Abstract

In this research, cotton fabrics were selectively oxidized by periodate to produce aldehyde groups at C2 and C3 positions. Their changes in physico-chemical properties such as crystallinity, surface morphology, tensile strength, iodine sorption value and aldehyde group content were determined by different analytic methods. It was concluded that the periodate oxidization could decrease the crystallinity, reduce the tensile strength and create a number of aldehyde groups in cotton. Subsequently, the original and periodate oxidized cotton fabrics were subjected to cellulase treatment for evaluating the influences of oxidization on the enzymatic performance of cellulase. The results indicated the conversion of alcohol to aldehyde groups promoted the binding of cellulase to cotton substrates. Meanwhile, it was found that the higher periodate oxidization led to greater hydrolysis of cotton because of the higher adsorption ability of cellulase and larger amorphous areas in cotton after periodate oxidization.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cotton contains cellulose of high molecular weight together with some natural non-cellulosic substances (Lin et al. 2008; Rajendran and Sivalingam 2013). Cotton fiber is the most important textile fiber because it is naturally abundant, biodegradable, comfortable, stable to chemicals and safe to living bodies (Fu and Lu 2013; Hao et al. 2012a, b). In recent years, cellulase enzymes have been widely utilized to produce special finishing effects on cotton substrates such as stone-washed or bio-polishing appearance (Hao et al. 2017; Ibrahim et al. 2011). Further, the enzymatic saccharification of cotton cellulose has been an acceptable way of obtaining diverse cellulosic bio-chemicals such as glucose and ethanol (Baratieri et al. 2008). Generally, cellulase refers to a group of enzymes including endo-glucanase (EC 3.2.1.4), exo-glucanase (EC 3.2.1.74 and EC 3.2.1.91) and β-glucosidases (EC 3.2.1.21), which can synergistically degrade the 1, 4-beta-D-glycosidic linkages in cotton molecules with the assistance of mechanical forces (Hao et al. 2014; Ling et al. 2018; Xia et al. 2017).

When cellulase is used for hydrolyzing cotton, various factors play important roles such as physical properties and composition of the substrate, available surface area, enzyme complex synergy, and physico-chemical modifications to the substrate (Chang and Holtzapple 2000; Garcia-Ubasart et al. 2013; Hao et al. 2016; Hendriks and Zeeman 2009; Laureano-Perez et al. 2005; Shaikh et al. 2011). Structural parameters of cotton including the degree of swelling, orientation and crystallinity produce remarkable influences on its enzymatic hydrolysis (Zhang and Lynd 2004). Some physical or chemical pretreatments can decrease or eliminate the natural recalcitrance of cellulose towards cellulase attack, leading to higher hydrolytic effect (Lu et al. 2016). The physical pretreatment is usually focused on increasing surface area of cellulosic materials. Mandels et al. (1974) observed an increase of saccharification ability of cellulase from Trichoderma viride on the cellulose pretreated by ball milling. van Wyk (1997) found a homogenization and ultrasonication pretreatment could produce a 5–30% increase to the hydrolysis rate of cellulase for different types of cellulose. Su et al. (2017) recently disclosed that ultrasound treatment led to the erosion of cellulose, thus increasing its accessibility and resulting in a significant enhancement in enzymatic hydrolysis. Szabo and Csiszar (2017) investigated the effect of various factors such as amplitude of sonication, duration of hydrolysis, form of the substrates and their movement, and the distance of fabric layers to the tip of horn on the efficiency of the enzymatic hydrolysis of cellulose with low frequency ultrasound. They found that low frequency ultrasound had a much more pronounced effect on the enzyme catalyzed hydrolysis of cotton than the conventional agitating methods.

Chemical pretreatment was also utilized to change interchain hydrogen bonding of cellulose for improving the enzymatic hydrolysis to it. Alkali pretreatment of cellulose was proven to be a positive means of increasing the hydrolysis rate because the alkali could swell the cellulose to increase its susceptibility. Liquid hot water pretreatment could effectively improve the enzymatic hydrolysis of some cellulosic materials (Lu et al. 2016). However, some chemical pretreatments to cotton might have negative impacts on the hydrolytic properties of cellulase. Hao et al. (2012b) once pretreated the cotton with a cationic agent to change its surface electric properties before cellulase hydrolysis. They revealed that the cationization pretreatment obviously facilitated the binding efficiency of cellulase protein but the hydrolytic activity towards this pretreated cotton was reduced because of the movement restriction and dysfunction of cellulase protein by the cationization.

Chemical modification to cotton by oxidizing agents is now a novel procedure to add its functionality. Oxidation reaction creates various functional groups including aldehyde, ketone and carboxyl groups depending on the nature of the oxidant and specific oxidation conditions. Most oxidations proceed with low selectivity, but the oxidation of cotton with periodate is a highly selective process. This reaction cleaves the C2-C3 bond of the glucopyranoside ring according to the mechanism of Malaprade reaction and introduces two aldehyde groups at C-2 and C-3 positions resulting in a dialdehyde compound (Vicini et al. 2004). Periodate oxidation can minimize the degradation and largely retain the morphological and mechanical properties of the starting cotton materials. Shaikh et al. (2011) once developed dialdehyde cellulose for enhancing enzymatic hydrolysis of cellulose substrate by hydrolytic (cellulase) enzymes. They found that the dialdehyde cellulose could be hydrolyzed to a higher extent than the starting cellulose at high levels of aldehyde content, which was attributed to H-bonding of aldehyde with other hydroxyls in cellulose as well as formation of hemiacetal like structures. Further, a series of dialdehyde cellulose derivatives including dicarboxylate, dicarboxy and Schiff’s base were prepared by the authors for proposing a strategy by chemical modification to achieve a greater extent of hydrolysis of cellulose.

In this research, the cotton substrate was selectively oxidized by sodium periodate and subsequently subjected to enzymatic hydrolysis by cellulase. The modification from oxidation would be evaluated by the changes in the physico-chemical properties of cotton using instrumental and chemical analytic methods. The periodate oxidation would disrupt the inner structure of cotton, thereby increasing the accessibility of cellulase to it and thus enhancing the enzymatic actions of cellulase. Apart from investigating the influences of periodate oxidization on enzymatic hydrolysis of cotton, the binding properties of cellulase to oxidized cotton would be theoretically analyzed by Langmuir isotherm model. It was observed that the binding capacity of cellulase was improved with the increasing oxidation extent of cotton. Thus, this method could potentially be used to immobilize more cellulase protein on cotton substrate.

Experimental

Materials

Cotton knit fabrics (175 g/m2) after conventional preparation were purchased from Sunvim Textile Company of China. They were boiled in 98 °C hot distilled water for 15 min prior to use for removing any residuals. The cellulase enzyme (100 mg/ml protein content, from Trichoderma reesei) was obtained from Haiyi Chemicals Company of China and used directly. Deionized water was employed throughout the work. All other chemicals were purchased as analytical reagent from Aladin Chemicals Company and used without further purification.

Periodate oxidation of cotton fabrics

Cotton fabrics were subjected to the oxidation by sodium periodate in the following method. The cotton fabrics (5 g for each sample) were treated with two NaIO4 charges (0.03 mol/l as a low dosage and 0.06 mol/l as a high dosage), respectively, for 6 h in closed vessels at room temperature in the absence of light. The liquor ratio was set at 1:50 and the vessels were stirred gently at a speed of 60 r/min. After completion of the oxidation, the cotton samples were soaked into the 0.1 M glycerol solutions for 30 min to remove unreacted oxidant and then rinsed using cold distilled water to neutral condition. Finally, the samples were dried in a regular dryer.

Enzymatic treatment of cotton fabrics

Enzymatic treatment of cotton fabrics was carried out at 55 °C and pH 5.0 in a dyeing machine with a 120r/m rotation speed. The cotton substrates (2 g for each sample) were soaked in cellulase solutions (100 ml) with initial cellulase concentrations of 2.5–40 mg/g of cellulase to cotton. An aliquot of 5 mL was withdrawn after defined time for measuring the residual cellulase concentration using Bradford method. The sample was centrifuged at 10,000 rpm for 5 min and the supernatant was further filtered through a 0.25 μm syringe filter to remove the impurities. The cotton samples were washed thoroughly with water (3 × 20 ml, 60 °C for 10 min) and the amount of bound cellulase was determined by subtracting the free protein from the initial protein loaded in the solution. Finally, the treated cotton fabrics were dried and conditioned at 20 °C under 65% relative humidity. The soluble reducing sugars released after 30 min treatment were determined according to the DNS method using glucose for calibration (Miller 1959). All the experiments were run in triplicate and the average data were presented.

Determination of weight loss and strength of cotton fabrics

Weight loss of oxidized cotton fabrics, as a result of treatment, was evaluated by applying the direct gravimetric method (Hao et al. 2014). The tensile strength of all cotton fabrics was tested by using a YM065A Tensile Testing Machine (Laizhou Electronics Corporation, China) with a strain rate of 200 mm/min. Samples pieces of 50 × 200 mm dimensions were prepared and the distance between the clamping grips was 100 mm. The final tensile strength of the fabrics was reported as the mean value of 20 measurements.

Determination of aldehyde content in cotton fabrics

Titration method by hydroxylamine hydrochloride/sodium hydroxide was used to determine the aldehyde content in cotton samples(Ding et al. 2017; Zhao and Heindel 1991). The amino groups in hydroxylamine hydrochloride can react with the aldehyde groups in cotton, liberating an equimolar amount of hydrogen chloride to aldehyde groups. Thus, aldehyde content (mmol/g) can be accurately quantified by titrating the amount of liberated hydrogen chloride using 0.1 M NaOH solution. Each test was run in triplicate and the mean result was reported.

Determination of iodine sorption value of cotton fabrics

Iodine sorption value (ISV) of cotton samples was determined by previously mentioned method (Pejic et al. 2015; Siroka et al. 2008). In brief, a sample of cotton (0.2 g) was immersed in 2 ml I2/KI solution for 5 min. After that, 100 ml of saturated sodium sulphate was added and the specimen shaken for 1 h at 25 °C. After that, the solution was filtered and the iodine concentration of the sample and blank solution was determined by titration using 0.02 M sodium thiosulphate.

Assessment of cotton wettability

The wettability of cotton was determined by the water drop absorbency according to the AATCC Test Method 79-2000. A drop of deionized water was dropped from a fixed height onto the smooth surface of sample and meanwhile the time for the water drop to be absorbed was recorded as the wetting time (s).

Fluorescence measurement

Intrinsic fluorescence spectra of cellulase were plotted using a Cary Eclipse fluorescence spectrophotometer with quartz cuvette under an excitation wavelength of 280 nm. Emission spectra were rectified using buffer solution as a blank before sample testing. All the measurements were subsequently carried out within the range from 300 to 550 nm under a constant 600 nm/min scanning speed at 25 °C.

FTIR, XRD and SEM analysis

FTIR spectra of cotton fabrics were recorded using a Nicolet Spectrometer with a universal ATR sampling accessory. All samples were investigated from 4000 to 400 cm−1 with an accumulation of 40 scans and resolution of 4 cm−1. For X-ray diffraction (XRD) analysis, the cotton samples were ground into fine powder and then tested from 5 to 40° diffraction angle at 2° min−1 scan rate on an X-ray powder diffractometer. The crystallinity index (CrI) was calculated according to the ratio of the area from the crystalline phase to total area after a deconvolution process using PeakFit Software. The morphology of cotton fabrics was evaluated by a field-emission scanning electron microscope (JEOL JSM-5300) operated at the 15 kV accelerating voltage.

Results and discussion

Physicochemical properties of periodate oxidized cotton

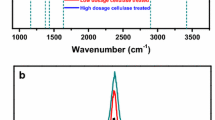

During the periodate oxidization process, the glucopyranose rings in cotton are selectively cleaved at vicinal C-2 and C-3 positions and the attached secondary diol moieties are turned into aldehyde groups (Guigo et al. 2014). Mid-infrared spectra can be used to detect the changes in the cotton after oxidation. Figure 1 shows the FT-IR spectra of original and oxidized cotton. For all samples, the broad peaks around 3300 cm−1 and 2900 cm−1 are assigned to O–H and C–H stretching, respectively. For the oxidized cotton, a new characteristic band appears at around 1730 cm−1 due to the stretching vibration of the C=O bonds in the aldehyde groups newly generated (Fan et al. 2001). Usually, the identification of the aldehyde groups in cotton is difficult because they can present in hydrated forms or as hemiacetal which do not show a classical peak of the aldehyde (Vicini et al. 2004). Other characteristic bands at 1429 cm−1 (CH2 scissoring motion), 1372 cm−1 (C–H bending) and 1163 cm−1 (C–O–C bond vibration) don’t show apparent changes after the periodate oxidation (Lin et al. 2008). The absorption band at 890 cm−1 indicates the presence of hemiacetal C–O–C bridges in cotton samples. A small 890 cm−1 peak is inherently present in the spectrum of original cotton because intramolecular hemiacetal groups are also present in its molecular backbone (Zhang et al. 2017).

XRD analysis is widely employed for evaluating the crystallinity of cotton substrate (French and Santiago Cintrón 2013; Langan et al. 2001; Nishiyama et al. 2012; Sugiyama et al. 1991; Wada et al. 1997; Yue et al. 2012). The XRD spectra of original and periodate oxidized cotton are presented in Fig. 2 to demonstrate the changes in crystalline structure after periodate oxidation. The diffractograms show that no new crystalline lattice type is developed after oxidation. By using the XRD deconvolution method, the crystallinity index (CrI) is calculated to be 59.3%, 57.0% and 52.6% for original, low and high dosage periodate oxidized samples, respectively. This definitely reveals the periodate oxidation can slightly decrease the crystallinity of cotton. The loss in crystallinity is because the periodate oxidation can disrupt of the order structure of cotton. Many previous studies have also shown the periodate oxidation results in a continuous decrease in crystallinity of cellulose (Kim et al. 2000; Siller et al. 2015; Rowland and Cousins 1966; Varma and Chavan 1995). However, some researchers have reported a slight increase in crystallinity after periodate oxidation due to partial dissolution of the oxidized fraction (Xu and Huang 2011). In addition, some authors have concluded that the crystallinity and ultrastructure of cellulose are kept intact because the oxidation is only performed at the cellulose surface, leaving the core unaffected (Guigo et al. 2014).

SEM micrographs of original and oxidized cotton samples are shown in Fig. 3. The typical appearance with rifts, twists and wrinkles can be observed on the original cotton. No obvious difference is shown for low dosage periodate oxidized one. Upon oxidation with higher dosage of NaIO4, the rift patterns on the fabric are clearly changed and even occasional breaks are generated, signifying the surface oxidative damage. This means the periodate oxidation can break the glycoside bonds to result in degradation and fracture of cotton framework (Liu et al. 2012).

Other properties of cotton such as the iodine sorption value (ISV), tensile strength, aldehyde content and hydrophilicity are displayed in Fig. 4. The ISV of cotton can disclose the accessibility of cotton amorphous region to aqueous solutions. As shown in Fig. 4a, the average ISV is 67.0 mg/g, 94.1 mg/g and 109.3 mg/g for original, low and high dosage periodate treated cotton, respectively. The higher ISV value of cotton after oxidation in comparison to the starting one suggests that there is a structural change in favor of increasing the amorphous area (Fakin et al. 2006; Pejic et al. 2015).

Periodate oxidation involves a depolymerisation process of cotton and brings about its destruction. As also shown in Fig. 4a, the periodate oxidation results in rapid strength loss of cotton. This is mainly attributed to the combined effect of molecular scission due to non-Malaprade side reactions and the formation of hemi-acetal crosslinks between aldehyde and alcohol groups. Chains scission has once been considered as the single cause of strength loss. However, the formation of crosslinks between molecular chains will restrict their free movement relative to one another and inevitably reduce the number that can be extended simultaneously. Consequently, molecular chains in the cotton that would have broken simultaneously will break successively in the oxidized ones to decrease their tensile strength (Nevell and Zeronian 1962).

As shown in Fig. 4b, the aldehyde content is 54.1 μmol/g, 113.3 μmol/g and 187.4 μmol/g for original, low and high dosage periodate treated cotton, respectively. Higher concentration of periodate creates more aldehyde groups in the cotton. However, the obtained results are significantly lower than that in periodate oxidized viscose samples (1284.0 μmol/g) probably because of higher accessibility of viscose fibers to the oxidizing agent (Nikolic et al. 2014). For the wettability shown in Fig. 4b, it is observed that the water absorbency time is increased from 1.6 s for original cotton to 7.5 s and 18.1 s for low and high dosage periodate oxidized cotton, respectively. This indicates the conversion of hydroxyl to aldehyde groups will reduce the hydrophilicity of cotton substrate because of weaker water combination ability of aldehyde groups than the hydroxyl groups.

The enzymatic actions of cellulase on periodate oxidized cotton

The binding ability of cellulase

The effective binding of cellulase on cotton surface to form an enzyme–substrate complex is a key step for enzymatic attack (Wang et al. 2018). Cellulase molecules have intrinsic fluorescence in the aqueous solution, which can be used to trace their transfer from solution onto the cotton. The emission spectra of cellulase before and after cotton immersion are presented in Fig. 5. It is noticed that the cellulase in solution shows a high emission peak at about 358 nm. After the cotton immersion, the position of emission peaks do not shift but a significant decrease of fluorescence intensity occurs. This means some cellulase molecules are spontaneously bound by cotton due to the existing attractive forces such as electrostatic forces, van der Waals forces and hydrophobic interactions between them. Cellulose-binding domains (CBDs) in the cellulase structure also play an important role in its binding to cellulose substrates. Apparently, higher periodate dosage results in higher binding of cellulase. This indicates the conversion of alcohol to aldehyde groups facilitates the mutual interactions between them. The aldehyde groups newly created in the oxidized cotton can react with amino groups in cellulase protein to form Schiff’s base (schematically illustrated in Fig. 6). Due to the large number of amino groups distributed in the cellulase protein, there is a possibility for the multipoint bonds between the oxidized cotton and cellulase (Nikolic et al. 2017). Although periodate ion is capable of entering the cotton to oxidize inside glucose unit, the cellulase protein molecules are too huge to access the interior aldehyde groups and thus the main attachment occurs only on the surface of oxidized cotton.

The adsorption isotherm expresses the specific relation between the free cellulase and its degree of accumulation on cotton surface at a constant temperature. Figure 7 presents the adsorption isotherms of cellulase on different cotton fabrics at 25 °C. Langmuir model has been widely employed for analyzing the adsorption data of cellulase on cellulosic substrates because it provides a good fit in most cases and represents a simple model to reflect the interactions between them (Peitersen et al. 1977). The Langmuir model suggests the uptake of cellulase on the cotton surface by a monolayer occupation and its linear form is as follows (Hao et al. 2012b; Li et al. 2012):

where qmax represents the theoretical maximum binding capacity of per unit weight of cotton substrate and KL characterizes the affinity of cellulase to cotton, respectively.

By plotting Ce/qe against Ce, the results of Langmuir parameters are determined and listed in Table 1. In the range of tested concentrations, the high data conformity to the Langmuir model suggests the binding of cellulase to cotton takes place in a monolayer manner. The mean binding capacity reaches 10.31 mg/g, 10.92 mg/g and 11.93 mg/g for original, low dosage and high dosage periodate oxidized cotton, respectively, meaning the conversion of alcohol to aldehyde groups promotes the binding of cellulase to cotton substrates.

The hydrolytic properties of cellulase

Once the cellulase is bound by cotton substrates, the water molecules are rapidly transferred to their active sites and the chemical reaction between water and cellulose is catalyzed immediately. Commonly, the extent of enzymatic hydrolysis largely depends on the nature of cotton substrate present in the solution. The experimental results of enzymatic hydrolysis to different cotton fabrics are shown in Fig. 8a, where it is observed that the total reducing sugar increases with the increasing initial cellulase concentrations. This means the enzymatic degree is determined by the concentrations of the complex formed by cellulase and cotton. It is also found that the higher periodate oxidization generates greater hydrolysis of cotton. This result is in accordance with the cellulase binding data, meaning more cellulase on cotton can lead to greater hydrolysis. Moreover, the periodate oxidization creates more amorphous area in cotton structure, which will lead to an increased number of available hydrolytic sites for cellulase. As shown in Fig. 8b, the hydrolytic degree of cotton fabrics can also be testified by measuring their weight loss during the cellulase treatment. The aggressive attacks of cellulase to the surface and accessible amorphous areas of the cotton will remove the microfibrils from the surface and yield short-chain oligomers, resulting measurable weight loss. Accordingly, higher periodate oxidization leads to higher weight loss because of the same reason as reducing sugar analysis.

Conclusions

The cotton fabrics were selectively oxidized by periodate to produce aldehyde groups in them. FTIR analysis indicated a new characteristic band appeared at around 1730 cm−1 due to the stretching vibration of the C=O bonds in the aldehyde groups. XRD analysis definitely demonstrated the oxidation slightly decreased the crystallinity of cotton because the periodate oxidation could disrupt the order structure of cotton sample. SEM micrographs showed the high dosage periodate oxidization resulted in some surface oxidative damage. Moreover, the periodate oxidization could generate obvious changes in other physico-chemical properties such as tensile strength, wettability and ISV. The aldehyde content was increased from 54.1 μmol/g for original to 113.3 μmol/g and 187.4 μmol/g for low and high dosage periodate oxidized cotton, respectively. The conversion of alcohol to aldehyde groups resulted in obvious decrease in cotton wettability in terms of the water absorption time. Subsequently, the original and periodate oxidized cotton fabrics were subjected to cellulase treatment. It was determined by Langmuir adsorption model that higher periodate oxidation resulted in higher binding of cellulase to cotton bulk because the aldehyde groups newly created in the oxidized cotton could react with amino groups in cellulase to form Schiff’s base. Finally, it was found the enhanced binding of cellulase and enlarged amorphous area in cotton structure as available hydrolytic sites led to greater hydrolysis of cotton.

References

Baratieri M, Baggio P, Fiori L, Grigiante M (2008) Biomass as an energy source thermodynamic constraints on the performance of the conversion process. Bioresource Technol 99:7063–7073

Chang VS, Holtzapple MT (2000) Fundamental factors affecting enzymatic reactivity. Appl Biochem Biotech 84–86:5–37

Ding W, Zhou J, Zeng Y, Wang Y, Shi B (2017) Preparation of oxidized sodium alginate with different molecular weights and its application for crosslinking collagen fiber. Carbohydr Polym 157:1650–1656

Fakin D, Golob V, Kleinschek KS, Marechal AML (2006) Sorption properties of flax Fibers depending on pretreatment processes and their environmental impact. Text Res J 76:448–454

Fan QG, Lewis DM, Tapley KN (2001) Characterization of cellulose aldehyde using Fourier transform infrared spectroscopy. J Appl Polym Sci 82:1195–1202

French AD, Santiago Cintrón M (2013) Cellulose polymorphy, crystallite size, and the segal crystallinity index. Cellulose 20:583–588

Fu K, Lu D (2013) Effect of ethanediamine on bio-polishing of cotton fabrics with cellulase. Cellulose 20:3093–3100

Garcia-Ubasart J, Torres AL, Vila C, Pastor FIJ, Vidal T (2013) Biomodification of cellulose flax fibers by a new cellulase. Ind Crop Prod 44:71–76

Guigo N, Mazeau K, Putaux J, Heux L (2014) Surface modification of cellulose microfibrils by periodate oxidation and subsequent reductive amination with benzylamine: a topochemical study. Cellulose 21:4119–4133

Hao L, Wang R, Liu J, Cai Y, Liu R (2012a) Investigating the adsorption performance of nanoscale pigment on cationized cotton substrate. Powder Technol 222:176–181

Hao L, Wang R, Liu J, Liu R (2012b) The adsorptive and hydrolytic performance of cellulase on cationised cotton. Carbohydr Polym 89:171–176

Hao L, Wang R, Zhang L, Fang K, Men Y, Qi Z, Jiao P, Tian J, Liu J (2014) Utilizing cellulase as a hydrogen peroxide stabilizer to combine the biopolishing and bleaching procedures of cotton cellulose in one bath. Cellulose 21:777–789

Hao L, Wang R, Wang L, Fang K, Liu J, Men Y (2016) The influences of enzymatic processing on physico-chemical and pigment dyeing characteristics of cotton fabrics. Cellulose 23:929–940

Hao L, Wang R, Fang K, Cai Y (2017) The modification of cotton substrate using chitosan for improving its dyeability towards anionic microencapsulated nano-pigment particles. Ind Crop Prod 95:348–356

Hendriks ATW, Zeeman MG (2009) Pretreatments to enhance the digestibility of lignocellulosic biomass. Bioresource Technol 100:10–18

Ibrahim NA, El-Badry K, Eid BM, Hassan TM (2011) A new approach for biofinishing of cellulose-containing fabrics using acid cellulases. Carbohydr Polym 83:116–121

Kim UJ, Kuga S, Wada M, Okano T, Kondo T (2000) Periodate oxidation of crystalline cellulose. Biomacromol 1:488–492

Langan P, Nishiyama Y, Chanzy H (2001) X-ray structure of mercerized cellulose II at 1Å resolution. Biomacromol 2:410–416

Laureano-Perez L, Teymouri F, Alizadeh H, Dale BE (2005) Understanding factors that limit enzymatic hydrolysis of biomass. Appl Biochem Biotech 121–124:1081–1099

Li Y, Du Q, Liu T, Sun J, Jiao Y, Xia Y, Xia L, Wang Z, Zhang W, Wang K, Zhu H, Wu D (2012) Equilibrium, kinetic and thermodynamic studies on the adsorption of phenol onto graphene. Mater Res Bull 47:1898–1904

Lin H, Yao LR, Chen YY, Wang H (2008) Structure and properties of silk fibroin modified cotton. Fiber Polym 9:113–120

Ling Z, Zhang X, Yang G, Takabe K, Xu F (2018) Nanocrystals of cellulose allomorphs have different adsorption of cellulase and subsequent degradation. Ind Crop Prod 112:541–549

Liu X, Wang L, Song X, Song H, Zhao JR, Wang S (2012) A kinetic model for oxidative degradation of bagasse pulp fiber by sodium periodate. Carbohydr Polym 90:218–223

Lu X, Zheng X, Li X, Zhao J (2016) Adsorption and mechanism of cellulase enzymes onto lignin isolated from corn stover pretreated with liquid hot water. Biotechnol Biofuel 9:118–129

Mandels M, Hontz L, Nystrom J (1974) Enzymatic hydrolysis of waste cellulose. Biotechnol Bioeng XVI:1471–1493

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Nevell TP, Zeronian SH (1962) The effect of periodate oxidation and of subsequent borohydride reduction on the tensile strength of cotton. J Text I 53:90–93

Nikolic T, Milanovic J, KramarA Petronijevic Z, Milenkovic L, Kostic M (2014) Preparation of cellulosic fibers with biological activity by immobilization of trypsin on periodate oxidized viscose fibers. Cellulose 21:1369–1380

Nikolic T, Korica M, Milanovic J, Kramar A, Petronijevic Z, Kostic M (2017) TEMPO-oxidized cotton as a substrate for trypsin immobilization: impact of functional groups on proteolytic activity and stability. Cellulose 24:1863–1875

Nishiyama Y, Johnson GP, French AD (2012) Diffraction from nonperiodic models of cellulose crystals. Cellulose 19:319–336

Peitersen N, Madeiros J, Mandels M (1977) Adsorption of Trichoderma cellulase on cellulose. Biotechnol Bioeng XIX:1091–1094

Pejic B, Baralic AM, Kojic Z, Skundric P, Kostic M (2015) Oxidized cotton as a substrate for the preparation of hormone-active fibers-characterization, efficiency and biocompatibility. Fiber Polym 16:997–1004

Rajendran K, Sivalingam T (2013) Industrial method of cotton fabric finishing with chitosan-ZnO composite for anti-bacterial and thermal stability. Ind Crop Prod 47:160–167

Rowland SP, Cousins ER (1966) Periodate oxidative decrystallization of cotton cellulose. J Polym Sci Part A 4:793–799

Shaikh HM, Adsul MG, Gokhale DV, Varma AJ (2011) Enhanced enzymatic hydrolysis of cellulose by partial modification of its chemical structure. Carbohydr Polym 86:962–968

Siller M, Amer H, Bacher M, Roggenstein W, Rosenau T, Potthast A (2015) Effects of periodate oxidation on celulose polymorphs. Cellulose 22:2245–2261

Siroka B, Noisternig M, Griesser UJ, Bechtold T (2008) Characterization of cellulosic fibers and fabrics by sorption/desorption. Carbohydr Res 343:2194–2199

Su R, Yang R, Yang J, Du R, Huang R, Qi W, He Z (2017) Oscillating cellulase adsorption and enhanced lignocellulose hydrolysis upon ultrasound treatment. Trans Tianjin Univ 23:11–19

Sugiyama J, Persson J, Chanzy H (1991) Combined infrared and electron diffraction study of the polymorphism of native celluloses. Macromolecules 24:2461–2466

Szabo OE, Csiszar E (2017) Some factors affecting efficiency of the ultrasound-aided enzymatic hydrolysis of cotton cellulose. Carbohydr Polym 156:357–363

van Wyk JPH (1997) Cellulose hydrolysis and cellulase adsorption after pretreatment of cellulose materials. Biotechnol Tech 11:443–445

Varma AJ, Chavan VB (1995) A study of crystallinity changes in oxidised celluloses. Polym Degrad Stab 49:245–250

Vicini S, Princi E, Luciano G, Franceschi E, Pedemonte E, Oldak D, Kaczmarek H, Sionkowska A (2004) Thermal analysis and characterisation of cellulose oxidised with sodium methaperiodate. Thermochim Acta 418:123–130

Wada M, Okano T, Sugiyama J (1997) Sychrotron-radiated X-ray and neutron diffraction study of native cellulose. Cellulose 4:221–232

Wang R, Yang C, Fang K, Cai Y, Hao L (2018) Removing the residual cellulase by graphene oxide to recycle the bio-polishing effluent for dyeing cotton fabrics. J Environ Manag 207:423–431

Xia J, He A, Li R, Zhang Y, Xu J, Liu X, Xu J (2017) Enzymatic activity and protein expression of cellulase from rice straw produced by Trichoderma reesei in the presence of oxygen vectors. Ind Crop Prod 109:654–660

Xu YH, Huang C (2011) Effect of sodium periodate selective oxidation on crystallinity of cotton cellulose. Adv Mater Res 197–198:1201–1204

Yue Y, Zhou C, French AD, Xia G, Han G, Wang Q, Wu Q (2012) Comparative properties of cellulose nano-crystals from native and mercerized cotton fibers. Cellulose 19:1173–1187

Zhang YHP, Lynd LR (2004) Towards an aggregated understanding of enzymatic hydrolysis of cellulose: noncomplexed cellulase systems. Biotechnol Bioeng 88:797–824

Zhang L, Ge H, Xu M, Cao J, Dai Y (2017) Physicochemical properties, antioxidant and antibacterial activities of dialdehyde microcrystalline cellulose. Cellulose 24:2287–2298

Zhao H, Heindel ND (1991) Determination of degree of substitution of formyl groups in polyaldehyde dextran by the hydroxylamine hydrochloride method. Pharm Res 8:400–402

Acknowledgments

We acknowledge the Natural Science Foundation of Shandong Province (ZR2018MB019) and Taishan Scholars Program of Shandong Province of China for supporting this project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hao, L., Wang, R., Zhao, Y. et al. The enzymatic actions of cellulase on periodate oxidized cotton fabrics. Cellulose 25, 6759–6769 (2018). https://doi.org/10.1007/s10570-018-2016-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-018-2016-8