Abstract

From the last two decades, white biotechnology, with particular reference to deploying enzyme bio-catalysis, has gained special research interest to valorize the bio-sources lignocellulosic biomass. In this context, ligninolytic enzymes from a white biotechnology background have tremendous potentialities to transform biomass following the green agenda. The enzyme-based white biotechnology is now considered a key endeavor of twenty-first century, as it offers socio-economic and environmental merits over traditional biotechnology, such as eco-friendlier processing conditions, no/limited use of harsh chemicals/reagents, high catalytic turnover, high yield, cost-effective ratio, low energy costs, green alternative of complex synthesis, renewability, reusability, and recyclability. Research efforts are underway, around the globe, to exploit naturally occurring biomass, as a green feedstock and low-cost substrates, to generate value-added bio-products, bio-fuels, and bio-energy. One core problem in developing an eco-friendlier and economical bioprocess is the pre-treatment of lignocellulosic biomass to entirely or partially remove the lignin barrier from cellulose fibers, thereby allowing the enzymes to access the cellulose fibers and generate the products of industrial interests. The entire process requires lignocelluloses deconstruction where ligninolytic enzymes in synergies with redox mediators systems have not explored much. The limited exploitation of ligninolytic enzymes with tremendous catalytic efficiencies has created a massive research gap that we have tried to cover herein. This review further insights the white biotechnology, also termed industrial biotechnology, which uses microorganisms and their unique enzyme system to facilitate the clean and sustainable deconstruction process.

Graphic Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

With the rapid development of society, the current economic, social, and environmental apprehensions have triggered the scientific community to explore greener and renewable raw materials for sustainable energy and bioproducts. Fossil-based raw feedstocks are non-renewable and also adversely affect the natural ecosystem and thus constituting serious risks to human health. Therefore, fossil fuels no longer accomplish the supply for bioenergy and many other value-added biochemicals [1, 2]. At contemporary, the onslaught of climate change, increasing agro-industrial waste materials, and valorization of natural resources profoundly affect nature [3]. In this avenue, biorefining might offer a significant connection to a sustainable and green industry by effective exploitation of waste biomass resources into biofuel and diverse commodity products [4]. Lignocellulosic biomass appears to be a low-cost, abundant and bio-renewable resource on earth, which holds the immense potential to create an imperishable global energy future. Removal of lignin from plant biomasses promotes the hydrolysis efficacy of cellulose and hemicellulose and thus enabling the use of carbohydrate portion of lignocellulose in producing ethanol and other biofuels [5, 6]. Approximately, a huge amount of lignin (50–60 million tons) is generated yearly by only the paper and pulp industry and is foreseen to continuously rise because of the increasing biorefinery developments to replace fossil feedstocks with renewable lignocellulosic waste biomass. According to a recent DOE (department of energy) statement, about 0.225 billion tons of lignin can be generated by the processing of 750 million tons of biomass to biofuel [7]. Only 2% of this lignin content is commercially used, whereas the rest is usually burned to supply processing heat and steam for the paper and pulp mills [8].

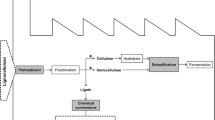

Though industrial waste as lignocellulosic biomass is a huge source of carbohydrates and lignin, its direct utilization as a starting feedstock for chemicals and biofuels is hindered by their intricate structure. Thus, deconstruction and depolymerization of the highly recalcitrant lignocellulosic biomasses into industrially pertinent compounds exhibits the major obstacle to realizing the economic viability of the biomass-based technologies. Due to the complicated cross-linked and three-dimensional polymeric network, lignin structure is extremely recalcitrant to decomposition [9,10,11]. Chemical, physical, and physicochemical are among the current lignocellulosic decomposition alleyways for the lignin breakdown because of notable conversion efficiency but are associated with high energy requirement, by-products generation, and undesired solubilization of hemicellulose. The biological method presents the characteristic advantages of the lack of yield loss that is otherwise associated with the thermal breakdown of lignin. It also offers the prospect of target-oriented lignin biodegradation by applying selective ligninolytic microorganisms and their enzyme systems, thereby circumventing the generation of unwanted by-products or intermediates. Importantly, the biocatalytic processes executed under mild reaction conditions that reduce the energy input, cost and ecological influence [12, 13]. In nature, white-rot fungi (WRF) and certain bacteria are the selective and efficient lignin biodegraders. The ligninolytic enzyme system is categorized into two main classes namely peroxidases (manganese, lignin, and versatile peroxidase) and laccases (Table 1) [14]. To date, very scarce reports have been documented in the scientific literature on the exploitation of ligninolytic enzymes-based pretreatment processes for degradation and deconstruction of biomass. Figure 1 illustrates the schematic representation of ligninolysis and lignin deconstruction potential of ligninolytic enzymes. Therefore, this review exploits the untapped potential of lignin-modifying enzymes (LMEs) in the effective utilization of lignocellulosic biomass for the biosynthesis of a range of important compounds such as biofuel, paper pulping, and animal feed.

Schematic representation of ligninolysis and lignin deconstruction potential of ligninolytic enzymes. The upper starting part represents the natural lignin with sinapyl alcohol, p-coumaryl alcohol, and coniferyl alcohol units. The middle part represents the unique action mechanisms of ligninolytic enzymes, i.e., laccase, lignin peroxidase, and manganese peroxidase as models. The last part shows various mono-lignin products that can be obtained after multiple steps involved in the ligninolysis process

2 Lignocellulosic Biomass: Structural-Compositional Aspects and Recalcitrance

Lignocellulose is composed of three basic constituents that include lignin, cellulose, and hemicelluloses. On average, lignocellulosic biomass comprises 50–80% (on dry basis) of carbohydrates that consist of hexose and pentose sugar units. Cellulose is a linear polysaccharide composed of reoccurring units of D-glucose subunits connected through β-(1,4)-glycosidic linkages with an amorphous and crystalline structure. The cellulose chains are associated together forming cellulose fibrils, which are feebly united via van der Waals forces and hydrogen bonding [15]. A strong hydrogen-bonded network within the cellulose inhibited the activity of enzymes for the hydrolytic reaction [16]. Hemicelluloses are multifaceted heterogeneous polysaccharides consisting of a wide variety of hexoses (glucose, mannose, and galactose), pentoses (xylose and arabinose), and sugar acids. Hemicelluloses are comparatively easy to hydrolyze owing to the amorphous structures, and low molecular weight properties with short lateral chains. These are organized in branched chains by β-1,4- with occasional β-1,3-glycosidic linkages and exist as intermediates between cellulose and lignin structures [17]. Lignin is a non-carbohydrate aromatic polymer of phenyl propane and methoxy groups, which renders them highly challenging to hydrolyze [18]. It typically makes about 20–30% of the dry weight of wood and is documented to be the most plentiful organic material on the earth after cellulose [19]. Lignin is interconnected with cellulose and hemicelluloses and generates physical seals around these components preventing the enzymatic attack [20]. Lignin polymer is composed of three monolignols explicitly coniferyl alcohol, p-coumaryl alcohol, and sinapyl alcohol (Fig. 2) [21]. The chemical linkages that principally contribute to the lignin resistance are C–C and ether bonds [22]. Due to the non-susceptibility of these bonds to hydrolytic agents, lignin is highly recalcitrant to degradation. With regard to substituents attached to the phenylpropanoid backbone, lignin is classified into guaiacyl-syringyl and guaiacyl lignin. Guaiacyl lignin exhibits methoxy groups in the 3-carbon position, whereas guaiacyl- syringyl lignin encompasses methoxy groups both in the 3-and 5-carbon positions. Generally, the molecular weight, composition, and magnitude of lignin vary according to the type of plant. Notably, hardwoods, softwoods, and grasses depend on the lignin distribution in the plant material, where the softwoods contain the highest lignin content (28–32%), followed by hardwoods (20–25%) and grasses (17–24%) [23, 24].

a The three constitutive monomers of lignin: p-coumaryl alcohol, coniferyl alcohol, and sinapyl alcohol; b Structure illustrating the principal bonds in lignin, a three-dimensional highly cross-linked biopolymer. Reprinted from Longe et al. [21] with permission from the American Chemical Society. Copyright (2018) American Chemical Society

The biotransformation of lignocelluloses to bio-refineries is substantially refrained by the compositional, chemical and structural properties of biomass, which renders these resources a challenging task to be exploited as cellulosic feedstocks for biofuel production. Hemicellulose and cellulose after hydrolyzing into their sugar components can be bio-transformed into bioethanol and other commodity chemicals through fermentation processes. Nevertheless, fermentable sugars required for fermentation are constricted inside the recalcitrant lignocellulosic structure. Therefore, biomass pretreatment is a core step to entirely or partially eliminate lignin walls for a more efficient enzymatic attack for polysaccharides hydrolysis in the lignocellulosic biomass. Pretreatment results in the degradation of the outer coating of lignin that hinder enzymatic approachability to cellulose and hydrolyzes the cellulose crystalline structure. The efficient yield of glucose-enriched fermentable hydrolysate from the feedstock cellulose content is an indispensable criterion in the processing and utilization of lignocellulose for biofuel production [25].

3 Chemical Pretreatment Methods: Advantages and Drawbacks

In bioprocess engineering, pretreatment is referred to as a process that transforms lignocellulosic biomass from its pristine form, resilient to cellulolytic hydrolysis, into a form that is more amenable to cellulose hydrolysis. An ideal pretreatment should also carry out the hydrolysis of hemicelluloses to its monomeric fermentable sugar units without the generation of accompanying fermentation and hydrolysis inhibitors, such as organic acids, phenolic compounds, furfural, and 5-hydroxymethylfurfural, which might affect subsequent processing steps and reduce the competitive ethanol yield [26, 27]. As described in many reports, different methods such as chemical (acid or basic catalysts), physical, and biological methods can be carried out for pretreatment purposes. In contrast to acid and liquid-hot-water pretreatments, alkali pretreatments greatly solubilize lignin and xylan side chains, leading to a profound improvement for efficient enzymatic hydrolysis [20, 28]. Alkaline-based delignification is generally more robust at dissolving a larger portion of lignin while leaving behind significant hemicellulose in an insoluble polymeric form. In comparison with acid pretreatment, alkaline processes cause relatively less sugar loss and many of the caustic salts can be regenerated and recovered. However, the use of alkali solutions such as NaOH, Ca(OH)2 or ammonia causes swelling, resulting in increased internal surface area, decreased crystallinity and degree of polymerization, alteration in lignin structure, and separation of lignin-carbohydrate linkages. It also results in a noticeable carbohydrate degradation from very harsh alkaline pretreatment [29, 30]. The application of mild alkaline pretreatments with lime Ca(OH)2 can overcome this problem, and the efficacy of lime pretreatment has been documented for different lignocellulosic biomasses such as corn Stover, sugarcane bagasse, and switchgrass [31]. Pretreatment of lignocellulosic biomass with the ligninolytic enzymes is a novel, environmental-friendly and most workable approach than chemical conversion because of the highest yields, negligible byproduct generation, minimum energy necessities, and the mild processing conditions. The pretreatment process for lignocellulose depolymerization in the current industrial practice is highly argued and at contemporary, no appropriate and cost-efficient pretreatment strategy is still available in the market.

4 Biological Method: A Green Lignocellulose Pretreatment Approach

The biological method is a promising alternative pretreatment for a cleaner and greener technology and has received incredible importance in the biotechnology community and researchers. In the wave of green technology paradigm, biological pretreatment approach offers numerous merits over chemical and physical conversion methods, for example: (i) greater reaction and substrate specificity, (ii) minimal requirements of energy (iii) less ecological concerns, and (iv) elevated titers of the target products [25, 32]. Deconstruction and depolymerization of lignocellulosic agricultural biomass residues by microbial lignocellulolytic consortia are accountable for a balanced carbon cycle in the ecosystem [33]. However, the biotechnological adaptation of biological processes should initiate by manipulating or engineering microbial strains for the high-level production of lignocellulolytic enzymes. Improvement of strains by genetic engineering and the establishment of an enzyme cocktail are the two major strategies that may be employed for overall cost reduction [34, 35].

5 Fungal Pretreatment

Fungal pretreatment relates to the employment of fungal strains for the disruption and modification of lignocellulosic architecture for succeeding enzymatic processing [36, 37]. White rot, brown rot, and soft rot are three major types of fungi that are commonly associated with fungal pretreatment for lignin degradation. By colonization on the cell lumina, WRF disrupts the cell wall structure of lignocellulosic biomass. Further propagation of the fungal mycelia leads to erosion of the cell wall. Brown rot fungi (BRF) generally found on gymnosperm wood generate brownish rotten wood, which is readily fragmented into smaller parts. Soft rot fungi (SRF) produce numerous small pores in the secondary layer without destroying the middle lamella [38]. Among the main categories, most common fungi associated with the depolymerization of lignocellulosic biomass are WRF such as Pycnoporus cinnabarinus, Pleurotus ostreatus, BRF Fomitopsis pinicola, and SRF Trichoderma sp. [39,40,41,42,43,44].

6 White-Rot Fungi and Their Unique Ligninolytic Armory

In nature, white rot Basidiomycota are the most promising lignin decomposers and inarguably the most suitable candidates for utilization in industrial bioprocess require delignified lignocellulosic feedstocks as substrates. It is reported that MnP (E.C. 1.11.1.13), LiP (E.C. 1.11.1.14) and laccase (E.C. 1.10.3.2) are principle LMEs of WRF that are responsible for not only lignin deconstruction but are also involved in degrading a diversity of xenobiotic and bioremediation of toxic industrial effluents. After purification, characterization, and immobilization, this set of unique extracellular enzymes could also be used in pulp and paper industries as non-polluting and economical bio-pulping and bio-bleaching agents to substitute environmentally unfriendly chemicals (e.g. chlorine) and saving energy expenses of mechanical pulping [45]. These enzymes also find broad-spectrum biotechnological applications such as wastewater remediation, clarification of numerous fruit juices, wines and musts, bio-bleaching of cotton, and bio-stoning of denim fabric in denim industries, as well as in pulp and paper industries [46, 47].

Extracellular ligninolytic enzymes are equipped with the potential capability to oxidative depolymerization of lignin molecules and their derivatives in cell-free systems. This set of enzymes is categorized into two classes i.e. oxidases and peroxidases. Among these, the only laccase belongs to the oxidase type, whereas MnP, LiP, and VP are belonging to the peroxidase type. The high redox potential renders these enzymes as exceptional candidates for the lignin amendment and transformation in lignocellulosic substrates [10, 48].

LiP, also known as diaryl propane oxygenase, is a heme-containing glycosylated ligninolytic biocatalyst that catalyzes H2O2-mediated oxidative deconstruction of lignin and lignin-related recalcitrant aromatic compounds to multiple end-products. After the discovery in the extracellular culture of WRF P. chrysosporium [49], its numerous isozymes were recognized in P. chrysosporium [50], T. versicolor [51], P. radiata [52], and P. sordida [53]. For instance, Farrell and coworkers, [50] reported the presence of six LiP isozymes viz. H1, H2, H6, H7, H8, and H10 in the culture broth of P. chrysosporium BKM-F-1767. Likewise, five LiP isozymes in the same strain with different substrate specificity, stability, isoelectric point, and sugar content were characterized [54]. The molecular weight and isoelectric point range of this monomeric hemoprotein ranges from 38 to 43 kDa and 3.3 to 4.7, respectively [54]. It optimally works at acidic pH (around pH 3.0) in the presence of veratryl alcohol as the substrate [55, 56]. High redox potential enables LiPs to oxidize an array of non-phenolic lignin structures including arylglycerol-aryl ethers thus constituting more than 90% degradation of lignin [57]. Their oxidative properties involve the formation of one-electron oxidation based radical cation, leading to intramolecular addition, demethylation, rearrangements, and side-chain cleavage [58]. Notably, the presence of various tryptophan residues on the surface of the enzyme molecule results in the modification of catalytic performance, substrate specificity and stability of the enzyme [59].

MnP has been documented as the most common LME produced by nearly all wood-rotting basidiomycetes [60]. In general, WRF secretes multiple forms of this glycosylated heme protein in their ligninolytic culture with diverse molecular weights ranged from 40 to 50 kDa. Up to 11 various MnP different isoforms have been reported in the culture extract of Ceriporiopsis subvermispora [61]. MnP follows a catalytic cycle similar to other heme-containing peroxidases, such as LiP or HRP except utilizing Mn2+ as a typical electron donor. Regarding catalytic mechanism, MnP carries out the preferential oxidation of phenolic structures to phenoxy radicals in H2O2–assisted enzyme reaction by concomitant Mn2+ oxidation to a highly reactive Mn3+, which resultantly, can degrade a wide range of phenolic molecules including phenols, cleave and dyes [62]. However, the degradation potential of MnP can be protracted to non-phenolic structures with the advent of low-molecular-weight mediators i.e. thiyl or lipid radicals [63]. Furthermore, many other synergistically-acting proteins with MnPs has also extended the roles of these biocatalysts in fungal ligninolysis. The literature survey demonstrated numerous reports on the MnP-assisted oxidative depolymerization of synthetic and natural lignins as well as many other refractory compounds [60, 64, 65].

Laccases are N-glycosylated extracellular blue multi-copper oxidases with ubiquitous distribution in eukaryotes and prokaryotes. However, laccases from microbial origins, in particular, from WRF have enticed incredible interest because of pronounced oxidation ability to multiple compounds and a wider spectrum of substrate specificity [66]. Based on copper centers, these enzymes are characterized into groups including type 1 (blue), type 2 (normal), and type 3 or coupled binuclear. Type 1 and type 2 exhibits one Cu atom each, whereas type 3 possesses two Cu atoms [67]. The biocatalytic efficacy of laccases relied on the oxidation–reduction potential of the type 1 copper ion, where oxidation of substrate happens. The higher redox potential of the microbial laccases than plant-based enzymes indicates their higher catalytic efficiency and activity relative to plants-sourced enzymes. On the other hand, type 2 and type 3 form a tri-nuclear cluster (T2/T3) for molecular oxygen reduction to water by transferring electrons from T1 to the tri-nuclear site [68]. Usually, the biocatalytic reaction of laccases implicates four substrates oxidation together with oxygen reduction to two molecules of water. The utilization of atmospheric oxygen as a source of electron acceptor is beneficial in laccase-mediated catalytic reaction than the use of H2O2 by peroxidases. Nonetheless, these enzymes necessitate the use of redox mediators i.e. acetosyringone, 2,2′-azino-bis(3-ethylbenzothiazoline-6-sulphonic acid (ABTS), syringaldehyde (SA), vanillin, and 1-hydroxy benzotriazole for abatement of numerous recalcitrant and non-phenolic environmental contaminants. In spite of this shortcoming, the use of laccases has gained noteworthy interest due to their tremendous biotechnological applications.

Versatile peroxidase (VP) produced by Bjerkandera sp. and Pleurotus sp. exhibits bifunctional characteristics of both LiP and MnP to oxidize veratryl alcohol and aromatic compounds (as LiP) and Mn2+ to Mn3+ (as MnP). It adopts an analogous catalytic mechanism as the other peroxidases [69], but the oxidation sites diverge from LiP and MnP according to the spectroscopic, site-directed mutagenesis and crystallographic analyses. The VP-assisted oxidized Mn3+ possesses the same features with Mn3+ oxidized by MnP because it functions as a diffusible oxidizing agent for phenolic lignin. Furthermore, it also comprises the residues that interact with veratryl alcohol and aromatic compounds in such a way as LiP ensures [70].

7 Ligninolytic Pretreatment: Deriving More Value from Lignocellulosic Waste

Biological degradation and conversion of lignocellulosic biomass is a complicated process, where several process variables such as cultivation conditions, cultivation duration, fungal strains, enzyme system, and fungal degradation mechanisms are involved. Though fungal assisted biomass pretreatment demand low energy and is carried out under mild environmental conditions; the necessity of a longer cultivation period (10 to 100 days) of these processes is the major issue for their exploitation to achieve high decomposition at the industrial level. Hence, it is of worth significance to find a highly efficient lignin degradation approach. In recent times, researchers are rekindling their interest in applying enzymes as an alternative to fungi because of the problems associated with the direct application of fungi, such as satisfactory growth challenges on a larger scale, longer incubation durations, and mycelial penetration into the substrate. Among a range of biological strategies, the direct use of enzymes is one of the newest strategies in the degradation of lignocellulosic biomass. Ligninolytic enzymes treatment may portray a more effective and simpler treatment method to address the problems that come across during the fungal pretreatment. Hence, enzymatic pretreatment has appeared a topic of choice for future consideration. Table 2 summarizes the application and comparative analysis of different technologies for biomass delignification process in terms of economic benefit and environmental impact [71].

In comparison with chemical utilization, enzymes-based treatment is extremely favorable owing to several advantages such as higher catalytic performance, greater reaction specificity, and milder processing conditions. A set of LMEs, explicitly MnP, LiP, laccase, and VP are predominantly involved in lignin modification and depolymerization [72,73,74]. In addition to these enzymes, reports have also demonstrated some accessory ligninolytic enzymes that can degrade lignin such as glyoxal oxidase (GLOX), aryl-alcohol oxidase (AAO), and feruloyl esterase (FEA). It is important to note that ligninolytic enzymes carry out lignin removal through oxidation and reduction reactions using oxygen as the final electron acceptor [75].

The delignification of plant biomasses by crude ligninolytic enzyme extracts presents numerous advantages that include;

- (i)

the occurrence of other auxiliary enzymes and mediators in crude extracts of WRF such as FEA may facilitate the ligninolytic consortium for effective lignin degradation by breaking the diferulic associations between xylan chains, thus unveiling the structures and liberating the lignin molecules [76].

- (ii)

Though the crude extract comprises ligninases as the predominant enzymes, the presence of some cellulolytic enzymes in enzyme extracts of WRF facilitates the simultaneous hydrolysis of the delignified lignocellulosic materials.

- (iii)

The ligninolytic and cellulolytic extracts can be applied in Simultaneous Pretreatment, Saccharification, and Fermentation (SPSF) process configuration that can save energy and time.

- (iv)

In contrast to acid and alkaline pretreatments, the biological method results in the generation of fewer inhibiting product. More than 35 different by-products are known to be generated from chemical pretreatment of lignocellulosic substrates. These by-products have shown a potential inhibitory effect on microbial growth and enzyme approachability [77].

- (v)

Ligninolytic pretreatment is carried out under gentle conditions excluding the necessity of extreme pH and temperature to accomplish the utmost hydrolysis efficiency.

In the past decade, many researchers have described the efficiency of the crude enzymes-based pretreatment approach in different lignocellulosic waste biomasses (Table 3). Pretreatment of various plant residues by the crude enzymatic extract from T. villosa Kreisel CCMB 651 resulted in a lignin loss of 35.05%, 39.61%, and 63.11% from sugarcane bagasse, coconut shell, and sisal fiber, respectively, after a treatment period of 4 h [78]. Naraian and coworkers, [79] achieved 5.2% lignin removal of corn cob by pretreatment with a crude ligninolytic enzyme consortium from P. florida PF05. The crude extract produced by S. commune IBL-06 in the solid-state culture of rice straw was capable of removing 47.5%, 61.7%, 67.2% and 72.3% lignin from corncobs, banana stalk, wheat straw, and sugarcane bagasse, respectively, after 48 h. It was also noted that the effective pretreatment of aromatic or phenolic compounds by ligninases also diminishes the toxic effect of the medium for consequent cellulolytic saccharification and fermentation process [9]. A laccase-based enzymatic pretreatment led to the highest lignin removal of 81.67% after a 6 h process optimized through the response surface statistical approach [80]. Asgher and coworkers, [25] pretreated sugarcane bagasse with the ligninolytic extract obtained from the P. ostreatus IBL-02 by growing on wheat straw. The as-obtained enzymes extract caused 33.6% removal of lignin in an eco-friendly manner. Likewise, a considerable reduction (39.6%) in the lignin contents of wheat straw was also noted by ligninolytic treatment [81]. Particularly, the treatment by a single type of ligninolytic enzyme is not very effective to accomplish greater lignin removal. Therefore, the delignification rate is maximized by applying a mixture of ligninolytic enzymes. For illustration, in contrast to P. chrysosporium (lacked in laccase activity) that caused only 17.2% of lignin exclusion, Phlebia floridensis showed the superior lignin removal efficiency (25.2%) in a wheat straw due to the contribution of three major types of ligninolytic enzymes [82].

For the first time, Longe et al. [21] investigated the potential of MnP, LiP, and laccase (major ligninolytic enzymes) for the depolymerization of three structurally different industrial lignins: alkali, kraft and organosolv lignin. As compared to MnP (0.8 V) and laccase (0.5–0.8 V), the utmost redox potential (1.2 V versus standard hydrogen electrode) of LiP enabled more easily oxidative depolymerization of lignin followed by MnP and laccase. Nevertheless, MnP exhibited the paramount ability to cleave overall bonds for lignin degradation compared with LiP and laccase. Results highlighted that all three lignins responded differentially to enzymatic depolymerization, and organosolv removal was generally much easier relative to alkali or kraft lignin. The aptitude of ligninases was assessed to improve lignocellulosic waste composting and compared with the inactivated counterparts as control. As compared to the control, the ligninolytic treatment augmented the degradation efficiency of hemicellulose and lignin by 11.74% and 5.24%, respectively [83].

The ligninolytic repository functions well in a wet and slightly acidic setting because of the release of organic acids by the wood rot basidiomycetes. Whereas, the bio-based delignification conditions are far from that prerequisite in each biotechnological application. It is worthy to mention that the ligninolytic enzymes can be acclimatized to non-native environments by advanced evolutionary approaches [84]. Recently, a directed evolution approach has garnered incredible interest to tailor ligninolytic enzymes and has been successfully applied to engineering aryl alcohol oxidase [85], laccase [86], dye-decolorizing peroxidase [87], versatile peroxidase [88], and unspecific peroxygenase [89]. Using this evolutionary technology, Brissos and coworkers, [87] created a dye-decolorizing peroxidase variant from P. putida MET94 that presented a 100-fold improved catalytic efficacy for depolymerization of 2,6-dimethoxy-phenol, a phenolic lignin prototype, under alkaline environments. Markedly, this evolved biocatalysts conquered greater tolerance to the high concentration of H2O2 and thus overcoming the major concerns of peroxidases for biotechnological exploitation. In another study, this strategy was implemented in the presence of high co-solvents concentrations of distinct chemical nature and polarities to obtain a variant with co-solvent promiscuity. The resultant evolved mutant displayed adequate catalytic performance and remained stable at high concentrations of the tested co-solvents (50% v/v). After 15 series of evolution, a fungal-derived laccase variant showed a pH-activity displacement towards the alkaline region and presented remarkable activity and improved kinetics against phenolic as well as non-phenolic structures after the five additional evolutionary rounds [90]. Installing consensus mutations into existing enzymes results in activity diversities with reference to the laboratory revived biocatalysts [91]. Apart from the academic outcomes, advancement in evolutionary technology on ligninolytic enzymes accompanied by advanced enzyme tailoring and synthetic biology approaches will confidently lead to more effective lignocellulosic bio-pretreatments, and also diversify and magnify the portfolio of bio-products from lignin polymer [92].

8 Redox Mediators: Small Molecules with a Strategic Role in Enzymatic Ligninolysis

A mediator is a small, diffusible aromatic molecule that functions as an electron carrier between the substrate and the biocatalyst. A wide variety of mediators (synthetic or natural) contributes to lignin degradation by lignin-modifying enzymes by readily diffusing into the lignin network following the activation by the enzyme. Moreover, it can modify the redox potential of the enzymes for accelerated lignin modification and depolymerization [93]. For effective depolymerization of lignin molecule, the mediator should possess some unique properties such as high water solubility, low molecular weight, high oxidation–reduction potential, and radicals forming ability, and profound biodegradation efficacy. Generally, WRF naturally secretes or produce mediators in their micro-environment [94]. Some soluble and colloidal lignins may act as natural redox mediators in the oxidative process. For instance, veratryl alcohol acts as a natural mediator for P. chrysosporium LiP, whereas 3-hydroxyanthranilic enabled P. cinnabarinus laccase to oxidizing non-phenolic lignin structures [95]. The use of mediators could also extend the capability of ligninolytic enzymes to oxidize a broad spectrum of substrates [96]. The catalytic effect of the LMS towards non-phenolic substrates depends on the mediator specificity towards various functional moieties, the redox potential of the mediator, and the steric interference of the catalytic substrate. Laccase without a mediator is no capable of oxidizing the dominant non-phenolic structures, which account for 80–90% of the lignin molecule [97]. This incompetence might be explained to low redox potential, and lacking sufficient energy for electrons extraction from the aromatic non-phenolic compounds. Figure 3 shows the oxidation of a non-phenolic β-O-4 laccase mediator system by the laccase-HBT mediator system from T. versicolor.

Oxidation of a non-phenolic β-O-4 laccase mediator system by Trametes versicolor laccase-HBT system. Reprinted from Christopher et al. [12], an open-access article distributed under the terms of the Creative Commons Attribution License (CC-BY)

Several mediators are only effective with ligninases rather than a combination of oxidative-hydrolytic enzymatic systems. Both sequential, as well as simultaneous pretreatment, using the lignin mineralizing system of T. hirsute with NHA as a redox mediator and xylanase from T. reesei has shown greater pulp lignin removal with reference to pretreatment using the solitary enzyme. Nevertheless, sequential pretreatment was found superior compared relative to simultaneous with delignification efficiency of 70.6% and 67.2%, respectively, because of the synergistic action of the enzymes [98]. Typical redox mediators for laccase activity include veratryl alcohol, vanillin, and syringaldehyde and synthetic mediators such as ABTS, 1-hydroxy benzotriazole (1-HBT), violuric acid (VA) or 2,2,6,6-tetramethylpiperidine 1-oxyl (TEMPO) [99]. The molecular structures of some natural and synthetic mediators of laccase are portrayed in Figs. 4 and 5. The selection of mediators can not only affect the degradative capacity but also induces the stereo-specificity of laccase in the substrate. For example, the addition of 3-hydroxyanthranilique acid (HAA) could promote laccase-catalyzed depolymerization of lignin by hindering the repolymerization process [95]. 4-tert-butyl-2,6-di-methyl phenol (TBDMP) and 2,4,6-tri-tert-butyl-phenol (TTBP) are associated with the rearrangement mechanism leading to cleavage of 4-O-5 bonds in lignin [100]. Longe et al. [21], for the first time, compared the impact of three novel additives comprising TTBP, TBDMP, and HAA with three classic mediators ABTS, VA, and 1-HBT and determined their efficiency to increase lignin degradation. Results indicated the marked reduction in molecular weight with the use of ABTS and VA, however, these mediators showed a slow depolymerization process than that to the other tested mediators. On the contrary, the addition of other mediators presented comparatively fewer influences on the molecular weight of lignin but had superior oxidation than individual laccase. Notably, laccase-VA systems achieved up to 73% reduction in molecular weight of organosolv lignin, whereas the combination of laccase with ABTS, 1-HBT, and TBDMP catalyzed the 49%, 39%, and 43% degradation of lignin, respectively. The detailed characterization of the lignin degraded metabolites by quantitative 2D-HMQC NMR highlighted the mediator-dependent oxidation, and the mediator depolymerizing lignin the most, resulted in more oxidation. S units and the β-O-4 bonds containing S units in the lignin structure were evidently targeted by the enzyme oxidation (Fig. 6).

Chemical structures of some synthetic laccase mediators: (1) > N–OH type; (2) phenothiazine-type; and (3) pyrazolone-type. Reprinted from Christopher et al. [12] an open-access article distributed under the terms of the Creative Commons Attribution License (CC-BY)

Chemical structures of some naturally occurring laccase mediators. Reprinted from Christopher et al. [12], an open-access article distributed under the terms of the Creative Commons Attribution License (CC-BY)

Summary of the different lignin linkages and other structures identified by 13C/1H correlation 2D NMR. X = H/OCH3. Reprinted from Longe et al. [21] with permission from the American Chemical Society. Copyright (2018) American Chemical Society

On the contrary, Rajak and Banerjee [80] recorded no stimulating role of mediators in lignin biodegradation by determining the impact of a series of mediators on lignocellulosic delignification with laccase enzyme produced from Lentinus squarrosulus MR13. As compared to the treatment without mediators, the laccase catalyzed experimental treatments revealed that mediators did not exhibit any notable promoting effect to improve percentage lignin degradation. This observation was in accordance with an earlier report, where mediators displayed no convincing role on the activity of laccase produced by Pleurotus sp. for boosting up lignin removal [101]. The lack of any substantial impact of a mediator’s addition in enhancing percentage lignin delignification might be ascribed to the occurrence of natural mediators in the culture broth that react naturally with the enzyme.

In spite of the significant advantages of the enzyme cocktail, both hydrolytic and oxidative enzymes experience many challenges in various ranges of pH and temperature optima and thermal stability. Moreover, the oxidized mediator may lead to the inactivation of xylanase and laccase itself [102, 103]. Likewise, the degraded products i.e. benzoic, caffeic, ferulic, p-coumaric, sinapic, and vanillic acids might also inhibit the catalytic activity of xylanase [104]. In addition, several challenges need to be addressed in developing efficient laccase mediator system such as (1) reducing bioprocessing costs, (2) utilization of natural and non-toxic mediators, (3) better regeneratibility, (4) greater redox potential, (5) effective oxidizing ability towards both non-phenolic and phenolic lignin molecules, (6) lack of any inhibiting influence on laccase activity and (8) aptitude to creating effective laccase-mediator system with multiplicity of laccases [12].

9 Detoxification of Lignocellulosic Hydrolysate by Enzymatic Treatment: Drive Towards Lignin Biotechnology

It is demonstrated that classical pretreatment techniques generate toxic side streams or inhibitors after the biomass delignification process. Production of these toxic residues affects the growth of fermentative microorganisms and cellulolytic enzymes resulting in a marked reduction in overall ethanol titer [105, 106]. Chemical and physical technologies such as NaOH precipitation, filtration, and anion exchange chromatography are costly, produce sugar loss, and are ineffective to complete elimination of inhibitors in the feedstock hydrolysates. Whereas, bio-based treatment by implicating ligninolytic fungi or their unique enzyme consortium substantially decrease toxic compounds in the hydrolysates. Phenolic compounds are regarded as the utmost degraded type by fungal LMEs amongst various kinds of toxic compounds generated in biomass hydrolysates [107]. These compounds caused the inhibition of fermentation process even at 1 ppm concentration [108], whereas other types of toxic compounds possess a distinct behavior. The nature of feedstock, enzyme attributes, and the pretreatment severity affect the detoxification of these compounds. Enzyme treatment has been effectively accomplished in the elimination of toxicity after various physicochemical pretreatments i.e. strong acids, organosolv, hot liquid water, and steam explosion. Moreover, the ligninolytic-assisted detoxification process increased the fermentation performance and thereby ethanol productivity [105]. For instance, enzymatic treatment of sugarcane bagasse hydrolysate results in an ethanol yield 5-times higher compared with ion exchange detoxification [109]. Under the optimized conditions of enzyme concentration, temperature, and mediators, the detoxification of phenolic compounds in rice straw hydrolysates was improved to 92% [110]. Recently, AAO, a less inspected ligninolytic enzyme, has been employed to detoxify furan derivatives including polyunsaturated alcohols and 5-hydroxymethylfurfural (HMF) [111, 112]. Carro and coworkers [113] reported that AAO efficiently transformed HMF into 2,5-furan dicarboxylic acid (FDCA). Similarly, AAO from P. eryngii also results in the efficient conversion of HMF into 2,5-formylfurancarboxylic acid (FFCA); but it was not able to direct HMF transformation into FDCA. Thus, the addition of a fungal heme peroxygenase was necessary to complete the HMF catalysis. It can be concluded that ligninases-based toxicity removal of hydrolysate is a futuristic and environmentally sound route for biotechnology industries for biofuel production. Nevertheless, this enzymatic approach should be standardized to expand their degradation ability towards many other types of toxic compounds from hydrolysates.

10 Conclusions and Future Perspectives

The development of sustainable technologies for modification and bioconversion of lignin and its building blocks into intelligent biomaterials and added-value products is obviously one of the emerging research concepts among the biotechnology community. Improved lignin processing for incorporating into bio-production is an ultimate objective and might encompass the exploration of biocatalysts with greater catalytic performance, tailored operational modes and consolidated bioprocessing conceptions. In this regard, the use of ligninolytic enzyme extracts has gained intensive research attention as a distinctive strategy that can help to develop an environmentally responsive and cost-efficient technology for deconstruction and detoxification of lignocellulosic raw feedstocks. Ligninolytic enzymatic machinery possesses desirable bio-physicochemical attributes and engenders the similar or higher conversion efficiency, detoxification and delignification magnitudes than the conventional approaches. Furthermore, the development of a novel strategy for simultaneous pretreatment, saccharification, and fermentation (SPSF) technology using ligninolytic and cellulolytic enzyme extracts may provide a cutting-edge approach in the field of biofuels that integrates applied biology, process, and environmental engineering. Application of indigenous biotechnology for the debasement of agricultural biomass will surely minimize the use of toxic chemicals being used in conventional pretreatment processes with associated environment protection and saving of a huge amount of foreign exchange by commercialization.

References

Tuck CO, Pérez E, Horváth IT, Sheldon RA, Poliakoff M (2012) Science 337(6095):695–699

Anastas PT, Zimmerman JB (2018) Curr Opin Green Sust Chem 13:150–153

De Bhowmick G, Sarmah AK, Sen R (2018) Bioresour Technol 247:1144–1154

Carmona-Cabello M, Garcia IL, Leiva-Candia D, Dorado MP (2018) Curr Opin Green Sust Chem 14:67–79

Li X, Xia J, Zhu X, Bilal M, Tan Z, Shi H (2019) Biochem Eng J 151:107363

Xia J, Yu Y, Chen H, Zhou J, Tan Z, He S, Li X (2019) BioResources 14(3):6767–6780

Bozell JJ, Holladay JE, Johnson D, White JF (2007) Top Value Added Candidates from Biomass, Volume II: Results of Screening for Potential Candidates from Biorefinery Lignin. Richland, WA: Pacific Northwest National Laboratory.

Gosselink RJ, De Jong E, Guran B, Abächerli A (2004) Co-ordination network for lignin–standardization, production, and applications adapted to market requirements (EUROLIGNIN). Ind. Crops Prod. 20:121–129

Asgher M, Wahab A, Bilal M, Iqbal HMN (2016) Biocatal Agricult Biotechnol 6:195–201

Ruiz-Dueñas FJ, Morales M, García E, Miki Y, Martínez MJ, Martínez AT (2009) J Exp Bot 60:441–452

Paliwal R, Giri K, Rai JPN (2019) Microbial Ligninolysis: Avenue for Natural Ecosystem Management. In Biotechnology: Concepts, Methodologies, Tools, and Applications (pp. 1399–1423). IGI Global.

Christopher LP, Band Y, Ji Y (2014) Front. Energy Res 2:12

Kamimura N, Sakamoto S, Mitsuda N, Masai E, Kajita S (2019) Curr Opin Biotechnol 56:179–186

Dashtban M, Schraft H, Syed TA, Qin W (2010) Int J Biochem Mol Biol 1(1):36

Pérez J, Munoz-Dorado J, De la Rubia TDLR, Martinez J (2002) Int Microbiol 5(2):53–63

Nishiyama Y, Langan P, Chanzy H (2002) J Am Chem Soc 124:9074–9082

Kumar P, Barrett DM, Delwiche MJ, Stroeve P (2009) Ind Eng Chem Res 48:3713–3729

Kuila A (ed) (2019) Sustainable Biofuel and Biomass: Advances and Impacts. CRC Press, Boca Raton

Abdel-Raheem A, Shearer CA (2002) Fungal Divers 11:1–19

Sun Y, Cheng JY (2002) Bioresour Technol 83(1):1–11

Longe LF, Couvreur J, Leriche Grandchamp M, Garnier G, Allais F, Saito K (2018) ACS Sustain Chem Eng 6(8):10097–10107

Bugg TDH, Ahmad M, Hardiman EM, Rahmanpour R (2011) Nat Prod Rep 28:1871–1960

Palmqvist E, Hahn-Hägerdal B (2000) Bioresour Technol 74:17–24

Agarwal UP, McSweeny JD, Ralph SA (2011) J Wood Chem Technol 31:324–344

Asgher M, Ahmad Z, Iqbal HMN (2013) Ind Crop Prod 44:488–495

Galbe M, Zacchi G (2002) Appl Microbiol Biotechnol 59:618–628

Ferreira S, Gil N, Queiroz JA, Duarte AP, Domingues FC (2010) Bioresour Technol 101:7797–7803

Bilal M, Asgher M, Iqbal HM, Ramzan M (2017) Waste Biomass Valori 8(7):2271–2281

Iglesias G, Bao M, Lamas J, Vega A (1996) Bioresour Technol 58:17–23

Sierra R, Granda C, Holtzapple MT (2009) Biotechnol Prog 25:323–332

Park I, Kim I, Kang K, Sohnd H, Rhee I, Jin I, Jang H (2010) Process Biochem 45:487–492

Bilal M, Iqbal HMN, Hu H, Wang W, Zhang X (2017) Renew Sust Ener Rev 82:436–447

Zainith S, Purchase D, Saratale GD, Ferreira LFR, Bilal M, Bharagava RN (2019) 3 Biotechnology 9(3): 92.

Gusakov AV, Salanovich TN, Antonov AI, Ustinov BB, Okunev ON, Burlingame R, Emalfarb M, Baez M, International D, Drive IP (2007) Biotechnol Bioeng 97:1028–1038

Ummalyma SB, Supriya RD, Sindhu R, Binod P, Nair RB, Pandey A, Gnansounou E (2019) Biological pretreatment of lignocellulosic biomass—Current trends and future perspectives. In: Second and Third Generation of Feedstocks (pp. 197–212). Elsevier, New York.

Lee JW, Gwak KS, Park JY, Park MJ, Choi DH, Kwon M, Choi IG (2007) J Microbiol 45:485–491

Isroi MR, Syamsiah S, Niklasson C, Cahyanto MN, Lundquist K, Taherzadeh MJ (2011) BioResources 6:5224–5259

Hatakka A, Hammel KE (2010) Fungal biodegradation of lignocelluloses. In: Hofrichter M (ed) Ind. Appl., Second. Springer, Berlin, pp 319–340.

Lomascolo A, Record E, Herpoel G, Delattre M, Robert JL, Georis J, Dauvrin T, Sigoillot JC, Asther M (2003) J Appl Microbiol 94:618–624

Baldrian P (2006) FEMS Microbiol Rev 30:215–242

Lee JW, Kim HY, Koo BW, Choi DH, Kwon M, Choi IG (2008) J Biosci Bioeng 106:162–167

Asgher M, Ijaz A, Bilal M (2016) Turk J Biochem 41(1):26–36

Asgher M, Khan SW, Bilal M (2016) Rom Biotechnol Lett 21(1):11133

Asgher M, Ramzan M, Bilal M (2016) Chin J Cataly 37(4):561–570

Hakala TK, Lundell T, Galkin S, Maijala P, Kalkkinen N, Hatakka A (2005) Enzym Microb Technol 36(4):461–468

Asgher M, Shahid M, Kamal S, Iqbal HMN (2014) J Mol Catal B Enzym 101:56–66

Bilal M, Nawaz MZ, Iqbal H, Hou J, Mahboob S, Al-Ghanim KA, Cheng H (2018) Protein Peptide Lett 25(2):108–119

Chowdhary P, Shukla G, Raj G, Ferreira LFR, Bharagava RN (2019) SN Appl Sci 1(1):45

Tien M, Kirk K (1983) Science 221:661–663

Farrell RL, Murtagh KE, Tien M, Mozuch MD, Kirk TK (1989) Enyzm Microb Technol 11:322–328

Johansson T, Welinder KG, Nyman PO (1993) Arch Biochem Biophys 300:57–62

Moilanen AM, Lundell T, Vares T, Hatakka A (1996) Appl Microbiol Biotechnol 45:792–799

Sugiura T, Yamagishi K, Kimura T, Nishida T, Kawagishi H, Hirai H (2009) Biosci Biotechnol Biochem 73:1793–1798

Glumoff T, Harvey P, Molinari S, Goble M, Frank G, Palmer JM (1990) Eur J Biochem 187:515–520

Tien M, Kirk TK (1988) Biomass, part B: Lignin, pectin and chitin. In: Wood WA, Kellog SC (eds) Methods in enzymology. Academic Press, San Diego, pp 238–249

Furukawa T, Bello FO, Horsfall L (2014) Front Biol 9:448–471

Martinez AT, Speranza M, Ruiz-Dueñas FJ, Ferreira P, Camarero S, Guillen F, Martinez MJ, Gutierrez A (2005) Int Microbiol 8:195–204

Kirk TK, Tien M, Kersten PJ (1986) Biochem J 236:279–287

Ivancich A, Mazza G, Desbois A (2001) Biochemistry 40:6860–6866

Hofrichter M (2002) Enzym Microb Technol 30:454–466

Lobos S, Larrain J, Salas L, Cullen D, Vicuna R (1994) Microbiology 140(10):2691–2698

Tuor U, Wariishi H, Schoemaker HE, Gold MH (1992) Biochemistry 31:4986–4995

Abdel-Hamid AM, Solbiati JO, Cann IKO (2013) Adv Appl Microbiol 82:1–28

Hofrichter M, Steffen K, Hatakka A (2001) Decomposition of Humic substances by Ligninolytic Fungi. In: 5th Finnish Conference on Environmental Science and Proceedings, Turku, Finland (pp. 56–60).

Hofrichter M, Ullrich R, Pecyna MJ, Liers C, Lundell T (2010) Appl Microbiol Biotechnol 87:871–897

Gasser CA, Ammann EM, Shahagaldian P, Corvini PF (2014) Appl Microbiol Biotechnol 98:9931–9952

Ouzounis C, Sander C (1991) FEBS Lett 279:73–78

Falade AO, Mabinya LV, Okoh AI, Nwodo UU (2018) Microbiol Open 7(6):e00722

Wong DWS (2009) Appl Biochem Biotechnol 157:174–209

Pérez-Boada M, Ruiz-Dueñas FJ, Pogni R, Basosi R, Choinowski T, Martínez MJ, Piontek K, Martínez AT (2005) J Mol Biol 354:385–402

Plácido J, Capareda S (2015) Biores Bioproc 2(1):23

Bilal M, Asgher M, Iqbal HMN, Hu H, Zhang X (2017) LWT-Food Sci Technol 80:348–354

Bilal M, Asgher M, Iqbal HMN, Hu H, Zhang X (2017) Int J Biol Macromol 98:447–458

Bilal M, Iqbal HM (2019) Biocatal Agricult Biotechnol 101205.

Ibarra D, Romero J, Martínez MJ, Martínez AT, Camarero S (2006) Enzym Microb Technol 39:1319–1327

Hermoso JA, Sanz-Aparicio J, Molina R, Juge N, Gonzalez R, Faulds CB (2004) J Mol Biol 338:495–506

Chandel AK, Silvério S, Singh OV (2013) BioEnergy Res 6:388–401

Silva MLC, de Souza VB, da Silva SV, Kamida HM, de Vasconcellos-Neto JRT, Góes-Neto A, Koblitz MGB (2014) Adv Biosci Biotechnol 5(14):1067

Naraian R, Singh D, Verma A, Garg SK (2010) J Environ Biol 31:945–951

Rajak RC, Banerjee R (2016) RSC Adv 6(66):61301–61311

Asgher M, Bashir F, Iqbal HMN (2014) Chem Eng Res Des 92(8):1571–1578

Arora DS, Mukesh C, Gill PK (2002) Int Biodeterior Biodegrad 50:115–120

Feng C, Zeng G, Huang D, Hu S, Zhao M, Lai C, Li N (2011) Process Biochem 46(7):1515–1520

Ayuso-Fernández I, Ruiz-Dueñas FJ, Martínez AT (2018) Proc Natl Acad Sci 115(25):6428–6433

Vina-Gonzalez J, Elbl K, Ponte X, Valero F, Alcalde M (2018) Biotechnol Bioeng 115:1666–1674

Scheiblbrandner S, Breslmayr E, Csarman F, Paukner R, Fuhrer J, Herzog PL, Shleev SV, Osipov EM, Tikhonova TV, Popov VO (2017) Sci Rep 7:13688

Brissos V, Tavares D, Sousa AC, Robalo MP, Martins LO (2017) ACS Catal 7:3454–3465

Gonzalez-Perez D, Mateljak I, Garcia-Ruiz E, Ruiz-Duenas FJ, Martinez AT, Alcalde M (2016) Catal Sci Technol 6:6625–6636

Mate DM, Palomino MA, Molina-Espeja P, Martin-Diaz J, Alcalde M (2017) Protein Eng Des Sel 30:189–196

Torres-Salas P, Mate DM, Ghazi I, Plou FJ, Ballesteros AO, Parisutham V, Kim TH, Lee SK (2014) Bioresour Technol 161:431–440

Risso VA, Gavira JA, Gaucher EA, Sanchez-Ruiz JM (2014) Proteins 82:887–896

Zhang R, Li C, Wang J, Yan Y (2018) Biochemistry 58(11):1501–1510

Lange H, Decina S, Crestini C (2013) Eur Polym J 49:1151–1173

Niku-Paavola M-L, Anke H, Poppius-Levlin K, Viikari L (2003) Appl. Enzym. to Lignocellul. In: Mansfield SD, Saddler JN (eds) Siderophores as natural mediators in laccase-aided degradation of lignin. ACS symp Ser 855, Washington DC, pp. 176–190.

Eggert C, Temp U, Eriksson KEL (1996) Appl. Environ Microbiol 62:1151–1158

Wang X, Yao B, Su X (2018) Int J Mol Sci 19(11):3373

Kawai S, Asukai M, Ohya N, Okita K, Ito T, Ohashi H (1999) FEMS Microbiol Lett 170:51–57

Oksanen T, Buchert J, Amann M, Candussio A, Viikari L (2002) Prog Biotechnol 21:255–262

Ander P, Eriksson KE (1976) Arch. Microbiol. 109:1–8

Nanayakkara S, Patti AF (2014) Saito K. Green Chem. 16:1897–1903

Rajak RC, Banerjee R (2015) RSC Advances 5(92):75281–75291

Woolridge E (2014) Catalysts 4:1–35

Valls C, Colom JF, Baffert C (2010) Gimbert, Roncero MB, Sigoillot JC. Biochem Eng J 49:401–407

Kapoor M, Kapoor RK, Kuhad RC (2007) J Appl Microbiol 103:305–317

Moreno AD, Ibarra D, Fernández JL, Ballesteros M (2012) Bioresour Technol 106:101–109

Luo H, Zheng P, Xie F, Yang R, Liu L, Han S, Bilal M (2019) RSC Advances 9(12):6919–6927

Jurado M, Prieto A, Martínez-Alcalá Á, Martínez ÁT, Martínez MJ (2009) Bioresour Technol 100:6378–6384

Delgenes JP, Moletta R, Navarro JM (1996) Enzyme Microb Technol 19:220–225

Chandel AK, Kapoor RK, Singh A, Kuhad RC (2007) Bioresour Technol 98:1947–1950

Lee K, Kalyani D, Tiwari MK, Kim T, Dhiman SS, Lee J, Kim I (2012) Bioresour Technol 123:636–645

Dijkman WP, Groothuis DE, Fraaije MW (2014) Angew Chem 53:6515–6518

Ferreira P, Medina M, Guillén F, Martinez M, Van Berkel W, Martinez A (2005) Biochem J 389:731–738

Carro J, Ferreira P, Rodríguez L, Prieto A, Serrano A, Balcells B, Ardá A, Jiménez-Barbero J, Gutiérrez A, Ullrich R, Hofrichter M, Martínez AT (2015) FEBS J 282:3218–3229

Asgher M, Bhatti HN, Ashraf M, Legge RL (2008) Biodegradation 19:771–783

Tuomela M, Hatakka A (2011) “Oxidative fungal enzymes for bioremediation”. In: Moo-Young M, Agathos S, eds. Comprehensive Biotechnology. 183. Spain, Elsevier.

Asgher M, Wahab A, Bilal M, Iqbal HM (2018) Waste Biomass Valori 9(11):2071–2079

Sondhi S, Kaur R, Kaur S, Kaur PS (2018) Int J Biol Macromol 117:1093–1100

Lassouane F, Aït-Amar H, Amrani S, Rodriguez-Couto S (2019) Bioresour Technol 271:360–367

Bilal M, Jing Z, Zhao Y, Iqbal HM (2019) Biocatal Agricult Biotechnol 19:101174

Zhang R, Wang L, Han J, Wu J, Li C, Ni L, Wang Y (2020) J Hazard Mat 383: 121130.

Wesenberg, D. I. Kyriakides, SN. Agathos (2003) Biotechnol Adv 22: 161–187.

Rekik H, Jaouadi NZ, Bouacem K, Zenati B, Kourdali S, Badis A, Jaouadi B (2019) Int J Biol Macromol 125:514–525

Guo J, Liu X, Zhang X, Wu J, Chai C, Ma D, Ge W (2019) Int J Biol Macromol 138:433–440

Vandana T, Kumar SA, Swaraj S, Manpal S (2019) BioResources 14(3):5380–5399

Shaheen R, Asgher M, Hussain F, Bhatti HN (2017) Int J Biol Macromol 103:57–64

Hofrichter M, Steinbüchel A (Eds.) (2001) Biodegradation of lignin. In: Hofrichter M, Steinbuchel A, eds. Lignin, Humic substances and Coal. Weinheim, Wiley-VCH. pp. 129–180, 2001.

Bilal M, Asgher M, Hu H, Zhang X (2016) Water Sci Technol 74(8):1809–1820

Bilal M, Asgher M (2016) J Mol Catal B: Enzymatic 128:82–93

Gaur N, Narasimhulu K, Pydisetty Y (2018) RSC adv 8(27):15044–15055

Zhang H, Zhang J, Zhang X, Geng A (2018) Process Biochem 66:222–229

Zhang H, Zhang X, Geng A (2020) Biochem Eng J 153: 107402.

Min C, Shanjing YAO, Zhang H, Liang X (2010) Chin J Chem Eng 18(5):824–829

Liu J, Zhang S, Shi Q, Wang L, Kong W, Yu H, Ma F (2019) Int Biodeterior Biodegrad 136:41–48

Sáez-Jiménez V, Fernández-Fueyo E, Medrano FJ, Romero A, Martínez AT, Ruiz-Dueñas FJ (2015) PLoS ONE 10(10):e0140984

Rodríguez‐Couto (2019) Current Trends in the Production of Ligninolytic Enzymes. A Handbook on High Value Fermentation Products, Volume 2: Human Welfare, 67.

Asgher M, Ahmad Z, Iqbal HM (2017) Carbohydr Polym 161:244–252

Nagula KN, Pandit AB (2016) Biorzsour Technol 213:162–168

Mukhopadhyay M, Banerjee R (2014) 3 Biotech 5(3), 227–236.

Rico A, Rencoret J, del Río JC, Martínez AT, Gutiérrez A (2014) Biotechnol Biofuels 7(1):6

Gutiérrez A, Rencoret J, Cadena EM, Rico A, Barth D, José C, Martínez ÁT (2012) Bioresour Technol 119:114–122

Annunziatini C, Baiocco P, Gerini MF, Lanzalunga O, Sjögren B (2005) J Mol Catal B: Enzym 32(3):89–96

Oudia A, Queiroz J, Simões R (2008) Appl Biochem Biotechnol 149(1):23–32

Acknowledgements

Authors are grateful to their representative institutes/universities for providing literature facilities.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

We do not have any conflicting, competing and financial interests in any capacity.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bilal, M., Iqbal, H.M.N. Ligninolytic Enzymes Mediated Ligninolysis: An Untapped Biocatalytic Potential to Deconstruct Lignocellulosic Molecules in a Sustainable Manner. Catal Lett 150, 524–543 (2020). https://doi.org/10.1007/s10562-019-03096-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-019-03096-9