior to thermal annealing limitation for plastic substrate [3, 12]. In addition, such films can be fabricated at room temperature and normal pressure, obviating the need for high-vacuum systems [13]. The sol–gel method can provide colloidal solvents or precursor compounds when metal halides are hydrolyzed under controlled conditions [14, 15].

In this letter, for the first time, we present an easy-to-follow synthesis procedure to prepare new organic (1-bromoadamantane) ultrathin film dielectric layer at 25 °C. Then the electrical properties of the sample have been examined for advanced flexible metal–insulator-metal (MIM) capacitor applications. The electrical insulating properties of flexible MIM device prepared employing organic (1-bromoadamantane) ultrathin film as a dielectric layer exhibited low leakage current density, and better capacitance density. Moreover, this organic (1-bromoadamantane) ultrathin film had dielectric constants less than 2.4, making them suitable candidates for use in future flexible MOS devices as a gate dielectric.

2 Experimental details

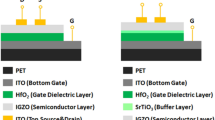

The fabrication process for the flexible MIM device is described in the following: a plastic 25 μm thick DuPont Kapton® polyimide (PI) film was used as flexible substrate for the fabrication of MIM capacitor. The PI film was cleaned ultrasonically with ethanol (Fluka; water content: <0.1 %) for 30 min and DI water and then high-pressure N2 gas was used to remove the water and any remaining particles from the PI surface. After cleaning up a PI substrate, a ~100 nm thick Cr and ~20 nm thick Au were deposited sequentially on the PI substrate by thermal coater. The Cr layer was used as the adhesion layer between the PI substrate and the Au thin film. Au was deposited for the gate electrode over the Cr coated PI substrate. To deposit 1-bromoadamante ultrathin film, a sol–gel solution was prepared by dissolving 5 gm 1-bromoadamante (99 %, Aldrich, USA) into 15 ml CHCl3 (98 %, Aldrich, USA) as the solvent. It is then stirred for 1 h with a magnetic stirrer at room temperature. To prepare ultrathin film, mixed solutions of 1-bromoadamante and CHCl3 were applied by spin coating onto PI substrate in two steps. Mixed solutions were first spread at 1,000 rpm for 20 s and then at 3,000 rpm for 30 s at room temperature using a Clean Track Model-MK8 (TEL, Japan) spin coater. At the end of the experiments, 300-nm thick Al films were pattered as the top electrode using shadow mask and a thermal coater.

The surface morphology of the organic (1-bromoadamantane) ultrathin film over PI was evaluated using field-emission scanning electron microscopy (FE-SEM, JOEL JSM-5410) and atomic force microscopy (AFM, Digital Instruments Nanoscope, D-5000) at a scan size of 1 μm × 1 μm and a scan rate of 1 Hz. We also used AFM techniques to measure the thickness of the organic (1-bromoadamantane) ultrathin film. Fourier-transform infrared (FTIR) spectra were collected with the use of KBr pellets (2 mg per 300 mg KBr) on a spectrometer (Model 580, Perkin-Elmer) with a resolution of 4.00 cm−1. Infrared spectra were recorded in the range of 3,200–600 cm−1 to determine the functional groups in molecular structure. The FTIR measurements were carried out at room temperature. To measure of the leakage currents and capacitances of the organic (1-bromoadamantane) ultrathin film was performed using an Agilent-4156 probe station and an HP-4284A C–V analyzer, respectively. The MIM configuration represents in Fig. 1a. Figure 1b shows a photograph of the flexible capacitor device on PI substrate under a large surface strain.

3 Results and discussion

The surface morphology of organic (1-bromoadamantane) ultrathin film was investigated using FE-SEM. Figure 2a displays top-view FE-SEM image of the as-deposited, sol–gel spin-coated organic (1-bromoadamantane) ultrathin film at 25 °C. As shown in Fig. 2a, well-ordered, continuous, clean, smooth, and crack-free organic (1-bromoadamantane) ultrathin film was grown successfully on PI substrate by sol–gel spin-coating. Generally, it is well know that the surface roughness of the film is another important factor affecting the performance of MOS devices. Hence, the surface morphology of organic (1-bromoadamantane) ultrathin film was further investigated by tapping mode atomic force microscope (AFM). We used tapping-mode AFM on a length scale of 1 × 1 μm to determine the surface roughness of the organic (1-bromoadamantane) ultrathin film. Figure 2b indicates the surface roughness of the film surface was ~1.54 nm. AFM image indicates that the organic (1-bromoadamantane) ultrathin film has flat, uniform surface morphologies. This is also consistent with SEM, which showed the clean, smooth, and crack-free organic ultrathin film/Au/Cr/PI. We have also used tapping-mode AFM to measure the thickness of organic (1-bromoadamantane) ultrathin film on Au/Cr/PI. In order to obtain more accurate ultrathin film thickness, first step is we need make a crack on the sample by folding and found the crack region on the AFM images. Then we can use the scan line onto a crack region to measure the thickness of organic (1-bromoadamantane) ultrathin film (Fig. 2c). The thickness of organic (1-bromoadamantane) ultrathin film was ~10 nm, as shown in Fig. 2c.

a Plane-view FE-SEM image of the organic (1-bromoadamantane) ultrathin film deposited onto flexible substrate at 25 °C, b AFM image of organic (1-bromoadamantane) ultrathin film and their plane view showing the surface roughness c AFM image of crack on organic (1-bromoadamantane) ultrathin film for determining the film thicknesses and thickness of film is shown inset of Fig. c; and d A typical FTIR spectrum of an organic (1-bromoadamantane) ultrathin film/PI

To gain the more insight about the functional groups, a Fourier Transform Infrared (FTIR) spectrometer was used to examine the functional groups of the organic (1-bromoadamanate) ultrathin film surface. The IR absorption spectrum of the organic (1-bromoadamanate) ultrathin film is shown in Fig. 2d. The spectra for the films deposited with organic (1-bromoadamanate) ultrathin film have a sharper spectral profile, which means that films have less disordered structure. As shown in Fig. 2d, a sharp peak due to the C–Br stretching mode appears at ~673 cm−1 in the absorption spectrum. Bands between 805 and 981 cm−1 are believed to be due to C–C stretching and C–C–C bending mode. While a sharp peak at 1,045 cm−1 from CC stretching and CCC bending mode can be detected in organic (1-bromoadamantane) ultrathin film. It is ambiguous to tell the origin of the 1,404, 1,493 and 1,542 cm−1 peak appeared in Fig. 2d. The strong peak at 2,850, 2,927 and 3,024 cm−1 from stretching mode for the C–H2, C–H and C=C–H bonds in new organic ultrathin film deposited by sol–gel spin-coating can also be detected. The IR spectrum (Fig. 2d) of 1-bromoadmantane ultrathin film is more consistent with that reported previously [16–20].

The organic (1-bromoadamantane) ultrathin film has exhibited excellent low leakage current density and better capacitance. The excellent low leakage current density and better capacitance can be explained by taking into account optimum polarity of the thin film due to the presence of polar, non-polar and low-polar molecules. As shown in Fig. 2d, we can see clearly the presence of C–C, C–H, C=C, and C–Br bonds in organic ultrathin film. The bromine atoms has diameter of 115 pm, which is significantly larger than hydrogen (25 pm), fluorine (50 pm) and carbon (70 pm). Consequently, bromine atoms impart higher electronic polarization [21]. In addition incorporation of bromine atoms in the films results in relatively high permittivity of the films. Thus, dielectric properties are augments. Apart from dielectric properties, better adhesive properties are also achieved by virtue of bromine atoms, which promote cross-linking [22].

Electrical characterization is undertaken to investigate the electrical insulation properties of the ultrathin film. A leakage current density–voltage measurement (J-V) is performed on the organic (1-bromoadamantane) ultrathin film to determine the leakage current characteristics and dielectric breakdown voltage. The J-V response is also used to determine the available range for high-quality C–V measurement. Figure 3a shows the leakage current density versus applied voltage characteristic of a new organic (1-bromoadamantane) ultrathin film for flexible MIM structure prepared at 25 °C. The leakage current densities of the range between 10−10–10−9 A cm−2 at ~5 V are within accepted values for low dielectric constant materials. The ultrathin film achieves consistent dielectric breakdown value of ~5 V and exhibit leakage current density below 2.43 × 10−5 prior to breakdown. The probe was moved to different points on the MIM device, gave similar results. Therefore, this implies that the organic (1-bromoadamantane) ultrathin film has excellent low leakage current (5.63 × 10−10 A cm−2 at 5 V) property on the PI substrate. Fig. 3b represents a characteristic C–V plot for an organic (1-bromoadamantane) ultrathin film which has a thickness of ~10 nm. Herein, we have measured the capacitance density for the organic (1-bromoadamantane) ultrathin film; the measured capacitance density was 2.01 fF μm−2 at 1 MHz. The better capacitance of this room temperature-deposited organic (1-bromoadamantane) ultrathin film would allow its future flexible electronic devices to be operated in the low voltage and low process temperature regime.

Furthermore, according to the capacitance and thickness data, we estimated the dielectric constant (k) of the new organic (1-bromoadamantane) ultrathin film to be ~2.3. Dielectric constant calculated from equation C i = kε 0 A/d, where k is the dielectric constant, C i is the capacitance, ε 0 is the permittivity constant, A is the capacitance area (which is different for different specific samples), and d is the insulator thickness. The dielectric strength is the direct current voltage between two electrodes at which dielectric breakdown occurs and is an indicator of how good an insulator the material i.e. 1-bromoadamantane. These results demonstrated that the 1-bromoadamantane exhibit superior insulating properties versus the corresponding neat polymers of the different thickness, and compared many other previously reported materials (Table 1) [23, 24]. Hence, the low dielectric constant value for our sol–gel derived flexible capacitor is promising candidates for interlayer metal insulators in next-generation microelectronics. However, we need further measurements of the leakage current properties after different bending conditions, convex and concave setting to confirm the feasibility for use in future flexible microelectronics.

Figure 4a shows the leakage current density for the organic (1-bromoadamantane) ultrathin film subjected to three different bending times. As shown in Fig. 4a the organic (1-bromoadamantane) ultrathin film retained its low leakage current density after different bending conditions (such as 1,000, 5,000, and 10,000 times bend). And all of the curves showed the leakage current density between 10−10–10−8 A cm−2 at applied 5 V for positive biasing conditions after bending the device up to 1,000, 5,000, and 10,000 times. This implies that the new organic ultrathin film over PI substrate exhibited superior reliability after bending the capacitor. After measuring the bending test, the breakdown voltage (V) remained the same as was prior to bending (~5 V), indicating that using the sol–gel spin-coating methods to form the organic (1-bromoadamantane) ultrathin film provides superior electrical properties and reliability for the MIM configuration. Based on the above result, we further conclude that the electrical performance of our flexible-base device is comparable to that of other devices, even after folding or bending the sample unlimitedly.

a Leakage current density plotted as a function of the voltage, measured at positive biased voltages, for the organic (1-bromoadamantane) ultrathin film flexible MIM device after being subjected to repeated bending for various times. The photograph in the inset of a shows our homemade bending instrument and the fabricated flexible capacitor under an applied strain; b and c represent convex and concave leakage current density, the photograph in the inset of b and c show the convex-and concave-shaped settings of our MIM device

In addition, we perform two additional measurements of our sol–gel-derived MIM device on a flexible PI substrate. We measured the leakage current density in both convex (Fig. 4b and concave (Fig. 4c) settings). The radii of curvature (R C ) of both convex and concave settings are 2 and 4 cm. In both cases (convex and concave settings) with R C 2 and 4 cm, we have obtained the electron leakage current density and breakdown voltage under positive biasing conditions for organic ultrathin film/PI substrate are <10−9 A cm−2 and 5 V, respectively. As shown in Figs. 4b, c, the thickness of the organic ultrathin film remained unchanged when the MIM capacitor was subjected to 2 and 4 cm concave- or convex-type conditions. Again, the sol–gel-derived organic (1-bromoadamantane) ultrathin film behaved as a very stable electrical insulator, even after bending the device at the different radii of curvature. In this way, we conclude that our result also is similar to bending condition. Thus, revealing that the organic (1-bromoadamantane) ultrathin film exhibited superior electrical performance.

4 Conclusions

In summary, we have successfully deposited the new organic (1-bromoadamantane) ultrathin film using the sol–gel spin-coating method on Au/Cr/PI substrate at 25 °C. The ultrathin film exhibited a low leakage current density of 5.63 × 10−10 A cm−2 at 5 V and a better capacitance density of 2.01 fF μm−2 at 1 MHz. The electrical behavior of organic (1-bromoadamantane) ultrathin film is tested under various bending treatment conditions revealed that our flexible device functioned independent of the bending conditions (i.e., the number of bends and the bending radii), even after bending the capacitor up to 10,000 times. Moreover, the most obvious finding emerge from this study is that organic (1-bromoadamantane) ultrathin film have low dielectric constant, low leakage current, high resistance to moisture absorption and better adhesion is obtained due to optimum polarity of the precursor material of the thin film. Thus, we firmly believe that the organic (1-bromoadamantane) ultrathin film is the leading candidate for use as a gate dielectric layer for advanced flexible MIM capacitors.

References

L. Sun, G. Qin, H. Huang, H. Zhou, N. Behdad, W. Zhou, Z. Ma, Appl. Phys. Lett. 96, 013509 (2010)

A. Facchetti, M.-H. Yoon, T.J. Marks, Gate dielectrics for organic field-effect transistors: New opportunities for. Org. Electron. 17, 1705 (2005)

D. Shamiryan, T. Abell, F. Iacopi, K. Maex, Mater. Today 7(1), 34 (2004)

The International Technology Roadmap for Semiconductors, Semiconductor Industry Association, San Francisco, CA, (2005)

Y. Xu, D.W. Zheng, Y. Tsai, K.N. Tu, B. Zhao, Q.-Z. Liu, M. Brongo, C.W. Ong, C.L. Choy, G.T.T. Sheng, C.H. Tung, J. Electron. Mater. 30, 309 (2001)

Z. Zhang, H. Deng, P. Yang, J. Mater. Sci. Mater. Electron. 22, 488 (2011)

C.-C. Wu, Y.-J. Tsai, P.-L. Liu, Y.-L. Yang, F.-H. Ko, J. Mater. Sci. : Mater. Electron. 10.1007/s10854-012-0773-y (2012)

S.-Y. Cha, H.-J. Kim, D.-J. Choi, J. Mater. Sci. 45, 5223 (2010)

G. Luka, T.A. Krajewski, B.S. Witkowski, G. Wisz, I.S. Virt, E. Guziewicz, M. Godlewski, J. Mater. Sci. Mater. Electron. 22, 1810 (2011)

Z. Li, A. Rahtu, R.G. Gordon, J. Electrochem. Soc. 153(11), C787 (2006)

J.B. Woods, D.B. Beach, C.L. Nygren, Z.-L. Xue, Chem. Vap. Depos. 11, 289 (2005)

J.N. Tiwari, J.S. Meena, C.-S. Wu, R.N. Tiwari, M.-C. Chu, F.-C. Chang, F.-H. Ko, ChemSusChem 3, 1051 (2010)

S.W. Kang, W.K. Kim, S.W. Rhee, J. Mater. Sci. 42, 652 (2007)

H.-C. You, T.-H. Hsu, F.-H. Ko, J.-W. Huang, T.-F. Lei, IEEE Electron Device Lett. 27, 644 (2006)

J.S. Meena, M.-C. Chu, S.-W. Kuo, F.-C. Chang, F.-H. Ko, Phys. Chem. Chem. Phys. 12, 2582 (2010)

L.A. Fraczyk, Y. Huang, Spectrochimica Acta Part A 57, 1061 (2001)

N. Polfer, B.G. Sartakov, J. Oomens, Chem. Phys. Lett. 400, 201 (2004)

J.O. Jensen, Spectrochim. Acta Part A 60, 1895 (2004)

L.A. Fraczyk, Y. Huang, Spectrochim. Acta Part A 57, 1061 (2001)

O. Pirali, M. Vervloet, J.E. Dahl, R.M.K. Carlson, A.G.G.M. Tielens, J. Oomens, Astrophys. J. 661, 919 (2007)

C.P. Smyth, Dielectric Behavior and Structure-Dielectric Constant and Loss Dipole Moment and Molecular Structure (McGraw Hill, New York, 1955)

T. Shirafuji, Y. Nishimura, K. Tachibana, H. Ishii, Thin Solid Films 518, 993 (2009)

D.-H. Kim, S.-H. Choi, N.G. Cho, Y.E. Chang, H.-G. Kim, J.-M. Hong, I.-D. Kim, Electrochem. Solid-State Lett. 12(8), H296 (2009)

M.-H. Yoon, H. Yan, A. Facchetti, T.J. Marks, J. Am. Chem. Soc. 127, 10388 (2005)

Acknowledgments

The authors are grateful to the National Nano Device Laboratories for their support in device fabrication and to the Ministry of Education of Taiwan for financially supporting this research under Aiming for the Top University Program.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Meena, J.S., Chu, MC., Singh, R. et al. Controlled deposition of new organic ultrathin film as a gate dielectric layer for advanced flexible capacitor devices. J Mater Sci: Mater Electron 24, 1807–1812 (2013). https://doi.org/10.1007/s10854-012-1016-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-012-1016-y