Abstract

Loose saturated cohesionless soils are most susceptible to liquefaction, however there are strong historical evidence suggesting that soils containing fines such as silty sands are also prone to liquefaction during earthquakes. The liquefaction of silty sands is observed in a number of recent case studies. Unfortunately, there is a lack of studies, as to how does altering fines content affects the liquefaction resistance of sand. There is a need to clarify the effects of fines content and permeability on the liquefaction resistance of sandy soils. The objective of the present study was to conduct model tests on locally available sandy soils with varying percentages of non-plastic silts using one-dimensional shaking table. The acceleration and frequency of shaking were kept as 0.245 g and 1 Hz, respectively. The system behavior during shaking, effects of permeability on liquefaction resistance, and pore water pressure buildup also comes under the scope of the study. It was observed that as the silt content increases, the number of cycles required to produce maximum pore water pressure increases and liquefaction resistance increases up to optimum fines content and then the trend reverses. Also, liquefaction resistance increases when permeability decreases up to limiting fines content. Since Kerala is one of the coastal states and is included in earthquake zone III, such liquefaction studies are having significance.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Liquefaction is one of the significant and complex themes in geotechnical earthquake engineering. Liquefaction-induced failure has been and continues to be a major cause of destruction during earthquakes. The direct and indirect costs related to ground failure may far exceed the damage caused by other types of failures, such as structural collapses. Its devastating effects sprang to the attention of geotechnical engineering in 1964 when the Niigata earthquake, Japan followed the Alaska earthquake. Both earthquakes produced severe damage to buildings, the foundation of structures, and natural slopes due to liquefaction. After that, soil liquefaction has received a lot of considerations, and the corresponding technologies to analyze and prevent liquefaction have significantly improved over the years. A qualitative understanding of sand liquefaction and its effects under cyclic loading was first presented by Casagrande [1]. The term liquefaction was initially coined by Mogami and Kubo [2]. The cause of liquefaction of sands has been understood for many years. Interestingly, the majority of historical cases of liquefaction have occurred in sandy soils containing some portion of fines, which are typically classified as soil particles with diameters ranging from 0.075 to 0.002 mm. However, while the undrained response of clean sands has been extensively investigated and documented, there still exists a limited understanding as to how the smaller fines particles affect the undrained response and liquefaction potential of sand.

Nowadays, evaluation of soil liquefaction resistance is an essential aspect of geotechnical engineering practice. There are various laboratory and field methods to assess soil liquefaction. The deformation in the soil elements and stress conditions is affected significantly by the boundary conditions, and the loading conditions are not the real-field conditions generally. Therefore, it is believed that large soil specimen can reproduce the actual seismic ground shaking. Since shake table test can simulate actual seismic conditions, among the various laboratory tests, the present study focuses on the shake table test.

Some laboratory tests, performed using the triaxial shear apparatus, have suggested that the addition of fines to sand increases the flow potential of a sandy soil [3], while design charts such as those used in the simplified procedure [4] suggest non-plastic fines increase the cyclic liquefaction resistance of sandy soil. Given that liquefaction often occurs in sands with some amount of fines particles, it is crucial to properly understand how fines influence the undrained behavior of sand and liquefaction resistance. The factors controlling the liquefaction of clean sand are well-understood. But, the understanding of the liquefaction behavior of sand with non-plastic fines is not complete. There is a lack of opinion on whether the inclusion of non-plastic fines will increase or reduce the liquefaction tendency. Also, there is no clear idea about permeability and pore water generation during liquefaction.

Several researchers have conducted laboratory tests to study the effect of non-plastic fines or effect of composite materials on liquefaction resistance [5,6,7,8,9]. However, contradictory conclusions were drawn in the literature, and whether the non-plastic fines increase or decrease the liquefaction resistance is unclear.

The effect of fine content studied by Maheshwari and Patel [10] suggested that to improve the liquefaction resistance non-plastic fine contents may be in the range of about 12–15%. The liquefaction resistance decreases with an increase in fines percentage, for the same SPT N value [11].

Polito and Martin [12] varied non-plastic fines content (FC) from 4 to 75% and has concluded that the structure of the soil can be considered as composed of silt particles contained within a sand matrix. The relative density of the soil controls the resistance to liquefaction and is independent of the silt content of the soil. Tests conducted on sand with 0–55% silt content observed that liquefaction resistance of sand–non-plastic fines mixtures might either decrease or increase with increasing values of fines content [7]. Also, for low values of fines content, when compared at the same intergranular void ratio, an increase in fines content increases the liquefaction resistance.

The threshold fine content (which is the limiting fine content) for Ahmedabad sand was found to be 30% [8] and after that, the potential for liquefaction decreases. The relative density and limiting silt content of a specimen influence the pore pressure response [13]. Also, the rate of generation of excess pore water pressure to cycles of loading was found to initially increase with the increase in silt content till the limiting silt content, and after that, it reverses its trend when the specimens were tested at a constant gross void ratio. From cyclic triaxial tests carried on sand–silt mixtures with non-plastic fines content varying from 0 to 50%, [14] reported that the liquefaction resistance decreases as the non-plastic fines content increases. Fines separated from collected soil itself were used in this study.

Monkul and Yamamuro [15], concluded from their study that the relative size of the silt grains must be considered in geotechnical engineering practice to characterize the influence of silt on liquefaction potential of sands. Liquefaction potential of the sand increases steadily with increasing non-plastic fines content for the studied range (0–20%). It is suggested that the commonly used comparison bases (i.e., void ratio, intergranular void ratio, relative density) are not sufficient for assessing the influence of non-plastic fines on liquefaction potential of silty sands.

From these studies, it is clear that there is no definite relationship that could be evolved between the percentage of non-plastic fines and liquefaction resistance. And also, tests were conducted mainly using triaxial apparatus. Hence, shake table studies can provide necessary additional data for a better understanding of the liquefaction process in sand with non-plastic fines. Not much shake table studies on the generation of pore water pressure in the Indian context are reported, describing the relationship between fines content, permeability, and liquefaction resistance. This paper presents a study on the liquefaction behavior of sands of different gradation and permeability under various fines content procured from deposits in Kerala using one-dimensional shaking table.

2 Experimental Investigation

2.1 Materials

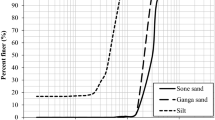

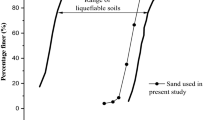

Soil Sample—The sand used in this study was collected from Cherthala beach, Alleppey District, Kerala. Soil type is classified as SP. The light brown sand sample (Fig. 1a) was sieved through a 75 µm sieve to remove fines from the sand. The particle size distribution curve of clean sand shows that the curve falls within the boundaries of potentially liquefiable soil range proposed by Tsuchida [16] (Fig. 1b).

Non-plastic fines—Quarry dust (<75 µm) was used in this study as non-plastic fines. It is a by-product of rubble crusher unit in Aluva, Kerala. The particle size distribution of quarry dust was conducted as per IS:2720 (Part 4—1985, 1995) and found that 99% of quarry dust falls under the category silt. Properties of quarry dust are tabulated in Table 1.

In order to study the effects of non-plastic fines content on the liquefaction resistance of sands, four combinations of sand and Quarry dust were created using Cherthala sand. Sand with 0%, 5%, 10%, and 20% Fines Content (FC) was tested with a constant relative density of 30%, and the input acceleration is kept constant as approximately 0.245g throughout the test. Table 2 shows the properties of different sand mixtures.

Test setup—For the experimental investigation, a rigid rectangular box made of steel and perspex glass mounted on a one-dimensional shake table was used. The box is 1.50 m long, 0.50 m wide, and 0.60 m deep. The box is provided with baffle walls at the bottom portion to regulate water uniformly for the saturation of sand. The more details of the experimental setup can be obtained from [17].

Above the baffle wall, a filter media is provided to restrict the entry of sand into the baffle wall portion, which could be easily removed and placed back. Acceleration sensors and pore water pressure sensors are used to measure acceleration and pore water pressure, respectively. Figure 2 shows a schematic representation of the test setup and the locations of pore water pressure sensors are shown in Fig. 3 (Table 2).

Sand bed preparation—Sand pluviation technique was adopted to prepare the sample bed by pouring the soil mixture loosely into the box using a conical hopper with a 60° base angle to ensure uniform deposition of sand. The pore water pressure sensors are tied in exact position before filling the sand so that the relative position of the sensor to sand bed remains unchanged. Sample bed in shake table was prepared in four layers. Weight required for each layer is found out and is filled with a funnel to ensure uniform deposition.

The main mechanism associated with the phenomenon of liquefaction is the generation of excess pore water pressure (EPWP) under undrained loading conditions. Thus, in order to gain insight to the effect of fines, typical shake table test results on sand–fine mixtures (0%, 5%, 10%, and 20% of fines content) demonstrating the general trend of the effect of fines content on excess pore water pressure generation for a constant relative density (30%) were analyzed. The pore pressure values were recorded at three levels by means of pore pressure sensors at top, middle, and bottom of the soil model by five sensors in each level. The constant acceleration value throughout the experiment was approximately 0.245 g (Fig. 4). S1 indicates the acceleration sensor 1, which was fixed at the bottom of the shake table during shaking.

3 Analysis of Results

3.1 Excess Pore Water Pressure Variation with Time at Different Locations

It is observed from the data that excess pore water pressure gradually increases, reaches its maximum value, and then starts dissipating continuously or remains constant till the end of the test. And, it was also clear that, pore water pressure dissipation was higher in bottom layer compared to middle and top layer. That is, from bottom of shake table to top, excess pore water pressure dissipation decreases. Variation of excess pore water pressure (EPWP) versus time for relative density of 30% with 0% fines content from 15 pressure sensors has been depicted in Fig. 5. From the figure, it was clear that, bottom layer had highest EPWP values and top layer had lowest EPWP values. And also inferred that, sensors provided nearer to the edge of shake table, such as A1, A2, A3 and E1, E2, E3 show higher values compared to other sensor values. It may be due to the boundary effects. Sensors provided at B, C, and D locations show similar values and it was clearly found in Fig. 6. Similar trend was observed for all other tests with varying percentages of fines contents.

3.2 Effect of Fines Content on Excess Pore Water Pressure Generation and Excess Pore Water Pressure Ratio (EPWPR)

Variation of EPWPR at C1, C2, and C3 for different percentages of fines content is shown in Fig. 7. From the figure, it can be observed that there is a decrease in the value up to 10% FC and after that a slight increase in the EPWPR value. To measure the liquefaction resistance, excess pore water pressure ratio (ru) is defined as the ratio of excess pore water pressure due to shaking to initial vertical effective stress at that point. Figure 8 shows the variation of average EPWP and EPWPR values near the peak value for three cycles at the central section. The results are plotted for 30% relative density for different fine contents at top, middle, and bottom positions of sensors (C).

From the figure, it can be observed that, liquefaction resistance increases up to 10% fines content due to decrease in pore pressure ratio and decreases toward 20% FC due to increase in pore pressure ratio. Average EPWPR developed at the center of the sand bed (C2) in 0% fines content test was about 1.08 and goes on decreasing to 0.8 for 10% FC and then increases to a value 0.98 for 20% FC. The general trend of developing maximum EPWP value at bottom layer and maximum pore pressure ratio at the top layer was satisfied in all the test results at middle and bottom positioned sensors. Slight variations were shown in sensors positioned at top in the average EPWPR values when fines were added.

3.3 Effect of Fines Content on Permeability of Sand

Coefficient of permeability (k) values was obtained from falling head permeability test conducted on sand–silt mixtures and is tabulated in Table 3. It shows that permeability decreases with increase in non-plastic silt content. This behavior of decreasing permeability with increasing silt content can be explained in view of void ratio. The variation of coefficient of permeability with silt content can also be explained by effective particle size (D10) variation. Effective sizes in table decrease rapidly with increasing silt content of specimen, up to 20% silt content. From literature (Hazen 1892; Kresic 1998), it was seen that coefficient of permeability is a function of D10. Therefore, D10 is the most important controlling factor for permeability. As the fines content increases there is a chance of increasing the volume of the soil mass (dilatancy effect) as a result of which a reduction in the settlement measurement is noted (Table 3).

4 Conclusions

Four tests on shake table were performed using pure Cherthala sand and three combinations of sand and non-plastic silt (quarry dust). Tests were performed at varying silt contents and at constant acceleration of 0.245 g and relative density of 30%. The results are interpreted in terms of the excess pore water pressure generation (EPWP) and excess pore water pressure ratio (EPWPR). The current study was able to identify key factor critical silt content, which governs the liquefaction behavior of silty sands. The major conclusions based on this study can be drawn as follows.

-

1.

Inclusion of non-plastic silt in the clean sand increases liquefaction resistance of sample. The optimum value of silt contents for 30% relative density was found to be 10%.

-

2.

The rate of generation of excess pore water pressure with respect to cycles of loading was found to initially decrease with increase in silt content till the optimum silt content of 10% was reached and thereafter it reverses at 20%, when the specimens were tested at a constant relative density.

-

3.

In constant relative density approach, the pore pressure ratio with respect to cycles of loading was found to initially decrease till limiting fines content and thereafter it increases. This pore pressure response implies that the liquefaction resistance increases till the limiting fines content and thereafter decreases.

-

4.

Increasing silt content decreases the permeability throughout the sand-silt mixtures. It was due to the decrease in effective size of sand–silt mixtures.

References

Casagrande, A.: Characteristics of cohesionless soils affecting the stability of slopes and Earth fills. J. Boston Soc. Civ. Eng. (1940)

Mogami, T., Kubo, K.: The behaviour of soil during Vibrations. In: Proceedings of 3rd International Conference on Soil Mechanics and Foundation Engineering, Zurich, vol. 1(1), pp. 152–155 (1953)

Cubrinovski, M., Ishihara, K.: Flow potential of sandy soils with different grain compositions. Soils Found. 40(1), 103–119 (2000)

Seed, H.B., Idriss, I.M.: Simplified procedure for evaluation soil liquefaction potential. J. Soil Mech. Found. Div., ASCE 97(SM9), 1249–1273 (1971)

Prakash, S., Sandoval, J.A.: Liquefaction of Low Plasticity Silts. Soil Dyn. Earthquake Eng. 11, 373–379 (1992)

Guo, T., Prakash, S.: Liquefaction of silts and silt-clay mixtures. J. Geotech. Geoenviron. Eng. ASCE 125(8), 706–710 (1999)

Xenaki, V.C., Athanasopoulos, G.A.: Liquefaction resistance of sand-silt mixtures: an experimental investigation of the effect of fines. Soil Dyn. Earthquake Eng. 23, 183–194 (2003)

Sitharam, T.G., Govindaraju, L., Srinivasa Murthy, B.R.: Evaluation of liquefaction potential and dynamic properties of silty sand using cyclic triaxial testing. Geotech. Test. J. 27(5), 423–429 (2004)

Maheshwaari, B.K., Singh, H.P., Saran, S.: Effects of reinforcement on the liquefaction resistance of Solani sand. J. Geotech. Geoenviron. Eng., ASCE 138(7), to be Published in July 2012

Maheshwari, B.K., Patel, A.K.: Effects of non-plastic silts on liquefaction potential of Solani sand. J. Geotech. Geol. Eng. 28, 559–566 (2010)

Tokimastsu, K., Yoshimi, Y.: Empirical correlation of soil liquefaction based on the SPT N-value and fines content. Soils Found., JSSMFE 24(4), 56–74 (1983)

Polito, C.P., Martin, J.R.: Effects of non-plastic fines on the liquefaction resistance of sands. J. Geotech. Geoenviron. Eng., ASCE 127(5), 408–415 (2001)

Dash, H.K., Sitharam, T.G.: Undrained cyclic pore pressure response of sand–Silt mixtures: effect of non-plastic fines and other parameters. J. Geotech. Geol. Eng. 27(1), 501–517 (2009)

Boominathan, A., Rangaswamy, K., Rajagopal, K.: Effect of non-plastic fines on liquefaction resistance of Gujarat sand. Int. J. Geotech. Eng. 4(1), 241–253 (2010)

Monkul, Murat, Yamamuro, J.A.: Influence of silt size and content on liquefaction behavior of sands. Can. Geotech. J. 48(6), 931–942 (2011). https://doi.org/10.1139/t11-001

Tsuchida, H.: Prediction and countermeasure against the liquefaction in sand deposits. Abstract of the Seminar in the Port and Harbor Research Institute (1970)

Beena, K.S., Unni Kartha, G.: Stone columns for liquefaction mitigation: an experimental investigation. In: 6th International Geotechnical Symposium on Disaster Mitigation in Special Geoenvironmental Conditions, IIT Chennai, pp. 169–172 (2014)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Beena, K.S., Jayakrishnan, V., Unni Kartha, G., Shafnas, P.S. (2021). Studies on the Effect of Fines Content on Liquefaction Resistance Using Shake Table Tests. In: Patel, S., Solanki, C.H., Reddy, K.R., Shukla, S.K. (eds) Proceedings of the Indian Geotechnical Conference 2019. Lecture Notes in Civil Engineering, vol 138. Springer, Singapore. https://doi.org/10.1007/978-981-33-6564-3_60

Download citation

DOI: https://doi.org/10.1007/978-981-33-6564-3_60

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-33-6563-6

Online ISBN: 978-981-33-6564-3

eBook Packages: EngineeringEngineering (R0)