Abstract

Loose saturated cohesionless soils are most susceptible to liquefaction, however there are strong historical evidence suggesting that soils containing fines such as silty sands are also prone to liquefaction during earthquakes. The liquefaction of silty sands has been observed in a number of recent case studies. This paper presents the effects of fine silts on liquefaction potential of sandy soil. Tests have been conducted on the vibration table at different accelerations and pore water pressure is measured. During the lab investigation, locally (Roorkee, India) available Solani Sand and Dhanauri Silt have been used. The soil samples have been prepared by varying silt content and the initial relative density. The results of the study performed are used to clarify the effects of non-plastic fines content on the Solani sand. As the silt content increases, the number of cycles required to produce maximum pore water pressure increases. For a particular level of excitation, rate of pore water pressure generation is maximum at critical silt content. It is observed that critical silt content to generate maximum pore water pressure is different for different accelerations. Further, effect of silt content is very much dependent on relative density.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

It has been understood from literature that the presence of silt and clay particles will in some manner affect the resistance of sand to liquefaction. However, a review of studies published in the literature indicates that no clear conclusions can be drawn as to in what manner altering the fines content affects the liquefaction resistance of a sand under cyclic loading. This is particularly true for soils containing non-plastic fines. Studies have reported that increasing the silt content in sand may increase or decrease the liquefaction resistance of the sand, or increase the liquefaction resistance until some critical silt content is reached. Additionally, several studies have shown that the liquefaction resistance of silty sand is more closely related to its initial relative density than to its silt content. The presence of plastic or clayey fines is generally considered to decrease the liquefaction susceptibility of a soil. Numerous field studies have shown that soils with more than 10 or 15 percent fines do not liquefy during earthquakes. During the 1970’s, Engineers in the Peoples Republic of China (PRC) developed a set of criteria in their building codes, commonly referred to as the Chinese criteria, which deem certain soils as “nonliquefiable” due to their plastic nature (Jennings 1980; Finn 1982).

Both clean sands and sands containing fines have been shown to liquefy in the field (Prakash 1981; Kramer 1996). Based upon case histories of actual soil behavior during earthquakes, there is evidence that soil with greater fines contents are less likely to liquefy in a seismic event. Okashi (1970) observed that during the 1964 Niigata earthquake in Japan, sands were more likely to liquefy if they had fines content of less than 10 percent. Tokimatsu and Yoshimi (1983) found in a study of 17 worldwide earthquakes that 50 percent of the liquefied soil had fines contents of less than 5 percent. They also found that sands with fine contents greater than 10 percent had a greater liquefaction resistance than clean sands at the same SPT blow count.

While some research reports have shown that an increase in fines content results in an increase in liquefaction resistance, other has shown the opposite effect. Chang et al. (1982) noted that case studies reveal that most liquefaction resulting from earthquakes has occurred in silty sands and sandy silts. Field based methods for determining liquefaction susceptibility, such as methods based on SPT blow counts or CPT measurements, must account for the presence of fines in the soil (Tatsuoka et al. 1980). Seed et al. (1985) modified the cyclic stress ratio (CSR) versus normalized SPT blow count curves originally proposed by Seed and Idriss (1971) to account for the increase in liquefaction resistance provided by increased fines content. The revised chart provides a series of curves for 5 percent, 15 percent, and 35 percent fines. These curves indicate that a larger CSR is required to liquefy a soil with higher fines content for a given blow count. Several investigators have found that the cyclic resistance of a sandy soil increases with increasing silt contents. For specimens prepared to a constant gross void ratio, Chang et al. (1982) found that after a small initial drop, cyclic resistance increased dramatically with increasing silt content. Dezfulian (1984) reported a trend of increasing cyclic resistance with increasing silt content. On the other hand numerous authors have reported a decrease in cyclic resistance with increasing silt content. Shen et al. (1977), Tronsco and Verdugo (1985), and Vaid (1994) have all reported this trend for specimens prepared either to a constant gross void ratio or a constant dry density.

Koester (1994) found that for specimens prepared to a constant gross void ratio, as silt content increased the cyclic resistance of the soil decreased until some limiting silt content was reached at which point the cyclic resistance began increasing. Several studies have shown that cyclic resistance is more closely related to sand skeleton void ratio than it is to gross void ratio, gross relative density, or fines content. Finn et al. (1994) found that at the same gross void ratio, the cyclic strength of a sand decreases with increasing fines content. They also found that at the same sand skeleton void ratio, cyclic strength remains constant with increasing fine content, as long as the fines can be accommodated in the void spaces created by the sand skeleton. Not all soils, however, exhibit a constant cyclic resistance with a constant sand skeleton void ratio. Thus, based upon the conflicting evidence presented in the literature, the fines content of a sandy soil does not alone provide a definitive measure of its liquefaction potential.

In recent studies, Guo and Prakash (1999) analyzed the test data of El Hosri et al. (1984) and Sandoval (1989). Polito and Martin (2001) conducted cyclic triaxial testing on two different sands with different silt contents. They had concluded that if the silt content of the soil is below the limiting silt content, there is sufficient room in the voids created by the sand skeleton to contain the silt and the soil can be described as consisting of silt contained in sand matrix. The cyclic resistance of the soil can be controlled by the relative density of the specimen. Yamamuro and Kelly (2001), based on the drained and undrained triaxial compression tests on silty sands with different confining pressures, observed that sands with high silt contents were more compressible than sands with low silt contents. Carraro et al. (2003) performed undrained triaxial tests on Ottawa sand with non plastic silts over a wide range of relative densities and concluded that for a given relative density, the cyclic resistance of sand increases slightly when small amount of non plastic silts are added.

The manner in which pore pressure generation varies as the quantity and type of fine-grained material in sand is an important aspect of the present investigation. In addition to affecting the liquefaction behavior of the soil, the rate and magnitude of pore pressure generation during seismic loading has a profound effect on the strength of the soil and the stability of structures constructed from, or founded on it. Pore pressure generation during cyclic loading can be examined in terms of the number of cycles of loading that the soil has undergone. A laboratory parametric study has been conducted (Patel 2006). Data from the liquefaction table tests were analyzed to evaluate the effect of fines content on the pore pressure generation characteristics of Solani sand. Pore pressure generation was evaluated in terms of the number of cycles of loading required to cause a given rise in pore pressure. The effect of different acceleration levels along with percentage silt content on the liquefaction resistance of sand is also analyzed.

2 Test Set Up and Investigation

The tests were performed on a simple but an indigenously fabricated vibration table (Gupta 1977) in the Soil Dynamics Laboratory of the Dept. of Earthquake Engineering, IIT Roorkee, India. The test bin is a water tight tank 1.05 m long, 0.60 m wide and 0.40 m high, in which soil sample is prepared. The tank is mounted on a horizontal shake table. The sides of the tank consist of a rigid mild steel frame with 5 mm thick steel panels. Thus it is a tank with rigid walls. The horizontal shake table consists of a rigid platform on which the test tank is mounted. The platform rests on four wheels supported on four knife edges. This is driven in horizontal direction by a 3 H.P. A.C. motor through crank mechanism for changing rotary motion into translatory motion. The crank mechanism consists of a device for changing the amplitude of motion through two eccentric shafts. By changing the relative position of two shafts the amplitude can be fixed as desired. The pore pressure measurement is performed with the help of a glass tube piezometer attached to the tank through a rubber tube at a height of 50 mm from the base of the tank and extended up to the center of the tank. At the mouth of tube a porous stone was fixed. Whole test set up is shown in Fig. 1. The table can produce steady state vibrations. One-dimensional harmonic excitation can be generated. The maximum amplitude of horizontal acceleration which can be generated is up to 1 g.

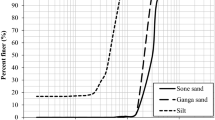

2.1 Properties of Sand and Silt

Sand from the local SOLANI river bed was used for all the tests. Silts were collected from the DHANAURI river bed near KAUKHEDA village. Standard dry sieve analysis was performed on sand. Hydrometer analysis was performed for the gradation of silt. The specific gravity, maximum void ratio, minimum void ratio tests were conducted for sand, silt and sand silt mixture. Tables 1 and 2 provide the various properties of sand and silt used respectively.

2.2 Preparation of Soil Sample

A known quantity of water i.e. 100 kg, sufficient to submerge the piezometer was taken in the tank. Air bubbles from the piezometer tube were removed. The porous stone for the piezometric tubes was kept in boiled water for about half an hour to remove any air present in that. A thin layer of grease was then coated on them and placed in position. Then the known quantity of sand and silt as calculated for various percentage of silt were measured. The sand and silt was mixed properly. For this dry mixing was done. Then the mixture was poured into the tank with the help of a funnel maintaining a constant height from the top of the water surface. By this method all the soils were poured into the tank. After all the soil mixture being poured, it was left for few hours for settlement of finer particles. Duration for this depends on the fines contents. For pure sand about 2 h was enough however sand with fines required more time i.e. about 8–10 h for the settlement. As the finer particles settled, the water overlying the soil sample was removed by siphoning and weighted accurately. After all the water has been removed, the top of soil sample, which was completely submerged, was leveled. The height of the sample thus prepared was about 260 mm. Total effective depth of the tank is 380 mm, thus the top surface of the prepared sample is about 120 mm below the top of the tank. With the help of dry weight of sand or sand silt mixture and amount of water left, the dry density of deposit and relative density were computed.

2.3 Procedure

After preparing the desired soil sample and before starting the experiment, the frequency is fixed at desired level i.e. 5 cps. Simultaneously level of excitation should also be fixed. The value of static pore water pressure is read from the manometer graph and marked. The piezometer was fixed at 5 cm from the base of the tank and extended up to the center of the tank. The flywheel is set to zero. Then the machine is switched on and hence vibration is imparted to the tank. The rise of pore water pressures are recorded after every 5 s interval till the peak is reached. The time required to achieve the peak is noted with the help of a stop watch having accuracy 0.01 s. At the time when peak value of pore water pressure is obtained, first the hand break is applied and then the motor is switched off. After the test is over the sample is left for few hours for the fine particles to settle down. Then the excess water overlying the sample is removed by siphoning and weighted accurately. Then with the dry weight of sand or sand silt mixture and amount of water left, the dry density and void ratio of the deposit is computed.

2.4 Tests Performed

Tests were performed on the saturated sand and sand-silt samples at different relative densities to study the effect of fines on the liquefaction potential of sand. All the tests were performed at a constant frequency of 5 cps. The tests were conducted on six combinations of sand and silt mixtures i.e. (a) sand without silt; (b) sand with 5% silt; (c) sand with 10% silt; (d) sand with 15% silt; (e) sand with 20% silt and (f) sand with 25% silt.

All these combinations were tested for three different acceleration i.e. 0.3 g, 0.4 g and 0.6 g keeping the frequency constant at 5 Hz. The chosen level of acceleration covers the range of all moderate and strong earthquakes.

3 Experimental Results

As the predominant frequency in an earthquake generally varies from 2 to 5 cps, the present investigations had been carried out at a frequency of 5 cps. Key results are discussed in following sections.

3.1 Pore Water Generation

In the test setup, main output was excess pore water pressure and the other parameters are correlated with excess pore water pressure. In the following sections, the effect of silt content and relative density on the pore pressure is discussed.

3.1.1 Effect of Silt Content

Figure 2a represents the pore water pressure generation with number of cycles for different silt contents for 0.3 g acceleration. As the number of cycles increases, the pore water pressure increases for all the silt contents, which is as expected. Also, it has been observed that the generation of pore water pressure is more for 5% silt content compared to the soil sample without silt. Further it can be observed that the pore water pressure generation, decreases as silt content increases beyond 5%. Thus for 0.3 g acceleration, critical silt content is 5%. The trend of the present results is similar to that presented by Prakash and Sandoval (1992).

Figure 2b and c shows results for 0.4 g acceleration and 0.6 g acceleration respectively. It can be observed that trends are similar to that shown in Fig. 2a; however the critical silt content for 0.4 and 0.6 g are 10 and 0%, respectively. Thus critical silt content (for which maximum pore water pressure is observed) is not unique and very much dependent on the level of excitation.

3.1.2 Effect of Relative Density

Figure 3a–f present the effect of relative density on pore pressure generation for different silt contents. Three excitations 0.3, 0.4 and 0.6 g were considered for each result. For 0% silt content, from Fig. 3a it can be observed that the pore pressure increases as acceleration increases. This is because of almost the same relative density for all three levels of excitations. Figure 3b and c show the results for 5 and 10% silt contents respectively. It can be observed that the pore pressure generation is highest for 0.3 g acceleration for both the cases. This may be attributed to the fact that the relative density is lowest for 0.3 g acceleration. It can be noticed that the effect of relative density is dominating over the level of acceleration.

For 15% silt content, Fig. 3d shows that the pore water pressure is maximum at 0.6 g as the relative density is also minimum for this excitation. Figure 3e shows that for 20% silt content, the pore water pressure is maximum at 0.4 g acceleration and minimum at 0.6 g acceleration. This is because relative density is lowest at 0.4 g and highest at 0.6 g acceleration. Thus again it can be observed that the relative density is dominating. Figure 3f shows result for 25% silt content. The pore water pressure is maximum at 0.3 g acceleration corresponding to the lowest relative density and pore water pressure is minimum corresponding to the highest relative density at 0.4 g acceleration. Therefore, in general, it was observed that at low value of relative density, pore water pressure is high which was as expected.

3.2 Rate of Generation of Pore Water Pressure

The rate of pore pressure generation is also one of the important parameters in liquefaction analysis (Seed et al. 1975). In following sections, the effect of silt content at constant value of acceleration is observed on this parameter. It is observed that the maximum and minimum rate of pore pressure generation is different for different level of acceleration.

In Fig. 4a, for 0.3 g acceleration, it is observed that maximum rate of pore water pressure generation decreases as the silt content increases. Maximum rate of generation is obtained at 5% silt content (which is also critical silt content) and minimum rate of generation at 15% silt content. Rate of pore pressure generation for other silt content lies in between 5 and 15%.

From Fig. 4b, for 0.4 g acceleration, it is observed that maximum rate of pore pressure generation is obtained at 10% silt content (which is critical silt content) and minimum rate of pore water pressure occurs at 15% silt contents. Rate of generation of pore pressure for the other silt contents exist in between these two limits. In case of 0.6 g, maximum rate of generation occurs both at 5 and 15% silt contents and minimum at 10% silt content which has been shown in Fig. 4c. However, the effect of silt content on maximum values is not as significant as observed for 0.3 and 0.4 g acceleration.

4 Discussion of Results

From this study distinct behavioral pattern has been found for the cyclic resistance of soils composed of sand and non-plastic silt. Out of these characteristics, control is determined by whether there is sufficient room in the voids created by the sand skeleton to contain the silts present without disturbing the structure of the sand. This silt content has been called the critical silt content and occurred around 5% for 0.3 g acceleration, around 10% for 0.4 g acceleration and around 0% for 0.6 g acceleration used in this study.

If the silt content of the soil is below the critical silt content, there is sufficient room in the voids created by the sand skeleton to contain the silt. The cyclic resistance of the soil is then controlled by the relative density of the specimen, where the relative density is calculated using the gross void ratio of the specimen and the maximum and minimum void ratio for that particular mixture of sand and silt. As relative density increases, the soil’s cyclic resistance increases because of generation of pore water pressure decrease. If the silt content is greater than the critical silt content, the specimen’s structure consists predominately of sand grains suspended within a silt matrix with little sand grain to sand grain contact (Koester 1994). Above the critical silt content, the amount of sand present in the soil and its relative density has little effect on its cyclic resistance.

The seemingly contradictory reports concerning the effects of non-plastic fines content on the liquefaction resistance of sands that have appeared in the literature (e.g. Shen et al. 1977; Koester 1994) were reconciled in light of the behavioral patterns found in this study. These behaviors were found to depend primarily upon the critical silt content of the soil and the relative density of the specimen. The pore water pressure is controlled by the initial relative density of the soil.

5 Conclusions

Numerous studies reported in the literature have produced varying answers to the question about the effect of increasing non-plastic silt content on the liquefaction resistance of sand. In order to answer this question and to reconcile the results of these studies, 18 tests on liquefaction table was performed using pure sand and five combinations of sand and non-plastic silt. Tests were performed at varying silt contents and relative density. The results interpreted in terms of the pore water pressure and the rate of pore water pressure generation. The current study was able to identify two key factors: initial relative density and critical silt content, which govern the liquefaction behavior of silty sands. Using these factors, the majority of the seemingly contradictory behaviors reported in the literature can be explained.

The major conclusions based on this study can be drawn as follows.

-

1.

The critical silt content is different for different amplitude of excitations. The critical silt content for 0.3, 0.4 and 0.6 g amplitude of excitation are found to be 5, 10 and 0%, respectively. However, it shall be noted that these values of critical silt content are based on the limited tests conducted. More tests required to be conducted to reach at concrete conclusion.

-

2.

The initial relative density is the major governing parameter for the development of pore water pressure. If the relative density of specimen is more, the generation of pore water pressure is less because there is more compaction of sample resulting lesser void ratio within the sample to generate the pore pressure and vice versa.

-

3.

Also the level of excitation plays an important role for the development of pore water pressure. As the level of excitation increases, the pore pressure generation and its rate of generation also increases. Also both of these parameters decrease as the level of excitation decreases.

-

4.

Rate of pore water pressure generation is maximum at the starting of the excitation, then it decreases and finally tend to zero. If the rate of generation is more the same amplitude of vibration will need less number of cycles to generate the maximum pore water pressure. In such cases, even in short duration earthquake, liquefaction may occur.

It is acknowledged that the above outcome is based on the limited tests conducted on the vibration table, more number of tests may require to clarify various effects.

References

Carraro JAH, Bandini P, Salgado R (2003) Liquefaction resistance of clean and nonplastic silty sands based on cone penetration resistance. J Geotech Geoenviron Eng ASCE 129(11):965–976

Chang NY, Yeh ST, Kaufman LP (1982) Liquefaction potential of clean and silty sands. Proceedings of 3rd International Earthquake Microzonation Conference, vol 2. Seattle, USA, pp 1017–1032

Dezfulian H (1984) Effects of silt content on dynamic properties of sandy soils. Proceedings of the 8th World Conference on Earthquake Engineering. San Francisco, USA, pp 63–70

El Hosri MS, Biarez H, Hicher PY (1984) Liquefaction characteristics of silty slay. Proceedings of 8th World Conference of Earthquake Engineering. San Francisco, USA, pp 277–284

Finn WL (1982) Soil liquefaction studies in the Peoples Republic of China. In: Soil mechanics—transient and cyclic loads, John Wiley and Sons, New York, pp 609–626

Finn WDL, Ledbetter RH, Wu G (1994) Liquefaction in silty soils: design and analysis. In: Ground failures under seismic conditions, Geotechnical special publication, No. 44, ASCE, pp 51–76

Guo T, Prakash S (1999) Liquefaction of silts and silt-clay mixtures. J Geotech Geoenviron Eng ASCE 125(8):706–710

Gupta MK (1977) Liquefaction of saturated sands during earthquakes. Ph.D. Thesis, Department of Earthquake Engineering, University of Roorkee, Roorkee, India

Jennings PC (1980) Earthquake engineering and hazards reduction in china. CSCPRC, Report No. 8, National Academy of Sciences, Washington, D.C

Koester JP (1994) The influence of fine type and contents on cyclic resistance. In: Ground failures under seismic conditions, Geotechnical special publication, No. 44, ASCE, pp 17–33

Kramer SL (1996) Geotechnical earthquake engineering. Pearson Education, First Indian reprint 2003

Okashi Y (1970) Effects of sand compaction on liquefaction during Tokachioki earthquake. Soils Found JSSMFE 10(2):112–128

Patel AK (2006) Effect of fines on liquefaction potential. M. Tech. Dissertation, Department of Earthquake Engineering, Indian Institute of Technology Roorkee, Roorkee, India

Polito CP, Martin JR (2001) Effects of nonplastic fines on the liquefaction resistance of sands. J Geotech Geoenviron Eng ASCE 127(5):408–415

Prakash S (1981) Soil dynamics. McGraw-Hill Book Company, New York

Prakash S, Sandoval JA (1992) Liquefaction of low plasticity silts. J. of Soil Dynamics and Earthquake Engineering, Elsevier Science Publishers Ltd., 11:373–379

Sandoval J (1989) Liquefaction and settlement characteristics of silt soils. Ph.D. thesis, University of Missori-Rolla, Rolla, USA

Seed HB, Idriss IM (1971) Simplified procedure for evaluating soil liquefaction potential. J Soil Mech Found Div ASCE 97(9):1249–1274

Seed HB, Martin PP, Lysmer J (1975) The generation and dissipation of pore water pressure during soil liquefaction. Earthquake Engineering Research Centre, California, Report No. 75/26

Seed HB, Tokimatsu K, Harder LF, Chung RM (1985) Influence of SPT procedures in soil liquefaction resistance evaluations. Journal of Geotechnical Engineering, ASCE 111(12):1425–1445

Shen CK, Vrymoed JL, Uyeno CK (1977) The effects of fines on liquefaction of sands. Proceedings of the 9th International Conference on Soil Mechanics and Foundation Engineering, vol 2. Tokyo, Japan, pp 381–385

Tatsuoka F, Iwasaki T, Tokida K, Yasuda S, Hirose M, Imai T, Kon-No M (1980) Standard penetration tests and soil liquefaction potential evaluation. Soils Found JSSMFE 20(4):95–111

Tokimatsu K, Yoshimi Y (1983) Empirical correlation of soil liquefaction based on SPT N-value and fines content. Soils Found JSSMFE 23(4):56–74

Tronsco JH, Verdugo R (1985) Silt content and dynamic behavior of tailing sands. Proceedings of 12th International Conference on Soil Mechanics and Foundation Engineering. San Francisco, USA, pp 1311–1314

Vaid VP (1994) Liquefaction of silty soils. Ground failures under seismic conditions, Geotechnical special publication, No. 44, ASCE, pp 1–16

Yamamuro JA, Kelly MC (2001) Monotonic and cyclic liquefaction of very loose sands with high silt content. J of Geotechnical and Geoenvironmental Eng, ASCE 127(4):314–324

Acknowledgments

Authors are thankful to Prof. and Head of Department of Earthquake Engineering, Indian Institute of Technology Roorkee, India for providing laboratory facilities and assistance for conducting of tests. This support is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Maheshwari, B.K., Patel, A.K. Effects of Non-Plastic Silts on Liquefaction Potential of Solani Sand. Geotech Geol Eng 28, 559–566 (2010). https://doi.org/10.1007/s10706-010-9310-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-010-9310-z