Abstract

Vehicle fires in parking structures developing into large conflagrations are rare but can result in severe economic losses. It is important to understand the hazard posed by modern vehicle fires to determine whether current fire codes for parking garages are mandating adequate fire protection requirements. There has been an increase in the fire hazard from changes in vehicle design and increased use of plastics and other combustible materials in vehicle construction, along with denser parking of vehicles in parking structures. This manifests as faster flame spread within the vehicle, easier ignition and more rapid fire spread to neighboring vehicles. Based on the findings, test data from vehicles older than 2000–2005 model years should not be used as basis for development of codes and regulations. Open parking structures emerge as the main area of concern regarding fires in modern vehicles. The lack of any requirements for active protection systems in the fire codes, and trends in vehicle and garage design suggest that large, devastating fires in these structures could become increasingly common. The spread of fire between vehicles, especially from the initial to the second and third vehicles, is critical in determining the extent of the fire and the ability of the fire department to successfully control and extinguish. Future research should be conducted into earlier detection, sprinkler protection, and fire spread between vehicles to address the hazard.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The effect on fire dynamics in residential fires due to modern construction techniques, floor plans, and use of polymer materials has been significantly studied in recent years. Less effort has focused on the impact on fire hazards from changes in vehicle design and changes in production techniques and material usage in vehicle construction. Vehicles have become larger, with increasing amounts of flammable plastic materials replacing metals. The adoption of different motor technologies and the use of alternative fuels such as battery electric vehicles and hydrogen fuel cells present different vehicle configurations and burn characteristics. Large lithium-ion batteries and hydrogen fuel cells in vehicles may represent a change in the type of hazard and required fire protection and firefighting techniques in parking structures. These developments will have significant implications touching on many different areas, such as design of parking garages and vehicle carriers, suppression systems, as well as firefighter tactics.

A project was conducted to review the current literature on vehicle fire hazards and protection requirements, and thoroughly identify and evaluate the hazards associated with modern vehicle fires, including how, and to what degree, they may differ from older vehicles. Tests were sought out in published fire science literature where vehicle information was available, and where it would be possible to compare results across decades. A large number of vehicle fire tests conducted from the 1970s through the 2010s were evaluated. Tests were included for analysis if sufficient information was available about the vehicle model, and the tests were instrumented to yield data about the heat release output and mass loss of the vehicle. Two issues with this data were that many full-scale vehicle fire tests are dated as they use decades old vehicles (or do not report the model used) and the tests are conducted in the open with little instrumentation and hence minimal data on heat release and mass loss.

Current design guidelines, codes and criteria for vehicle storage facilities and carriers were evaluated, including how these structures and vehicles may be impacted by fires. A summary of some of the findings are from the project are presented here. The full report of this work is available on the NFPA Research Foundation website [1]. The report also discusses marine vehicle carriers in more detail, but with strict protection requirements and enforcement, and as evidenced by recent fire incidents, were found to be adequately protected from modern vehicle fires when these are followed.

2 Identification of the Problem

There is a concern that the materials used in modern vehicles has the potential to present an increase in energy content during a fire, both in intensity and duration, compared to older vehicles [2]. These changes in materials may have an impact on the fire hazard posed by vehicles. Especially concerning is that many design guidelines and standards were developed using supposedly conservative values based on vehicle fire tests performed many decades ago and assume there will be limited fire spread between vehicles before suppression (see for example [3, 4]). The assumptions, forming the basis for the fire resistance and suppression system requirements, may in-fact underestimate the hazards from a vehicle fire. If fires in modern vehicles do present a greater hazard due to the changing materials, the increased fire intensity will have an external impact on the design of parking facilities, mainly enclosed garages, vehicle carriers, ferries, and any other facilities where a large number of vehicles are densely positioned. The possible change in the fire hazard associated with modern vehicle design has two major causes:

-

1.

Larger vehicles with increased use of polymers and other combustible materials in construction. These materials often ignite easier, contain more chemical energy per volume, and burn more intensely and/or longer than legacy materials.

-

2.

Rapid growth of alternative fuel vehicles replacing internal combustion engines (ICE). These include plug-in hybrid electric vehicles (PHEVs), fully electric vehicles (EVs), and hydrogen fuel cell vehicles.

Changes to the design of parking structures themselves also contribute, as will be discussed later. Statistics on vehicle fires are published by National Fire Data Center and the US Fire Administration [5]. Analyzing data for 2002–2005, Ahrens [6] states that in the USA only 1% of vehicle fires, or 4300 annually (with 2 fatalities annually), occurred in “storage” locations, which include those in parking garages. Evaluating data for fires occurring in commercial parking garages in the USA for the period 2014–2018, Ahrens [7] found that on average there were annually 1858 fires, causing $22.8 million in direct property damage and 20 civilian injuries. The number of electric vehicles (EVs) on the road around the world has increased in the last few years representing between 2 and 4% of all sales. The rate of sales growth is also rising dramatically, nearly doubling from 2017 to 2018 [8]. Hydrogen fuel cell vehicles are currently less developed and still in the research stage, with a few thousand sold and refueling stations limited to a few test areas [9].

2.1 Notable Vehicle Fire Incidents

Though fires involving automobiles are not uncommon, there have been several incidents in the last decade that are noteworthy for the severity of the event. One of the larger recent events occurred in Liverpool, England in December of 2017 in an open, 8-level concrete parking garage with a 1600 car capacity. A fire starting in a single vehicle, suspected due to mechanical or electric failure, and spread to the whole parking structure, resulting in damage to over 1400 vehicles, and structural damage so severe the building will be demolished [10]. In accordance with local codes, the parking garage had no automatic detection or suppression system. Once the fire fully developed, fire crews reported additional vehicles becoming involved every 30 s [11].

Another fire with very extensive impact occurred in January of 2020 in an open parking garage at Stavanger airport in Sola, Norway [12]. The fire is reported to have started from an electrical failure in a 2006 model year diesel-fueled car [13]. The fire destroyed 200 to 300 vehicles inside the building, and part of the five-story steel structure collapsed. The building had no detection system, and even though the driver was in the initial vehicle when the fire started, news articles about the incident report that it took the fire department approximately 19 min from ignition until first units arrived [14]. The first firefighters claimed to have seen as many as 10 vehicles burning on arrival.

Automobile fires themselves are the second largest cause of fatalities in the US (after residential fires) [15]. However, most of the large, notable parking garage fires in recent years have led to large material losses, but have not involved any human fatalities and few injuries [7].

3 Current Protection Requirements

Fire protection requirements for vehicle parking structures are governed by national codes that vary between jurisdictions. For this analysis, those applicable to the USA, UK and European Union (EU) area were evaluated. In the United States and some other jurisdictions, the relevant code is National Fire Protection Association (NFPA) 88A, Standard for Parking Structures [16]. The European Union has no overarching building code requirements in this area, instead the codes are set at the member state level. The United Kingdom has a separate building code for its member countries. There are however many broad similarities in how parking structures are treated in these countries. In general, the requirements for parking structures deal with two points; fire resistance, manifested as a time to failure under a standardized fire test, and requirements for detection and extinguishment. As the composition of vehicle construction changes, the requirements for the structures may need to be adapted to provide adequate protection.

Throughout NFPA 88A and codes used in EU countries and the UK, a distinction is made between parking structures with an open configuration and those with an enclosed configuration. An open parking structure is typically one with distributed openings on two or more sides, with a given minimum of the total area of the outside perimeter and interior walls being open to the exterior. To ensure structural integrity, and limiting fire spread, open parking structures are typically required to only be constructed of noncombustible or limited combustible materials in standardized tests, except in specific circumstances, such as when equipped with automatic sprinklers or with mandated height limitations.

Open parking structures constructed of noncombustible materials are, per current codes in most cases, not required to have neither an automatic sprinkler system nor a fire alarm system. Enclosed parking structures are typically required to have both alarms and automatic sprinkler systems. The reasoning for the lack of protection requirements for open structures is likely one of practicality, as well as the capability of these structures to vent hot gases which slows fire spread, and possibly a faster fire department response as fires are more easily noticed and accessed in the interior. Practical reasons for limiting protection requirements in open parking garages include cost of installation and maintenance of these systems, the low rate of fire injuries in these facilities, and difficulties associated with operating water-based sprinkler systems in unconditioned parking structures. Car stackers, or automated-type parking structures, are required to have a sprinkler system, but a fire alarm system is not required. For the sprinkler system design, NFPA 13, for example, considers automobile parking structures(i.e. garages) as an ordinary hazard (group 1) while car stacker systems are considered an extra hazard (group 2) [17].

The International Building Code (IBC) [18] contains similar requirements to those in NFPA 88A and many other codes. In 2018, a change was approved (as modified) for the next 2021 edition of the IBC which require automatic sprinkler systems be installed in open parking garages with greater than 48,000 ft2 (4459 m2) fire area or 55 ft (16.8 m) in height [19]. An overview of the wide range of sprinkler requirements in car parks throughout the EU/EEA is summarized by the European Fire Sprinkler Network (EFSN) [20]. In most of the codes used in individual EU states codes, enclosed parking garages require sprinklers, and there is some requirement for automatic sprinklers in open garages above a certain floor area, height, or when located below an assembly or hotel occupancy. The floor area above which sprinklers are required in the EU countries surveyed varies from 1000 to 4500 m2, the latter a value larger than that proposed for 2021 edition of the IBC. Looking specifically at the largest EU countries, in Germany sprinklers are not required for car parks not underground or under other occupancies. In France there is no requirement for sprinklers for above ground, open parking garages per current codes. If sprinklers are installed, the required fire resistance rating for structural members can be reduced. The United Kingdom detail fire safety regulations in Approved Document B of the current building code (2010) [21]. Per the latest 2019 edition it does not require sprinklers in open parking facilities.

4 Modern Vehicle Fire Hazards

The protection requirements in NFPA standards, IBC and most European codes that deal with vehicle fires are based on certain assumptions about the fire hazard that a burning vehicle could present. This is necessarily influenced by the results from fire tests on vehicles available at the time the standards are created. In most areas there have been little change to the fundamental protection requirements since the 1970s except various revisions, editorial changes, and updates throughout the years. For example, provisions for natural gas vehicles and automatic stacker systems have been added. There are many developments to modern vehicles which may increase the fire hazard, including changes to materials, construction techniques, and use of the vehicle. In the US and Europe, vehicles (on average) have become larger and there has also been an increased use of plastics and polymers within the vehicle over the past few decades. Furthermore, there has been a rapid growth of vehicles using different power sources, replacing the traditional internal combustion engines (ICE).

4.1 Vehicle Sizes and Use of Plastics

There has been a steady increase in the use of polymeric or plastic materials in the auto industry. In most cases the plastics have a higher heat of combustion than the materials they replace (often metals) [23] yielding a higher chemical energy per weight of material, and more potential energy in the same volume [23]. Often, they also ignite and sustain a fire more easily, support more rapid flame spread, and produce more toxic smoke than the materials they replaced. In many sizeable consumer markets, there has also been a general shift to heavier and larger personal vehicles [24]. This could lead to more severe vehicle fires, either in intensity (peak heat release rate), fire duration, or both. As an example, two of the most popular vehicles in the USA for many decades were the Toyota Corolla and Ford F150. Both these vehicles increased in width over the period from the 1970s to 2018 by 21 cm (8.3 in) and 8 cm (3.1 in) respectively. The curb weight also increased by 430 kg (948 lb) and 150 kg (332 lb) for the Corolla and F150 respectively. The trend appears to be similar in the EU where the Volkswagen Golf has been among the most sold vehicle since the 1980s [25]. The Golf has undergone a similar increase in physical size and weight from 1st generation in 1974 to 8th generation in 2019. During this time the width increased from 1.6 to 1.8 m, and weight from approximately 800 kg [26] to 1336 kg [27] (with slight variation depending on trim options).

Data can be found on the amount of plastics used in the average vehicle fleet over time, mostly for the US market. Similar trends can be expected to apply to other Western markets. In developing countries, the vehicle fleet trends are likely to be different. Plastics are often used to reduce the weight of vehicles, primarily to improve fuel efficiency. But as customers have bought larger and heavier vehicles, the weight of the average vehicles has remained steady or gone up in the last decade, while the percentage and absolute weight of plastics used has similarly gone up. It is reported that the weight of the average light vehicle in 1976 was 1618 kg (3567 lb), which had risen to 1805 kg (3979 lb) in 2018, an increase of about 12% [22][28]. In this context, and throughout this report, “light vehicle” or “light-duty vehicle” denote passenger vehicles, excluding trucks. The Environmental Protection Agency (EPA) classify these as having a Gross Vehicle Weight Rating of less than 8500 lbs (3856 kg) [29].

The Economics and Statistics Department of the American Chemistry Council released a report “Plastics and Polymer Composites in Light Vehicles” [22] analyzing the material composition of light vehicles assembled in the NAFTA countries (USA, Mexico, and Canada), representing 16.8 million vehicles produced in 2018. Annual plastic content by weight is provided for 2008 to 2018. A report by Argonne National Lab [28] similarly analyzed the US light vehicle fleet providing annual data for 1995 to 2014. A government steel industry report from 1991 gives some 5-year average data for material content of US vehicles for the years 1976–1990 [30]. Combining these data sources, the weight of plastics in the average US/NAFTA vehicles from 1976 to 2018 are plotted in Fig. 1, in kilograms and as percentage of average vehicle weight.

When evaluating numbers in the EU, there is less centralized reporting, but a report by Gletty et al. [31] for ENSOP (Ecole Nationale Supérieure Des Officiers De Police) school for firefighters in France state that percentage weight of plastic, composites and rubber in the average vehicle has gone from 10% in 1989 to 25% in 2014. Note that this also include tires, which is excluded from the US numbers. Hence, an increase in plastic usage similar to that in the USA is found, but the difference in measurements makes it difficult to compare directly.

In large part, plastics usage has replaced metal in vehicle construction. For example, from 1970 to 2004, the average steel content per US vehicle dropped by 458 kg (1010 lb), a 32% reduction [32]. Many different types of plastic are used in vehicle interiors, cushions, panels, wiring, etc. Three types represent over two-thirds of the total plastic by weight in US light vehicles: polypropylene (PP), polyurethane (PU) and polyvinyl chloride (PVC). The percent of total plastic weight and heat of combustion for these are shown in Table 1 [22].

4.2 Plastic Fuel Tanks

Another development is the increasing use of plastic fuel tanks, which have largely replaced metal tanks. The share of cars built in Europe with plastic fuel tanks is reported to be over 85% today [3]. It was estimated to be around 75% for US cars in 2010 [34] and has likely risen since then. This will increase the amount of plastic in the vehicle on the order of 8 to 10 kg (18–22 lb) per tank (1995 numbers) [35] by replacing a non-flammable, metal fuel tank with high-density polyethylene (HDPE) plastic. This could also potentially result in the earlier release of fuel from the tank, in the case of fire in the vehicle, or in adjacent vehicles. If, for example, fuel leaks from a vehicle and ignites, the fuel could run under several neighboring vehicles in a garage, ferry or transport vessel, and melt the fuel tanks of those vehicles. This could result in more rapid fire spread to multiple vehicles in short order. The heat transfer through the tank into the fuel inside is faster with a metal tank, which can lead to a pressure increase and potentially cause leaking at the fittings. But testing showed that this process occurs slower than the melting of a plastic tank [36]. However, with a sufficiently severe thermal exposure, both plastic and metal fuel tanks will eventually leak or rupture.

4.3 Alternative Fuel Vehicles

Increasing usage of alternative fuel vehicles such as electric vehicles, hydrogen fuel cells and LNG powered vehicles present different fuel types and configurations, sometimes resulting in dramatically altered fire characteristics. It is important to note that even though hydrogen fuel cells and large battery packs represent high-density fuel sources, they replace the gasoline stored in ICE vehicles (an exception being hybrid vehicles). The degree to which the fire hazard is increased with an alternative fuel vehicle compared to a traditional vehicle, or simply changed, needs to be established, and can depend on the environment where the fire occurs.

Lithium-ion batteries used in modern EVs present a different fire hazard than traditional ICE vehicles [37]. Fires in lithium-ion batteries are more difficult to extinguish than gasoline or diesel fires, requiring large amounts of water to fully contain the hazard. Fire crews are required to apply water to the exterior of the battery pack for hours, while continuously monitoring the temperature [38]. Even if there is no immediate fire following a collision, damage to the integrity of the battery pack can result in thermal runaway with later ignition and reignition which has proven difficult to contain [39]. The EV brand Tesla started installing a metal plate under the vehicle floor pan to protect the battery from impact after fire incidents involving EVs, where it was suspected that impact damage to the battery from road debris initiated thermal runaway and a fire [40].

The main hazard from a hydrogen fuel cell vehicle is rupture of the hydrogen storage tank and release of the gas. Due the high storage pressure, leaking or burning hydrogen would be ejected in a jet, as opposed to a gasoline-fueled car where the spilled fuel gathers underneath the car. In an open space without a ceiling, the vertical flame can be a benefit compared to a running pool fire, but a powerful hydrogen jet flame could present a new, unexpected hazard in an enclosure such as a parking facility, multi-level vehicle storage, or vehicle carrier vessel. A hydrogen fire can also be virtually invisible to the naked eye [41], which poses a large risk to first responders, and possibly to certain visual-based fire detection systems. Hydrogen fuel cell vehicles are still in a very limited test release phase, estimated at about 6000 vehicles in the USA, and 12,000 worldwide (as of 2018) [9]. These vehicles are operating in small test areas with a few refueling stations. Issues with hydrogen fueled vehicles will certainly be a concern in the future and should be further studied as the fleet size and use area increases. They are not yet close to widespread adoption so the specific hazards from hydrogen vehicles will not be further discussed.

4.4 Modern Parking Structures

There have been changes in parking garage configurations, often driven by a high cost of property and lack of space in urban environments. This has led to multi-level parking garages, often integrated with other buildings such as shopping or restaurant venues [42]. Vehicle stacking systems and similar methods for more dense space usage pack large vehicle fire loads into smaller areas and to greater heights. These systems use various configurations, such as lifting one vehicle directly above another, lifting a vehicle at an angle to park another partially under or “car vending machines” where vertical and horizontal lift systems move vehicles in and out of storage towers. Use of every available surface in a structure also leads to parking spaces being placed on access ramps between levels. This presents a hazard in the case of a gasoline leak (either from a fire or some other cause) as the fuel will run down under other vehicles, potentially spreading the fire to multiple neighboring vehicles. This scenario makes multi-vehicle conflagrations more likely. Fires in parking garages are relatively rare events, with the fire frequency lower than in other occupancies, but still account for over 4000 fires per year in the USA [6].

4.4.1 Building Design

The goal when designing commercial parking structures is to minimize the amount of area used by each vehicle for efficient use of space. Typical parking structures in the USA are designed with each individual space requiring around 30 m2 (322 ft2) [43], which includes the space needed for maneuvering in the garage. The area of the parking space is much smaller, typically less than 18.5 m2 (200 ft2), with widths typically less than 3.05 m (10 ft). In Europe the spaces tend to be smaller still. For example, the French standard NF-P 91-100 [44] set the minimum size as 2.3 m wide (7.5 ft) by 5 m long (16.4 ft), with a single track traffic lane at least 3 m (10 ft) wide. Giving total minimum space as low as 18.4 m2 (198 ft2). In the United Kingdom the norm is described as being 2.4 m (7.9 ft) wide by 4.8 m (15.7 ft) long, with a 6 m (19.7 ft) roadway between, for a total of 25.9 m2 (279 ft2) [45].

As cars have become larger and wider, the distance between adjacent vehicles has shrunk, making fire spread from vehicle to vehicle more likely. The geometry of the parking structure will have a large influence on fire spread. Even in an open garage there are ceilings, beams and walls, resulting in a hot upper layer of gases which heat the surrounding vehicles and ignite exposed combustibles. Access to fresh air may be limited, potentially stagnating overall fire growth, but possibly promoting incomplete combustion and more toxic fire products (e.g. high levels of CO). Open structures will, in theory, allow the fire products to vent, but there will also be ample fresh air to sustain burning and environmental elements such as wind can affect fire spread. The ventilation can also be compromised, as was noted in the report after the Liverpool car park fire in 2017, several sides of the parking garage were almost completely covered in plastic advertising posters, which severely reduced the airflow [3].

Stacker systems are required to have an automatic sprinkler system per NFPA 13, but with the upper vehicle obstructing the water spray, it is only expected to control the fire and limit spread until the fire department arrives. The increased application density and reduced protection area associated with an Extra Hazard 2 classification is intended to ensure this is successful. To reduce the density requirements, sprinklers can also be placed between each of the vehicles where they would have a greater chance of fully extinguishing the fire. Testing of a two-car stacker system, without sprinklers, by Building Research Establishment (BRE) in the UK [46] found that the fire quickly (within 10 min) reached 8 MW and was difficult to extinguish due to the orientation of the fuel packages and ability to preheat and ignite the vertically adjacent vehicles.

5 Modern Vehicle Hazard Assessment

The hazards associated with modern vehicles were analyzed from both sides of the issue:

-

1.

Impact of changes to vehicle design, material use and fuels

-

2.

The design of fire protection systems used for parking and vehicle storage.

This established a picture as to the degree the various types of modern vehicles represent a changed fire hazard compared to legacy vehicles. The changes to modern vehicle construction and materials that was discussed in Sect. 4 have an effect on the fire behavior in several ways, including peak heat release rate (HRR), fire duration, and heat flux to nearby objects.

5.1 Vehicle Design

5.1.1 Heat Release Rate

As described in Sect. 4, the total amount of plastics and polymers used in vehicles has increased over the years, and these materials have typically replaced non-flammable materials such as steel or aluminum. The total fire energy from a vehicle generally scales with weight. Thus, it can be assumed that the change in available chemical energy is directly equal to the weight of plastic added, multiplied by the heat of combustion for the material.

There is not a substantial amount of heat release data for burning automobiles and the data that is available is not consistent in how the tests were configured, including ignition sources, data collection, and other variables. This leads to scatter in the data, making it difficult to make any definitive conclusions. A number of full-scale fires tests were evaluated, and the most useful data are presented below.

5.1.2 Vehicle Fire Tests

Tohir and Spearpoint [24] gathered and summarized a large amount of data on free-burn, full-scale vehicle fire tests (with vehicles up to 2002 model years), including where available; model year, curb weight, mass loss, peak heat release rate, and total heat released. They attempted to establish a correlation between vehicle model year and peak HRR.. The data shows a wide range of peak HRRs, making it difficult to establish clear correlations due to limited number of tests of similar size vehicles across several decades. As the data in Table 2 from multiple sources shows, there are light-weight vehicles with peak HRR over 8 MW, and medium- and heavy-weight vehicles with a HRR less than 3 MW. Analyzing the data from various tests and looking at the mass loss as a percentage of vehicle weight, it is found that there is a wide range in this value, from 13 to 25%. However, the mass loss percentage does correlate with the peak heat release rate. Some tests had, for various reasons, more complete burning of the vehicle than others. In general, the tests with a mass loss percentage below about 17% show a much lower peak HRR compared to other tests of similar size vehicles. A selection of fire test results was chosen based on having a higher mass loss percentage, from about 17 to 25%, indicating more complete burning of the vehicle, and a higher peak HRR. Details of the tests are shown in Table 2. The data is from Tohir and Spearpoint, Lam et al. [47] and BRE [46]. The data has been sorted by increasing mass loss percentage as it is generally associated with larger fires.

As the table indicates, there is no obvious correlation between peak HRR and either age of vehicle or curb weight. The placement and method of ignition, as well as ventilation and other environmental factors, has a large impact on how a vehicle fire develops. If the mass loss percentage is high (20%+), both older and smaller vehicles can yield high peak HRRs and total heat released. It is important to note that the mass loss percentage is of total mass, not combustible mass. As the percentage of vehicle weight that is made up of plastic (replacing non-combustible items) has increased since the 1970s, it has thus become increasingly likely that a higher percentage of the vehicle weight is consumed in a fire. It is shown that both older and newer vehicles are able to produce large fires (7 MW or greater), but it is possible that it is more likely to occur with modern vehicles. This data is not conclusive in this hypothesis however.

The fire sizes used as the basis for parking garage fire codes are not explicitly stated, but there are design fire scenarios for tunnel fires where values such as peak HRR is provided. For example, Ingason [48] summarized several HRR values provided as guidelines for tunnel design. This included a car fire scenario of 4 MW peak HRR, proposed by Ingason in 1995. Reference is also made to French regulations, where a design fire with peak HRR of 8 MW is associated with “2–3 cars, tunnel height 2.7 m”. Comparing this to the HRR data for a single car fire shown in and Table 2, it is clear that these proposed design fires for tunnels will underestimate the peak HRR for a single car fire in many instances. Another document on tunnel design fires published by National Cooperative Highway Research Program (NCHRP) in 2011 [49], references a number of vehicle HRRs from different sources. Several single vehicle HRRs are again around the 5 MW range, for example a design fire from Germany, and a reference to “absolute minimum water requirements” that specifies a car fire as 5 MW. The article does reference the 2008 edition of NFPA standard 502 “Standard for Road Tunnels, Bridges, and Other Limited Access Highways” [50], which specifies a car fire as 5–10 MW. This range does encompass the peak HRR of the majority of single car fire tests reviewed here, but with such a wide range it leaves important decisions up to the discretion of the designer.

5.1.3 Plastic Fire Energy

Using the data documented in Sect. 4.1, an estimate of the increase in heat release rate associated with the growth of plastic use can be calculated with assumptions made for the heat of combustion of the plastics. This will vary with the type of plastic, from about 15 to 43 kJ/g [33] [51]. Heats of combustion were found from the literature for all but four of the plastics, which represent a total of 10.1% by weight. The weighted and absolute average heat of combustion for the remaining 90% were both around 30 kJ/g (30.3 and 29.5 kJ/g respectively). Evaluating the changes in plastic content over time shows that for the three 5-year periods from 1976 to 1990, the total heat content (i.e. fire energy) from plastic content increased by an annual average between 47 and 52 MJ per year. Noting that there is a data-gap from 1991 to 95, the increase in plastic energy content from 1995 onwards was an average of 65.5 MJ/year. The total increase in energy content from plastics in the average vehicle (in the USA/NAFTA) from 1976 to 2018 was 2298 MJ, a total increase of 91%. The increase in vehicle curb weight and plastic fire energy is plotted in Fig. 2.

A series performed on vehicles from the 1970s [4] gave an average value of 3300 MJ over three vehicle tests. Using this value, the 2298 MJ increase in potential fire energy from the plastic content up to 2018 represents a 70% increase in total fire energy from a full vehicle fire from 1970s. This is clearly a major increase in potential fire energy. Other factors may be important to the fire dynamics as well, such as the ease of ignition of plastics, and more rapid fire growth rate of vehicle fires involving significant plastic content.

5.1.4 Fire Spread

When used externally on the vehicle to replace previously non-flammable metal components, plastic components can contribute to faster fire spread through the initiating car, and also to neighboring vehicles. There is also an increasing amount of plastics in the engine compartment of modern vehicles. A test series reported by the Motor Vehicle Fire Research Institute (MVFRI) found that in the case of post-collision fires, the plastics and flammable fluids in the engine were able to sustain a fire large enough to penetrate into the passenger compartment [52]. In addition to threatening the occupants, the passenger compartment is where the largest amount of flammable materials are located. The interior materials can sustain a fire with a higher potential to spread beyond the vehicle of origin. Fires that do not spread into the passenger compartment are typically much less severe or may even burn themselves out before spreading to adjacent vehicles [46].

Tohir [53] provides a summary of the multi-vehicle full-car fires that have been performed with adequate details to make a reasonable analysis on fire spread. Tohir [53] cites three studies as the most detailed and reliable; Joyeux [54], Steinert [56], and BRE [46]. These studies had vehicles spaced between 0.4 and 0.8 m (1.3 to 2.6 ft) apart. As detailed in the studies, ignition of the second vehicle took place between 5 and 28 min after ignition of the first vehicle, typically due to radiative heating of rubber components of the adjacent vehicle. As can be seen from the dates of these tests, most of the cars used in the testing were decades old, indicating the need for updated testing with more current vehicles.

Testing by the BRE in the UK on flammable exterior materials for vehicles found a critical heat flux range of 11.0–18.5 kW/m2, with most plastic components at the upper end of the range; bumpers at 17.5 kW/m2, fuel tanks at 16.5 kW/m2, and the tires near the bottom at 11.0 kW/m2. An upper layer temperature of 500–600°C is typically associated with the criteria of incident heat flux on the floor of 20–25 kW/m2, where most ordinary flammable materials in residential settings will ignite [57], thus the temperature criteria would be lower for these vehicle components. As discussed in Sect. 3, parking garages often have limited ceiling heights, due to cost and space concerns, or to conform to apartment or retail ceiling heights for surrounding occupancies in multi-use buildings. The buildup, and trapping, of hot gases is therefore critically important when considering fire spread in parking structures.

5.1.5 BRE (UK) Vehicle Fire Tests

A full-scale test series by BRE involved several multi-vehicle car fires in a parking garage mockup [46]. The tests found that with the second vehicle involved the ceiling temperatures reached 1100°C, and a third car that was separated from the two others by an empty parking spot quickly ignited. The BRE test series involved a “car park enclosure”, which was not a fully open garage. There was extensive ventilation around the vehicles, approximately 10 m2 of openings, including a fully open wall. The openings on the walls were low to the ground, supplying air to the fire, but not venting hot gases as might be the case with a fully open configuration. Large beams and beam pockets are also common in multi-level parking garages which can trap hot gases. Beams were relatively shallow in the BRE garage mockup. The BRE tests can therefore be considered somewhere between an enclosed and fully open garage; the ventilation area is more than is expected in, for example, a small underground garage but venting of hot gases is more restricted than in a code-defined open configuration.

Many parking garage codes require a one hour or more resistance rating for structural members, for example NFPA 88A required open garages have a fire resistance rating of 1 to 2 h. Per the E119 curve, that means the ability to resist a max temperature exposure of just over 1000°C at around 2 h [58]. In the BRE testing it was found that a temperature of over 1100°C can develop under the ceiling in even a relatively open garage with single vehicles burning after 5–10 min, significantly earlier than prescribed in the E119 testing.

5.1.6 Plastic Fuel Tanks

A plastic fuel tank in passenger vehicles will introduce approximately 8 to 10 kg (18–22 lb) of HDPE (high-density polyethylene) to the vehicle [28]. With polyethylene (PE) having a heat of combustion of 43.6 kJ/g [33] in a fully involved fire this would yield at least 371 MJ of energy released. Compared to the total fire energy of a fully involved vehicle (3500 MJ and up) this is a relatively small contribution. The large mass of plastic, and high heat of combustion results in replacing a metal fuel tank with a plastic one will account for 16% of the increase in potential fire energy from added plastic in vehicles from 1970 today. It should be noted that the fuel tank is already included in the total vehicle plastic content calculated above.

An important concern with plastic fuel tanks is the release of fuel when exposed to an external flame. There are fire resistance requirements for plastic fuel tanks, specified in the United Nations document ECE R34.01, Annex 5 Sect. 5.0 “Resistance to Fire” [59]. This standard requires a tank to show no leak of fuel after exposure to a direct flame for 2 min. The flame source is from a pool fire, typically using diesel or gasoline, that is slightly larger than the footprint of the tank, and a distance away equivalent to the height above the road as the tank would be installed in the vehicle. In the case of burning gasoline underneath a car from a full fuel tank release, the fire exposure could last much longer than the two minutes required in the tests. The concern with the two-minute requirement lies in the inability for firefighting personnel to arrive in that timeframe to extinguish a fire before the tank would melt and empty its contents. Furthermore, even if the structure is sprinklered, the fire would be shielded which could slow down sprinkler activation time and inhibit extinguishment. Based on this requirement, a worst-case assumption could be that a plastic fuel tank would leak fuel after two minutes of direct fire exposure. A series of tests performed by the Southwest Research Institute, and summarized by Digges [60, 61], tested six different fuel tanks placed above fires that lasted past the two-minute requirement. The time when the tanks started to leak fuel was found to be from 10 s before the two-minute requirement, up to 2:36 min after the two minutes (i.e., 1:50 to 4:36 min). It should be noted that the failure before the two minutes was performed on a tank installed in a vehicle already damaged by fire, which could have led to increased ventilation. Per this testing, in a best-case scenario, a plastic fuel tank will leak fuel 4:36 min after exposed to an under-car fire. Only one metal tank was tested in this series. It was found to fail 4:22 min after the required time, i.e., 6:22 min after the fire started. The plastic fuel tank failed due to leaks and minimal venting whereas the metal fuel tank developed excessive pressures and vented large amounts of fuel vapors.

5.2 Battery Electric Vehicles

The two main types of alternative fuel vehicles that are in use or development are fully battery-electric vehicles (EVs) and hydrogen fuel cell vehicles. As noted in Sect. 4.3, hydrogen vehicles are not yet close to widespread use so these vehicles will not be evaluated here.

5.2.1 Battery Energy Release

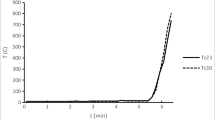

Two pairs of similar EV and ICE vehicle models from two manufacturers were tested by Lecocq [62]. The first pair were smaller vehicles, both around 1100 kg, while the second pair were larger at 1400 and 1500 kg for the ICE and EV model respectively. The vehicles were ignited by a gas burner placed in the front seat, with the window open. The peak heat release rate results were similar for the first pair at 4.2 MW and 4.8 MW, with the ICE vehicle being higher. For the second, larger pair, the EV had a peak of 4.7 MW, while the ICE vehicle had a peak HRR of 6.1 MW. The HRR plots for all four tests are shown in Fig. 3. The ICE vehicles are represented by solid lines, while dotted lines are used for the EVs.

Heat release rate for two pairs of similar ICE and EV vehicles for tests conducted by Lecocq [62]

The figure shows that the heat release rate for the first vehicle pair is very similar, both in peak HRR, and in growth rate. The second pair start with similar growth for the first 20 min, when the HRR for ICE 2 rapidly increased to its peak value and stays higher than the EV 2 curve until near the end.

Another paired-vehicle test series using sets of similar ICE vehicles and EVs were performed by Lam et al. [47] of the National Research Council Canada. All vehicles were exposed to an identical, realistic simulated pool fire; a propane burner placed underneath the vehicle. The HRR was measured by a hood, as well as temperature and heat flux. This test is also a good representation for the dynamics of fire spread between vehicles in a garage or carrier vessel caused by burning, leaking fuel pooling under the neighboring vehicles. The findings from the study concluded that:

Overall, the EVs did not present a greater hazard than the ICEVs. The peak HRR and heat flux levels measured in the ICEV tests were due to the burning of a full tank of gasoline and were higher than those measured in the comparison EV tests.

The tests also found that the peak HRR from the burning gasoline occurred at the same time or earlier than that for the EV batteries. A later study of EV fires by Sun et al. [63] also found that peak heat release rate for EVs and ICEs is similar, but state that further study is warranted for other aspects of lithium-battery fires, such as re-ignition, thermal runaway, and storage and charging of large number of vehicles inside structures. As the fuel tank or batteries placed underneath the vehicle is the main distinguishing feature between ICE vehicles and EVs, a pool fire placed under the vehicle is likely the fire scenario where the largest differences between the two vehicle types would manifest. The other difference could be in ignition and the response to collision damage and effects of a fuel leak versus a damaged battery. Testing that has been performed on EVs and ICEs indicate that when ignited externally, EVs can yield similar HRR as ICE vehicles. But there is still limited data on fires resulting from thermal runaway in a full battery placed in an EV. More research is needed on battery failures leading to fully involved EV fires.

There is currently rapid development of EVs (especially compared to ICEs), where new models have dramatic changes in the vehicle design that could significantly change the behavior in a fire. For example, the trend for larger, more energy-dense battery packs, or double electric motors (front and rear) for improved performance alters the fire properties of a vehicle significantly. This can make it difficult to draw conclusions based on EV fire tests performed on models even just a few years old. As the peak HRR depends on the battery capacity [63], this is an important factor when determining whether tests are applicable to current vehicles, or the ones used in a given location. Results from testing performed on an EV with a 40-kWh battery cannot necessarily be directly applied to a large vehicle with a 100-kWh battery. As older EVs and/or smaller battery packs are much cheaper to acquire for testing, there are financial obstacles to getting data on the newest and largest EVs on the market.

5.2.2 EV Fire Extinguishment

As shown in Fig. 3, this test performed on two pairs of similar ICE vehicles and EVs find that peak HRR is lower for the EV in each case, and largely similar in growth rate and fire development time. Despite similarities in fire characteristics, there are some fundamental differences in burning behavior between ICE vehicles and EVs. For ICE vehicles in a fire, the fuel tank will eventually rupture or melt, and depending on the nature and orientation of the surface underneath, free-flowing gasoline can disperse from the burning vehicle and spread the fire to neighboring items. A lithium-ion battery back will remain in place, generally underneath the passenger compartment making up the floor of the vehicle. As the fire penetrates the layers of the battery, high-temperature jet flames can occur which can extend some distance from the vehicle. This flame may or may not extend further than running gasoline would, as that depends on the slope where the vehicle is parked, and the nature of the battery rupture. In a narrow parking spot this flame could ignite another vehicle parked immediately next to the EV. The recommendations to firefighters to deal with EVs is to apply very large amounts of water directly to the outside of the battery, potentially for several hours [38]. These issues are important for firefighters to keep in mind and are a concern for extinguishment tactics, water supply and containment of the fire.

5.3 Modern Vehicles Fire Spread

The combination of several factors discussed previously has led to changes in vehicle fire hazards where a major concern has become the spread of fire between vehicles. Factors such as changes in the mix of vehicle construction materials, overall enlarging of vehicle physical dimensions, and tighter parking arrangements has increased the risk of fire spread between vehicles. It appears that fire spread from vehicle to vehicle was not considered a major risk in the early versions of the codes, using data from tests of older vehicles and considering less compact parking structure designs.

For example, the introduction to a study by Mangs and Keski-Rahkonen [4] of vehicles built in the 1970s notes (emphasis added) “In an open car park building, the fire is likely to be constrained to the burning car or at most be spread to one or two adjacent cars”. As the report on the Liverpool/Kings Dock car park fire of 2017 noted [3] (emphasis added): “in 1968, The Ministry of Technology and Fire Offices’ Committee Joint Fire Research Organization researched and concluded that fire spread from one vehicle to others would not occur and that if it did, the Metropolitan Brigades would invariably be in attendance within 3 to 4 min”. First published in 2001, NFPA 1710 “Standard for the Organization and Deployment of Fire Suppression Operations, Emergency Medical Operations, and Special Operations to the Public by Career Fire Departments” [64] sets a benchmark goal of a total response time of the first fire engine in 5:20 min, and 9:20 for full assignment of larger resources, for 90% of incidents. However, not all fire departments are able to achieve this. For example, a study by International Association of Fire Fighters (IAFF) noted that 34% of fire departments surveyed exceeded the travel time limits for both the first-due engine and the full response [65]. Time must also be account for to navigate modern large and cramped parking structures, which can take well beyond 3 to 4 min. As surveillance video of the Liverpool Echo Arena fire showed, the fire was not even reported to the local fire department until at least 13 min after smoke was first observed, and the fire department arrived at 21 min after observation of smoke [3].

A series of tests evaluating the fire spread between vehicles in different parking configurations (side by side, front to front) were performed in the UK [46] using vehicles constructed in the late 1990s to early 2000s. The tests found that fires starting inside the cabin spread to adjacent vehicles after 10 min in one test, and after 20 min in two others. In one test, ignition of a third vehicle two spots over occurred less than 5 min later. After spreading to the second vehicle the fire quickly grew beyond 10 MW. If the fire department is not on the scene before the fire spreads to the second vehicle, there is a high likelihood they will be unable to extinguish it with the first on-scene equipment, or even contain the spread, as has been the case in several recent parking garage fires.

5.3.1 Spill Fire as Method of Fire Spread

One possible scenario in which multiple vehicles can become involved in a parking structure fire would involve the leaked contents of a fuel tank igniting and spreading the fire to surrounding vehicles. Nearly all modern vehicles use plastic fuel tanks, which are mandated to remain intact for two minutes when exposed to direct flame impingement. Testing has shown that most tanks remain intact for 2 to 4 min, before starting to leak their contents to the ground below [60]. The behavior of the fuel upon tank rupture is critical to determine the conditions under which the spread of the fire to adjacent vehicles is possible.

A number of researchers have studied the spread of liquid fuels in spills and the effect of this burning configuration on fire dynamics. Notably, Putorti [66] and Mealy et al. [67][68] have studied fuel spills for a wide range of fuels, including gasoline and diesel. These studies have also looked at the effect of the substrate on the fire characteristics, including concrete which would be a typical flooring material in parking structures (asphalt is typically only allowed on the lowest level [18]). Important parameters for a burning fuel spill include the spill dynamics (i.e., size of the spill, thickness of the fuel layer etc.), flame dynamics (heat release rate and burning rate of the spilled fuel, etc.) and time of ignition relative to start of the spill. Measurements on flat, level surfaces have found that spills, especially of limited volumes of fuel, will have lower heat release rates than of pan fires with the same fuel. This is due to the thin fuel layer of the expanding spill and heat transfer to the surface substrate. This impedes the heat feedback mechanism that allows for liquid fuel vaporization and reducing the fuel burning rate and heat release [69]. The heat release rates can be substantially less than found for confined pool fires in metal pans [68]. Eventually the fuel layer becomes so thin that the heat loss to the substrate becomes greater than the heat feedback from the flame, preventing further fuel vaporization and the fire is not sustained.

The heat release rate of the fire is greatly impacted by the time of ignition relative to the start of the spill. Ignition immediately after the fuel is spilled can lead to larger heat release as the fuel layer thickness is deeper as the fuel has not spread and the pool has not thinned out. If ignition does not occur until later after the spill begins, especially for a finite fuel volume, the fuel may spread leaving a thin layer with reduced heat release potential. Hence, it is unclear how effective an ignited fuel spill would be for spreading fire from a burning vehicle to adjacent vehicle. If the adjacent vehicles are quite close and ignition occurs before the spill area becomes large and the fuel layer becomes quite thin, spread to adjacent vehicles may be possible. A sloped ramp will allow the fuel to reach the neighboring vehicle but will also more quickly reduce the thickness of the pool. The interaction between these competing effects must be studied further. Tests have been performed to determine the time required until the fuel tank leaks [61, 62], but these did not evaluate what occurs once the fuel is released.

5.4 Thermal Effects of Modern Vehicle Fires

As was found in testing by BRE, the ceiling temperature that develops above a burning modern car inside a parking garage can, in as little as 10 min, reach the value associated with the 2-h mark in the ASTM E119 testing (and the similar ISO fire curve). A fire in a single vehicle will start to burn out and will not sustain this temperature as long as the E119 curve, but with more vehicles parked close by catching on fire, the structural elements can very quickly be exposed to a significant fire load, potentially more severe than what is experienced in the standard tests used for design purposes. Ship and Spearpoint [70] tested relatively small cars in a low (2.2 m) corridor-like configuration, to simulate a fire in the France-England Channel Tunnel train shuttle wagons. Under this configuration the ceiling temperatures reached above 1000°C at around 7 min. These results show that the typical configuration of a parking garage will have a significant effect on the resulting hazards from a vehicle fire, including fire spread. This configuration may not be fully accounted for in the fires used for building design if data from less confined tests are used.

5.4.1 Spalling of Concrete

Concrete spalling is reliant on high temperatures over a long period of time, potentially several hours, and is a complex phenomenon that is difficult to predict [71]. But generally, internal concrete temperatures are required to reach at least 374°C, the critical point of steam. Any constant exposure above this level can eventually lead to spalling, and the higher the concrete temperature the quicker it occurs. Significant spalling was observed in both the Liverpool, England 2017 fire (see Fig. 4) and the Stavanger, Norway 2020 parking garage fire (Fig. 5), and is an active area of research [72]. The spalling created large penetrations between the different garage levels and undoubtedly contributed to vertical fire spread. It is important to note that spalling typically occurs after several hours, once the fire has grown to a substantial size [71]. The spalling phenomenon is unlikely to have any effect on the early phases of the fire. It is not unique to vehicle fires and has the potential to occur in any building with uncontrolled fire spread through a large fuel load.

Concrete spalling in Liverpool, England 2017 fire [3]

Concrete spalling in Stavanger, Norway 2020 fire [74]

5.4.2 Failure of Structural Steel

The critical temperature for steel is usually taken as 538°C (1000°F), where the modulus of elasticity of construction steel has been reduced by half, and deformations become permanent [73]. The critical temperature refers to the internal steel temperature, but with the high heat transfer coefficient of uninsulated steel this can occur rapidly once the air temperature reaches similar levels. Vehicle fire tests with a lower ceiling height have found that these temperatures are measured within a few minutes after ignition of the vehicle. With a single burning vehicle, it is not certain a high enough ceiling temperature can be sustained for long enough to pose a threat to overhead load-bearing steel members, especially in a well-ventilated open garage configuration. But with fire spread to multiple vehicles, it is likely that this scenario has the potential to rapidly threaten the integrity of steel structures. The most dramatic example of this is the collapse of large parts of the steel parking garage at the Stavanger Airport after a fire in January 2020. One news article reports that the steel structure started to collapse after “nearly two hours” [74] though the specific timeline has not been confirmed. Columns and beams in the garage that collapsed were constructed of unprotected steel, with pre-cast concrete floors elements. The building had been granted a deviation from the local code-required 15-min fire resistance for steel members, needing only a 10-min fire resistance [75]. This deviation was granted based on the belief that local fire departments would be on the scene early enough to control and/or extinguish a fire in the structure.

For high-rise building construction, there is extensive research on fire protection of load bearing steel members. A multitude of techniques exist to increase the fire resistance to a range of levels, depending on the application and code requirements, from intumescent paint to full coverage in insulated batting. The different systems will have varying cost of installation and maintenance, as well as architectural impact, and most can be applied directly to parking garage design.

5.5 Vehicle Stacking Systems

A single test of a sprinklered two-car stacker configuration was performed by BRE in September of 2009 [76]. This test showed that sprinklers placed overhead contained the fire to the lower vehicle, allowed some spread to the above vehicle, but prevented it from becoming fully involved. This was a replication of a test performed with no sprinkler protection in January 2009 [46] where both vehicles became fully involved and consumed by the fire. The sprinklers were installed in accordance with protection requirements for an Ordinary Hazard 2 item, as the European standard for sprinkler systems; BS EN 12,845, does not explicitly cover car stackers. Per the NFPA codes, a car stacker system is specifically classified at a higher level; Extra Hazard group 2. This includes four quick response sprinklers above both cars, including sprinklers in the stacker system.

The fire was ignited on the seat of the lower vehicle. After 13 min the first roof sprinkler activated, followed by a second at 23 min, and were left on for one hour before being shut off. The fire continued to burn after this. After the test it was found that the lower vehicle was almost entirely consumed by the fire, while the upper vehicle suffered significant exterior and engine compartment damage, but fire never spread to the interior. The test showed that two activated overhead sprinklers control and limit the spread of the fire in the stacker system, but does not extinguish the fire, nor prevent total consumption of the lower vehicle. Photographs of the two tests show the upper vehicle fully involved at 10 min in the non-sprinklered test, while in the sprinklered test at 1 h 23 min show no flames inside the passenger compartment of the upper vehicle.

6 Existing Design Criteria and Modern Vehicle Fires

The current design of parking garages is dictated by the fire safety codes and regulations. While catastrophic vehicle fire incidents remain relatively rare, the impact when the fire spreads out of control can be extreme. Consider that the annual property damage caused by all vehicle fires in the USA averaged US$22.8 million (2014–2018) [7]. The Echo arena fire in Liverpool, England will by some estimates cost almost US$25 million [77]. The direct property loss associated with the Stavanger, Norway fire is estimated as high as US$47 million, which is not including flight disruptions at the airport [78]. To what degree the current protection requirements in NFPA 88A and IBC 2019 edition (as well as other codes with similar requirements) are appropriate for the hazards will be discussed below for the two types of parking garages: enclosed and open.

6.1 Enclosed Parking Garages

Enclosed parking garages (including those attached to or within other occupancies) which require automatic detection and notification systems, as well as sprinkler or smoke extraction, appear to be well-protected against modern vehicle fires. The limited number of tests of full vehicle fires with overhead sprinklers in a typical garage configuration show that the sprinklers are able to extinguish the fire. In the case of fire within a vehicle stacker, where the lower vehicle is burning, the sprinklers may only be able to control the fire and prevent further fire spread. Testing at BRE showed that the fire flared back up when the sprinklers were turned off. But with sufficient water supply this should allow firefighting personnel to arrive and extinguish the fire. Note that this testing was only done on a two-level stacker system with sprinklers over both cars. It is unclear how the sprinklers would perform on larger systems, or a stacker with only ceiling level sprinklers. The sprinkler requirements for enclosed parking structures are likely to prevent large, out of control fires in these structures if systems are correctly designed, maintained, and operational. Some questions remain regarding the ability to properly protect larger stacker systems.

6.2 Open Parking Garages

With regards to civilian injuries, the current codes for open parking garages could be considered very successful. In the US, there is an annual average of fewer than 20 people injured in over 1800 parking garage fires, some of whom are also intimate with the fire, (i.e., inside the initiating vehicle). This is due to several factors; people spend little time in parking garages, typically are awake, and are usually spread out. The egress paths are also clear, numerous, and easy to reach. Structural integrity requirements are mainly for the benefit of firefighters and property protection. Considering property loss, the findings indicate that modern vehicle fires present an unacceptable hazard in open parking structures under the current code requirements in NFPA 88A (as well as similar code requirements elsewhere). Important factors that impact fire hazard in open parking garages include:

-

Potential for very rapid spread of fire between vehicles due to:

-

The increased use of plastics in vehicle construction

-

The shrinking distance between parked vehicles

-

The low ceilings in many garages increasing heat transfer from hot gases

-

-

No requirement for automatic fire detection, notification or extinguishment.

-

Large, tightly packed garages with long fire department response times and difficult extinguishment

The potential for very large losses is significant, and there is a small safety margin as many factors can allow a small fire to become a major one. Trends in vehicle and parking garage design indicate that this margin will continue to shrink in the future. With no detection or notification system, preventing a single car fire from spreading and potentially causing a conflagration throughout the whole structure is therefore solely reliant on the fire being discovered by occupants or staff, who rapidly notify the local fire department, who are able to arrive in relatively short amount of time. In both the fire incidents at Liverpool (England) and Stavanger airport (Norway), the design was based on an expectation that the fire department would be on the scene in 5–10 min after ignition. This is approximately the time when a fire can start to spread to other vehicles as found in some tests [46]. However, in both cases it took 20 min or more for fire department to arrive, and as a result the fire already involved multiple vehicles when firefighting personnel arrived.

In open parking garages the effect of wind through the building venting the hot gases from a vehicle fire has not been thoroughly evaluated, but given the low-ceiling height, and rapid fire growth and spread (often via direct radiative heating from the burning vehicle, which would not be significantly mitigated by ventilation) it is likely this would not significantly slow the fire spread in many scenarios. In fact, wind will provide more oxygen to the fire and can increase the fire spread. As was seen in the fire incidents discussed previously, when late notification and/or response is combined with a rapid fire spread between vehicles the result can be a fire that is beyond control by the time the fire department arrives. These considerations may require further evaluation of the how ‘open’ parking structures are defined and classified.

7 Addressing Hazards from Modern Vehicles

While catastrophic vehicle fire incidents remain relatively rare, the impact when the fire spreads rapidly can be extreme, which can mean spread to just one or two neighboring vehicles. Preventing these fires, that are infrequent but with outsized property damage impact, is economically challenging, and is likely to depend on a combination of pressure from updated building/fire codes and insurers. The two possible approaches to reduce the risk of large catastrophic fires in open parking structures is (1) improved detection; to allow the fire department to respond more rapidly, and/or (2) automatic suppression of the early fire. To provide options for the developer and allowing flexibility in the codes, these could be codified as equal or equivalent options, provided further testing shows detection gives a significant benefit. This should include fire engine accessibility considerations within the garage as well.

7.1 Detection and Notification

There are significant challenges to installing detection and notification systems in any parking garage open to the environment. Smoke alarms that rely on optical obscuration will be susceptible to false alarms due to environmental particles such as dust, exhaust fumes, and tire rubber abrasion. Heat alarms can be slow to activate in cases where wind flowing through the garage moves the hot gases away before enough heat can accumulate under the ceiling. Potential solutions to these problems include infrared flame detectors and other visual systems, or smart detectors where multiple signals are interpreted by computer algorithms to distinguish false alarms from actual fires. These are marketed towards enclosed garages but could conceivably be used in open ones as well. These would still impose a cost on the developer for installation during construction, and there will be significant ongoing maintenance costs to keep alarms functional in these harsh environments. As there are very few people injured in parking garage fires, the main purpose of detector coverage would be improved fire department response time. It is expected that this would translate into a reduction in property damage, but it is not clear how significant it would be. If the earlier notification enables the fire department to arrive when the fire is contained to a single vehicle, they are likely to extinguish it and stop a potentially devastating fire. If the fire has already spread to more vehicles when the firefighters arrive, even with automatic detection, there is a chance there would not be any difference in the resulting property damage.

7.2 Automatic Sprinkler Systems

The effects of sub-freezing temperatures in open parking garages can be addressed with dry-pipe sprinklers where water does not enter the pipes until the sprinkler heads are activated. This typically only adds a delay of a few tens of seconds and should have no significant impact on the effectiveness of the sprinklers. Any automatic sprinkler system using spot-type temperature activation could have reduced effectiveness when the wind blows the hot gases away from the sprinkler head at the ceiling, potentially causing significant delays in activation. During the devastating fire at the Stavanger airport in Norway in 2020 there was a sustained wind with a velocity of up to 15 m/s at the time of the incident. It is uncertain what the delay in activation would have been with a strong wind affecting the formation of a hot layer near the sprinkler heads. Hot gases being pushed downwind could activate sprinklers remote from the seat of the fire. This has the potential to reduce fire spread driven by wind, which is a concern in firefighting. However, if the sprinklers directly above the initiating vehicle do not activate, or do so much later, there would be less cooling effect on neighboring vehicles to limit the spread via direct radiative heating or burning pool fire spread. It is important that the effects of wind on sprinkler activation and water dispersion is assessed and considered for these applications.

To use an activation method not reliant on the temperature of sprinkler heads at a single location (usually at the ceiling), a more complex system must be designed where sprinklers are tied to other fire detection methods. Deluge systems where all sprinklers are activated whenever a fire is sensed at any detector would have serious false alarm concerns. Tying the systems to smaller zones could alleviate this somewhat, and false activation in a parking garage, designed for outdoor exposure, is certainly less damaging to the building and the contents than is the case inside commercial or residential settings. So called smart systems or “electronic sprinklers”, where individual, or groups of, sprinklers are connected to detectors and will be activated for limited areas where a fire is detected (or for example a 9-sprinkler grid around the fire, cooling the surrounding vehicles) could be a possible approach. These are an emerging trend for storage applications [79] but have not been tested for outdoor application or parking garages. These systems also require a very high level of complexity in design, installation and especially in maintenance, to ensure that the system operates properly in a harsh environment. Even if they were tested and found to be appropriate for the garage setting, for the foreseeable future this is likely to only be worthwhile for certain high-risk, high-value, and/or specialized building configurations.

8 Conclusions

An analysis was performed of the current understanding of the fire hazard modern vehicles represent to parking garages. The changes in vehicle and garage design have been documented, and the factors that most impact the fire development have been identified. Fires in vehicles are not uncommon, but large fires in parking structures are infrequent, and loss of life in these incidents is rare. Fires in parking structures can lead to large economic losses, as evidenced by recent fires in the open parking garages at Liverpool’s Echo Arena and Stavanger Airport in Norway. These incidents involved hundreds of automobiles and ultimately resulted in structural collapse of the parking structure and tens of millions of dollars in losses.

From the 1970s to 2018 there was a large increase in the use of plastic materials in vehicle construction in western markets, both in absolute weight of plastic and as percentage of vehicle weight, adding to the total fuel load of the average vehicle. Full-scale fire tests of vehicles are highly sensitive to the test conditions and setup, and despite the increase in potential fuel, published literature does not conclusively show that modern vehicles burn with a significantly higher heat release rate or for a longer time than those from 40 years ago. The increased plastic content instead manifests as faster flame spread within the vehicle, easier ignition and more rapid fire spread to neighboring vehicles. There is limited test data available on this spread between multiple vehicles, especially on newer models. Some tests of multiple modern vehicles have shown very rapid fire spread between vehicles in a parking garage configuration, on the order of 10–20 min. Based on the findings, test data from older vehicles (>15–20 years at the time of writing) should not be used as basis for development of codes and regulations.

Electric vehicles represent a large and growing share of the vehicle fleet in many western countries. These vehicles have not been shown in testing to yield larger fires than vehicles with internal combustion engines of similar size and design. Lithium-ion battery fires have different burn characteristics and present different challenges for firefighters as large amounts of water are required to cool the battery unit for an extended time to prevent reignition.

Evaluating modern vehicle fire hazards and current code requirements, it was found that for enclosed parking garages, the requirement for sprinkler protection appears adequate to control a vehicle fire until fire-fighting personnel arrive. Open parking structures emerge as the main area of concern regarding fires involving modern vehicles. The lack of any requirements in fire codes for active protection systems in open parking structures, and trends of larger vehicle widths and tighter parking spaces in garages suggest that large, devastating fires in these structures could become increasingly common. Though the risk of civilian injuries is likely to remain low, these fires could cause extremely large property losses, business disruption, and adverse environmental impact. There is currently insufficient testing of the fire dynamics of multiple vehicles in a parking structure to understand the fire spread mechanisms and rates in these configurations. The spread of fire between cars in a garage, especially from the initial to the second and third vehicles, is shown to be critical in determining the extent of the fire and the ability of the fire department to successfully control and extinguish it. Full-scale testing with a range of configurations should be performed to evaluate the spread dynamics and critical parameters. This data can be used as basis to evaluate additional scenarios with computational modeling.

If fire department response is to remain the sole means of fire control and extinguishment in open parking garages, a method to ensure rapid fire detection and notification should be evaluated and possibly mandated. Further testing is also necessary to determine the minimum response times required to control a vehicle fire, and whether automatic detection can provide the required benefit over the current system of manual notification of fires (i.e., guest or staff noticing and alerting). Available tests of vehicle fires involving sprinklers indicate good performance in controlling a single vehicle fire. But the number of tests is limited, and the most recent tests used 1992–2001 model year vehicles in a mock-up garage setting. Further testing should be conducted to evaluate more challenging scenarios with newer vehicles, such as delayed activation of the sprinklers, vehicle stacker configurations, and multiple-vehicle fires. For open garages, environmental effects, such as cold weather and wind, can cause significant delays on the activation of sprinklers and further evaluation of these effects is warranted.

References

Boehmer H, Klassen MS, Olenick SM (2020) Modern vehicle hazards in parking garages and vehicle carriers. Fire Protection Research Foundation, National Fire Protection Association, Quincy, MA

Oliver G (2014) Plastics and composites are reshaping car design, IHS report shows, American Chemistry Matters. https://blog.americanchemistry.com/2014/11/plastics-and-composites-are-reshaping-car-design-ihs-report-shows/ Accessed 12 Nov 2019.

Merseyside Fire and Rescue Service (2018) Kings dock car park fire. Protection Report, Liverpool, United Kingdom

Mangs J, Keski-Rahkonen O (1994) Characterization of the fire behaviour of a burning passenger car. Part I: Car fire experiments. Fire Safety J 23(1):17–35. https://doi.org/10.1016/0379-7112(94)90059-0

National Fire Data Center (2018) Highway vehicle fires (2014–2016), Topical Fire Report Series 19(2). Emmitsburg, MD

Ahrens M (2008) US Vehicle fire trends and patterns. Fire Analysis and Research Division, National Fire Protection Association, Quincy, MA

Ahrens M (2020) Sprinklers in commercial garage fires. National Fire Protection Association, Quincy, MA

IEA (2019) Global EV Outlook 2019, IEA, Paris, https://www.iea.org/reports/global-ev-outlook-2019

Antoni L, Garland N, Han J, Rex M, Samsun RC (2019) AFC TCP 2019 survey on the number of fuel cell vehicles, hydrogen refueling stations and targets. IEA Technol Collab Program

BBC (2018) Ferocious fire ripped through Liverpool Echo Arena car park. https://www.bbc.com/news/uk-england-merseyside-42533830. Accessed 22-Sept-19

Bona E (2018) ECHO Arena car park fire could have been stopped from spreading if the building had sprinklers, Liverpool Echo, https://www.liverpoolecho.co.uk/news/liverpool-news/echo-arena-car-park-fire-14100388. Accessed 10-July-19

The Local (2020) Flights at Norwegian airport delayed as 'hundreds' of cars burn in fire. https://www.thelocal.no/20200108/norway-airport-flights-held-as-hundreds-of-cars-burn-in-fire. Accessed 1-March-20

Frafjord E (2020) Samme Opel-modell forårsaket storbrann i irsk parkeringshus, NRK nyheter (Norwegian). https://www.nrk.no/rogaland/samme-opel-modell-forarsaket-storbrann-i-irsk-parkeringshus-1.14851110. Accessed 12 Jan 2020

Klingenberg M, Ramsdal R (2020) Brannvesenet: Det tok 20 minutter fra bilbrannen startet til første brannmann ankom. tu.no (norwegian). https://www.tu.no/artikler/brannvesenet-det-tok-20-minutter-fra-bilbrannen-startet-til-forste-brannmann-ankom-br/484013?key=jviLk7I5. Accessed 26 March 20

Digges KH, Gann RG, Grayson SJ, Hirschler MM, Lyon RE, Purser DA, Tewarson A (2008) Human survivability in motor vehicle fires. Fire Mater 32(4):249–258. https://doi.org/10.1002/fam.964

NFPA (2019) NFPA 88A-2019 standard for parking structures. National Fire Protection Association, Quincy, MA