Abstract

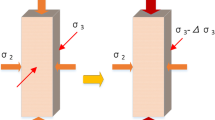

The deep surrounding rock is in a three-directional stress state before mining. The process of roadway excavation is the process of confining pressure unloading due to the engineering needs. Therefore, the confining pressure effect plays an indispensable and important role in deep engineering. Based on the above engineering background, the current research status and development trend on the confining pressure effect are introduced. Besides, combined with the results of rock mechanics tests, the basic mechanical parameters, strength and deformation evolution law, energy evolution law, damage evolution law, and failure characteristics of coal and rock under different confining pressures are revealed. Meanwhile, four new insights are proposed: (1) It is urgent to establish the detailed evaluation index system to quantitatively and qualitatively characterize the brittleness and ductility of rock under the confining pressure effect; (2) It is necessary to strengthen the research on the time-dependent deformation mechanism and the construction of time-dependent strength evolution model of coal and rock, so that the localization of time effect is gradually transferred from rheological mechanics to other mechanical fields; (3) It is valuable to strengthen the research on the mechanical properties of coal and rock under the confining pressure effect from the microscopic perspective; (4) It is meaningful to strengthen the creep mechanical experimental research on coal and rock with the new stress path of “three stages” loading, which includes initial high in-situ stress state reduction, constant axial pressure with unloading confining pressure, and constant confining pressure with loading axial pressure corresponding to three stages of the stress variation characteristics of the surrounding rock around the roadway of deep mines: before excavation, being excavated, and after excavation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

A comprehensive and accurate understanding of the mechanical properties of coal and rock under the confining pressure effect can provide certain theoretical basis and practical value for controlling the stability of underground engineering (including the long-term stability of whole-coal seam, half-coal seam, and whole-rock seam roadway surrounding rock) (Chen et al. 2021a; Tang et al. 2019; Vazaios et al. 2019; Xiao et al. 2018; Yao et al. 2016; Yao et al. 2020). Currently, a great of research on the mechanical properties of coal and rock with the confining pressure effect has been done, and the domestic and foreign scholars have achieved relatively abundant research achievements mainly from loading methods (true or conventional triaxial static loading, and true or conventional triaxial dynamic loading, and true or conventional triaxial dynamic and static coupling loading), the loading stress paths (conventional triaxial loading, triaxial hierarchical loading, triaxial cyclic loading and unloading, etc.), even the research perspectives (macroscopic, mesoscopic, microscopic), and other aspects. However, there are still few studies and reports on the effect of confining pressure on the mechanical properties of coal and rock. Therefore, it is necessary to strengthen and comprehensively review the confining pressure effect on the mechanical properties of coal and rock.

Additionally, both coal and rock have the attributes of “heterogeneity, discontinuity, and anisotropy,” which to a great extent determine their strength bearing capacity, deformation capacity, energy storage and consumption capacity, and even crack initiation and propagation capacity. Besides, in terms of the construction and mining process of coal mine, the underground space of coal mine will be affected by different degree of in-situ stress, especially the roadway surrounding rock of coal mine is under long-term high in-situ stress condition (including the confining pressure effect, water-rock effect, temperature effect, and the external strong disturbance). Among them, especially the mining depth transferring into 800 m, there is more significant effect of high in-situ stress. And it is easy to cause the mechanical behavior characteristics of “large deformation, high energy level, strong time-dependent, difficult maintenance, and non-linearity” (Chen et al. 2021b; Zhang et al. 2021a; Zhou et al. 2005; Zhu et al. 2014), which will significantly affect the roadway stability of coal mines and the mining efficiency of coal resources. The mining coefficient, mining technology, and lithologic environment of metal mines are relatively smaller and simpler compared with coal mines. However, the construction and operation of metal mines still cannot get rid of the long-term effects of in-situ stress (including the confining pressure effect and the external strong disturbance). Especially the mining depth transferring into 1500 m, there is more significant effect of high in-situ stress, which mainly showing a series of strong dynamic disasters such as “rock burst”. Therefore, from the perspective of coal or rock’s property characteristics or field disaster prevention and stability control, it is necessary to strengthen the comprehensive study on the fundamental theory of “the effect of confining pressure on the mechanical properties of coal and rock.” A series of fundamental theories apply to the field practice are summarized systematically, such as strength criterion, brittle-ductility transformation, damage evolution, energy competition evolution mechanism, and crack initiation and propagation mechanism (Chen et al. 2019a; Chen et al. 2019b; Chen et al. 2021c; Galindo et al. 2017; Liu et al. 2018; Wang et al. 2017; Wang et al. 2021a; Xi et al. 2018; Zhang et al. 2013; Zhang et al. 2018a).

Method and material

Methods

The literature review method, theoretical derivation, comprehensive evaluation method, and other methods are adopted to review the effect of confining pressure on mechanical properties in coal and rock.

Materials

All the materials mentioned in this article are referred to Fu et al. (2016), Feng et al. (2019), Hashiba et al. (2006), Hamza and Stace (2018), Hao et al. (2020), Li et al. (2019), Miao et al. (2021), Walton et al. (2015), Wang et al. (2021a), Yao et al. (2016), Zhou et al. (2014), Zheng (2019), Zhang and Song (2020), Zhang et al. (2020), Zhang et al. (2018b), and Zhang et al. (2021b), and they contained different types of coal and rock.

Evolution characteristics of basic mechanical parameters

The acquisition of the basic parameters of coal and rock and the exploration of their evolution law is an important research direction in rock mechanics, including the evolution characteristics of the basic mechanical parameters of coal and rock under the confining pressure effect.

Stress-strain curve types and zonal rupture

As shown in Fig. 1, in general, there are two types of typical stress-strain curves, namely “I type” and “II type” stress-strain curves (Song and Zhang 2021; Zhang et al. 2019). Among them, Wawersik and Fairhurst (1970) divided the stress-stress curve into “I type” and “II type” stress-strain curve according to the post-peak stress-strain characteristics of the brittle rock to establish the brittle-ductility transformation model; Ge et al. (1992) has corrected the type classification of post-peak stress-strain curve of brittle rock, and the type of peak stress–strain curve of coal and rock is divided into “obvious brittle failure” type and “not obvious brittle failure” type, and established the new brittle-ductility transformation model.

Sketch map of stress-strain curve types and zonal rupture: a “I type”; b “II type” (Modified with Song and Zhang 2021; Zhang et al. 2019). a—Residual strength zone, b—strain softening zone, c—plastic zone, d—elastic zone, e—initial damage zone; I—initial compaction stage (OA), II—linear elastic deformation stage (AB), III—plastic deformation stage (BC), IV—post-peak strain softening stage (CD), VI—post-peak residual strength stage (DE)

However, as shown in Fig. 1, no matter the “I type” or the “II type” stress-strain curve, each stage of the stress-strain curve (I—initial compaction stage (OA), II—linear elastic deformation stage (AB), III—plastic deformation stage (BC), IV—post-peak strain softening stage (CD), and V—residual strength stage (DE)) corresponds to the fracture zoning state of surrounding rock in deep roadway: e-initial damage zone, d-elastic zone, c-plastic zone and loosening zone (including b-strain softening zone and a-residual strength zone). The surrounding rock of deep roadway is in the complex environment, and the characteristics of high stress and strong time-dependent are obvious. The confining pressure effect also significantly affects the stability of surrounding rock of deep roadway. Therefore, further research on the stress-strain curve types of deep coal and rock and its relationship with the zonal fracture of deep roadway can provide some fundamental theoretical basis for the stability control of the surrounding rock around the roadway of deep mines.

Additionally, can it get some new ideas of laboratory mechanical test be extended from the above “I type” or “II type” stress-strain curve corresponding to the zonal fracture characteristics of the surrounding rock around the roadway of deep mines? Such as the new methods and new ideas with conducting the initial high in-situ stress state reduction of the triaxial mechanics experiment according to the stress distribution characteristics and the external deformation law of the surrounding rock around the roadway of deep mines in the pre-excavation, excavation and post-excavation states (Zhang and Song 2020; Zhang et al. 2020; Zhang et al. 2021b), which can make the conclusion and parameters obtained of indoor mechanics test more accurate and applicable, to better serve the deep engineering.

Elastic modulus (E) and Poisson’s ratio (μ)

A large number of studies have shown that the basic mechanical parameters of coal and rock are obtained by calculating the stress-strain curve characteristics of either “I type” or “II type” stress-strain curve: Elastic (strain hardening, drop, volume, deformation) modulus, Poisson’s ratio, and the confining pressure effect have significant influence on them (Hao et al. 2020; Huang and Liu 2013; Jiang et al. 2019; Liang et al. 2010; Rybacki et al. 2015; Rybacki et al. 2016; Tang et al. 2019; Wang et al. 2021a; Xie et al. 2021a; Xie et al. 2021b; Xu and Yang 2016; Xue et al. 2014; Yang et al. 2011; Zhang et al. 2007; Zhu et al. 2019).

In general, the evolution law between the elastic modulus and Poisson’s ratio with the confining pressure of coal and rock is shown as follows: with the increases of the confining pressure, the elastic modulus and Poisson’s ratio basically show the trends of increase, decrease, respectively, but their evolution characteristics are both nonlinear (see Fig. 2). However, if there is a significant bedding effect in the coal and rock, its elastic modulus first increases, then decreases, and finally increases with the increases of the confining pressure (Hao et al. 2020). Besides, the temperature effect (see Fig. 2), pre-set crack effect, the effect of stress path, cycle effect, depth effect, the rate effect, lithologic effect, size effect, etc. will also significantly affect the evolution characteristics of the elastic modulus (strain hardening, drop, volume, deformation) and Poisson’s ratio with the confining pressure.

Typical evolution trend of mechanical parameters: a E; b μ (Modified with Yao et al. 2016).

Additionally, from a large number of research achievements (Hao et al. 2020; Huang and Liu 2013; Jiang et al. 2019; Liang et al. 2010; Rybacki et al. 2015; Rybacki et al. 2016; Tang et al. 2019; Wang et al. 2021a; Xie et al. 2021a; Xie et al. 2021b; Xu and Yang 2016; Xue et al. 2014; Yang et al. 2011; Zhang et al. 2007; Zhu et al. 2019), it can be found that the confining pressure effect has the significant influence on the elastic modulus and Poisson’s ratio of coal and rock, but all have obvious upper and lower limits in the evolution law, and it is not infinitely nonlinear. Meanwhile, the fluctuated range of elastic modulus and Poisson’s ratio are both small. Can it explain the essence of the confining pressure effect is that it cannot change the inherent properties of coal and rock (including the internal components)? Such as the different effect mechanism of the confining pressure effect and the water-rock effect, the confining pressure effect is only to limited change the deformation and bearing capacity of coal and rock by an outside force, but the water-rock effect is to change the deformation and bearing capacity of coal or rock by changing their inherent properties, and the effect can be unlimited. They are just the author’s personal opinions, and relevant evidence needs to be further studied and verified.

Cohesion (C) and internal friction angle (φ)

It is generally appreciated that the main purpose of the conventional triaxial mechanical tests is to obtain the Cohesion and the internal friction angle of coal and rock, which is the significance of the conventional triaxial mechanical tests and can also provide the important basic mechanical parameters for the inversion verification of the corresponding mechanical tests in terms of the numerical simulation. It also indirectly indicates that the confining pressure effect has a significant contribution to the mechanical properties of coal and rock.

Additionally, when the domestic and foreign scholars conducted the laboratory triaxial tests on the confining pressure effect, most of them would conduct the tests coupled with other experimental conditions, which can better obtain the evolution law of Cohesion and internal friction angle of coal and rock. Relevant studies showed that the bedding effect and depth effect both can significantly affect the evolution law of Cohesion and internal friction angle of coal and rock (Hao et al. 2020; Zheng 2019). Besides, relevant studies have shown that the size effect and temperature effect can both significantly weaken the strength properties of coal and rock (Yang et al. 2020; Zhu et al. 2019). Therefore, would the Cohesion and internal friction angle, which is closely related to strength properties, and be significantly affected by the size effect and temperature effect? Currently, there are few reports by domestic and foreign scholars on the answer to this problem, which needs further research and verification.

Summary of evolution characteristics of basic mechanical parameters

A new laboratory test method of “three-stage” loading stress path is proposed (Zhang and Song 2020; Zhang et al. 2020; Zhang et al. 2021b) according to the zonal rupture of the surrounding rock around the roadway of deep mines. Besides, the confining pressure effect has a significant influence on evolution characteristics of basic parameters of coal and rock, but its influence has upper limit. However, whether the water-rock effect, temperature effect, and size effect have upper limit influence on the evolution characteristics of basic mechanical parameters of coal and rock remains to be studied and verified.

Strength properties

Based on the evolution characteristics of basic mechanical parameters of coal and rock under the confining pressure effect obtained, the strength properties of coal and rock is also a key scientific issue that needs to be strengthened. The strength properties of coal and rock are closely related to its own bearing capacity and deformation characteristics. And they included the stress drop and brittle-ductile transformation characteristics, time dependence of strength and strength failure criterion of coal and rock under the confining pressure effect.

Stress drop and brittle-ductile transformation characteristics

Additionally, when most domestic and foreign scholars study the influence of confining pressure effect on the strength characteristics of coal and rock, it is easy to find the stress drop phenomenon and brittle-ductility transformation characteristics during the deformation process of coal and rock under the confining pressure effect. Therefore, the focus and attention of domestic and foreign scholars on the phenomenon of stress drop and the brittle-ductility transformation of rock are enhanced to further study the influence of confining pressure effect on the strength characteristics of coal and rock.

Stress drop originated from a mechanical phenomenon in early warning and monitoring for the earthquake, and it is also one of the important parameters for studying the earthquake fault mechanism and seismic energy (Shapiro and Dinske 2021; Wang et al. 1988; Zang 1984; Zhang et al. 2021c). Besides, Salamon (1970) explained the stress drop phenomenon before the main fracture of rock in laboratory mechanical tests in 1970 for the first time, which is affected by a variety of factors, including the strain rate effect and scale effect.

σc-uniaxial compressive strength (UCS), σt-uniaxial tensile strength (UTS), ε1i-unrecoverable axial strain, \({\varepsilon}_{{^p}}\)-plastic strain necessary for frictional strengthening, \({\varepsilon}_c^p\)-plastic strain necessary for cohesion loss, Pdec-average force decrement period, Pinc-average force increment period, Wqzt-content of quartz, Wclay-content of clay, Wcarb-content of carbonate minerals, YMS_C-composite determination of elastic modulus, PR_C-composite determination of Poisson ratio, SF-stiffness factor, GF-texture factor, FF-foliation factor, Wdol-content of clay and dolomite, Wtotal-total mineral weight, Fmax-the maximum applied force, P-the penetration depth at the maximum force, E-elastic modulus, M-post-peak modulus, τp-peak of shear strength, τr-residual of shear strength, Wx-weight fraction of component, QFM = quartz + feldspar + mica, Carb = carbonate, H-hardening modulus, defined as the slope of the linearized plastic yielding platform; β-the internal friction angle of brittle rock, Ebrit, μbrit are the normalized elastic modulus and Poisson’s ratio, respectively; K, λ are the bulk modulus and the Lame’s constant, respectively; ρ-the density of rock; σp, σr are the peak strength and residual strength, respectively; εp, εr are the peak strain and residual strain, respectively; εR-the pre-peak recoverable strain, We, Wp are the recoverable elastic energy and the bursting energy stored before fracturing, respectively; Wini-energy at onset of fracture initiation (dilatancy), Fsb-fraction of strong/brittle minerals, Fwd-fraction of weak/ductile minerals, Fcb-fraction of carbonates, φ-porosity (in vol%), Wxx-weighting factor [0-1] for fraction xx, QFP = Qtz+Fsp+Py(pyrite); Qtz = quartz, Fsp = feldspar, Cb = carbonates, Cly = clay, Dol = dolomite, Cal = calcite, Mca = mica, TOC = total organic carbon; q-percentage of fines obtained from Protodyakonov’s impact test; Hμ-micro-indentation hardness, Hm-macro-indentation hardness, c = 2.6 for Vicker’s hardness testing; Ha-hardness (resistance to deformation, in GPa), Kc-fracture toughness (resistance to fracture propagation, in MPa·m1/2; C-characteristic crack length, a-indentation diagonal length for Vicker’s indentation testing in glass; W-work consumed in the failure of rock; h-core disk thickness, d-core diameter; σc-NC = UCS of a normally consolidated rock in non-over pressurized areas, σc-NC≈0:5σreff, with σreff -effective in-situ stress corresponding to normal consolidation at the depth of interest; OCR = σmaxH/σact-over consolidation ratio, σmaxH≈8.6·σc0.5-maximum effective stress that a rock was subjected in history; σact-current effective stress, and b≈0.89; GC-the critical energy release rate; B-the brittleness index; φ-the internal friction angle

Additionally, there are two types of rock deformation associated with sudden stress drops: viscous sliding phenomena and brittle fracture. Among them, the temperature effect and lithologic effect are the main contributing factors for the viscous sliding phenomenon, while the confining pressure effect and lithologic effect are the main contributing factors for the brittle fracture phenomenon (Zang 1984). The results showed that the confining pressure effect, temperature effect, and lithology effect all significantly affect the stress drop phenomenon during the deformation process of rock. Besides, the explanation and characterization of the relationship between the stress-drop phenomenon generated in the deformation process of rock and the brittle-ductility transition characteristics of rock are shown in Fig. 3. Among them, to better reveal the connection and mechanism between the stress drop phenomenon and brittle-ductility transition characteristics, domestic and foreign scholars mainly through the introduction of brittleness index B to semi-quantitative or qualitative characterized, and the rank evaluation system of brittleness is established according to the scope of the brittleness index values, the various definition of brittleness index B and the rank evaluation system of brittleness is shown in Tables 1 and 2, respectively.

ε1-Axial strain; M-post-peak modulus, E-the unloading elastic modulus (see Fig. 3)

Therefore, the quantitative and qualitative characterization of brittleness and ductility of rock is a hot spot, which should need to be a further breakthrough in future research, and the brittle-ductility transition characteristics are closely related to the confining pressure effect. And subsequent studies on the quantitative and qualitative characterization of brittleness and ductility of rock under the confining pressure effect should be strengthened. Meanwhile, the detailed evaluation index system with obvious hierarchical effect should be established to in-depth reveal the brittleness and ductility of rock.

Time dependence of strength

Among the characteristics such as “high energy level, large deformation, strong time-dependent and difficult maintenance” of the surrounding rock around the roadway of deep mines, the strong time-dependent characteristic is the most easily to be ignored. Meanwhile, most of the studies on the rock mechanics considering time effect by domestic and foreign scholars are only limited to the rheological mechanics field, and it is easy to ignore the existence of time effect in the studies on the mechanical properties of rock and coal under the conventional static, dynamic, static, and dynamic loading coupling conditions. Therefore, strengthening the research on the time-dependent strength characteristics is helpful to accurately master the strength attenuation law of rock, and it is also helpful to accurately determine the reasonable supporting time of the surrounding rock around the roadway of deep mines, to better control the long-term stability of the surrounding rock around the roadway of deep mines. And the time-dependent strength characteristics of rock and coal under the confining pressure effect are comprehensively reviewed in order to enhance the focus of scholars’ response to the application of the time effect and the innovative perspective.

Additionally, related studies (Fu et al. 2016; Hashiba et al. 2006; Zhou et al. 2014) showed that the strength of coal and rock could exhibit a negative decay exponential function with the time extension under the external loading, which is often presented with the sudden failure mechanical behavior of coal and rock due to strength weakening in engineering. It is well known that the surrounding rock around the roadway of deep mines is stable after excavation, the overburden loading is constant. Currently, because of its internal joint with holes, fissures, even all kinds of microstructures, each part of the internal components both exist more or less differently, meanwhile affected by the different degree of mining disturbances, the continuous migration and secondary redistribution of abutment pressure, temperature effect, gas pressure, dissolved water pressure, and other factors make the accurate determination of reasonable support time to control the stability of the surrounding rock around the roadway of deep mines is a key scientific issue that needs to be solved. Meanwhile, the corresponding rock and coal has its characteristics such as heterogeneity, discontinuity, anisotropy, as well as the difference of its spatial structure and composition, which can also make its strength and deformation-bearing capacity different under the same continuous loading rate in the laboratory mechanical tests. However, the time effect is a good factor to better measure and characterize the strength attenuation and deformation bearing capacity of coal or rock, but it is also the most easily ignored by domestic and foreign scholars when studying the mechanical properties of coal and rock.

Strength failure criterion

The establishment and application of the strength failure criterion are inseparable from the contribution of confining pressure effect. Currently, the strength failure criteria are mainly as follows.

-

1.

Mohr-Coulomb failure criterion (M-C)

The M-C criterion mainly contains two parameters, which are the Cohesion C and the internal friction angle φ. The relationship between the shear strength and the Cohesion and the internal friction angle can be expressed as follows:

Additionally, it can be obtained through stress transformation:

where σ1 and σ3 are the axial pressure and confining pressure of coal and rock, respectively. β is the angle between the direction of maximum principal stress and the fracture plane.

Additionally, it can be expressed that:

Besides, since the M-C strength criterion ignores the influence of intermediate principal stress on the strength failure characteristics of coal or rock (Xu and Yu 2006), domestic and foreign scholars have conducted a large number of studies on the strength failure criterion of coal and rock considered the intermediate principal stress effect, and the following typical strength failure criteria have been obtained.

-

2.

Hoek-Brown failure criterion (H-B)

Hoek-Brown strength failure criterion was proposed by Hoek and Brown in 1980 for the first time. Its expression is as follows:

where σ1, σ3, and σc are the maximum principal stress, minimum principal stress and, uniaxial compressive strength of coal and rock, respectively, and m and s are the corresponding parameters of coal and rock, respectively.

If the first stress invariant is used to express the failure criterion, its expression can be:

Among them,

where σ1, σ2, and σ3 are the maximum, intermediate, and minimum principal stresses of coal and rock, respectively; I1 is the first stress invariant; J2 is the second deviatoric stress invariant; θσ is the Lode angle; m and m are the corresponding parameters of coal and rock, respectively.

-

3.

Modified H-B failure criterion

Additionally, Mogi proposed the Mogi strength failure criterion in 1967, and the corresponding expression is as follows:

where f is the function symbol of the π-plane shape (determined by the type of rock) and ω is constant (ω < 1).

After that, many domestic and foreign scholars have replaced and modified the parameters of the Mogi strength failure criterion, and obtained the modified H-B strength failure criterion. The corresponding expression is as follows:

where n, m, s, and a are the corresponding parameters of coal and rock (0 < n < 0.5). Besides, when n = 0 and a = 0.5, the modified H-B strength failure criterion degenerates into the H-B strength failure criterion. When s = 1, the type of rock that applicable to the strength criterion is intact rock.

Additionally, if I1 and θσ are used to express the criterion, its expression can be:

-

4.

Drucker-Prager failure criterion (D-P)

D-P strength failure criterion is mainly derived from the Von Mises strength failure criterion, which is considered the hydrostatic pressure effect and the intermediate principal stress effect. The specific expression is as follows:

Among them,

where α and K are the parameters of rock mass, whose specific values depend on the type of rock mass. When α = 0, the criterion degenerates to the Von Mises strength failure criterion.

Additionally, if I1 and θσ are used to express the criterion, its expression can be:

-

5.

Mogi-Coulomb criterion

Mogi strength failure criterion mainly describes the relationship between octahedral shear stress and effective average stress, and the corresponding expression is as follows:

Among them,

where f is the function symbol of the π-plane shape (determined by the type of rock).

Additionally, many scholars continuously extended the Mogi-Coulomb strength failure criterion, and the corresponding expression is as follows:

or

Additionally, if I1 and θσ are used to express the criterion, its expression can be:

where τoct, σm,2, A, B are the octahedral shear stress, effective average stress, and the corresponding coefficient, respectively. When σ2 = σ3, the strength failure criterion degenerates into the M-C strength failure criterion.

-

6.

Zhang-Zhu criterion (GZZ)

Zhang-Zhu three-dimensional nonlinear strength failure criterion of rock mass was drawn by Prof. Zhu from Tongji University for the first time (Zhang 2008; Zhang and Zhu 2007). Its essence is the three-dimensional H-B strength failure criterion of rock mass, and its corresponding expression is as follows:

Additionally, if I1 and θσ are used to express the criterion, its expression can be:

In conclusion, the establishment of the strength failure criterion for coal or rock is inseparable from the contribution of confining pressure effect. Therefore, it is necessary to strengthen the comprehensive review and in-depth study of the confining pressure effect if the strength failure criterion with stronger applicability and wider application scope is to be established.

Summary of strength properties

The detailed evaluation index system with obvious hierarchical effect should be established in terms of new technology. From the selection, types classification, the determination of weight and ratio, quantitative classification of index factors, and finally form the evaluation index system, to achieve the leap and breakthrough from laboratory theory to engineering field application.

Deformation properties

Generally speaking, the deformation behavior of coal and rock under the external loading is mainly corresponding to the external characteristics of “large deformation, strong time-dependent and difficult maintenance” shown in the roadway surrounding rock of deep mine, to provide a certain theoretical basis for better controlling the stability of the surrounding rock around the roadway of deep mines.

Dilatancy deformation characteristics

Generally, the parameters described the dilatancy deformation behavior of coal and rock are mainly as follows: dilatancy angle ψ and plastic shear strain γp (Salehnia et al. 2017; Walton et al. 2015), and their corresponding expressions can be expressed as:

where \(\dot{\varepsilon_v^p}\) and \(\dot{\varepsilon_1^p}\) are the increments of volume plastic strain and axial plastic strain, respectively; \(\varepsilon {\displaystyle \begin{array}{c}p\\ {}1\end{array}}\) and \(\varepsilon {\displaystyle \begin{array}{c}p\\ {}3\end{array}}\) are the axial plastic strain and radial plastic strain, respectively.

As shown in Fig. 4, the relationship of the dilatancy angle with the plastic shear strain of different types of rocks under the confining pressure effect is that with the increases of the plastic shear strain, the dilatancy angle of rock shows the nonlinear evolution characteristics with firstly sharply increase and then slowly decrease under different the pressure effect, which indicates that there is the significant correlation between the dilatancy angle and the plastic shear strain. Meanwhile, it is not difficult to find that the relationship between the dilatancy angle and the confining pressure of the same rock is that with the increases of the confining pressure, the dilatancy angle of the same rock shows a decreasing trend, and the confining pressure effect is significant. It also indicates that the confining pressure effect can significantly affect the dilatancy deformation behavior of rock. Besides, the peak dilatancy angle evolution characteristics of Carrara Marble are significantly different under the same confining pressure, and the lithologic effect is significant.

Evolution characteristics of dilatancy angle of Carrara Marble under different confining pressures (Modified with Walton et al. 2015).

In conclusion, the confining pressure effect can significantly affect the dilatancy deformation characteristics of coal and rock. Besides, there are many factors (such as depth effect, Klinkenberg effect, etc.) that affect the dilatancy deformation behavior characteristics of coal and rock, which need to be further strengthened and improved in the future.

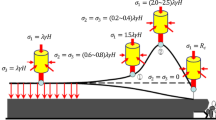

Creep deformation characteristics

Currently, there are many reports on the creep deformation characteristics of coal and rock. However, due to the long-term period of creep mechanical tests, the multi-stages stress level hierarchical loading mode is mostly adopted, and relatively few creep mechanical tests of coal and rock under the confining pressure effect are conducted (Kang 2021). However, the actual loading with the overlying strata imposed on the surrounding rock around the roadway of deep mines is a constant value, and the roadway stability in deep mines is becoming unbalanced under the coupling effect with the time effect, confining pressure effect, and even the disturbance effect, which formed the significant rheological external characteristics with “large deformation and difficult maintenance, strong time-dependent.” The stress variation characteristics of the surrounding rock around the roadway of deep mines include three stages: before excavation, being excavated, and after excavation. Therefore, it is meaningful to strengthen the creep mechanical experimental research on coal and rock with the new stress path of “three stages” loading, which includes initial high in-situ stress state reduction, constant axial pressure with unloading confining pressure, and constant confining pressure with loading axial pressure (time effect) (Zhang and Huo 2021). It can better reveal the time-dependent failure mechanism of the roadway surrounding rock in the deep mine. Furthermore, it can also provide the theoretical basis and reference for the stability control of deep mine roadway, which is more consistent with the field practice of deep engineering.

Generally speaking, the creep deformation characteristics of intact and broken muddy siltstones mainly presented the “three-stage” evolution law: I decelerated creep stage, II stable creep stage, and III accelerated creep stage in Fig. 5. Besides, it could be found that the confining pressure effect has a significant influence on the creep deformation characteristics of both intact rock and fractured rock, and the confining pressure effect is significant. And it could be seen from Fig. 5 that the confining pressure effect is more sensitive to the creep deformation characteristics of the fractured rock compared with that of the intact rock so that the creep deformation characteristics of the fractured rock under different confining pressures differ more significantly.

Creep deformation characteristics under different confining pressures: a intact muddy siltstone and b fractured muddy siltstone (Modified with Hamza and Stace 2018)

Additionally, as shown in Fig. 5, the time taken for the creep deformation at all stages of intact rock and broken rock is the same with the time perspective, and the time effect is not significant. However, most domestic and foreign scholars mainly focus on the time-dependent creep deformation characteristics of the rock. Therefore, the authors suggest that the research scope of the time effect during the deformation and fracture process of rock should be expanded and extended, which should from the current rheological mechanics gradually shift to the rock dynamics mechanics, damage mechanics, and even quantum mechanics. In this way, the fundamental mechanics theory obtained can provide a more accurate theoretical basis and reference for the field practice of deep engineering.

Progressive deformation characteristics

As we all know, the fracture of coal and rock is a process, not an instant formation. In other words, the rock must experience the gradual deformation process under the action of external loading, after which it would finally form the complete fractural characteristics. Therefore, it is helpful to better reveal the progressive failure mechanical behavior mechanism of coal and rock by conducting a comprehensive review and in-depth study of the progressive deformation characteristics of coal and rock under the confining pressure effect.

As shown in Fig. 6, the anisotropic deformation of sandstone presented the significant phased gradual evolution characteristics no matter under the conventional triaxial loading or the true triaxial loading condition, which can better correspond to the zonal fracture characteristics in “Stress-strain curve types and zonal rupture” section. The axial strain corresponding to the crack initiation stress, damage stress, and peak stress basically linearly increases with the increases of the confining pressure under the conventional triaxial loading condition, and the confining pressure effect is significant. However, the maximum principal strains corresponding to the crack initiation stress, damage stress, and peak stress of sandstone shows different evolution law with the increases of the intermediate principal stress under true triaxial loading conditions. Its strength thresholds corresponding to the maximum principal strain basically linear increases with the increase of the intermediate principal stress (III and IV stages are both linear evolution characteristics), and the corresponding radial and volumetric progressive deformation characteristics corresponding to the crack initiation stress, damage stress, and peak stress of sandstone with the confining pressure under the conventional triaxial loading or the true triaxial loading condition can reference Li et al. (2019). It can see that the progressive deformation mechanism of rock under the true triaxial loading condition is relatively complex, which needs to be further studied using high-precision auxiliary monitoring equipment and means (real-time dynamic 3D CT scanner, 3D printing visualization technology, etc.) in the future.

Progressive deformation characteristics of sandstone under the conventional triaxial test: a axial strain and b maximum principal strain (Modified with Li et al. 2019). ε1ci, ε1cd, ε1cf in (a) are axial strains corresponding to crack initiation stress, damage stress, and peak stress, respectively; ε1ci, ε1cd, ε1cf, ε2ci, ε2cd, ε2cf, ε3ci, ε3cd, ε3cf in (b) are maximum principal strains corresponding to crack initiation stress, damage stress, and peak stress, respectively; σ3 is confining pressure, σ2 is intermediate principal stress. III: stable crack development stage, IV: unstable crack development stage

Summary of deformation properties

Time-dependent deformation is one of the mechanical characteristics of coal and rock under confining pressure. The time effect should from the current rheological mechanics gradually shift to other fields of mechanics in terms of new technology. New technology included 3D (dimensions) printing technology, AE (acoustic emission technology), CT (computerized tomography), real-time scanning technology, neutron imaging real-time monitoring technology, and molecular dynamics numerical simulation technology. Then the results could reflect the importance of the time effect for the early-warning and prevention of disasters in deep mines.

Energy evolution properties

According to the stress condition of rock, it is bound to produce deformation or failure characteristics when subjected to the external field. However, the deformation and failure process of rock can be regarded as the process of energy transfer and conversion between the rock mass and the outside system started from the perspective of thermodynamics according to the principle of minimum energy consumption (Zhang et al. 2018b).

Additionally, domestic and foreign scholars have proposed two kinds of energy-driven mechanism theories for the failure of rock. The one is that when the limit of its internal energy storage Ec and the energy-driven value Ee reach the same value during the deformation process of rock (Ec = Ee), the rock will be a failure. The other one is that there is an obvious stage-corresponding relationship between the energy-driven evolution characteristics during the deformation process of rock and the stress-strain curve, and the gradual deformation of rock at each stage is driven by the energy accumulation inside the rock. When the stress reaches the peak stress strength, macroscopic crack generated in rock and formed the macroscopic damage, the accumulation energy can be gradually dissipation and release, and then rock occurs the failure phenomenon.

Therefore, it is helpful to further reveal the energy dissipation mechanism of coal and rock by conducting the comprehensive review and in-depth study of the energy evolution characteristics of coal and rock under the confining pressure effect, which can provide some fundamental theoretical basis and guidance for the early-warning and prevention of disaster (rock burst, etc.) in deep engineering.

Energy evolution law

As shown in Fig. 7, the confining pressure effect significantly affects the evolution characteristics of the total input energy, elastic energy, and dissipated energy of coal. The specific characteristics are as follows: The total input energy, elastic energy, and dissipated energy of coal all increase with the increases of the confining pressure, but their increasing rates are significantly different (linear and nonlinear increased phenomenon existed), which may be related to the properties of coal. Besides, there are significant differences in the total input energy, elastic energy, and dissipated energy required of coal under external loading, which indicates that the lithologic effect also significantly affects the evolution characteristics of various types of energy of coal.

In conclusion, the comprehensive review accurately grasp the energy evolution law under the confining pressure effect of coal and rock; meanwhile, the accurate quantification of the elastic energy, total input energy, and dissipation energy, and the establishment of accurate and efficient grade evaluation index system can provide the accurate and fundamental theoretical basis for the early-warning and prevention of disasters in deep mines. Therefore, it is necessary to strengthen the comprehensive review and exploration of the energy evolution law of coal and rock under the confining pressure effect.

Energy strength failure criterion

Relevant studies show that the strength-bearing capacity of a rock system is closely related to its internal capacity of energy storage, accumulation, and dissipation. Therefore, some scholars put forward the corresponding energy-strength criteria based on the internal relationship between strength and energy.

Xie et al. (2005) studied the internal failure relationship between the energy dissipation and the strength and proposed the overall failure energy-strength criterion of rock based on the elastic energy released. The corresponding failure energy-strength criterion of rock under the compression and tension condition is expressed as follows:

1. Under the compression condition (σ1>σ2>σ3≥0, the compressive stress is positive)

or

2.Under the tension condition (σ3<0)

or

Additionally, to further elaborate the overall failure energy-strength criterion based on the elastic energy released, Guo et al. (2016) introduced the released dispersion coefficient N of the elastic strain energy and proposed the strength criterion based on the elastic strain energy. The specific expression is as follows:

-

1.

Under the compression condition (σ1≥σ2≥σ3≥0, the compressive stress is positive)

or

-

2.

Under the tension condition (σ3≤0)

or

Additionally, Huang et al. (2008) fully considered the hydrostatic pressure effect, intermediate principal stress effect, and Lode angle effect, and proposed the generalized poly-axial strain energy-strength criterion (GPSE) for brittle rock. The specific expression is as follows:

Among them,

where σ1, σ2, and σ3 are the maximum, intermediate, and minimum principal stresses, respectively; σc and σt are the uniaxial compressive strength and uniaxial tensile strength, respectively; and E0, μ, and Ue are the initial elastic modulus, Poisson’s ratio, and elastic energy density, respectively. I1, J2, σoct are the first stress invariant, the second deviatoric stress invariant, and the octahedral normal stress, respectively. γ, γ0, η, β, ξ, f, and φ are the ratio of the triaxial tension strength to the compression strength, the reference ratio of the triaxial tension strength to the compression strength, the ratio of the uniaxial tension strength to the uniaxial compression strength, the material parameter, the exponential function symbol of parameter, and the internal friction angle of rock, respectively.

In conclusion, although the established strength criterion based on the energy can comprehensively consider the influence characteristics of the intermediate principal stress effect, hydrostatic pressure effect, Lode angle effect, brittleness, and other factors, its essence is still inseparable from the outstanding contribution of the confining pressure effect. Therefore, whether from the perspective of energy evolution characteristics or the establishment of strength criteria of rock, whether under the true triaxial loading or conventional triaxial loading condition, the confining pressure effect plays a pivotal role. And the confining pressure effect is one of the major factors that must be considered in future research.

Summary of energy evolution properties

Combined with the strength failure criterion, an appropriate energy failure criterion needs to be established, which can effectively characterize the progressive failure process of coal and rock. Therefore, it is necessary to semi-quantitative and quantitative reveal the energy competition evolution mechanism of coal and rock from different scales (microscopic, mesoscopic, and macroscopic) using high-precision equipment, multiple methods, and innovative technology, to achieve from laboratory theory gradually transition to the field engineering application.

Damage evolution properties

Coal or rock is a kind of medium with internal defects. It is bound to be accompanied by the change of internal microstructure during the action process of the external loading, and then its mechanical properties would be also changed. Naturally, it is also accompanied by the change of internal damage. The confining pressure effect is one of the external loading factors, which can also lead to the obvious damage of coal and rock. Therefore, it has the important theoretical significance and practical value of deep engineering to comprehensively review the damage evolution characteristics of coal and rock under the confining pressure effect.

Definition of damage

The definition of damage variable is the core issue to study the damage evolution law of rock and coal under the loading action. In the field of damage mechanics, there are many definitions of damage caused by coal and rock under external loading. Specific and typical damage definitions are as follows:

-

1.

Damage variable D is defined by the elastic modulus (Lemaitre 1996)

-

2.

Damage variable D is defined by the deformation modulus (Wang et al. 2021b)

-

3.

Damage variable D is defined by the damage area (Chen et al. 2019c)

Among them,

-

4.

Damage variable D is defined by the acoustic wave velocity (Xu et al. 2010)

Among them,

-

5.

Damage variable D is defined by the parameters of acoustic emission (Chi et al. 2020)

-

6.

Damage variable D is defined by the parameters of energy (Xu et al. 2019)

In the above equations, E0 and E1 are the elastic modulus of none damaged and damaged rock or coal, respectively. ε, εd, and ε0 are the strain generated in the process of none failure, failure with final loading, and the initial loading, respectively; ζ and F0 are the parameters of Weibull distribution function, F* is the strength of rock element, ϕ(F) is the probability of Weibull distribution, S* and Sm are the damaged area and total area of coal or rock material, respectively; The meanings of α, K, I1, and J2 are explained in “Strength failure criterion” section; v and v0 are the initial velocity and the velocity of acoustic wave after impact loading of coal or rock, respectively; ρ, E, and μ are the density, elastic modulus, and Poisson’s ratio of coal or rock, respectively. Nt and Na are the cumulative energy values of acoustic emission of coal or rock under the initial loading and complete failure. Udj is the dissipated energy generated by coal or rock during the jth cyclic loading and unloading process; Udt is the total dissipated energy with failure of coal or rock under cyclic loading and unloading of equal loading; and Nj is the cumulative cycles number at all levels of loading (j = 1,2,3...).

In conclusion, the internal damage evolution process of coal and rock is complex under the external loading, and the definition of damage variables is varied. Therefore, it is necessary to elaborate on the damage evolution law of coal and rock under the confining pressure effect.

Damage evolution law

General speaking, the damage evolution characteristics during the whole deformation process of rock and the deformation characteristics of the stress-strain curve at each stage show the significant phased corresponding relationship, which indicates that the deformation process of rock from the deformation to the failure is a gradual changeable process, rather than an instantaneous completion.

As shown in Fig. 8, the damage evolution law of Beishan granite showed the significant “three stages” evolution law under the different confining pressures, namely the initial damage development stage, the damage increased sharply stage, and the damage deceleration increased stage; the damage evolution law of each stage were significantly corresponding to the stress-strain curve of elastic deformation stage, the plastic deformation stage, and the post-peak deformation stage. However, the brittle failure characteristics of Beishan granite under low confining pressure are significant, and the corresponding damage rapid development, which belongs to the type of high-speed damage development. But the ductile failure characteristics of Beishan granite are more significant under medium confining pressure, and the speed during the whole development process of damage is slowed down, which belongs to the type of medium-high speed damage development. And the ductile failure characteristics of Beishan granite are obvious under high confining pressure, and the corresponding damage development process is slow, which belongs to the type of low-speed damage development. The damage development speed of rock indirectly corresponds to the evolution degree of meso-mechanical behavior such as the development, expansion, and nucleation of internal cracks or defects, which can better reveal the failure mechanical behavior mechanism of rock under the external loading condition.

Damage evolution characteristic of Beishan granite under different confining pressures (Modified with Miao et al. 2021).

Additionally, it can be found that the confining pressure effect not only significantly affects the brittle-ductile transformation characteristics of coal and rock, but also significantly affects the damage evolution law during the whole deformation process. Therefore, it is necessary to comprehensively review the damage characteristics of coal and rock under the confining pressure effect.

Summary of damage evolution properties

Although there are many definitions of the damage caused by the deformation of coal and rock, which indicates that the deformation process of rock from the deformation to the failure is a gradual changeable process, rather than an instantaneous completion. Besides, the damage evolution law of coal and rock corresponds to the progressive failure characteristics under the confining pressure effect. Therefore, the quantitative and qualitative characterization of damage properties of rock and coal is a hot spot, and the damage properties are closely related to the confining pressure effect.

Fracture properties

Based on the comprehensive description of the evolution characteristics of the basic mechanical parameters and the evolution laws of strength, deformation, energy, and damage, the fracture characteristics of coal and rock under the confining pressure effect are comprehensively characterized from the macroscopic, mesoscopic, and microscopic perspectives.

Macroscopic failure characteristics

As shown in Fig. 9, the macroscopic failure modes of hard rock can be divided into three categories under the true triaxial loading condition: tensile failure, tension-shear mixed failure, and shear failure. Among them, with the increases of the minimum principal stress, the failure mode of sandstone gradually shifts from the tensile failure to the shear failure, and the confining pressure effect is significant. Besides, the corresponding upper boundary is as follows: the failure mode of hard rock under the conventional triaxial loading (σ2 = σ3) gradually shifts from the tensile failure to the tension-shear failure with the increases of confining pressure, and finally, the macro failure mode under the high confining pressure is a shear failure. However, the corresponding lower boundary under the generalized triaxial tensile stress loading (σ1 = σ2) is as follows: with the synchronous increases of the maximum and intermediate principal stress, the failure mode transformation characteristics of hard rock: tensile failure → tension-shear mixed failure → shear failure.

Failure characteristics of sandstone under different stress conditions (Feng et al. 2019)

In conclusion, the intermediate principal stress effect and the biaxial loading effect both belong to the category of confining pressure effect, and both can significantly affect the macroscopic failure mode of rock.

Mesoscopic failure characteristics

Additionally, it is not enough to reveal the failure mechanism to preliminarily clarify the macroscopic failure characteristics of rock under the confining pressure effect. Therefore, it is necessary to strengthen the further exploration of the meso-fracture mechanism of rock, which can make the conclusions better serve deep engineering.

Relevant studies showed that the rock shows three significant mesoscopic failure types (Zheng et al. 2020): tensile failure of trans granular fracture with brittle failure at low σ3, shear slip failure along intergranular fracture with ductile failure at high σ3 and low σ2, and tensile-shear mixture mode of trans granular fracture with brittle failure at high σ3 and σ2 under the different intermediate principal stress and minimum principal stress; the confining pressure effect is significant, which also more intuitively reveals the mesoscopic failure mechanism of rock under the confining pressure effect.

Microscopic failure characteristics

Most domestic and foreign scholars are limited to the scope of macroscopic and mesoscopic failure scale of coal and rock, including the research of “the influence of confining pressure effect on the failure characteristics of coal and rock.”

To better reveal the failure mechanism of coal and rock from the microscopic perspective, the research group of Prof. Zhao from China University of Mining and Technology (Beijing) established the micro-structure of kaolinite and montmorillonite by using the first-principles calculation method, and better revealed their anisotropy characteristics.

Additionally, as shown in Fig. 10, the research group used the molecular dynamics method to propose a quantum mechanics theoretical concept (including chemical bonds, crystal cells, etc.) based on the microscopic perspective to study the failure mechanism of coal and rock. It is concluded that the failure of coal and rock under different loading modes is mainly caused by the chemical bond fracture, dislocation, and recombination of the internal microscopic structure of coal and rock (Han et al. 2019; Yang et al. 2019a; Yang et al. 2019b).

Summary of fracture properties

The fracture mode and the classification of crack of coal and rock are still in the qualitative research stage. Therefore, the semi-quantitative or quantitative identification, characterization and judgment for the fracture characteristics of coal and rock under the confining pressure effect is a hot spot. Based on new technologies, methods, and theories, the semi-quantitative or quantitative fracture law of coal and rock under the confining pressure effect needs to be breakthrough.

New perspective on the confining pressure effect

After years of research and development, abundant research achievements have been made in the research on the confining pressure effect of coal and rock. Based on the existing test system functions and research conditions, several new perspectives are proposed for future research on the confining pressure effect of coal and rock:

-

1.

It is necessary to quantitatively and qualitatively characterize the brittleness and ductility of rock and coal under the confining pressure effect for setting up the detailed and obvious hierarchical evaluation index system with the combination of multiple approaches including the fusion of more advanced scientific methods such as the Big Data, artificial intelligence, and the multi-disciplinary crossing such as the calculated rock mechanics, statistical rock mechanics, which is one of the key scientific issues that need to breakthrough in the future.

-

2.

It is urgent to strengthen the research on the time-dependent deformation of coal and rock and the construction of time-dependent strength model. Then the positioning of time effect is gradually transferred from the rheological mechanics to other mechanical fields, and the blank of time effect research in other mechanical fields will be filled in the future.

-

3.

Based on the perspective of quantum mechanics, it is urgent to strengthen the research on the mechanical properties and failure mechanism of coal and rock from the microscopic perspective (located at atomic, crystal bond, chemical bond or cell scale).

-

4.

It is meaningful to strengthen the creep mechanical experimental research on coal and rock with the new stress path of “three stages” loading, which includes initial high in-situ stress state reduction, constant axial pressure with unloading confining pressure, and constant confining pressure with loading axial pressure corresponding to three stages of the stress variation characteristics of the surrounding rock around the roadway of deep mines: before excavation, being excavated, and after excavation. Furthermore, it can provide the theoretical basis and reference for the roadway stability control of deep mines.

Conclusion and summary

In the future, in terms of the combination of multiple approaches including the fusion of more advanced scientific methods such as the Big Data, artificial intelligence, etc. and the multi-disciplinary crossing such as the transparent catastrophical rock mechanics, statistical rock mechanics, calculated rock mechanics, intelligent rock mechanics, multi-scale rock mechanics, etc., the comprehensive research of the confining pressure effect of coal and rock will gradually breakthrough and improve part of the branch of deep rock mechanics theory, the conclusions, and results can also better serve the practice of deep engineering. And the main conclusions are summarized as follows:

-

1.

According to the corresponding characteristics of stress-strain curve and zonal rupture of the surrounding rock around the roadway of deep mines, a new laboratory test method of “three-stage” loading stress path loading and unloading is proposed. Based on this method, the conclusions obtained in the laboratory can be better applied to the stability maintenance of the surrounding rock around the roadway of deep mines.

-

2.

The confining pressure effect has a significant influence on deformation, strength, energy, damage, and evolution characteristics of basic parameters of coal and rock, but its influence has upper limit. However, whether the water-rock effect, temperature effect, and size effect have the upper limit influence on the evolution characteristics of basic mechanical parameters, strength, deformation, energy, and damage of coal and rock remains to be studied and verified.

-

3.

The quantitative and qualitative characterization of brittleness and ductility properties, energy properties, damage properties, and even fracture properties of rock and coal need to be further breakthrough in future research. Besides, the evolution characteristics of brittle-ductility transition properties, energy properties, damage properties, and even fracture properties are closely related to the confining pressure effect. Meanwhile, the detailed evaluation index system with obvious hierarchical effect should be established in terms of new technology. The new technology included the Big Data, 5G technology, and intelligent transparent monitoring technology. Besides, from the selection, types classification, the determination of weight and ratio, quantitative classification of index factors, and finally form the evaluation index system, to achieve the leap and breakthrough from laboratory theory to engineering field application.

-

4.

The time effect should from the current rheological mechanics gradually shift to the rock dynamics mechanics, damage mechanics, and even quantum mechanics. New technology included 3D printing, AE, CT, neutron imaging technology, molecular dynamics simulation technology. Then the results can reflect the importance of the time effect for the early-warning and prevention of disasters in a deep mine.

-

5.

Currently, the fracture mode, the classification of crack, and crack of the derivative expansion law of coal and rock is still in the qualitative research stage. Therefore, based on new technologies, methods, and theories, the semi-quantitative or quantitative identification, characterization, and judgment for the fracture characteristics and crack propagation evolution law of coal and rock under the confining pressure effect needed to be constantly breakthrough.

References

Altindag R (2010) Assessment of some brittleness indexes in rock-drilling efficiency. Rock Mech Rock Eng 43(3):361–370. https://doi.org/10.1007/s00603-009-0057-x

Chen Z, He C, Ma G, Xu G, Ma C (2019a) Energy damage evolution mechanism of rock and its application to brittleness evaluation. Rock Mech Rock Eng 52(4):1265–1274. https://doi.org/10.1007/s00603-018-1681-0

Chen GQ, Jiang WZ, Sun X, Zhao C, Qin CA (2019b) Quantitative evaluation of rock brittleness based on crack initiation stress and complete stress-strain curves. B Eng Geol Environ 78:5919–5936. https://doi.org/10.1007/s10064-019-01486-2

Chen Y, Zhang L, Xie H, Liu JF, Liu H, Yang BQ (2019c) Damage ratio based on statistical damage constitutive model for rock. Math Probl Eng 2019(6):1–12. https://doi.org/10.1155/2019/3065414

Chen JH, Liu P, Zhao HB, Zhang C, Zhang JW (2021a) Analytical studying the axial performance of fully encapsulated rock bolts. Eng Fail Anal 128:105580. https://doi.org/10.1016/j.engfailanal.2021.105580

Chen JH, Zhao HB, He FL, Zhang JW, Tao KM (2021b) Studying the performance of fully encapsulated rock bolts with modified structural elements. Int J Coal Sci Tech 8(1):64–76. https://doi.org/10.1007/s40789-020-00388-z

Chen JH, ZhaoYQ ZHB, Zhang JW, Zhang C, Li DQ (2021c) Analytic study on the force transfer of full encapsulating rockbolts subjected to tensile force. Int J Appl Mech 13(9)

Chi XL, Yang K, Wei Z (2020) Investigation of energy and damage evolutions in rock specimens with large-scale inclined prefabricated cracks by uniaxial compression test and ae monitoring. Adv Civ Eng 2020(11):1–12. https://doi.org/10.1155/2020/8887543

Feng XT, Kong R, Zhang XW, Yang CX (2019) Experimental study of failure differences in hard rock under true triaxial compression. Rock Mech Rock Eng 52:2109–2122. https://doi.org/10.1007/s00603-018-1700-1

Fu JX, Song WD, Hashiba K (2016) Recent studies on time-dependent behavior of rock strength and the effects of confining pressure. Chin J Rock Mech Eng 35(S2):3653–3661. https://doi.org/10.13722/j.cnki.jrme.2015.1534

Galindo RA, Serrano A, Olalla C (2017) Ultimate bearing capacity of rock masses based on modified Mohr-Coulomb strength criterion. Int J Rock Mech Min Sci 93:215–225. https://doi.org/10.1016/j.ijrmms.2016.12.017

Ge XR, Zhou BH, Liu MG (1992) A new understanding of post-failure behavior of rock. Chin Min Mag, 60-63. (in Chinese). CNKI:SUN:ZGKA.0.1992-02-016.

Guo JQ, Liu XR, Wang JB, Huang ZH (2016) Strength criterion of rock based on elastic strain energy. Rock Soil Mech 37(S2):129–136. https://doi.org/10.16285/j.rsm.2016.S2.015

Hamza O, Stace R (2018) Creep properties of intact and fractured muddy siltstone. Int J Rock Mech Min Sci 106:109–116. https://doi.org/10.1016/j.ijrmms.2018.03.006

Han ZF, Yang H, He MC (2019) A molecular dynamics study on the structural and mechanical properties of hydrated kaolinite system under tension. Mater Res Express 6(8):0850c3. https://doi.org/10.1088/2053-1591/ab2562

Hao XJ, Wang SH, Xu QS, Yang DQ, Zhang Q, Jin DX, Wei YN (2020) Influences of confining pressure and bedding angles on the deformation, fracture and mechanical characteristics of slate. Constr Build Mater 243:118255. https://doi.org/10.1016/j.conbuildmat.2020.118255

Hashiba K, Okubo S, Fukui K (2006) A new testing method for investigating the loading rate dependency of peak and residual rock strength. Int J Rock Mech Min Sci 43(6):894–904. https://doi.org/10.1016/j.ijrmms.2005.12.005

Hou ZK, Yang CH, Wei X, Wang L, Wei YL, Xu F, Wang H (2016) Experimental study on the brittle characteristics of Longmaxi formation shale. J China Coal Soc 41(5):1188–1196. https://doi.org/10.13225/j.cnki.jccs.2015.0957

Huang BX, Liu JW (2013) The effect of loading rate on the behavior of samples composed of coal and rock. Int J Rock Mech Min Sci 61:23–30. https://doi.org/10.1016/j.ijrmms.2013.02.002

Huang SL, Feng XT, Zhang CQ (2008) A new generalized poly-axial strain energy strength criterion of brittle rock and poly-axial test validation. Chin J Rock Mech Eng 27(1):124–134

Jiang GH, Zuo JP, Li YL, Wei X (2019) Experimental investigation on mechanical and acoustic parameters of different depth shale under the effect of confining pressure. Rock Mech Rock Eng 52(4):4273–4286. https://doi.org/10.1007/s00603-019-01870-0

Kang HP (2021) Temporal scale analysis on coal mining and strata control technologies. J Min Strata Control Eng 3(1):013538.1-013538.23

Lemaitre J (1996) Damage mechanics tutorial. Translated by Ni JG, Tao CH. Beijing: Science Press, 55-127. (in Chinese).

Li ZL, Wang LG, Lu YL, Li WS, Wang K, Fan H (2019) Experimental investigation on true triaxial deformation and progressive damage behaviour of sandstone. Sci Rep 9(1):3386. https://doi.org/10.1038/s41598-019-39816-9

Liang WG, Xu SG, Mo J, Wu D, Zhang CD (2010) Test study of strain rate effects on mechanical performances of salt rock. Chin J Rock Mech Eng 29(01):43–50. https://doi.org/10.1590/S1516-05722012000500005

Liu QS, Wei L, Lei GF, Liu Q, Liu H (2018) Experimental study on damage strength of crack initiation and evaluation of brittle parameters of sandstone. Chin J Geotech Eng 40(10):1782–1789. (in Chinese). https://doi.org/10.11779/CJGE201810004

Miao SJ, Liu ZJ, Zhao XG, Huang ZJ (2021) Characteristics of energy dissipation and damage of Beishan granite under cyclic loading and unloading. Chin J Rock Mech Eng 1-11. (in Chinese). 10.13722/j.cnki.jrme.2020.0953.

Rybacki E, Reinicke A, Meier T, Makasi M, Dresen G (2015) What controls the mechanical properties of shale rocks? -Part I: Strength and Young’s modulus. J Petrol Sci Eng 135:702–722. https://doi.org/10.1016/j.petrol.2015.10.028

Rybacki E, Meier T, Dresen G (2016) What controls the mechanical properties of shale rocks? -Part II: Brittleness. J Petrol Sci Eng 144:39–58. https://doi.org/10.1016/j.petrol.2016.02.022

Salamon MD (1970) Stability, instability and design of pillar workings. Int J Rock Mech Min Sci Geomech Abstr 7(6):613–631. https://doi.org/10.1016/0148-9062(70)90022-7

Salehnia F, Collin F, Charlier R (2017) On the variable dilatancy angle in rocks around underground galleries. Rock Mech Rock Eng 50:587–601. https://doi.org/10.1007/s00603-016-1126-6

Shapiro SA, Dinske C (2021) Stress drop, seismogenic index and fault cohesion of fluid-induced earthquakes. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-021-02420-3

Shi GC, Chen G, Pan YT, Yang XL, Liu Y, Dai GZ (2019) Stress-drop effect on brittleness evaluation of rock materials. J Cent South Univ 26(7):1807–1819. https://doi.org/10.1007/s11771-019-4135-2

Song Z, Zhang J (2021) Research on the progressive failure process and fracture mechanism of rocks with the structural evolution perspective. J Struct Geol. https://doi.org/10.1016/j.jsg.2021.104484

Tang JZ, Yang SQ, Tian WL, Tao Y (2019) Effect of confining pressure on mechanics and deformation behavior of sandstone containing a single inclined joint. Eur J Environ Civ En 11:1–24. https://doi.org/10.1080/19648189.2019.1694076

Tarasov B, Potvin Y (2013) Universal criteria for rock brittleness estimation under triaxial compression. Int J Rock Mech Min Sci 59:57–69. https://doi.org/10.1016/j.ijrmms.2012.12.011

Vazaios I, Vlachopoulos N, Diederichs MS (2019) Assessing fracturing mechanisms and evolution of excavation damaged zone of tunnels in interlocked rock masses at high stresses using a finite-discrete element approach. J Rock Mech Geotech Eng 11(4):701–722. https://doi.org/10.1016/j.jrmge.2019.02.004

Walton G, Arzúa J, Alejano LR, Diederichs MS (2015) A laboratory-testing-based study on the strength, deformability, and dilatancy of carbonate rocks at low confinement. Rock Mech Rock Eng 48(3):941–958. https://doi.org/10.1007/s00603-014-0631-8

Wang PD, Wu DM, Chen YT (1988) Study on relationship among moment, magnitude, source size and stress drop. Crustal Deformation and Earthquake 8(2):109–123 (in Chinese)

Wang Y, Li CH, Hu YZ, Zhou XL (2017) A new method to evaluate the brittleness for brittle rock using crack initiation stress level from uniaxial stress-strain curves. Environ Earth Sci 76(23):799.1–799.18. https://doi.org/10.1007/s12665-017-7117-4

Wang HT, He MM, Pang F, Chen YS, Zhang ZQ (2021a) Energy dissipation-based method for brittleness evolution and yield strength determination of rock. J Petrol Sci Eng. https://doi.org/10.1016/j.petrol.2021.108376

Wang Y, Feng WK, Hu RL, Li CH (2021b) Fracture evolution and energy characteristics during marble failure under triaxial fatigue cyclic and confining pressure unloading (FC-CPU) conditions. Rock Mech Rock Eng 54:799–818. https://doi.org/10.1007/s00603-020-02299-6

Wawersik WR, Fairhurst C (1970) A study of brittle rock fracture in laboratory compression experiments. Int J Rock Mech Min Sci Geomech Abstr 7(5):561–575. https://doi.org/10.1016/0148-9062(70)90007-0

Xi Y, Li J, Zeng YJ, Jiang TX (2018) Research on lateral scale effect and constitutive model of rock damage energy evolution. Geotech. Geol Eng 36:2415–2424. https://doi.org/10.1007/s10706-018-0473-3

Xia YJ, Zhou H, Zhang CQ, He SH, Gao Y, Wang P (2019) The evaluation of rock brittleness and its application: a review study. Eur J Environ Civ En 1-41. https://doi.org/10.1080/19648189.2019.1655485

Xiao TL, Huang M, Li XP (2018) Research on strength and deformation with marble of deep rock mass considering confining pressure effect. Chin J Under Spa Eng 14(02):362–368 (in Chinese)

Xie HP, Ju Y, Li LY (2005) Criteria for strength and structural failure of rocks based on energy dissipation and energy release principles. Chin J Rock Mech Eng 24(17):3003–3010. (in Chinese). https://doi.org/10.1007/s11769-005-0030-x

Xie HP, Gao MZ, Fu CH, Lu YQ, Yang MQ, Hu JJ, Yang BG (2021a) Mechanical behavior of brittle-ductile transition in rocks at different depths. J China Coal Soc 46(3):701–715. (in Chinese). https://doi.org/10.13225/j.cnki.jccs.yt21.0157

Xie HP, Li CB, Gao MZ, Zhang R, Gao F, Zhu JB (2021b) Conceptualization and preliminary research on deep in situ rock mechanics. Chin J Rock Mech Eng 40(02):217–232. (in Chinese). https://doi.org/10.13722/j.cnki.jrme.2020.0317

Xu P, Yang SQ (2016) Permeability evolution of sandstone under short-term and long-term triaxial compression. Int J Rock Mech Min Sci 85:152–164. https://doi.org/10.1016/j.ijrmms.2016.03.016

Xu SQ, Yu MH (2006) The Effect of the intermediate principal stress on the ground response of circular openings in rock mass. Rock Mech Rock Eng 39(2):169–181. https://doi.org/10.1007/s00603-005-0064-5

Xu JY, Lu XC, Zhang J, Wang ZD, Bai EL (2010) Research on energy properties of rock cyclical impact damage under confining pressure. Chin J Rock Mech Eng 29:4159–4165 (in Chinese)

Xu Y, Li CJ, Zheng QQ, Ni X, Wang QQ (2019) Analysis of energy evolution and damage characteristics of mudstone under cyclic loading and unloading. Chin J Rock Mech Eng 38(10):2084–2091. (in Chinese). https://doi.org/10.13722/j.cnki.jrme.2019.0153

Xue L, Qin SQ, Sun Q, Wang YY, Lee L, Li WC (2014) A study on crack damage stress thresholds of different rock types based on uniaxial compression tests. Rock Mech Rock Eng 47(4):1183–1195. https://doi.org/10.1007/s00603-013-0479-3

Yagiz S (2009) Assessment of brittleness using rock strength and density with punch penetration test. Tunn Under Sp Tech 24(1):66–74. https://doi.org/10.1016/j.tust.2008.04.002

Yang SQ, Jing HW, Li YS, Han LJ (2011) Experimental investigation on mechanical behavior of Coarse marble under six different loading paths. Exp Mech 51(3):315–334. https://doi.org/10.1016/10.1007/s11340-010-9362-2

Yang H, He MC, Lu CS, Gong WL (2019a) Deformation and failure processes of kaolinite under tension: insights from molecular dynamics simulations. Sci China Phys Mech 62(6):062412 (in Chinese)

Yang H, Han ZF, Hu J, He MC (2019b) Defect and temperature effects on mechanical properties of kaolinite: a molecular dynamics study. Clay Miner 54(2):153–159. https://doi.org/10.1180/clm.2019.22

Yang SQ, Tian WL, Derek E, Wang JG, Fan LF (2020) An experimental study of effect of high temperature on the permeability evolution and failure response of granite under triaxial compression. Rock Mech. Rock Eng 53(7):4403–4427. https://doi.org/10.1007/s00603-019-01982-7

Yao MD, Rong G, Zhou CB, Peng J (2016) Effects of thermal damage and confining pressure on the mechanical properties of coarse marble. Rock Mech Rock Eng 49(6):2043–2054. https://doi.org/10.1007/s00603-016-0916-1

Yao QL, Wang WN, Zhu L, Xia Z, Wang XH (2020) Effects of moisture conditions on mechanical properties and AE and IR characteristics in coal-rock combinations. Arab J Geosci 13(14). https://doi.org/10.1007/s12517-020-05610-5

Zang SX (1984) Earthquake stress drop and the stress drop of rock fracture. Acta Seismologica Sinica:182–194 (in Chinese)

Zhang LY (2008) A generalized three-dimensional Hoek-Brown strength criterion. Rock Mech Rock Eng 41(6):893–915. https://doi.org/10.1007/s00603-008-0169-8

Zhang JW, Huo YH (2021) Study on creep behavior of deep sandstones under stepwise incremental loading and unloading condition. J. China Coal Soc (in Chinese). 10.13225/j.cnki.jccs.YT21.0039.

Zhang JW, Song ZX (2020) Mechanical response and failure characteristics of deep sandstone under triaxial loading and unloading. J Min Saf Eng 37(02):409–418+428 (in Chinese). 1673-3363-(2020)02-0409-101

Zhang LY, Zhu HH (2007) Three-dimensional Hoek-Brown strength criterion for rocks. J Geotech Geoenviron Eng 133(9):1128–1135. https://doi.org/10.1061/(ASCE)1090-0241(2007)133:9(1128)

Zhang H, Kang YL, Chen J, Wang YZ (2007) Experimental study on mechanical properties of dense sandstone under different confining pressures. Chin J Rock Mech Eng 37(8):1462–1468. (in Chinese). https://doi.org/10.11779/CJGE201508015

Zhang Q, Zhu HH, Zhang LY (2013) Modification of a generalized three-dimensional Hoek-Brown strength criterion. Int J Rock Mech Min Sci 59:80–96. https://doi.org/10.1016/j.ijrmms.2012.12.009

Zhang ZP, Xie HP, Zhang R, Zhang ZT, Gao MZ, Jia ZQ, Xie J (2018a) Deformation damage and energy evolution characteristics of coal at different depths. Rock Mech Rock Eng 52:1–13. https://doi.org/10.1007/s00603-018-1555-5

Zhang J, Chi A, Li YW, Guo R, Zeng J (2018b) Energy-based brittleness index and acoustic emission characteristics of anisotropic coal under triaxial stress condition. Rock Mech Rock Eng 51:3343–3360. https://doi.org/10.1007/s00603-018-1535-9

Zhang JH, Wang LG, Dong Y, Chen YD, Jiang Y, Sun HS, Chen JR, Fan YQ (2019) Research on the development mechanism of post-peak cracks in sandstone under different confining pressures. Math Probl Eng 2019(2):1–10. https://doi.org/10.1155/2019/6208207

Zhang JW, Song ZX, Wang SY (2020) Experimental investigation on permeability and energy evolution characteristics of deep sandstone along a three-stage loading path. B Eng Geol Environ 80(1):1–14. https://doi.org/10.1007/s10064-020-01978-6

Zhang C, Wang FT, Bai QS (2021a) Underground space utilization of coalmines in China: a review of underground water reservoir construction. Tunn Undergr Sp Tech 107:103657. https://doi.org/10.1016/j.tust.2020.103657

Zhang JW, Song ZX, Wang SY (2021b) Mechanical behavior of deep sandstone under high stress—seepage coupling. J Cent South Univ 28:1–17. https://doi.org/10.1007/s11771-021-4791-x