Abstract

Cellulase treatment for decreasing viscosity of cellulose (dissolving pulp) is a promising approach to reduce the use of toxic chemicals, such as hypochlorite in the dissolving pulp manufacturing process. In this study, the use of an endoglucanase-rich cellulase to replace the hypochlorite for this purpose and its improvements of the Fock reactivity were investigated. The results showed that at a given viscosity level, the replacement of hypochlorite treatment with a cellulase treatment in the bleach plant under otherwise the same conditions led to a higher Fock reactivity (72.0 vs 46.7 %). These results were due to the enzymatic peeling/etching mechanism, which partially peeled the primary wall of the fibers, thus improving the accessibility of fibers. The improved accessibility of the enzymatic treated pulp was supported by the positive fiber morphological changes determined, based on the SEM, BET and WRV methods. The alkali solubility results further supported the conclusion.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent years, the regenerated cellulose and cellulose derivatives, characterized as sustainable and compatible with the environment, are in high demand (Quintana et al. 2013; Wang et al. 2015). Dissolving pulp, known as high purity cellulose, can be used as the main feedstock for the manufacture of regenerated cellulose (e.g., viscose rayon and lyocell), cellulose derivatives (cellulose esters and ethers) and other new cellulose-based products (MCC or NCC) (Li et al. 2015a; Sixta et al. 2013).

The pre-hydrolysis kraft (PHK) process has emerged as an important commercial dissolving pulp production process, which fits the biorefinery concept well (Sixta et al. 2013; Wang et al. 2015). The viscosity and reactivity are the most important quality parameters for dissolving pulp in terms of processability of the downstream production process. A moderate reduction in viscosity or molecular weight (Mw) is a pre-requisite for a good processability during the viscose rayon process and the quality of the final product (Henriksson et al. 2005). In the viscose process, a pre-aging step is required for decreasing the viscosity of mercerized pulp to 200–250 mL/g prior to the xanthation step (Strunk et al. 2012). Apart from the viscosity, the reactivity of dissolving pulps, an indicator of the ability of cellulose to react with CS2 under alkaline conditions in the viscose process, is of critical importance for viscose rayon production (Christoffersson et al. 2002). A pulp with high reactivity can produce a high-quality viscose product with low demand of carbon disulfide, allowing a cost-effective production and low environmental impact (Ibarra et al. 2010b). A low viscosity and a high reactivity can improve the homogeneity and quality of resulting cellulose product and lower the demands of reactants (Tian et al. 2014). A good control of viscosity and increase in its reactivity are always of practical interest.

In practice, the viscosity control of dissolving pulp in its manufacturing process is traditionally done in the bleaching process, and hypochlorite (H) remains the most common bleaching reagent to control the viscosity (degree of polymerization, DP) due to a number of reasons, including its cost advantage (Biermann 1996; Wang et al. 2015). However, toxic organics that contain chlorine, known as adsorbable organic halogens (AOX), will be produced during the H bleaching.

Cellulase treatment has been increasingly popular in the dissolving pulp industry in recent years because not only can it precisely adjust pulp viscosity, but it can also improve pulp reactivity in a green way (Gehmayr et al. 2011; Gehmayr and Sixta 2012). Some studies have also revealed that cellulase treatment can adjust cellulose DP and enhance the cellulose reactivity, which were beneficial for the processability of dissolving pulp and final product quality during the viscose process (Ibarra et al. 2010a; Miao et al. 2014a; Wang et al. 2015). However, the commercialization of enzymatic treatment in the dissolving pulp industry still has a long way to go.

In this study, the use of endoglucanase-rich cellulase (EG) to replace the hypochlorite (H) for viscosity control and its impact on the Fock reactivity of the resulting pulp were investigated. A semi-bleached PHK pulp was selected for this purpose. Firstly, the chlorine dioxide (D) and alkaline extraction (E) treated pulp (DE pulp) was respectively treated by EG or H to get similar target viscosity prior to the final bleaching stages. The focus was on the determination of changes in the Fock reactivity as a result of EG treatment, which is compared with the conventional H treatment. The fundamentals associated with the EG treatment were investigated by determining the fiber morphological changes and alkaline solubility.

Experimental

Materials

A semi-bleached dissolving pulp (DE pulp) from the prehydrolysis kraft (PHK)-based process was collected from the E-stage washer of the bleach plant at a mill in Canada. The bleaching sequence in the mill is DEHEpD (D: chlorine dioxide bleaching, H: hypochlorite bleaching, Ep: peroxide reinforced alkaline extraction). All the wet samples were stored in sealed plastic bags in a refrigerator prior to the sequent treatments and analyses.

A commercial endoglucanase-rich cellulase FiberCare D (EG) was supplied by Novozymes A/S (Denmark) and its cellulase activity of 470 U/mL was determined as sodium carboxymethyl cellulose (CMC-Na) activity.

Hypochlorite (H), hydrogen peroxide (P) and alkaline (E) solutions were purchased from Sigma Aldrich, and the chlorine dioxide (D) was prepared in the lab. The active ingredient in H (based on active chlorine), P (H2O2), E (NaOH) and D (based on active ClO2) was determined as 12.5, 12.8, 50 and 1.1 %, respectively.

The HEpD and (EG)EpD bleaching

The DE pulp was treated by H or EG, followed by the same bleaching sequence (Ep-D) as shown in Table 1, to get the similar viscosity.

The H bleaching was conducted at 10 % pulp consistency for 150 min using a polyethylene bag in a water bath (60 °C). The sodium hypochlorite charge was 4.7 mg/g odp (based on active chlorine) and the initial pH was adjusted to 11 by NaOH. After the completion of the H treatment, the sample was filtered and washed.

The enzymatic treatment were conducted at 10 % pulp consistency for 90 min in a citrate buffer system (pH 4.8) using a polyethylene bag in a water bath (55 °C). The enzyme dosage was 0.18 U/g odp or 0.4 mg/g odp unless otherwise stated. After the completion of the EG treatment, the sample was placed in hot water (90 °C) for 15 min to denature the enzymes, and subsequently filtered and washed.

Analyses

Intrinsic viscosity

The intrinsic viscosity of all samples was measured according to the T 230 om-99 standard method using cupriethylenediamine (CED) solution as solvent. All measurements were carried out in duplicate, and the average was reported.

Fock reactivity

Fock reactivity of dissolving pulp was conducted according to the modified method (Tian et al. 2013), in which the xanthation of cellulose was performed at 19 °C in a water bath, and all of the pulp samples were air dried to constant moisture content in a constant temperature/humidity room. All measurements were carried out in duplicate, and the average was reported.

SEM and LM

The morphology of untreated or treated dissolving pulp was observed by using a JEOL 6400 scanning electron microscopy (SEM) (Japan). The pulp samples were golden-coated prior to the determination.

Light microscopy (LM) images were captured by using the Leica DM4000 M microscope (Germany). Slides used for LM images were prepared normally on a glass slide, by pipetting a solution of water and fibers and using a glass cover slip.

Specific surface area, pore structure and fines content

The specific surface area and pore size were measured based on the Brunauer–Emmett–Teller (BET) analysis of nitrogen absorption isotherms using a Belsorp-Max volumetric gas adsorption instrument (Bel Japan, Inc., Osaka, Japan).

The water retention value (WRV) refers to the total water in the pores or the total pore volume of a substrate. The WRV was measured by following the SCAN-C 62:00.

The fiber fines contents of all samples were measured using a fiber quality analyzer (Op Test Equipment, Inc.).

Alkali solubility in NaOH (10 or 18 %) and in NaOH/ZnO system

The untreated or treated pulp was extracted with a NaOH of 10 or 18 %, and the dissolved carbohydrates were determined. The alkali solubility in a 10 or 18 % NaOH, known as S10 (hemicelluloses and degraded cellulose with low molecular weight) or S18 (hemicelluloses), respectively, was determined according to TAPPI T235 cm-00. All measurements were carried out in duplicate, and the average was reported.

The solubility in NaOH/ZnO was determined according to the method reported by Ambjörnsson et al. (2014) with a little modification (stirring 300 rpm for 20 min at 4 °C during the reaction). After the completion of treatments, the samples were filtrated and washed, and the insoluble cellulose contents in NaOH/ZnO were determined. All measurements were carried out in duplicate.

Results and discussion

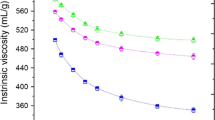

Effect of cellulase treatment on the changes of viscosity and Fock reactivity

In the present industrial practice, a hypochlorite stage (H) is usually applied to control the viscosity of dissolving pulp, for example, in a five stage process of DEHEpD. In this project, we aimed to replace the H stage using an endoglucanase-rich cellulase. The results are shown in Table 2. With an H or EG stage, followed by the remaining bleaching stages, the DEHEpD or the DE(EG)EpD pulps had much lower viscosity (560 and 557 mL/g, respectively), while without the H or EG treatment, the DEEpD pulp had a very high viscosity of 827 mL/g, only slightly lower than the original one of 944 mL/g. It is well known that during the H treatment, the random oxidative degradation occurs under the alkaline condition (pH 9–11), which is responsible for the viscosity decrease (Sixta 2006), while during the cellulase treatment, the enzymatic hydrolysis leads to the viscosity decrease (Duan et al. 2015). Based on the H and EG treatment conditions (Table 1) and viscosity decrease (Table 2), it can be concluded that an enzymatic treatment at 0.4 mg/g odp can yield similar pulp viscosity to that with an H treatment at 4.7 mg/g odp as active chlorine charge, under the conditions studied.

Also shown in Table 2 are the Fock reactivity results of the same samples. The original DE pulp showed a low reactivity (37.2 %). Without an H or EG treatment, the DEEpD pulp showed a similar reactivity to the DE pulp, which indicated that the subsequent EpD-bleaching sequence had a negligible effect on the cellulose reactivity. After the H treatment, the reactivity of DEHEpD pulp increased from 37.2 to 46.7 %, which corresponds to the decreased viscosity from 944 to 560 mL/g. Interestingly, at a similar viscosity level (557 mL/g), with the enzyme treatment, the reactivity of the DE(EG)EpD pulp significantly improved from 37.2 to 72.0 %, which is much higher than that of the DEHEpD pulp (46.7 %). The results revealed that apart from the decreased viscosity, the enzymatic treatment also exerted additional effects on cellulosic fibers, which resulted in an enhanced reactivity.

In the literature, sulfite- based dissolving pulp was treated by cellulase (Engstrom et al. (2006), and the results showed that the increased Fock reactivity may be caused by a decrease in the cellulose viscosity and other factors after the EG post-treatment. In another study, Miao et al. (2014b) reported a significant increase in the Fock reactivity after a post-treatment using enzyme or refining/enzyme treatment on a PHK hardwood dissolving pulp.

Proposed hypothesis for the enhanced reactivity of dissolving pulp treated by EG compared to H

The schematic of the H and EG treatment for the enhanced accessibility of pulp fibers was illustrated in Fig. 1. Compared to a similar viscosity decrease as the result of H treatment, the EG treatment further resulted in more pronounced fiber morphological changes in both the fiber level and microfiber level: (1) partially peeling/etching the primary wall, resulting in more reactive/accessible cellulosic fiber structures towards mercerization and xanthation; (2) increasing the pore size, pore volume, as result of enzymatic attacking of the amorphous cellulose, subsequently enhancing the swelling of fibers/microfibrils under the alkaline conditions, thus finally facilitating the alkaline solubility and xanthation process.

Some researchers, using pure cellulose, such as cotton and microcrystalline cellulose (MCC, Avicel) as substrates, reported that the initial mode of enzymatic attack took place on the outer layer of the cellulose surface where the constituent fibers were peeled along their length, layer by layer, in an “onion peeling” manner (Penttilä et al. 2010; Wang et al. 2006). Le Moigne et al. (2010) investigated the peeling effect of enzymes mixture on the structural changes and alkaline solubility of two sulfite dissolving pulps, and concluded that the increased alkaline solubility of the enzymatically peeled substrates at a short time (less than 10 min) were due to: (1) a digestion of the primary wall, and, (2) a destructive action on the inside of the fiber (a decreased DP and an increased swelling of fibers).

Influences of H and EG treatment on fiber morphologies

Pore structure, specific surface area (SSA) and fines content

Shown in Table 3 are the fiber morphologic properties of the treated pulps in terms of pore structure, SSA and fines content. It is evident that after the H or EG treatment, the total pore volume of the treated pulp increased from 2.12 mL/g of the DE pulp to 2.33 mL/g of the DEH pulp, and to 2.82 mL/g of the DE(EG) pulp. In addition, the improvements of mean pore diameter were also observed after the H treatment (from 6.55 to 7.46 nm) and the EG treatment (from 6.55 to 9.93 nm). The SSA, increased from 1.29 m2/g (DE pulp) to 1.43 m2/g (DEH pulp) and to 1.87 m2/g (DE(EG) pulp), which was consistent with the increased fines content (from 9.12 to 10.85 % and to 12.60 %, respectively). The water retention value (WRV), which was indicative of fibers swelling, also increased from 115 % (DE pulp) to 119 % (DEH pulp) and to 128 % (DE(EG) pulp), as a result of the H and EG treatment. The increased WRV can be attributed to the increased pore volume and SSA of the fibers. In an early study, Miao et al. (2014a) found that after the cellulase treatment of a fully bleached PHK dissolving pulp, the surface area of pulp fiber increased and thus the treated fibers exhibited more open structure, which would allow more hydroxyl groups to expose, therefore, more reactive sites for xanthation reactions.

In the literature, it has been documented that the enzymatic treatment can modify the fiber morphologies (pore structure, WRV and SSA). Cao and Tan (2002) reported that the enzymatic post-treatment of a sulfite softwood dissolving pulp can increase its WRV by breaking down the hydrogen bonds, which was correlated to the enhanced alkali solubility in NaOH solution at a low temperature. Gehmayr and Sixta (2011) investigated the effect of enzyme and acid degradation on the reactivity of dissolving pulp that was made from the paper-grade pulp, and found that the pulp after an enzymatic post-treatment showed a higher Fock reactivity due to an opening effect on the enzymatically treated fiber structures that were represented by the increased WRV.

Scanning electron microscopy (SEM)

The morphological changes of fibers as a result of H or EG treatment can also be supported from the SEM images (Fig. 2). Compared to the DE fibers with a clean and smooth surface (Fig. 2a), the fibers after H treatment (the DEH pulp) had a slightly rough surface due to the oxidative degradation by hypochlorite (Fig. 2b), while the fibers after cellulase treatment exhibited a very rough surface as some of the fiber primary wall were peeled due to the enzymatic hydrolysis (Fig. 2c). It can be explained by the fact that the oxidation reaction during H treatment was more uniform under the condition studied, resulting in slight changes on fiber surface, while the enzymatic hydrolysis during EG treatment was more localized and its attacks on fibers became more intensified once the weak points on the primary wall were firstly created, thus leading to a very coarse surface (Clarke et al. 2011; Thygesen et al. 2011).

In the literature, Gehmayr and Sixta (2012) reported that after the EG treatment (500ECU/g odp) of softwood sulfite dissolving pulp, a damaged fiber surface and cracked S1 cell wall layer were evident on the treated fibers. Similar results were reported by Zhang et al. (2013), who investigated the enzyme-assisted refining, and found that after the cellulase treatment of a bleached pine kraft pulp, the primary layer of cell wall was peeled off and the S1 layers became exposed.

Based on the above discussion, these favorable changes related to the fiber morphological changes, including the pore volume, pore size, and fibers swelling and SSA, as a result of enzymatic treatment, can have direct positive effects in further improving the Fock reactivity, which explains why the EG treated pulp can have higher Fock reactivity than the H treated pulp.

Influence of H and EG treatments on alkali solubility

Alkali solubility in 18 and 10 % NaOH (S18 and S10)

As shown in Table 4, both the S18 and S10 contents in those treated pulps increased as the results of H or EG treatment. For example, the S18 content increased from 3.52 % of the DE pulp to 3.73 % of the DEH pulp and to 4.32 % of the DE(EG) pulp, while the S10 content increased from 5.34 % of the DE pulp to 5.90 % of the DEH pulp and to 7.15 % of the DE(EG) pulp. The higher S18 and S10 contents in the EG-treated pulp can be due to that the more opened-up fiber structures may facilitate the removal of hemicelluloses and degraded cellulose under the alkaline condition. In a study, Miao et al. (2014a) found that the alkali solubility (S10 and S18) gradually increased when a PHK dissolving pulp was after a post-treatment with an increased cellulase dosage from 0 to 5 u/g od pulp.

The alkaline solubility in NaOH/ZnO system

The solubility of dissolving pulp in alkaline solutions, such as NaOH–water (Le Moigne et al. 2010), NaOH/urea (Li et al. 2015b) and NaOH/ZnO (Ambjörnsson et al. 2014) at low temperature, has been reported as an indirect measure of cellulose accessibility and reactivity. The results on swelling and dissolution behavior of each pulp in the NaON/ZnO system are illustrated in Fig. 3. Evidently, the EG-treated pulp had the lowest insoluble cellulose content (highest solubility) in the NaOH/ZnO system in comparison with the original pulp and the H-treated pulp (65.7, 76.9 and 80.2 % for the DE(EG) pulp, DEH pulp and DE pulp, respectively). These results can be further supported by the light microscopy (LM) images (the inserts in Fig. 3). It can be observed that the DE(EG) pulp showed the most pronounced swelling and dissolution, followed by the DEH pulp, and the lowest was obtained from the original DE pulp. The highest solubility of the DE(EG) pulp in the NaOH/ZnO system can be attributed to a combination of a partial degradation of primary fiber wall layers (Fig. 2c), the more porous fiber structures (Table 3) as well as the reduction of the cellulose DP (Table 2) (Trygg and Fardim 2011).

In the literature, Ambjörnsson et al. (2014) reported that the dissolution of a softwood kraft pulp in a NaOH/ZnO system was improved from 29 to 81 % by means of a three-stage pretreatment with an initial xylanase treatment, followed by an alkaline extraction, and finally an endoglucanase stage. In another study, Chiriac et al. (2014) also found that enzymatic treatment can enhance the dissolution degree of cellulose in a NaOH solution at low temperature. Moreover, Grönqvist et al. (2014) studied the effect of fiber porosity changes of spruce sulfite dissolving pulp on alkali solubility, and reported that the combined mechanical and enzymatic process can significantly increase the fiber porosity, consequently enhancing the solubility in the NaOH/ZnO system.

Conclusions

Using an endoglucanase-rich cellulase (EG) treatment, rather than hypochlorite (H) treatment in the bleach plant of a prehydrolysis kraft (PHK) dissolving pulp manufacturing process for the viscosity control and improvement of its reactivity was evaluated. The results showed that at a given viscosity level (~560 mL/g), the cellulase treated (DE(EG)EpD) pulp had a higher Fock reactivity than the hypochlorite-treated (DEHEpD) pulp (72.0 vs 46.7 %). The improved reactivity can be attributed to the increased cellulose accessibility from the enzymatic peeling/etching on the fiber structures, which were supported by: (1) the partially peeled primary wall (based on the SEM images), and, (2) the changes of fiber morphologies (based on the BET and WRV results). Compared to the hypochlorite-treated (DEH) pulp, the cellulose treated (DE(EG)) pulp also showed higher S10/S18 content and alkali solubility in NaOH/ZnO system.

Based on these results, it is concluded that the cellulase treatment is a promising and green alternative to hypochlorite treatment for the viscosity control and reactivity improvement in the dissolving pulp industry.

References

Ambjörnsson HA, Östberg L, Schenzel K, Larsson PT, Germgård U (2014) Enzyme pretreatment of dissolving pulp as a way to improve the following dissolution in NaOH/ZnO. Holzforschung 68(4):385–391

Biermann CJ (1996) Handbook of pulping and papermaking. Academic press, New York

Cao Y, Tan H (2002) Effects of cellulase on the modification of cellulose. Carbohydr Res 337(4):1291–1296

Chiriac AI, Pastor FIJ, Popa VI, Aflori M, Ciolacu D (2014) Changes of supramolecular cellulose structure and accessibility induced by the processive endoglucanase Cel9B from Paenibacillus barcinonensis. Cellulose 21(1):203–219

Christoffersson KE, Sjöström M, Edlund U, Lindgren Å, Dolk M (2002) Reactivity of dissolving pulp: characterisation using chemical properties, NMR spectroscopy and multivariate data analysis. Cellulose 9(2):159–170

Clarke K, Li X, Li K (2011) The mechanism of fiber cutting during enzymatic hydrolysis of wood biomass. Biomass Bioenergy 35(9):3943–3950

Duan C, Long Y, Li J, Ma X, Ni Y (2015) Changes of cellulose accessibility to cellulase due to fiber hornification and its impact on enzymatic viscosity control of dissolving pulp. Cellulose 22(4):2729–2736

Engstrom A-C, Ek M, Henriksson G (2006) Improved accessibility and reactivity of dissolving pulp for the viscose process: pretreatment with monocomponent endoglucanase. Biomacromolecules 7:2027–2031

Gehmayr V, Sixta H (2011) Dissolving pulps from enzyme treated kraft pulps for viscose application. Lenzing Ber 89:152–160

Gehmayr V, Sixta H (2012) Pulp properties and their influence on enzymatic degradability. Biomacromolecules 13(3):645–651

Gehmayr V, Schild G, Sixta H (2011) A precise study on the feasibility of enzyme treatments of a kraft pulp for viscose application. Cellulose 18(2):479–491

Grönqvist S et al (2014) Fibre porosity development of dissolving pulp during mechanical and enzymatic processing. Cellulose 21(5):3667–3676

Henriksson G, Christiernin M, Agnemo R (2005) Monocomponent endoglucanase treatment increases the reactivity of softwood sulphite dissolving pulp. J Ind Microbiol Biotechnol 32(5):211–214

Ibarra D, Köpcke V, Ek M (2010a) Behavior of different monocomponent endoglucanases on the accessibility and reactivity of dissolving-grade pulps for viscose process. Enzyme Microb Technol 47(7):355–362

Ibarra D, Kopcke V, Larsson PT, Jaaskelainen AS, Ek M (2010b) Combination of alkaline and enzymatic treatments as a process for upgrading sisal paper-grade pulp to dissolving-grade pulp. Bioresour Technol 101(19):7416–7423

Le Moigne N, Jardeby K, Navard P (2010) Structural changes and alkaline solubility of wood cellulose fibers after enzymatic peeling treatment. Carbohydr Polym 79(2):325–332

Li J, Liu Y, Duan C, Zhang H, Ni Y (2015a) Mechanical pretreatment improving hemicelluloses removal from cellulosic fibers during cold caustic extraction. Bioresour Technol 192:501–506

Li R, Wang S, Lu A, Zhang L (2015b) Dissolution of cellulose from different sources in an NaOH/urea aqueous system at low temperature. Cellulose 22(1):339–349

Miao Q, Chen L, Huang L, Tian C, Zheng L, Ni Y (2014a) A process for enhancing the accessibility and reactivity of hardwood kraft-based dissolving pulp for viscose rayon production by cellulase treatment. Bioresour Technol 154:109–113

Miao Q, Tian C, Chen L, Huang L, Zheng L, Ni Y (2014b) Combined mechanical and enzymatic treatments for improving the Fock reactivity of hardwood kraft-based dissolving pulp. Cellulose 22(1):803–809

Penttilä PA et al (2010) Changes in submicrometer structure of enzymatically hydrolyzed microcrystalline cellulose. Biomacromolecules 11(4):1111–1117

Quintana E, Valls C, Vidal T, Roncero MB (2013) An enzyme-catalysed bleaching treatment to meet dissolving pulp characteristics for cellulose derivatives applications. Bioresour Technol 148:1–8

Sixta H (2006) Pulp bleaching. Handbook of pulp. Wiley-VCH Verlag GMbH & Co. KGaA, Weinheim, pp 609–932

Sixta H et al (2013) Novel concepts of dissolving pulp production. Cellulose 20(4):1547–1561

Strunk P, Lindgren Å, AGNEMO BER, Eliasson B (2012) Chemical changes of cellulose pulps in the processing to viscose dope. Cellul Chem Technol 46(9):559–569

Thygesen LG, Hidayat BJ, Johansen KS, Felby C (2011) Role of supramolecular cellulose structures in enzymatic hydrolysis of plant cell walls. J Ind Microbiol Biotechnol 38(8):975–983

Tian C, Zheng L, Miao Q, Nash C, Cao C, Ni Y (2013) Improvement in the Fock test for determining the reactivity of dissolving pulp. Tappi J 12(11):21–26

Tian C, Zheng LQ, Miao QX, Cao CY, Ni YH (2014) Improving the reactivity of kraft-based dissolving pulp for viscose rayon production by mechanical treatments. Cellulose 21(5):3647–3654

Trygg J, Fardim P (2011) Enhancement of cellulose dissolution in water-based solvent via ethanol–hydrochloric acid pretreatment. Cellulose 18(4):987–994

Wang L, Zhang Y, Gao P, Shi D, Liu H, Gao H (2006) Changes in the structural properties and rate of hydrolysis of cotton fibers during extended enzymatic hydrolysis. Biotechnol Bioeng 93(3):443–456

Wang Q, Liu S, Yang G, Chen J, Ni Y (2015) Cationic polyacrylamide enhancing cellulase treatment efficiency of hardwood kraft-based dissolving pulp. Bioresour Technol 183:42–46

Zhang Z-J, Chen Y-Z, Hu H-R, Sang Y-Z (2013) The beatability-aiding effect of Aspergillus niger crude cellulase on bleached Simao pine kraft pulp and its mechanism of action. BioResources 8(4):5861–5870

Acknowledgments

The authors gratefully acknowledge the financial support from the Canada Research Chairs and NSERC CRD program, and the Tianjin Municipal Science and Technology Commission (Grant No. 12ZCZDGX01100).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Duan, C., Verma, S.K., Li, J. et al. Viscosity control and reactivity improvements of cellulose fibers by cellulase treatment. Cellulose 23, 269–276 (2016). https://doi.org/10.1007/s10570-015-0822-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-015-0822-9