Abstract

The development of a versatile platform that can separate oil/water mixture, remove dye from water, and purify wastewater is extremely desirable, yet still hard to realize. Herein, to address this challenge, a composite hydrogel was produced by freezing–thawing treatment using chitosan, polyvinyl alcohol, and carbon black as the raw materials. The obtained hydrogel displayed both slippery oil-repellency and water-affinity in air, underwater, when submerged in oil, and exploiting this special wettability, the hydrogel coated mesh can be used to separate oil/water mixtures efficiently. After 25 oil–water separation cycles, the hydrogel-coated filter still had a separation efficiency of over 98%. With its superhydrophilicity and active functional groups, the resulting hydrogel was able to absorb dye molecules dissolved in water effectively. Due to the photothermal effect of carbon black, the local temperature of the hydrogel was increasing quickly under sunlight illustration, which allowed it to be an advanced platform for daily wastewater purification through solar distillation.

Graphical abstract

A versatile hydrogel platform for oil–water separation, dye adsorption, and domestic wastewater purification was developed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nowadays, the oily wastewater discharged from daily activities and industrial production processes is increasing, and leakage accidents are frequent, posing a severe threat to drinking water safety, ecological environment, marine life, and human health (Kintisch. 2010; Peterson et al. 2003; Aurell and Gullett 2010; Shannon et al. 2008; Wang et al. 2015). According to statistics, the cost of treating oily wastewater exceeds 38.3 billion dollars per year (Arnold et al. 2004; Liu et al. 2018). Therefore, it is urgent to develop an efficient and economical method to treat oily wastewater. General oily pollution treatment technologies include skimming (Nam et al. 2018), adsorption (Saruchi et al. 2015; Saruchi et al. 2016a, b; Saruchi et al. 2019), flotation (Saththasivam et al. 2016), centrifugation (Turano et al. 2002), chemical flocculation (Mostefa and Tir 2004), and in situ burning (Gelderena et al. 2017), etc. Traditional treatment technologies are inefficient and costly and suffer from secondary pollution. Designing porous membranes with opposite wetting behavior to water and oil has proven to be a good alternative for oil–water separation (Yuan et al. 2008; Xue et al. 2014; Wei et al. 2018). Hydrophobic/oleophilic membranes are typically developed for oil–water separation, but this type of membrane is easily contaminated by oil during the separation process, causing the desired separation efficiency to be decreased significantly. Moreover, water is always contacting the membrane before oil, due to its bigger density, which will prevent the separation. To overcome these limitations, separation membranes with underwater superoleophobicity have been explored, and they are more resistant to oil fouling when immersed in water. However, the oil will adhere to the membrane surface when the loss of water occurs, leading to decreased separation performance in continuous oil–water separation. Designing membranes with hydrophilicity and oleophobicity in both air and underwater is hoped to address these issues but has been proven to be difficult to realize, as it requires a complex interface with surface energy greater than water. Recently, Kong et al. produced a polymer blend coated mesh, which can exhibit superhydrophilic/superoleophobic properties after surface reconfiguration of the coating (Kong et al. 2021). Our group also developed a poly(vinyl alcohol) composite hydrogel coating that has water-attracting and oil-repelling in air, water, and oil surroundings (Lu et al. 2020). Furthermore, Wang et al. developed a superhydrophilic, underwater superoleophobic cellulose hydrogel-coated mesh (CHCM) produced from deep eutectic solvents. Based on this pre-wetted CHCM, the separation efficiency of various oil–water mixtures is above 98.0%, and the CHCM also has good recyclability and durability (Wang et al. 2021). Yang et al. firstly coated polydopamine (PDA) on the surface of paper fibers (PF@PDA) via CuSO4/H2O2 triggering to accelerate the reaction rate. Then, the BaSO4 nanosheets were deposited on the surface of PF@PDA membrane by alternating soaking process (ASP) to obtain superhydrophilic/underwater superoleophobic membrane (PF@PDA/BaSO4) for oil/water separation (Yang et al. 2020).

Apart from the oily wastewater problem, discharge of dye wastewater also leads to serious environmental pollution as well as resource waste. With the continuous increase of social demand, a large number of commodity dyes are used in paper, textile, paint, and other industries, and more than 280 thousand tons of wastewater are discharged into the environment every year, causing the treatment of dyeing wastewater to be a big challenge (Kalsoom et al. 2015). Among all technologies for treating dye wastewater, the adsorption method has attracted much attention due to the higher efficiency, recyclability of sorbent, simplicity (Saruchi et al. 2016a, b; Saruchi et al. 2019; Saruchi et al. 2021). Due to the different physical and chemical properties of soluble dyes and insoluble oils, one approach can only be applicable for one of the two contaminants (Zhu et al. 2017). Therefore, it is urgent to develop a versatile platform that can effectively achieve both oil–water separation and dye removal.

In this study, we have developed a composite hydrogel coating by the freezing–thawing method using polyvinyl alcohol, chitosan, and carbon black as the main raw materials. The obtained hydrogel coating exhibited both water-affinity and oil-repellency, and oil droplets could move freely on the water-wetted hydrogel surface. It also displayed superoleophobicity underwater and had excellent oil fouling resistance when submerged in an oil bath. Exploiting its water-attracting and oil-repellent property, the hydrogel-coated mesh can be used for the oil–water mixture and oil-in-water emulsion separation with high separation efficiency and good reusability. Importantly, the polyvinyl alcohol, chitosan, and carbon black in the hydrogel network were able to interact with the dye molecules through electrostatic effect, hydrogen bond interaction, and π-π interaction, allowing the dyes dissolved in water to be removed by our hydrogel effectively. Considering the simple fabrication process and integration of multiple functions of our hydrogel coating, this study is hoped to offer new insight into the areas of membrane separation industries and water purification.

Experimental section

Materials

Polyvinyl alcohol (PVA, 1799, Mw = 75, 000 Da, 99% hydrolyzed) and carbon black (CB) were obtained from Aladdin Chemical Reagent (Shanghai, China). Chitosan (CS, Mw = 130, 000 Da, Deacetylation: 80% ~ 95%, Viscosity: 20 ~ 300 cps), sodium hydroxide (NaOH), ethanol, and acetic acid (GR grade, ≥ 99.8%) were offered by Sinopharm Chemical Reagent Co, Ltd. Poly (diallyldimethylammonium chloride) (PDDA, Mw = 200, 000–350, 000 Da), perfluorooctanoic acid (signify as PFOA) were all obtained from Sigma-Aldrich. Sodium perfluorooctanoate (signify as PFOA-Na) with a concentration of 1.0 M was fabricated by the reaction of NaOH and PFOA in deionized water. Malachite green (MG), fluorescein sodium salt (FS), rhodamine B (RB), crystal violet (CV), orange II sodium salt (O II), sunset yellow FCF (SY), and methylene blue (MB) were purchased from Shanghai Macklin Biochemical Co., Ltd. Methyl orange (MO) was bought from Shanghai Aladdin Industrial Co., Ltd. All chemical reagents are of analytical-grade and used as received without further purification. Commercially available glass slide and copper mesh (200 mesh) were cleaned with acetone, ethanol, and deionized water successively in an ultrasonic cleaner before use.

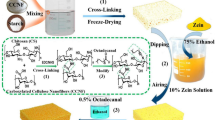

Preparation of the PVA-Chitosan-Carbon black (PCC) hydrogel

1.5 g of PVA was magnetically dispersed into 15 mL of deionized water at a temperature of 90 °C to form solution A. 0.8 g of CS and 0.32 g of acetic acid were added into 25 mL of deionized water under stirring at 50 ℃ to form solution B. Solution A was added into solution B under stirring to form a hybrid solution. Then, 0.8 g CB and 0.4 g PDDA were ultrasonically dispersed in the mixed solution, denoted as solution C. The solution C was rapidly injected into a plastic dish. The dish containing solution C was frozen at -25 °C for 6 h and thawed at room temperature for 2 h, and this freezing and thawing treatment was repeated three times. After removing from the plastic dish, the PCC hydrogel was obtained. Finally, the PCC hydrogel was immersed into 1.0 M PFOA-Na solution for 5 min and washed with deionized water to achieve the slippery oil-repellent property.

Characterizations

Contact angle (CA) and sliding angle (SA) values were acquired using a Krüss DSA 100 (Krüss Company, Ltd., Germany) apparatus at room temperature. Scanning electron microscopy measurements were performed using JSM-6701F field-emission scanning electron microscopy (FESEM, JEOL, Japan). Energy-dispersive X-ray (EDX) spectroscopy analysis was conducted on a NORAN System Six X-ray microanalysis system (THERMO) connected to the FESEM system. We perform oil-in-water emulsion separation through a solvent filtration unit (Tianjin Jinteng Technology Co., Ltd.). The digital image of the distributed droplets in the oil-in-water feed emulsions and filtrates were acquired by an optical microscope (Stemi 508 trino Microscope, ZEISS). UV–visible absorption spectroscopy data were obtained using a HITACHI U-3010 UV–vis spectrophotometer. The PCC Hydrogel absorber was illuminated using a solar simulator (CEL-PE300L-3A). Thermal images were collected, using an IR Thermal Camera (FLIR Ts-650).

Results and discussion

Surface topography and chemistry analysis

The PCC hydrogel was developed through freezing–thawing treatment using CS, PVA, and CB as the raw materials. The CS was chosen due to its rich source, biocompatibility, and its active hydroxyl and amino groups, and PVA was applied to crosslink with CS to form a double network hydrogel that possessed enhanced mechanical property. CB with photothermal effect can convert solar radiation into heat, which was beneficial to power the evaporation of water.

The surface topography and chemistry of the obtained PCC hydrogel are shown in Fig. 1. As shown in Figs. 1a and 1b, the hydrogel coating surface was un-flat and covered by raised textures with varied sizes, and there were some microporous structures distributed randomly between the raised structure (see Fig. 1c). The elements of oxygen (O), carbon (C), fluorine (F), and nitrogen (N) were well distributed on the hydrogel surface, according to EDX analysis (see Fig. 1d-g). Moreover, the content of the F element was found to be as high as 16.7%, implying that the PCC hydrogel surface was enriched in low-surface-energy fluorocarbon groups.

Surface wettability in the air surrounding

PCC hydrogel surface displayed water-attracting and oil-repelling properties in the air environment. As shown in Fig. 2a, the water droplet was able to wet the PCC hydrogel surface completely and immediately (less than 0.5 s), displaying a water CA of 0° eventually. In comparison, oil droplets such as rapeseed oil exhibited a CA of 65.5° and were pinning on the surface. Moreover, the rapeseed oil droplet did not show any diffusing even after 20 min, as shown in Fig. 2c and Figure S1 (\({\mathrm{a}}_{1}\)-\({\mathrm{d}}_{1}\)). Amazingly, when wetted by water, a water layer forms on the surface of the hydrogel, which acts as a lubricant to achieve slippery oil-repellent properties. As shown in Fig. 2b, all tested oil droplets with small CA values floated on the water-wetted hydrogel surface, and they could move freely on it due to the fluidity of the water lubricant. As shown in Fig. 2d and Fig. 2e, a rapeseed oil droplet was moving readily on the water-wetted PCC hydrogel surface tilted by 4° without any oil tracing left on the surface.

Wetting property in air. Droplets of water (dyed by methylene blue) and different oil droplets on the dry (a) and water-wetted (b) PCC hydrogel surface; Oil droplet was pinning on the dry PCC hydrogel surface (c), while it was moving freely on the water-wetted hydrogel surface (d and e). The scale bar is 1 cm

Mechanism of the water-attracting and oil-repelling wettability

The total surface free energy of a solid (\({\gamma }_{s}\)) was considered as the sum of contributions from the dipole hydrogen bonding (\({\gamma }_{s}^{d}\)) and dispersion force components (\({\gamma }_{s}^{p}\)) (Fowkes. 1964; Owens and Wendt 1969; Fowkes et al. 1988). The water-attracting and oil-repelling properties can be achieved on one surface if it had an adequately big \({\gamma }_{s}^{p}\) and an adequately small \({\gamma }_{s}^{d}\) simultaneously, based on recent research (Fowkes et al. 1988). As for the PCC hydrogel coating, the fluorinated groups minimize the \({\gamma }_{s}^{d}\) constituent, resulting in oil repellency, whereas the hydrophilic carboxyl, hydroxyl, and quaternary ammonium groups were able to increase the \({\gamma }_{s}^{p}\) constituent, leading to a strong affinity to water molecules. When wetted by water, the PCC hydrogel surface was covered by a water layer that can serve as a lubricant to resist oil droplets. With the help of the mobility of the water lubricant, oils immiscible with water were moving easily on the water-wetted PCC hydrogel without any pinning (Fig. 2e). The detailed surface wettability mechanism was described in the Supporting Information section.

Underwater wetting behavior analysis

PCC hydrogel possessed extremely strong water affinity, which allowed it to display superoleophobic and self-cleaning underwater. All tested oil droplets exhibited oil CA greater than 150° and SA less than 5° on the PCC hydrogel surface underwater. Figure 3a shows that a jet of toluene was bouncing off the hydrogel surface readily without any residue leaving underwater. Sticky crude oil was further chosen to check the oil repellency of the hydrogel. The dry PCC hydrogel was fouled by dropping crude oil on it, and then the oil-fouled hydrogel was immersed in water to test its self-cleaning property. The result shows that the crude oil droplets pinned on the hydrogel surface shrank into spheres within a few seconds and then detached from the surface within two seconds, leaving a completely clean surface (see Fig. 3b). Thanks to its strong water affinity, a hydration layer around the hydrogel was forming, which could serve as shielding to reduce the oil-solid interface and decrease the oil adhesion strength (Zhang et al. 2018).

Wetting behavior in oil surrounding

We next study the wetting behavior of the PCC hydrogel under an oil environment, to further analyze the water affinity strength of the hydrogel. As shown in Fig. 4a, a water droplet (dyed with methylene blue) was able to wet the PCC hydrogel surface completely with a time less than 0.14 s under oil conditions, when contacting the PCC hydrogel under oil. This phenomenon indicated that the PCC hydrogel could still bind water strongly even immersion in oil. Interestingly, a mirror-like phenomenon was observed on the water-wetted PCC hydrogel surface summered in an oil bath. This was because a water layer forming on the PCC hydrogel surface can act as a shielding layer to prevent the oil from contacting the surface (see Fig. 4b). Importantly, the water layer remained stable even after immersion in oil for one day, allowing the PCC hydrogel surface to be completely clean when taken out from oil (see Fig. 4c). These results indicated that the PCC hydrogel had a strong water affinity strength even immersion in an oil bath for a long time.

Mechanical property analysis

The mechanical properties of the obtained PCC hydrogel were also analyzed, and the result showed that it possessed enhanced stiffness and elasticity. As shown in Fig. 5a, a PCC hydrogel sample (5.3 cm × 2.2 cm × 0.25 cm) can support a 2.4 kg steel block, implying its high mechanical strength. However, the single network PVA hydrogel sample with the same shape failed when loaded with the same weight (as shown in Figure S2). The obtained PCC hydrogel also had improved elasticity. As shown in Fig. 5b, PCC hydrogel could be stretched to 215% of the original length, and it was restored to its original shape when the load was removed.

Oil/water separation analysis

The PCC hydrogel-coated mesh is hydrophilic and oil-repellent, and it is a suitable membrane for oil/water separation due to these properties. When the oil–water mixture (namely water/toluene mixture) was contacting the separation membrane, water was passed through the membrane and collected underneath, while oil was remaining above it without any permeation (see Fig. 6a). Other types of oil/water mixtures can be separated in the same way with high separation efficiency (see Fig. 6b). Thanks to its slippery oil repellency, residual oil stains on the membrane surface after separation can be easily removed by water rinsing. Moreover, the the membrane still had enhaced separation efficiency to the water/toluene mixtures with varied pH value and temperatue, as shown in Figure S5. Imporatanly, the hydrogel-coated filter still had a separation efficiency of over 98% even after 25 oil–water separation cycles (see Fig. 6c).

Oil/water separation analysis. The PCC hydrogel coated copper mesh was used as a separation membrane for oil/water separation (a); Variation of separation efficiency for different oil/water mixtures; The T-W, R-W, O-W, E-W, and H-W in image b represented toluene-water, rapeseed oil–water, olive oil–water, engine oil–water, and hexadecane-water, respectively (b); The oil/water separation efficiency of the separation membrane as a function of separation cycles (c)

The PCC hydrogel-coated copper mesh can also be used for oil-in-water emulsion separation. As shown in Fig. 7, the filtrate (hexadecane-in-water) changed from milky white to transparent after one cycle of separation. No hexadecane droplets with the size in the range of 1–7 μm were observed in the filtrate, as evidenced by optical microscope analysis (as shown in Fig. 7b). When the oil-in-water emulation contacted the PCC hydrogel-coated copper mesh, the continuous water phase quickly penetrated the hydrogel surface to form a water hydration layer and then continuously passed through the coated mesh with the help of gravity and capillary force. Meanwhile, oil droplets dispersed in the water bath were repelling by the hydration layer around the PCC hydrogel, and they were gathering together, growing into oil droplets of bigger size, and floating up the water surface to become a free oil layer eventually. As a result, emulsion separation was realized by the PCC hydrogel-coated copper mesh.

Removing dyes from water

Discharge of dye wastewater leads to serious environmental pollution as well as resource waste. Herein, our created PCC hydrogel can be applied as an absorbent platform for removing dyes from water. The PCC hydrogel sample with the weight of 1 g was placed into the RB dye-colored aqueous solution (18 mg/L, 10 ml) at room temperature. When contacted with the RB aqueous solution, the RB dye molecular was absorbed in the PCC hydrogel network instantaneously. Automatically, the color of the RB aqueous solution was fading gradually with the time going on. The RB dye-colored solution became transparent after PCC hydrogel abortion for 8 h, and no RB was found in the solution, evidenced by UV–vis spectra analysis (see Figure S6). Other types of dyes such as MG and CV dissolved in water can also be absorbed efficiently in the same way, as shown in Fig. 8. Furthermore, our PCC hydrogel can also function as a filter module for dyes removal, after putting the powdered hydrogel into a syringe. The dyes including MB and CV were retained above the filter (see Figures S8 a and b), and the filtrate became transparent after one cycle of treatment (see Figures S8 c and d). These results showed that the obtained PCC hydrogel was a good candidate for removing dyes from water.

As for the PCC hydrogel, the water-affinity of the PCC hydrogel could provide sufficient contact between it and the dyes molecular in the solution (Bazrafshan et al. 2013; Holkar et al. 2016). Importantly, the unique chemistry of the PCC hydrogel offered the active sites for dyes absorption. The active amino and hydroxyl groups on the CS molecular chain can chelate and adsorb dyes by electrostatic effect and hydrogen bond interaction (Nikolaos et al. 2007; George et al. 2010, 2008; Chandi et al. 2021). With the help of the hydroxyl groups in the PVA, the dye absorption performance of PCC hydrogel was further improved. Also, the well-distributed CB particles in the hydrogel were able to interact with dyes by π-π interaction (Tian et al. 2020; Das et al. 2008; Ramesha et al. 2011; Xiao et al. 2016). The combination of electrostatic effects, hydrogen bonding interactions, and π-π interactions of PCC hydrogels enables the efficient removal of dyes dissolved in water (see Figure S7). Moreover, the absorption capacity of the PCC hydrogel was varied to the dye solutions with different pH values and concentrations, as shown in Figure S9.

Daily wastewater purification

Finally, the PCC hydrogel was demonstrated as an advanced platform for daily wastewater purification through solar distillation. Herein, a homemade device was designed for water purification as shown in Figure S10. The PCC hydrogel sheet was floating on the wastewater surface, the transparent plastic wrap, pebbles, and the beaker located in the wastewater container were applied for water vapor generation, water condensing, purified water movement guiding, and purified water containing, respectively. Due to the photothermal effect of CB, the local temperature of PCC hydrogel rapidly rises from 18.5 °C to 40.6 °C under sunlight illustration (see Fig. 9a), which allowed it to power water evaporation. When touching the plastic warp, the water vapor condensed on it, and then the condensed water was guided to flow on the bent plastic wrap and finally collected in the beaker underneath. Figures 9b, c, and d show the wastewater images in our daily life gathered from the kitchen, laundry, and bathing before and after purification. The result showed that all three solutions changed from milky to transparent after purification. Moreover, there was no emulsified droplet in the purified water evidenced by dynamic light scatting analysis, and the pH values for the three water samples after purification were all close to 7 (see Figure S11 and Figure S12). The PCC hydrogel exhibited a high water steam generation rate of ~ 1.21 kg \({\mathrm{m}}^{-2}{\mathrm{h}}^{-1}\) under one sun illumination. These results implied that our PCC hydrogel is hoped to be a promising alternative for daily wastewater purification.

Conclusions

In summary, a PCC hydrogel was fabricated through the freezing–thawing method. The resulting PCC hydrogel displayed both water-attracting and oil-repellency in air, water, and oil surroundings. Water was able to wet the hydrogel surface completely and easily. Wetted hydrogel surfaces appear oil repellent in air, have superoleophobicity underwater, and show resistance to oil fouling when submerged in oil. Due to the crosslinking between CS and PVA, the resulting dual network PCC hydrogel possessed enhanced stiffness and elasticity. Because of its water-affinity and oil-repellency, the hydrogel-coated mesh was able to separate immiscible oil–water mixtures and oil-in-water emulsions with high separation efficiency. The PCC hydrogel was able to interact with the dye molecules through electrostatic effect, hydrogen bond interaction, and π-π interaction, allowing it to serve as an absorbent to remove dyes from water effectively. Finally, the PCC hydrogel was demonstrated as an advanced platform for daily wastewater purification, through solar distillation, exploiting its photothermal effect-induced temperature accelerating. Possible applications of our PCC hydrogel could be found in the areas of membrane separation industries, wastewater purification, and sewage treatment.

References

Arnold R, Burnett DB, Elphick J, Feeley T, Galbrun M, Hightower M, Jiang Z, Khan M, Lavery M, Luffey F (2004) Managing water-from waste to resource. Oilfield Rev 16:26–41

Aurell J, Gullett BK (2010) Aerostat sampling of PCDD/PCDF emissions from the Gulf oil spill in situ burns. Environ Sci Technol 44:9431–9437

Bazrafshan E, Mostafapour FK, Hosseini AR, Khorshid AR, Mahvi AH (2013) Decolorisation of Reactive Red 120 dye by using single-walled carbon nanotubes in aqueous solutions. J Chem 2013:1–8

Chandi PES, Senthilkumar SGK, Selvaraju N (2021) A detailed insight on fabricated porous chitosan in eliminating synthetic anionic dyes from single and multi-adsorptive systems with related studies. Chemosphere 281:103706

Das B, Voggu R, Rout CS, Rao CNR (2008) Changes in the electronic structure and properties of graphene induced by molecular charge-transfer. Chem Commun 5155–5157

Fowkes FM (1964) Attractive Force at Interface. Ind Eng Chem 56:40–52

Fowkes FM, Huang YC, Shah BA, Kulp MJ, Lloyd TB (1988) Interaction of Hydrophobized Filaments in Aqueous Electrolyte Solutions. Colloids Surf 29:243–261

Gelderena LV, Malmquistb LMV, Jomaas G (2017) Vaporization order and burning efficiency of crude oils during in-situ burning on water. Fuel 191:528–537

George ZK, Dimitrios NB, Nikolaos KL (2008) Low-Swelling Chitosan Derivatives as Biosorbents for basic Dyes. Langmuir 24:4791–4799

George ZK, Margaritis K, Nikolaos KL (2010) Relating Interactions of Dye Molecules with Chitosan to Adsorption Kinetic Data. Langmuir 26:9617–9626

Holkar CR, Jadhav AJ, Pinjari DV, Mahamuni NM, Pandit AB (2016) A critical review on textile wastewater treatments: Possible approaches. J Environ Manage 182:351–366

Kalsoom U, Bhatti HN, Asgher M (2015) Characterization of plant peroxidases and their potential for degradation of dyes: a review. Appl Biochem Biotechnol 176:1529–1550

Kintisch E (2010) An audacious decision in crisis gets cautious praise. Science 329:735–736

Kong WT, Li FR, Pan YL, Zhao XZ (2021) Hygro-responsive, Photo-decomposed Superoleophobic/Superhydrophilic Coating for On-Demand Oil-Water Separation. ACS Appl Mater Interfaces 13:35142–35152

Liu Y, Su Y, Guan J, Cao J, Zhang R, He M, Gao K, Zhou L, Jiang Z (2018) 2D heterostructure membranes with sunlight-driven self-cleaning ability for highly efficient oil-water separation. Adv Funct Mater 28:1706545

Lu JW, Gao ZS, Xu T, Zhu XT, Miao X, Song YM, Ren GN, Li XM (2020) Robust Hydrogel Coating with Oil-Repellent Property in Air, Water, and Oil Surroundings. ACS Appl Mater Interfaces 12:49138–49145

Mostefa NM, Tir M (2004) Coupling flocculation with electroflotation for waste oil/water emulsion treatment. Optimization of the Operating Conditions Desalination 161:115–121

Nam C, Li H, Zhang G, Lutz LR, Nazari B, Colby RH, Chung TCM (2018) Practical oil spill recovery by a combination of polyolefin absorbent and mechanical skimmer. ACS Sustain Chem Eng 6:12036–12045

Nikolaos KL, George ZK, Alexandros AV, Dimitrios NB (2007) Chitosan Derivatives as Biosorbents for Basic Dyes. Langmuir 23:7634–7643

Owens DK, Wendt RC (1969) Estimation of the Surface Free Energy of Polymers. J Appl Polym Sci 13:1741–1747

Peterson CH, Rice SD, Short JW, Esler D, Bodkin JL, Ballachey BE, Irons DB (2003) Long-term ecosystem response to the exxon valdez oil spill. Science 302:2082–2086

Ramesha GK, Vijaya Kumara A, Muralidhara HB, Sampath S (2011) Graphene and graphene oxide as effective adsorbents toward anionic and cationic dyes. J Colloid Interface Sci 361:270–277

Saruchi KBS, Jindal R, Kumar V (2015) The adsorption of crude oil from an aqueous solution using a gum tragacanth polyacrylic acid based hydrogel. Petrol Sci Technol 33:278–286

Saruchi KV, Vikas P, Kumar R, Kumar B, Kaur M (2016a) Low cost natural polysaccharide and vinyl monomer based IPN for the removal of crude oil from water. J Petrol Sci Eng 141:1–8

Saruchi KV, Kaith BS, Jindal R (2016b) Synthesis of Hybrid Ion Exchanger for Rhodamine B Dye Removal: Equilibrium, Kinetic and Thermodynamic Studies. Ind Eng Chem Res 55:10492–10499

Saruchi SM, Hatshan MR, Kumar V, Rana A (2021) Sequestration of Eosin Dye by Magnesium (II)-Doped Zinc Oxide Nanoparticles: Its Kinetic, Isotherm, and Thermodynamic Studies. J Chem Eng Data 66:646–657

Saruchi, Vaneet K (2019) Separation of crude oil from water using chitosan based hydrogel. Cellulose 26: 6229–6239

Saruchi, Thakur P, Kumar V (2019) Kinetics and thermodynamic studies for removal of methylene blue dye by biosynthesize copper oxide nanoparticles and its antibacterial activity. J Environ Health Sci 17: 367–376

Saththasivam J, Loganathan K, Sarp S (2016) An overview of oil-water separation using gas flotation systems. Chemosphere 144:671–680

Shannon MA, Bohn PW, Elimelech M, Georgiadis JG, Mariñas BJ, Mayes AM (2008) Science and technology for water purification in the coming decades. Nature 452:337–346

Tian XX, Zhu HS, Meng X, Wang J, Zheng CL, Xia YZ, Xiong Z (2020) Amphiphilic Calcium Alginate Carbon Aerogels: Broad-Spectrum Adsorbents for Ionic and Solvent Dyes with Multiple Functions for Decolorized Oil-Water Separation. ACS Sustainable Chem Eng 8:12755–12767

Turano E, Curcio S, Paola MGD, Calabrò V, Iorio G (2002) An integrated centrifugation-ultrafiltration system in the treatment of olive mill wastewater. J Membr Sci 209:519–531

Wang B, Liang W, Guo Z, Liu W (2015) Biomimetic super-lyophobic and super-lyophilic materials applied for oil/water separation: a new strategy beyond nature. Chem Soc Rev 44:336–361

Wang HQ, Li JC, Yu X, Zhao XY, Zeng XH, Xu F, Tang X, Sun Y, Lin L (2021) Facile fabrication of super-hydrophilic cellulose hydrogel-coated mesh using deep eutectic solvent for efficient gravity-driven oil/water separation. Cellulose 28:949–960

Wei YB, Qi H, Gong X, Zhao SF (2018) Specially wettable membranes for oil-water separation. Adv Mater Interfaces 5:1800576

Xiao JL, Lv WY, Xie Z, Tan YQ, Song YH, Zheng Q (2016) Environment-friendly reduced graphene oxide as a broad-spectrum adsorbent for anionic and cationic dyes via π-π interaction. J Mater Chem A 4:12126–12135

Xue ZX, Cao YZ, Liu N, Feng L, Jiang L (2014) Special wettable materials for oil/water separation. J Mater Chem A 2:2445–2460

Yang J, Xie AT, Cui JY, Chen YY, Lang JH, Li CX, Yan YS, Dai JD (2020) An acid-alkali-salt resistant cellulose membrane by rapidly depositing polydopamine and assembling BaSO4 nanosheets for oil/water separation. Cellulose 27:5169–5178

Yuan JK, Liu XG, Akbulut O, Hu JQ, Suib SL, Kong J, Stellacci F (2008) Superwetting nanowire membranes for selective absorption. Nat Nanotechnol 3:332–336

Zhang S, Jiang G, Gao S, Jin H, Zhu Y, Zhang F, Jin J (2018) Cupric Phosphate Nanosheets-Wrapped Inorganic Membranes with Superhydrophilic and Outstanding Anticrude Oil-Fouling Property for Oil/Water Separation. ACS Nano 12:795–803

Zhu H, Chen D, Li N, Xu Q, Li H, He J, Lu J (2017) Dual-layer copper mesh for integrated oil-water separation and water purification. Appl Catal B 200:594–600

Acknowledgments

This work was supported by the National Nature Science Foundation of China (11704321) and Yantai Science and Technology Plan Projects (2019XDHZ087).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

ESM 1

Supporting Information: Experimental details and further information on characterization associated with this paper can be found in this section.(DOC 9451 kb)

Rights and permissions

About this article

Cite this article

Li, F., Miao, G., Gao, Z. et al. A versatile hydrogel platform for oil/water separation, dye adsorption, and wastewater purification. Cellulose 29, 4427–4438 (2022). https://doi.org/10.1007/s10570-022-04535-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-022-04535-4