Abstract

In this study, we evaluated three cell retention devices, an alternating tangential flow (ATF) system, a spin-filter, and a Centritech Lab III centrifuge, for the production of recombinant human Factor VIII co-expressed with von Willebrand factor. From the results, it was found that the FVIII activity in bioreactor was significantly higher in the ATF perfusion culture than two other perfusion cultures. Moreover, the FVIII activity yield was unexpectedly low in the ATF perfusion culture. We have, therefore, studied the reasons for this low FVIII activity yield. It was revealed that the inactivation and the surface adsorption of FVIII onto the harvest bag were not the main reasons for the low yield in the ATF perfusion culture. The FVIII activity yield was not increased by the use of a hollow fiber filter with 0.5 μm pore size instead of 0.2 μm pore size. Additionally, the retention of FVIII molecules by the hollow fiber filter was a dominant factor in the low FVIII activity yield in the ATF perfusion culture. We demonstrated that FVIII yield was significantly improved by controlling transmembrane pressure (TMP) across the hollow fiber filter membrane. Taken together, these results suggest that TMP control could be an efficient method for the enhancement of FVIII yield in an ATF perfusion culture.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Human Factor VIII is an essential anti-hemophilic protein in the blood coagulation cascade. Plasma-derived or recombinant human FVIII is used to treat hemophilia A, which is caused by a genetic deficiency of FVIII. Commercially available rhFVIII products have been produced including full-length rhFVIII (FL-rhFVIII) and B-domain deleted rhFVIII (BDD-rhFVIII) in either Chinese hamster ovary (CHO) cells or baby hamster kidney (BHK) cells (Boedeker 2001). Recently Octapharma AG announced the availability of rhFVIII produced in human embryonic kidney cell line, HEK293 (Casademunt et al. 2012).

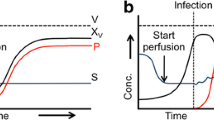

The major drawback of rhFVIII production techniques is the low expression level due to the large molecular size and structural complexity of FVIII. There are several methods to overcome a low expression level, such as deletion of B-domain of FVIII (Berntorp 1997), co-expression of the von Willebrand factor (vWF) (Berntorp 1997; Boedeker 2001; Jiang et al. 2002; Kaufman et al. 1988, 1989; Weiss et al. 1977), use of HKB11 cell as a host cell (Mei et al. 2006), codon optimization of human FVIII cDNAs (Ward et al. 2011), bioengineering of FVIII through elimination of a dispensable disulfide loop (Selvaraj et al. 2012), development of lentiviral vectors (Mufarrege et al. 2014) and over-expression of HSP70 (Ishaque et al. 2007). In terms of culture mode, perfusion culture is more preferable over batch or fed-batch culture because of a high instability of FVIII in the cell culture supernatant (Boedeker 2001; Kelley et al. 2010; Weiss et al. 1977).

In this study, we used CHO cells co-expressing BDD-rhFVIII and vWF as a stabilizer. The three systems, such as a spin-filter, a Centritech Lab III system, and an ATF system, were evaluated for their use as a perfusion device. A spin-filter and a Centritech Lab III system are traditional perfusion devices that have been widely used for several decades. In a spin-filter, cells are separated according to the mesh size of the spin-filter (Himmelfarb et al. 1969; Yabannavar et al. 1992). The cell separation by a Centritech Lab III system is based on sedimentation caused by centrifugal force (Johnson et al. 1996; Kim et al. 2008; Tokashiki et al. 1990). The ATF system from Refine Technology is a recently developed perfusion device that uses a hollow fiber filter module as a cell separation device (Crowley et al. 2012; Shevitz 2003). In the ATF system, cells are separated by repeated and rapid flow between the bioreactor and the hollow fiber filter due to the action of a diaphragm pump.

In this study, we found that the FVIII activity yield is unusually low in only the ATF perfusion culture. To our knowledge, such a low yield of the target protein has not been reported during the production of other therapeutic proteins and antibodies in ATF perfusion cultures. Chotteau et al. (Chotteau, V., Tördahl, K. and Perroud, P., 21st ESACT Meeting, 2009) reported that there was no retention of a monoclonal antibody in perfusion with an ATF-2 device and 0.2 μm hollow fiber filter. In our study also, the minimum yield of recombinant human chorionic gonadotropin between the bioreactor and the harvest in the perfusion culture with the ATF-4 system and 0.2 μm hollow fiber filter was above 77 % (data not shown). Recently Clincke et al. (2013) reported that CHO cells were cultivated and maintained at a very high cell density of 20–30 × 106 cells/mL in an ATF perfusion culture using a WAVE bioreactor. They observed the retention of the produced monoclonal antibody (MAb). The minimum yield of MAb in the harvest was approximately 40 % in the ATF perfusion culture.

The present study aims to investigate the reasons for the unexpected low FVIII activity yield in the ATF perfusion culture. The possible factors that may be responsible for the low FVIII activity yield were studied. Especially, we examined the relationship between TMP across the hollow fiber filter membrane and FVIII activity yield.

Materials and methods

Cell line and inoculum preparation

A CHO cell line co-expressing BDD-rhFVIII and vWF, which was previously described in the patent KR 101119079 B1 was used for the perfusion culture. The inocula for the bioreactor culture were produced using Erlenmeyer flasks (Corning, NY, USA). Erlenmeyer flasks were maintained at 100 rpm on an orbital shaker in a humidified 5 % CO2 incubator (Sanyo, Osaka, Japan) at 34 °C. Both in an Erlenmeyer flask and bioreactor, cells were cultured in a CHO DHFR-medium (SAFC biosciences, Louis, MO, USA) supplemented with glutamine. Cells were passaged twice a week by dilution with fresh medium.

Perfusion culture

Three different cell retention devices, a Centritech Lab III centrifuge (Carr Centritech, Clearwater, FL, USA), a spin-filter (New Brunswick Scientific, Edison, NJ, USA), and an ATF-4 system (Refine Technology, Pine Brook, NJ, USA) were used for perfusion culture. Perfusion cultures were performed in a 5 L BioFlo 310 bioreactor (New Brunswick Scientific) with a working volume of 3 L. The ATF-4 system used was controlled by the C24-4 version 1.01 controller from Refine Technology. A polyethersulfone (PES) hollow fiber filter cartridge (Refine Technology) for ATF-4 system with a 0.2 μm (F4:RF-02PES, Refine Technology, USA) or 0.5 μm (F4:RF-05PES, Refine Technology) pore size was used for ATF perfusion. A Centritech Lab III centrifuge was operated in the intermittent pump mode for perfusion. Operating parameters such as separation time, discharge time, separation speed, discharge speed, rotor speed, feed flush time, concentrate flush time, final flush time, waiting time, and number of cycles were set at 6 s, 5 s, 38 rpm, 30 rpm, 800 rpm, 46 s, 37 s, 60 s, 40 min, and 39 cycles, respectively, at a perfusion rate of 2 vvd (volume of medium perfused per bioreactor volume per day). An internal spin-filter (#M1273-3202, New Brunswick Scientific) was used with a BioFlo 310 bioreactor for perfusion culture. The spin-filter module had a filter screen with 12–14 μm mesh size and a low shear marine blade impeller.

The same culture parameters, as described below, were used for the three perfusion cultures. The seed cells grown in Erlenmeyer flasks were inoculated in the BioFlo 310 bioreactor. The bioreactor was equipped with a dissolved oxygen (DO) probe, pH probe, and temperature probe. Culture temperature, DO, pH, and agitation speed were controlled automatically and monitored using BioCommand software (New Brunswick Scientific) and a personal computer. The DO concentration was kept at approximately 50 % of air saturation by adjusting the air/O2 ratio of the inlet gas. The agitation speed was also varied between 100 and 150 rpm to maintain the DO level. The pH was kept at a constant value of 7.0 by adding a 7.5 % (w/v) NaHCO3 solution or adjusting the CO2 ratio of the inlet gas. The culture temperature was maintained at 34 °C.

Approximately 30 mL of the samples were taken once every day after the perfusion was started. After centrifugation for cell separation, an aliquot of the sample was immediately frozen at −80 °C for further analysis. Glucose, lactate, glutamine, and ammonia concentrations were analyzed off-line by a YSI 7100 multiparameter bioanalytical system (YSI Inc, Yellow Springs, OH, USA). Cell density and viability were measured by an automated trypan blue cell density examination system (Cedex, Innovatis GmbH, Bielefeld, Germany). Viable cell density was stably maintained by cell bleeds. The perfusion rate was controlled by adding fresh medium and withdrawing an equal volume of clarified supernatant with a peristaltic pump. Perfusion was started when the residual glucose level was below 1 g/L. The perfusion rate was adjusted in order to maintain glucose level above 1 g/L. A 20 L BioEaze bag (SAFC biosciences) was used as a harvest bag. The harvest bag was placed in a 4 °C refrigerator until replacement with a new harvest bag.

Dead-end filtration

The harvested supernatant from both Centritech Lab III and spin-filter perfusion was filtered by a Millipak 200 filter (Merck Millipore, Billerica, MA, USA) with 0.2 μm pores. Before first use, the filter was wetted out by flowing distilled deionized water with a peristaltic pump. After filtration of 5 L supernatant, the FVIII activity in the feed sample and filtrate was measured by a one-stage clotting assay.

Storage and surface adsorption experiments

The stability of FVIII was assessed at three different temperatures: 4, −20 and −80 °C. Centrifugation was performed for 4 min at 3000 rpm using Centrifuge 5810R (Eppendorf, Hamburg, Germany) to clarify the supernatant from the ATF perfusion culture. The clarified supernatant containing FVIII was stored in triplicate 1 mL aliquots in polypropylene tubes at each temperature. The FVIII activity was measured at 24 h after storage.

The adsorption experiment was performed for two FVIII activities at 4 °C. The FVIII activities of the high- and low-activity preparation were 2.1 and 0.115 AU, respectively. These preparations were obtained from the ATF perfusion culture. Each duplicate 12 L sample was stored at 4 °C in the 20 L BioEaze bag (SAFC biosciences, USA), which was used as a harvest bag. The surface material of the BioEaze bag is a single layer of Dow ATTANE™, an ultra low density polyethylene (ULDPE). The FVIII activity in the supernatant was measured at times 0, 3, 6, 18, and 24 h, respectively.

Controlled TMP experiment

A KrosFlo Research IIi tangential flow filtration system (Spectrum Laboratories, Inc., Compton, CA, USA) was utilized to measure the transmembrane pressure across the MiniKros plus hollow fiber filter module (Spectrum Laboratories, Inc.) with a 0.2 μm pore size and 3100 cm2 surface area. Polysulfone pressure transducers were connected to the inlet, the outlet, and the permeate port of the MiniKros plus hollow fiber filter module. The culture supernatant from the Centritech Lab III perfusion was circulated through a MiniKros plus hollow fiber filter through the built-in peristaltic pump of a KrosFlo Research IIi system. The TMP was controlled by the peristaltic pump speed and the KrosFlo automatic backpressure valve according to the manufacturer’s instructions. Pressure changes at each point were monitored simultaneously using KF COMM software from Spectrum Laboratories. The TMP was calculated by using the following formula:

FVIII activity and antigen assay

FVIII activity was measured by a one-stage clotting assay with an ACL TOP 500 CTS (Instrumentation Laboratory, Bedford, MA, USA) according to the manufacturer’s instructions and as per the Fourth International WHO standard. FVIII antigen content (FVIII:Ag, FVIII antigen) was quantified by an anti-FVIII light chain sandwich enzyme-linked immunosorbent assay (ELISA) using an in-house BDD-rhFVIII antigen as a standard and an in-house ELISA kit.

vWF antigen assay

vWF protein content (vWF:Ag, VWF antigen) was quantified by a sandwich ELISA, REAADS® von Willebrand factor antigen test kit (Corgenix Inc., Broomfield, CO, USA) according to the manufacturer’s instructions.

Statistical analysis

Data were statistically analyzed by a two-tailed Student’s t test using Microsoft Excel. Statistical significance was defined as P < 0.05.

Results and discussion

Cell growth and FVIII production

Three different perfusion cultures were performed to compare performance in the production of BDD-rhFVIII co-expressed with vWF. Figure 1a shows cell growth performance during perfusion culture using the three different devices.

Comparison of three cell retention devices. Cell growth performance (a), FVIII activity in the bioreactor (b), FVIII activity in harvest (c), and FVIII activity yield (d). The FVIII activity in the bioreactor was calculated based on the average of FVIII activity measured in daily samples taken from the bioreactor until the next harvest. Error bars represent standard deviations. Number (n) of separate experiments: n = 3 (Centritech Lab III), n = 2 (spin-filter) and n = 1 for ATF. AU indicates arbitrary unit

In the Centritech Lab III perfusion culture, viable cell density was stabilized at an average of 3.50 × 107 cells/mL at a perfusion rate of 2 vvd after day 10. Since the separation efficiency rapidly decreased above 4 × 107 cells/mL, viable cell density was controlled below 4 × 107 cells/mL. Viable cell density in the spin-filter perfusion was maintained at an average of 1.76 × 107 cells/mL for the culture duration after day 10 at a perfusion rate of 1.5 vvd in order to avoid filter clogging and extend culture duration. In the ATF perfusion culture, viable cell density was stabilized at an average of 5.02 × 107 cells/mL at a perfusion rate of 2 vvd. However, after day 27 viable cell density was increased to between 8 and 10 × 107 cells/mL in order to evaluate the performance of the ATF system in a very high cell density.

The FVIII activity in the bioreactor varied between 0.1 and 0.2 AU in both the Centritech Lab III and spin-filter perfusion cultures (Fig. 1b). The average value of FVIII activity in the bioreactor was 0.138 and 0.131 AU in the Centritech Lab III and spin-filter perfusion cultures, respectively. The average FVIII activity in the harvest after cell density stabilization was 0.13 and 0.17 AU in the Centritech Lab III and spin-filter perfusion cultures, respectively (Fig. 1d). As shown in Fig. 1c, these two perfusion cultures showed more than a 70 % FVIII activity yield.

As shown in Fig. 1b–d, the FVIII production profile in the ATF perfusion culture was significantly different from the other two perfusion cultures. The FVIII activity in the bioreactor was rapidly increased up to 1.05 AU according to an increase in culture time (Fig. 1b). In contrast, FVIII activity in the harvest was continuously decreased with an increase in the culture time, and FVIII activity in the final harvest bag was 0.024AU (Fig. 1d). At the beginning of the ATF perfusion culture, the FVIII activity yield was 71.2 % (Fig. 1c). This yield at the start of perfusion culture was almost equivalent to that in the Centritech Lab III or spin-filter perfusion cultures. However, FVIII activity yield rapidly decreased over the culture time. The average FVIII activity yield was only 8.2 % in the ATF perfusion culture. This yield was 10-fold lower than that in the other two perfusion cultures. Such a low yield of the interest protein as well as FVIII in ATF perfusion culture, has not been previously reported.

Effect of storage temperature on FVIII activity yield

Since the FVIII molecule is an unstable protein in a CHO cell culture supernatant as described previously (Kaufman et al. 1988), there is a strong possibility that inactivation of FVIII may occur. Therefore, a FVIII storage stability test was performed to check whether FVIII inactivation occurs during storage in the harvest bag. A polypropylene tube was utilized as a storage container in order to exclude the problem of surface adsorption of FVIII molecules (McLeod et al. 2000). When the perfusion rate was 4 vvd, the harvest bag was replaced with a new harvest bag after every 24 h. Therefore, if the FVIII activity had not decreased after 24 h storage, it was obvious that the inactivation of FVIII was not a dominant factor in the reduction of the FVIII activity yield.

As shown in Table 1, FVIII activity recovery after 24 h storage at 4 °C was 92.8 %. A slightly lower FVIII activity recovery was noted in the other two storage conditions, 86.9 % for −20 °C (*P < 0.05) and 90.9 % for −80 °C. Hence, this result implies that although inactivation of FVIII may occur during storage in the harvest bag, it is not a dominant factor that affects FVIII activity yield.

Effect of the adsorption of FVIII molecule onto the container surface on FVIII activity yield

McLeod et al. (2000) previously reported the loss of recombinant FVIII activity during storage in polyvinyl chloride (PVC) containers, but not in polypropylene syringes. They obtained a 41.9 % and a 43.7 % FVIII activity recovery in undiluted (146 IU/mL) and diluted (10 IU/mL) samples after 48 h of storage in a PVC bag at room temperature. However, only 1.8 % FVIII activity was obtained in FVIII diluted to 2 IU/mL. Hence, in their study, they found that the loss of FVIII activity was due to the adsorption of FVIII:Ag onto the surface of PVC. Their result suggests that the adsorption of FVIII:Ag can also be an important cause for low FVIII activity yield in the ATF perfusion culture.

Therefore, we measured FVIII activity yield after 24 h storage at 4 °C in the harvest bag to check whether the loss of FVIII activity was due to FVIII:Ag adsorption onto the surface of the harvest bag. Table 2 shows that the recovery of FVIII activity was 89 % for 2.1 AU and 95.7 % for 0.115 AU after 24 h. This loss of activity could be due to the inactivation of FVIII during storage. Therefore, we concluded that the loss of FVIII activity shown in Table 2 might be mostly due to the inactivation of FVIII during storage. It was also concluded that the adsorption of FVIII:Ag onto the surface of the harvest bag was not a very significant cause. The results of Tables 1 and 2 evidently showed that the adsorption of FVIII:Ag onto the surface of the harvest bag and inactivation of FVIII were not the main causes of a low FVIII activity yield in the ATF perfusion culture.

Effect of the retention of FVIII:Ag by the hollow fiber filter on FVIII activity yield

The last possible cause of low FVIII activity yield was the retention of FVIII:Ag by the hollow fiber filter membrane. Since fouling of the hollow fiber filter is an intrinsic problem of a membrane-based perfusion culture (Mercille et al. 1994), the possibility of a reduction of yield due to fouling obviously exists even in an ATF perfusion culture. Since most of the secreted FVIII exists as a FVIII/vWF complex in the supernatant of a CHO cell culture (Kaufman and Pipe 1999; Kaufman et al. 1989; Wise et al. 1991), a reduction in the amount of FVIII:Ag will be accompanied by a decrease in the amount of vWF:Ag. Moreover, the loss of co-secreted vWF:Ag will occur at the same rate, because vWF has the capacity to form a complex with FVIII at a certain ratio from 1:1 to 1:70 as described previously (Kaufman and Pipe 1999; Vlot et al. 1995). Therefore, we performed FVIII:Ag and vWF:Ag assays to assess the possibility of retention of FVIII:Ag due to the filtration action of ATF hollow fiber filter.

As shown in Table 3, the FVIII activity yield at day 35 of ATF perfusion culture was 3.13 %. The vWF yield by vWF:Ag ELISA and the FVIII:Ag yield by FVIII:Ag ELISA was 2.99 and 2.50 %, respectively. The decreasing ratio of FVIII:Ag yield was quite similar to the ratio of the reduction of vWF:Ag yield. It was also very similar to the decreasing ratio of the FVIII activity yield. Since inactivation and protein loss by surface adsorption was shown to not be dominant factors in low FVIII activity yield, these results clearly indicate that the retention of FVIII:Ag by the hollow fiber filter was the main cause of the reduction of FVIII activity yield. Furthermore, these results also suggest that the increase in FVIII activity in the bioreactor during ATF perfusion culture was due to the accumulation of retained FVIII:Ag (Fig. 1b).

Retention of FVIII:Ag by dead-end filtration

The culture supernatant collected in the harvest bag in both the Centritech Lab III and spin-filter perfusion cultures must be clarified using a filter with a pore size smaller than 0.2 μm in order to proceed to the purification processes. Therefore, the actual FVIII activity yield should be calculated after filtration of the harvest. Figure 2 shows the FVIII activity yield after filtration using a membrane with 0.2 μm pores for supernatants from both perfusion cultures. After membrane filtration, a decrease in FVIII activity yield was observed. The FVIII activity yield was 63.7 % for the Centritech Lab III and 52.8 % for the spin-filter. Although these yields was significantly higher than that in the ATF perfusion culture, this also provided clear evidence of the retention of FVIII:Ag by filtration action.

Effect of the pore size of hollow fiber filter on FVIII activity yield

ATF perfusion culture was performed using a hollow fiber filter with 0.5 μm pores in order to evaluate the effect of the increased pore size on FVIII activity yield. The FVIII activity yield with a 0.5 μm pore size was 53.4 % in the first harvest, 20.1 % in the second harvest, and 17.8 % in the third harvest, (Fig. 3b). FVIII activity yields from the same perfusion day in the ATF perfusion using a hollow fiber membrane filter with 0.2 μm pores gave 57.4, 21.1, and 16.9 %, respectively, as shown in Fig. 3a. The FVIII activity yield of both perfusion cultures was very similar. In addition, a similar decreasing trend in FVIII activity yield over the culture time was observed in both perfusion cultures. Consequently, it is obvious that increasing the pore size of the hollow fiber filter in the ATF perfusion culture is not an exact solution for increasing FVIII activity yield (Fig. 3).

Effect of TMP on FVIII activity yield, FVIII:Ag yield, and vWF:Ag yield

A controlled TMP experiment with a hollow fiber filter was performed in order to evaluate the increased TMP on the FVIII activity yield, FVIII:Ag yield, and vWF:Ag yield. The yields after hollow fiber filtration under controlled TMP are shown in Fig. 4. FVIII activity yield, FVIII:Ag yield, and vWF:Ag yield were 93.7, 91.9 and 89.2 %, respectively, on applying TMP of less than 10 psi (the average TMP was 2.83 psi). However, these yields were rather significantly decreased when a TMP of more than 10 psi was applied. At 10 psi TMP, FVIII activity yield, FVIII:Ag yield, and vWF:Ag yield decreased to 34.6, 33.6, and 35.9 %, respectively. At above 10 psi, data showed that these yields, FVIII activity yield, FVIII:Ag yield, and vWF:Ag yield, decreased to between 16 and 20 %. These results suggest that the control of TMP under 10 psi can be a good way of enhancing FVIII activity by reducing the retention of FVIII:Ag in an ATF perfusion culture. However, further studies are needed to elucidate the mechanism by which the FVIII yield is decreased under an increased TMP of more than 10 psi.

FVIII activity, FVIII:Ag concentration and vWF:Ag concentration after hollow fiber filtration under controlled transmembrane pressure. The measured transmembrane pressure is indicated in the X-axis. BF means before filtration. AU indicates arbitrary unit. Psig is the abbreviation of pounds per square inch gage. Error bars represent standard deviations with n = 3. *P < 0.001 (two-tailed Student’s t test)

In addition to fouling of the hollow fiber filter, another important factor to be considered in this study is the multimer of vWF co-expressed with FVIII. It has been reported that the hydrodynamic radius of vWF multimer can be increased up to 466 nm under shear stress (Hoyer and Shainoff 1980; Shankaran et al. 2003). Also, it has been reported that the fully stretched vWF multimer showed an end-to-end length ranging from 2300 to 2800 nm (Seyfried et al. 2010). Thus, it can be hypothesized that the co-expressed vWF in this study may partly contribute to the retention of FVIII:Ag due to filtration. However, exact details regarding the effect of vWF multimer on the FVIII yield in ATF perfusion have not yet been reported upon. The current experimental results do not enable further conclusions to be drawn to prove our hypothesis. Thus, further studies are needed in order to better understand the relationship between vWF multimer and the retention of FVIII:Ag.

Conclusions

In this study, we reported the observation that FVIII activity yield in an ATF perfusion culture was considerably lower, compared with two other perfusion systems such as a spin-filter and Centritech Lab III centrifuge. Our results successfully demonstrated that the low FVIII activity yield in an ATF perfusion culture was not due to inactivation or surface adsorption of FVIII molecules, but due to the retention of the FVIII molecules by hollow fiber filtration. Controlled TMP below 10 psi resulted in remarkable enhancement of FVIII yield in hollow fiber filtration. From these observations, we suggest that TMP across a hollow fiber filter is a key factor in increasing the production yield of FVIII in an ATF perfusion culture. Although further studies are needed to develop a precise control method for TMP and to determine an optimal TMP, our findings can be applied to improving the production yield of other target proteins in an ATF perfusion culture.

References

Berntorp E (1997) Second generation, B-domain deleted recombinant factor VIII. Thromb Haemost 78:256–260

Boedeker BG (2001) Production processes of licensed recombinant factor VIII preparations. Semin Thromb Hemost 27:385–394

Casademunt E, Martinelle K, Jernberg M, Winge S, Tiemeyer M, Biesert L, Knaub S, Walter O, Schroder C (2012) The first recombinant human coagulation factor VIII of human origin: human cell line and manufacturing characteristics. Eur J Haematol 89:165–176

Clincke MF, Molleryd C, Zhang Y, Lindskog E, Walsh K, Chotteau V (2013) Very high density of CHO cells in perfusion by ATF or TFF in WAVE bioreactor. Part I. Effect of the cell density on the process. Biotechnol Prog 29:754–767

Crowley J, Wubben M, Martin JMC (2012) Process for cell culturing by continuous perfusion and alternating tangential flow. US Patent 8206981 B1

Himmelfarb P, Thayer PS, Martin HE (1969) Spin filter culture: the propagation of mammalian cells in suspension. Science 164:555–557

Hoyer LW, Shainoff JR (1980) Factor VIII-related protein circulates in normal human plasma as high molecular weight multimers. Blood 55:1056–1059

Ishaque A, Thrift J, Murphy JE, Konstantinov K (2007) Over-expression of Hsp70 in BHK-21 cells engineered to produce recombinant factor VIII promotes resistance to apoptosis and enhances secretion. Biotechnol Bioeng 97:144–155

Jiang R, Monroe T, McRogers R, Larson PJ (2002) Manufacturing challenges in the commercial production of recombinant coagulation factor VIII. Haemophilia 8(Suppl 2):1–5

Johnson M, Lanthier S, Massie B, Lefebvre G, Kamen AA (1996) Use of the Centritech Lab centrifuge for perfusion culture of hybridoma cells in protein-free medium. Biotechnol Prog 12:855–864

Kaufman RJ, Pipe SW (1999) Regulation of factor VIII expression and activity by von Willebrand factor. Thromb Haemost 82:201–208

Kaufman RJ, Wasley LC, Dorner AJ (1988) Synthesis, processing, and secretion of recombinant human factor VIII expressed in mammalian cells. J Biol Chem 263:6352–6362

Kaufman RJ, Wasley LC, Davies MV, Wise RJ, Israel DI, Dorner AJ (1989) Effect of von Willebrand factor coexpression on the synthesis and secretion of factor VIII in Chinese hamster ovary cells. Mol Cell Biol 9:1233–1242

Kelley B, Jankowski M, Booth J (2010) An improved manufacturing process for Xyntha/ReFacto AF. Haemophilia 16:717–725

Kim BJ, Oh DJ, Chang HN (2008) Limited use of Centritech Lab II centrifuge in perfusion culture of rCHO cells for the production of recombinant antibody. Biotechnol Prog 24:166–174

McLeod A, Walker I, Zheng S, Hayward C (2000) Loss of factor VIII activity during storage in PVC containers due to adsorption. Haemophilia 6:89–92

Mei B, Chen Y, Chen J, Pan CQ, Murphy JE (2006) Expression of human coagulation factor VIII in a human hybrid cell line, HKB11. Mol Biotechnol 34:165–178

Mercille S, Johnson M, Lemieux R, Massie B (1994) Filtration-based perfusion of hybridoma cultures in protein-free medium: reduction of membrane fouling by medium supplementation with DNase I. Biotechnol Bioeng 43:833–846

Mufarrege EF, Antuña S, Etcheverrigaray M, Kratje R, Prieto C (2014) Development of lentiviral vectors for transient and stable protein overexpression in mammalian cells. A new strategy for recombinant human FVIII (rhFVIII) production. Protein Expr Purif 95:50–56

Selvaraj SR, Scheller AN, Miao HZ, Kaufman RJ, Pipe SW (2012) Bioengineering of coagulation factor VIII for efficient expression through elimination of a dispensable disulfide loop. J Thromb Haemost 10:107–115

Seyfried BK, Friedbacher G, Rottensteiner H, Schwarz HP, Ehrlich H, Allmaier G, Turecek PL (2010) Comparison of plasma-derived and recombinant von Willebrand factor by atomic force microscopy. Thromb Haemost 104:523–530

Shankaran H, Alexandridis P, Neelamegham S (2003) Aspects of hydrodynamic shear regulating shear-induced platelet activation and self-association of von Willebrand factor in suspension. Blood 101:2637–2645

Shevitz J (2003) Fluid filtration system. US 6544424 B1

Tokashiki M, Arai T, Hamamoto K, Ishimaru K (1990) High density culture of hybridoma cells using a perfusion culture vessel with an external centrifuge. Cytotechnology 3:239–244

Vlot AJ, Koppelman SJ, van den Berg MH, Bouma BN, Sixma JJ (1995) The affinity and stoichiometry of binding of human factor VIII to von Willebrand factor. Blood 85:3150–3157

Ward NJ, Buckley SM, Waddington SN, VandenDriessche T, Chuah MK, Nathwani AC, McIntosh J, Tuddenham EG, Kinnon C, Thrasher AJ (2011) Codon optimization of human factor VIII cDNAs leads to high-level expression. Blood 117:798–807

Weiss HJ, Sussman II, Hoyer LW (1977) Stabilization of factor VIII in plasma by the von Willebrand factor. Studies on posttransfusion and dissociated factor VIII and in patients with von Willebrand’s disease. J Clin Invest 60:390–404

Wise RJ, Dorner A, Krane M, Pittman D, Kaufman R (1991) The role of von Willebrand factor multimers and propeptide cleavage in binding and stabilization of factor VIII. J Biol Chem 266:21948–21955

Yabannavar VM, Singh V, Connelly NV (1992) Mammalian cell retention in a spinfilter perfusion bioreactor. Biotechnol Bioeng 40:925–933

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, SC., An, S., Kim, HK. et al. Effect of transmembrane pressure on Factor VIII yield in ATF perfusion culture for the production of recombinant human Factor VIII co-expressed with von Willebrand factor. Cytotechnology 68, 1687–1696 (2016). https://doi.org/10.1007/s10616-015-9918-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10616-015-9918-1