Abstract

The paper presents a complex study of the effect of Mg substitution on the functional properties of Ni-ferrite ceramics prepared by self-combustion sol–gel method. The sintered ceramics have pure cubic spinel structures with an increase of the lattice parameter and the grain size with Mg content. The electrical properties of Mg x Ni1−x Fe2O4 (x = 0; 0.17; 0.34; 0.5; 0.66; 1) ceramics have been investigated. The complex impedance spectra suggest a grain boundary contribution in the conduction process and reveal that the real part of impedance and the imaginary component (reactance) increase with increasing the Mg amount. The temperature dependence of dielectric properties shows that the hopping of charge carriers is thermally activated. The resistivity as a function of frequency for different degree of humidity was also investigated. All the investigated samples show a typical ferrimagnetic character with a strong non-linearity, small coercitive field (~50 Oe) and a saturation field of ~1kOe, typical to the investigated Mg x Ni1−x Fe2O4 ceramics. The Curie temperature determined from magnetic susceptibility versus temperature dependences presents a decrease with the addition of non-magnetic Mg2+ ion concentration from 603 °C (for x = 0) to 384 °C (for x = 1).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Ferrite materials are among the most attractive complex oxides due to their particular electric and magnetic properties which make them ideal candidates for applications in the field of electronics and telecommunication industry, for high-quality filters, radiofrequency and microwaves circuitry, antennas, inductors, coils, transformer cores, deflection yokes, read/write heads for high-speed digital tapes, power applications and many other devices [1–4]. Their properties are very sensitive to the composition (substitution degree and cation distribution on the tetrahedral and octahedral sites of the crystalline sublattices) and to the specific microstructural characteristics (grain size and shape, inhomogeneities, grain boundaries, porosity) determined by the synthesis method and processing conditions. Among the electrical properties of ferrites, the most important characteristics are the dielectric constant, dielectric losses and ac conductivity [5, 6], which should be determined over the range of frequency required for specific applications.

MgFe2O4 ferrites have a normal spinel cubic structure with soft magnetic properties and an intrinsic semiconductor character. They have a broad range of applications in heterogeneous catalysis, adsorption, magnetic, biomedical and in gas sensing applications [7, 8]. Ni ferrites (NiFe2O4) possess an inverse spinel structure, in which half of the ferric ions fill the tetrahedral sites (A-sites) and the rest occupy the octahedral sites (B sites) of the spinel lattice AB2O4. Ni ferrites combine useful magnetic properties with a relatively low-electrical conductivity; low-eddy current loss in ac-applications and have numerous applications in electric devices, hyperthermia and high-frequency applications [9, 10]. Therefore, the structural and functional properties of Mg x Ni1−x Fe2O4 ceramics are very interesting to be investigated, because they might combine complex characteristics derived from the structure and cation distributions. The dc- and ac electrical properties of Mg and Ni ferrites produced by solid-state method [11, 12] were reported and interpreted in terms of the role of Ni substitution, but no microstructural characteristics were given. In the literature, the electrical properties of Cr-doped Mg0.50Ni0.50Fe2O4 ceramics prepared by citrate-gel self-combustion were discussed in terms of grain boundary–grain core effects on the impedance characteristics [13]. Also, some results about structural and electrical characterization at room temperature were reported for Mg-doped NiFe2O4 ceramics produced from fine powders synthesized by citrate gel process [14] and their possible use as a green anode was investigated [15].

In our previous work, the structural, electrical and magnetic properties of Mg x Ni1−x Fe2O4 (with x between 0 and 1) ceramics prepared by self-combustion sol–gel method and sintered at 900 °C were reported [16]. A more detailed investigation of the electrical properties of dense ceramics sintered at higher temperatures, of 1200 °C/8 h, as a function of composition, frequency and temperature was undertaken, and the main results of the study are reported in this paper. The humidity sensing capacity and the magnetic properties of such ceramics were also tested for completing the investigation.

Experimental details

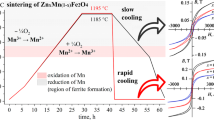

Mg x Ni1−x Fe2O4 powders with nominal compositions x = 0, 0.17, 0.34, 0.50, 0.66 and 1 were synthesized by using a self-combustion sol–gel method starting with Ni, Fe and Mg nitrates as cation sources and citric acid as combustion/chelating agent, as described in detail in the [16]. The full formation of the ferrite phase was observed after thermal treatment at 500 °C for 3 h. The resulted powders were uniaxial pressed and sintered at 1200 °C for 8 h, in order to obtain dense ceramic. The relative densities of the sintered ceramics are in the range of 90–95 %.

The phase composition of the sintered ceramics was checked with a SHIMADZU XRD 6000 diffractometer using Ni-filtered CuKα radiation (λ = 1.5418 Å) with scan step increments of 0.02° and counting time of 1 s/step, for 2θ ranged between 20° and 80°. The microstructures were investigated using a SEM analysis performed with a scanning electron microscope (SEM, Hitachi S-3400N II microscope). The electrical measurements were performed on parallel-plate capacitor configuration, applying Pd–Ag electrodes on the polished surfaces of the sintered ceramic discs. The complex impedance in the frequency domain (20 Hz to 2 MHz) and temperature between (25 and 250) °C was determined by using an impedance bridge type Agilent E4980A Precision LCR Meter. The ceramics were tested for humidity-sensing capacity by employing the ferrite disc with porous Ag electrodes in a thermostatic bath exposed to different relative humidities below 85 %, obtained by using saturated salt solutions as humidity-generating source.

The magnetic properties at room temperature were determined under a magnetic field of 0-1.4T (14000Oe) using a Vibrating Sample Magnetometer MicroMagTM VSM model 3900 (Princeton Measurements Co.). The temperature dependence of magnetic susceptibility was determined using a coil inside which the ferrite sample was placed, and the change in magnetic inductance of the coil was measured using an RLC bridge (Agilent E4980A).

Results and discussions

Phase analysis and microstructural properties

X-ray diffraction analysis realized on the ceramic samples (Fig. 1a) demonstrates for all the compositions the presence of a well-crystallized, pure spinel cubic phase, identified by the JCPDS: 86-2267 and JCPDS 88-2267 fiches. The lattice constants were determined for all samples by Rietveld refinements using the GSAS software suite, developed by Larson and Dreele [17].

We considered the following initial structural parameters and the structural model for all the samples: metal and iron atoms in the Wyckoff 8a and 16d special position and O atoms in the 32e special positions; space group Fd3m [18]. The Rietveld refinement profiles for a few selected compositions of the series Mg x Ni1−x Fe2O4 (x = 0, 0.50 and 1) are presented in Fig. 1b, and the computed lattice constant, elementary unit cell volume and oxygen parameters calculated by the Rietveld method for all the samples are listed in Table 1. It is noticed that the lattice parameter increases with the increase in Mg concentration, which might be attributed to the larger ionic radius 0.72 Å of Mg2+ than of the Ni2+ ion 0.69 Å [19, 20].

The SEM micrographs of the Mg x Ni1−x Fe2O4 ceramic with various compositions x = 0, 0.17, 0.34, 0.5, 0.66 and 1 after sintering at 1200 °C/8 h are shown in Fig. 2a–f. The grain size of the investigated samples was determinated from the SEM microstructures using the linear intercept method. The ceramics with low Mg contents (x = 0 and x = 0.17) have finer grains (average grain size around ~0.5–1 μm for the composition x = 0), with irregular and inhomogeneous shape aspect and apparent high porosity, while the compositions x ≥ 0.34 present homogeneous microstructure, with faceted crystallite grains and well defined growth terraces of irregular shape (Fig. 2d), almost perfect triple points and grain sizes above 1 μm. Figure 2 indicates that the average grain size systematically increases when increasing the Mg concentration and for x = 1 reaches values of about ~3–4 μm (Fig. 2f). The composition MgFe2O4 is characterized by a dense microstructure with a reduced number of rounded pores at triple points and large ceramic blocks fully densified (Fig. 2f).

Electrical properties

The electrical properties have been studied by impedance spectroscopy (IS). This method enables to explain the properties of the ferrite ceramics in relationship with their microstructures and compositions, by observing the contributions from various ceramic components (i.e. grains and grain boundaries). The real and imaginary parts of the room temperature complex impedances (Fig. 3) have similar orders of magnitudes for all the compositions, with exception of x = 0. This composition shows about two orders in magnitude smaller impedance values (in the range of ~50 kΩ) compared to impedances in the range of few MΩ characteristic to x = 1. Quite small impedance values of about ~80 kΩ also present the composition x = 0.50 (Fig. 3) and these features can be assigned to a higher conductivity of x = 0 and x = 0.50 samples. The complex impedance plots from Fig. 3 (inset) show flattened semicircles with two components: the high-frequency arc is usually associated to the bulk (grain cores), while the low-frequency arc to the grain boundaries contributions. Such impedance behaviour is described by a series model of two parallel RC components, i.e. (R g , C g ) for grain bulk and (R gb , C gb ) for grain boundaries. The two components indicate two distinct relaxation phenomena with sufficiently different relaxation times: τ gb = R gb C gb and τ bulk = R bulk C bulk [21]. The centres of the semicircular arcs are depressed below the real axis indicating a high degree of heterogeneity (i.e. a broad distribution of relaxation times) and deviation from the ideal Debye relaxation behaviour [22]. Both grain core and grain boundaries resistances increase from R g = 0.04 MΩ and R gb = 0.05 MΩ characteristic to x = 0 to R g = 6.97 and R gb = 6.06 MΩ, respectively, for x = 1, which indicates a general tendency from a predominant semiconductive character towards better dielectric properties when increasing the Mg addition (x). The electrical properties (permittivity and resistivity) are not so different within the ceramic grain volume, i.e. they have similar impedance values and characteristic relaxation times for grain core and grain boundary contributions and these components are visible as two separate maxima in the X(f) plots (Fig. 4).

The real and imaginary impedances versus frequency of the ceramic samples with selected compositions x = 0, 0.50 and 1, at two temperatures (T = 30 °C and 250 °C), are shown in Fig. 4. The two impedance components show different weights on the effective electrical properties and contributions to the Debye-like relaxation process, i.e. the two maxima of the X(f) dependences (Fig. 4) for various compositions. When increasing temperature, both the real and imaginary parts of impedance strongly reduce (about 103 times, as shown in Fig. 4b, d, f by comparison with Fig. 4a, c, e) and this results in an overall increase of the ceramic ferrite conductivity. The relaxation maximum of the imaginary part shifts to higher frequencies and at higher temperature (T = 250 °C), and the X(f) dependence shows only one impedance component at the instrumental limit for high frequencies. The decrease of resistance of both the ceramic grains and grain boundaries has been explained by the role of thermal activation of the localized charges. Two types of thermal activations, i.e. carrier density in the case of band conduction and carrier mobility in case of hopping, are usually considered responsible for the reduction of resistivity of ferrites with increasing temperature [23]. The two components are assigned to the ceramic structure with a semiconductive grain bulk with high permittivity and conductivity (characterized by the low-frequency maxima of the X(f) dependence as in Fig. 4) surrounded by a more resistive grain boundary layers (described by the higher frequency maxima of the X(f) dependence). As in other ferrites, the low-resistivity bulk is due to the simultaneous presence of ferrous (Fe+2) and ferric (Fe+3) ions on equivalent lattice sites which produces hopping electronic conduction [24] and they are accompanied by different levels of local oxygen stoichiometry. The grain boundary resistivity has values of a few orders of magnitude higher than the bulk grain ones and both are frequency dependent.

The differences of the impedance components and their values are most probably not related to the intrinsic permittivity of the ceramic ferrites, but rather to extrinsic contributions (i.e. from uncompensated charges, oxigen vacancies, fluctuations of the magnetic ions oxidation states within the ceramic volume) resulted during the ceramic processing. They are not homogeneously distributed within the ceramic volume, and they give rise sometimes to distinct relaxation contributions. Even their nature is difficult to be clearly assigned (although the large majority of papers consider as coming from grain boundary-grain bulk phenomena), their temperature evolution allows to determine activation energies.

For a more detailed investigation, if the multiple relaxations and/or conduction processes are involved in the complex dielectric response of Mg x Ni1−x Fe2O4 ceramic ferrites, we have investigated the temperature dependence of imaginary part of dielectric modulus (M″) (M*(f) = M′(f) + iM″(f), where \( M{^{\prime}} (f) = \frac{\varepsilon {^{\prime}} (f)}{{\varepsilon ^{\prime 2} (f) + \varepsilon ^{\prime\prime 2} (f)}} \) and \( M{^{\prime\prime}} (f) = \frac{\varepsilon {^{\prime\prime}} (f)}{{\varepsilon {^{\prime}}^{2} (f) + \varepsilon {^{\prime \prime}}^{2} (f)}} \)) (Fig. 5a–f).

The variation of M″ as a function of temperature gives useful information concerning the charge transport mechanism such as electrical transport and conductivity relaxation and has been successfully used to distinguish localized dielectric relaxation processes from long-range conductivity and short/long range polaron hoping in materials (Fig. 5a–f). In the studied (25–250) °C temperature range, M″present maximum for all compositions, indicating the dielectric relaxation processes, but for the samples with compositions of x = 0, 0.17, 0.34 and 1 it was observed the presence of two types of dispersion phenomena given by the presence of second maximum at higher temperature (up to 200 °C). The principal maximum present in all ferrite compositions shows a shift from temperature around ~50 °C for x = 0 to higher temperature ~175 °C for x = 1 with increasing the Mg2+ substitution.

The observed relaxation phenomena observed from frequency dependence of the imaginary part of dielectric modulus versus temperature (Fig. 5a–f) are thermally activated phenomena, for which the characteristic activation energy can be deduced from the maximum of the imaginary part of the dielectric modulus using the Arrhenius law:

where, ω = 2πf m is the pulsation corresponding to the maximum peak of M″, ω 0 is a pre-exponential factor, k B is the Boltzmann constant and E a is the activation energy.

Thus, the evolution with temperature of the characteristic relaxation time of each impedance component has been determined (whenever possible, in the available frequency and temperature range) and the corresponding activation energy for both peaks was determined from Arrhenius plots (Table 2).

The activation energies present enhanced values when increasing the substitution of Ni2+ with Mg2+, from 0.33 eV for x = 0 to 0.43 eV for x = 1. Due to the increasing concentration of Mg2+ ion, some of the Mg2+ ions may occupy tetrahedral sites resulting in a migration of Fe3+ ions into octahedral sites. The increase in concentration of Fe3+ ions at B sites increases the hopping rate of electrons, and then for composition with x = 1 it was obtained a high value of activation energy. The compositions with x = 0 and x = 0.5 present the lowest activation energy (calculated from M″(f, T)), perhaps due to the partial compensation n–p developed by goals that accompany transitions Ni2+/Ni3+. These values of the activation energies are explained in the frame of electron contribution due to the transition between ferrous ions (Fe2+) and ferric ions (Fe3+) and are in the range of ones reported in other ferrite materials [15, 20, 25, 26]. The present values are typically activation energies for complex oxides materials (spinel materials).

The temperature dependence of the real part of permittivity and dielectric losses for Mg x Ni1−x Fe2O4 ferrites at 100 kHz are shown in Fig. 6a, b. An increasing of the dielectric constant (ε′) with temperature is observed, mainly due to interfacial and dipolar polarizations, which are strongly temperature dependent (Fig. 6a) [27]. The interfacial polarization is due to the accumulation of charges at the grain boundary and an increase in polarization results as more charges reach the grain boundary with increase in temperature. From the literature, the polarization in ferrites is due to a mechanism similar to the conduction process [28]. The polarization is determinated by the exchange of electrons between ferrous ions (Fe2+) and ferric ions (Fe3+) on the octahedral site which may lead to local displacement of electrons in the direction of applied field. Also, the hole exchange between Ni3+ and Ni2+ in p-type ferrites results in local displacements of electrons or holes in the direction of the electric field which then cause polarization. The polarization decreased with increasing frequency and then reaches a constant value due to the fact that beyond a certain frequency of external field the electron hopping cannot follow the alternating field. All the compositions present a maximum at about T ~130 °C and ~200 °C.

Figure 6b shows the variation of tangent losses with temperature at a frequency of 100 kHz for all the investigated samples. It can be seen that dielectric losses are higher when increasing temperature, as it was observed in the literature in the large majority of ferrites [9, 29, 30]. The hopping of charge carriers is thermally activated with the temperature rise; hence, the dielectric polarization increases producing an increase in ε′ and tangent loss with temperature. The increase in tangent loss is a result of the decreasing resistivity of all the compositions with temperature.

In order to understand the conduction mechanism in Mg x Ni1−x Fe2O4 ceramic ferrites, the variation of ac conductivity with frequency is evaluated from the imaginary part of permittivity and is presented in Fig. 7. The ac conductivity of the all investigated samples increases with increasing the applied frequency. Since the increase in frequency enhances the hopping frequency, the conduction mechanism of ferrite is explained on the basis of temperature-induced changes of hopping dynamics of charge carriers between the Fe2+ and Fe3+ on the octahedral sites. With exception of composition x = 0.5, the room temperature conductivity decreases with about two orders in magnitude (10−3–10−5) when increasing Mg addition (x). Thus, the effect of composition on the ac conductivity shows a general trend of decrease with the addition of Mg2+ ions.

The frequency dependence of the ac conductivity σ(ω) can be express as:

where σ(ω) is the total conductivity, σ dc is the frequency-independent dc-conductivity due to the translation hopping and is a frequency independent function; σ ac is ac conductivity due to the hopping processes at the octahedral site and is a frequency dependent function, and A is a constant having the units of conductivity and the exponent 0 < n < 1 are temperature and material intrinsic property dependent constant. The first term is predominant in low frequencies and at high temperatures, while the σ ac is predominant at high frequencies and at low temperatures.

The experimental data were fitted with the power law (σ ac = Aω n) in the range of 1kHz-1MHz, and values of the n exponent, obtained at room temperature, were shown in Fig. 8. The values of n increase for the compositions up to x = 0.5 and decrease after these values due to substitutions of Ni2+ with Mg2+ which are accompanied most probably by a partial charge compensation n–p realized around the composition x = 0.5. However, the extrinsic contributions to the conductivity might also be responsible for this anomaly observed for x = 0.50 composition. The obtained results are in a good agreement with data reported in the literature for similar systems [26, 31].

Humidity testing

Further, the Mg x Ni1−x Fe2O4 ceramics with different compositions (x = 0, 0.5 and 1) were tested for their capability to detect variations of humidity. It is known that the electrical properties are very sensitive to the water adsorption on the grain ceramic surface [32]. Although for such purposes, porous ceramics are necessary, while the present samples have a low-porosity degree of only 8–10 %, their resistivity response to various degrees of humidity were checked as a function of composition and they are represented in Fig. 9a–c. The resistivity decreases with increasing frequency and with increasing the addition of Mg, at room temperature. It can be seen a small variation of resistivity with increasing the degree of humidity, at lower frequency, especially for the samples with composition x = 0.5 for which a larger decrease of resistivity with humidity level is noticed. An important role in the study of the effect of humidity on the electrical resistivity, in the ceramic ferrites, is played by the microstructure (porosity, structural defects and grain size). Smaller grains suggest an increase of the grain boundary surface which normally accounts for high resistivity, demonstrated also from the SEM microstructures (Fig. 2).

Magnetic properties

The magnetic properties are presented in Fig. 10a, b. The M(H) loops at room temperature (Fig. 10a) show a typical ferrimagnetic character for all the investigated compositions, with a strong non-linearity, a very small coercitive field about 50 Oe and saturation field of ~1 kOe, irrespective of composition. The composition affects the saturation magnetization: smaller magnetic moment values resulted when increasing Mg content, from M s = 50 emu/g for x = 0 to M s = 30 emu/g for x = 1, at room temperature. The minimum value of saturation magnetization is obtained for x = 0.50, also possible determined by changes of the substitution positions in the A- and B-sites for this particular composition, which also show anomalous dielectric properties. The obtained values are similar to ones reported in the literature for bulk ferrites with compositions x = 0 and x = 1 [33–37]. The decrease in value of M s can be attributed to the site occupancies of metal cations in the A- and B-site, as was also observed and discussed in previous works [16, 38]. The magnetic properties can be explain taking into account that the Mg2+ ions preferentially occupy the octahedral sites, and then they can partially fill tetrahedral sites, whereas the Ni2+ ions occupy only the octahedral sites. Considering the interstitial sites occupied by each substituted cations and the experimental magnetic data, it can be calculated the cation distribution for the ferrites [20].

The temperature dependence of magnetic suscceptibility normalized at room temperature value has been measured in the range of (30–700) °C and it is illustrated in Fig. 10b. The Curie temperature represents the temperature above which the magnetic domains with spontaneous magnetization disappear. This temperature separates the disordered paramagnetic phase on the ordered ferrimagnetic phase. In case of ferrites, at the Curie point both the magnetizations and permeability show a sharp decline. As it was observed from Fig. 10a, the magnetic properties of ferrites are affected by both the type of substituent and microstructures [38]. The stronger magnetic interaction is also demonstrated by the values of magnetic Curie temperature which present a decrease with the addition of non-magnetic Mg2+ ion concentration from 603 °C (for x = 0) to 384 °C (for x = 1) (Fig. 10b). The Curie temperature of MgFe2O4 is lowered with 219 °C by comparison with that of NiFe2O4. The same results were reported in literature for spinel ferrites prepared by co-precipitation route [27].

Conclusions

Ni–Mg spinel ferrites have been synthesis using a self-combustion sol–gel method and then the powders were sintered at 1200 °C/8 h. The spinel structure was confirmed by X-ray diffraction and the lattice parameter presents an increase with substitution of Ni2+ with Mg2+. SEM images of Mg x Ni1−x Fe2O4 ceramic indicate that the average grain size of the particles increases with increasing Mg addition up to ~3–4 μm for Mg ferrites. Effect of Mg concentration on dielectric properties of investigated ferrites was studied using Impedance Spectroscopy method. The complex impedance data show two semicircles arcs indicated two distinct relaxation phenomena and an increasing of the resistance corresponding to the grain and grain boundary from R g = 0.04 and R gb = 0.05 MΩ for x = 0 to R g = 6.97 and R gb = 6.06 MΩ for x = 1. It was observed, a general tendency from a predominant semiconductive character towards better dielectric properties when increasing the Mg addition (x). The real and imaginary impedances versus frequency revealed different weights on the effective electrical properties. Effects of Mg concentrations in the activation energy were calculated from temperature dependence of imaginary part of dielectric modulus for different frequency and present an enhanced values when increasing the substitution of Ni2+ with Mg2+, from 0.33 eV for x = 0 to 0.43 eV for x = 1. The ac conductivity has a general increasing trend as a function of composition and frequency. The resistivity response to various degrees of humidity were checked as a function of composition and showed a small variation of resistivity with increasing the degree of humidity, at lower frequency. The magnetic properties of the investigated ceramic ferrites demonstrated a reduce of magnetic moment with increasing Mg content, from M s = 50 emu/g for x = 0 to M s = 30 emu/g for x = 1, and also a reduction of Curie temperature with 219 °C for MgFe2O4 as against NiFe2O4. This behaviour can be attributed to the site occupancies of metal cations in the A- and B-site.

References

Somiya S, Aldinger F, Claussen N, Spriggs RM, Uchino K, Koumoto K, Kaneno M (2003) Handbook of advanced ceramics 2. Academic, London

Gillot B (1998) Fine–grained spinel ferrites: from the reactivity to magnetic properties. Eur Phys J 4:243–250

Sugimoto M (1999) The past, present and future of ferrites. J Ceram Am Soc 82:226–280

Pardavi-Horvath M (2000) Microwave applications of soft ferrites. J Magn Magn Mater 215:171–183

Yamamoto Y, Makino J (1994) Core losses and magnetic properties of Mn–Zn ferrites with fine grain sizes. J Magn Magn Mater 133:500–503

Batoo KM (2011) Study of dielectric and impedance properties of Mn ferrites. Phys B 406:382–387

Bangale SV, Patil DR, Bamane SR (2011) Preparation and electrical properties of nanocrystalline MgFe2O4 oxide by combustion routeArch. Appl Sci Res 3(5):506–513

Sivakumar N, Narayanasamy A, Greneche JM, Murugaraj R, Lee YS (2010) Electrical and magnetic behaviour of nanostructured MgFe2O4 spinel ferrite. J Alloy Comp 504:395–402

Ponpandian N, Balaya P, Narayanasamy A (2002) Electrical conductivity and dielectric behaviour of nanocrystalline NiFe2O4 spinel. J Phys 14:3221–3237

Bae S, Lee SW, Takemura Y (2006) Applications of NiFe2O4 nanoparticles for a hyperthermia agent in biomedicine. Appl Phys Lett 89(252503):1–4

El Hiti MA (1995) DC conductivity for Ni x Mg1–x Fe2O4 ferrites. Phase Trans 54:117–125

El Hiti MA (1996) AC electrical conductivity of Ni–Mg ferrites. J Phys D Appl Phys 29:501–509

Hashim M, Alimuddin Singh F, Mohammed EM, Kumar S, Kumar R (2012) Investigation of electrical properties of Ni–Mg ferrite nano particles using impedance spectroscopy. AIP Conf Proc 1447:223–224. doi:10.1063/1.4709960

Berchmans LJ, Selvan RK, Selva Kumar PN, Augustin CO (2004) Structural and electrical properties of Ni1−x Mg x Fe2O4 synthesized by citrate gel process. J Magn Magn Mater 279:103–110

Berchmans LJ, Kalai Selvan R, Augustin CO (2004) Evaluation of Mg2+-substituted NiFe2O4 as a green anode material. Mater Lett 58:1928–1933

Airimioaei M, Palamaru MN, Iordan AR, Berthet P, Decorse C (2013) Structural investigation and functional properties of Mg x Ni1−x Fe2O4 Ferrites. J Am Ceram Soc. doi:10.1111/jace.12683

Larson C, Von Dreele RB (2001) General structure analysis system. Los Alamos National Laboratory, Los Alamos. ftp://ftp.lanl.gov/public/gsas

Sickafus KE, Wills JM (1999) Structure of spinel. J Am Ceram Soc 82(12):3279–3292

Kittle C (1999) Introduction to solid state physics, 7th edn. Wiley, New York

Naeem M, Abbas Shah N, Hussain Gul I, Maqsood A (2009) Structural, electric and magnetic characterization of Ni–Mg spinel ferrites. J Alloy Comp 487:739–743

Younas M, Nadeem M, Atif M, Grossinger R (2011) Metal-semiconductor transition in NiFe2O4 nanoparticles due to reverse cationic distribution by impedance spectroscopy. J Appl Phys 109:093704–093708

Barsoukov E, Macdonald JR (2005) Impedance spectroscopy theory, experiments and applications. Wiley, New York

Idrees M, Nadeem M, Hassan MM (2010) Investigation of conduction and relaxation phenomena in LaFe0.9Ni0.1O3 by impedance spectroscopy. J Phys D 43:155401–155409

Loyau V, Wang GY, Lo Bue M, Mazaleyrat F (2012) An analysis of Mn–Zn ferrite microstructure by impedance spectroscopy, scanning transmission electron microscopy and energy dispersion spectrometry characterizations. J Appl Phys 111:053928–053929

Ghatak S, Meikap AK, Sinha M, Pradhan SK (2010) Electrical conductivity, magnetoconductivity and dielectric behaviour of (Mg, Ni)-ferrite below room temperature. Mater Sci Appl 1:177–186

Veena Gopalan E, Malini KA, Saravanan S, Sakthi Kumar D, Yoshida Y, Anantharaman MR (2008) Evidence for polaron conduction in nanostructured manganese ferrite. J Phys D Appl Phys 41:185005–185014

Fawzi AS, Sheikh AD, Mathe VL (2010) Structural, dielectric properties and AC conductivity of Ni(1−x)Zn x Fe2O4 spinel ferrite. J Alloy Comp 502:231–237

Sarah P, Suryanarayana SV (2003) Magnetic properties of diphasic composites of LiF5O8-BaTiO3, Indian. J Phys 77:449–452

Ponpandian N, Narayanasamy A (2002) Influence of grain size and structural changes on the electrical properties of nanocrystalline zinc ferrite. J Appl Phys 92:2770–2778

Sivakumar N, Narayanasamy A, Ponpandian N, Greneche JM, Shinoda K, Jeyadevan B, Tohji K (2006) Effect of mechanical milling on the electrical and magnetic properties of nanostructured Ni0.5Zn0.5Fe2O4. J Phys D 39:4688–4694

Curecheriu LP, Buscaglia MT, Buscaglia V, Mitoseriu L, Postolache P, Ianculescu A, Nanni P (2010) Functional properties of BaTiO3–Ni0.5Zn0.5Fe2O4 magnetoelectric ceramics prepared from powders with core-shell structure. J Appl Phys 107(104106):1–11

Rezlescu N, Doroftei C, Popa PD (2007) Humidity sensitive electrical resistivity of MgFe2O4 and Mg0.9Sn0.1Fe2O4 porous ceramics. Rom J Phys 52(3–4):353–360

Fang J, Shama N, Tung LD, Shin EY, O’Connor CJ, Stokes KL, Caruntu G, Wiley JB, Spinu L, Tang J (2003) Ultrafine NiFe2O4 powder fabricated from reverse microemulsion process. J Appl Phys 93:7483–7485

Kulkarni RG, Joshi HH (1986) Comparison of magnetic properties of MgFe2O4 prepared by wet-chemical and ceramic methods. J Solid State Chem 64:141–147

Smit J, Wijn HPJ (1959) Ferrites. Cleaver-Hume Press, London

Šepelak V, Feldhoff A, Heitjans P, Krumeich F, Menzel D, Litterst FJ, Bergmann I, Becker KD (2006) Nonequilibrium cation distribution, canted spin arrangement, and enhanced magnetization in nanosized MgFe2O4 prepared by a one-step mechanochemical route. Chem Mater 18:3057–3067

Šepelak V, Baabe D, Mienert D, Litterst FJ, Becker KD (2003) Enhanced magnetisation in nanocrystalline high-energy milled MgFe2O4. Scr Mater 48:961–966

Sattar AA, Wafik AH, El-Sayed HM (2001) Infrared spectra andmagnetic studies of trivalent doped Li-ferrites. J Phys Stat Sol 186(3):415–422

Acknowledgements

This work was financially supported by PN-II-ID-PCE-2011-3-0745 project.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Mocanu, Z.V., Airimioaei, M., Ciomaga, C.E. et al. Investigation of the functional properties of Mg x Ni1−x Fe2O4 ceramics. J Mater Sci 49, 3276–3286 (2014). https://doi.org/10.1007/s10853-014-8033-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8033-6