Abstract

Amorphous copper cobalt carbonate hydroxide (CuCoCH) was prepared on copper foam (CF) by successive ionic layer adsorption and reaction (SILAR) method for non-enzymatic glucose sensing. The binder-free approach facilitates the transfer of electrons in the CuCoCH/CF electrode, its hierarchical porous network structure promotes the diffusion of glucose and its large surface area provides abundant catalytic sites for electrocatalysis oxidation of glucose. Moreover, the easily controllable Cu/Co ratio and the synergistic effect of copper and cobalt in CuCoCH increase the electrocatalytic activity for glucose oxidation. As a result, the CuCoCH/CF electrode exhibits a linear range of 0.005–3.47 mM, a sensitivity of 1.5167 mA·mM−1·cm−2 and a detection limit of 2.3 μM (S/N = 3) for glucose detection. Meanwhile, it also demonstrates satisfactory selectivity, reproducibility, stability and practical applicability, indicating the CuCoCH/CF electrode prepared by this facile method is promising in non-enzymatic glucose sensing.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

As a common chronic disease worldwide, diabetes causes physical disability like stroke, kidney failure, heart disease, etc. and even death [1, 2]. The content of glucose in blood is an indicator for clinical diagnosis and monitoring of diabetes. In order to control the disease, it is very important for diabetics to detect changes in blood glucose concentration multiple times a day. Therefore, it is of great significance to develop an efficient and reliable glucose sensor. Most of the commercially available glucose meters are glucose oxidase (GOD) enzyme-based electrochemical sensors [3]. Despite its excellent selectivity, this enzyme has the drawbacks of high cost, complicated immobilization process and chemical instability [4]. Therefore, researchers have tried to prepare enzyme-free glucose electrochemical sensors with various materials including noble metals [5,6,7], transition metals and their compounds [8,9,10], conductive polymers [11], carbon [12, 13] and composites of above materials [14,15,16].

Among them, transition metals have been widely studied due to their high electrocatalytic activity, high electroactivity, low cost and environmental friendliness. Copper, cobalt and nickel are commonly used transition metal nanozymes for glucose sensors, including their metals and alloys [17,18,19], oxides [20,21,22,23], hydroxides [24,25,26,27], sulphides [28,29,30,31], etc. Different types of transition metal nanozymes have different properties such as conductivity, catalytic activity and sensitivity, which lead to their different performance in sensors. For example, the oxides have received extensive attention due to their high catalytic activity, while sulphides can obtain high sensitivity [30]. Therefore, it is of great significance to develop new types of transition metal-based non-enzymatic glucose sensors. The using of bimetallic nanozymes is an efficient strategy to improve the sensing performance of nanozymes and various bimetallic nanozymes were designed [32,33,34]. For instance, Li et al. prepared MCo (M=Cu, Fe, Ni and Mn) bimetallic nanoparticle-doped carbon nanofibers (MCo–CFs) for non-enzymatic glucose detection. The large surface area of CuCo–CFs and synergistic effect of the CoIII/IV and CuII/III redox make CuCo–CFs the best catalytic activity with a large sensitivity of 507 μA·cm−2·mM−1 and a wide linear range of 0.02–11 mM [35].

In recent years, bimetallic carbonate hydroxides have been used in the field of electrochemistry such as supercapacitors, water splitting due to their rich redox reaction, favourable synergistic effects and superior electrochemical stability [36,37,38]. Despite their excellent electrochemical properties, bimetallic carbonate hydroxides are rarely used in electrochemical sensors. Zhao et al. prepared a layer of cobalt copper carbonate hydroxide nanowires (CCCH) with a large specific surface on copper foam (CF) by hydrothermal method to increase the loading of NiCo layered double metal hydroxide (NiCo-LDH), which formed a NiCo-LDH/CCCH/CF structure for enzyme-free glucose detection and exhibited high sensitivity of 10.78 μA·μM−1·cm−2, large linear concentration range of 0.001–1.5 mM and fast response–recovery time of 2.0 s [39].

To study the catalytic effect of bimetallic carbonate hydroxides on glucose oxidation, we prepared copper cobalt carbonate hydroxide (CuCoCH) on copper foam by SILAR for non-enzymatic glucose sensing. In the SILAR process, a substrate is immersed in one precursor solution to adsorb the ions; after removing the excess ions, the substrate is immersed in the other precursor solution, and ions of opposite charge are adsorbed and react to obtain the target product on the substrate. Different substrates have obvious effects on the performance of electrochemical sensors [9]. Copper foam (CF) was used as a substrate for electrochemical sensors because of its good electrical conductivity, large specific surface area and good supporting properties [39]. In the SILAR process, the large specific surface area and rough surface of copper foam can increase the adsorption capacity of ions. At the same time, the in situ preparation can make good contact between the material (CuCoCH) and the substrate (CF), which is conducive to the transfer of electrons. Most importantly, the ratio of Cu/Co can be easily tuned and the synergistic effect of copper and cobalt can increase the electrocatalytic activity of CuCoCH towards glucose oxidation. Therefore, this facile prepared CuCoCH/CF electrode is expected to show good sensing performance for glucose detection.

Experimental

Reagents and materials

NaOH, Na2CO3, CoSO4·7H2O, CuSO4·5H2O and L-ascorbic acid (AA) were provided by Tianjin Fuchen reagent Co. Ltd. D-(+)-Glucose and L-cysteine (L-cys) were obtained from Shanghai Yuanye Bio-technology Co., Ltd. Dopamine hydrochloride (DA) and uric acid (UA) were purchased from Sigma-Aldrich. Acetone, ethanol and methanol were bought from Sinopharm Chemical Reagent Co., Ltd. All chemicals were of analytical grade and used as received without further dispose. Copper foam (δ = 1.0 mm, 90 ppi) was provided by Yiyang Formmetal new material Co., Ltd. Deionized water was produced by a Millipore ultrapure water system. The simulated human serum was purchased from Acmec Biochemical Company.

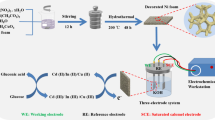

Preparation of CuCoCH/CF electrode

Copper foam with the area of 1.2 × 0.8 cm2 was sonicated with acetone, deionized water and absolute ethanol sequentially and dried in air. SILAR method was used to prepare CuCoCH/CF electrode. As shown in Scheme 1, copper foam was immersed in a mixed solution of 0.2 M CuSO4–CoSO4 (Cu/Co molar ratio: 1:3) for 1 min, which was then was then rinsed with deionized water to remove the excess irons and immersed in a solution of 0.2 M Na2CO3 for another 1 min. After that, it was washed with deionized water and dried at 50 °C for 20 min to obtain the CuCoCH/CF electrode. The proposed reaction scheme of the formation of CuCoCH material is shown in Scheme 2. A mixed solvent of water and methanol (Vwater/Vmethanol = 4:1) was used for the two solutions in order to enhance the hydrophilicity of copper foam. For comparison, bare copper foam (CF) was used as electrode after cleaning.

Characteristics

The morphology of CuCoCH was observed by Hitachi model SU 8020 UHR field emission scanning electron microscope (FESEM) (Japan), and the element composition analysis was performed by the equipped energy-dispersive X-ray spectroscopy (EDS). The ESCALAB 250Xi (Thermo Fisher Scientific, USA) was used to conduct X-ray photoelectron spectroscopy (XPS) test with a monochromatized Al Ka line source. The Fourier transform infrared (FTIR) spectroscopy of the CuCoCH sample was tested on a FTIR-8400S (Shimazu, Japan) spectrometer.

Electrochemical measures

The electrochemical measurements were taken on a CHI 660E electrochemical workstation (Chenhua Inc., China) with a three-electrode system. The CuCoCH/CF electrode (active area of 0.8 cm2), Pt wire and Ag/AgCl electrode were used as the working electrode, the counter electrode and the reference electrode, respectively. NaOH (0.1 M) was used as the electrolyte. For EIS measurements, the electrolyte was 1 M KOH. The EIS measurements were taken under open-circuit potential with the frequency range from 0.01 to 100 kHz at an amplitude of 5 mV.

Results and discussions

Structure and morphology analyses

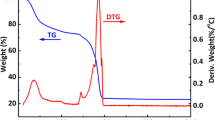

The CuCoCH/CF electrode was characterized by SEM, EDS and FTIR, and the results are shown in Fig. 1. From the SEM image shown in Fig. 1a, the amorphous CuCoCH has a hierarchical porous network structure, which is composed of many nanoflowers about 100–200 nm in size. These nanoflowers are connected to each other, forming many large pores that are favourable for glucose diffusion and electrolyte infiltration, which facilitates the transfer of electrons in the CuCoCH/CF electrode. Figure 1b shows that there are a large number of smaller nanoparticles on the surface of the nanoflowers, which can increase the specific surface area of the material, thereby increasing the electrocatalytic active sites of the electrode. Elemental scan analysis was performed on the CuCoCH sample (Fig. 1c). The EDS is shown in Fig. 1d, indicating the existence of Cu, Co, C and O, and the atomic ratio of Cu to Co was estimated to be 2.5:1. From the elemental mapping shown in Fig. 1e, the four elements distributed homogeneously, revealing the uniform structure of the electrode. The CuCoCH sample was also characterized by the FTIR spectrum over the range of 4000–400 cm−1. As shown in Fig. 1f, the broad peak centred at approximately 3325 cm−1 can be ascribed to the stretching vibration of O–H. The two peaks at 1517,1409 cm−1 are assigned to the stretching vibrations of vOCO2 and the asymmetrical stretching vibration of CO3−2, respectively. The ownership of the peak at 1055 cm−1 remains controversial. It was considered as the symmetrical stretching vibration of CO3−2 [40] or assigned to metal–OH bond [41]. The peaks at 872 and 748 cm−1 are due to the in-plane and out-of-plane bending vibration of CO32−. The band below 600 cm−1 are associated with metal–oxygen bonds. Our results are similar to previous report [40], indicating the formation of CuCoCH.

The chemical states of the CuCoCH sample were investigated by X-ray photoelectron spectroscopy (XPS) and are shown in Fig. 2. Figure 2a shows a full survey of the CuCoCH sample, indicating the existence of Co, Cu, C and O elements in the sample. Figure 2b shows that the peaks corresponding to C 1 s are located at 284.9 eV and 288.4 eV. The former corresponds to the C=C originates from carbon contamination in the test, and the latter corresponds to the C-O in the sample [42]. Figure 2c shows the peak of O1s at 531.2 eV which can be ascribed to hydroxyl group (O–H) [43]. According to Fig. 2d, the peaks at 936.0 eV (Cu2p3/2) and 956.0 eV (Cu2p1/2) correspond to Cu2+ [34, 40, 44], and the peaks at 943.7 eV and 963.5 eV are satellite peaks. From Fig. 2e, the peaks at 781.8 eV (Co2p3/2) and 797.7 eV (Co2p1/2) correspond to Co2+ [34, 40, 44], and the peaks at 787.0 eV and 802.9 eV are satellite peaks.

Electrochemical characterization of CuCoCH/CF electrode

The electrochemical behaviours of CF and CuCoCH/CF electrodes in 0.1 M NaOH with or without 0.5 mM glucose were investigated by cyclic voltammetry. As shown in Fig. 3a, the oxidation peak of CuCoCH/CF electrode towards glucose is significantly larger than that of CF. It also shows the current responses around 0.4–0.6 V of CuCoCH/CF electrode increase obviously with the addition of glucose compared those without glucose, indicating the electrode has good electrocatalytic activity for glucose. Figure 3b shows the CV curves of CuCoCH/CF electrode towards various concentration of glucose, the current responses increases gradually and linearly with the increased concentration of glucose in the range of 0 to 3 mM (shown in the inset of Fig. 3b), revealing its high sensitivity to glucose content, which could be attributed to the synergistic effect produced by the copper–cobalt bimetallic material. The mechanism of the electrocatalytic reaction between CuCoCH/CF and glucose on the electrode surface is speculated as follows: Co2+ was first oxidized to Co3+ (Eq. (1)), then Cu2+ was oxidized to Cu3+ (Eq. (2)) and Co3+ was oxidized to Co4+ (Eq. (3)), which finally oxidized the glucose into gluconolactone at about 0.5 V (Eq. (4) and (5))[35, 45].

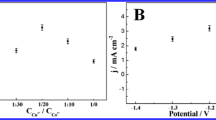

The electrochemical performance of CuCoCH/CF electrode was further investigated by EIS. Figure 3c shows the Nyquist plots of bare CF and CuCoCH/CF electrodes. The value of charge transfer resistance (Rct) at the surface of the electrode can be obtained from the diameter of the semicircle in high frequency region of EIS plot [43]. From Fig. 3c, a small semicircle of bare CF electrode was observed, and the semicircle of CuCoCH/CF electrode was only slightly larger than that of bare CF electrode due to the coating of CuCoCH, implying the Rct of CuCoCH/CF electrode was small and close to that of bare CF electrode, which reveals its good conductivity and fast electron transfer ability. The ratio of Cu to Co had obviously influence on the catalytic activity of CuCoCH/CF electrode. The CV curves of CuCoCH/CF electrodes with different Cu/Co feed ratios (Fig S1) showed that the electrode with the Cu/Co feed ratio of 1:3 exhibited high electrocatalytic activity and obvious oxidation peak for glucose oxidation. As cobalt-based material showed higher current responses than copper-based material towards glucose oxidation, with the increase in the cobalt content, the current responses increased; with further increase in the cobalt content, the CV curve showed the characteristic of cobalt with two pairs of redox peaks of CoII/III and CoIII/IV and the oxidation peak at about 0.5 V became less obvious. Therefore, the Cu/Co feed ratio of 1:3 was used in subsequent experiments.

The kinetic control mechanism of a sensor can be investigated by cyclic voltammeter (CV) measurement under different scan rate. The CV curves of CuCoCH/CF electrode with different scan rate are shown in Fig. 4a. The redox peaks at about 0.5 V increase with the increase of scan rate. It was also observed that the other pair of redox peaks at about 0.2 V become apparent with the increase of scan rate, further verified the existence of two pairs of redox peaks of cobalt. From Fig. 4b, the oxidation and reduction peak currents show good linear relationship with the square root of the scan rate in the range of 20–120 mV/s, implying a diffusion-controlled process in the redox reaction.

Detection performance of the as-prepared sensor

In order to test the linear range of the as-prepared CuCoCH/CF electrode for glucose detection, amperometric measurement was taken by successive addition of glucose into 0.1 M NaOH at a potential of 0.6 V. The amperometric responses of the electrode is shown in Fig. 5a. The corresponding linear relationship between the response current and the glucose concentration is shown in Fig. 5b. The CuCoCH/CF electrode exhibits good linearity in the range of 0.005–3.47 mM. The linear equation is: y = 1.51664x + 0.05339 (R2 = 0.993), the sensitivity is 1.517 mA·mM−1·cm−2, and the detection limit is 2.3 μM. The sensing performances of CuCoCH/CF-based sensor were compared with some reported CuCo bimetallic material-based non-enzymatic glucose sensors and are listed in Table 1. In general, the sensitivity and linear range is similar or better than the reported results, and the detection limit is similar or lower than the reported results, demonstrating the as-prepared CuCoCH/CF sensor exhibited a good sensing performance.

Selectivity, reproducibility and stability of the as-prepared sensor

Selectivity is of great importance in glucose detection for practical application. The common interfering species existing in human blood serum, such as uric acid, ascorbic acid, dopamine and cysteine, were studied in the glucose detection process. As the glucose concentration in normal human blood is almost ten times higher than interfering species, the selectivity of CuCoCH/CF-based sensor was evaluated by comparing the current responses of 100 μM glucose and 10 μM of UA, AA, DA and cysteine in 0.1 M NaOH. As shown in Fig. 6a, 100 μM glucose produces a remarkable current response, while the successive addition of 10 μM interferents produced no evident response, after the final addition of glucose, the current response increased obviously again and was almost the same as before, implying that CuCoCH/CF-based sensor has good selectivity towards glucose.

In order to evaluate the reproducibility, amperometric responses of five independent CuCoCH/CF electrodes were measured towards 0.5 M glucose under the same condition. From Fig S2, the current responses were almost the same and the calculated relative standard deviation (RSD) was 4.1%, implying the excellent reproducibility of the as-prepared electrodes. In addition, the stability of the sensors was investigated by storing CuCoCH/CF electrodes in a refrigerator at 4 °C and then examining amperometric responses towards 1 M glucose every 5 days. As shown in Fig. 6b, the CuCoCH/CF electrodes still retained 88% of the initial current after 25 days, indicating their good stability.

Real sample analysis

To verify the feasibility of the developed glucose sensor, the performance of CuCoCH/CF-based sensor was test in simulated human serum sample. The simulated serum (20 μL) was added into 0.1 M NaOH (20 mL) and different standard glucose solution was added to the diluted serum sample and the recovery of glucose was calculated. As shown in Table S1, the relative standard deviations (RSDs) were less than 5% and the recovery was in range of 98–103%, demonstrating the CuCoCH/CF-based sensor is feasible and reliable in the detection of glucose lever in actual samples.

Conclusion

In conclusion, CuCoCH was prepared on copper foam by SILAR method and its morphology, structure and electrochemical properties were characterized. The in situ preparation, the good conductivity of the electrode, the hierarchical porous network structure, the large surface area and the synergistic effect of copper and cobalt in CuCoCH increased the electrocatalytic activity and facilitated electron transfer for glucose oxidation. Therefore, the CuCoCH/CF electrode had good electrocatalytic activity for glucose detection in 0.1 M NaOH, which exhibited good performances such as a linear range of 0.005–3.47 mM, a sensitivity of 1.5167 mA·mM−1·cm−2 and a detection limit of 2.3 μM. The sensor had good selectivity, reproducibility and stability. It also showed its feasibility in the detection of real samples. The preparation method of CuCoCH/CF electrode is simple, fast and easily controllable, and can be extended to other metal compound-based non-enzymatic glucose sensors.

Data and code availability

All data generated or used during the study are available from the corresponding author by request.

References

Steppan CM, Bailey ST, Bhat S, Brown EJ, Banerjee RR, Wright CM, Patel HR, Ahima RS, Lazar MA (2001) The hormone resist in links obesity to diabetes. Nature 409:307–312. https://doi.org/10.1038/35053000

Lee I, Loew N, Tsugaw W, Ikebukuro K, SodeK, (2019) Development of a third-generation glucose sensor based on the open circuit potential for continuous glucose monitoring. Biosens Bioelectron 124:216–223. https://doi.org/10.1016/j.bios.2018.09.099

Bauer JA, Zámocká M, Majtán J, Bauerová-Hlinková V (2022) Glucose oxidase, an enzyme “Ferrari”: its structure, function, production and properties in the light of various industrial and biotechnological applications. Biomolecules 12:472. https://doi.org/10.3390/biom12030472

Yan X, Gu Y, Li C, Zheng B, Li Y, Zhang T, Zhang Z, Yang M (2019) Non-enzymatic glucose sensor based on the CuS nanoflakes–reduced graphene oxide nanocomposite. Anal methods 10:381–388. https://doi.org/10.1039/C7AY02290E

Ma D, Tang X, Guo M, Lu H, Xu X (2015) Fabrication and characterization of non-enzymatic glucose sensor based on bimetallic hollow Ag/Pt nanoparticles prepared by galvanic replacement reaction. Ionics 21:1417–1426. https://doi.org/10.1007/s11581-014-1290-1

Shim K, Lee WC, Park MS, Shahabuddin M, Yamauchi Y, Hossain MSA, Shim YB, Kim JH (2019) Au decorated core-shell structured Au@Pt for the glucose oxidation reaction. Sens Actuators B Chem 278:88–96. https://doi.org/10.1016/j.snb.2018.09.048

Li J, Yan L, Wang H, Wang H, Chen X, Wang L, Wu M (2017) Au NPs/ITO prepared by dopamine reduction and its application in glucose sensing. J Mater Sci Mater Electron 28:3067–3074. https://doi.org/10.1007/s10854-016-5894-2

ShervedaniRK KM, Amini A (2014) Prickly nickel nanowires grown on Cu substrate as a supersensitive enzyme-free electrochemical glucose sensor. Sens Actuators B Chem 204:783–790. https://doi.org/10.1016/j.snb.2014.08.033

Fallatah A, Almomtan M, Padalkar S (2019) Cerium oxide based glucose biosensors: influence of morphology and underlying substrate on biosensor performance. ACS Sustain Chem Eng 7:8083–8089. https://doi.org/10.1021/acssuschemeng.8b02286

Wang Q, Chen Y, Zhu R, Luo M, Zou Z, Yu H, Jiang X, Xiong X (2020) One-step synthesis of Co(OH)F nanoflower based on micro-plasma: as an effective non-enzymatic glucose sensor. Sens Actuators B Chem 304:127282. https://doi.org/10.1016/j.snb.2019.127282

Huang PC, Shen MY, Yu HH, Wei SC, Luo SC (2018) Surface engineering of phenylboronic acid-functionalized poly(3,4-ethylenedioxythiophene) for fast responsive and sensitive glucose monitoring. ACS Appl Bio Mater 1:160–167. https://doi.org/10.1021/acsabm.8b00060

Quintero-Jaime AF, Quílez-Bermejo J, Cazorla-Amorós D, Morallón E (2021) Metal free electrochemical glucose biosensor based on N-doped porous carbon material. Electrochim Acta 367:137434. https://doi.org/10.1016/j.electacta.2020.137434

Rahsepar M, Foroughi F, Kim H (2019) A new enzyme-free biosensor based on nitrogen-doped graphene with high sensing performance for electrochemical detection of glucose at biological pH value. Sens Actuators B Chem 282:322–330. https://doi.org/10.1016/j.snb.2018.11.078

Prasad R, Bhat BR (2015) Multi-wall carbon nanotube–NiO nanoparticle composite as enzyme-free electrochemical glucose sensor. Sens Actuators B Chem 220:81–90. https://doi.org/10.1016/j.snb.2015.05.065

Ejaz A, Jeon S (2017) Synthesis and application of electrochemically reduced N–rGO–Co(OH)2 nanocomposite for concurrent detection of biomolecules. Electrochim Acta 235:709–719. https://doi.org/10.1016/j.electacta.2017.03.036

Duan X, Liu K, Xu Y, Yuan M, Gao T, Wang J (2019) Nonenzymatic electrochemical glucose biosensor constructed by NiCo2O4@ Ppy nanowires on nickel foam substrate. Sens Actuators B Chem 292:121–128. https://doi.org/10.1016/j.snb.2019.04.107

Qiu R, Zhang XL, Qiao R, Li Y, Kim YI, KangYS, (2007) CuNi dendritic material:synthesis, mechanism discussion, and application as glucose sensor. Chem Mater 19:4174–4180. https://doi.org/10.1021/cm070638a

Noh HB, Lee KS, Chandra P, Won MS, Shim YB (2012) Application of a Cu–Co alloy dendrite on glucose and hydrogen peroxide sensors. Electrochim Acta 61:36–43. https://doi.org/10.1016/j.electacta.2011.11.066

Suneesh PV,VargisVS, RamachandranT, Nair BG, Babu TGS (2015) Co–Cu alloy nanoparticles decorated TiO2 nanotube arrays for highly sensitive and selective nonenzymatic sensing of glucose. Sens Actuators B Chem 215: 337–344 https://doi.org/10.1016/j.snb.2015.03.073

Sedaghat S, PiepenburgCR ZA, Qi Z, Peana S, Wang H, Rahimi R (2020) Laser-induced mesoporous nickel oxide as a highly sensitive nonenzymatic glucose densor. ACS Appl Nano Mater 3:5260–5270. https://doi.org/10.1021/acsanm.0c00659

Khan AY, Bandyopadhyaya R (2021) Highly sensitive non-enzymatic glucose sensor with copper oxide nanoparticle impregnated mesoporous silica. J Porous Mater 28:1097–1104. https://doi.org/10.1007/s10934-021-01064-6

Liu W, Chai G, Zhao X, Dai Y, Qi Y (2020) Effect of different copper sources on the morphology of cuprous oxide and its application as a non-enzymatic glucose sensor. Sens Actuators B Chem 321:128485. https://doi.org/10.1016/j.snb.2020.128485

Zhou Q, Zhang Y, Zeng T, Wan Q, Yang N (2021) Morphology-dependent sensing performance of CuO nanomaterials. Anal Chim Acta 1171:338663. https://doi.org/10.1016/j.aca.2021.338663

Tao Y, Liu Q, ChangQ DJ, Tao Z, Guan H, Chen G, Mao Y, Xie J, Dong C (2019) In situ fabrication of Co(OH)2 by hydrothermal treating Co foil in MOH (M ¼ H, Li, Na, K) for non-enzymatic glucose detection. J Alloy Compd 781:1033–1039. https://doi.org/10.1016/j.jallcom.2018.12.148

Wang S, Zhang L, Tian Y, Lin L, Zhuiykov S (2019) Fabrication of Ni(OH)2&NiOOH film/Ni electrode and the effect of NaOH concentration on its glucose detection. J Electrochem Soc 166:B1732–B1741. https://doi.org/10.1149/2.0721916jes

Zhe T, Sun X, Liu Y, Wang Q, Li F, Bu T, Jia P, Lu Q, Wang J, Wang L (2019) An integrated anode based on porous Ni/Cu(OH)2 nanospheres for nonenzymatic glucose sensing. Microchem J 151:104197. https://doi.org/10.1016/j.microc.2019.104197

Shi N, Sun S, Zhang B, Du Q, Liao Y, Liao X, Yin G, Huang Z, Pu X, Chen X (2020) Co(OH)2 nanosheets decorated Cu(OH)2 nanorods for highly sensitive nonenzymatic detection of glucose. Nanotechnology 31:325502. https://doi.org/10.1088/1361-6528/ab8c77

HuangW LF, Huang Y, YangW PJ (2021) Facile one-pot synthesis of hollow-structured CuS/Cu2S hybrid for enhanced electrochemical determination of glucose. Electrochemistry 89:340–347. https://doi.org/10.5796/electrochemistry.21-00027

Vilian ATE, Hwang SK, Ranjith KS, Cho Y, Huh YS, Han YK (2021) A facile method for the fabrication of hierarchically structured Ni2CoS4 nanopetals on carbon nanofibers to enhance non-enzymatic glucose oxidation. Microchim Acta 188:106. https://doi.org/10.1007/s00604-021-04749-6

Kim WB, Lee SH, Cho M, Lee Y (2017) Facile and cost-effective CuS dendrite electrode for non-enzymatic glucose sensor. Sens Actuators B Chem 249:161–167. https://doi.org/10.1016/j.snb.2017.04.089

Keerthi M, Mutharani B, Chen SM, Ranganathan P (2019) Carbon fibers coated with urchin-like copper sulfide for nonenzymatic voltammetric sensing of glucose. Microchim Acta 186:807. https://doi.org/10.1007/s00604-019-3915-6

Pan W, Zheng WuX, Gao J, Liu Y, Yuan Q, Gan W (2021) Facile synthesis of 2D/3D hierarchical NiCu bimetallic MOF for non-enzymatic glucose sensor. Microchem J 170:106652. https://doi.org/10.1016/j.microc.2021.106652

Kim SE, Muthurasu A (2020) Metal-organic framework–assisted bimetallic Ni@Cu microsphere for enzyme-free electrochemical sensing of glucose. J Electroanal Chem 873:114356. https://doi.org/10.1016/j.jelechem.2020.114356

DingJ ZL, Wang X, Chai L, Wang Y, Jiang M, Li TT, Hu Y, Qian J, Huang S (2020) General approach to MOF-derived core-shell bimetallic oxide nanowires for fast response to glucose oxidation. Sens Actuators B Chem 306:127551. https://doi.org/10.1016/j.snb.2019.127551

Li M, Liu L, Xiong Y, Liu X, Nsabimana A, Bo X, Guo L (2015) Bimetallic MCo (M = Cu, Fe, Ni, and Mn) nanoparticles doped-carbon nanofibers synthetized by electrospinning for nonenzymatic glucose detection. Sens Actuators B Chem 207:614–622. https://doi.org/10.1016/j.snb.2014.10.092

Guo SH, Yuan PW, Wang J, Chen WQ, Ma KY, Liu F, Cheng JP (2017) One-step synthesis of copper-cobalt carbonate hydroxide microsphere for electrochemical capacitors with superior stability. J Electroanal Chem 807:10–18. https://doi.org/10.1016/j.jelechem.2017.11.009

Wan L, Wang Y, Zhang Y, Du C, Chen J, Tian Z, Xie M (2021) FeCoP nanosheets@Ni-Co carbonate hydroxide nanoneedles as free-standing electrode material for hybrid supercapacitors. Chem Eng J 415:128995. https://doi.org/10.1016/j.cej.2021.128995

KangJ SJ, Xie J, Ye H, Chen J, Fu XZ, Du G, Sun R, Wong CP (2018) Tubular Cu(OH)2 arrays decorated with nanothorny Co–Ni bimetallic carbonate hydroxide supported on Cu foam: a 3D hierarchical core–shell efficient electrocatalyst for the oxygen evolution reaction. J Mater Chem A 6:10064–10073. https://doi.org/10.1039/C8TA02492H

Zhao Z, Sun Y, Song J, Li Y, Xie Y, Cui H, Gong W, Hu J, Chen Y (2021) Highly sensitive nonenzymetic glucose sensing based on multicomponent hierarchical NiCo-LDH/CCCH/CuF nanostructures. Sens Actuators B Chem 326:128811. https://doi.org/10.1016/j.snb.2020.128811

Liu S, Hui KS, Hui KN, Jadhav VV, Xia QX, Yun JM, Cho YR, Mane RS, Kim KH (2016) Facile synthesis of microsphere copper cobalt carbonate hydroxides electrode for asymmetric supercapacitor. Electrochim Acta 188:898–908. https://doi.org/10.1016/j.electacta.2015.12.018

Vassileva DSK (2002) Infrared study of some synthetic phases of malachite (Cu2(OH)2CO3)–hydrozincite (Zn5(OH)6(CO3)2) series. Spectrochim Acta A Mol Biomol Spectrosc 58:2051–2059. https://doi.org/10.1016/S1386-1425(01)00677-1

Zhou H, Wu D, Cai W (2022) Carbon nanotubes coated with hybrid nanocarbon layers for electrochemical sensing of psychoactive drug. Electrochim Acta 430:141001. https://doi.org/10.1016/j.electacta.2022.141001

Wei H, Xu Q, Li A, Wan T, Huang Y, Cui D, Pan D, Dong B, Wei R, Naik N, Guo Z (2021) Dendritic core-shell copper-nickel alloy@metal oxide for efficient non-enzymatic glucose detection. Sens Actuators B Chem 337:129687. https://doi.org/10.1016/j.snb.2021.129687

Ni G, Wang F, Pan Z, Zhang R (2021) Bimetallic CuCo derived from prussian blue analogue for nonenzymatic glucose sensing. Electroanalysis 33:845–853. https://doi.org/10.1002/elan.202060402

Li W, Lv S, Wang Y, Zhang L, Cui X (2019) Nanoporous gold induced vertically standing 2D NiCo bimetal-organic framework nanosheets for non-enzymatic glucose biosensing. Sensors Actuators: B Chem 281:652–658. https://doi.org/10.1016/j.snb.2018.10.150

Luo X, Huang M, Bie L, He D, Zhang Y, Jiang P (2017) CuCo2O4 nanowire arrays supported on carbon cloth as an efficient 3D binder-free electrode for non-enzymatic glucose sensing. RSC Adv 7:23093–23101. https://doi.org/10.1039/c7ra01840a

Babu KJ, Sheet S, Lee YS, kumar GG, (2018) Three-dimensional dendrite Cu–Co/reduced graphene oxide architectures on a disposable pencil graphite electrode as an electrochemical sensor for nonenzymatic glucose detection. ACS Sustain Chem Eng 6:1909–1918. https://doi.org/10.1021/acssuschemeng.7b03314

DingY SH, Ren C, Zhang M, Sun K (2020) A nonenzymatic glucose sensor platform based on specific recognition and conductive polymer-decorated CuCo2O4 carbon nanofibers. Materials 13:2874. https://doi.org/10.3390/ma13122874

Tsai PJ, Chuang KL, Yang CJ, Lee HT, Lu FH (2019) Synthesis of Cu–Co bimetallic nanoparticles using TiN-coated electrodes for glucose-sensing applications. J Alloy Compd 785:191–199. https://doi.org/10.1016/j.jallcom.2019.01.141

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (21804035).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declared they have no conflict of interest to declare in this work.

Ethical approval

Not involved.

Additional information

Handling Editor: Catalin Croitoru.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, S., Xu, W., Zeng, D. et al. Amorphous copper cobalt carbonate hydroxide prepared by SILAR on copper foam for non-enzymatic glucose sensing. J Mater Sci 58, 199–210 (2023). https://doi.org/10.1007/s10853-022-08064-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-08064-0