Abstract

Along with the increase of mining depth, the dynamic disasters related to the instability and destruction of coal-rock are becoming more and more serious. In this paper, the uniaxial compression model of coal-rock was established by means of the micro particle flow PFC2D software firstly, and then the variation of stress field and damage field of coal-rock were analysed. Finally, the time–space constitutive model of coal-rock was discussed and modified. The research results show that: the compression stress field of coal-rock has obvious time–space effect, and along with the change of compressive stress, the stress field was transferred to the inner coal-rock body; the coal-rock damage evolution process has a similar temporal and spatial relations with the stress field evolution, the number of damage cracks were increasing with the constant change of compressive stress, and transferred to the inner coal-rock body with “string wave” feature; the time–space damage constitutive model of coal-rock established on the basis of local crack and the stress concentration factor of coal-rock was reasonable and effective, the damage degree of the whole coal-rock could be predicted by the variation of local coal-rock stress and cracks. In overall, the successful verification of the time–space relationship of coal-rock damage and stress transfer indicated that the possibility of using the constitutive model developed in this study to investigate coal-rock stability in coal mine.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

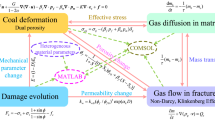

Coal–gas outburst, rock burst and other coal-rock dynamic disasters are closely related to the instability and failure of coal-rock mass (Zhang et al. 1991; Wen et al. 2015; Khaled et al. 2016). Under the influence of mining, the stress on coal-rock will increase, followed by stress concentration, and finally leads to the stress field of external coal-rock transferred to the internal area (Li 1987). With this time–space process, the primary fracture of coal-rock mass is continuous evolution, the new crack initiation and development, and eventually leading to the macro failure of the coal-rock mass and induce dynamic disasters. Therefore, it has important practical significance for coal resources achieving scientific and safe mining to studies the temporal-spatial effects of the compressive stress field and the damage mechanism of coal-rock.

In terms of the evolution of stress field and the unstable failure of coal-rock damage, Matsuki et al. (2009) defined regional stress for a heterogeneous rock mass composed of different rock bodies and studied the stress distribution in the damage process of anisotropic rock mass. Carranza-Torres and Fairhurst (1999) introduced the elastic–plastic mechanical response of rock mass in underground excavation based on the Brown Hawke failure criterion and the extent of plastic behavior and the related stress and displacement fields were given by closed-form expressions. Ju et al. (2007) analyzed the variation of stress field and deformation law of overburden strata in deep coal mine. The study found that with the increase of mining progress, the blocks at different positions of the overlying strata in the mining area continued to rupture and the key layer was moved along the vertical direction with the change of the semi elliptical stress field. Peng et al. (2010) analyzed the influence of mining fracture on the stress distribution of the mining and concluded that the distribution characteristics, position, direction of the fracture affected the distribution of mining stress and gas pressure in coal seam. Liu et al. (2008) studied the generation, propagation and coalescence mechanism of cracks in intermittent jointed rock mass and found that the fracture zone of roadway surrounding rock was not even developed, it was first produced in the vicinity of the roof joint, and then developed to the adjacent parts of the roadway surrounding. Zhang et al. (2010) analysed the relationship between the distribution of micro cracks and the macroscopic failure of rock mass. Yin (2008) by means of the particle flow software PFC, studied the fracture morphology, the number of cracks, the space position and the stress–strain curve of the rock mass unstable failure.

These studies obtained many meaningful results, however, there was little literature about the relationship between the stress field evolution and the damage and fracture law of the coal-ock. Therefore, in this paper, the uniaxial compression model of coal-rock established with the micro particle flow PFC2D software, and analyzed the temporal-spatial effects of stress field and the evolution characteristics of the damage field in coal-rock by monitoring the parameters of stress and cracks.

2 Uniaxial Compression Model of Coal-Rock

2.1 Particle Flow Profile

Using the discrete element method, Cundall et al. (1979) established particle flow theory to offer a microscopic analysis of the damage evolution mechanism and failure process of rock materials. Particle flow code (PFC) presents two bond models, namely, contact bond and parallel bond, to simulate the damage of the particle bond (Itasca Consulting Group 2008). Contact bond refers to the bond between the particle points, and the force can only be generated when the particle demonstrates relative displacement. Given that the moment of force cannot be transmitted, the contact bond applies to granular materials (e.g., soil mass). Parallel bond refers to the plane-to-plane bond between particles. Given that the moment of force can be transmitted, the parallel bond applies to compact materials, such as rocks. The uniaxial compression model of rock specimens was built using the parallel bond.

2.2 Physical–Mechanical Parameters of Coal-Rock

Particle flow theory represents the macroscopic physico-mechanical properties of rocks as their microscopic physico-mechanical properties. However, the microscopic parameters of coal-rocks do not directly correspond to their macroscopic parameters. The microscopic parameters were checked and corrected prior the numerical simulation of the uniaxial compression model. During this process, a large number of numerical simulation tests were performed as either laboratory or in situ field tests under similar conditions. The numerical simulation results were compared with the laboratory or in situ field test results, and the microscopic parameters were repeatedly adjusted via trial and error (Itasca Consulting Group Inc. 2004).

In the process of particle flow, the microscopic physico-mechanical parameters of the uniaxial compression model of coal-rock were compared with a certain coal mine coal-rock specimen uniaxial compression test. The microscopic parameters of PFC model (Table 1) are close to the macro mechanical parameters of the real coal-rock mass. Under the size of 50 mm × 100 mm simulation test conditions (corresponding to the experimental size), the stress–strain curves (Fig. 1) and the final failure characteristics (Fig. 2) are in good agreement with the experimental results.

2.3 Uniaxial Compression Model of Particle Flow

The non-standard sized (90 m × 40 mm) uniaxial compression model of particle flow (Fig. 3) was established on the basis of the above parameters. In order to analyze stress field time–space effects and damage field evolution law in coal-rock, three measuring circle (radii = 15 mm) were arranged in the model interior (the total measure area accounted for 58.9 % of the total area of the model), and the measuring centers were (−30 mm, 0), (0, 0) and (30 mm, 0). In the process of loading, the stress and damage in the measurement loop were recorded by the fish language function. Owing to actual mines mining coal body does not produce to internal displacement, so in the process of loading retained the left side of the wall body fixing.

3 Test Result Analysis

3.1 Time–Space Effects of Compressive Stress Field in Coal-Rock

Figure 4 shows the stress-time curves of compressed coal-rock. The green curve represents the average stress change characteristics of the whole coal-rock, and the red, blue and black curves represent the average stress changes characteristics in the measuring area of 1, 2 and 3, respectively. Figure 5 shows the stress concentration factor and time curves of compressed coal-rock.

The stress concentration factor K was defined as follow:

where σ i —the average stress in the i measuring area and i = 1, 2, 3 respectively. σ—the average stress of the whole model.

According to Fig. 4, with the change of compressive stress of coal-rock, the stress evolution characteristics between local measuring area of the coal-rock and the whole model are similar. They all gone through three stages of compaction, elastic compression and plastic deformation. As can be seen from Fig. 5 that in the process of coal-rock compression, the stress concentration has obvious time–space effect. During the process (before point 1) of stress gradually increase of the whole coal-rock, the stress in measuring circles is also gradually increasing, and the stress concentration factor of each monitoring area is approximately 1. At point 1, the stress of the external coal-rock (the monitoring area 3) reaches its peak, then the stress concentration coefficient begins to decrease, which means that the bearing capacity of external coal-rock begin to decline. At point 2, the stress of the whole coal-rock reaches its peak and at point 3, the stress of the middle area of coal-rock (the monitoring circle 2) reaches its peak, but the stress concentration coefficient is still more than 1, which means that it can continue to beer exceed damage stress of the whole coal-rock. At point 4, the stress of the internal coal-rock (the monitoring area 1) reaches its peak, and the stress concentration coefficient is still increasing, bearing a bigger damage stress of the whole coal-rock. All in all, the stress of coal-rock gradually transported to the internal area along with the process of coal-rock compression and the deeper, the greater the stress concentration factor.

Then, the bearing capacity of each area of the coal-rock begins to decrease and at point 5, the stress concentration factor of the middle part of the coal-rock begins to decrease, the damage stress of coal-rock is mainly borne by the internal part. After point 5, the stress concentration factor of the middle coal-rock is <1, the residual damage stress is completely concentrated in the internal part. It can be seen that the decline of mechanical bearing capacity also from the external coal-rock to the internal coal-rock.

In summary, the damage evolution process of coal-rock has obvious time–space effect, the stress of different space position in different time has the following relation:

where k it —the stress concentration factor at t moment in the i measuring area.

According to formula (2) and the numerical simulation results, the time–space effect of coal-rock damage and stress change are as follow:

where t 0 is the time from point 0 to point 1; t 1 is the time from point 1 to point 2; t 2 is the time from point 2 to point 3; t 3 is the time from point 3 to point 4; t 4 is the time from point 4 to point 5; t 5 is the time from point 5 to point 6;

3.2 Evolution Law of Compressive Damage Field in Coal-Rock

According to Table 2 and Fig. 6, along with the variation of stress field of coal-rock, the cracks in the whole coal-rock or monitoring area are ever-changing and also have obvious temporal-spatial relations. It is very clearly that the number of cracks in measuring circle 3 is larger than that in measuring circle 2 and in measuring circle 2 is larger than that in measuring circle 1 in every time. This reflects that the coal-rock damage has a strong regional characteristics. At point 1 and point 2, the number of increment of cracks in measuring area 3 is the largest, followed by measuring area 2 and measuring area 1, the damage is mainly concentrated on the external coal-rock. At point 3, the number of increment of cracks in measuring area 2 is bigger than that in measuring area 3 and measuring 1, show that the damage transfer to the middle area (measuring area 2) of the coal-rock. At point 4 and point 5, the number of increment of cracks in the measuring area 1 is larger than that in measuring area 2 and measuring area 3, the damage transfer to the inner area (measuring area 1) of the coal-rock. Meanwhile, it is found that although the damage path and damage time of the monitoring areas are different, the total damage number of cracks in each monitoring areas are almost the same. The evolution law of coal-rock compression damage field and the time–space law of stress field are in good agreement. Figure 7 shows the spatial–temporal characteristics of coal-rock damage, along with the time the damage of coal-rock constantly transfer to the interior, and the damage evolution has obvious characteristic of “string wave”.

3.3 Space–Time Evolution Constitutive Model

The concept of damage was first introduced by the Soviet Union scholar (Kachanov 1958). In his paper, the continuity factor and effective stress were used to describe the deterioration of the properties of the metal in the process of creep fracture. Later, Rabotnov (1969) introduced the concept of damage variable. There are many various definitions for damage variable, due to the damage of the material is caused by the material micro structure and some macroscopic physical performance changes, so we can choose the damage variable from two aspects of microcosmic and macroscopic. From the microscopic aspect, the number of cracks (Ge et al. 1999; Kim et al. 2013), length (Ren and Ge 2001), area (Voyiadjis and Kattan 2015), volume (Peng and Yang 2000) can be selected and from the macroscopic aspect, the elastic coefficient (Mizuno et al. 2010), the yield stress (Murti et al. 1991), the elongation (Cao and Xian 2001), the density (Kupchella et al. 2015), the resistance sound emission (Iturrioz et al. 2013) can be selected. In this paper, the damage variable was defined by the parameter of crack.

The damage variable as follows:

where C it —the number of cracks in the i measuring area at t moment; C i —the total number of cracks in the i measuring area at the moment that the coal-rock was completely damaged.

Therefore, based on the principle of crack characteristics and strain equivalence principle (Lemaitre et al. 1999), the damage constitutive equation of coal-rock uniaxial compression is:

where E—elastic modulus of intact coal-rock.

Then, the damage constitutive characteristics of coal-rock are discussed through the parameters of the crack and the stress in the measuring area 3.

From formula (4) and formula (5), the damage constitutive equation of coal-rock as a whole and monitoring area 3 are:

where C t —the number of cracks of the whole model at t moment; C—the total number of cracks of the whole model at the moment that the coal-rock was completely damaged.

Then, bring the formula (2) into the formula (6):

Formula (7) is the damage constitutive equation of the whole coal-rock based on the stress concentration coefficient and the crack parameter of the external part.

Figure 8 is a complete coal-rock stress–strain curve based on the formula (6) and the formula (7), they all in good agreement with the actual values. Thus, the compression damage constitutive equation of coal-rock can be established according to the crack parameters. In view of the fact that it is very difficult to monitor the crack damage parameters of intact coal-rock, it is meaningful to monitor the crack parameters of local coal-rock then gain the damage constitutive equation of intact coal-rock by the formula (7). Then the impact and the instability characteristics of coal mine can be analyzed.

4 Conclusion

The compression stress field of coal-rock has obvious time–space effect, along with the change of the Compressive stress, the stress field is transferred to the internal coal-rock body constantly.

The damage evolution of the coal-rock also has obvious temporal-spatial relations. With the change of the coal-rock compression stress field, the crack number in coal-rock body is increasing, and it is transferred to the internal as the “string wave”. The evolution law of coal-rock compression damage field and the time–space law of stress field are in good agreement.

The time–space damage constitutive model of coal-rock established on the basis of local crack and the stress concentration factor of coal-rock was reasonable and effective, the damage degree of the whole coal-rock could be predicted by the variation of local coal-rock stress and cracks.

References

Cao S, Xian X (2001) Testing study on the characteristics of creep and damage of coal and other rocks. Chin J Rock Mech Eng 20(6):817–822

Carranza-Torres C, Fairhurst C (1999) The elasto-plastic response of underground excavations in rock masses that satisfy the Hoek-Brown failure criterion. Int J Rock Mech Min Sci 36(6):777–809

Cundall PA, Strack OD (1979) A discrete numerical model for granular assemblies. Geotechnique 29(1):47–65

Ge X, Ren J, Pu Y et al (1999) A real-time CT triaxial testing study off meso-damage evolution law of coal. Chin J Rock Mech Eng 18(5):497–502

Itasca Consulting Group (2008) PFC2D (particle flow code in 2dimensions) fish in PFC2D. Itasca Consulting Group, Minneapolis

Itasca Consulting Group Inc. (2004) Manual of particle flow code in 2-dimension (Version 3.10). Itasca Consulting Group Inc., Minneapolis

Iturrioz I, Lacidogna G, Carpinteri A (2013) Acoustic emission detection in concrete specimens: experimental analysis and lattice model simulations. Int J Damage Mech 23(3):327–358

Ju Y, Zuo J, Song Z et al (2007) Numerical simulation of stress distribution and displacement of rock strata of coal mines by means of DDA method. Chin J Geotech Eng 29(2):268–273

Kachanov LM (1958) Time rupture process under creep conditions. Izvestia Akademii Nauk SSSR, Otdelenie Tekhnicheskich Nauk 12(8):26–31

Khaled MM, Michael MM, Heather EL et al (2016) Analysis of the current rib support practices and techniques in U.S. coal mines. Int J Min Sci Technol 26(1):77–87

Kim J, Yi J, Kim J et al (2013) Fatigue life prediction methodology using entropy index of stress interaction and crack severity index of effective stress. Int J Damage Mech 22(22):375–392

Kupchella R, Stowe D, Xiao X et al (2015) Incorporation of material variability in the Johnson Cook model. Procedia Eng 103:318–325

Lemaitre J, Sermage JP, Desmorat R (1999) A two scale damage concept applied to fatigue. Int J Fract 97(1–4):67–81

Li Z (1987) Study on mechanism of coal and gas outburst in in-seam drivage. J China Coal Soc 1:17–27

Liu G, Zhao J, Song H et al (2008) Model experiments on the broken zone in intermittently jointed surrounding rock. J China Univ Min Technol 37(1):62–66

Matsuki K, Nakama S, Sato T (2009) Estimation of regional stress by FEM for a heterogeneous rock mass with a large fault. Int J Rock Mech Min Sci 46(1):31–50

Mizuno M, Okayasu M, Odagiri N (2010) Damage evaluation of piezoelectric ceramics from the variation of the elastic coefficient under static compressive stress. Int J Damage Mech 19(3):375–390

Murti V, Zhang W, Valliappan S (1991) Stress invariants in an orthotropic damage space. Eng Fract Mech 40(6):985–990

Peng Y, Qi Q, Wang Y et al (2010) Study of field measurement of mining induced coal fracture field and its application. J Rock Mech Eng 29(S2):4188–4193

Rabotnov YN (1969) Creep rupture. Applied mechanics. Springer, Berlin, pp 342–349

Ren J, Ge X (2001) Study of rock meso-damage evolution law and its constitutive model under uniaxial compression loading. Chin J Rock Mech Eng 20(4):425–431

Voyiadjis GZ, Kattan PI (2015) Investigation of the damage variable basic issues in continuum damage and healing mechanics. Mech Res Commun 68:89–94

Wen Z, Wang X, Song Z et al (2015) Study on bearing mechanical behaviour of the pre-damaged coal rock. J Mines Met Fuels 63(9):246–250

Xiang-he PENG, Chun-he YANG (2000) The damage and its description of concrete under complex loading history. Chin J Rock Mech Eng 19(2):157–164

Yin X (2008) Numerical tests on geotechnical properties of rock and soil materials. Wuhan Institute of rock and soil mechanics, Chinese Academy of Sciences, Wuhan

Zhang M, Xu Z, Pan Y (1991) A united instability theory on coal (rock) burst and outburst. J China Coal Soc 16(4):48–53

Zhang X, Ruan H, Jia C (2010) Progress in theory of damage mechanics of rock. Sichuan Build Sci Res 36(2):134–138

Acknowledgments

This work is supported by the National Basic Research Program of China under Grant No. 2012CB72310402; the National Natural Science Foundation of China under Grant No. 51304126; the research fund for excellent young and middle-aged scientists of Shandong Province under Grant No. BS2013NJ007; Fok Ying Tung Education Foundation under Grant No. 141046; State Key Laboratory of open funds under Grant No. SKLGDUEK1520; Shandong University of Science and Technology Graduate Innovation Fund No. YC150309; the Tai’shan Scholar Engineering Constructin Fund of Shandong Province of China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, X., Wen, Zj. & Jiang, Yj. Time–Space Effect of Stress Field and Damage Evolution Law of Compressed Coal-Rock. Geotech Geol Eng 34, 1933–1940 (2016). https://doi.org/10.1007/s10706-016-0074-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-016-0074-y