Abstract

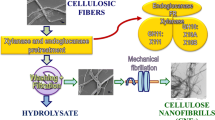

Three recombinant GH5 endoglucanases chosen for their contrasting hydrolytic activities, and a commercial endoglucanase were used to treat cellulose nanofibers (CNFs) after they were milled from bleached eucalyptus pulp with a supermasscolloider. This enzyme “post-treatment” resulted in different properties for the CNFs depending on enzyme treatment. The degree of polymerization, water retention value and enzymatic digestibility were used to estimate the extent of fibrillation. Morphologies of CNFs were observed by SEM and TEM. Electron microscopy images indicated endoglucanase post-treatment could efficiently improve the nanosize uniformity of CNFs from supermasscolloider fibrillation. All GH5 endoglucanase post-treated CNFs had a diameter between 3 and 19 nm with 70–89 % between 5 and 9 nm. The recombinant GH5 with no reported activity on crystalline cellulose was the most aggressive of the GH5s studied in reducing the DP of CNFs.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nanocomposites derived from renewable sources such as cellulose nanomaterial are biodegradable and have attracted great interest for sustainable economic development. Cellulose nanofibers (CNFs) have low thermal expansion, high aspect ratio, good mechanical and optical properties (Moon et al. 2011), as very important characteristics for applications in nanocomposites, paper making, coating additives, security papers, food packaging, and gas barriers (Nair et al. 2014). CNFs are often produced through mechanical means with or without chemical or enzymatic pretreatment (Henriksson et al. 2007; Tsuguyuki et al. 2007; Zhu et al. 2011; Chen et al. 2011). Energy consumption is a major concern for CNFs production through purely mechanical means (Iwamoto et al. 2007; Wang et al. 2012a). Endoglucanase pretreatment can reduce mechanical energy input by at least 30 % with a microfluidizer when compared to no enzymatic pretreatment, while producing similar quality CNFs in terms of fibril length and diameter (Wang et al. 2015a). However, further reduction in energy consumption is required and scale-up of microfluidization can be difficult for commercial applications.

In recent years, disk milling as with a supermasscolloider (SMC) has received much attention for its potential in commercial scale-up (Hoeger et al. 2013; Raj and Kokta 1991). CNFs were successfully produced by fibrillation of softwood and hardwood pulps using SMC (Raj and Kokta 1991; Wang et al. 2012a). Typical operation conditions are 1.0–2.0 wt % solids loading with disk rotating speed at 1500 rpm (Hu et al. 2015; Iwamoto et al. 2007; Wang et al. 2012a), higher than that used in microfluidization or homogenization processes. However, the CNFs obtained through SMC appear to be less homogeneous in terms of fibril diameters, compared with CNFs produced by high-pressure homogenization or microfluidization, with large bundles of fibrils clearly observed (Qing et al. 2013; Wang et al. 2012a).

Endoglucanase pretreatment can produce more uniform fibril diameter (approximately 5–10 nm) after subsequent microfluidization (Wang et al. 2015a). Here we hypothesize that post-milling enzymatic treatment can reduce non-uniformity in the diameters of the cellulose fibrils produced by disk milling such as with a commercial SMC. When combined with enzymatic pretreatment, it could reduce energy consumption in mechanical fibrillation, but also further reduce fibril diameter and diameter non-uniformity for transparent cellulose nanocomposite applications. This post milling enzymatic treatment approach has not been reported in the literature. Here, we evaluate the effectiveness of post milling enzymatic treatment of a fibril sample from SMC processing using three purified rGH5 endoglucanases, Ph-GH5, Fn-GH5, Ru-GH5 and a commercial endoglucanase, FR. The three rGH5s were chosen for their contrasting hydrolytic activities, as indicated by literature. The Ph-GH5 endoglucanase derived from Pyrococcus horikoshi, a hyperthermophilic achaeon, exhibits strong hydrolyzing activity toward crystalline cellulose as demonstrated by (Kang et al. 2007) with EGPh, while Fn-GH5 derived from Fervidobacterium nodosum hydrolyzes disordered cellulose with no detected activity on Avicel as demonstrated by (Wang et al. 2010) with FnCel5A. Ru-GH5 derived from a yak rumen metagenome is reported to have both endoglucanase and exoglucanase activity, and is able to hydrolyze not only disordered cellulose but also crystalline cellulose as demonstrated by (Bao et al. 2011) with Rucel5B.

Materials and methods

Materials

The same kraft bleached eucalyptus pulp (BEP) (Fibria, Aracruz, Brazil) used in a previous study (Wang et al. 2012a) was used here. The same pulping procedures (Wang et al. 2012a) was also used to produced air dried fibers. The fibers were stored in freezer. A commercial endoglucanase FR was used for comparison study.

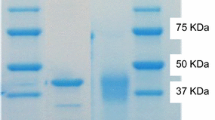

Gene construction, enzyme production and purification of rGH5s

Ph-GH5, Fn-GH5 and Ru-GH5, were heterologously expressed in Escherichia coli. Ph-GH5 from Pyrococcus horikoshii was prepared as described in our previous study (Wang et al. 2015a), with sequence based on EGPh (Ando et al. 2002; Kashima et al. 2005). Gene construct for Fn-GH5 expression is based on GenBank accession number GU944824 as described for rFnCel5A from Fervidobacterium nodosum (Wang et al. 2010). The sequence for Fn-GH5 is provided in Table S1. The Ru-GH5 construct is based on GenBank accession number GQ849224 derived from a yak rumen metagenomic library as described for Rucel5B (Bao et al. 2011); this enzyme possesses activity on both disordered and crystalline cellulose (Bao et al. 2011). The sequence for Rucel5B is provided in Table S2. All genes were commercially synthesized with codon bias optimized for E. coli expression in pJexpress414 (DNA2.0, Menlo Park, CA, USA).

E. coli BL21 (DE3) was host for enzyme production in auto-induction medium with lactose inducer (Studier 2005). MDG culture was grown at 37 °C overnight for inoculation of the auto-induction medium at 20 °C and growth for 30 h. Cells were harvested by centrifugation and lysed by sonication. Ph-GH5 was purified as previously described (Wang et al. 2015a). Fn-GH5 lysate was heat-treated for half an hour at 60 °C and centrifuged prior to purification on Q-Sepharose using a 0–1 M NaCl gradient in 50 mM Tris pH 8.5 buffer. Ru-GH5 was purified on Q-Sepharose using a 50 mM–1 M NaCl gradient in 50 mM Tris pH 8 buffer. Purified proteins were ultrafiltrated (Amicon Ultra-15 centrifugal filters) for concentration and buffer (50 mM bis–Tris, pH 7.0, 0.15 M NaCl) exchanged.

Enzyme assays

The method for enzyme hydrolytic activities determination towards carboxymethyl cellulose (CMC, Sigma-Aldrich, St. Louis, MO) and p-nitrophenyl-β-d-cellobioside (p-NPC; Sigma-Aldrich, St. Louis, MO) were described in the previous study (Wang et al. 2015a). The protein content of the enzymes were determined using the Bio-Rad protein assay using bovine serum albumin (BSA) as standard (Bradford 1976).

FR pretreatment of BEP fiber

In some experiments, commercial endoglucanase FR was used to pretreat BEP fiber before mechanical fibrillation. Enzyme loadings of 0.01 and 1 mg/g (abbreviation of mg protein/g fiber) were used for pretreatment. BEP fiber suspensions were made 5 % (w/v) in 50 mM acetate buffer (pH 5.0) with enzyme loading of 0.01 or 1 mg/g, incubated at 50 °C in a shaker (MaxQ™ 4450, Thermo, Waltham, MA) for 24 h at 200 rpm. FR pretreated solids were washed with the buffer and water (3–4 times) by centrifugation. The washed fibers were used for mechanical fibrillation and subsequence analysis.

SMC fibrillation

Untreated and FR pretreated BEP fibers were fibrillated continuously in a SMC (Model: MKZA 6-2, Disk model: MDGA 6-80#, Masuko Sangyo Co., Ltd, Japan) by circulating the fiber and or fibril suspension using a peristaltic pump (Cole-Parmer, Chicago, IL, USA). A rotating speed of 1500 rpm with 2.0 % (w/v) solid consistency (total 4 L pulp suspension) was used according to previous optimization study (Hu et al. 2015). The SMC was equipped with an energy meter for recording the energy consumption. The disk gap was first set to zero with no loading pulp, and then adjusted down to −100 microns with the addition of BEP fiber suspension. Samples were taken during fibrillation at 0, 0.25, 0.5, 1, 2 and 3 h for analyses.

Enzymatic digestibility of SMC fibrillated fibrils

Enzymatic hydrolysis of SMC fibrillated fibrils was conducted at 50 °C and 200 rpm for 0–96 h at 5 % (w/v) solids loading buffered (sodium acetate) at pH 5.0 using a commercial complex cellulase Cellic®CTec2 (complimentarily provided by Novozymes, North America, Franklinton, NC, USA). The CTec2 loading was 1 mg protein/g fiber (=1.8 FPU/g fiber). The solids and enzymatic hydrolysate were separated by centrifugation. Glucose in hydrolysate was analyzed using a glucose analyzer (2700S, YSI Inc., Yellow Springs, OH, USA).

Endoglucanase post-mill treatment of CNFs

CNFs produced by SMC for 1 h from untreated BEP and FR (0.01 mg/g) pretreated BEP were further post-treated using Ru-GH5 (1 mg/g), Ph-GH5 (1 mg/g), Fn-GH5 (1 mg/g), or FR (0.01 and 0.1 mg/g). CNFs from SMC were mixed with each endoglucanase at a solid concentration of 1 % (w/v, dilute by 50 mM acetate buffer at pH 5.0), incubated in the shaker for 24 h at 200 rpm. Post-treatments using Ph-GH5 and Fn-GH5 were conducted at 70 °C, while FR and Ru-GH5 were conducted at 50 °C. Endoglucanases were denatured at the end of post-treatment by incubating in boiling water for 20 min. The resultant fibrils were stored at 4 °C for further analysis.

Determinations of degree of polymerization and water retention value

The degree of polymerization (DP) and water retention value (WRV) of the fibers and SMC fibrillated CNFs were measured using TAPPI Standard Test Method T230 om-99 (TAPPI 1999) and a modified Scandinavian test method SCAN-C 62:00 (Luo et al. 2011), respectively.

Electron microscopy and imaging analysis

Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) imaging were carried as described previously (Wang et al. 2015a). Approximately 100 fibril diameters were measured from two independent images of the same sample for diameter distribution analyses.

Results and discussion

Characterization of endoglucanases

The recombinant endoglucanases for this study were chosen because of their contrasting hydrolytic activities, but yet with similar structure (all are GH5s by CAZy classification). Ph-GH5 as reported for EGPh (Kang et al. 2007) exhibits strong hydrolyzing activity toward crystalline cellulose including Avicel, while Fn-GH5 as reported for FnCelA5 (Wang et al. 2010) hydrolyzes disordered cellulose with no detected activity on Avicel (Wang et al. 2011). However, chimeric constructs of FnCel5A with CBMs effectively hydrolyze Avicel (Wang et al. 2012b). Ru-GH5 as reported for Rucel5B (Bao et al. 2011) is reported to possess both endoglucanase and exoglucanase activities, and is able to hydrolyze both disordered and crystalline cellulose. For comparison of enzyme activities under our experimental conditions, the activities with CMC (a disordered cellulose) and p-NPC are listed in Table 1. Ph-GH5 and Fn-GH5 are hyperthermostable with activities at 70 °C 2–4 times of that at 50 °C based on both the p-NPC and CMC method. Fn-GH5 showed the highest activity toward both p-NPC and CMC at 70 °C. p-NPC activity of Ru-GH5 was much higher than Ph-GH5, while CMC activities of Ru-GH5 and Ph-GH5 were similar.

SMC fibrillation

Energy consumption of SMC fibrillation increased linearly with grinding time (Fig. S1). Energy consumption of BEP was 1.8 MJ/kg at 1 h grinding with slope of 4.75 MJ/kg h. FR pretreatment can lower SMC fibrillation energy consumption. With FR loadings of 0.01 and 1 mg/g, energy consumption decreased to 1.7 and 1.6 MJ/kg at 1 h grinding with slope reduced to 4.56 and 4.00 MJ/kg h, respectively.

DP of fibrillated cellulose can be used for measuring the extent of fibrillation. This is because DP reduction or cellulose degradation is an unintended consequence of cellulose nanofibrillation in producing CNF (Iwamoto et al. 2007). The DP of FR pretreated BEP was 75.5 and 43.3 % of untreated BEP at 0.01 and 1 mg/g loading, respectively (Fig. 1). SMC fibrillation can reduce DP rapidly at 0.25 h. DP reductions were 150, 200 and 351 respectively for BEP, FR (0.01 mg/g) and FR (1 mg/g) at 0.25 h fibrillation. DP reduction however was insignificant after 0.25 h grinding. Compared to microfluidization, DP reductions were 121, 364 and 391 respectively for the same BEP, FR (0.01 mg/g) and FR (1 mg/g) after 20 passes through a 200 μm Microfluidizer chamber (Wang et al. 2015a, b).

WRV and enzymatic digestibility are also used to measure the degree of cellulose fibrillation. WRV and enzymatic digestibility of cellulose fibrils increased with FR pretreatment and mechanical fibrillation (Figs. 1, 2). WRV of untreated BEP was 108, and increased to 278 after FR (1 mg/g) pretreatment and to 1470 after 1 h SMC fibrillation. The enzymatic digestibility of untreated BEP can be increased from 28.8 to 70.5 % with only 0.25 h grinding and cellulase loading of 1 mg protein/g fiber. This was due to mechanical deconstruction of cell wall as described previously (Hoeger et al. 2013; Leu and Zhu 2013). WRV and enzymatic digestibility was not affected after fibrillation more than 1 h, which was in agreement with DP data.

Fibril morphologies after SMC fibrillation

SEM images of SMC fibrillated cellulose fibrils were shown in Fig. 3. FR pretreatment reduced fibrils length from 1–3 to 0.5–1 mm and 0.1–0.5 mm at FR loading of 0.01 and 1 mg/g, respectively, in agreement with DP reductions from 1107 to 836 and 479. Increasing SMC grinding time resulted in shorter and thinner fibrils. FR pretreatment facilitated microfibrillation to result in higher DP and diameter reductions with much shorter fibrillation time than those without FR pretreatment. With only 0.25 h grinding, FR pretreated fiber length decreased dramatically (Fig. 3b2, c2) especially at FR loading of 1 mg/g. Little changes in CNF diameters were observed at fibrillation time beyond 1 h especially for CNFs from FR pretreatment based on TEM imaging (Fig. S2).

Endoglucanase post-treatment

Post-treatments using Ph-GH5 and Fn-GH5 were conducted at 70 °C, while FR and Ru-GH5 were conducted at 50 °C. Post-treatments were applied to SMC fibrillated BEP fibrils using Ru-GH5 (1 mg/g), Ph-GH5 (1 mg/g), Fn-GH5 (1 mg/g) and FR (0.01 and 0.1 mg/g). Fibril DP and diameter distribution along with TEM images of post-treated fibrils are shown in Figs. 4 and 5. Endoglucanase cleaves β-1,4 linkages of cellulose, which creates new chain ends and reduces the cellulose chain length. Sample DP and morphologies of post-treated fibrils varied with the kind of endoglucanase used due to their unique properties. At FR loading of 0.01 mg/g, post-treatment slightly improved the fibril separation as can be seen from Fig. 4a, b. The distribution probability of fibril diameters between 7 and 12 nm increased from 53 (without post-treatment) to 83 % (with FR post-treatment at 0.01 mg/g). Post-treatment using Ru-GH5 at 1 mg/g reduced fibril DP to 750 (Fig. 4c) compared with 465 from post-treatment using FR at 0.01 mg/g loadings. Ru-GH5 narrowed fibrils diameter distribution to 3–15 nm (Fig. 4c). Post-treatments using Ph-GH5 and Fn-GH5 substantially reduced fibrils DP to approximately 330 or lower as shown in Figs. 4d–f. It appears that the most effective endoglucanase activities were achieved in the first 2 hours (compare Fig. 4eI with eII). All these post-treatments reduced the fibril diameter distribution to below 19 nm. Post-treatment using FR at 0.1 mg/g reduced fibril diameters to a range between 3 and 11 nm with 88 % of fibrils within 5–9 nm. According to fibril DP and morphologies, Fn-GH5 works the best on SMC fibrillated BEP compared with Ru-GH5 and Ph-GH5 based on fibril length, diameter and size uniformity. The large area TEM images clearly shows that the Ru-GH5 (Fig. 4c) and Ph-GH5 (Fig. 4d) treated CNF both have more large fibril bundles than the CNF from Fn-GH5 (Fig. 4eIII). The diameter distribution data were taken primarily from unaggregated fibrils due to difficulties in measurements, which were biased and led to similar distributions shown. However, the uniformity in fibril diameter was achieved using Fn-GH5 at the expense of fibril DP (related to length), i.e., the DP were 750, 331, and 218 for the fibrils treated by Ru-, Ph-, and Fn-GH5, respectively. These results suggest that hydrolysis of the disordered regions of fibrils by Fn-GH5 is the dominant enzymatic factor contributing to fibril length and morphology, in agreement with the high CMC activity of Fn-GH5 (Table 1). Mechanical fibrillation can degrade crystalline cellulose and create more disordered cellulose, which not only expose disordered regions of the fibers and thus make them more accessible to enzyme attack, but also decrease the crystallinity (Wang et al. 2012a). SMC fibrillation of 1 h with Fn-GH5 (1 mg/g) post-treatment produced more uniform nanosized fibrils than 30 or 40 passes of microfluidization with endoglucanase pretreatment (Wang et al. 2015a).

An extremely low amount FR (0.01 mg/g) pretreatment before SMC fibrillation can promote CNF production. Figure 5a shows that CNF produced by pretreatment with FR at 0.01 mg/g and subsequent SMC fibrillation for 1 h can produce relatively uniform CNFs with diameters ranging from 5 to 17 nm. The effect of FR pretreatment is very obvious when compared with the CNFs shown in Fig. 4a without pretreatment. Pretreatment using FR at 0.01 mg/g is much more effective than post-treatment under the same FR dosage in producing uniform fibril diameters as can be seen by comparing the fibrils show in Fig. 4b with those shown in Fig. 5a. The same series of post-treatments using FR at 0.01 and 0.1 mg/g, and Ru-GH5, Ph-GH5, Fn-GH5 all at 1 mg/g were applied to FR pretreated SMC fibrillated fibrils. All post-treatments improved the uniformity of CNF diameters. CNF diameter distributions between 5 and 9 nm from different post-treatment are listed in Table 2. More than 80 % of fibrils had a diameter distribution between 5 and 9 nm after post-treatment on FR pretreated SMC fibrils. All these results and analyses were based on TEM images, which were taken from limited samples.

Conclusions

Supermasscolloider fibrillation combined with endoglucanase (FR, Ru-GH5, Ph-GH5 and Fn-GH5) post-treatment for CNFs production was investigated in this study. Cellulose fibrils from 1 h SMC fibrillation were used for post-treatment. Post-treatment can efficiently improve the fibril diameter uniformity in a range of 3–19 nm, i.e., significantly reduced fibril bundles. When post-treatment was applied to enzymatically pretreated SMC fibrils, more than 80 % fibrils had a diameter distribution between 5 and 9 nm. Notably, the recombinant GH5 endocellulase with no reported activity with crystalline cellulose was the most aggressive in reducing the DP of SMC fibrils. Endoglucanase post treatment can be an effective approach to improve cellulose nanofibrillation for the production of uniform CNFs.

References

Ando S, Ishida H, Kosugi Y, Ishikawa K (2002) Hyperthermostable endoglucanase from Pyrococcus horikoshii. Appl Environ Microbiol 68(1):430–433

Bao L, Huang Q, Chang L, Zhou J, Lu H (2011) Screening and characterization of a cellulase with endocellulase and exocellulase activity from yak rumen metagenome. J Mol Catal B Enzym 73(1):104–110

Bradford M (1976) A rapid and sensitive for the quantitation of microgram quantitites of protein utilizing the principle of protein-dye binding. Anal Biochem 72(1–2):248–254

Chen W, Yu H, Liu Y, Chen P, Zhang M, Hai Y (2011) Individualization of cellulose nanofibers from wood using high-intensity ultrasonication combined with chemical pretreatments. Carbohydr Polym 83(4):1804–1811

Henriksson M, Henriksson G, Berglund LA, Lindström T (2007) An environmentally friendly method for enzyme-assisted preparation of microfibrillated cellulose (MFC) nanofibers. Eur Polymer J 43:3434–3441

Hoeger IC, Nair SS, Ragauskas AJ, Deng Y, Rojas OJ, Zhu JY (2013) Mechanical deconstruction of lignocellulose cell walls and their enzymatic saccharification. Cellulose 20(2):807–818

Hu C, Zhao Y, Li K, Zhu JY, Gleisner R (2015) Optimizing cellulose fibrillation for the production of cellulose nanofibrils by a disk grinder. Holzforchung 69(8):993–1000

Iwamoto S, Nakagaito AN, Yano H (2007) Nano-fibrillation of pulp fibers for the processing of transparent nanocomposites. Appl Phys A 89(2):461–466

Kang HJ, Uegaki K, Fukada H, Ishikawa K (2007) Improvement of the enzymatic activity of the hyperthermophilic cellulase from Pyrococcus horikoshii. Extremophiles 11(2):251–256

Kashima Y, Mori K, Fukada H, Ishikawa K (2005) Analysis of the function of a hyperthermophilic endoglucanase from Pyrococcus horikoshii that hydrolyzes crystalline cellulose. Extremophiles 9(1):37–43

Leu SY, Zhu JY (2013) Substrate-related factors affecting enzymatic saccharification of lignocelluloses: our recent understanding. Bioenerg Res 6(2):405–415

Luo X, Zhu JY, Gleisner R, Zhan HY (2011) Effect of wet pressing-induced fiber hornification on enzymatic saccharification of lignocelluloses. Cellulose 18:1339–1344

Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40(7):3941–3994

Nair SS, Zhu JY, Deng Y, Ragauskas AR (2014) High performance green barriers based on nanocellulose. Sustain Chem Process 2:23–30

Qing Y, Sabo R, Zhu JY, Agarwal U, Cai Z, Wu Y (2013) A comparative study of cellulose nanofibrils disintegrated via multiple processing approaches. Carbohydr Polym 97(1):226–234

Raj RG, Kokta BV (1991) The effect of processing conditions and binding material on the mechanical properties of bagasse fibre composites. Eur Polymer J 27(10):1121–1123

Studier FW (2005) Protein production by auto-induction in high-density shaking cultures. Protein Expr Purif 41(1):207–234

TAPPI, S. 1999. T230 om-99, Viscosity of pulp (capillary viscometer method)

Tsuguyuki S, Satoshi K, Yoshiharu N, Akira I (2007) Cellulose nanofibers prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolecules 8(8):2485–2491

Wang Y, Wang X, Tang R, Yu S, Zheng B, Feng Y (2010) A novel thermostable cellulase from Fervidobacterium nodosum. J Mol Catal B Enzym 66:294–301

Wang Y, Tang R, Jin T, Gui G, Wang X, Ying M, Yan F (2011) Quantitative investigation of non-hydrolytic disruptive activity on crystalline cellulose and application to recombinant swollenin. Appl Microbiol Biotechnol 91(5):1353–1363

Wang QQ, Zhu JY, Gleisner R, Kuster TA, Baxa U, Mcneil SE (2012a) Morphological development of cellulose nanofibrils (CNF) of a bleached eucalyptus pulp by mechanical fibrillation. Cellulose 19(5):1631–1643

Wang Y, Tang R, Tao J, Wang X, Zheng B, Feng Y (2012b) Chimeric cellulase matrix for investigating intramolecular synergism between non-hydrolytic disruptive functions of carbohydrate-binding modules and catalytic hydrolysis. J Biol Chem 287(35):29568–29578

Wang W, Mozuch MD, Sabo RC, Kersten P, Zhu JY, Jin Y (2015a) Production of cellulose nanofibrils from bleached eucalyptus fibers by hyperthermostable endoglucanase treatment and subsequent microfluidization. Cellulose 22(1):351–361

Wang W, Sabo R, Mozuch M, Kersten P, Zhu JY, Jin Y (2015b) Physical and mechanical properties of cellulose nanofibril films from bleached eucalyptus pulp by endoglucanase treatment and microfluidization. J Polym Environ 23(4):551–558

Zhu JY, Sabo R, Luo X (2011) Integrated production of nano-fibrillated cellulose and cellulosic biofuel (ethanol) by enzymatic fractionation of wood fibers. Green Chem 13(5):1339–1344

Acknowledgments

The authors are grateful for the financial supports by a USDA Agriculture and Food Research Initiative (AFRI) Competitive Grant (No. 2011-67009-20056), Chinese Scholarship Council (CSC), National Natural Science Foundation of China (Grant No. 31370571). The funding from these programs made the visiting appointment of Wang at the USDA Forest Products Laboratory (FPL) possible. We also acknowledge Thomas Kuster of the Analytical Chemistry and Microscopy Lab of FPL for SEM imaging and Debra Sherman of DS imaging LLC, West Lafayette, IN, for TEM imaging.

Author information

Authors and Affiliations

Corresponding authors

Additional information

This work was conducted on official government time of Zhu, Kersten, Mozuch, and Sabo, while Wang was a visiting student at the US Forest Service, Forest Products Lab.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wang, W., Mozuch, M.D., Sabo, R.C. et al. Endoglucanase post-milling treatment for producing cellulose nanofibers from bleached eucalyptus fibers by a supermasscolloider. Cellulose 23, 1859–1870 (2016). https://doi.org/10.1007/s10570-016-0946-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-016-0946-6