Abstract

Herbal waste produced during the manufacturing of herbal products is a potential feedstock for anaerobic digestion due to high amount of organic matter that can be transformed into biogas as an energy resource. Therefore, the present study was undertaken to convert herbal waste produced during the manufacturing of common of Ayurveda products into biogas through anaerobic digestion process using batch test study under controlled mesophilic temperature conditions of 35 °C with food to inoculum ratio of 0.75. The maximum biomethane potential (BMP) of 0.90 (gCH4COD/g CODfed) and sludge activity of 0.70 (gCH4-CD/gVSS) was exhibited by WS herbal waste owing to its high chemical oxygen demand (COD) of 4 g/g and better solubilization potential of the organic matter showing change in volatile suspended solids (ΔVSS) of 79%. On the other hand, the waste derived from the TA herb, exhibited the least biogas yield of 0.55 (gCH4COD/g CODfed) and sludge activity of 0.40 (gCH4-CD/gVSS), albeit with higher organic matter present. This was due to the possible hindrance of waste solubilization by the presence of lignin. The waste derived from VVL and PE showed intermediate BMP and sludge activity. The methane generation rate constant (k), a key indicator of the biodegradation potential, was also evaluated. The k values showed similar trend as of BMP values ranging from 0.081 to 0.15 d−1 thus indicating the influence of presence of lignin and the change in ΔVSS. The present study proves anaerobic digestion to be an alternative treatment method to be a milestone for management of herbal wastes and can be successfully implemented on real-scale systems.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Effective and all-around management of herbal waste is necessary for leveraging sustainability goals. Plant-based medicine for the primary healthcare is increasingly used owing to its negligible side effects and being less expensive (Duraipandiyan et al., 2006; Wayland, 2001). A significant amount of herbal waste is generated currently from the herbal/Ayurvedic manufacturing industries. Herbal waste, a category of biomedical waste, is produced from the harvesting and sequential processing of various types of herbs. This includes an array of different parts of the herbs, viz., the leaves, stems, roots, flowers, and even the fruits of medicinal plants (Bekdaş & Karaboyacı, 2019; Franz et al., 2011). Herbal waste can also include the byproducts of herbal medicine production, such as discarded plant material from the extraction of pharmaceutical medicine compounds. The complex herbal waste from the Ayurvedic medicine industries constitutes plant extracts, plant parts, toxic solutes, and heavy metal ions. High BOD and COD concentrations of these complex herbal waste require appropriate treatment to alleviate environmental contamination. Further, mixing of the waste with oils and other waste products during the production creates a nuisance. Thus, unplanned and improper disposal of herbal waste has the potential to cause several environmental impacts, not barring air and water pollution and soil contamination (Das et al., 2017; Glassmeyer et al., 2009; Zuccato et al., 2006). To evade the negative impacts of herbal waste, the recent practice is to incinerate the waste; however, the incineration of herbal waste emits toxic and carcinogenic compounds into the air, which can lead to health problems for humans and animals (Chen et al., 2013; Kampa & Castanas, 2008). Moreover, the improper disposal of herbal waste can also lead to the spread of disease-causing organisms, such as bacteria and fungi. Therefore, to address the problem of herbal waste, implementation of proper disposal method or controlling of such wastes at the source is a need of the hour (Ali et al., 2012; Rajan et al., 2019).

On the other hand, the overwhelming demand for renewable energy has led to the exploration of various sources of bioenergy. One of the promising sources is biogas, a renewable energy source that can be harnessed from different wastes through anaerobic digestion. Anaerobic digestion is a commonly used process for the production of biogas from solid (Li et al., 2011), liquid, and organic wastes (Nair et al., 2022; Rajmohan et al., 2021). In this method, a bacterial consortium converts complex chemicals into gases like methane and carbon dioxide. However, the biogas yield from the digestion of some of the solid, liquid, and organic wastes can be low, limiting their potential for bioenergy production (Bharathiraja et al., 2018; Merlin Christy et al., 2014). There is no study available currently on the potential of biogas production of herbal waste by anaerobic digestion process, which could alleviate the environmental challenges with the herbal waste.

To overcome this challenge, the anaerobic digestion (AD) of herbal waste for biogas production was explored for the first time in this study. The aim was to improve biogas production efficiency and quality while reducing greenhouse gas emissions. An experimental batch test on commonly encountered byproducts of herbs under mesophilic temperature conditions was carried out.

Materials and method

Materials

The herbal wastes were collected from a leading Ayurvedic medicinal manufacturing industry located in Guwahati city, Assam, India. The wastes from four commonly encountered herbs, viz., Ashwagandha (Withania Somnifera (WS)), Amla (Phyllanthus Emblica (PE)), Draksha (Vitis Vinifera Linn (VVL)), and Yavani (Trachyspermum Ammi-TA), were collected from the aforementioned industry in solid form during August–September 2022 for the present study. These herbal wastes are produced in the manufacturing of Chyavanprash and other medicines in the batch process in this study. The wastes from these herbs were chosen as they represent the majority of the herbal waste that is disposed of in the landfills or the waste dump sites. The collected herbal waste samples were oven dried for 24 h at 60 °C to reduce the moisture content. Thereafter, samples were grinded and passed through a 50-micron sieve size and finally used 25 g for all the experimental and analysis work. The samples were characterized in terms of COD, TOC (Table 1), and substrate concentrations (Table 2). Henceforth, the waste samples derived from the parent herbs will be referred by their scientific herb names.

Characteristic of the inoculum

For anaerobic digestion, the seed sludge used as inoculum was collected from a full-scale wastewater treatment plant of 20 MGD (million gallons per day) located in New Delhi, India. The reagents required for preparing the nutrients or the defined media for the batch study was supplied by Hi-Media chemicals. The physiochemical parameters (COD, VSS, pH, and TOC) of the herbal waste and sludge were assessed as per the methods prescribed in manual of soil and solid waste analysis published by Dominant Publishers (India) (Singh et al., 2015). The characteristics of the seed sludge in terms of pH, VSS (volatile suspended solids), N as TKN (total Kjeldahl nitrogen), and P (total phosphorus) were determined prior to the start-up of batch test experiment. The VSS, TKN, and P of the seed sludge was found to be 35%, 2.23%, and 3.9%, respectively. However, the pH value of the sludge was assessed to be 7.32.

Method

Batch test study

A representative sample of the herbal waste to be treated was placed in a sealed reactor vessel with a known quantity of inoculum containing microorganisms that help in breaking down the waste in this batch testing. Serum bottles of 120-mL volume were used as the reactor, which was filled with sludge (inoculum), herbal waste sample, and the defined media (nutrient) and acclimatized to ensure consistency and homogeneity. A sludge of 5 mL and the defined media of 95 mL was used in each reactor that were initially filled with the required waste. The reactors were filled to its capacity of 100 mL only to accommodate the rubber stopper that was fastened during the batch test. the chemical oxygen demand (COD), total organic carbon (TOC), pH of the herbal waste, and the volatile suspended solids (VSS) of the sludge were determined prior to the commencement of the batch test. Further, VSS of the sludge was also estimated after the termination of the batch test. The present study for anaerobic digestion of herbal waste was carried out at a food-to-mass (F/M) ratio of 0.75 that was in accordance with Emembolu et al. (2017) and Hamza et al. (2018), and the defined media was prepared in accordance with the available studies (Hussain et al., 2008, Mata-Alvarez et al., 1992). Further, inverted glucose bottles with 500-mL volume containing 5% NaOH (w/v) with normal tap water was used for gas collection. The whole setup was placed in a temperature-controlled incubator at 35 ± 2 °C, as shown in Fig. 1. The anaerobic digestion process continued over a period of 7 weeks. During the process, the microorganisms metabolize the organic matter of the waste, to produce biogas as a byproduct. In order to make the background methane correction, the blank reactors containing media and sludge were also run parallel. The biogas production was monitored after every 24 h using the water replacement method and the volume of biogas produced in each reactor was recorded. In order to assess the effectiveness of the anaerobic digestion process, the routine parameters including pH and temperature were also monitored regularly. All the experiments in the present study were carried out in triplicate samples and average of the close two values were reported in the results.

Statistical analysis

The data analysis was carried out using statistical software in order to determine the significance of the results. The methane generation rate constant was also assessed using nonlinear regression with the Quasi-Newton algorithms. The methane generation rate was assessed using the equation described below:

where Ymax is the maximum methane produced (mL), Yt is the cumulative CH4 produced in time t (mL), Y0 is the initial methane generation (mL), k is the methane generation rate constant (d−1), and t is times (d).

Results and discussion

Characteristics of feedstock and substrate

The physiochemical characteristics of herbal waste (COD, TOC, and pH) and sludge (VSS and pH) were determined and summarized in Table 1. The observed data revealed that the maximum and minimum COD concentration was exhibited by WS and VVL samples, respectively (Table 1). Moreover, the TOC lies in the range of 12.59 to 8.17 for the studied samples. The WS waste exhibited a maximum TOC of 12.59%, while the waste derived from VVL showed the lowest TOC (8.17%). The COD and TOC of TA and PE exhibited intermediate physicochemical characteristics. This gives an indication that a significant organic matter is present in WS and TA in comparison to VVL and PE.

The difference in volatile suspended solids (ΔVSS) of the sample before commencement and after termination of the batch test was also measured (Table 1). The difference in the VSS indicate the solubilization potential of organic waste matter for volatile fatty acid production which subsequently plays a significant role in biogas production. The maximum solubilization of the waste organic matter was observed in WS as inferred from the ΔVSS value. However, the least solubilization of the waste occurred for TA as the ΔVSS was minimum (Table 1). Further, the ΔVSS value indicate that PE and VVL would exhibit intermediate waste solubilization potential. The pH of all the studied samples ranged from 7.2 to 7.8. The aforementioned parameters were evaluated as these would be useful in understanding the mechanism behind the methane generation potential for a given sample which was discussed in the following sections.

Batch test result

Methane generation rate constant (k)

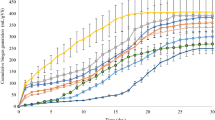

The methane generation rate constant k (d−1) indicates the biodegradability rate of a sample in terms of conversion of organic matter for the methane generation. The temporal variation of the cumulative methane gas output was presented in (Fig. 2a). The methane generation rate constant was determined with the help of Eq. 1, using the Ky plot software (Kumar et al., 2016). The software minimizes the error between the measured experimental data and theoretical plots for an optimized value of k. The results indicate that the theoretical plots were in well agreement with the experimental data, and therefore the obtained k is deemed to be reliable.

The estimated k value is a key indicator of the biodegradation potential of the studied waste samples. A higher k value of 0.15 d−1 was exhibited by WS, which corroborated with the initial physicochemical indicators (Table 1). Interestingly, the k value of TA was lesser than VVL and PE although TA exhibited higher organic matter as indicated by COD and TOC values. Hence, higher COD and TOC values need not necessarily be a key indicator for the long-term methane generation process. In other words, herbal waste having higher COD and TOC value might not lead to higher methane gas generation. This is owing to the solubilization potential of waste samples during the anaerobic digestion process. The TA exhibited a lower solubilization potential in the acidogenesis stage (less ΔVSS), and therefore, it contributed marginally to the production of methane. Further, as the ΔVSS of VVL and PE was higher than Yavani; similarly, the k value was also observed to be relatively higher (Fig. 2b).

Biochemical methane potential (BMP) and sludge activity

The substrate’s anaerobic degradation rate was also assessed in terms of its biochemical methane potential (BMP), or the amount of methane generation per gram of COD degradation (gCODfed) after a specific period. The quantity of CH4 (mL) at STP is converted to g CH4-COD and the ratio of gCH4-COD/gCODfed was termed as biochemical methane potential (Table 2). The biochemical methane potential of all the samples lies in the range of 0.55 to 0.90. The maximum BMP of 0.90 observed in WS while the minimum BMP of 0.55 was observed in TA (Fig. 3). An intermediate BMP was exhibited by VVL and PE.

Sludge activity is another parameter represented as CH4 (mL) or g of CH4-COD produced per gram of VSS (sludge). Higher methane production indicates better methanogenic activity. A sample with good sludge activity results in a greater breakdown of organic compounds, converting them into simpler compounds, such as biomass and CO2.

It is a parameter that generated by multiplying BMP values by F/M as presented in Eq. 2:

The sludge activity values of all the samples in the present study lies in the range of 0.40 to 0.70 g CH4-COD/gVSS. The maximum sludge activity was observed in WS while the minimum sludge activity was observed in TA sample (Fig. 4). The BMP and sludge activity of WS were the highest possibly owing to the higher organic content (TOC and COD) that reflects the presence of a greater quantity of organic compounds in the substrate. Thus, a higher organic content provides a larger pool of potential substrates for methanogenesis, resulting in increased methane production. On the other hand, the least BMP and sludge activity was exhibited by TA; notwithstanding its higher organic content than VVL and PE, this was due to the lesser reduction in the VSS of the sludge after the completion of anerobic digestion process. Higher organic content need not necessarily result in higher solubilization of the organic matter due to the presence of higher lignin content (Table 1). Therefore, a less reduction in the VSS was exhibited by TA in contrast to VVL and PE and hence lesser BMP and sludge activity.

Conclusion

The present study reveals that the herbal waste can be degraded anaerobically under mesophilic temperature conditions with 55 to 90% overall conversion of organic matter to methane in a period of ~ 50–60 days. Of all the studied wastes, the maximum methane production and sludge activity was observed for Ashwagandha (WS) and the least was exhibited by Yavani (TA). The other two studied wastes, viz., Draksha (VVL) and Amla (PE), showed intermediate biomethane potential and sludge activity. Higher organic content was understood to be the dominant factor for maximum BMP of Ashwagandha (WS). On the other hand, the presence of higher lignin content in Yavani (TA) posed a severe hindrance for the biogas yield. Also, Yavani (TA) exhibited least BMP in spite of the presence of relatively higher organic matter than VVL and PE. Therefore, it is presumed that the prediction of biogas yield and BMP values generally depends on the reduction of VSS after anaerobic digestion rather than presence of COD and TOC in a system. The study for the first time revealed that herbal waste from plant herbs is a sustainable and effective approach to producing biogas through anaerobic digestion. The methane generation rate was considerably high under the studied temperature conditions. Moreover, it was observed that the generation rate of the biogas from the herbal waste was influenced by the presence of lignin, organic content, and the difference of the volatile suspended solids in the sludge. This study will further pave the way for future research on utilizing herbal waste and transforming such waste into a value-added product. Moreover, the other by-products of the anaerobic digestion, viz., compost can be utilised as fertilizers in soils for better crop yield.

Availability of data and materials

All the data have been included in the manuscript by the authors, however, any raw data if required, will be made available on request.

References

Ali, M., Duba, K. S., Kalamdhad, A. S., Bhatia, A., Khursheed, A., Kazmi, A. A., & Ahmed, N. (2012). High rate composting of herbal pharmaceutical industry solid waste. Water Science and Technology, 65(10), 1817–1825. https://doi.org/10.2166/wst.2012.082

Bekdaş, F., & Karaboyacı, M. (2019). Production of paper from rose wastes Turkish. Journal of Forestry Türkiye Ormancılık Dergisi, 20(3), 250–253. https://doi.org/10.18182/tjf.606686

Bharathiraja, B., Sudharsana, T., Jayamuthunagai, J., Praveenkumar, R., Chozhavendhan, S., & Iyyappan, J. (2018). Biogas production – A review on composition, fuel properties, feed stock and principles of anaerobic digestion. Renewable and Sustainable Energy Reviews, 90(July), 570–582. https://doi.org/10.1016/j.rser.2018.03.093

Chen, Y., Zhao, R., Xue, J., & Li, J. (2013). Generation and distribution of PAHs in the process of medical waste incineration. Waste Management, 33(5), 1165–1173. https://doi.org/10.1016/j.wasman.2013.01.011

Das, V., Satyanarayan, S., & Satyanarayan, S. (2017). Recycling of recalcitrant solid waste from herbal pharmaceutical industry through vermicomposting. International Journal of Environment Agriculture and Biotechnology, 2(3), 1151–1161. https://doi.org/10.22161/ijeab/2.3.19

Duraipandiyan, V., Ayyanar, M., & Ignacimuthu, S. (2006). Antimicrobial activity of some ethnomedicinal plants used by Paliyar tribe from Tamil Nadu India. BMC Complementary and Alternative Medicine, 6, 1151–1161. https://doi.org/10.1186/1472-6882-6-35

Emembolu, L., Nwabanne, J., & Elijah, O. (2017). Kinetic modeling of anaerobic digestion of restaurant waste water. British Journal of Applied Science & Technology, 21(4), 1–12. https://doi.org/10.9734/bjast/2017/33397

Franz, C., Chizzola, R., Novak, J., & Sponza, S. (2011). Botanical species being used for manufacturing plant food supplements (PFS) and related products in the EU member states and selected third countries. Food and Function, 2(12), 720–730. https://doi.org/10.1039/c1fo10130g

Glassmeyer, S. T., Hinchey, E. K., Boehme, S. E., Daughton, C. G., Ruhoy, I. S., Conerly, O., Daniels, R. L., Lauer, L., McCarthy, M., Nettesheim, T. G., Sykes, K., & Thompson, V. G. (2009). Disposal practices for unwanted residential medications in the United States. Environment International, 35(3), 566–572. https://doi.org/10.1016/j.envint.2008.10.007

Hamza, R. A., Sheng, Z., Iorhemen, O. T., Zaghloul, M. S., & Tay, J. H. (2018). Impact of food-to-microorganisms ratio on the stability of aerobic granular sludge treating high-strength organic wastewater. Water Research, 147, 287–298. https://doi.org/10.1016/j.watres.2018.09.061

Hussain, A., Kumar, P., & Mehrotra, I. (2008). Treatment of phenolic wastewater in UASB reactor: Effect of nitrogen and phosphorous. Bioresource Technology, 99(17), 8497–8503. https://doi.org/10.1016/j.biortech.2008.03.059

Kampa, M., & Castanas, E. (2008). Human health effects of air pollution. Environmental Pollution, 151(2), 362–367. https://doi.org/10.1016/j.envpol.2007.06.012

Kumar, P., Hussain, A., & Dubey, S. K. (2016). Methane formation from food waste by anaerobic digestion. Biomass Conversion and Biorefinery, 6(3), 271–280. https://doi.org/10.1007/s13399-015-0186-2

Li, Y., Park, S. Y., & Zhu, J. (2011). Solid-state anaerobic digestion for methane production from organic waste. Renewable and Sustainable Energy Reviews, 15(1), 821–826. https://doi.org/10.1016/j.rser.2010.07.042

Mata-Alvarez J., Llabrés, P., Cecchi, F., & Pavan, P. (1992). Anaerobic digestion of the Barcelona central food market organic wastes: Experimental study. Bioresource Technology, 39(1), 39–48. https://doi.org/10.1016/0960-8524(92)90054-2

Merlin Christy, P., Gopinath, L. R., & Divya, D. (2014). A review on anaerobic decomposition and enhancement of biogas production through enzymes and microorganisms. Renewable and Sustainable Energy Reviews, 34, 167–173. https://doi.org/10.1016/j.rser.2014.03.010

Nair, L. G., Agrawal, K., & Verma, P. (2022). An overview of sustainable approaches for bioenergy production from agro-industrial wastes. Energy Nexus, 6(March), 100086. https://doi.org/10.1016/j.nexus.2022.100086

Rajan, R., Robin, D. T., & Vandanarani, M. (2019). Biomedical waste management in Ayurveda hospitals – Current practices and future prospectives. Journal of Ayurveda and Integrative Medicine, 10(3), 214–221. https://doi.org/10.1016/j.jaim.2017.07.011

Rajmohan, K. S., Ramya, C., & Varjani, S. (2021). Trends and advances in bioenergy production and sustainable solid waste management. Energy and Environment, 32(6), 1059–1085. https://doi.org/10.1177/0958305X19882415

Singh, W. R., Pankaj, S. K., & Kalamdhad, A. S. (2015). Reduction of bioavailability and leachability of heavy metals during agitated pile composting of Salvinia natans weed of Loktak lake. International Journal of Recycling of Organic Waste in Agriculture, 4(2), 143–156. https://doi.org/10.1007/s40093-015-0094-2

Wayland, C. (2001). Gendering local knowledge: Medicinal plant use and primary health care in the Amazon. Medical Anthropology Quarterly, 15(2), 171–188. https://doi.org/10.1525/maq.2001.15.2.171

Zuccato, E., Castiglioni, S., Fanelli, R., Reitano, G., Bagnati, R., Chiabrando, C., Pomati, F., Rossetti, C., & Calamari, D. (2006). Pharmaceuticals in the environment in Italy: Causes, occurrence, effects and control. Environmental Science and Pollution Research, 13(1), 15–21. https://doi.org/10.1065/espr2006.01.004

Acknowledgements

The authors appreciate everyone supported the proposed research.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Shivani Patel and Mimansa Babbar: material preparation, data collection and analysis, and writing original draft preparation. Athar Hussain, Partha Das, and T.V. Bharat: conceptualization, curation, resources, methodology, and analysis. Manjeeta Priyadarshi: result analysis, writing review, and manuscript revision formatting. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

The submitted work is an original composition that should not have been previously published in any way, shape, or form (in whole or in part), nor should it be an expansion of another piece of writing.

Consent to participate

Not applicable.

Consent to publish

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Patel, S., Das, P., Priyadarshi, M. et al. Anaerobic digestion of herbal waste: a waste to energy option. Environ Monit Assess 196, 600 (2024). https://doi.org/10.1007/s10661-024-12769-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10661-024-12769-x