Abstract

The heterostructure of graphene and ZnO nanorods is attractive as a tin oxide-free electron transport layer for a broad variety of excitonic photovoltaic technologies. This work focuses on the effect of electrodeposition variables on morphology and performance of vertically aligned zinc oxide nanorods (ZVNRs) on graphene. This in situ growth technique has potential for fabrication of a wide variety of graphene heterostructures under mild synthesis conditions to prevent graphene damage. Large area graphene was grown by chemical vapor deposition, stacked up to four atomic layers, and transferred to glass. ZVNRs were electrodeposited on the graphene-coated glass and the topography was controlled by changing the electrodeposition parameters of the time, temperature, stirring, and seeding layers. The mechanisms controlling the cathodic electrodeposition of nanocrystals on graphene were studied by scanning electron microscopy of the ZVNRs topography. The effect of the topography of the ZVNRs on the electron generation and transport was studied for photoanode application in reference dye-sensitized solar cells. The charge transfer resistance and kinetics of the materials as photoanodes were measured with the techniques of linear sweep voltammetry, open circuit voltage decay, and electrochemical impedance spectroscopy. The optimization of ZnO growth resulted in an increase of the surface-to-volume ratio of the electrode from 10 to 250 mm−1, 60-fold increase of electron lifetime and ten-fold increase in power output. The results of this study provide fundamental understanding for designing electrodeposition processes of the hybrid ZVNR/graphene material.

Graphic abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

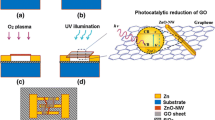

A photoelectrochemical cell is a device that harvests sunlight to convert it into other forms of energy such as chemical or electrical and is based on a photoanode connected to a counter-electrode via an electrolyte. The photoanode absorbs the photons and drives oxidation reactions of a mediator in the electrolyte, which are regenerated in the counter-electrode. Nanostructured wide-bandgap semiconductors, like TiO2 or ZnO, spread over a transparent conductor are attractive as photoanodes due to their low cost and wide availability. The limited solar spectrum range that ZnO or TiO2 absorbs in the ultraviolet portion of the sun spectrum is expanded to visible range by sensitizing the photoanodes with photoactive materials, such as organic and metalorganic dyes [1] quantum dots [2], plasmonic nanoparticles [3], perovskites [4, 5], and photosynthetic biomolecules [6, 7]. A large portion of the photoanode cost corresponds to the choice of transparent conductor, typically doped tin oxide. Tin oxides are fragile materials derived from non-abundant sources, like cassiterite, which classifies as conflict mineral and can adversely affect both water quality, human health and social conditions [8,9,10]. Graphene is a sustainable alternative to tin oxides, as it can be obtained from a variety of organic sources, including waste byproducts, as illustrated in Fig. 1. Pristine CVD-graphene with large domain size stands out as the most promising graphene variant for TC application, not only due to its superior optoelectronic properties, but also because large area films can be produced at an industrial scale [11].

Sustainable fabrication of tin-oxide free photoanode. a Synthesis of high-quality graphene, a carbon-based transparent conductor produced from abundant renewable resources. b Electrodeposition of ZnO nanostructures on graphene to make a hybrid photoanode. c Use of ZVNR/G hybrid as a photoanode, electron transfer processes occurring: arrows in green indicate power generating processes, arrows in red indicate power loss processes

ZnO and TiO2 are the two most common wide-bandgap semiconductors for photoanodes with very similar bandgaps; however ZnO has an electron mobility that is two to three orders of magnitude larger [12]. Additionally, ZnO is also more reactive and it can be synthesized into its crystalline form under mild conditions with a variety of shapes, being more compatible for in situ growth on graphene, considering the high oxidation susceptibility of the latter. The vertically aligned ZnO nanorods (ZVNRs) offer a large surface area for light scattering and absorption. Their short radial distance promotes rapid transport of minority charge carriers towards the junction for exciton separation, they have lower electron transfer resistance through the semiconductor in comparison to nanoparticles assemblies where electrons must cross several interfaces with high probability of recombination [13,14,15]. The ZVNR/graphene heterostructure (ZVNR/G) has been reported recently as an electron transport layer in perovskite solar cells with efficiency of 12.87% for pristine graphene and 16.82% for nitrogen-doped graphene [16]. Therefore, understanding how the parameters for ZVNR in situ growth on graphene affect its topography and photoanode performance is fundamental for the future development of low-cost, sustainable photoelectrochemical cells.

Electrodeposition of nanostructured thin films has been gaining attention lately due to the high-end quality of the film, the excellent process control and its advantages over other techniques like doctor-blade and chemical vapor deposition [17]. Crystalline nanostructures can be obtained with electrodeposition at temperatures below 100 °C without further need for thermal treatments, which is a critical requirement for the development of flexible devices on polymeric substrates. This technique is an in situ deposition method, which results in reduced interfacial resistance. It is also facile and low-cost, as no expensive facilities or high energy processes are required. Cathodic deposition of transparent ZnO films on conductive glasses from a simple aqueous Zn(NO3)2 electrolyte was first reported in 1996 by Ozaki and Omi, with films showing (0001) preferred orientation under certain conditions [18]. A systemic study of the electrodeposition of ZVNRs on tin oxide substrate using nitrate ion as a precursor was first reported in 2012 [19]. The reaction leading to oxide formation is the electrogeneration of a base (Eq. 1) followed by dehydration (Eq. 2) as described in Eqs. 1 and 2:

In a photoanode, the power conversion efficiency is strongly dependent on the semiconductor surface area since it determines the junction area at which the photoelectrochemical reactions take place. For an array of ZVNRs, the surface area can be increased by reducing the diameter of the rods and increasing their length. Several approaches are used to reduce the diameter of ZVNRs, one of the most effective being the use of seed layer, also called buffer layer. This seed layer provides a dense source of nucleation centers for the growth of the ZVNRs [20].

Graphene variants like reduced graphene oxide [21], oxidized CVD-graphene [22], pristine CVD-graphene [23], and graphene foam [24] have been studied as conductive substrates for the fabrication of the ZVNR/G by electrodeposition. The mild growth conditions of electrodeposition prevent graphene damage by oxidation. A negative bias applied seems to protect graphene from defect introduction, as it has been observed in electrochemical delamination from metallic foils [25]. We have demonstrated that cathodic electrodeposition on graphene offers a feasible in situ route to fabricate the ZVNR/G hybrid, while preserving the sp2 structure of graphene. The ZVNR growth conditions on graphene have been optimized to obtain continuous carpet of crystalline vertically aligned nanorods highly texturized in the [0001] direction. The graphene substrate has been observed to induce mosaicity and crystal distortions that could be attributed to misfit dislocations in the ZVNRs, due to the lattice mismatch between graphene and ZnO that generates an out-of-plane strain [26].

In this work, we explore the effects of electrodeposition parameters on the ZVNR morphology and the performance of the hybrid as a photoanode in a DSC. The electrodeposition parameters investigated were temperature, time, stirring, and the use of a seeding layer. The photoelectron generation and transport in the ZVNR/G was studied via linear sweep voltammetry (LSV), open circuit voltage decay (OCVD), and electrochemical impedance spectroscopy (EIS). This study aims to explore the fundamentals of crystal growth in graphene as a sustainable conductive substrate and elucidate the predominant mechanisms of power generation and loss of the heterostructure in solar energy harvesting application.

2 Methods

2.1 Graphene transparent conductive layer

A continuous graphene film was grown on Cu foil using ambient-pressure CVD to yield a domain size up to 300 mm. A Cu foil is annealed for two hours at 1030 °C in the furnace at atmospheric pressure with Ar (300 sccm) and H2 (15 sccm). Then, graphene is grown with 375 sccm of diluted methane in Ar (90 ppm) and 15 sccm of H2 for 60 min and cooled with Ar (300 sccm) and H2 (15 sccm). More details are provided in Supporting Information (SI) [26, 27]. The graphene on copper was spin-coated on one side with PMMA. The copper was etched in 0.3 M FeCl3 and cleaned with DI water. The floating graphene/PMMA film was stacked onto a second graphene/Cu film. The etching and stacking processes were repeated until 4-layered graphene (4LG) was obtained. The 4LG was then transferred onto a clean glass substrate, with the graphene in contact with the glass. The PMMA was dissolved in acetone, the graphene annealed in Ar/H2 at 250 °C, and 10/120 nm Cr/Au contacts were e-beam evaporated.

2.2 Electrodeposition of ZVNR and pre-deposition of seeding layer on graphene

The ZVNR electrodeposition and pre-deposition of seeding layer on graphene was performed using a CHI 660C electrochemical station and CHI6005E electrochemical work station software.

For the ZVNR electrodeposition, a three-electrode configuration was used, with graphene-on-glass as the working electrode, platinum mesh as the counter-electrode, and Ag/AgClsat’d as the reference electrode. PMMA was used as dielectric coating on the Cr/Au contact. For the ZVNR growth, a cathodic potential was applied to the graphene in 10 mM Zn(NO3)2 aqueous solution to maintain a current density of 0.4 mA cm−2, which had been optimized in our previous report to obtain well-aligned crystalline ZVNRs on graphene [25]. We studied the effect of three growth variables: temperature, time and stirring. The temperature studied varied between 70 and 80 °C, the time was varied from 0.5 to 2 h, and stirring and non-stirring conditions were compared. The Zn(NO3)2 solution was refreshed every 10 min for all experiments.

To pre-deposit a seed layer, a Zn(OH)x compact film was electrodeposited at − 1.2 V vs Ag/AgClsat’d (− 1 V vs Standard Hydrogen Electrode, SHE) from 50 mM Zn(NO3)2 aqueous solution at room temperature, until a charge density of 30 mC cm−2 was obtained (~ 23 min). The film was converted into ZnO by annealing at 200 °C for 1 h [28, 29]. Other methods for seeding layer deposition that were explored produced larger diameter VNRs and their details can be found in the SI.

2.3 ZVNRs topography characterization

The ZVNRs topography was analyzed using Scanning Electron Microscopy (SEM) and image analysis. SEM was performed using the FEI NovaNanoSEM 450 and no conductive coating was necessary. Geometrical measurements were taken from top and cross-section SEM micrographs with ImageJ software. The average ZVNRs diameter (⍉NR), length, aperture angle (for truncated pyramidal ZVNRs), density (ρNR, number of ZVNRs in a given area) and surface-to-volume ratios were obtained by counting and measuring at least 200 ZVNRs from at least 5 different areas for each sample.

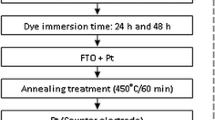

2.4 Photoelectron transport characterization

The electron transport measurements were performed using a dye-sensitized solar cell (DSC) configuration. The photo-anode was sensitized through a 12-h immersion in a 0.3 mM ethanoic solution of N3 dye (cis-Bis(isothiocyanato) bis(2,2′-bipyridyl-4,4′-dicarboxylato) ruthenium(II)) (Sigma-Aldrich). The counter-electrode was prepared by e-beam evaporation of a 40 nm/40 nm Ti/Pt film on a clean glass substrate. The photoanode and counter-electrode were clipped together to assemble the DSC, using a polydimethylsiloxane spacer. The cell was filled with an electrolyte of acetonitrile and ethylene carbonate in 2:1 volume ratio, 0.1 M LiI, 0.03 M I2, and 5% m v−1 LiClO4. The DSCs were tested under a xenon lamp (USHIO UXL-75XE) with a power density of 100 mW cm−2, calibrated with a Newport Power Meter 1918-R. Electrochemical characterization of the devices was performed with the CHI 660C in a two-electrode configuration and CHI6005E electrochemical work station software was used for recording the data.

The linear sweep voltammetry (LSV) was performed from 0.2 to -0.8 V. The open circuit voltage decay (OCVD) was measured by monitoring the open circuit voltage (VOC) of the DSC after switching from illuminated to dark operation. Electron lifetime τn was calculated from the OCVD according to Eq. 3 [30]:

The electrochemical impedance spectroscopy (EIS) was performed under illumination in the frequency range between 0.1 Hz and 100 kHz, setting the bias voltage at the VOC of the device and the amplitude at 10 mV. EIS of the photo-electrode was interpreted according to the most widely accepted model (Fig. S1). The equivalent circuit of a DSC is composed of electron diffusion through ZnO (Rd) coupled to electron recombination reactions with the electrolyte (Rk) in a transmission line model, in series to the charge transfer resistance at the ZnO/G interface (RZnO/G) [31, 32]. More details on the impedance fitting can be found in SI [26].

3 Results and discussion

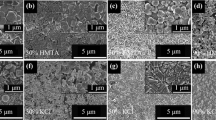

ZVNRs were electrodeposited on graphene under variable conditions. Table 1 details the electrodeposition parameters of stirring, seed layer, temperature (T), and time (t) studied for each sample and the morphology parameters of ZVNR density (ρNR) and diameter (⍉NR) obtained from the analysis of SEM micrographs.

3.1 Effect of temperature and time

3.1.1 Effect of temperature and time in the ZVNRs topography

The electrodeposition solution temperature ranging from 70 to 80 °C affects the topography of the ZVNRs, as shown in Fig. 2a–c′. At 70 °C, a sparse layer of randomly oriented ZVNR structures, while at 75 °C increased coverage and alignment is obtained, and the temperature at 80 °C causes even greater compactness and uniformity. The incomplete graphene coverage at 70 °C indicates that exclusion zones are formed due to concentration depletion that hinder further nucleation near existing growing nuclei [33]. As higher temperatures are applied, mass transfer is more efficient, leading to complete coverage of the graphene surface. A higher nucleation density causes the ZVNR average diameter to reduce from 475 nm at 70 °C, to 364 nm at 75 °C and 360 nm at 80 °C. At the same time, the NR density increases from 1.8 × 108 cm−2 for 70 °C, to 3.4 × 108 cm−2 for 75 °C and 3.5 × 108 cm−2 for 80 °C. Above 80 °C, the ZnO crystal growth rate in the lateral directions is faster, and the VNRs’ walls eventually merge into grain boundaries to form a continuous ZnO layer rather than a ZVNRs carpet.

Extending the time of electrodeposition from 0.5 to 2 h results in an increase of ZVNRs dimensions, as reported previously on FTO [34]. The diameter increases from 360 to 790 nm, and the length increases from 0.9 mm to 3.1 mm, as observed in the SEM micrographs in Fig. 2c″–d″. The lateral growth of the ZVNR occurs at slower rate than the longitudinal, because of the higher energy configuration of the (0001) planes. However, the slower growth in lateral directions still leads to the broadening of the ZVNR diameter at extended time, which results in the merging of the ZVNR into a mostly continuous film of ZnO.

3.1.2 Effect of temperature and time in the ZVNR/G electrochemical characteristics

Figure 3a shows the potential-time (V–t) curves for the electrodeposition of ZVNRs at the different temperatures. The potential range for the deposition is within the zone for ZnO formation in the Pourbaix diagram for the Zn/H2O system [35]. The curve corresponds to a mass transfer-controlled process showing four distinct regions [36, 37]. In stage I, a sudden increase of the potential is related to the double charge layer formation. Stage II is a short period of potential reduction, during which independent nuclei appear and grow on the surface of the graphene. This growth continues until the formation of exclusion zones that virtually arrest further nucleation and a minimum potential is reached. Stage III is another region of potential increase which is more extended than stage I. During stage III, the two opposing processes of independent nuclei growth and nuclei overlapping take place simultaneously. This leads to electrode relative passivation due to gradual coverage of the conductive graphene, raising the overpotential required to maintain constant mass deposition. Finally, a plateau is reached in stage IV, in which the available graphene surface is either coated with ZnO or is an exclusion zone. During stage IV, steady growth occurs because a constant ionic concentration is maintained in the bulk of the electrolyte by refreshing the solution. Faster deposition rates in the [0001] direction lead to ZVNR formation [36, 37]. As a general trend, less overpotential is required at higher temperatures to maintain the galvanostatic conditions, due to the additional energy provided by the heat. The V–t curve obtained at 80 °C is absent of the potential drop seen in region II. This indicates that independent nuclei formation and nuclei overlapping occur almost instantaneously, and growth is not inhibited by exclusion zones at this temperature.

Effect of time and temperature in the electrochemical characteristics of ZVNR/G hybrid. a Applied potential as a function of time for ZVNR electrodeposition on graphene at constant current density of 0.4 mA cm−2. Photoelectrochemical response of DSC fabricated with ZVNR/G sensitized with N3 dye in I−/I3− under a Xe lamp with a power density of 100 mW cm−2. b Linear sweep voltammogram, c VOC decay, d calculated electron lifetime τ and e Nyquist plot of electrochemical impedance

The heterostructure of ZVNR/G was used as the photoanode in a DSC. The transient photovoltage measurements in Fig. 3c show that as the ZVNR film becomes more compacted, the cells produce a higher photovoltage under illumination. The heterostructure grown at 70 °C yields a Voc of 150 mV, at 75 °C it yields 190 mV, and at 80 °C it yields 300 mV. A slower Voc decay indicates that the electron lifetime τ is longer for the more compacted ZVNR films, as shown in Fig. 3c, d. The EIS of the devices grown at the different temperatures are described by the Nyquist plots in Fig. 3e, showing that as the graphene’s surface becomes more densely coated, a larger Rk results, due to blocking the contact between graphene and electrolyte. A more compacted film blocks the contact of the electrolyte with the graphene, increasing the Rk and slowing down the photoelectron loss kinetics, as observed in ZVNR/FTO photoanodes [34]. The formation of a more compact film also reduces the surface area and increases the imaginary impedance (Z″) values, due to a reduction of the effective capacitance of the nanoporous film [38].

The desirable ZVNR morphology would be compacted at the bottom to prevent recombination losses from exposed graphene but with gaps between the ZVNRs at the top to provide higher interfacial area at the junction of the device. Therefore, for the remainder of the growth experiments, we used 80 °C during the first 10 min of growth and then cooled down the solution to 75 °C until the end of the ZVNR growth. The term “80–75 °C” will be used to refer to this growth condition.

As time is extended from 0.5 h to 2 h, using the 80–75°Cconditions, the photoanode Rk, VOC and \(\tau\) increases because of its morphology (Fig. 3c–e),ascribed to the blocking of the graphene from the electrolyte, which prevented power loss events [34], and reduction of surface area [38]. The DSC Voc doubles when the ZVNR were grown for 2 h instead of 30 min.

3.2 Effect of stirring

3.2.1 Effect of stirring in the ZVNRs topography

Even though the higher temperature and longer growth time increase the photovoltage of the electrode, the photocurrent remains low (Fig. 3b). Therefore, the stirring conditions during electrodeposition were varied to modify the mass transfer during ZVNR growth. When the VNRs grow in stirred conditions, straight rods grow as shown in Fig. 4a, while in unstirred conditions truncated pyramidal rods develop, shown in Fig. 4b. The length of the VNRs increase to 4.7 mm in unstirred conditions, compared to 3.1 mm for stirred conditions, while the diameter is reduced from 790 to 487 mm, which is expected to maintain constant mass deposition, i.e. constant current density. The truncated pyramidal shape and the increase in length are a result of increased Zn+ concentration gradient. Anisotropic growth occurs mostly along the c-direction of the crystal in unstirred conditions because Zn+ diffusion is significantly slower than OH− generation. As the ratio of OH− to Zn+ increases in the immediate vicinity of the electrode, most Zn+ ions are consumed at the tip of the rods, limiting lateral growth [19, 39]. In unstirred conditions, a threefold increase in VNR density is observed to yield 5 × 108 VNRs cm−2, compared to 1.9 × 108 VNRs cm−2 in stirred conditions.

3.2.2 Effect of stirring in the ZVNR/G electrochemical characteristics

The V–t curves for the growth of the ZVNRs in unstirred and stirred conditions are compared in Fig. 5a. Similar growth mechanisms are observed under stirred and unstirred conditions, where 4 distinct growth stages take place, as analyzed previously [36, 37]. However, in unstirred conditions, nuclei formation in stage II occurs at faster rates. The reduced diffusion of ions along the graphene surface in unstirred conditions probably accelerates electro-crystallization, leading to faster achievement of the minimum potential, as exclusion zones form much faster. At the same time, nuclei growth in stage III occurs at much slower rates in unstirred compared to stirred conditions, and surface saturation takes 6 times longer. The slower mass transfer at the surface of the graphene when unstirred leads to slower deposition rate [40]. The potential plateau of stage IV has a similar value of ~ − 0.7 V vs SHE for unstirred and stirred conditions, given that the current density and temperature are identical. Therefore, the stirring conditions do not modify the thermodynamics of the system, but only the mass transfer kinetics.

Effect of stirring and seed layer in the electrochemical characteristics of ZVNR/G hybrid. a Applied potential as a function of time for ZVNR electrodeposition on graphene at constant current density 0.4 mA cm−2. Photoelectrochemical response of DSC fabricated with ZVNR/G sensitized with N3 dye in I−/I3− electrolyte under a Xe lamp with a power density of 100 mW cm−2 b linear sweep voltammogram, c Open circuit voltage decay (OCVD) d calculated electron lifetime and e Nyquist electrochemical impedance plot

The truncated pyramidal shape and higher density of the ZNVRs grown in unstirred conditions leads to a photocurrent twice as large as obtained for ZVNR grown under stirred conditions. This can be observed in Fig. 5b. However, the lower recombination resistance reduces the electron lifetime, which in turn lowers the VOC, as shown in Fig. 5c–e. This result indicates that the increased space between ZVNRs causes electrolyte infiltration and short-circuiting between the redox mediator and the electrocatalytic graphene. The reduction of Z″ values also indicate an increase of surface area [38]. Because non-stirred conditions resulted in larger surface area and photocurrent, with slight reduction of VOC (Fig. 5c), these conditions were preferred for further experiments.

3.3 Effect of seed layer

3.3.1 Effect of seed layer in the ZVNRs topography

The large domains in pristine CVD-graphene provide high mobility which is a desirable trait for transparent conductor application. However, the surface of CVD-graphene is very smooth, which results in lower nucleation rates and larger ZVNR diameter than those obtained in FTO [39], reduced graphene oxide (rGO) [41], and oxidized CVD-graphene [21]. We deposited a seed layer to increase ZVNR nucleation density without reducing optoelectronic performance of the pristine CVD-graphene. Three methods were compared for depositing the seed layer: (i) spin coating of ZnO NPs [42, 43], (ii) spincoating of zinc acetate [44], and (iii) electrodeposition of ZnOHx [28], all followed by thermal treatment. Methods (i), (ii) and (iii) result in ZVNRs diameters of 330, 274, and 135 nm respectively (Table S1), compared to the 487 nm obtained without seed layer. Electrodeposition of seed layer is the method that yields the smaller ZVNR diameter, with one order of magnitude increase in density, compared to those obtained without seed layer. Electrodeposition of seed layer is the method that yields the smaller ZVNR diameter, with one order of magnitude increase in density, as summarized in Table 1, and consistent with results on FTO [19]. Therefore, we focused on the electrodeposition as the method for depositing the seed layer. More details on the methods (i) and (ii) can be found in the SI.

3.3.2 Effect of seed layer in the ZVNR/G electrochemical characteristics

The presence of the seed layer on the graphene, modified the V–t curve of ZVNR growth, as shown in Fig. 5a. The V–t curve does not show the stages I, II, and III previously observed, but starts directly at the plateau potential of ~ − 0.7 V vs SHE. This indicates that the ZVNR electrodeposition on seed layer starts directly with growth stage, skipping the process of nucleation altogether. The plateau potential with and without seed layer is the same due to identical thermodynamic conditions, and similar to what was observed when comparing stirred and unstirred conditions.

Reducing the VNR diameter with the electrodeposited seed layer results in better light scattering, with a ten-fold increase in transmittance at 550 nm (Fig. S2). The larger junction area of smaller diameter ZVNRs, indicated by the smaller Z″ [38], causes an overall three-fold increase in photocurrent generation and reduces the Rk (Fig. 5a, e). The photovoltage and electron lifetime remain high due to blocking of fast reactions at the graphene with the compact bottom layer of ZnO (Fig. 5c, d). The combination of higher photocurrent and open circuit voltage results in increased maximum power generation from 8 mW cm−2 (power conversion efficiency (PCE) of 8 × 10–3%) without seed layer to 63 mW cm−2 (PCE of 6.3 × 10–2%) with seed layer.

3.3.3 Optimization of seed layer deposition for reducing ZVNR diameter

The process of seed layer electrodeposition for ZVNR growth is detailed in Fig. 6a. At room temperature, the electrodeposition of a compact amorphous Zn(OH)x layer takes place [28, 36]. Then, the Zn(OH)x is decomposed into ZnO, a phase transition that occurs between 119 to 153 °C, we therefore performed the thermal treatment at 200 °C [28, 29] The result is a compact film of ZnO NPs that control ZVNR growth and prevent shunt circuit contact with the transparent conductor. The seed layer deposition was optimized to further reduce the ZVNRs diameter. The initial conditions for the seed layer electrodeposition were 50 mM Zn(NO3)2, − 1 V vs SHE, to attain 30 mC cm−2 and thermal treatment heating rate of 5 °C min−1, which yield 134 nm diameter VNRs (sample I). The increase of seed layer nucleation rate was attempted as detailed in Fig. 6b–c, by increasing the concentration of Zn(NO3)2 to 200 mM (sample II) and the potential to − 1.1 V (sample III), but these did not reduce of the VNR diameters either (see Fig. 6b–c). The total charge was also reduced to 25 mC cm−2 (sample IV) to limit Zn(OH)x nuclei growth, but no reduction of the VNR diameter was observed either. As the variation of Zn(OH)x electrodeposition conditions was not effective in reducing the VNR diameter, we opted for varying the thermal treatment instead in order to control the phase transition from Zn(OH)x to ZnO (sample V). The heating rate of the material was accelerated by placing the sample directly in an oven at 200 °C. As a result, this faster nucleation rate of ZnO from Zn(OH)x was effective in reducing the diameter to 83 nm. Therefore, we present the mechanism for seed layer formation and illustrate it in Fig. 6d. The deposition of Zn(OH)x does not determine the grain size for the seed layer, as it is an amorphous and unstable film [28]. Instead, it is the phase transition itself, essentially the ZnO nucleation stage from Zn(OH)x, which determines the size of the seed layer grains, and therefore, controls the ZVNR diameter. The electrodeposition of a Zn(OH)x seed layer followed by thermal treatment may be preferred over other electrodeposition methods of ZnO seed layer, like pulsed electrodeposition [45], because electrodeposition of the former takes place at room temperature, while the latter only produces a compact and continuous film when performed using a solution heated above 60 °C [46]. The stability of graphene on the substrate may be compromised when applying several electrodeposition methods at high temperature, because of the increased energy of water molecules that may be introduced between graphene and glass, causing film peeling. Therefore, using a room temperature electrodeposition method may be advantageous for seed layer deposition in certain applications where a shorter time of exposure to high temperature electrodeposition bath is desired.

a Process of electrodeposition of seed layer and ZVNRs growth. b Effect of seed layer deposition on the ZVNR diameter distribution and SEM imaging. Seed layer deposition variables (I) control: 50 mM Zn(NO3)2, stirred, − 1 V vs SHE, 30 mC cm−2, slow heating, (II) 200 mM Zn(NO3)2, (III) − 1.1 V vs SHE, (IV) 25 mC cm−2, (V) fast heating. c Average ZVNR diameter obtained for each variable. d Mechanism of seed layer formation which controls the diameter of the ZVNR.

3.4 Discussion

We have studied the experimental correlations between the ZVNR/G electrodeposition parameters on the performances of the heterostructure as an electron transport layer and summarized them in Fig. 7. The ZVNR film can be made compact and dense by increasing both temperature (2–3) and time (4), to evenly cover the graphene surface and block recombination losses with the electrolyte. Charge collection of the photoanode was improved by blocking graphene, with a longer electron lifetime, larger photovoltage and higher recombination resistance. However, the reduction of surface area when the film becomes more compact limits the photocurrent generated because of hindered light scattering. Non-stirred conditions (5) promoted formation of longer truncated pyramidal ZVNRs and the use of a seed layer (6) reduced the ZVNR diameter. These two variables together resulted in a greater surface to volume ratio of ZVNR, for improved light scattering and higher photocurrent generation, while retaining high photovoltage, for a total ten-fold improvement in power conversion. We explored the mechanism of seed layer electrodeposition to further reduce the ZVNR diameter. We found that the final diameter of the ZVNR is controlled by the seed layer process and depends on the phase transition from Zn(OH)x to ZnO during thermal treatment, rather than on the electrodeposition parameters.

a Performance parameters for DSCs prepared with ZVNR/G photoanodes sensitized with N3 dye in I−/I3− electrolyte under a Xe lamp with a power density of 100 mW cm−2: (1) 70 °C, (2) 75 °C, and (3) 80 °C grown stirred for 30 min with and no seed layer, (4) time increased to 1 h at 75–80 °C, (5) stirring was removed, (6) seed layer was pre-deposited. b Illustration of the effect that electrodeposition parameters have on the mechanisms of power generation (green arrows) and loss (red arrows) in ZVNR/G photoanode in a DSC

4 Conclusions

Pristine CVD-graphene with large domains is an attractive option as a transparent conductor for photoelectrochemical cells due to its excellent optoelectronic properties. However, the preparation of graphene heterostructures to fabricate photoelectrochemical is challenging, as the smooth non-reactive surface of CVD-graphene delays nucleation, making it difficult to grow very small nanocrystals like ZVNRs in situ. Very small nanocrystals are desirable to provide large junction area with the hole acceptor that ultimately determines the photocurrent generation. At the same time, the high catalytic activity of carbon results in electron recombination and power loss when it contacts the electrolyte or other hole acceptor material. Electrodeposition is a promising method for in situ growth of crystalline materials on graphene. We have studied the experimental correlations between the parameters of ZVNR electrodeposition on graphene and the corresponding performances of the heterostructure as a photo-electrode. Increasing temperature and time of ZVNR film growth increase compaction and density, resulting in an evenly covered graphene surface. This blocks recombination losses with the electrolyte, which improve the charge collection of the photoanode. However, the reduction of surface area and hindered light scattering due to compacting of the film limits the photocurrent generated. Non-stirred conditions promoted formation of longer truncated pyramidal ZVNRs and the use of a seeding layer reduced the ZVNR diameter. These two variables together resulted in a greater surface to volume ratio of ZVNR, for improved light scattering and higher photocurrent generation, while retaining high photovoltage, for a total ten-fold improvement in power conversion. Controlling the seed layer deposition can reduce further the ZVNR diameter. The results of this study provide fundamental understanding for fabrication of hybrid ZVNR/G material by electrodeposition that can be used as an electron transport layer in a broad spectrum of photovoltaic devices, including cells sensitized with organic and metalorganic dyes, quantum dots, plasmonic nanoparticles, perovskites, and photosynthetic biomolecules.

Data availability

Data and materials used in the study are available upon request to the email cchaves@itcr.ac.cr.

References

Mathew S, Yella A, Gao P, Humphry-Baker R, Curchod BFE, Ashari-Astani N, Tavernelli I, Rothlisberger U, Nazeeruddin MK, Gratzel M (2014) Dye-sensitized solar cells with 13% efficiency achieved through the molecular engineering of porphyrin sensitizers. Nat Chem 6:242–247. https://doi.org/10.1038/nchem.1861

Li T, Lee Y, Teng H (2012) High-performance quantum dot-sensitized solar cells based on sensitization with CuInS2 quantum dots/CdS heterostructure. Energy Environ Sci 5:5315–5324. https://doi.org/10.1039/C1EE02253A

Chandrasekhar PS, Komarala VK (2015) Effect of graphene and Au@SiO2 core-shell nano-composite on photoelectrochemical performance of dye-sensitized solar cells based on N-doped titania nanotubes. Rsc Adv 5:84423–84431. https://doi.org/10.1039/C5RA13799C

Kazim S, Nazeeruddin MK, Graetzel M, Ahmad S (2014) Perovskite as light harvester: a game changer in photovoltaics. Angew Chem Int Ed 53:2812–2824. https://doi.org/10.1002/anie.201308719

Thakur UK, Askar AM, Kisslinger R, Wiltshire BD, Kar P, Shankar K (2017) Halide perovskite solar cells using monocrystalline TiO2 nanorod arrays as electron transport layers: impact of nanorod morphology. Nanotechnology 28:274001. https://doi.org/10.1088/1361-6528/aa75ab

Thavasi V, Lazarova T, Filipek S, Kolinski M, Querol E, Kumar A, Ramakrishna S, Padros E, Renugopalakrishnan V (2009) Study on the feasibility of bacteriorhodopsin as bio-photosensitizer in excitonic solar cell: a first report. J Nanosci Nanotechnol 9:1679–1687. https://doi.org/10.1166/jnn.2009.si07

Mershin A, Matsumoto K, Kaiser L, Yu D, Vaughn M, Nazeeruddin MK, Bruce BD, Graetzel M, Zhang S (2012) Self-assembled photosystem-I biophotovoltaics on nanostructured TiO2 and ZnO. Sci Rep 2:234. https://doi.org/10.1038/srep00234

Badding MA, Fix NR, Orandle MS, Barger MW, Dunnick KM, Cummings KJ, Leonard SS (2016) Pulmonary toxicity of indium-tin oxide production facility particles in rats. J Appl Toxicol 36:618–626. https://doi.org/10.1002/jat.3253

Polgreen L (2008) Congo’s riches, looted by renegade troops. The New York Times. https://www.nytimes.com/2008/11/16/world/africa/16congo.html. Accessed 12 Aug 2015

Commission S A E (2012) Final Rule-CONFLICT MINERALS. Securities and Exchange Commission. https://www.sec.gov/rules/final/2012/34-67716.pdf S.A.E. Accessed 12 Aug 2015

Xu XZ, Zhang ZH, Dong JC, Yi D, Niu JJ, Wu MH, Lin L, Yin RK, Li MQ, Zhou JY, Wang SX, Sun JL, Duan XJ, Gao P, Jiang Y, Wu XS, Peng HL, Ruoff RS, Liu ZF, Yu DP, Wang EG, Ding F, Liu KH (2017) Ultrafast epitaxial growth of metre-sized single-crystal graphene on industrial Cu foil. Sci Bull 62:1074–1080. https://doi.org/10.1016/j.scib.2017.07.005

Zhang QF, Dandeneau CS, Zhou XY, Cao GZ (2009) ZnO nanostructures for dye-sensitized solar cells. Adv Mater 21:4087–4108. https://doi.org/10.1002/adma.200803827

Kayes BM, Atwater HA, Lewis NS (2005) Comparison of the device physics principles of planar and radial p-n junction nanorod solar cells. J Appl Phys 97:114302. https://doi.org/10.1063/1.1901835

Lewis NS (2007) Toward cost-effective solar energy use. Science 315:798–801. https://doi.org/10.1126/science.1137014

Mu QH, Li YG, Zhang QH, Wang HZ (2011) Template-free formation of vertically oriented TiO2 nanorods with uniform distribution for organics-sensing application. J Hazard Mater 188:363–368. https://doi.org/10.1016/j.jhazmat.2011.01.125

Chandrasekhar PS, Dubey A, Qiao Q (2020) High efficiency perovskite solar cells using nitrogen-doped graphene/ZnO nanorod composite as an electron transport layer. Sol Energy 197:78–83. https://doi.org/10.1016/j.solener.2019.12.062

Mamaghani KR, Naghib SM (2017) The effect of stirring rate on electrodeposition of nanocrystalline nickel coatings and their corrosion behaviors and mechanical characteristics. Int J Electrochem Sci 12:5023–5035. https://doi.org/10.20964/2017.06.68

Izaki M, Omi T (1996) Transparent zinc oxide films prepared by electrochemical reaction. Appl Phys Lett 68:2439–2440. https://doi.org/10.1063/1.116160

Khajavi MR, Blackwood DJ, Cabanero G, Tena-Zaera R (2012) New insight into growth mechanism of ZnO nanowires electrodeposited from nitrate-based solutions. Electrochim Acta 69:181–189. https://doi.org/10.1016/j.electacta.2012.02.096

Elias J, Tena-Zaera R, Levy-Clement C (2007) Electrodeposition of ZnO nanowires with controlled dimensions for photovoltaic applications: role of buffer layer. Thin Solid Films 515:8553–8557. https://doi.org/10.1016/j.tsf.2007.04.027

Rosas-Laverde NM, Pruna A, Busquets-Mataix D, Pullini D (2020) Graphene oxide-assisted morphology and structure of electrodeposited ZnO nanostructures. Materials 13:365. https://doi.org/10.3390/ma13020365

Xu C, Lee JH, Lee JC, Kim BS, Hwang SW, Whang D (2011) Electrochemical growth of vertically aligned ZnO nanorod arrays on oxidized bi-layer graphene electrode. CrystEngComm 13:6036–6039. https://doi.org/10.1039/C1CE05695F

Hambali NA, Yahaya H, Mahmood MR, Terasako T, Hashim AM (2014) Synthesis of zinc oxide nanostructures on graphene/glass substrate by electrochemical deposition: effects of current density and temperature. Nanoscale Res Lett 9:609. https://doi.org/10.1186/1556-276X-9-609

Huang S, Wu PF, Yue HY et al (2019) ZnO nanosheet arrays/graphene foam: voltammetric determination of dopamine in the presence of ascorbic acid and uric acid. J Mater Sci 30:16510–16517. https://doi.org/10.1007/s10854-019-02027-z

Gao LB, Ren WC, Xu HL, Jin L, Wang ZX, Ma T, Ma LP, Zhang ZY, Fu Q, Peng LM, Bao XH, Cheng HM (2012) Repeated growth and bubbling transfer of graphene with millimetre-size single-crystal grains using platinum. Nat Commun 3:699. https://doi.org/10.1038/ncomms1702

Villarreal CC, Pirzada D, Wong A, Vi D, Pham T, Mulchandani A (2018) Characterisation of the heterojunction microstructure for electrodeposited vertical ZnO nanorods on CVD-graphene. Mater Res Express 5:085031. https://doi.org/10.1088/2053-1591/aace06

Malekpour H, Ramnani P, Srinivasan S, Balasubramanian G, Nika DL, Mulchandani A, Lake R, Balandin AA (2016) Thermal conductivity of graphene with defects induced by electron beam irraditiation. Nanoscale 8:14608–14616. https://doi.org/10.1039/C6NR03470E

Zarebska K, Kwiatkowski M, Gniadek M, Skompska M (2013) Electrodeposition of Zn(OH)(2), ZnO thin films and nanosheet-like Zn seed layers and influence of their morphology on the growth of ZnO nanorods. Electrochim Acta 98:255–262. https://doi.org/10.1016/j.electacta.2013.03.051

Wang MS, Jiang LX, Kim EJ, Hahn SH (2015) Electronic structure and optical properties of Zn(OH)(2): LDA+U calculations and intense yellow luminescence. RSC Adv 5:87496–87503. https://doi.org/10.1039/C5RA17024A

Zaban A, Greenshtein M, Bisquert J (2003) Determination of the electron lifetime in nanocrystalline dye solar cells by open-circuit voltage decay measurements. ChemPhysChem 4:859–864. https://doi.org/10.1002/cphc.200200615

Sarker S, Ahammad AJS, Seo HW, Kim DM (2014) Electrochemical impedance spectra of dye-sensitized solar cells: fundamentals and spreadsheet calculation. Int J Photoenergy 2014:851705. https://doi.org/10.1155/2014/851705

Bisquert J (2002) Theory of the impedance of electron diffusion and recombination in a thin layer. J Phys Chem B 106:325–333. https://doi.org/10.1021/jp011941g

Scharifker B, Hills G (1983) Theoretical and experimental studies of multiple nucleation. Electrochim Acta 28:879–889. https://doi.org/10.1016/0013-4686(83)85163-9

Son DY, Bae KH, Kim HS, Park NG (2015) Effects of seed layer on growth of ZnO nanorod and performance of perovskite solar cell. J Phys Chem C 119:10321–10328. https://doi.org/10.1021/acs.jpcc.5b03276

Wipperman K, Schultze JW, Kessel R, Penninger J (1991) The inhibition of zinc corrosion by bisaminotriazole and other triazole derivatives. Corros Sci 32:205–230. https://doi.org/10.1016/0010-938X(91)90044-P

Nasirpouri F (2017) Electrodeposition of nanostructured materials. Springer, Cham 62:1–325. https://doi.org/10.1007/978-3-319-44920-3

Goux A, Pauporte T, Chivot LD (2005) Temperature effects on ZnO electrodeposition. Electrochim Acta 50:2239–2248. https://doi.org/10.1016/j.electacta.2004.10.007

Dupuy L, Haller S, Rousset J, Donsanti F, Guillemoles FG, Lincot D, Decker (2010) Impedance measurements of nanoporosity in electrodeposited ZnO films for DSSC. Electrochem Commun 12:697–699. https://doi.org/10.1016/j.elecom.2010.03.009

Yin Z, Wu S, Zhou X, Huang X, Zhang Q, Boey F, Zhang H (2009) Electrochemical deposition of ZnO nanorods on transparent reduced graphene oxide electrodes for hybrid solar cells. Small 6:307–312. https://doi.org/10.1002/smll.200901968

Wan WT, Zhu LP, Hu L, Chen GF, Mi WB, Ye ZZ (2014) Investigation of morphology evolution of Cu-ZnO nanorod arrays and enhancement of ferromagnetism by codoping with N. Phys Lett A 378:2763–2767. https://doi.org/10.1016/j.physleta.2014.07.040

Tatiparti SSV, Ebrahimi F (2012) Potentiostatic versus galvanostatic electrodeposition of nanocrystalline Al-Mg alloy powders. J Solid State Electrochem 16:1255–1262. https://doi.org/10.1007/s10008-011-1522-5

Bera D, Qian L, Sabui S, Santra S, Holloway PH (2008) Photoluminescence of ZnO quantum dots produced by a sol-gel process. Opt Mater 30:1233–1239. https://doi.org/10.1016/j.optmat.2007.06.001

Greene LE, Law M, Goldberger J, Kim F, Johnson JC, Zhang YF, Saykally RJ, Yang PD (2003) Low-temperature wafer-scale production of ZnO nanowire arrays. Angew Chem Int Ed Engl 42:3031–3034. https://doi.org/10.1002/anie.200351461

Hsieh CT, Yang SY, Lin JY (2010) Electrochemical deposition and superhydrophobic behavior of ZnO nanorod arrays. Thin Solid Films 518:4884–4889. https://doi.org/10.1016/j.tsf.2010.03.081

Bhardwaj M, Balani K, Balasubramaniam R, Pandey S, Agarwal A (2011) Effect of current density and grain refining agents on pulsed electrodeposition of nanocrystalline nickel. Surf Eng 27(9):642–648. https://doi.org/10.1179/026708410x12683118611185

Salazar R, Lévy-Clément C, Ivanova V (2012) Galvanostatic deposition of ZnO thin films. Electrochim Acta 78:547–556. https://doi.org/10.1016/j.electacta.2012.06.070

Acknowledgements

A.M. acknowledges the financial support from W. Ruel Johnson Chair in Environmental Engineering. C.V. acknowledges Instituto Tecnológico de Costa Rica for the scholarship to pursue her Ph.D. studies at UC Riverside.

Funding

The study was performed with the financial support from W. Ruel Johnson Chair in Environmental Engineering. Instituto Tecnológico de Costa Rica supported the Ph.D. studies of C.V. in UC Riverside with a scholarship.

Author information

Authors and Affiliations

Contributions

CV was responsible for device design, materials fabrication, electrochemical measurements and original draft preparation; DP and AW collaborated in materials fabrication and electrochemical measurements; AW revised the manuscript; AM guided the revision of the manuscript and design of the study. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest or competing interests regarding the publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Villarreal, C.C., Pirzada, D., Wong, A. et al. Electrodeposition of ZnO nanorods on graphene: tuning the topography for application as tin oxide-free electron transport layer. J Appl Electrochem 51, 977–989 (2021). https://doi.org/10.1007/s10800-021-01531-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-021-01531-7