Abstract

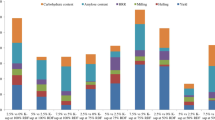

The present study aimed to assess not only the efficacy of sap from two seaweeds Kappaphycus alvarezii (K-sap) and Gracilaria edulis (G-sap) on productivity and quality of Zea mays under rain-fed condition, but also to quantify whether sap application is beneficial in terms of lowering the carbon and phosphate footprint of mineral fertilizers per unit of produce. Field experiment was carried out to test 18 treatments, viz., 5 concentrations (2.5, 5.0, 7.5, 10 and 15 %) each of K-sap and G-sap applied along with recommended rate of fertilizers (RRF); 3 concentrations (7.5, 10 and 15 %) of each of the two types of sap applied along with 50 % RRF; alongside 2 control treatments T1 (water spray along with 100 % RRF) and T18 (water spray along with 50 % RRF). The optimal treatments that enhanced the grain productivity of maize were 5 % G-sap or 7.5 % K-sap applied in conjunction with 100 % RRF and the grain yield enhancements ranged from 21.4 to 29.8 % as compared to T1. Significant increase in P (35.5 %) and K (14.4 %) content in grains was observed through G-sap application, suggesting bio-stimulation in absorption of these elements. Notably, stover yield production at reduced RRF in certain combinations with sap was at par with T1 suggesting a possible saving on fertilizer requirement for fodder production under rain-fed conditions. Compared to T1, there was marked reduction of 17.5 and 23.1 % in global warming potential per unit of produce when 7.5 % K-sap and 5 % G-sap were used respectively in conjunction with 100 % RRF.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Maize is the leading cereal crop worldwide (Ranatunga et al. 2009) grown in more than 160 countries, mainly for feed followed by food and raw material for industries. It is the principal staple food for the people in South America, Africa and some parts of Asia and is also used as fodder crop for livestock in the developing countries including India. Thus maize is the largest single source of dietary protein for millions of people around the globe. Increasing maize productivity is thus a priority in view of burgeoning feed, food, fodder and industrial demand in contrast to near-constant land resource (Dass et al. 2008; Chaudhary et al. 2014). In reality, the reverse trend is being observed as average annual rates of change in global maize yields has been much slower in recent decades when compared to that in 1960s and 1970s (FAO 2014). Part of this problem may be attributed to the shift from biological to chemical-based N management which brought out marked improvement in yield of maize but was simultaneously associated with marked decline in soil carbon status over the last five decades (Khan et al. 2007). Increasing crop productivity in a sustainable manner without impairing soil health and with minimum carbon foot print should be the focus of the approaches to meet the increasing demand for maize production. Crops like maize are heavy feeder of nutrients; hence, the crop nutrient demand is high. However, the poor socio-economic conditions of farmers in the developing countries prevent them from applying fertilizers even at the recommended rates to realize optimum yields. This is evident from the fact that estimated yield gaps—expressed as a percentage of potential yields—surpass 50 % in most developing regions of the world, which, if reduced, can manifest into better food security, nutrition and livelihood of the rural folk (FAO 2014).

Seaweed-based extracts can be effective in improving maize productivity under such nutrient and soil moisture limiting situation. Besides being able to partly offset the requirement of chemical fertilizers due to the presence of some macro- and micro-nutrients (Mondal et al. 2013; Pramanick et al. 2013), the seaweed extracts can enhance the yield of crops due to the presence of plant growth regulators like IAA, kinetin, zeatin and gibberellins (Crouch and Van Staden 1993; Khan et al. 2009; Thirumaran et al. 2009; Zodape et al. 2009; Prasad et al. 2010; Briceño-Domínguez et al. 2014). Further, the presence of quaternary ammonium compounds like glycine betaine and choline chloride (Blunden et al. 1986; Mondal et al. 2015) may impart tolerance during environment stress conditions (Ashraf and Foolad 2007; Sharma et al. 2014), especially under rain-fed conditions. Apart from improving crop productivity, seaweed extracts have also been beneficial in improving the germination of seedlings as well as the post-harvest shelf life of perishable products (Khan et al. 2009; Hernández-Herrera et al. 2014).

Technologies have been developed for large-scale cultivation of the two seaweeds, Kappaphycus alvarezii and Gracilaria edulis (Eswaran et al. 2005, Ganesan et al. 2011). Improvements in productivity and quality of many crops have been reported through foliar application of sap (liquid seaweed extract) of K. alvarezii (Zodape et al. 2010; Shah et al. 2013). Rathore et al. 2009 have reported a 57 % increase in yield of soybean, under rain-fed conditions over control following 15 % Kappaphycus seaweed extract application. Recently, Pramanick et al. 2013 have reported a 39 and 34 % increase in yield of green gram over control following application of 15 % Kappaphycus and Gracilaria sap in combination with mineral fertilizers, respectively. Similarly, Dwivedi et al. 2014 have also reported a 49.2 and 37.8 % improvement in yield of black gram over control following application of 15 % Kappaphycus and Gracilaria sap in combination with mineral fertilizers, respectively. However, reports elucidating the influence of seaweed extracts on maize quality and productivity are very limited. Recently, our efforts to assess the efficacy of seaweed extracts in enhancing the productivity and quality of maize in north-east India, a nutrient-deficient region with an average productivity of 1.5 t ha−1, has revealed that application of Kappaphycus and Gracilaria seaweed extracts have improved the yield by 10.5–13.1 %, respectively, when applied along with chemical fertilizers at the recommended rate (Layek et al. 2014; Layek et al. 2015). Further, we have recently reported that one of the formulations prepared by removing gibberellins from the Kappaphycus sap improved stover yield of maize without compromising on grain productivity (Mondal et al. 2015). However, there are no reports that evaluate the efficacy of Kappaphycus and Gracilaria seaweed sap under rain-fed conditions. Moreover, in the previous studies, the improvement in yield was not explained in relation to various growth indices, which was one of the objectives for carrying out the present study.

It has been conjectured that seaweed extracts can partially substitute for the requirement of chemical fertilizers (Hernández-Herrera et al. 2014) when applied concomitantly. The manufacture of chemical fertilizers accounts for various environmental impacts and has a definite carbon foot print. Life cycle assessment is an important tool to evaluate the various environmental impacts including carbon foot print in a process chain. Thus, any improvement in crop productivity over and above that produced under the recommended rate of chemical fertilizers following application of seaweed extract would result in reduction of carbon foot print and other environmental impacts per unit of produce which we intended to quantify. Thus the specific objectives of the present study were to (1) evaluate the efficacy of Kappaphycus and Gracilaria seaweed saps on growth, productivity and nutritional quality of rain-fed maize under recommended and reduced fertilizer application regime; and (2) to deduce the gains in terms of global warming potential and eutrophication potential on account of mineral fertilizer per 100 kg of maize grain produced using sap application as an agro-practice.

Materials and methods

Experimental site, design and treatment

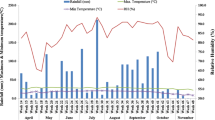

The field trial was carried out at Birsa Agricultural University farm, situated in Chhotanagpur Plateau of Jharkhand state in India during kharif season (July–October) of 2012. The experimental site was located at 23°17′ N latitude and 85°19′ E longitude at an altitude of 625 m above mean sea level. The mean maximum temperature varied from 28.8 to 30.2 °C and minimum temperature from 16.9 to 20.6 °C, while the average relative humidity was 76 % during the crop period. The soil at the experimental site was well-drained sandy loam alfisols, classified according to the USDA soil taxonomy as hyperthermic, mixed-type Paleudtalf. The initial soil pH was 5.5 with an organic carbon content of 0.45 %, while the available N, K and P contents were 235, 179.2 and 11.7 and kg ha−1, respectively. The experiment was laid out in a randomized block design with 18 treatments with each treatment replicated 3 times. The net plot size was 5 m × 4.8 m. A spacing of 60 cm × 25 cm was maintained in each plot with a plant density of 6.67 × 104 ha−1. A total of 18 treatments comprising of two seaweed saps (K. alvarezii and G. edulis, henceforth referred to as K-sap and G-sap, respectively), each of which was applied at five different concentrations (2.5, 5.0, 7.5, 10 and 15 % v/v of seaweed sap with water) in conjunction with recommended rate of fertilizers (150:60:40 kg N:P2O5:K2O ha−1 , henceforth abbreviated as 100 % RRF) and three concentrations (7.5, 10 and 15 % v/v of seaweed sap with water) of both the saps along with 50 % recommended rate of fertilizers (50 % RRF) along with two controls (T1-water spray with 100 % RRF and T18- water spray with 50 % RRF), respectively. With 50 % RRF, only higher concentrations of sap (7.5 % onwards) were taken with the hypothesis that lower concentration of sap with lower level of fertilizer (50 % RRF) may not respond, as is also evident from previous preliminary trials.

Extraction of sap from seaweeds

The K. alvarezii and G. edulis seaweeds were cultivated in Tamil Nadu, India. The sap from K. alvarezii (commercially available as Aquasap, manufactured by M/s Aquagri Processing Pvt. Ltd, the licensee of CSIR-Central Salt & Marine Chemicals Research Institute’s sap technology) was expelled mechanically by milling under ambient conditions from its fresh biomass after washing the seaweed with fresh water. The resultant slurry obtained by milling was clarified by centrifugation in order to obtain the seaweed sap following which it was preserved (Eswaran et al. 2005). On the other hand, G-sap was prepared by mechanically expelling the sap from its fresh biomass after washing the seaweed with seawater at pilot plant located at regional station of CSIR-CSMCRI in Tamil Nadu, which was followed by filtration through mesh size of approximately 20–50 μm. This sap was preserved using a mixture of 0.02 % propyl paraben, 0.2 % methyl paraben and 0.1 % potassium benzoate. The liquid filtrates obtained in the above manner were considered as 100 % concentration of each sap and further diluted as per the treatments. The estimation of inorganic constituents, plant growth regulators and quaternary ammonium compounds in sap was determined as per the procedure described in Mondal et al. (2015). The sap composition used for the present study were from the same lot as that described earlier by us in Layek et al. (2015) (Table 1).

Field management, soil sampling, plant measurements and analysis

The maize variety used was HQPM-1 under rain-fed conditions. Initially, the land was prepared by ploughing twice followed by planking. Earthing up was carried out at 25 days after sowing (DAS). Irrigation was not applied as the crop was totally rain-fed. The total rainfall received during the crop period was 856 mm. A total of three sprays of K- and G-sap were applied in the morning around 8 a.m. at 20 days interval starting from 30 DAS at the knee high stage, the second being at tasseling stage (50 DAS) and finally the third spray applied at grain filling stage (70 DAS). The spray volume was 500 L ha−1 for the first spray while it was 700 L ha−1 for the second and third sprays. Foliar application was carried with the required concentrations of different saps using a manually operated knapsack sprayer. Similarly, in control treatment instead of sap, equivalent volume of water was sprayed and the crop was fertilized as per treatment through urea, di-ammonium phosphate (DAP) and muriate of potash (MOP). Pond water having a pH of 7.2 was used in the experiment for dilution of saps and it had the following chemical composition: 4.5 mmol L−1 bicarbonates, 0.29 mmol L−1 calcium, 0.24 mmol L−1 magnesium, 0.13 mmol L−1 nitrate, 3 mmol L−1 chloride, 0.08 mmol L−1 potassium and 0.09 mmol L−1 sulphur. Half dose of N and full dose of P and K were applied initially and remaining dose of N was top dressed in two splits at 35 and 50 DAS.

Soil samples were collected from a depth of 0–15 cm from each plot before sowing and after harvest of the crop. The available nitrogen was determined by alkaline permanganate method (Subbiah and Asija 1956), whereas potassium was extracted by neutral normal ammonium acetate method (Hanway and Heidel 1952) and phosphorus by Bray P-1 reagent (Jackson 1973) and estimated by flame photometry and spectrophotometry, respectively. Organic carbon was determined according to the Walkley and Black method, as described in Nelson and Sommers (1982). Plant height was measured from base to top leaf in centimeters (cm) from 5 plants in each plot during 3 different growth stages at 35, 55 and 75 DAS and also at maturity. Leaf surface area of one plant per plot was estimated by gravimetric method on the basis of leaf area ratio (leaf area per unit dry weight of leaf) and ground area of 0.1625 m2 was used to compute the LAI values. Dry matter production was also measured periodically by destructive sampling of 1 plant from each of the 54 plots at 35, 55, 75, 95 DAS and at maturity using which crop growth rate (CGR), relative growth rate (RGR) and net assimilation rate (NAR) were computed as per the formula given below and described in Radford (1967) at particular stages of growth and expressed in g m−2 day−1, g g−1 day−1 and g m−2 day−1 respectively.

Where, W 1 = dry weight of plant at time t 1 , W 2 = dry weight of plant at time t 2 ; L 2 and L 1 are the leaf area per unit area at time t 1 and t 2 , respectively, and LnW 1 and LnW 2 are the natural logarithm of total dry weight of plant at the time interval t 2 and t 1 , respectively.

All the cobs of the net plot area were harvested after maturity of plants and expressed in no of cobs per hectare. After drying for 3 days, seeds were removed manually and counted and expressed as number of seeds per cob. Average weight of 100 seeds was also determined from each treatment of the experiment. Grain, stone and stalk yield were expressed in kg ha−1 for every individual treatment. The mineral contents (P, K, Ca, Mg, S, Cu and Zn) of maize grains were determined by WD-X-Ray Fluorescence method (Patidar et al. 2013). Briefly, 3 g of powdered sample was mixed with 1 g of boric acid, pelletized in 40-mm aluminium cups with a Pelletizer (Kimaya engineers, India) at 20 t pressure with 10 s dwelling time. Elemental concentrations in these pellets were than analyzed in WD–XRF spectrophotometer, S4 pioneer (Bruker AXS, Germany) equipped with advanced optical systems, two detectors (Flow and Scintillation), 4–5 crystals, Rh anode and SPECTRAplus Software. Measurement conditions for each analyte were optimized from calibration curves obtained using certified reference materials viz., SRM 1515 apple leaves and SRM 1573a tomato leaves obtained from National Institute of Standards and Technology, USA. N content of the maize grain was determined by Kjeldahl method and nitrogen use efficiency (NUE) was calculated from crop yield and applied N. Partial factor productivity of applied N, abbreviated as nitrogen use efficiency (expressed as kg harvest product per kg N applied) was determined as described by Dobermann (2005). Carbohydrate was extracted (Smith et al. 1964) and determined using UV-Vis spectrophotometer (Analytical Instruments, Model TD-60) (Murphy 1958) while protein content was determined by using Bradford method (Bradford 1976).

Life cycle impact assessment

Life cycle impact in terms of global warming potential (GWP) and eutrophication potential (EP) of the mineral fertilizers was determined using GaBi software (version 6.0). The goal of the life cycle impact assessment (LCIA) was to determine the carbon foot print of the various mineral fertilizers used in the present study from cradle to gate with system boundaries as depicted in Fig. 1. As relevant datasets for the same were not available for the Indian conditions, datasets from the Ecoinvent database (version v 2.2) were used as a substitute. The datasets for urea as N production, DAP production both in terms of N and P2O5 and MOP as K2O were used inclusive of their transport to regional storage. Further the bulk transport of potassic fertilizer through oceanic transport assuming a distance of 5,500 nautical miles was also included as MOP is entirely imported in India. However, the use phase of the various fertilizers was not considered. LCIA of sap production was however, not carried out. The functional unit of the present study was the application of 100 % RRF or 50 % RRF per hectare as mentioned in “Experimental site, design and treatment”. The impacts were calculated using LCIA-CML 2001 Nov 2010 procedure and expressed as kg CO2 equivalents per 100 kg of maize grain yield for GWP (100 years) and kg phosphate equivalents for EP per 100 kg of maize grain yield, respectively.

Economic analysis

Benefit:cost ratio (B:C ratio), which is the ratio of net return on investment to the total cost of cultivation was used in order to explain the economics of maize cultivation. The prevailing market price for maize grain (INR 11,750 t−1), stalk (INR 200 t−1) and stone (INR 1,000 t−1) were used to calculate the economic returns from the produce. The common per hectare cost of cultivation excluding the fertilizer cost was INR 15543. The variable cost was attributed to different fertilizer and sap doses, which varied according to the treatment. While the cost of 100 % RRF was INR 6524, that of both the seaweed saps was taken as INR 30 L−1.

Statistical analysis

Linear mixed model was employed for analysis of variance (ANOVA) by REML computational procedure in Systat 13.0 software using the treatments as fixed effects and the replications as random effects. Post hoc comparison of means was carried out using least significant difference (LSD) at the probability level of 5 %.

Results

Composition of seaweed saps

Table 1 shows the composition of the two seaweed saps used in the present study. It can be seen that both the saps contain significant amounts of quaternary ammonium compounds (glycine betaine and choline chloride) besides various plant growth regulators, macro- and micro-nutrients. Interestingly, potassium content in Kappaphycus sap is considerably higher than Gracilaria sap, while the sodium content is much lower.

Growth attributes

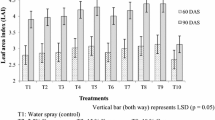

The results on growth attributes, viz., plant height, dry matter accumulation and leaf area index recorded at periodic intervals are presented corresponding to the different treatments (fixed effects) in Table 2. The results revealed that increase in plant height was observed only in the treatment receiving 100 % RRF in conjunction with foliar spray of 7.5 % K-sap concentration (T4), when compared to that receiving 100 % RRF only (T1), while no significant effect on plant height was obtained by Gracilaria sap application at any of the concentrations when applied in conjunction with 100 % RRF (Table 2). The results were same at all the days of observation except at 35 DAS when all the treatments were at par. Application of either of the sap at any of the concentrations could not increase the plant height when conjugated with 50 % RRF, when compared to 50 % RRF application only (T18).

At all the days of observations, higher dry matter accumulation over 100 % RRF (T1) was observed in T4 (+100 % RRF+ 7.5 % K-sap) and T11 treatments (100 % RRF + 5 % G-sap) with T4 and T11 being at par with one another. When applied along with 100 % RRF, all other doses of K- or G-sap except 15 % were superior to T1, but lower than T4 and T11 (Table 2). Application of 15 % of either of the saps with 100 % RRF did not increase the DMA over T1. Except at 35 DAS, DMA gradually increased with increasing concentration of K-sap up to 7.5% and up to 5 % G-sap with 100 % RRF, while decreasing thereafter indicating inhibitory effect at higher concentrations. Similarly, treatments 7.5 % K-sap (T7) and 7.5 % G-sap (T15) in combination with 50 % RRF enhanced DMA over 50 % RRF (T18); however, further increase beyond this dose had no effect. Leaf area measurements at 35, 55 and 75 DAS revealed that in combination with 100 % RRF, LAI increased with increasing concentration up to 7.5 % of K-sap (T4) and 5 % of G-sap (T11), following which it decreased (Table 2). Both these treatments were at par for LAI at all the stages of the plant growth. At 35 DAS, LAI increased significantly over 50 % RRF by application of K-sap with 50 % RRF, while at 55 DAS, the advantage was maintained only with 7.5 % G-sap. Compared to all other treatments, highest crop growth rate was observed at all the crop stages by application of 7.5 % K-sap and 5 % G-sap, respectively, along with 100 % RRF which were at par with one another (Table 3). Improvement in CGR by the two saps along with 50 % RRF application, when compared to RRF alone were not observed between 55 and 75 days of crop growth. In agreement to CGR, T4 and T11 were at par and also recorded the maximum values of RGR at all the crop stages. Comparing over 50 % RRF only, maximum increase in RGR was found only between 75 and 95 DAS using 7.5 % K-sap + 50 % RRF, while 7.5 % G-sap in conjugation with 50 % RRF recorded increase only between 95 DAS and harvest. During all the observed intervals, T4 and T11 gave the highest net assimilation rate that was unmatched with any of the other treatments and both these treatments were at par. All the treatments involving combination of either of the saps with 50 % RRF showed higher NAR over its control (T18) while being at par with one another.

Yield attributes

Among the yield attributing parameters, the plant population as well as number of cobs per unit area did not differ significantly due to the treatments (Table 4). However as compared to RRF, grains per cob increased with increasing concentration of sap from 2.5 to 7.5 % of K-sap (T4) and up to 5 % of G-sap (T11) when they were applied in conjunction with 100 % RRF. Both T4 and T11 were at par. Beyond these dosages, there was decrease in number of seeds formed, which was at par with 100 % RRF only in case of K-sap but significantly higher in case of G-sap till the highest concentration. In combinations involving 50 % RRF, increase over 50 % RRF was only found at 7.5 % concentration of either of the saps and further increase in their concentrations decreased the number of grains formed per cob. Only 7.5 % of K-sap or 5 % of G-sap, respectively, in combination with 100 % RRF resulted in improvement in test weight over 100 % RRF only while all other sap doses with 100 % RRF were at par with T1. K-sap or G-sap applied at 7.5 % in combination with 50 % RRF was the only treatment that resulted in higher test weight compared to 50 % RRF only.

In agreement with yield attributes, compared to 100 % RRF, the grain yield of maize also significantly increased with increasing level of sap concentration up to 7.5 % in case of K-sap and 5 % in case of G-sap when applied in conjunction with 100 % RRF, which decreased with further increase of the sap concentrations (Table 4). The highest maize yield was obtained by application of 5 % G-sap along with 100 % RRF (4,375 kg ha−1) and this treatment (T11) was superior to all other treatments, except application of 7.5 % K-sap along with 100 % RRF (T4). Compared to T1, the improvement in grain yield was 29.8 and 21.4 % through G-sap and K-sap conjugation, respectively with 100 % RRF (Table 4). Under nutrient limiting situation, i.e. compared to the treatment where 50 % RRF was applied, the only improvement in yield was obtained when this fertilizer regime was applied along with 7.5 % concentration of either K- or G-sap. The corresponding yield increases over T18 through K- and G-sap were 22.5 and 28.0 %, respectively, through K- and G-sap conjugation with reduced RRF (Table 4). The stone and stalk yield of maize followed similar pattern as that for grain yield for T4 and T11 treatments. Compared to T18, 50 % RRF conjugated with 7.5 % of G-sap could only bring about improvement in stalk yield. K-sap in combination with 50 % RRF did not improve in stalk yield at any of the doses. There was no significant change in harvest index (Table 4) due to conjugation of different saps applied at different concentrations over and above either 100 % RRF or 50 % RRF.

Nutritional quality of grains

There was no statistical difference in the grain mineral content with respect to Ca, Mg, S, Cu and Zn due to any of the sap and fertilizer conjugation treatments when compared to their respective base treatments (Table 5). There was an increase in K content in case of combined use of 5 % G-sap and 100 % RRF over T1. Use of 7.5 % K-sap in conjunction with 50 % RRF brought an increase in K content in maize grains when compared to that in 50 % RRF use only.

The application of both the types of seaweed saps in conjugation with RRF increased carbohydrate content in grains significantly with increasing concentrations up to the highest level of 15 %, as compared to T1. At 15 % concentration + 100 % RRF level, K-sap was significantly superior to G-sap. Application of either of these saps at any of the concentrations in conjunction with reduced fertilizer dose also improved the grain carbohydrate content with respect to T18 up to the highest dose. However, in agreement with the grain yield improvement, the highest carbohydrate productivity was found in treatment where 100 % RRF was combined either with 7.5 % K-sap or with 5 % G-sap. Compared to T18, significant improvement in carbohydrate productivity was observed in treatment with 7.5 % K-sap or G-sap applied along with 50 % reduced fertilizer dose (Table 5).

In sharp contrast with carbohydrate content, the protein content in maize grains was highest at 5 % K-sap (T3) and 2.5 % G-sap (T10) concentrations when applied along with 100 % RRF as compared to T1. T3 and T10 were at par with respect to each other. The grain protein content was also found to be highest in T3; however, this treatment was at par with 100 % RRF + 7.5 % K-sap application, which also recorded the maximum grain yield. Significant improvement in protein productivity with reduced fertilizer dose was obtained only at 7.5 % concentrations of either of the saps and in no case was the protein yield significantly decreased over T18 (Table 5).

Economics of maize cultivation using seaweed sap, soil fertility status and nitrogen use efficiency

Cost of cultivation of maize varied due to fertilizer level and concentrations of the two types of seaweed sap applied. Maize fertilized with 100 % RRF and sprayed with 15 % concentration of seaweed sap incurred maximum cost of cultivation. Maize sprayed with 7.5 % K-sap or 5 % G-sap at 100 % RRF had similar gross return. However, 5 % G-sap along with 100 % RRF gave highest net return and benefit: cost ratio and had greater advantage over 7.5 % K-sap at 100 % RRF. A higher return per unit investment was apparent when the sap spray was combined with 100 % RRF as compared to 50 % RRF (Table 6).

Soil fertility status after harvest of the crop measured in terms of available P and K was positively influenced by the different treatments. Foliar spray of seaweed sap and fertilizer level did not influence the soil organic carbon and available N. Compared to that in RRF, the available phosphorous increased with the application of 5 % G-sap along with 100 % RRF and this treatment was at par with 7.5 K-sap along with 100 % RRF. Available K status of soil considerably declined in all the treatments to its initial status. Different concentrations of both the saps, when conjugated with mineral fertilizers at 100 % or 50 % RRF, did not influence the available potassium status of soil (Table 7). At similar concentrations of sap, 50 % RRF always had higher NUE. Compared over T1, significant enhancement in NUE were found in T4 and T11, which themselves were found at par (Table 7).

Environmental impact

Compared to RRF, there was a marked reduction of 17.5 and 23.1 % in global warming potential on account of mineral fertilizer per 100 kg of maize grain produced when 7.5 % K-sap and 5 % G-sap were used in conjunction with 100 % RRF (Fig. 2a). Similarly use of seaweed saps in increasing maize yield resulted in reduction of 0.66–0.88 g P-equivalent per 100 kg of grains produced, thus contributing to a favourable impact on aquatic eutrophication potential (Fig. 2b).

Graph depicting a fertilizer global warming potential per unit of maize grain production (kg CO2-equivalents 100 kg−1); and b fertilizer eutrophication potential per unit of maize grain production (kg PO4-equivalents 100 kg−1) of the various treatments. LSD at 5 % = 1.5 for Fig. 1a and 0.01 for Fig. 1b. Treatment legends are those as described in the tables

Discussion

Growth and yield attributes

Crop production primarily deals with yield of harvestable economic products and the aim was to study how growth and development of crop plants take place and finally end up with the maximum proportion of harvestable economic parts of the total dry matter so produced. The results revealed that vegetative growth was significantly higher over RRF when the crop was applied the RRF and as well sprayed with either 7.5 % K-sap (T4) or 5 % G-sap (T11), both of which were statistically equivalent. The enhanced DMA at harvest (86.9 % higher over RRF) in the treatment using 7.5 % K-sap along with 100 % RRF was attributed to maintenance of 16.9–49.5 % higher leaf area index (Table 2), higher CO2 assimilation rate evident by 1.7–2.5 fold higher crop growth rate, 10.2–33.2 % higher relative growth rate and 25.8–51.5 % higher net assimilation rate, during the different crop growth stages observed (Table 3). The increased DMA (88.2 % higher over RRF at harvest) by 5 % G-sap + RRF might be explained by similar improvements in growth indices, viz., 14.5–35.2 % higher LAI (Table 2), 1.8–2.6 folds higher CGR, 5.8–38.7 % higher RGR and 31.4–45.4 % higher NAR during different growth phases (Table 3). Crop production is determined by CGR which is a linear function of intercepted irradiance (Whigham 1983). Higher LAI leads to increased DMA due to higher CGR (Shibles and Weber 1965) and consequently higher grain yield (Patra et al. 1995). The observed enhanced vegetative growth of maize plants due to the two seaweed saps may be attributed to the presence of plant growth hormones like cytokinins in them which promote cell division and cell enlargement (Blunden et al. 1979; Crouch et al. 1990; Crouch and Van Staden 1993; Mondal et al. 2015). According to Stevens and Westwood (1984), cytokinins play an important role towards enhanced translocation of nutrients from roots to other plant parts. Interestingly, our studies revealed that compared to RRF only, T4 and T11 treatments led to significant improvement in the photosynthetic surface area as indicated by enhancement of leaf area index (29.1 and 33.5 % higher, respectively by K- and G-sap over control at 55 DAS), however, the magnitude of increase was not commensurate with the observed crop growth rate which was found to be much higher. This connotes enhanced efficiency of photosystem by K- and G-sap application which was also corroborated by 45.4–51.5 % higher net assimilation rate observed during 55–75 DAS in these treatments when compared with the control receiving RRF only (Table 3). Moreover, the percentage of increase in LAI was higher during the early stages of crop growth than at the later stages (Table 2), indicating that higher photosynthate accumulation rate might have been maintained starting from early vegetative stage culminating in higher dry matter accumulation in these treatments. Although photosynthesis was not studied in the present experiment, earlier studies confirmed enhanced net photosynthetic rate and other gas exchange parameters in maize by application of Kappaphycus-based sap formulations (Mondal et al. 2015). Improvements in NAR might have been due to the presence of phytohormones such as gibberellic acid (GA3) in the seaweed saps which accelerated the mobilization of photosynthates from leaves to stem (Alvim 1960). The seaweed saps contain GB/choline in substantial amounts (Mondal et al. 2015) which are known to play a profound role in enhancing photosynthetic activity by maintaining higher levels of photosynthetic pigment (Blunden et al. 1996; Guinn et al. 2011). Comparing the effect of K- as well as G-saps along with RRF at 5 % concentration, it is evident that G-sap treated plants accumulated higher dry matter compared to K-sap treated ones (Table 2). Differences in hormone concentration might be the possible reason for this difference in efficacy of the two seaweed saps. It can be seen that gibberellic acid was not detected in the G-sap because of which reciprocal interactions with cytokinins and other growth regulators might have been prevented leading to enhanced efficacy of G-sap in increasing the vegetative growth at lower concentration. Antagonistic interaction of gibberellic acid with zeatin and kinetin has been earlier reported in maize by Mondal et al. 2015. Weiss and Ori (2007), Greenboim-Wainberg et al. (2005) and Fleishon et al. (2011) have also proposed cross talk between these hormones.

There was no significant difference in number of cobs formed per unit area due to the different sap and fertilizer combinations and the yield enhancement was primarily attributed to improvement in number of grains formed in each of the cobs and weight of individual seeds (Table 4). Though 7.5 % K-sap (T4) or 5 % G-sap (T11) when applied together with 100 % RRF resulted in the maximum improvement in grain number, lower doses were also superior to 100 % RRF (Table 4). In contrast, for 100-seed weight, none of the sap concentrations led to larger grains other than T4 and T11, indicating specificity of dosage requirement for achieving grains (Table 4). The fact that no significant change was evident in harvest index (Table 4) due to conjugation of different saps applied at different concentrations over and above either 100 % RRF or 50 % RRF connoted an identical pattern of photosynthate partitioning between vegetative and reproductive parts in these treatments. This observation is supported by the fact that the treatments recording maximum stalk yield (Table 4) followed the same trend as found in grain yield parameter. However, most interestingly, stalk yield obtained by application of 50 % reduced fertilizer dose in conjunction with any of the G-sap concentration and 7.5 % K-sap concentration applied was found at par with that obtained with 100 % RRF (Table 4). These observations suggest possible saving on chemical fertilizer requirement to a large extent under rain-fed conditions for stalk (used as a fodder) production.

The enhanced grain and stover yield thus correlated well with the higher vegetative growth parameters discussed earlier. Similar to the results obtained in this study, Mondal et al. (2015) also attributed the yield improvement in maize to an increase in number of grains per plant which was brought about by enhanced cob length and consequent greater kernel set, although no improvement in single seed weight was observed in that study. The higher rate of photosynthate accumulation combined with delay in senescence of the leaves leading to pronounced retardation in loss of green colour may be attributed to the presence of cytokinins. This might have boosted the photosynthate supply to the grains forming larger seeds which ultimately resulted in realizing higher grain yield (Beckett and Van Staden 1990). In addition, the seaweed saps contain KCl and glycine betaine and beneficial effect of their combined presence was conjectured to be responsible for conferring protection against photosynthetic enzyme inactivation, eventually leading to higher productivity of maize (Mondal et al. 2015). GB is known to play a vital role towards osmotic adjustment in plants, especially during stress (Blunden et al. 1996; Guinn et al. 2011). In addition, seaweed extracts have been ascribed to enhance antioxidant and activity of free radical scavenging enzymes imparting protection from cell damage (Khan et al. 2009) at times of day-to-day abiotic stress experienced by crops grown under uncontrolled field conditions (Layek et al. 2015), which often is the case in rain-fed agriculture. The results of the present experiment showed enhancement in grain yield and quality at even low doses, especially, 5 % G-sap in conjunction with RRF gave significantly higher improvements in many parameters. However, all the lower concentrations were not tested in conjunction with 50 % RRF in the present experiment and thus need to be addressed in future studies.

Nutritional quality of grains

In spite of realizing greater yield in the treatments receiving 100 % RRF along with either 7.5 % K-sap or 5 % G-sap, there was no significant reduction over 100 % RRF with respect to mineral composition studied, viz., P, K, Ca, Mg, S, Cu and Zn, in the grains due to dilution effect (Table 5). On the contrary, there was an increase in K (14.4 %) content in case of combined use of 5 % G-sap and 100 % RRF, suggesting bio-stimulation in absorption of this mineral element (Table 5). In our study, K-sap contributed to the increase in carbohydrate and protein content of grain as well as their yields. Such enhancement might be attributed to the protective effect of the quaternary ammonium compounds like glycine betaines which are present in sap. These compounds may reduce the degradation of macromolecules like complex proteins, enzymes and offer stability to membranes in response to environmental stress, which might increase photo-assimilation rate eventually leading to enhancement of protein and carbohydrate (Layek et al. 2015). Our results corroborate with the findings of Anantharaj and Venkatesalu (2002) and Sivasankari et al. (2006), where sugar content of leguminous plants were increased by liquid seaweed extracts. Pise and Sabale (2010) also reported significant influence of seaweed extract on protein content of fenugreek and attributed this to the promoter effects of these extracts on root proliferation stimulating better nutrient uptake, especially of those which are constituents in protein synthesis (nitrogen, phosphorus and sulphur). Similar findings were also reported for okra and wheat by Zodape et al. (2009).

Economics of maize cultivation using seaweed sap, soil fertility status and Nitrogen use efficiency

The enhanced quantity and quality of maize using seaweed sap was also complemented by higher monetary returns. Our results indicated that the highest net return and benefit: cost ratio were obtained by applying 5 % G-sap along with 100 % RRF, thus indicating that G-sap outperformed K-sap (Table 6).

Foliar spray of seaweed sap and fertilizer level did not influence the soil organic carbon and available N (Table 7) which indicated that decomposition and accumulation of soil organic matter was maintained at equilibrium state. Soil phosphorous increased significantly with the application of 5 % G-sap or 7.5 K-sap along with 100 % RRF (Table 7). Since 5 % G-sap in conjunction with 100 % RRF showed higher P content in grain (Table 5), it may be possible that the increase in available P content in soil may have been probably due to higher phosphorus solubilization on account of soil enzymatic processes. Soil biochemical changes influenced by sap might be an important aspect of study, especially because a significant amount of sap gets into the soil by drift during foliar spray. Thus effect of sap on biological chemical and biochemical activity in different layers of soil up to the full root zone of the crop should be studied to understand any such nutrient transformation processes taking place. NUE was found improved in some treatments receiving sap in conjugation with 100 % (T4 and T11) or 50 % RRF (T7 and T15) indicating better utilization of nitrogen supplied (Table 7). Other NUE indices were not assessed since unfertilized plots were not considered in the study. Given the encouraging results, future experiments should also assess the other NUE indices. Comparing the treatment employing 50 % RRF only, significantly highest NUE was obtained in the treatments where 50 % RRF was combined either with K-sap or G-sap at 7.5 % concentration. At similar sap concentrations for both the saps, NUE were found significantly higher on conjunction with 50 % RRF than 100 % RRF.

Environmental impact

Globally, the agricultural sector contributes significantly to carbon emissions due to usage of varying nitrogen fertilizers (Hillier et al. 2009). Apparently, the magnitude of improvement in yield on account of seaweed sap application brought out a significant reduction in fertilizer carbon footprint and eutrophication potential per 100 kg of produce, thus demonstrating positive influence on environment. These reductions amounted to savings of 3.11 and 4.11 kg CO2-equivalent per 100 kg of grain production through K-sap and G-sap, respectively. The sap from the seaweeds are having a minimal carbon footprint as cultivation of these seaweeds does not require any fossil inputs like mineral fertilizers and pesticides or any resources like fresh water (Layek et al. 2015) and as a result the incremental yield and quality enhancement is achieved in a green manner. The environmental impact of the use of seaweed sap in agriculture would be still more favourable if the use phase of the mineral fertilizers in soil is considered as the present study has not taken into account the losses in the form of N2O, NH4 emissions which have significant greenhouse gas potential. Enhanced carbon sequestration potential through productivity increase due to seaweed sap application was also earlier reported by Mondal et al. (2015).

Conclusion

The foliar spray of K. alvarezii and G. edulis seaweed saps significantly improved the yield and quality of maize grains which was attributed to increased dry matter accumulation because of higher photosynthetic capacity and net assimilation rate brought about by the effect of different plant growth regulators as well as other constituents present in these seaweed saps. Application of 5 % G. edulis along with the recommended rate of fertilizer was found to be the most remunerative giving the highest net return and benefit:cost ratio, thus outperforming both economically and environmentally. The increase in stalk productivity in some treatments involving combinations of either of the saps with reduced rate of fertilizers over the recommended rate suggests a possible saving on chemical fertilizer requirement under rain-fed conditions for stalk production which can serve as fodder. A significant reduction observed in fertilizer carbon footprint and eutrophication potential per unit of produce suggests that seaweed-based saps can not only prove to be excellent organic fertilizers for enhancing productivity but can also play a beneficial role in the arena of global warming and sustainability.

References

Alvim PDT (1960) Net assimilation rate and growth behavior of beans as affected by gibberellic acid urea and sugar sprays. Plant Physiol 35:285--288

Anantharaj M, Venkatesalu V (2002) Studies on the effect of seaweed extracts on Dolichos biflorus. Seaweed Res Util 24:129–137

Ashraf M, Foolad MR (2007) Roles of glycine betaine and proline in improving plant abiotic stress resistance. Environ Exp Bot 59:206–216

Beckett RP, Van Staden J (1990) The effect of seaweed concentrate on the yield of nutrient stressed wheat. Bot Mar 33:147–152

Blunden G, Cripps AL, Gordon SM, Mason TG, Turner CH (1986) The characterization and quantitative estimation of betaines in commercial seaweed extracts. Bot Mar 24:155–160

Blunden G, Jenkins T, Liu YW (1996) Enhanced leaf chlorophyll levels in plants treated with seaweed extract. J Appl Phycol 8:535–543

Blunden G, Wildgoose PB, Necholson FE (1979) The effect of aqueous seaweed extract on sugar beet. Bot Mar 22:539–541

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254

Briceño-Domínguez D, Hernández-Carmona G, Moyo M, Stirk W, van Staden J (2014) Plant growth promoting of seaweeds liquid extract produced from Macrocystis pyrifera under different pH and temperature conditions. J Appl Phycol 26:2203–2210

Chaudhary DP, Jat SL, Kumar R, Kumar A, Kumar B (2014) In: Chaudhary DP, Kumar S, Singh S (eds) Maize: nutrition dynamics and novel uses. Springer, India, pp 153–156

Crouch IJ, Beckett RP, Van Staden J (1990) Effect of seaweed concentrate on the growth and mineral nutrition of nutrient-stressed lettuce. J Appl Phycol 2:269–272

Crouch IJ, Van Staden J (1993) Evidence for the presence of plant growth regulators in commercial seaweed products. Plant Growth Regul 13:21–29

Dass S, Jat ML, Singh KP, Rai HK (2008) Agro-economic analysis of maize-based cropping systems in India. Ind J Fertil 4:53–62

Dobermann AR (2005) “Nitrogen use efficiency—state of the art”. Agronomy and Horticulture, Faculty publications. Paper 316. http://digitalcommons.unl.edu/agronomyfacpub/316

Dwivedi SK, Pal A, Meshram MR (2014) Effects of seaweed saps on soil health and productivity of potato (Solanum tuberosum L.). Curr Adv Agric Sci 6:133–137

Eswaran K, Ghosh PK, Siddhanta AK, Patolia JS, Periyasamy C, Mehta AS, Mody KH, Ramavat BK, Prasad K, Rajyaguru MR, Kulandaivel S, Reddy CRK, Pandya JB, Tewari A (2005) Integrated method for production of carrageenan and liquid fertilizer from fresh seaweeds, U.S. Patent No. 6,893,479

FAO (2014) The state of food and agriculture—innovation in family farming. Food and Agriculture Organization of the United Nations, Rome

Ganesan M, Sahu N, Eswaran K (2011) Raft culture of Gracilaria edulis in open sea along the south-eastern coast of India. Aquaculture 321:145–151

Greenboim-Wainberg Y, Maymon I, Borochov R, Alvarez J, Olszewski N, Ori N, Esed Y, Weiss D (2005) Cross talk between gibberellin and cytokinin: the Arabidopsis GA response inhibitor SPINDLY plays a positive role in cytokinin signalling. Plant Cell 17:92–102

Guinn EJ, Pegram LM, Capp MW, Pollock MN, Record MT (2011) Quantifying why urea is a protein denaturant, whereas glycine betaine is a protein stabilizer. Proc Natl Acad Sci U S A 108:16932–16937

Hanway JJ, Heidel H (1952) Soil analysis method as used in Iowa state college soil testing Laboratory. Iowa Agriculture 57:1–31

Hernández-Herrera RM, Santacruz-Ruvalcaba F, Ruiz-López MA, Norrie J, Hernández-Carmona G (2014) Effect of liquid seaweed extracts on growth of tomato seedlings (Solanum lycopersicum L.). J Appl Phycol 26:619–628

Hillier J, Hawes C, Squire G, Hilton A, Wale S, Smith P (2009) The carbon foot prints of food crop production. Int J Agric Sust 7:107–118

Jackson ML (1973) Soil chemical analysis. Prentice Hall, New Delhi

Khan SA, Mulvaney RL, Ellsworth TR, Boast CW (2007) The myth of nitrogen fertilization for soil carbon sequestration. J Environ Qual 36:1821–1832

Khan W, Rayirath UP, Subramanian S, Jithesh MN, Rayorath P, Hodges DM, Critchley AT, Cragie JS, Norrie J, Prithiviraj B (2009) Seaweed extracts as biostimulants of plant growth and development. J Plant Growth Regul 28:386–399

Layek J, Ramkrushna GI, Das A, Ghosh A, Krishnappa R, Panwar AS, Azad Thakur NS, Ngachan SV, Zodape ST, Buragohain J, Mawlong B (2014). Seaweed sap as organic bio-stimulant for rice and maize production. Research Bulletin no.82. ICAR Research Complex for NEH Region, Umiam, Meghalaya, India

Layek J, Das A, Ramkrushna GI, Trivedi K, Yesuraj D, Chandramohan M, Kubavat D, Agarwal PK, Ghosh A (2015) Seaweed sap potential towards sustainable improvement of maize productivity: a dominant staple food crop of the North-east India. Int J Environ Stud 72:305–315

Mondal D, Ghosh A, Prasad K, Singh S, Bhatt N, Zodape ST, Chaudhary JP, Chaudhari J, Chatterjee PB, Seth A, Ghosh PK (2015) Elimination of gibberellin from Kappaphycus alvarezii seaweed sap foliar spray enhances corn stover production without compromising the grain yield advantage. Plant Growth Regul 75:657–666

Mondal D, Sharma M, Maiti P, Prasad K, Meena R, Siddhanta AK, Bhatt P, Ijardar S, Mohandas VP, Ghosh A, Eswaran K, Shah BG, Ghosh PK (2013) Fuel intermediates, agricultural nutrients and pure water from Kappaphycus alvarezii seaweed. RSC Adv 3:17989–17997

Fleishon S, Shani E, Ori N, Weiss D (2011) Negative reciprocal interactions between gibberellin and cytokinin in tomato. New Phytol 190:609–617

Murphy RP (1958) Extraction of plant samples and the determination of total soluble carbohydrates. J Sci Food Agri 9:714–717

Nelson DW, Sommers LE (1982) Total carbon, organic carbon and organic matter. In: Page AL (ed) Methods of soil analysis. Part 2: Chemical and microbial properties—agronomy. Soil Science Society of America, Madison, pp 570–571

Patidar R, Ghosh A, Paul P (2013) WD-XRF method for rapid analysis of macro and micronutrient uptake in maize grain upon foliar application of seaweed sap formulations. J Indian Chem Soc 90:2023–2028

Patra AK, Tripathy SK, Samui RC (1995) Physiological basis of yield variation in rain-fed groundnut. Indian J Plant Physiol 38:131–134

Pise NM, Sabale AB (2010) Effect of seaweed concentrates on the growth and biochemical constituents of Trigonella foenum-graecum L. J Phytol 2:50–56

Pramanick B, Brahmachari K, Ghosh A (2013) Effect of seaweed sap on growth and yield improvement of green gram. Afr J Ag Res 8:1180–1186

Prasad K, Das AK, Oza MD, Brahmbhatt H, Siddhanta AK, Meena R, Eswaran K, Rajyaguru MR, Ghosh PK (2010) Detection and quantification of some plant growth regulators in a seaweed-based foliar spray employing a mass spectrometric technique sans chromatographic separation. J Agr Food Chem 58:4594–4601

Radford PJ (1967) Growth analysis formula—their use and abuse. Crop Sci 7:171–175

Ranatunga MAB, Meenakshisundaram P, Arumugachamy S, Maheswaran M (2009) Genetic diversity analysis of maize (Zea mays L.) inbreds determined with morphometric traits and simple sequence repeat markers. Maydica 54:113–123

Rathore SS, Chaudhary DR, Boricha GN, Ghosh A, Bhatt BP, Zodape ST, Patolia JS (2009) Effect of seaweed extract on the growth, yield and nutrient uptake of soybean (Glycine max) under rain-fed conditions. S Afr J Bot 75:351–355

Shah MT, Zodape ST, Chaudhary DR, Eswaran K, Chikara J (2013) Seaweed sap as an alternative liquid fertilizer for yield and quality improvement of wheat. J Plant Nutr 36:192–200

Sharma HSS, Fleming C, Selby C, Rao JR, Martin T (2014) Plant biostimulants: a review on the processing of macroalgae and use of extracts for crop management to reduce abiotic and biotic stresses. J Appl Phycol 26:465–490

Shibles RM, Weber CR (1965) Interception of solar radiation and dry matter production by various soybean planting pattern. Crop Sci 6:49–52

Sivasankari S, Venkatesalu V, Anantharaj M, Chandrasekaran M (2006) Effect of seaweed extracts on the growth and biochemical constituents of Vigna sinensis. Bioresour Technol 97:1745–1751

Smith D, Paulsen GM, Raguse CA (1964) Comparative accuracy and efficiency in determination of carbohydrate from grasses and legume tissue. Plant Physiol 39:960–962

Stevens GA, Westwood MN (1984) Fruit set and cytokinines like activity in the xylem sap of Sweet Cherry (Prunus avium) as affected by root stock. Physiol Plantarum 61:464–468

Subbiah BV, Asija GL (1956) A rapid procedure for the determination of available N in soils. Current Sci 25:259–260

Thirumaran G, Arumugam M, Arumugam R, Anantharaman P (2009) Effect of seaweed liquid fertilizer on growth and pigment concentration of Abelmoschus esculentus (L) Medikus. Amer-Euras J Agronomy 2:57–66

Weiss D, Ori N (2007) Mechanisms of cross talk between gibberellin and other hormones. Plant Physiol 144:1240–1246

Whigham DK (1983) Soybean. In: Smith WH (ed) Symposium on potential productivity of field crops under different environment. IRRI, Los Banos, pp 205–225

Zodape ST, Mukherjee S, Reddy MP, Chaudhary DR (2009) Effect of Kappaphycus alvarezii (Doty) Doty ex silva. Extract on grain quality, yield and some yield components of wheat (Triticum aestivum L). Int J Plant Prod 3:97–101

Zodape ST, Mukhopadhyay S, Eswaran S, Reddy MP, Chikara J (2010) Enhanced yield and nutritional quality in greengram (Phaseolus radiata L.) treated with seaweed (Kappaphycus alvarezii) extract. J Sci Ind Res 69:468–471

Acknowledgments

We gratefully acknowledge the support of the Council of Scientific and Industrial Research (CSIR), New Delhi, for this project (MLP 0016). We also thank Dr. PK Ghosh for helping conceive this Pan-India multi-institutional multi-crop project and for all his personal encouragement. We also thank sincerely the following: M/s Aquagri Processing Pvt. Ltd. (the licensee of CSIR-Central Salt & Marine Chemicals Research Institute’s sap technology) and CSIR-CSMCRI for providing Kappaphycus sap; the Marine Biotechnology and Ecology discipline, especially Dr. CRK Reddy, Dr. K. Eswaran and Dr. V Mantri for their help in providing Gracilaria sap from Mandapam field station, Tamilnadu, India. Dr. K Prasad is acknowledged for analyzing the sap constituents and Dr. PK Agarwal for all his support. This manuscript bears CSIR-CSMCRI communication No. 052/2015.

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Singh, S., Singh, M.K., Pal, S.K. et al. Sustainable enhancement in yield and quality of rain-fed maize through Gracilaria edulis and Kappaphycus alvarezii seaweed sap. J Appl Phycol 28, 2099–2112 (2016). https://doi.org/10.1007/s10811-015-0680-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-015-0680-8