Abstract

Practices show that the triaxial stress change of mining-disturbed coal deeply affects its failure and permeability characteristics and easily cause the coal and rock dynamic disasters during deep underground mining process. The combined mechanic-damage-permeability experiments of gas-bearing coal were carried out under the mechanical paths of conventional triaxial compression (CTC), fixing axial pressure and unloading confining pressure (FAPUCP) and loading axial pressure and unloading confining pressure (LAPUCP). Then the effects of the deviatoric stress ratio (DSR) on the damage and permeability characteristics of coal were analyzed. The results proved that the distinguishing deformation and strength characteristics of coal were showed due to the different mechanical paths and the coal specimens were converted from brittle deformation to plastic deformation with the effect of higher confining pressure. The coal specimens of the three mechanical paths generated the main shear failure, tensile-shear failure and ‘X’ conjugate shear failure, respectively, and the fracture angles decreased in order. The damage and permeability of coal specimens could be more and more severe in the order of CTC, FAPUCP and LAPUCP paths, which was due to the different DSR. Thus, the deep mining-disturbed coal of lager DSR is seriously prone to cause the coal and rock dynamic disasters. The corresponding measures should be taken to reduce the DSR of mining-disturbed coal and then avoid the dynamic disasters.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

China is the major coal producer and consumer in the world (Li et al. 2015). The coal mining depth grows larger at an average rate of 10 ~ 25 m per year with the rapid economic development and large energy demand in China (Kong et al. 2014). According to a variety of figures, over 50 coal mines in China are of the mining depth of greater than 1000 m to date, of which the Suncun coal mine in Shandong Province, Eastern China, is more than 1500 m in mining depth (Xie et al. 2017).

The deep coal and rock mass would suffer from the process of repeatedly loading and unloading, compared with the shallow. With the combined effects of mining unloading and stress concentration, the actual triaxial stress of the deep coal mass is quite different from those of the shallow, showing that the horizontal stress in the same direction with mining is relieved and the vertical stress perpendicular to the mining direction increases sharply (Fig. 1) (Zhao et al. 2014). The experiment results show that the strength, deformation and seepage of coal are significantly sensitive to the stress (Lu et al. 2016), and thus the deep coal with strong mining disturbance is easy to undergo plastic deformation, crack propagation and even damage failure, which can deeply affect the permeability and may lead to the serious coal and rock dynamic disasters (Xue et al. 2015). Statistics show that the number of the roof and gas dynamic accidents accounts for 70% of the total number of accidents in coal mines, which not only cause fatalities, but also bring production losses and huge financial burdens for mining companies (Cheng et al. 2012; Pan et al. 2014). Part of the major coal and gas outburst accidents in China in recent years are shown in Table 1. Therefore, an understanding of the damage and permeability evolution laws of the mining-disturbed coal mass is significantly important to reveal the mechanism of coal and rock dynamic disaster.

The laboratory experiment is the quite important method for researching the damage and permeability characteristics of the loading coal and rock mass (Cai et al. 2014; Lu et al. 2019a, b). A lot of experiment research has been performed under different experimental conditions, e.g. coal specimen, mechanical path, loading rate (Hashiba et al. 2006), temperature (Yin et al. 2013), fluid media and pore pressure (Wang et al. 2013; Zhang et al. 2017a, b), in the world. The raw coal and reconstituted coal (Chen et al. 2013; Pan et al. 2014), the intact coal and damaged coal (Li et al. 2016; Lu et al. 2017), the soft coal and hard coal (Lu et al. 2019a, b), the coal and rock combination (Huang and Liu 2013), were always used as the experimental specimens. A serious of mechanical paths, such as conventional triaxial compression (Medhurst and Brown 1998; Xue et al. 2015), unloading confining pressure (Xue et al. 2017), equal and unequal reduction of axial stress and confining pressure (Chen et al. 2014), tiered cyclic loading (Jiang et al. 2017) and so on, were also set to the experimental conditions. However, most of the literatures conducted the experiments with the mechanical path of tri-axial compression or unloading confining pressure with the fixed axial pressure, while the path of loading axial pressure and unloading confining pressure simultaneously in accord with the actual stress state of the mining-disturbed coal was scarcely employed.

The related research shows that the damage and seepage mutation of coal and rock mass are mainly caused by the deviatoric stress (Zhang et al. 2017a, b). The deviatoric stress formula and the plastic zone radius of the circle roadway in nonuniform stress field were obtained, based on the stress of a circle hole in elastic–plastic mechanics and the deviatoric stress theory in plastic mechanics (Ma et al. 2015). The peak deviatoric stress of coal rock in the test of unloading confining pressure—reloading axial stress is lower than that in a conventional triaxial compression test, and the peak deviatoric stress linearly relates the degree of unloading confining pressure (Zhang et al. 2017a, b). As deviatoric stress and strain increase, permeability first decreases as pre-existing cleats close, and then increases as new vertical dilatant microcracks are generated (Wang et al. 2013). Permeability of sandstone under increasing deviatoric stress both in short-term and creep compression condition are measured with pulse transient technique and a linear relationship between the crack volumetric strain and permeability is concluded (Xu and Yang 2016). However, the above literatures focus only on the effects of the deviatoric stress on coal mass but neglect the role of confining pressure which also influence the damage degree and permeability change of coal and rock mass actually.

Based on the above, the deviatoric stress ratio (DSR) that represents the ratio of deviatoric stress to hydrostatic stress was put forward and the combined mechanic-damage-permeability experiments of gas-bearing coal were carried out under the mechanical paths set according to the actual triaxial stress of deep mining-disturbed coal. Then the effects of DSR on the damage and permeability characteristics of coal were analyzed and the mechanism of failure and permeability characteristics of mining-disturbed coal was revealed. The results would have important significance on the preventions of coal and rock dynamic disasters and safe mining of the deep underground coal.

2 Experimental Setup

2.1 Preparation of Coal Specimens

The underground coal appears in a broken structure with low strength and it is difficult to obtain a raw coal specimen due to the tectonic stress. Moreover, the repeatability of experiments and the ability to compare experimental results are poor even if the raw coal specimen can be produced (Jasinge et al. 2009). At the same time, the reconstituted coal specimens and raw coal specimens have good consistency on the deformation law. Therefore, the reconstituted coal specimens are chosen for the related study in this paper.

The raw materials for producing the reconstituted coal specimens were collected from the No.10 coal seam of Yangliu coal mine, Huaibei mining area, Eastern China, of which the burial depth is 610 m. The production process for the reconstituted coal specimens is as follows (Fig. 2): The raw coal materials were crushed and screened for 60 ~ 80 coal particles and then evenly mixed with a small amount of water; the coal particles were packed into the special mold with the inner diameter of 50 mm and applied the pressure of 100 MPa from the stiffness compressor for 3 h; the specimens were placed in a 60 °C vacuum oven for 24 h; standard specimens with an approximate height of 100 mm were obtained using a cutting machine.

2.2 Experimental Test

The experiments were carried out in the test system for coal adsorption-seepage-mechanic coupling properties, which includes the loading module, acoustic emission (AE) module and seepage module (Fig. 3) (Chen et al. 2013). The permeability of coal is measured via the pressure transient method and the AE signal is real-time monitored by CTA-1 AE acquisition system during the coal loading and unloading.

2.3 Experimental Procedure

Three mechanical paths, conventional triaxial compression (CTC), fixing axial pressure and unloading confining pressure (FAPUCP) and loading axial pressure and unloading confining pressure (LAPUCP), were proposed based on the actual triaxial stress of deep mining-disturbed coal. The stress–strain relationships of the reconstituted coal with different hydrostatic pressure were measured before designing the experimental procedure. It’s found that the compressive strength and residual strength increase gradually with the increase of the effective confining pressure. The compressive strength was about 24 MPa when the effective confining pressure was 6 MPa. The reconstituted coal would generate plastic flow rather than breakage when its stress reached the peak strength if the effective confining pressure was over 6 MPa. So the detailed experimental program was followed.

2.3.1 CTC

The hydrostatic pressure was loaded to 7 MPa while the gas pressure was fixed 1 MPa; the axial pressure (equal to deviatoric stress) was loaded with the force control rate of 80 N/s until the failure of the coal specimen and continuously loaded with the displacement control rate of 0.1 mm/min until the residual strength remained stable; the confining pressure remained 7 MPa during the whole loading process.

2.3.2 FAPUCP

The hydrostatic pressure was loaded to 7 MPa while the gas pressure was fixed 1 MPa; the axial pressure was loaded to 12 MPa with the force control rate of 80 N/s and then remained constant; the confining pressure was unloaded with the force control rate of 10 N/s until the failure of the coal specimen and continuously loaded with the displacement control rate of 0.02 mm/min until the residual strength remained stable.

2.3.3 LAPUCP

The hydrostatic pressure was loaded to 7 MPa while the gas pressure was fixed 1 MPa; the axial pressure was loaded with the force control rate of 80 N/s continuously and then the confining pressure started to be unloaded with the force control rate of 10 N/s when the axial pressure reached 12 MPa until the failure of the coal specimen; continuously, the axial pressure was loaded with the displacement control rate of 0.1 mm/min and the confining pressure was unloaded with the displacement control rate of 0.02 mm/min until the residual strength remained stable.

3 Experimental Results and Analysis

The combined mechanic-damage-permeability experiments of gas-bearing coal had been carried out to analyze the characteristics of deformation and strength, damage, failure and permeability based on the above experimental methods.

3.1 Deformation and Strength Characteristics

All the coal specimens of three mechanical paths had undergone the stages of elastic deformation, plastic deformation, yield failure and residual stability but showed the distinct deformation and strength characteristics due to the different mechanical paths (Fig. 4 and Table 2). The coal specimens were continuously compressed in the axial direction and expanded in the radial direction during the whole loading and unloading process. The axial strain increased and the radial strain decreased slightly before peak while intensely after peak. The volume of the coal specimens was reduced during elastic deformation while the dilatation appeared after the plastic deformation stage arrived. Therefore, the bulk strain of three mechanical paths increased during elastic deformation and reached to the maximum of 1.02%, 0.27% and 0.79% at the damage expansion point; it decreased slowly during plastic deformation and rapidly in post-peak.

The deviatoric stress of the CTC, FAPUCP and LAPUCP paths were 18.47 MPa, 6.92 MPa and 7.93 MPa respectively at the damage expansion point, of which the peak value reached 23.8 MPa, 8.6 MPa and 14.6 MPa with the confining pressure of 7 MPa, 2.5 MPa and 4.43 MPa. The deviatoric stress peak was linear with the confining pressure (Fig. 5). The post-peak strength remained 22.9 MPa, 5.4 MPa and 5.1 MPa after entering the stage of residual stability and the stress drop from the peak to residual stability were 0.9 MPa, 3.2 MPa and 9.5 MPa. It’s because that the higher the confining pressure, the larger the compressive strength and shear strength and the less prone to failure of the coal specimens. The confining pressure of CTC was the highest while that of FAPUCP was the lowest when the coal specimens were destroyed. So the deformation and strength of LAPUCP when being damaged completely were medium between those of CTC and FAPUCP. The coal specimens were converted from brittle deformation to plastic deformation with the effect of high confining pressure, leading to the increasing axial strain, decreasing radial strain and less post-peak stress drop. It’s believed that there is a critical confining pressure to transform the coal from brittle deformation to plastic deformation in theory.

3.2 Damage Characteristics

There are numerous AE parameters representing the damage characteristics of loading and unloading coal mass, of which the AE count was selected due to the limited length in this paper. The variation of stress and AE with different mechanical paths was shown in Fig. 6. The AE activities enhanced, reached the maximum and then weakened gradually, lagging behind the stress–strain curves during the loading and unloading. The AE count of CTC increased steadily and was of paroxysmal characteristic rather than continuous change with the maximum of 184, which case was named the stable-damage pattern. The AE counts of FAPUCP and LAPUCP increased slowly in the elastic deformation stage and rapidly in the yield failure stage with the maximum of 238 and 271, which cases were named the rapid-damage pattern. The cumulative AE counts (N) of the three mechanical paths increased from 28.5 thousand to 953.2 thousand during the whole loading and unloading process.

The deviatoric stress and the displacement of LAPUCP were greater than those of FAPUCP with the same confining pressure drop and thus the axial pressure did more work for the specimen of LAPUCP. The coal specimen of LAPUCP would release more elastic strain energy and generate more the cumulative AE count than that of FAPUCP. The coal specimen of CTC bore higher confining pressure than that of LAPUCP and tended to plastic deformation. So the interface slippage of the coal specimen of CTC would dissipate more external work and release less energy, compared to that of LAPUCP. In general, different mechanical paths could lead to different degrees of damage for coal specimens and it goes LAPUCP, FAPUCP and CTC in order of severity.

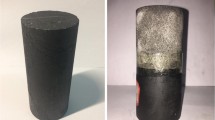

3.3 Failure Characteristics

The failure forms of coal specimens were widely different under different mechanical paths (Fig. 7). The coal specimen of CTC was damaged with the interface slippage and obvious radial expansion mainly under the constant confining pressure of 7 MPa. Thus the coal specimen of CTC occurred the main shear failure with the fracture angle (the angle between the main fracture direction and the maximum principal stress direction) of 28° under the action of pressure shear. The stress of the coal specimen of FAPUCP turned from triaxial compression to uniaxial compression gradually and the elastic strain energy stored in the coal specimen was released, leading to the swelling deformation and tensile stress of the coal specimen along radial direction. So the failure form of the coal specimen of FAPUCP turned from the pressure-shear to the tensile-shear with the fracture angle of 26° less than that of CTC. It’s known that the coal mass is prone to the conjugate shear failure when the deviatoric stress is much larger than the tensile strength according to the Coulomb failure criterion. The coal specimen of LAPUCP bore larger deviatoric stress than those of CTC and FAPUCP and thus occurred the ‘X’ conjugate shear failure with more tensile crack and the fracture angle of 26°. Therefore, the coal specimens of the three mechanical paths occurred the main shear failure, tensile-shear failure and ‘X’ conjugate shear failure, respectively, and the fracture angles decreased in order.

3.4 Permeability Characteristics

The permeability of all the coal specimens decreased firstly and then increased during the loading and unloading process (Fig. 8). The original fractures were closed by extrusion and no new fractures generated, leading to the decrease of porosity during elastic deformation. Accordingly, the permeability decreased and the minimum of CTC, FAPUCP and LAPUCP, only 66.2%, 66.0% and 57.4% of the original permeability, appeared when the deviatoric stress was 73.5%, 77.8% and 68.5% of the peak, respectively. The coal specimens started to be damaged and the porosity increased due to the enlarged original fractures and the generated new fractures after entering the plastic deformation stage. In turn, the permeability was rebounded and increased continuously while of which the final, 81.1%, 193.0% and 151.6% of the original permeability, were quite diverse under different mechanical paths. Under the condition of the same deviatoric stress, the coal specimen of LAPUCP bore lower confining pressure, enlarged the fracture aperture and thus was of greater permeability increment, compared with that of CTC. Under the condition of the same confining pressure, the coal specimen of LAPUCP bore larger deviatoric stress, generated more new fractures and thus was of greater permeability increment, compared with that of FAPUCP. However, the coal specimen of FAPUCP bore the lowest confining pressure and generated the most fractures, leading to the largest permeability increment during the post-peak stage.

4 Discussions

4.1 Concept and Physical Significance of DSR

The deformation of an object is the changes of volume and form under external forces based on the elastic–plastic mechanics theory. The volume change is due to the isotropic spherical stress while the plastic deformation and damage is caused by the anisotropic deviatoric stress (Thornton and Zhang 2010; Wang et al. 2012). The triaxial stress of any unit of coal mass can also be decomposed into spherical stress and deviatoric stress:

where \(\sigma_{i,j}\) is the stress tensor of coal mass; \(p\delta_{i,j}\) is the spherical stress tensor; \(\sigma_{i,j}^{^{\prime}}\) is the deviatoric stress tensor; \(p\) is the hydrostatic stress; \(\sigma_{1}\), \(\sigma_{2}\) and \(\sigma_{3}\) are the three principal stress.

The spherical stress tensor indicates the equal stress state of each direction and thus the hydrostatic stress is equal to the minor principal stress. The major principal deviatoric stress \((\sigma_{1} - p)\) can be converted into \((\sigma_{1} - \sigma_{3} )\), which plays a leading role in the coal mass damage. For simplicity, the deviatoric stress in this paper is the major principal deviatoric stress.

Researches show that the damage degree of coal mass is extremely different for the different hydrostatic stress, even though the deviatoric stress is equal. The damage and permeability characteristics of coal mass are affected not only by deviatoric stress but also by hydrostatic stress. Thus the DSR, the ratio of deviatoric stress to hydrostatic stress (or the minor principal stress), was put forward to analyzed the damage and permeability characteristics of plastic-deformation coal mass. The expression of DSR is that:

where \(\eta\) is DSR and \(\Delta \sigma_{1}\) is deviatoric stress.

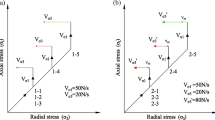

The DSR is proportional to the major principal stress and inversely proportional to the minor principal stress according to Formula (2). So DSR increases when the axial stress is loaded or the confining pressure is unloaded. The Mohr–coulomb criterion is widely used to descript the failure form of rock mass. The deviatoric stress determining the diameter of the Mohr circle and the minor principal stress determining its location, certain the relative position of the Mohr circle and envelope curve together (Fig. 9). Thus DSR determines the damage degree of coal and rock mass. The DSR increases and then the coal mass is damaged more badly when the deviatoric stress increases or the confining pressure decreases.

4.2 Effects of DSR on the Damage and Permeability Characteristics of Coal

The variation of DSR under three mechanical paths could be obtained according to the actual triaxial stress in Fig. 4 (Fig. 10a). All the DSRs increased gradually and reached about 3.4 when the coal was damaged, which were consistent with the slope of the line in Fig. 5. It’s indicated that there is a critical DSR that causes the damage of special coal. It also indirectly reflects that the DSR certains the damage degree of the loading coal.

The same axial loading or confining pressure unloading should be chosen for contrasting the damage and permeability characteristics of coal. The same loading intervals are the 12 ~ 19 MPa of axial pressure and 7 ~ 4.5 MPa of confining pressure under three mechanical paths. However, the coal mass of CTC presented the elastic deformation only without damage when the axial pressure was loaded from 12 to 19 MPa. Thus the experimental results of FAPUCP and LAPUCP with the confining pressure being unloaded from 7 MPa to 4.5 MPa were suitable for comparison (Fig. 10b).

The axial pressure of LAPUCP rised from 12 to 19 MPa while that of FAPUCP was constant at 12 MPa when the confining pressure decreased from 7 MPa to 4.5 MPa. Thus the DSR of LAPUCP increased from 0.71 to 3.24, of which the increment was larger than that of FAPUCP from 0.71 to 1.63. The cumulative AE count of LAPUCP increased nonlinearly from 14.2 thousand to 78.4 thousand while that of FAPUCP increased linearly from 18.9 thousand to 28.4 thousand; the relative permeability (\(k/k_{0}\)) decreased from 0.76 to 0.57 and then increased to 1.05 while that of FAPUCP decreased from 0.79 to 0.66 and then increased to 0.88 (Fig. 10b). Therefore, the variation of the cumulative AE count and the relative permeability were consistent with that of DSR during the confining pressure unloading. The larger DSR, the greater cumulative AE count and relative permeability. It further suggests that the damage degree and relative permeability of plastic-deformation coal are curtained by DSR to some extent.

The AE and relative permeability variation of FAPUCP and LAPUCP against DSR were analyzed further (Fig. 11). The cumulative AE counts of FAPUCP and LAPUCP increased linearly and exponentially, respectively, and thus the increment of LAPUCP was greater than that of FAPUCP obviously. The relative permeability of FAPUCP increased much greater than that of LAPUCP although both of which increased exponentially. Therefore, the coal specimen of LAPUCP was closed to be damaged completely while that of FAPUCP was only in the early stage of plastic deformation when the confining pressure was unloaded to 4.5 MPa. It’s indicated that the larger DSR, the greater damage degree and relative permeability.

In sum, DSR is the essential reason for the difference in the damage and permeability characteristics of the plastic-deformation coal. The coal of LAPUCP is of larger DSR than those of CTC and FAPUCP, leading to more serious damage and greater permeability. The mining-disturbed coal mass bore the major vertical stress and relieved horizontal stress, bringing about larger DSR during deep coal mining. If there is a thick-hard rock layer in the overburden, the vertical dynamic load coming from its breakage would also bring about the increase of DSR of the underlying coal (Xu et al. 2019, 2016). In the result, the damage and permeability of the mining-disturbed coal increased rapidly and were seriously prone to cause the coal and rock dynamic disasters, e.g. rib spalling, rock burst, coal and gas outburst and abnormal gas emission. Therefore, in order to avoid the dynamic disasters, the corresponding measures should be taken to reduce the DSR of mining-disturbed coal. Therefore, the corresponding measures, such as the destress blasting (Zhu et al. 2013), drilling boreholes and gas drainage (Xu et al. 2014), should be taken to reduce the DSR of mining-disturbed coal and then avoid the dynamic disasters.

5 Conclusions

The triaxial stress change of mining-disturbed coal affects its failure and permeability characteristics deeply. The combined mechanic-damage-permeability experiments of gas-bearing coal were carried out under the mechanical paths of CTC, FAPUCP and LAPUCP. Then the effects of DSR on the damage and permeability characteristics of coal were analyzed and the mechanism of the damage and permeability characteristics of mining-disturbed coal was revealed. The main conclusions of this study can be summarized as follows:

-

1.

The distinguishing deformation and strength characteristics of coal were showed due to the different mechanical paths. The volume of the coal specimens was reduced during elastic deformation while the dilatation appeared after the plastic deformation stage arrived. The deviatoric stress peak was linear with the confining pressure and the deformation and strength of LAPUCP were medium between those of CTC and FAPUCP when the coal specimens were damaged completely. The coal specimens were converted from brittle deformation to plastic deformation and of the less post-peak stress drop with the effect of higher confining pressure.

-

2.

The phenomena of damage dilatation and permeability increasing appeared after entering the plastic deformation stage. But the damage and permeability of coal specimens could be more and more severe in the order of CTC, FAPUCP and LAPUCP paths. The stable-damage pattern of CTC and the rapid-damage pattern of FAPUCP and LAPUCP were summarized according to the variation of AE.

-

3.

The coal specimen of CTC generated the main shear failure under the action of pressure shear. The failure form of the coal specimen of FAPUCP turned from the pressure-shear to the tensile-shear because the elastic strain energy was released along radial direction. The coal specimen of LAPUCP bore larger deviatoric stress and thus occurred the ‘X’ conjugate shear failure with more tensile crack. The fracture angles of the three mechanical paths decreased in order.

-

4.

The DSR was put forward and identified as the essential reason for the difference in the damage and permeability characteristics of the plastic-deformation coal. The coal of LAPUCP is of larger DSR than those of CTC and FAPUCP, leading to more serious damage and greater permeability. Thus the deep mining-disturbed coal of lager DSR is seriously prone to cause the coal and rock dynamic disasters. The corresponding measures should be taken to reduce the DSR of mining-disturbed coal and then avoid the dynamic disasters.

References

Cai Y et al (2014) Permeability evolution in fractured coal—combining triaxial confinement with X-ray computed tomography, acoustic emission and ultrasonic techniques. Int J Coal Geol 122:91–104

Chen H, Cheng Y, Zhou H, Li W (2013) Damage and permeability development in coal during unloading. Rock Mech Rock Eng 46:1377–1390

Chen H, Cheng Y, Ren T, Zhou H, Liu Q (2014) Permeability distribution characteristics of protected coal seams during unloading of the coal body International. J Rock Mech Min Sci 71:105–116

Cheng J, Cheng W, Zhang S (2012) Methods to determine the mine gas explosibility-An overview. J Loss Prevent Proc 25:425–435

Hashiba K, Okubo S, Fukui K (2006) A new testing method for investigating the loading rate dependency of peak and residual rock strength. Int J Rock Mech Min Sci 43:894–904

Huang B, Liu J (2013) The effect of loading rate on the behavior of samples composed of coal and rock. Int J Rock Mech Min Sci 61:23–30

Jasinge D, Ranjith PG, Choi SK, Kodikara J, Arthur M, Li H (2009) Mechanical properties of reconstituted Australian black coal. J Geotech Geoenviron 135:980–985

Jiang C et al (2017) Experimental study on seepage properties, AE characteristics and energy dissipation of coal under tiered cyclic loading. Eng Geol 221:114–123

Kong S, Cheng Y, Ren T, Liu H (2014) A sequential approach to control gas for the extraction of multi-gassy coal seams from traditional gas well drainage to mining-induced stress relief. Appl Energ 131:67–78

Li W et al (2015) Addressing the CO2 emissions of the world's largest coal producer and consumer: Lessons from the Haishiwan Coalfield, China. Energy 80:400–413

Li M, Cao J, Li W (2016) Stress and damage induced gas flow pattern and permeability variation of coal from Songzao Coalfield in Southwest China. Energies 9:351

Lu S, Cheng Y, Li W (2016) Model development and analysis of the evolution of coal permeability under different boundary conditions. J Nat Gas Sci Eng 31:129–138

Lu S, Li L, Cheng Y, Sa Z, Zhang Y, Yang N (2017) Mechanical failure mechanisms and forms of normal and deformed coal combination containing gas: model development and analysis. Eng Fail Anal 80:241–252

Lu S, Zhang Y, Sa Z, Si S (2019a) Evaluation of the effect of adsorbed gas and free gas on mechanical properties of coal. Environ Earth Sci 78:218

Lu S, Zhang Y, Sa Z, Si S, Shu L, Wang L (2019b) Damage-induced permeability model of coal and its application to gas predrainage in combination of soft coal and hard coal. Energy Sci Eng 7(4):1352–1367

Medhurst TP, Brown ET (1998) A study of the mechanical behaviour of coal for pillar design. Int J Rock Mech Min Sci 35:1087–1105

Ma N, Li J, Zhao Z (2015) Distribution of the deviatoric stress field and plastic zone in circular roadway surrounding rock. J China Univ Min Technol 44(2):206–213

Pan R, Cheng Y, Yuan L, Yu M, Dong J (2014) Effect of bedding structural diversity of coal on permeability evolution and gas disasters control with coal mining. Nat Hazards 73:531–546

Thornton C, Zhang L (2010) On the evolution of stress and microstructure during general 3D deviatoric straining of granular media. Géotechnique 60:333–341

Wang Z, Luo Y, Guo H, Tian H (2012) Effects of initial deviatoric stress ratios on dynamic shear modulus and damping ratio of undisturbed loess in China. Eng Geol 143–144:43–50

Wang S, Elsworth D, Liu J (2013) Permeability evolution during progressive deformation of intact coal and implications for instability in underground coal seams. Int J Rock Mech Min Sci 58:34–45

Xie H, Ju Y, Gao F, Gao M, Zhang R (2017) Groundbreaking theoretical and technical conceptualization of fluidized mining of deep underground solid mineral resources. Tunn Undergr Space Technol 67:68–70

Xu P, Yang S (2016) Permeability evolution of sandstone under short-term and long-term triaxial compression. Int J Rock Mech Min Sci 85:152–164

Xu C, Cheng Y, Ren T, Wang L, Kong S, Lu S (2014) Gas ejection accident analysis in bed splitting under igneous sills and the associated control technologies: a case study in the Yangliu Mine, Huaibei Coalfield, China. Nat Hazards 71:109–134

Xu C, Yuan L, Cheng Y, Wang K, Zhou A (2016) Square-form structure failure model of mining-affected hard rock strata: theoretical derivation, application and verification. Environ Earth Sci 75:1180

Xu C, Fu Q, Cui X, Wang K, Zhao Y, Cai Y (2019) Apparent-depth effects of the dynamic failure of thick hard rock strata on the underlying coal mass during underground mining. Rock Mech Rock Eng 52:1565–1576

Xue Y et al (2017) Mechanical behaviour and permeability evolution of gas-containing coal from unloading confining pressure tests. J Nat Gas Sci Eng 40:336–346

Xue Y, Gao F, Liu X (2015) Effect of damage evolution of coal on permeability variation and analysis of gas outburst hazard with coal mining. Nat Hazards 79:999–1013

Yin G, Jiang C, Wang JG, Xu J (2013) Combined effect of stress, pore pressure and temperature on methane permeability in anthracite coal: an experimental study. Transport Porous Med 100:1–16

Zhang Q, Fan X, Liang Y, Li M, Li G, Ma T, Nie W (2017a) Mechanical behavior and permeability evolution of reconstituted coal samples under various unloading confining pressures—implications for wellbore stability analysis. Energies 10:292

Zhang X, Zhang D, Leo C, Yin G, Feng D, Liyanapathirana DS (2017b) Damage evolution and post-peak gas permeability of raw coal under loading and unloading conditions. Transport Porous Med 117:465–480

Zhao XG et al (2014) Influence of unloading rate on the strainburst characteristics of Beishan granite under true-triaxial unloading conditions. Rock Mech Rock Eng 47:467–483

Zhu WC, Wei CH, Li S, Wei J, Zhang MS (2013) Numerical modeling on destress blasting in coal seam for enhancing gas drainage. Int J Rock Mech Min 59:179–190

Acknowledgements

The work was supported by the National Natural Science Foundation of China (Grant No. 51974321, 51874314 and 51774292).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xu, C., Fu, Q., Wang, K. et al. Effects of the Deviatoric Stress Ratio on the Coal Failure and Permeability During Deep Mining. Geotech Geol Eng 38, 6093–6105 (2020). https://doi.org/10.1007/s10706-020-01417-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-020-01417-z