Abstract

An efficient route for the Knoevenagel condensation of aromatic aldehydes with barbituric acids and 2-thiobarbituric acids in the presence of polyvinyl pyrrolidone (PVP) stabilized Ni nanoparticles in ethylene glycol has been reported. A range of biologically important arylidene barbiturates were obtained in high yields (82–97%) in a very short reaction time.

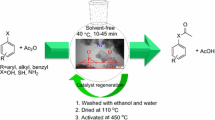

Graphical Abstract

A novel and highly efficient PVP-stabilized Ni nanoparticles catalyzed synthesis of arylidene barbiturates and arylidene 2-thiobarbiturates has been described.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The Knoevenagel condensation of aldehydes with active methylene compounds is an important and widely employed method for carbon–carbon bond formation in organic synthesis with numerous applications in the synthesis of fine chemicals, hetero Diels–Alder reaction and in synthesis of carbocyclic as well as heterocyclic compounds of biological significance. Barbituric acids and their derivatives have been widely used as a sedative, hypnotic, anaesthetic, anticonvulsant, antiosteoporosis, as well as antitumor agents [1]. Arylidene barbituric acids as well as their 2-thio analogues are useful as intermediates in synthesis of heterocyclic compounds [1], benzyl barbituric derivatives [2], oxadiazaflavines [3], and unsymmetrical disulphides [4]. Additionally, some of them have been recently studied as non-linear optical materials and dyes [5]. Various methods have been reported for the Knoevenagel condensation of carbonyl compounds with barbituric acids or 2-thio barbituric acids like homogeneous systems [6–8], solvent-free grinding using NH2SO3H [9], microwave irradiation [10], infra red promoted [11], ionic liquid mediated condensation [12], various acid and base catalyzed condensation reactions including dry condensation with acidic clay catalysts [13–20]. Recently, Ni supported on SiO2 has been used for the selective catalytic Knoevenagel condensation [21]. However, some of these methods have been associated with shortcomings such as longer reaction times, use of expensive catalysts, formation of undesirable di-substituted product, requirement of excess of solvent, lower yields, etc. Therefore, in view of the importance of barbituric acid derivatives, especially 5-arylidene barbiturates, development of a facile and practically efficient methodology for the target Knoevenagel condensation is desired.

Transition-metal nanoparticles have gained tremendous importance in the last two decades as they exhibit interesting electrical, optical, magnetic and chemical properties, especially catalytic properties (owing to their large surface area) which cannot be achieved by their bulk counterparts [22–31]. Metal nanoparticles offer new possibilities for designing and constructing structure controllable catalysts, which can be synthesized in a solvent or even be deposited on a support without obvious aggregation [32–34]. A variety of chemical methods have been developed for the preparation of metal nanoparticles [35] including those wherein, polymers carrying functional groups have been used as specific stabilizers for the solution synthesis of nanoparticles as they prevent irreversible aggregation of nanometer-sized metal particles due to steric repulsion [36, 37] and also make them “soluble” in solvents. Amongst these, the modified polyol method has been conveniently utilized for the heterogeneous nucleation and growth of nickel nanoparticles [38, 39]. Metal nanoparticles including monolayer protected ones, exhibit excellent catalytic activities for a variety of organic reactions [40–45].

Recently, there has been growing interest in using nickel nanoparticles in organic synthesis and these are foreseen as an active area of research in the future because of their potent catalytic activity, possible processability, easy preparation, high stability, ease of recyclability as well as greener compared to traditional Raney Ni catalyst. A great deal of work has demonstrated that the Ni(0)-catalyzed C–C bond forming reaction is an extremely powerful tool in organic synthesis [46]. However, an increasing number of examples are available in literature wherein Ni nanoparticles alone have been used as a catalyst during an organic transformation [47–55]. Such remarkable properties associated with Ni nanoparticles spurred us to study the possibility of Knoevenagel condensation of aromatic aldehydes with barbituric acids and 2-thiobarbituric acids in the presence of Ni nanoparticles as the active catalysts.

2 Experimental

2.1 General

All the chemicals used were of research grade and were used without further purification. The size and morphology of nickel nanoparticles were characterized with the help of transmission electron microscopy (JEOL 2100-F operating at 200 kV) and quasi-electron light scattering (QELS) analysis (PHOTOCOR-FC-1135P). EDAX spectrum was obtained using Cu grids on TECNAI G2 U-TWIN (300 kV). IR spectra were recorded on Perkin-Elmer FT-IR SPECTRUM-2000. X-ray diffraction pattern was obtained on BRUKER D8. 1H NMR spectra were recorded on Brucker Spectrospin AVANCE (300 MHz) with DMSO-d6 as the solvent and TMS as the internal standard. Melting points were recorded on a Tropical Labequip apparatus and are uncorrected. All the nanoparticle characterization data matched satisfactorily with the reported ones [39].

2.2 Preparation of Ni Nanoparticles

Nickel nanoparticles were prepared by the modified polyol process reported in the literature [39]. 20.0 mL of a 2 × 10−4 mol L−1 solution of NiCl2·6H2O in ethylene glycol was reduced with NaBH4 (0.180 g) in presence of PVP (Ni2+:PVP: 1:5 wt%) at 140 °C. The sample for TEM and EDAX analysis was obtained by the addition of acetone to the nickel nanoparticles dispersion in ethylene glycol, followed by centrifugation (6000 rpm). The particles, so obtained, were washed free of any residual components using ethanol. Subsequently, a drop of methanol dispersion of the nickel nanoparticles was placed on carbon coated Cu grid (mesh size 300). The ethylene glycol dispersion, as obtained directly from polyol process, was used as such for carrying out QELS analysis and for UV–Vis spectral analysis. IR spectra of the sample; isolated upon centrifugation followed by washing with acetone; was done using KBr pellets. Sample for the X-ray diffraction study was obtained by depositing a thin coating of the isolated nickel nanoparticles (dispersed in absolute ethanol) onto a glass plate followed vacuum drying.

2.3 General Procedure for the Synthesis of 5-Arylidene Barbituric Acids and 2-Thio Analogues (IIIa-x)

Aldehyde (I, 2 mmol) was added to a well stirred dispersion of nickel nanoparticles in ethylene glycol (2 mL/0.1 g of I: 1.5 mol%); as obtained directly from the modified polyol process; in a 25 mL round bottomed flask. To it, barbituric acid (II, 2 mmol) was added and the contents were stirred in an oil-bath maintained at 50 °C till a solid product separates out. Completion of the reaction was monitored by TLC using methanol: chloroform (10:90) as the eluant. All the reactions were invariably complete in 10–15 min. Upon completion, the reaction mixture was diluted with water (~25 mL) when a solid separated out. The solid product was filtered at pump using Whatman type 1 filter paper, washed with water, dried and recrystallised from hot glacial acetic acid. 5-arylidene barbiturates (and 2-thio analogues) were obtained as identified by their mp and spectral data.

2.4 General Procedure for the Recyclability of the Catalyst

Aldehyde (Ia, 2 mmol) was added to nickel nanoparticle dispersion in ethylene glycol (2 mL/0.1 g I; 1.5 mol%) in 25 mL round bottomed flask. Barbituric acid (II, 2 mmol) was added to the reaction mixture and it was stirred. Upon complete formation of IIIa as monitored by TLC, 10.0 mL of ethyl acetate were added to the reaction mixture. The reaction mixture was stirred until complete dissolution of IIIa in ethyl acetate was observed. The two layers were then separated. The ethylene glycol layer was sonicated for 5–10 min and reused for the same experiment for over five cycles.

2.5 Spectral Data

IIIa: 5-(4-Chlorobenzylidene)barbituric acid: M.P. = 297 °C (lit. [11] 298.5 °C); IR (KBr, cm−1) υmax = 3214, 3089, 2849, 1755, 1703, 1674, 1575. 1H NMR (300 MHz, DMSO) δ: 7.53 (d, 2H, J = 8.4 Hz), 8.08 (d, 2H, J = 8.7 Hz), 8.25 (s, 1H), 11.23 (s, 1H, NH), 11.38 (s, 1H, NH).

IIIm: 5-[4-(N,N-Dimethylamino)benzylidene]-2-thiobarbituric acid: M.P.≥300 °C (lit. [12] >300 °C); IR (KBr, cm−1) υmax = 3455, 3120, 2918, 1638, 1490, 1461. 1H NMR (300 MHz, DMSO) δ: 3.16 (s, 6H), 6.83 (d, 2H, Ar–H), 8.16 (s, 1H), 8.46 (d, 2H, Ar–H), 12.04 (s, 1H, NH), 12.14 (s, 1H, NH).

IIIq: 5-(4-Hydroxybenzylidene)-1,3-dimethylbarbituric acid: M.P. = 297 °C (lit.[18] 297 °C); IR (KBr, cm−1) υmax = 3209, 2987, 1669, 1642, 1609, 1530. 1H NMR (300 MHz, DMSO) δ: 3.20 (s, 3H), 3.22 (s, 3H), 6.88 (d, 2H, Ar–H), 8.27 (d, 2H, Ar–H), 8.31 (s, 1H), 10.81 (s, 1H, OH).

IIIv: 5-(4-Hydroxybenzylidene)-1,3-diphenyl-2-thiobarbituric acid: M.P. = 272 °C; IR (KBr, cm−1) υmax = 3340, 2925, 1655, 1603, 1571, 1560, 1532. 1H NMR (300 MHz, DMSO) δ: 6.87 (d, 2H, Ar–H), 7.28-7.47 (m, 10H, N-Ph), 8.32 (d, 2H, Ar–H), 8.36 (s, 1H), 11.00 (s, 1H, OH). 13C NMR (300 MHz, DMSO) δ: 114.93, 115.80, 124.00, 127.95, 128.57, 128.89, 129.05, 138.92, 140.54, 158.04, 163.96, 180.77. MS (ESI): 400 [M]+.

IIIw: 5-[4-(N,N-Dimethyl)benzylidene]-1,3-diphenyl-2-thiobarbituric acid: M.P. = 296 °C (lit. >300 °C); IR (KBr, cm−1) υmax = 3448, 2923, 1659, 1610, 1506, 1421.1H NMR (300 MHz, DMSO) δ: 2.99 (s, 3H), 3.03 (s, 3H), 6.80 (d, 2H, Ar–H), 7.15-7.68 (m, 10H, N-Ph), 8.27 (s, 1H), 8.39 (d, 2H, Ar–H).

IIIx: 5-(4-Chlorobenzylidene)-1,3-diphenyl-2-thiobarbituric acid: M.P. = 256–258 °C; IR (KBr, cm−1) υmax = 3423, 2926, 1710, 1682, 1566, 1547, 1489. 1H NMR (300 MHz, DMSO) δ: 7.15 (d, 2H, Ar–H), 7.20-7.55 (m, 10H, N-Ph), 8.09 (d, 2H, Ar–H), 8.43 (s, 1H). 13C NMR (300 MHz, DMSO) δ: 120.46, 124.43, 127.72, 128.72, 128.83, 134.75, 139.34, 141.53, 162.22, 177.13. MS (ESI): 418 [M]+, 420.

3 Results and Discussion

In this manuscript, we report a simple, easy and convenient protocol for the formation of 5-arylidene barbiturates and their 2-thio-analogues (III) by a condensation reaction between aromatic aldehydes (I) and barbituric acids or 2-thiobarbituric acids (II) catalyzed efficiently by PVP-stabilized Ni nanoparticles in ethylene glycol. Nickel nanoparticles were prepared by modified polyol process which is a promising technique for synthesizing nickel nanoparticles with excellent catalytic properties and high stability [39]. The Ni2+ salt was reduced with sodium borohydride in presence of PVP in ethylene glycol which led to the formation of highly monodispersed Ni nanoparticles as:

The metal dispersion so obtained was characterized by TEM analysis which revealed the formation of coated Ni nanoparticles with average diameter 11 nm (Fig. 1a, b). This result was further supported by QELS analysis which showed a maximum population distribution centered around 10–11 nm (Fig. 1c). Metallic nature of nanoparticles was confirmed by UV–Vis spectral data (Fig. 2) and by the energy-dispersive spectrum (EDAX) as shown in Fig. 3. IR spectra of the sample showed the presence of PVP along with the presence of ethylene glycol which remained adsorbed onto the particles despite repeated washing (Fig. 4). XRD analysis further supported the results (Fig. 5). Three peaks for Ni at 2θ = 44.5°, 51.8°, 76.4°, corresponding to the (111), (200), (222) lattice planes, were observed, revealing that the resultant particles were pure elemental Ni with a face-centered cubic (FCC) structure. The particle diameter was estimated by the Scherrer’s equation to be about 6.9 nm. No obvious peak of nickel oxide or hydroxide was detected. The results are in complete agreement with the reported data [39].

Ni nanoparticles were used in the form of dispersion in ethylene glycol as obtained by modified polyol process. Additionally, ethylene glycol served as a suitable solvent for the currently probed transformation as well, based on the solubility difference of the product from the starting materials, leading to separation of product from the reaction mixture upon completion, thereby facilitating easy isolation of solid product from the reaction mixture simply by filtration. As part of our program aimed at developing new and environmentally benign synthetic methodologies with Ni nanoparticles, a reaction of 4-chlorobenzaldehyde (Ia) was attempted with barbituric acid (IIa) in presence of Ni nanoparticles under different conditions. It was observed that 4-chlorobenzaldehyde (1 equiv.) reacted with barbituric acid (1 equiv.) in presence of Ni nanoparticles, dispersed in ethylene glycol (2 mL/0.1 g I; 1.5 mol%), at 50 °C to afford 4-chlorobenzylidene barbiturate (IIIa) in 10 min in 93% yield. Subsequently, reactions of other aldehydes also with barbituric acid (IIa) gave the corresponding arylidene barbiturates (IIIa-IIIj). Reactions of aldehydes with 2-thiobarbituric acid (IIb) yielded arylidene 2-thiobarbiturates (IIIk-o). Similarly, reactions of aldehydes with N,N-dimethyl barbituric acid (IIc) and N,N-diphenyl 2-thiobarbituric acid (IId) also gave corresponding arylidene barbiturates (IIIp-x) (Scheme 1).

All the reactions were performed at 50 °C to slightly increase the solubility of barbituric acids in ethylene glycol. Reaction time observed for all the transformations was 10–15 min. In order to confirm the effective involvement of Ni nanoparticles during this transformation, a blank reaction of Ia with barbituric acid (IIa) was performed in ethylene glycol alone (containing traces of PVP) at 50 °C. In the absence of Ni nanoparticles, the reaction was incomplete even after 10 h of stirring though formation of a small amount of IIIa (38%) was observed. Reactions with varying amounts of PVP were attempted. It is clear that PVP does not play a substantial role during the reaction, as is evident from the reaction time and yield. However, its presence can not be ignored due to its superior stabilizing properties. The reaction of Ia with barbituric acid was also attempted with Ni powder (size <150 micron) in ethylene glycol at 50 °C. The reaction was only 45% complete even after stirring for 24 h. All these results have been summarized in the form of Table 1.

The condensation could be achieved not only with aryl aldehydes but also with α,β-unsaturated aldehydes (Ih) as well as with heteroaromatic aldehydes (Ii). One common trait among all the synthesized arylidene barbiturates (III) was their distinct strong color. The scope and generality of this condensation has been illustrated by screening a variety of aromatic aldehydes (I) with diverse substitution pattern and barbituric acids (II). All the results have been summarized in Table 2.

Interestingly, the catalyst could be recycled easily simply by solvent extraction of the product from the reaction mixture. For this, ethyl acetate was used as it was completely immiscible with ethylene glycol at room temperature. Upon sonication, the ethylene glycol layer containing the Ni nanoparticles could be reused for the next cycle. The catalyst retained optimum activity till three cycles after which drop in yield was observed. Also, QELS analysis after second catalytic cycle showed no change in size. However, an increase in size (around 30 nm) after third cycle was observed along with presence of smaller sized particles (Fig. 6a–c).

Thus, we have developed a rapid, clean and highly efficient methodology for the Knoevenagel condensation of aromatic aldehydes with barbituric acids and 2-thiobarbituric acids catalyzed by PVP stabilized Ni nanoparticles to give 5-arylidene barbituric acids and their 2-thio analogues as the desired products in short time span and in quantitative yields by a simple and economical protocol. The reaction time, yield and handling highlight the efficiency of this novel protocol.

4 Conclusions

In conclusion, we have described a novel and highly efficient protocol for the synthesis of structurally complex and diverse 5-arylidene barbiturates and their corresponding 2-thio derivatives catalyzed effectively by PVP stabilized nickel nanoparticles in ethylene glycol at 50 °C. Owing to its several advantages over other methods, this method has proved to be a highly promising one, enjoying high practical utility.

References

Bojarski JT, Mokros JL, Barton HJ, Paluchowska MH (1985) Adv Heterocycl Chem 38:229; references therein

Frangin Y, Guimbal C, Wissocq F, Zamarlik H (1986) Synthesis 1046

Figueroa-Villar JD, Rangel CE, Dos Santos LN (1992) Synth Commun 22:1159

Tanaka K, Cheng X, Yoneda F (1988) Tetrahedron 44:3241

Rezende MC, Campodonico P, Abuin E, Kossanyi J (2001) Spectrochim Acta A 57:1183

Gursu E, Ulusoy N (1996) Acta Pharma Turc 38:107

Dyachkou AI, Ivin BA, Smorygo NA, Sochilin EG (1976) Zh Org Khim 12:1115

Dyachkou AI, Ivin BA, Smorygo NA, Sochilin EG (1976) Chem Abs 478074

Li JT, Dai HG, Liu D, Li TS (2006) Synth Commun 36:789

Dewan S, Singh R (2003) Synth Commun 33:3081

Alarreca G, Sanabria R, Miranda R, Arroyo G, Tamariz J, Delgado F (2000) Synth Commun 30:1295

Wang C, Ma J, Zhou X, Zang X, Wang Z, Gao Y, Cui P (2005) Synth Commun 35:2759

Bigi F, Conforti ML, Maggi R, Piccinno A, Sartori G (2000) Green Chem 2:101

Deb ML, Bhuyan PJ (2005) Tetrahedron Lett 46:6453

Lu J, Li Y, Bai Y, Tian M (2004) Heterocycles 63:583

Villemin D (1983) Chem Commun 1092

Hu Y, Chen Z, Le Z, Zheng Q (2004) Synth Commun 34:4521

Kaupp G, Jamal MRN, Schmeyers J (2003) Tetrahedron 59:3753

Haldar MK et al (2008) Bioorg Med Chem Lett 18:2373; references therein

Zhu W et al (2003) Synth Met 137:1127

Rajasekhar Pullabhotla VSR, Rahman A, Jonnalagadda SB (2009) Catal Commun 10:365

Alivisatos AP (1996) Science 271:933

Majetich SA, Jin Y (1999) Science 284:470

Rao CNR, Kulkarni GU, Thomas PJ, Edwards PP (2000) Chem Soc Rev 29:27

Schmid G (2004) Nanoparticles: from theory to application. Wiley-VCH, Weinheim

Jun Y, Choi J, Cheon J (2007) Chem Commun 1203

Lu AH, Salabas EL, Schüth F (2007) Angew Chem Int Ed 46:1222

Dahl JA, Maddux BLS, Hutchison JE (2007) Chem Rev 107:2228

Vollath D (2008) Nanomaterials. An introduction to synthesis, properties and applications. Wiley-VCH, Weinheim

Cushing BL, Kolesnichenko VL, O’Connor CJ (2004) Chem Rev 104:3893

Park J, Joo J, Kwon SG, Jang Y, hyeon T (2007) Angew Chem Int Ed 46:4630

Furlong DN, Wells D, Sasse WHF (1985) J Phys Chem 89:626

Martino A, Yamanaka SA, Kawola JS, Loy DA (1997) Chem Mater 9:423

Sault AG, Martino A, Kawola JS, Boespflug E (2000) J Catal 191:474

Roucoux A, Schulz J, Patin H (2002) Chem Rev 102:3757

Hyeon T (2003) Chem Commun 927

Chen DH, Wu SH (2000) Chem Mater 12:1354

Viau G, Toneguzzo P, Pierrand A, Acher O, Fièvet-Vincet F, Fièvet F (2001) Scripta Mater 44:2263

Couto GG, Klein JJ, Schreiner WH, Mosca DH, Oliveira AJA, Zarbin AJG (2007) J Colloid Interf Sci 311:461

Astruc D, Lu F, Aranzaes JR (2005) Angew Chem Int Ed 44:7852

Shon YS, Choo H (2003) CR Chimie 6:1009

Verma AK, Kumar R, Chaudhary P, Saxena A, Shankar R, Mozumdar S, Chandra R (2005) Tetrahedron Lett 46:5229

Reetz MT, Lohmer G (1996) Chem Commun 1921

Reetz MT, Westermann E (2000) Angew Chem Int Ed 39:165

Ramarao C, Ley SV, Smith SC, Shirley IM, DeAlmeida N (2002) Chem Commun 1132

Zhang Z (2005) Synlett 5:877

Corain B, Schmid G, Toshima N (2008) Metal nanoclusters in catalysis and materials science. The Issue of Size Control

Alonso F, Riente P, Yus M (2009) Synlett 1579

Alonso F, Osante I, Yus M (2007) Tetrahedron 63:93

Ferrando R, Jellinek J, Johnston RL (2008) Chem Rev 108:845

Sapkal SB, Shelke KF, Shingate BB, Shingare MS (2009) Tetrahedron Lett 50:1754

Saxena A, Kumar A, Mozumdar S (2007) J Mol Catal A Chem 269:35

Kidwai M, Bansal V, Saxena A, Shankar R, Mozumdar S (2006) Tetrahedron Lett 47:4161

Kumar A, Kumar S, Saxena A, De A, Mozumdar S (2008) Catal Commun 9:778

Jonnalagadda SB et al (2009) Catal Commun 10:365

Acknowledgements

KV is thankful to CSIR, New Delhi, India for the award of Junior Research Fellowship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khurana, J.M., Vij, K. Nickel Nanoparticles Catalyzed Knoevenagel Condensation of Aromatic Aldehydes with Barbituric Acids and 2-Thiobarbituric Acids. Catal Lett 138, 104–110 (2010). https://doi.org/10.1007/s10562-010-0376-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-010-0376-2