Abstract

The present investigation deals with the development and characterization of a new controlled release packaging system for food. Novel sustained system was developed by direct grafting of beta-cyclodextrin (βCD) on the carboxyl groups of TEMPO-oxidized cellulose nanofibers (TEMPO-CNF) in aqueous solution and without using any spacer. Carvacrol, an aromatic essential oil component, was then entrapped in the ensued CD-grafted TEMPO-CNF. Successful functionalization of TEMPO-CNF was confirmed by conductometric titration, Fourier Transform Infrared Spectroscopy, and gravimetric analyses. The βCD-grafted TEMPO-CNF films exhibited sustained release of carvacrol over 150 h before reaching the equilibrium in water. Antimicrobial activity of carvacrol against Bacillus subtilis was increased (or improved by 47 h) from 3 h when using TEMPO-CNF to around (or against) 50 h when using CD-grafted TEMPO-CNF. These promising results pave the way for the development of new bio-based controlled release packaging materials with efficient antibacterial activity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In contemporary society with increasing communication systems, worldwide logistics, industrialization, and changing consumer expectations generated concerns about food safety and preservation remain/persist as key challenges for the coming years [1]. In spite of the abundant food cultivated worldwide, people die either due to lack of food or food borne illnesses caused by the unsafe food containing bacteria, parasite, or viruses. In order to satisfy the changing consumer needs, the concept of active packaging was introduced which is a more advanced and creative system than traditional counterpart.

Conventionally, the antimicrobial compounds are either mixed or coated over food formulation for preservation and increased shelf life. However, this traditional method has some limitations such as the degradation of the organoleptic properties of food or the inactivation of the antimicrobial effect/activity after a very short period of time, which finally results into loading excessive amount of preservatives/antimicrobial agent chemicals in the food formulation. Besides, when the antimicrobial compounds are directly introduced in bulk, they may be unable to target the food surface, where most of the spoilage and contamination occur [2]. To overcome these issues, the elaboration of “controlled release” packaging system has drawn attention as a new kind of active food-packaging system [3,4,5].

Various methods exist in the literature for slow or controlled release of active compounds, namely (i) multilayer coatings developed inside or outside the packaging matrix [6], (ii) microencapsulation of active compounds embedded in the polymer [7, 8], or (iii) direct incorporation of the active compound in the polymeric matrix [9,10,11].

In the last decade, the attention has been shifted from petroleum-based polymers to bio-based materials such as low density polyethylene [12], cellulose derivative [13], polylactic acid [14], or wheat gluten [15] due to their economic and environmental advantages [16].

Cellulose nanofibers (CNF), nano form of cellulose fibers, are of high interest as they provide additional advantages of high strength, high aspect ratio, flexibility, and high surface area [17,18,19,20].

Cellulose nanofibers can be produced from a large number of various cellulosic sources by performing successive, high shear, but highly energy-intensive mechanical treatments [18]. To reduce this high demand in energy some pretreatments have been proposed to be carried out prior to the mechanical disintegration of the cellulosic fibers. This also allowed the very recent but rapid industrialization of CNF since 2011. One energy-efficient pretreatment, in particular, has been deeply studied, namely the 2, 2, 6, 6-tetramethylpiperidine-1-oxyl (TEMPO)-mediated oxidation. It aims to selectively convert the primary hydroxyl groups on the microfibril surface to carboxylate groups in order to individualize the microfibrils by electrostatic repulsions and/or osmotic effect in water. After performing a gentle mechanical treatment, well-dispersed TEMPO-oxidized cellulose nanofibril aqueous dispersion can be obtained. Presence of carboxylic group on the surface of TEMPO-CNF allows the different chemical surface modifications [21, 22].

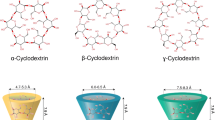

Cyclodextrins (CDs) are well known, naturally occurring trapping macromolecule, nontoxic, torus-shaped cyclic oligosaccharides composed of α-1,4-linked glucopyranose units. [7, 23]. Due to the three-dimensional truncated cone-shaped molecular structure, cyclodextrin forms inner hydrophobic cavity with outer hydrophilic wall [7]. CDs demonstrate excellent ability to entrap guest molecules such as drugs, food additives, or active compounds in order to form guest–host inclusion complexes (IC) by either hydrogen bonds, hydrophobic or van der Waals interactions. [24,25,26,27].

In spite of various applications in the medical, biomedical, and food-packaging fields [26], the use of CDs with nanocellulose for food packaging is rare. A number of cross-linking agents are utilized to graft βCD onto cellulose, such as epichlorohydrin, cyanuric chloride, N-methylolacrylamide, polycarboxylic acids (citric acid propionic acid and succinic acid) [28,29,30,31]. To our knowledge, only one study details such a combination [32]. Compared to our present work, this study focused on using enzymatically pretreated CNF, as paper coating, in combination with βCDs to gradually release an antibacterial compound, namely the carvacrol. No cross-linking agents were used to chemically link the βCDs to the nanocellulose. The nonporous CNF network proved to be sufficient to physically trap the IC formed between carvacrol and βCDs. This method, however, showed its limitations as the active IC were also released over time during the release assays.

That is why, in the present work, TEMPO-oxidized CNF were selected and investigated to promote their chemical interactions with βCDs. Carvacrol (2-methyl-5-(1-methylethyl)), an aromatic essential oil constituent, has also been studied as antibacterial compound. It is a monoterpenic phenol which is an active ingredient of Labiatae essential oil family that includes oreganum (60–70%) and thyme (45%) [33]. Carvacrol is a versatile molecule having diverse applications such as antitumor [34, 35], antiinflammatory [36], antimicrobial [37, 38], antimycotic [39], antioxidant [40], and insecticidal [41].

Carvacrol is allowed to be used as food additive in the USA [42] and Europe [43]. Nevertheless, its application in food is limited because of hydrophobic nature, insolubility in water, volatility, and odor. Therefore in this study, βCD is not only used to trap, control, and sustain the release of carvacrol but due to entrapment it reduces volatility and odor/smell.

Predominantly, enzymatically pretreated CNF with hydroxyl groups are chemically modified with CDs using a spacer such as polycarboxylic acid [27]. This investigation, for the first time, proposes the direct functionalization of TEMPO-CNF bearing carboxylic group with βCD (Fig. 1). Carvacrol was incorporated in the grafted CDs by immersion, and release studies were carried out in an aqueous medium. The antimicrobial activity of the active films against Bacillus subtilis was finally studied as a function of time and of the washing cycles performed with a nutrient medium simulating food.

Materials and methods

Materials

Commercial grade Ultrapure TEMPO-CNF at 1% concentration were purchased from Betulium Oy, Finland and used as received. βCD (CAS No. 7585-39-9), methanol (CAS No. 67-56-1), and carvacrol (CAS No. 499-75-2) were supplied from Sigma-Aldrich, France. Hydrochloric acid (CAS No. 7647-01-0) was obtained from Chimie plus, France. Sodium bromide (CAS No. 7647-15-6), sodium hypochlorite (CAS No. 7681-52-9), sodium hydroxide (CAS No 1310-73-2), nutrient broth and petri plates were received from Roth, France. Bacillus subtilis and nutrient agar were purchased from Humeau, France. For all experiments, only deionized water was used.

Grafting of TEMPO-CNF with βCD

Grafting on TEMPO-CNF film surface

A solution of 18.5 g/L was prepared with βCD at pH 7 and room temperature. TEMPO-CNF film (~0.2 g dried, prepared by solvent casting in Teflon molds at 40 °C) was immersed in the prepared solution for ~10 s at 25 °C. After drying, the film was quenched in incubator with vacuum (Glass oven B580) at 70 °C for 24 h to covalently graft the CDs on the surface of TEMPO-CNF films. The cured film was submitted to soxhlet extraction with water for 12 h to ensure that nongrafted βCD was eliminated.

Grafting using TEMPO-CNF suspension

A mixture of 10% w/w of βCD with TEMPO-CNF suspension (1% w/w) was prepared. pH was then lowered to 5 by the addition of acetic acid. After magnetic stirring for 2 h, films were casted in Teflon molds and let dried at 40 °C. The films were afterwards quenched in incubator with vacuum (Glass oven B580) at 70 °C for 24 h to covalently graft the CDs on the surface of CNF films. The cured films were submitted to soxhlet extraction with water for 12 h.

Carvacrol introduction and quantification

Carvacrol was incorporated by impregnation of the samples, neat TEMPO-CNF, and CD-grafted TEMPO-CNF, into a solution of carvacrol/ethanol in a ratio of 15/85 (w/w). Then all samples were stored in hermetic plastic bag to limit carvacrol evaporation after drying. The samples were impregnated for 10 min in the bath and dried at 30 °C for 20 min in a ventilated oven.

Sample characterizations

TEMPO-CNF morphology

Neat TEMPO-CNF and enzymatically pretreated CNF suspension were imaged using an atomic force microscope (AFM; Nanoscope III, Veeco, Canada). The suspensions were diluted and spread on mica plates at 0.01% concentration. The plates were dried overnight under room conditions in order to have adhesion between the plate and the film. Both CNF suspensions were characterized in tapping mode with a silicon cantilever (OTESPA, Bruker, USA) at different locations. Images were subjected to the first-order polynomial flattening in order to reduce the effects of bowing and tilt. The diameter of CNF was determined by image analyses using the ImageJ® software, based on at least 50 measurements using a minimum of 4 different images with 2 different samples.

Conductometric titration

Conductometric titration was carried out to obtain the total amount of carboxyl groups in the neat and grafted TEMPO-CNF films as previously proposed [44]. After the grafting with CDs, carboxyl groups were converted to ester groups, which reduced the amount of the former moieties. Therefore, conductometric titration was conducted directly on the TEMPO-CNF films to determine the grafting efficiency. Films were first cut into small pieces in order to attain uniform distribution during titration. Then, 0.2 g of dry TEMPO-CNF film pieces were titrated with 0.01 M NaOH (aq) by adding approximately 0.1 mL in 30 s intervals. Total carboxylate content was calculated on the basis of NaOH volume as follows:

where X is the carboxylate content in the sample, C NaOH the exact concentration of the sodium hydroxide solution in µmol/L, V 2 the volume of the sodium hydroxide solution consumed in the 2nd intersection point for weak acids in liters, and m the oven dry weight of sample (g).

Finally, the percentage of the grafting was determined using the total carboxylate content on each sample:

where X(reference) is the carboxylate content of the neat TEMPO-CNF and X(sample) the total carboxylate content of the CDs-grafted TEMPO-CNF.

Fourier transform infrared spectroscopy (FTIR)

Infrared spectra were recorded for neat and modified CNF in Attenuated total reflectance mode, using a Perkin Elmer Spectrum 65. All spectra were recorded between 4000 and 600 cm−1, with a resolution of 4 cm−1 and 16 scans. FTIR spectra shown in the figures are representative of the samples.

Gravimetric analyses

The quantitative determination of carvacrol adsorption in a saturated chamber can provide relative evidence of the quantity of βCD grafted on the CNF films. 0.2 g of reference TEMPO-CNF film and CDs-grafted TEMPO-CNF films were first dried in a saturated atmosphere and then placed in a desiccator with carvacrol recipient. Weight changes of each dried film were noted each day for 15 days.

Release study in aqueous medium

The release study was conducted on the samples containing carvacrol (section carvacrol introduction and quantification) in an aqueous medium. The test was carried out at 23 °C and under similar conditions at least twice for each sample. The samples of 0.2 g were immersed in 300 mL bath of deionized water that was continuously stirred using a magnetic stirring bar at ~200 rpm. At successive intervals (10, 20, 40, 60 min; 1, 2, 4, 6 h, and then, once per day), 3 mL of the solution was collected for UV analysis. The absorbance of the sampled medium was analyzed using a UV–Vis spectrophotometer SHIMADZU UV 1800 at a wavelength of 273 nm. The concentration of carvacrol released over time was determined by the following, previously established, calibration curve:

with R 2 = 0.9995

where A as the absorbance of carvacrol in water at 273 nm and C as the carvacrol concentration in g/L.

Antimicrobial activity assessment

Qualitative evaluation of release

The antibacterial effect of the CNF films was first assessed using the AFNOR EN 1104 standard against Bacillus subtilis spores. It consisted of placing the samples to be tested onto preinoculated agar (with B. subtilis) then incubated for 3 days at 30 °C.

Quantitative characterization of release

The bacterial activity of neat and CDs-grafted TEMPO-CNF impregnated with carvacrol was investigated against Bacillus subtilis bacteria using the standard Dynamic Shake Flask Method. The bacterial preinoculum cultures were grown overnight at 37 °C in 20 mL of nutrient broth (made of 1 g/L beef extract; 5 g/L neutralized peptone; 2 g/L yeast extract; 5 g/L NaCl) subjected to horizontal shaking at 200 rpm. The samples were introduced into 10 ml of 1/500 nutrient broth suspension with initial number of bacteria of 105 CFU/ml and subjected to vigorous shaking. The bacterial concentration (CFU/mL) of the microbial suspension was tested by plating serial dilutions on nutrient Agar to obtain the total viable count of bacteria (CFU—colony-forming units). Pristine nanofibers were used as a reference for antimicrobial agent and flasks containing only inoculum with the nutrient broth were used as a reference for bacterial growth. Before introducing into broth, dry sterilization at 60 °C was done with all the samples. The antibacterial activity, i.e., bacteria log reduction, of the samples was calculated as follows:

For investigating the impact of release of carvacrol on bacterial concentration with respect to time, sample aliquot from the inoculated flask was withdrawn at different time intervals i.e., after 3, 9, and 24 h.

Carvacrol release (food simulation)

In package, continuous washing of the active molecule took place by the liquid or moisture present in food formulation. Therefore, these conditions were simulated by studying the successive washing of the samples with the nutrient broth. The above procedure was slightly modified to determine the activity with respect to washing cycle. For this investigation, fresh inoculum with 1/500 nutrient broth was replaced after every 24 h in the sample tubes.

Result and discussion

Characterization of TEMPO-CNF suspension and films

TEMPO pretreatment selectively converts the C6 primary hydroxyl groups into carboxylate moieties which are used as the sites for the grafting. The image analysis showed that the diameter of TEMPO-oxidized CNF was 14 ± 7 nm, which is relatively similar to those stated in previous studies [20, 21] (Fig. 2).

Because of the entanglement of nanofibrils, however, it was difficult to estimate the length of the nanofibrils. Visual examination of AFM pictures demonstrated high quality of both nanofibrils and optical microscopy (not shown) confirmed low amount of macroscopic fibers and agglomeration. TEMPO-CNF forms transparent gel at a consistency of 1% which indeed constructs completely transparent flexible film like PLA.

Characterization of CDs-grafting on TEMPO-CNF

In spite of previous works on cellulose fiber grafting (example. Cusola et al. [45, 46]), there are very limited investigations available concerning the utilization of βCD and nanocellulose. CDs were either coated with nanocellulose on the paper surface [27] or grafted on the cellulosic substrate using citric acid before the coating with CNF [47]. When coating is employed (i.e., either mixture or physical absorption of βCD with CNF), encapsulated inclusion complex is released with βCD from the fibers and nanocellulose. In contrast, the grafting process allows multiple utilisations of the CDs-grafted CNF as release system of guest molecule. Thus, the grafting of CDs on CNF is a more interesting process when no CD release is expected and multiple uses are targeted. Unfortunately, the idea of using a crosslinker like citric acid favors nanocellulose degradation and creates artifacts with the addition of new function like nonreacting COOH functions. To our knowledge, no study has ever tried to avoid the use of any crosslinker in CD grafting as we proposed with TEMPO-CNF.

Figure 3 depicts the different strategies for the βCD on TEMPO-oxidized CNF. Thermal treatment was carried out at 70 °C during 24 h under vacuum, in order to successfully remove all traces of water to predominate forward reaction for the formation of ester bonds (Fig. 1).

The effect of grafting on surface charge was followed by conductometric titrations, summarized in Table 1. TEMPO-CNF gel has a carboxyl content of 1313 µmol/g which decreased to 812 µmol/g when titration was carried on TEMPO-CNF film due to the less accessible carboxyl groups after formation of the film. The surface of TEMPO-CNF has anionic carboxylic groups which were replaced by ester bond after covalent bonding with the hydroxyl group of βCD (Fig. 1). Therefore after βCD grafting, the carboxyl content decreased to 556 and 406 µmol/g for TM_CD_f and TM_CD_s, respectively. Considering the carboxyl content, the grafting efficiency was found to be 31.5% for grafting on film and 50% for grafting on CNF suspension.

Figure 4 shows the FTIR spectra of unmodified and modified cellulose nanofiber films. The spectrum of unmodified or neat cellulose nanofiber had a broadband in the wavenumber region 3000–3700 cm−1 assigned to the stretching vibrations of the internal hydrogen-bonded hydroxyl group and adsorbed water molecule. Cellulose also demonstrated characteristic groups at 1250–1460 cm−1 (δCH2), 2850–2980 cm−1 (νCH2), and 1170–1050 cm−1 (C–O–C for glycosidic bond, backbone of cellulose) [48].

TEMPO-mediated oxidation reaction forms a band at 1600 cm−1 corresponding to the carboxylate ions present on nanofibrils. After βCD grafting, this band widened and lowered in intensity, which can be easily attributed to the change of carboxyl groups into the ester bonds formed between βCD and cellulose. Also a new band at 1735 cm−1 in TM_CD_s has emerged that is assigned to the ester bond which indeed provides evidence for the grafting reaction.

Gravimetric method, an indirect method, was accomplished to prove the grafting with βCD. It was assumed that the presence of βCD will entrap volatile carvacrol molecule, present in the saturated atmosphere, and increase the overall weight of cellulose nanofiber films. The results obtained are shown in Fig. 5. After 8 days, the carvacrol adsorbed is 1.5, 2, and 9 ± 5% for TM, TM_CD_f, and TM_CD_s, respectively.

As already shown by Lavoine, Desloges [5], carboxylic content, present in neat tempo cellulose nanofibers, can also have interactions with carvacrol molecule which explains the mass increase with the TM films in the present study. The results, obtained by gravimetric method, provided evidence for the presence of βCD in grafted sample. Adsorption of higher quantity carvacrol in TM_CD_s indicated the higher amount of βCD and followed also the same trends in previous experiments.

Even if CDs have very similar chemical structure to the cellulose, it has been possible to prove the grafting of CD onto TEMPO-CNF by direct or indirect characterizations. These characterizations will help to investigate any influence on active molecule release and its consequent antimicrobial properties in a more explicit manner.

Carvacrol release characterization

After grafting, each film was impregnated for 10 min in the carvacrol/ethanol solution. The samples were dried for 30 min at 70 °C. High temperature was used to evaporate all the carvacrol present in the nanofibrous structure of the cellulose nanofiber leaving the oil present inside the grafted βCD. According to the study of Chalier, Ben Arfa [49] dealing with the effect of drying on the quantity of carvacrol remaining into paper coating, a drying at 50 °C for 210 s induces only losses of about 25% of the carvacrol initially introduced.

Therefore, best parameters were selected for this investigation. However, the exact quantification of the carvacrol is still quite difficult since it is a highly volatile molecule. The approximate amount of carvacrol introduced by impregnation was determined by the difference in the weight of film before and after impregnation after drying. The total amount of the carvacrol quantity is summarized in Table 1.

It was found that the amount of the carvacrol is the highest for TM_CD_s followed by TM_CD_f with lowest quantity in TM film. These results were expected, since βCD grafted on suspension contained highest quantity of βCD.

It is important to notice that the sustained release of carvacrol from cyclodextrin is the cumulative effect of grafting on the surface of TEMPO-CNF fibers, physical adsorption on the CNF and physical entrapment into the nanofilm of CNF. After washing with the water, only grafted or very strongly entrapped CD is present in the film. The release of carvacrol was then studied in an aqueous medium under sink conditions to simulate strong and continuous release by concentration difference. Despite the low solubility of carvacrol in water, its release was possible to be carried out into deionized water as shown in the Fig. 6.

Considering the release profiles, carvacrol was released very quickly when no CDs were used and reached an approximate plateau after 2 h. The impact of βCDs was thus clearly noticeable in Fig. 6a: the release of carvacrol was slowed down since CDs-grafted TEMPO-CNF released the whole amount of carvacrol after around 140 h later than the neat cellulose nanofibrils. Due to the high volatility of carvacrol in aqueous solution, high standard deviations were obtained for this experiment.

When considering the beginning of the curve till starting 50 h, the influence of the grafting strategy was even more prevalent (Fig. 6b). The amount of carvacrol release as a function of time was slightly higher in the TM_CD_f in comparison with that observed for TM_CD_s. This observation is due to the presence of higher amount of βCD, as confirmed by previous characterizations. These results enhanced the positive effect of βCD-grafted TEMPO-CNF on the prolonged release of molecules as recently proved in literature [47]. It is also worth noticing that the total amount of carvacrol present inside the sample was apparently different which also influences the release.

Antibacterial tests

The antibacterial action of carvacrol was already analyzed in many studies [49,50,51]. Its hydrophobic nature as well as the presence of free hydroxyl group are the prime factors responsible for its antibacterial activity. Hydrophobicity of carvacrol molecule influences interaction with lipid bilayer of the cytoplasmic membrane by aligning itself between the fatty acid chains causing the expansion and destabilization, thus rendering the permeability and fluidity of cell membrane and thereby resulting in the leakage of cell content [51].

The presence of the free hydroxyl groups and delocalized electrons destabilize the ion gradients present across the cell membranes which is responsible for the various survival processes inside the cell. The reduced gradient changes the energy transduction due to decrease in Adenosine Triphosphate (ATP) which transports the chemical energy for the metabolism of cell. This eventually led to the cell death. [50].

The tests to investigate the zone of inhibition, formed by the carvacrol, have been performed (not shown). As carvacrol is extremely volatile, the three samples impregnated with carvacrol have almost similar and very large zone of inhibition. This technique was then not adapted to analyze the prolonged release as all the excess of carvacrol was first released regardless of the samples. That is why a strategy of successive release has been performed.

Before such, quantitative bacterial reduction was analyzed in dynamic medium as a function of time using different samples (i.e., first analyses at 3 h then after 9 h and last sample at 24 h) as the release of molecules happens faster than their release into a solid medium and the volatility is limited in liquid immersion. Therefore, dynamic shake flask was selected for quantitative analysis to be in worst condition.

In the first set of experiments, bacterial reduction was calculated with different periods of contact time. Only one inoculum was done for both set of experiments governing the growth of bacteria in limiting nutrient medium. In both the experiments, 1/500 nutrient broth for inoculation was used which only supports the viability of the bacteria and not their multiplication. This was confirmed by maintaining the bacterial population unchanged after 24 h (see Fig. 7 for sample inoculum only).

TEMPO-CNF showed the early inhibition of bacteria. After some initial period of inhibition, all carvacrol was used leading to the growth of B. subtilis till inoculum level. After 8 h, there is no more effect of carvacrol which has been totally released. Considering the βCD-grafted cellulose nanofiber films, the release of carvacrol was slow and complete killing of bacteria after 24 h was observed. Furthermore, TM_CD_s showed more inhibition in the initial time period compared to the TM_CD_f, which also has higher quantity of initial carvacrol (Fig. 7).

Considering the grafted samples, gradual decrease of the bacterial population was found due to the presence sustained release of carvacrol. During the initial hours of contact (after 3 h), 0.5 log and 3 log reduction in the bacterial concentration was observed with TM_CD_f and TM_CD_s, respectively. Conversely to the neat TEMPO-CNF, grafted TEMPO-CNF demonstrated a complete killing effect after 24 h by virtue of the higher amount of the carvacrol present in the CD-grafted CNF.

Bacterial log reduction was also analyzed by replacing the new inoculated media over 24 h (Fig. 8). This experiment provided the impact of the amount of carvacrol on the bacterial growth. This provides an insight into the original condition in the packaging system where continuous or intermittent washing by food formulation (depending on the food type) and replenishing of active molecule took place. This simulates a packaging with multiple uses or medical packaging several times in contact with the human touch. This is a more critical situation and the best way to confirm a prolonged activity of our solution.

Neat CNF with carvacrol did not exhibit any significant antimicrobial activity as the carvacrol was already used in the initial contact period. After 24 h, no activity was observed and consequently no antibacterial properties were measured after successive releases. Both CDs-grafted TEMPO-CNF films released sustained rate carvacrol thanks to the prolonged release; they were still antibacterial after 48 h and 2 washing cycles. Moreover, in spite of having the higher grafting efficiency and higher amount of carvacrol, TM_CD_s lost its activity before TM_CD_f. This result was not expected but it provides an evidence for the heterogeneity of grafting and also proves that the TM_CD_f has more CD at the surface and so more carvacrol release. After 3 washing (72 h), no more activity was observed.

Due to its hydrophobic and volatile nature, with high sensory level, carvacrol is usually difficult to be used in the food-packaging industry. In this study, however, we developed a new antibacterial packaging that is able to gradually release small amounts of carvacrol over a longer period of time.

More experiments are, however, still needed to evaluate the multiple utilizations of grafted TEMPO-CNF films and study its impact on the organoleptic properties of the food

Conclusion

In spite of the efficient antimicrobial properties of carvacrol, its use in food application is still limited due to its volatility and pungent odor, which may alter the organoleptic properties of food strongly. Therefore, in the present study, a new sustained release packaging system was developed by grafting βCD on the surface of TEMPO-oxidized CNF without using any cross linkers.

βCD was directly grafted on CNF (suspension and film) with significant efficiency. Conductometric titration, FTIR, and gravimetric analysis confirmed the βCD grafting. As expected, CDs-grafted TEMPO-CNF released carvacrol gradually into water by increasing the time of release upto 150 h, whereas all carvacrol was released within 2 h with neat TEMPO-CNF.

Owning to the grafting, active samples/carvacrol-loaded samples were antibacterial for 48 h and even after being washed twice (i.e., 2 bacterial growth media). These results are, thus, very promising within the perspective of a food-packaging application. A packaging material with a very low amount of carvacrol and a long antibacterial property is expected to maintain or improve the shelf life of food over a longer period of time.

References

Horizon 2020 (2014–2015) Food Security, Sustainable Agriculture and Forestry, Marine, Maritime and Inland Water Research and the Bioeconomy, (commission, E., Ed.)

Han J (2000) Antimicrobial food packaging. Food Technol 54:56–65

Nobile M, Conte A (2013) Bio-based packaging materials for controlled release of active compounds, in packaging for food preservation. Springer, New York

Spaic M, Small DP, Cook JR, Wan W (2014) Characterization of anionic and cationic functionalized bacterial cellulose nanofibres for controlled release applications. Cellulose 21:1529–1540

Lavoine N, Desloges I, Sillard C, Bras J (2014) Controlled release and long-term antibacterial activity of chlorhexidine digluconate through the nanoporous network of microfibrillated cellulose. Cellulose 21:4429–4442

Liu K, Chen L, Huang L, Ni Y, Sun B (2015) Enhancing antibacterium and strength of cellulosic paper by coating triclosan-loaded nanofibrillated cellulose (NFC). Carbohydr Polym 117:996–1001

Marques HMC (2010) A review on cyclodextrin encapsulation of essential oils and volatiles. Flavour Fragrance J. 25:313–326

Zhai F, Li D, Zhang C, Wang X, Li R (2008) Synthesis and characterization of polyoxometalates loaded starch nanocomplex and its antitumoral activity. Eur J Med Chem 43:1911–1917

Bober P, Liu J, Mikkonen KS, Ihalainen P, Pesonen M, Plumed-Ferrer C, von Wright A, Lindfors T, Xu C, Latonen R-M (2014) Biocomposites of nanofibrillated cellulose, polypyrrole, and silver nanoparticles with electroconductive and antimicrobial properties. Biomacromolecules 15:3655–3663

Ferrocino I, Greppi A, La Storia A, Rantsiou K, Ercolini D, Cocolin L (2016) Impact of nisin-activated packaging on microbiota of beef burgers during storage. Appl Environ Microbiol 82:549–559

Jebel SF, Almasi H (2016) Morphological, physical, antimicrobial and release properties of ZnO nanoparticles-loaded bacterial cellulose films. Carbohydr Polym 149:8–19

Auxier JA, Schilke KF, McGuire J (2014) Activity retention after nisin entrapment in a polyethylene oxide brush layer. J Food Prot 6:1624–1629

Gao C, Yan T, Du J, He F, Luo H, Wan Y (2014) Introduction of broad spectrum antibacterial properties to bacterial cellulose nanofibers via immobilising ε-polylysine nanocoatings. Food Hydrocolloids 36:204–2011

Abdulkhani A, Hosseinzadeh J, Ashori A, Esmaeeli H (2015) Evaluation of the antibacterial activity of cellulose nanofibers/polylactic acid composites coated with ethanolic extract of propolis. Polym Compos

Mascheroni EG, Guillard V, Gastaldi E, Gontard N, Chalier P (2011) Anti-microbial effectiveness of relative humidity-controlled carvacrol release from wheat gluten/montmorillonite coated papers. Food Control 22:1582–1591

Johansson C, Bras J, Mondragon I, Nechita P, Plackett D, Simon P, Svetec DG, Virtanen S, Baschetti MG, Breen C, Clegg F, Aucejo S (2012) Renewable fibers and bio-based materials for packaging applications–a review of recent developments. BioResources 7(2):2506–2552

Lavoine N, Desloges I, Dufresne A, Bras J (2012) Microfibrillated cellulose - Its barrier properties and applications in cellulosic materials: a review. Carbohydr Polym 90:735–764

Turbak AF, Snyder FW, Sandberg KR (1983) Microfibrillated cellulose, a new cellulose product: properties, uses, and commercial potential. J Appl Polym Sci 37:815–827

Syverud K, Stenius P (2009) Strength and barrier properties of MFC films. Cellulose 16:75–85

Siró I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17:459–494

Isogai A, Saito T, Fukuzumi H (2011) TEMPO-oxidized cellulose nanofibers. Nanoscale 3:71–85

Saito T, Kimura S, Nishiyama Y, Isogai A (2007) Cellulose nanofibers prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolecules 8:2485–2491

Del Valle EM (2004) Cyclodextrins and their uses: a review. Process Biochem 39:1033–1046

Kayaci F, Uyar T (2011) Solid inclusion complexes of vanillin with cyclodextrins: their formation, characterization, and high-temperature stability. J Agric Food Chem 59:11772–11778

Wang J, Cao Y, Sun B, Wang C (2011) Physicochemical and release characterisation of garlic oil-β-cyclodextrin inclusion complexes. Food Chem 127:1680–1685

Thayyath SA, Jayachandran N, Peethambaran LD (2015) Synthesis, characterization and in vitro cytotoxicity analysis of a novel cellulose based drug carrier for the controlled delivery of 5-fluorouracil, an anticancer drug. Appl Surf Sci 355:64–73

Lavoine N, Givord C, Tabary N, Desloges I, Martel B, Bras J (2014) Elaboration of a new antibacterial bio-nano-material for food-packaging by synergistic action of cyclodextrin and microfibrillated cellulose. Innov Food Sci Emerg Technol 26:330–340

Zhang LZ, Zhou JP, Zhang LN (2013) Structure and properties of β-cyclodextrin/cellulose hydrogels prepared in NaOH/urea aqueous solution. Carbohydr Polym 94:386–393

Lee MH, Yoon KJ, Ko SW (2000) Grafting onto cotton fiber with acryl amidomethylated β-cyclodextrin and its application. J Appl Polym Sci 78:1986–1991

Martel B, Weltrowski M, Ruffin D, Morcellet M (2002) Poly carboxylic acids as crosslinking agents for grafting cyclodextrins onto cotton and wool fabrics: study of the process parameters. J Appl Polym Sci 83:1449–1456

Chao D, Li-Ying Q, Guang-Lei Z, Bei-Hai H, Hui-Ning X (2014) Preparation of antimicrobial cellulose fibers by grafting β-cyclodextrin and inclusion with antibiotics. Mater Lett 124:181–183

Lavoine N, Desloges I, Bras J (2014) Microfibrillated cellulose coatings as new release systems for active packaging. Carbohydr Polym 103:528–537

Arrebola ML, Navarro MC, Jiménez J, Ocaña FA (1994) Yield and composition of the essential oil of Thymus serpylloides subsp. serpylloides. Phytochemistry 36:67–72

Arunasree KM (2010) Anti-proliferative effects of carvacrol on a human metastatic breast cancer cell line, MDA-MB 231. Phytomedicine 17:581–588

Liang WZ, Chou CT, Lu T, Chi CC, Tseng LL, Pan CC, Lin KL, Kuo CC, Jan CR (2013) The mechanism of carvacrol-evoked [Ca2+]i rises and non-Ca2+-triggered cell death in OC2 human oral cancer cells. Toxicology 303:152–161

Hotta M, Nakata R, Katsukawa M, Hori K, Takahashi S, Inoue H (2010) Carvacrol, a component of thyme oil, activates PPARalpha and gamma and suppresses COX-2 expression. J Lipid Res 51:132–139

Obaidat MM, Frank JF (2009) Inactivation of Salmonella and Escherichia coli O157:h7 on sliced and whole tomatoes by allyl isothiocyanate, carvacrol, and cinnamaldehyde in vapor phase. J Food Prot 72:315–324

Upadhyay A, Johny AK, Amalaradjou MA, Ananda BS, Kim KS, Venkitanarayanan K (2012) Plant-derived antimicrobials reduce Listeria monocytogenes virulence factors in vitro, and down-regulate expression of virulence genes. Int J Food Microbiol 15:88–94

Marcos-Arias C, Eraso E, Madariaga L, Quindós G (2011) In vitro activities of natural products against oral Candida isolates from denture wearers. BMC Complement Altern Med. 11:119

El Babili F, Bouajila J, Souchard JP, Bertrand C, Bellvert F, Fouraste I, Moulis C, Valentin A (2011) Oregano: chemical analysis and evaluation of its antimalarial, antioxidant, and cytotoxic activities. J Food Sci 76:512–518

Karpouhtsis I, Pardali E, Feggou E, Kokkini S, Scouras ZG, Mavragani-Tsipidou P (1998) Insecticidal and genotoxic activities of oregano essential oils. J Agric Food Chem 46:1111–1115

US Food and Drug administration. (2014) Food additives permitted for direct addition to food for human consumption, Code of Federal Regulations Title 21 3

Council European Parliament (2004) Regulation (EC) no 1935/2004 on materials and articles intended to come into contact with food and repealing Directives 80/590/EEC and 89/109/EEC. Off J Eur Union 338:4–17

Orelma H, Filpponen I, Johansson L-S, Osterberg M, Rojas OJ, Laine J (2012) Surface functionalized nanofibrillar cellulose (NFC) film as a platform for immunoassays and diagnostics. Biointerphases 7:61

Cusola O, Tabary N, Bras J (2010) Functionalization of several cellulosic supports for the prolonged release of antibacterial agents. In 13èmes journées du Club Français des Cyclodextrines (POSTER)

Cusola O, Tabary N, Belgacem MN, Bras J (2013) Cyclodextrin functionalization of several cellulosic substrates for prolonged release of antibacterial agents. J Appl Polym Sci 129:604–613

Lavoine N, Desloges I, Bras J (2014) Microfibrillated cellulose coatings as new release systems for active packaging. Carbohydr Polym 103:528–537

Missoum K, Bras J, Belgacem M (2012) Organization of aliphatic chains grafted on nanofibrillated cellulose and influence on final properties. Cellulose 19:1957–1973

Chalier P, Ben Arfa A, Preziosi-Belloy L, Gontard N (2007) Carvacrol losses from soy protein coated papers as a function of drying conditions. J Appl Polym Sci 106:611–620

Ben Arfa A, Combes S, Preziosi-Belloy L, Gontard N, Chalier P (2006) Antimicrobial activity of carvacrol related to its chemical structure. Lett Appl Microbiol 43:149–154

Nostro A, Papalia T (2012) Antimicrobial activity of carvacrol: current progress and future prospectives. Recent Pat Anti-Infect Drug Discovery 7:28–35

Acknowledgements

This research was supported by new generation packaging (NEWGENPAK) Project of the Seven Framework Program of European Research under Grant Agreement No 290098. LGP2 is part of the LabEx Tec 21 (Investissements d’Avenir - Grant Agreement No ANR-11-LABX-0030) and of the Énergies du Futur and PolyNat Carnot Institutes (Investissements d’Avenir - Grant Agreements No ANR-11-CARN-007-01 and ANR-11-CARN-030-01). This research was made possible thanks to the facilities of the TekLiCell platform funded by the Région Rhône-Alpes (ERDF: European regional development fund).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saini, S., Quinot, D., Lavoine, N. et al. β-Cyclodextrin-grafted TEMPO-oxidized cellulose nanofibers for sustained release of essential oil. J Mater Sci 52, 3849–3861 (2017). https://doi.org/10.1007/s10853-016-0644-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0644-7