Abstract

The effect of the pre-treatment temperature and atmosphere on the surface composition and on the activity and stability of well defined Au/CeO2 catalysts in the low-temperature water-gas shift reaction in dilute water gas was investigated by X-ray photoelectron spectroscopy, kinetic measurements and in-situ IR spectroscopic (DRIFTS) measurements, comparing different reductive and oxidative conditioning procedures. Reductive conditioning at 200 °C yields the most active catalyst. Physical origin and consequences of the resulting differences in the reaction behavior are discussed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the recent decades oxide supported gold catalysts have attracted increasing interest as highly active catalysts for a number of oxidation and reduction reactions, including also the water-gas shift (WGS) reaction [1–4]. The latter reaction is particularly attractive due to its possible application for CO removal from CO contaminated H2-rich feed gases for Polymer Electrolyte Fuel Cells (PEFCs), as they are produced by partial oxidation and/or steam reforming of fossil fuels or biomass derived fuels [5,6]. High WGS activities reaction have been reported for Au/ZrO2 [7], Au/Co3O4 [8], Au/TiO2 [9,10], Au/Fe2O3 [11–14] and Au/CeO2 [3,14–20] catalysts, with the activity decreasing in the order Au/Fe2O3 ≅ Au/TiO2 ≅ Au/ZrO2 > Au/Co3O4 [3]. It is tempting and plausible to assume a similar reaction mechanism for these catalysts; a comprehensive and more quantitative understanding of the reaction on these catalysts is hindered, however, by the widely varying procedures and parameters for catalysts synthesis and catalyst pre-treatment (‘activation’), and also by the very different reaction conditions.

This is topic of the present paper, where we report on the effect of the catalyst pre-treatment, specifically the procedure and parameters of the activation process, on the activity, deactivation and reaction/deactivation behavior of Au/CeO2 catalysts in the WGS reaction. We will apply different oxidative, reductive or thermal activation procedures on the same raw catalyst precursor. This report is part of an extensive study on the WGS reaction on Au/CeO2 catalysts, which were prepared by a deposition-precipitation method [21,22]. First results on the kinetics and mechanism of the reaction and on the effects of catalyst loading for reaction in idealized gas mixtures have been reported recently in ref. [23], results on the effect of increasing CO2 and H2 contents and on the influence of the surface area of the support on the activity and in particular on the deactivation behavior were presented in refs. [24] and [25], respectively.

In previous studies three different general procedures have been applied for the activation of Au/CeO2 catalysts: reductive pre-treatment, calcination or thermal treatment in an inert atmosphere. In most cases reductive pre-treatment in H2 (1–10% H2 in inert gas as balance at different temperatures) was used to activate Au/CeO2 catalysts for the WGS reaction [18,26–28]. Reductive pre-treatment with CO was also investigated [27]. Since we wanted to avoid a possible blocking of active sites with carbonates and formates, whose generation could be observed in the presence of CO with DRIFTS [24], we did not test CO as reducing agent. Another possible conditioning procedure is calcination, which has also been reported for Au/CeO2 catalysts [12,14,15,19,28]. It should be noted that in some cases the measurement temperatures exceeded the conditioning temperatures [14,26,28], which can lead to further catalyst modification during the reaction. Thermal treatment in inert atmosphere was chosen as one conditioning procedure, since several groups reported a higher activity of Au/α-Fe2O3 catalysts for the room temperature CO oxidation, if the precipitate was not treated at higher temperatures [29–31]. Since in our measurements the WGS reaction is performed at 180 °C, the samples had to be conditioned at higher temperature in order to reduce activation effects induced by the reaction. Therefore, we investigated the effect of reductive, thermal and oxidative treatment in the temperature range between 200 and 400 °C, measuring the initial activity and following the subsequent deactivation in idealized reformate (dilute water gas). These kinetic measurements were complemented by in-situ IR spectroscopic measurements performed in a diffuse reflectance FTIR spectroscopy (DRIFTS) set-up, which allowed us to characterize the initial state of the catalysts after conditioning and the further accumulation of adsorbed reaction intermediates and side products during reaction in idealized reformate under similar conditions as in the kinetic measurements. In addition, we characterized the catalyst surface composition at different stages by X-ray photoelectron spectroscopy (XPS) and by thermal desorption spectroscopy (TPD).

Experimental

Catalyst preparation

The catalysts were prepared by a deposition-precipitation procedure, using commercial CeO2 powder as support (HSA 15 from Rhodia, calcined in air at 400 °C) and HAuCl4 · 4H2O for deposition of Au. Further details are given in refs. [21,22]. The Au metal content was determined via inductively coupled plasma atom emission spectroscopy (ICP-AES). All measurements were performed with catalysts having a BET surface of 188 m2 g−1 and 2.7 wt.% Au loading. Details of the conditioning procedures are described in section 3.1.

Catalyst characterization

The chemical composition of the catalysts was characterized by X-ray photoelectron spectroscopy (XPS, PHI 5800 ESCA system), using monochromatized AlKα radiation. The survey spectra were measured in the range between 0 and 1400 eV binding energy (BE). Detail spectra of gold (Au(4f)) and ceria (Ce(3d)) were measured in the range from 75 to 100 eV and from 875 to 925 eV (0.125 eV and 20 ms per step), respectively. In order to remove surface charging effects, the BEs were calibrated using the Ce4+(3d104f 0Vn) (u′′′) signal at 916.6 eV as reference [23,32]. The intensity scales of the Au(4f) and O(1s) detail spectra were normalized to constant Ce(3d) intensity. Fits of the Au(4f) peaks were performed based on the following assumptions: (i) the difference between Au(4f7/2) and Au(4f5/2) was fixed at 3.7 eV, (ii) the integral intensity of the Au(4f5/2) peak is 3/4 of that of the Au(4f7/2) peak, and (iii) the peak widths (FWHM) for both peaks are equal [33]. Furthermore, the Lorenz–Gauss ratio for each Au species was kept constant. The Ce(3d) region consist of five Ce(3d) peaks (three peaks resulting from CeO2 and two peaks resulting from Ce2O3), and the fits are based on the following assumption: (i) the difference between Ce(3d3/2) and Ce(3d5/2) is 18.5 eV, (ii) the integral intensity of the Ce(3d3/2) signal is 2/3; of the Ce(3d5/2) signal, (iii) the peak widths (FWHM) for both signals of one peak are equal, (iv) the peak widths of the v(Ce4+), v′′′ (Ce4+) and v0(Ce3+) peaks are equal, (v) the peak width of v′(Ce3+) is 1.56 of that of the v peak and (vi) the width of the v′′(Ce4+) is 1.71 of that of the v peak (see [23] and references therein). The Ce3+ concentration in ceria is determined via the following equation [32,34]:

For XPS measurements, catalyst conditioning was performed ex-situ.

Activity measurements

Activity measurements were performed in a quartz tube micro reactor (i.d. 4 mm) located in a ceramic tube oven with typically 75 mg powder (catalyst:α-Al2O3 = 1:20). The reaction was carried out in idealized reformate (dilute water gas, 1 kPa CO, balance N2 (dry) 2 kPa H2O, 60 N ml min−1). In order to obtain differential conversions, the catalyst samples were diluted with α-Al2O3 which is not active for the reaction in the studied temperature range (reaction temperature 180 °C). Water was added to the gas stream using a saturation unit. The influent and effluent gas was analyzed by on-line gas chromatography (DANI, GC 86.10) with H2 as carrier gas. High purity gases from Westphalen (CO 4.7, N2 6.0, H2 5.0) were used. Evaluation of the Weisz criterion showed the absence of mass-transport-related problems [35]. More details on the kinetic measurements are given elsewhere [36].

Infrared investigations

In-situ IR investigations were performed in a DRIFTS (diffuse reflectance infrared Fourier transform spectroscopy) configuration with a Magna 560 spectrometer form Nicolet, equipped with a liquid N2 cooled MCT narrow band detector and a commercial in-situ reaction cell unit from Harricks (HV-DR2). This set-up allows measurement in a continuous flow of gas mixtures, equal to those used in the activity measurements, and at elevated temperatures. Typically, 400 scans (acquisition time 3 min) at a nominal resolution of 8 cm−1 were added for one spectrum. The IR data were evaluated as Kubelka-Munk units, which are linearly related to the adsorbate concentration [37]. To analyze the product gas flow, a gas chromatograph (Chrompack CP 9001) was connected to the exhaust of the DRIFTS cell. For further details see ref. [38].

Results and discussion

Effect of the catalyst pre-treatment on the catalyst composition

The surface composition of the untreated, raw Au/CeO2 catalyst as well as that of differently pre-treated samples, after calcination at 200 °C (sample code ‘O200’) or 400 °C (‘O400’), or after reductive conditioning at the respective temperatures (‘H200’, ‘H400’), or after drying in inert atmosphere (N2) (‘N200’), was characterized by XPS, DRIFTS and TPD. For conditioning, the catalyst was first heated in N2 to the respective temperature, then kept at that temperature for 30 min in an N2 flow, and subsequently exposed to the respective conditioning atmosphere for 45 min (reductive and inert conditioning) or 30 min (oxidative conditioning), respectively. Afterwards it was kept for another 30 min at the conditioning temperature in an N2 stream and then cooled down to the reaction temperature in N2.

XPS results

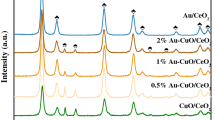

The main XPS results are listed in table 1, Au(4f) detail spectra are shown in figure 1 (upper left panel). The spectrum of the untreated catalyst (figure 1a) shows a broad peak with a maximum at about 84.8 eV, i.e., it is shifted to higher BEs compared to metallic gold (84.0 eV [39,40]). This behavior agrees closely with previous reports on untreated Au/CeO2 catalysts prepared via deposition-precipitation [23,28]. A formal evaluation of the Au0 content, assuming a BE of 84.0 eV and a FWHM of ∼2 eV (see section 2), would result in value of 40.2%. Considering, however, that final-state relaxation effects can lead to a considerable shift of the Au(4f) BE to higher energies for the very small particles expected for this catalyst, the above value for the Au0 content has to be used as lower limit.

XP spectra of the Au(4f) region (left upper panel) of the Ce(3d) region (bottom panel) and of the O(1s) region (right upper panel) of an (a) untreated Au/CeO2 (2.7 wt.% Au) pre-catalyst and after conditioning in (b) 10% O2/N2 at 200 °C, (c) 10% O2/N2 at 400 °C, (d) 10% H2/N2 at 200 °C and (e) 10% H2/N2 at 400 °C (parameters see text).

After calcination at 200 °C, the spectrum exhibits a wide peak with two weak maxima at about 84.6 and 87.9 eV (figure 1, curve b). The lower (Ce(3d) normalized) intensity of this and the following spectra compared to that in curve a is explained by the decreasing absorption of Ce(3d) intensity due to the more pronounced formation of Au particles. The onset at low BEs is slightly lower than 82 eV, it ends at about 92 eV. As shown in the fit to this curve, the absence of a distinct minimum can be explained by a higher contribution from Au3+ (85.8 eV [41]). Also in this case, particle size effects cannot be fully excluded, and therefore the formal Au0 content of 47% should be used as a lower limit. After calcination at 400 °C (figure 1, curve c), the increasing Au particle size allows a more reliable fit of the Au(4f) peak by contributions of Au0 and Au3+, as described in section 2.2. (Note that the Au0 particle sizes are still below the resolution limit of XRD.) Now the content of metallic gold amounts to ∼76%. Similar observations of largely metallic Au species after calcination of a Au/CeO2 catalyst at 400 °C (calcination in air, 10 h) were reported also by Fu et al. [42].

Reductive conditioning in 10% H2/N2 leads to significantly stronger reduction and Au0 formation than calcination. Reductive treatment at 200 °C (figure 1, curve d) and 400 °C (figure 1, curve e) results in Au(4f) peaks with a clear maximum at 83.9 eV. Fitting with Au0 and Au3+ signals yields Au0 contents of 80.3% and 90.3%, respectively. Similar to calcination, the higher conditioning temperature leads to a stronger reduction (oxide decomposition).

In total, reductive conditioning is more efficient in obtaining metallic Au species than calcination under otherwise similar conditions because of the combination of chemical reduction and thermal composition in H2 containing atmosphere, while in oxidative atmosphere these effects are counteracting. The incomplete reduction after the H400 pre-treatment may be related to diffusion of Aun+ into the ceria support during the heating step in the preparation process, as had been suggested by Fu et al. [19], or it results from Aun+ species at the interface between Au and support [2].

XPS data of the Ce(3d) region of the untreated Au/CeO2 catalyst and of the differently pre-treated samples (O200, O400, H200, and H400) are presented in the bottom panel in figure 1; the resulting Ce3+/Ce ratios and the I Au(4f)/I Ce(3) intensity ratios are collected in table 1. As described in the experimental part and in ref. [23], the Ce(3d) region includes a number of peaks, which result from different electronic states of Ce4+ and Ce3+. The relative intensity of the Ce3+ related peaks, normalized to the total Ce(3d) intensity, increased upon reductive treatment and with increasing temperature compared to the untreated Au/CeO2 sample. In contrast, oxidative pre-treatment results in a decrease of the Ce3+ amount after 200 °C calcination. After 400 °C calcination it increased slightly compared to the untreated sample, reaching values comparable to that of the H200 sample.

Qualitatively, these results for Ce agree with our expectations and with trends observed for Au. For heating in H2, thermal decomposition of CeO2, and chemical reduction both work in the same direction, whereas for calcination these two processes (decomposition and chemical oxidation) are counteracting. Comparison with previous data also shows good agreement. Tabakova et al. [28] evaluated the Ce3+ content of a Au/CeO2 catalyst prepared via a modified deposition-precipitation procedure to 16% and 21% before and after reductive treatment at 150 °C in 1% H2/Ar, respectively. Using a slightly different catalyst prepared via deposition-precipitation, they find no Ce3+ on the ‘as prepared’ catalyst, but ∼30% after reductive treatment in H2/Ar at 100 °C. For a similar type catalyst as used in the present study (2.7 wt.% Au/CeO2) Leppelt et al. [23] reported a Ce3+ concentration of 10% before reductive conditioning and ∼22% after H200 reductive treatment (table 1), and comparable amounts of Ce3+ were reported also in ref. [25] for an almost identical catalyst after similar treatment. Jacobs et al. [43] showed an increase of the Ce3+ amount to 19.2% in a 1 wt.% Au/CeO2 catalyst during reductive treatment in H2/He (200 °C) using in-situ XANES (1 wt.% Au/CeO2, 200 ccm H2, 300 ccm He, 45 min), compared to about 23% Ce3+ in a 1 wt.% Pt/CeO2 catalyst after reduction at 250–350 °C. Romeo et al. [32] reported 17% Ce3+ for their Pd/CeO2 catalyst (2 wt.% Pd) after reduction at 400 °C. In total, reductive treatment of noble metal/ceria catalysts at 200–400 °C results in Ce3+ contents of 15–25%, with the exact value depending on the ceria particle size as well as respective reduction conditions.

Next, we used the I Au(4f)/I Ce(3d) intensity ratio for an estimate of the trends in the Au particle size development, exploiting that for constant loading this value will decrease with increasing Au particle size because of the increasing Au(4f) absorption and the decreasing Ce(3d) absorption by the Au particles [44]. Clearly, this gains only qualitative information, but since the oxidative treatment results in particle sizes below the XRD detection limit, this at least gives qualitative information. The I Au(4f)/I Ce(3d) intensity ratio decays in the order RT > O200 > O400 > H200 = H400 (table 1). This sequence follows the same order as that found for the Au0 content, i.e., an increasing Au0 content goes along with larger particle sizes. The increasing Au0 content when going from the H200 to the H400 sample agrees also with the XRD observation of an increasing mean particle size for these samples (H200: 1.4 ± 0.4 nm, and H400: 2.6 ± 0.5 nm). In general, the presence of oxygen during the pre-treatment prevents the formation of larger Au0 particles on ceria compared to reductive treatment.

XP spectra of the O(1s) region of differently treated Au/CeO2 catalysts are presented in the right panel in figure 1 . For the untreated Au/CeO2 catalyst we find a broad peak with a maximum between 529.0 and 529.6 eV and a small shoulder at 531.3 eV. These features are assigned to lattice oxygen and OHad groups, respectively [39,45–49]. The area in the main peak at about 529.3 eV is about similar for all pre-treatment procedures (deviation < ±10%). The small variation can be explained by partial conversion of surface oxygen to OH groups, without significant variations in the total oxygen content. Calcination at 200 and 400 °C has no significant effect on the shape of the O(1s) signal. A small shift of the low energy ‘lattice oxygen’ peak maximum upon calcination can be explained as a result of (i) thermal decomposition of gold oxide [4], or (ii) decomposition of OH and carbonate species [18]. After reductive treatment at 200 and 400 °C, two additional peaks appear between 532 and 534 eV, which we attribute to OH groups and molecularly adsorbed water on the ceria support. This assignment, which follows interpretations of previous studies [47,49,50], agrees well with our DRIFTS results described below. They show a higher content of OH groups and chemisorbed water on the reduced catalysts compared to the calcined samples.

DRIFTS measurements

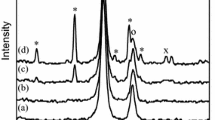

DRIFT spectra recorded on the untreated catalyst and after the different activation treatments at 180 °C (figure 2) reveal significant differences between the different catalysts. Most obvious are the differences in the OH-region. After reductive treatment (figure 2a, b) the spectra exhibit two peaks at 3649 and 3675 cm−1, which are commonly assigned to bridged OH groups [43,51,52]. In addition, we find a broad peak at 3300–3500 cm−1, characteristic for molecularly adsorbed water or hydrogen bonded OH groups on ceria [18,53,54]. After oxidative pre-treatment (figure 2c, d) as well as after drying in N2 (figure 2e) these bridged OH groups are not observed, instead we find vibrational features at 3520, 3710 and 3655 cm−1. Such signals had been attributed to linearly adsorbed (monodentate) and tridentate OH groups on ceria [46]. The broad ‘water peak at 3300–3500 cm−1 is not observed after these pre-treatments. In total, the DRIFT spectra confirm the XPS based conclusion of a strongly enhanced presence of molecularly adsorbed water after reductive treatment compared to calcination or drying in inert atmosphere. A similar correlation for the OH groups between both methods is not possible, since the strongly different background of the DRIFTS spectra renders a quantitative evaluation of the OH concentration impossible.

A peak at 2126 cm−1, in the CO region, observed after reductive treatment is attributed to an electronic transition from donor levels located near the conduction band such as Ce3+ or oxygen vacancies [53,55,56].

Independent of the conditioning procedure, carbonate species were clearly observed. After reductive pre-treatment of the Au/CeO2 catalyst at 200 and 400 °C, three major peaks in the OCO-bending vibration region at 1511, 1462, 1367 cm−1 (figure 2), respectively, provide unambiguous evidence for carbonates adsorbed on the ceria surface [57]. The first two peaks are observed also upon oxidation in O2 at 200 and 400 °C, while the peak at 1367 cm−1 is lower and split into two peaks at 1390 and 1310 cm−1. Evidently, carbonates formed on the catalyst prior to the conditioning procedure are not destroyed during the pre-treatment. This interpretation agrees well with previous reports that temperatures up to 1000 °C are required to fully decompose carbonate species on ceria [58,59].

TPD measurements

Additional information on the presence of OHad species and adsorbed water can be obtained by TPD experiments. Using the reduced H200 catalyst as example, we investigated the presence of these species and their interaction with the catalyst by O2 and H2O-TPD. The spectra were recorded in a N2 stream over pure ceria and over the Au/CeO2 catalyst, after reductive pre-treatment in H2 at 200 °C (figure 3). O2 desorption from pure ceria (126 μmol) occurs in a peak centered at about 450 °C (upper panel, curve a). In contrast, on the Au/CeO2 catalyst, O2 desorption was essentially absent (upper panel, curve b). Apparently, the presence of gold drastically increases the efficiency of the reductive treatment for removing weakly bond oxygen from the ceria support. This was tested in H2O-TPD experiments on similarly treated CeO2 and Au/CeO2 samples (figure 3, lower panel). The spectrum shows a sudden onset of H2O desorption at 270 °C, followed by a shoulder at 335 °C and two peaks with maxima at 425 and 565 °C, respectively for desorption from pure ceria (lower panel, curve a). These peaks can result either from desorption of molecularly adsorbed water or from recombination of adsorbed or bulk OH groups. For the Au/CeO2 catalyst, H2O desorption is indeed much less pronounced, as expected from the higher tendency for O2 desorption, which supports our above explanation. This result agrees well with observations of several authors, who showed an increasing tendency for ceria reduction at low temperature, in the presence of Au [26,43,60].

In total, these different spectroscopic measurements have clearly shown that

-

(i)

the reductively treated samples have more OH groups than oxidatively treated Au/CeO2 catalysts;

-

(ii)

Ce3+ defect sites are only created by reductive pre-treatment, while during oxidative treatment they are, depending on the temperature, more or less efficiently removed;

-

(iii)

the presence of Au particles results in an enhanced reduction of CeO2 during the reductive pre-treatment, equivalent to a more efficient removal of weakly bound oxygen;

-

(iv)

pre-treatment in the temperature range between 200 and 400 °C does not fully remove carbon containing species such as carbonates from the Au/CeO2 catalyst surface;

-

(v)

reductive pre-treatment leads to larger particle sizes compared to oxidative pre-treatment.

Activity and stability of the Au/CeO2 catalysts after different conditioning procedures

The evolution of the WGS reaction rate with time during reaction in idealized reformate on the differently pre-treated catalysts is illustrated in figure 4. Using the reaction rates after 1000 min for comparison, it is obvious from figure 4, that pre-treatment at 200 °C (a) H200, (b) O200, (c) N200 results in significantly higher activities than conditioning at higher temperatures (curves (d–g) in figure 4). In contrast to the conditioning temperature, the effect of the conditioning atmosphere is less clear. While after conditioning at 200 and 300 °C, respectively, slightly higher reaction rates are obtained after reduction than after calcination, the rate is 2 times higher after calcination at 400 °C than after reduction at this temperature. The highest activity after 1000 min of reaction is obtained for the H200 sample, after reductive pre-treatment at 200 °C.

Initial activity and deactivation of differently pre-treated Au/CeO2 catalysts in the WGS reaction in idealized reformate (1 kPa CO, 2 kPa H2O, rest N2) at 180 °C. Pre-treatment: (a) 200 °C in 10% H2/N2, (b) 200 °C in 10% O2/N2, (c) 200 °C in N2, (d) 300 °C in 10% H2/N2, (e) 300 °C in 10% O2/N2, (f) 400 °C in 10% O2/N2 and (g) 400 °C in 10% H2/N2 (other parameters see text).

Comparing these results with previously reported findings is almost impossible, since comparative studies on the effect of the conditioning process do not exist. In addition to varying the conditioning procedure or at least the conditioning parameters, also the procedure for catalyst preparation was changed, rendering quantitative conclusions on the effect of the conditioning procedure impossible. For instance, Tabakova et al. [28] compared two Au/CeO2 catalysts with identical gold contents (3 wt.%), which were synthesized via deposition-precipitation (AuCeDP) and via a modified deposition-precipitation procedure (AuCeMDP). The samples were reduced in a 1% H2/Ar atmosphere at different temperatures: the AuCeDP catalysts was reduced at 100 °C and the AuCeMDP sample at 150 °C. After these pre-treatments, the AuCeDP catalyst was by about a factor of five more active for reaction in a dilute CO/H2O mixture in Ar at 180 °C than the AuCeMDP sample. Hence, similar to our results reductive conditioning at lower temperatures results in a higher activity, but a preparation effect cannot be excluded, since the authors found a higher gold dispersion on the AuCeDP sample. Luengnaruemitchai et al. [14] reported a lower activity for a 1 wt.% Au/CeO2 catalyst (preparation: coprecipitation) after oxidative treatment at 110 °C for 2 hours in O2 than that determined by Andreeva et al. [26] for a similar loading catalyst (preparation: deposition-precipitation) after reduction at 100 °C in 1% H2/Ar. A similar trend results also from measurements by Tabakova et al. [28] and Fu et al. [15] for 3 wt.% (2.6 at.%) and 4.5 at.% (5.1 wt.%) Au/CeO2 catalysts, respectively.

Comparing the activities of the Au/CeO2 catalysts obtained after the different conditioning procedures with previously reported activities of Au/MeO x and in particular Au/CeO2 catalysts (see compilation of reaction data in table 2) shows that for comparable reaction conditions the catalysts prepared and investigated in this work are extremely active. They are clearly more active than the 400 °C calcined catalysts described by Fu et al. [15]. Sakurai et al. [9] studied the WGS reaction on various Au/Me x O y catalysts and reported the following range of activity (see also table 2): Au/TiO2 (3.4 at.%, DP) > Au/Fe2O3 (5 at.%, CP) > Au/Al3 (5 at.%, CP) > Au/ZnO (5 at.%, CP). The reaction rate of the most active catalyst, Au/TiO2, was 11 times lower than that of the Au/CeO2 catalyst described in this study, after reductive pre-treatment. The apparently very high reaction rates reported in ref. [11] can be explained by the much higher CO and H2O contents; for a similar gas mixture we would obtain a rate of 135 × 10−6 mol gcat −1 s−1, using the reaction orders of 0.5 determined for both reactants in dilute water gas previously [23].

The stability of the Au/CeO2 catalysts, as measured by the deactivation over 1000 min on-stream, also depends on the conditioning procedures (see figure 4 and table 3). Thermal treatment in inert atmosphere at 200 °C (N200) leads to the highest deactivation, while for reductive and oxidative conditioning at 200 and 300 °C, respectively, the deactivation is rather similar and significantly lower than for the N200 sample. For conditioning at 400 °C, oxidative treatment (O400) results in a more stable catalyst; the deactivation is significantly lower than for all other samples, while reductive conditioning results in deactivation effects comparable to those at lower temperatures. Nevertheless, the absolute activity of the O400 catalysts is significantly lower than that resulting after the other conditioning procedures.

Comparison of the present stability data with comparable data published previously shows a rather divergent situation. Luengnaruemitchai et al. [14] reported a dramatic decrease in conversion of their Au/CeO2 (1 wt.% Au, BET 124.1 m2/g) to approximately 37% of the initial activity in the course of 1000 min of reaction (2% CO, 20% H2O, balance helium). Previous measurements in our group on Au/CeO2 catalysts with gold contents between 0.8 and 12.6 wt.% led to results comparable to those of the present study (reductive conditioning, deactivation by 20 ± 5% of the initial activity over 1000 min) [23]. Andreeva et al. [26], on the other hand, reported about very stable Au/CeO2 catalysts (content 3 wt.% of gold), whose final activity exceeded the initial conversion after 3 weeks of operation. Furthermore they also observed a decreasing Au particle size, from initially rather large particles (5.5 nm diameter) towards smaller ones.

In total, the reaction measurements clearly demonstrate that reductive conditioning (reduction at 200 °C, H200) represents the optimum conditioning procedure for the deposition-precipitation prepared Au/CeO2 catalysts investigated in this study.

Influence of the conditioning procedure on the adlayer evolution during reaction in idealized reformate (DRIFTS)

The accumulation of adsorbed reaction intermediates and side products on the differentially conditioned catalysts was followed by in-situ IR spectroscopy (DRIFTS) measurements. Sequences of spectra recorded during 1000 min on-stream, under similar conditions as applied for the kinetic measurements, are displayed in figure 5. Full spectra are shown in the bottom panel, expanded representations of the O–H region, of the C–H region and of the CO2/CO region are presented in the upper left and upper right panel, respectively, for each catalyst. On all four catalysts three formate peaks at 1587, 1372 and 2836 cm−1 develop. The first two peaks are related to asymmetric and symmetric O–C–O modes of bidentate formate species [18,56,63]. The band at 2836 cm−1 can be assigned to the C–H vibration stretching mode of bidentate formate species [51,52,64]. The other peak in the C–H region, located at 2949 cm−1, results from bridged formate [18,51,64] on ceria. For all catalysts we find the characteristic 1420 cm−1 band of monodentate carbonate increasing with time. In a previous study we had identified this species as mainly responsible for the deactivation of the catalysts during the WGS reaction [24]. After oxidative conditioning we find an additional ‘carbonate’ species characterized by a peak at 1372 cm−1 [51–55,57], which can be distinguished from bidentate formate species by the fact that the time dependent variation of the related C–H vibration (2836 cm−1) is much less pronounced.

Series of DRIFT spectra obtained during the WGS reaction in idealized reformate (dilute water gas, 0.5 kPa CO, 1 kPa H2O, the rest N2) over 1000 min on Au/CeO2 catalysts pre-treated at 200 °C in (a) 10% H2/N2 and (b) 10% O2/N2 and at 400 °C in (c) 10% H2/N2 and (d) 10% O2/N2. Bottom: full spectrum, top left: detail spectra of the O–H region (raw data), top right detail spectra of the C–H region; from bottom to top after 23 s, 35 s, 47 s, 2 min, 4 min, 10 min, 30 min, 60 min, 240 min, 1000 min.

The two peaks at 2336 and 2362 cm−1 result from gas phase CO2, which is produced by the WGS reaction on Au/CeO2. They decay with time, both the decay with time as well as the initial and final intensity depend on the conditioning procedure. Comparison of the intensities of the CO2 signals and their variation with time with the CO2 formation rates after the different conditioning procedures (figure 4) yields qualitative agreement between these quantities, both for the absolute intensities and for the decay with time.

Also for the OH groups we see distinct differences and changes with time, where the main changes occurred during the first few minutes. For the reduced catalysts, the “water” peak at 3300–3500 cm−1 disappeared. The intensity of the bridged OH group at 3649 cm−1 [23,52,65] decreased strongly, and a new peak at 3630 cm−1 appeared. A peak at 3600 cm−1 (see ref. [23]) shifted to 3590 cm−1. Only small changes occurred for the second type of bridged OH groups (3675 cm−1). On the oxidized Au/CeO2 catalyst, where after the pre-treatment the OH groups differed significantly from those observed on reduced catalysts (see section 3.1), the same OH group related signals developed during the reaction. Already after 10 min WGS reaction, no difference in the OH groups is observed between reduced or oxidized Au/CeO2 catalysts. This finding leads to the suggestion that the initially different catalyst surfaces develop towards the same surface composition, at least with respect to the different types of surface sites. Quantitatively, however, there are still distinct differences. In the case of the reductively conditioned Au/CeO2 catalyst more bridged bond OH groups at 3649 cm−1 are present after conditioning and also after 1000 min on stream, although after that reaction time the difference to the oxidatively conditioned catalyst is less strong. Obviously, 1000 min reaction time is not sufficient to reach similar steady-state surface composition for the differently pre-treated catalysts.

The IR-data presented above are compatible with the mechanism we had recently proposed for the WGS reaction on Au/CeO2 catalysts, for the dominant reaction pathway [23], which involves the reaction of COad with OH groups to form adsorbates formates, which can migrate on the ceria substrate and return to the active sites to decompose into CO2 and H2. For present reaction conditions, decomposition of bidentate formates was determined as rate limiting step, although under steady-state conditions, formate formation must be equally fast as formate decomposition. In that mechanism, the ceria surface acts as buffer for adsorbed formate species, which can be considered as stable reaction intermediates. Independent of the pre-treatment, we found the same type of bidentate formates on all catalysts, indicating that the general reaction mechanism is not altered by the different pre-treatment procedure. The highest formate content is observed for the H400 pre-treated sample, it is lower for O400 and O200 catalysts, and lowest on the H200 catalyst. This trend is opposite to the change of the CO2 production rate with pre-treatment. Apparently, on the H200 catalyst the formate decomposition rate, which is identical to the CO2 formation rate, is highest. This results in the lowest steady-state content of active, bidentate formates.

On the other hand, under steady-state conditions the higher rate for formate decomposition must be supported also by a higher rate for formate formation. Differences in the formate formation rate seem to be correlated with the abundance of bridged OH groups on the surface, which is highest on the reductively pre-treated H200 catalyst, slightly lower for the H400 and significantly lower for the oxidatively pre-treated catalysts.

In that way, the pre-treatment is important since it affects both the bidentate formate decomposition rate and the formate formation rate as rate limiting steps in the WGS reaction [23]. The physical origin for the different rates for formate formation and decomposition must lie in the different Ce3+ and the Aun+ contents and in the different Au0 particle sizes. (The influence of a varying CeO2 particle size, which was kept constant in the present study, was investigated in ref. [25].) However, there is no clear trend which would identify one of these properties as the only decisive one.

Comparing the variation of the Au0 amounts in the differently conditioned samples (see table 1) with that in the activity measurements, there is no clear correlation between these two properties. On the other hand, also the Au3+ content is not directly correlated with the activity, since the H200 and O400 catalysts have about the same Au3+ content, while the reaction rate was about twice as high for the H200 catalysts as for the O400 sample. This result appears to be in contrast to the conclusion by Fu et al. [15,19], who proposed that the WGS activity is dominated by Au+ species and that Au0 only acts as a spectator. One should keep in mind, however, that their studies were performed on 400 °C calcined catalysts, which based on the present findings are considerably less active than the reductively pre-treated catalysts, and that they proposed a Au1+ species as active species (XPS BE: Au1+(4f): 84.6 eV, Au3+(4f): 85.9 eV), while the Aun+ species in the present study mainly refer to the Au3+ species characterized by a Au(4f7/2) BE of 85.8 eV. The variation in the Au particle size does follow the trend of the activity for the reductively pre-treated catalysts, but not when comparing with the oxidatively pre-treated catalysts. Also the Ce3+ content shows no clear correlation with the measured WGS activity, although previous reports demonstrated a significant role of the Ce3+ content in the WGS reaction [28,48,60,66]. The H400 sample, which has the lowest activity by far, has a significantly higher amount of Ce3+, compared to the other samples, while on the other hand the most active H200 sample has a significantly higher Ce3+ content than the (less active) oxidatively pre-treated catalysts. Comparison of the H200 and O200 catalysts shows little difference in activity, but significant differences in the Ce3+ content (14% versus 21%)

Based on these data we conclude that there is not a single effect or quantity determining the WGS activity of Au/CeO2 catalysts, but that this results from an interplay of different quantities such as the abundance of ionic Ce3+ and Aun+ species as well as the Au0 and ceria particle sizes and that these will affect the concentration of active reactants such as bridged OH groups as well as that of stable reaction intermediates such as bidentate formate. This result is not at all astonishing, since under steady-state conditions both formate formation as well as formate decomposition are equally important for the WGS activity, and the above quantities will affect the rates for these two reactions in a different way. In that sense, the most active catalyst is characterized by a high activity for formate formation and a high activity for formate decomposition, where the former seems to be correlated to a high abundance of bridged OH groups and the latter rate is dominated by the activity and abundance of active sites for formate decomposition and by the transport to these sites (see ref. [23]). These rates are likely to rely in different ways on the surface composition characterized by the content of Aun+ and Ce3+ and the respective particle of sizes, i.e., they are affected by different properties of the catalyst surface. The interplay between these two rates determines the amount of active (bidentate) formate species stored on the ceria surface. In that sense, the overall surface composition of the reductively pre-treated H200 catalyst seems to be optimal for achieving high rates for formate formation and formate decomposition at the same time.

Conclusion

We have investigated the influence of the conditioning procedure on the surface composition, activity and stability of 2.7 wt.% Au/CeO2 catalysts prepared by a deposition-precipitation procedure, comparing conditioning in inert, oxidative and reductive atmosphere at temperatures between 200 and 400 °C. Based on ex-situ (XPS) and in-situ (DRIFTS) spectroscopic and on kinetic measurements we could demonstrate that the conditioning procedure has significant influence on the surface composition, activity and stability of these catalysts. Comparing activities after 1000 min on stream, the optimum conditioning procedure involves reduction in 10% H2/N2 at 200 °C (45 min). The resulting catalysts are highly active also in comparison with data reported previously.

The catalyst activity drops with increasing pre-treatment temperature. The comparison of reductive and oxidative pre-treatments shows a higher activity for the reductively conditioned catalysts, except for the high temperature (400 °C) conditioned H400 catalysts, which turned out to have the lowest activity. The tendency for deactivation drops slightly with increasing conditioning temperature, except for the O400 catalyst, which shows a pronounced decay in deactivation, from about 25–26% at 200 and 300 °C to 14% after 400 °C calcination.

The spectroscopic measurements show that the activity is correlated with the abundance of bridged OH groups, which can react with CO to form adsorbed formates, and inversely correlated with the concentration of bidentate formate species, supporting our previous proposal that on these catalysts the WGS reaction proceeds via the formation and decomposition of adsorbed formates and that the ceria surface acts as storage for adsorbed formates. The fact that there is no clear correlation between any of the three properties Au3+ content, Ce3+ content and Au0 particle size and the WGS activity is interpreted in a way that none of these properties is solely decisive for the WGS activity, but that they affect in different ways the activities (rates) for formate formation and formate decomposition. Under steady-state conditions the two rates together determine the measured WGS rate and, via the ratio of the respective rate constants, the steady-state coverage of the bidentate formate intermediate. Accordingly, the most active H200 catalyst is characterized by a combination of these properties which is optimal for enhancing both formate formation and formate decomposition.

References

M. Haruta, N. Yamada, T. Kobayashi, S. Iijima (1989) J. Catal. 115:301

G.C. Bond, D.T. Thompson (2000) Gold Bull. 34:117

D. Andreeva (2002) Gold Bull. 35:82

M. Haruta, S. Tsubota, T. Kobayashi, H. Kageyama, M.J. Genet, B. Delmon (1993) J. Catal. 144:175

R. Kumar and S. Ahmed, in: Fuels processing for transportation fuel cell systems, eds. O. Savadogo, P.R. Roberge and T.N. Veziroglu (Les Éditions de l’École Polytechnique de Montréal, Montréal, Québec, Canada, 1995), pp. 224–238

D.L. Trimm, Z.I. Önsan (2001) Catal. Rev. 43:31

T. Tabakova, V. Idakiev, D. Andreeva, I. Mitov (2000) Appl. Catal. A 202:91

L.I. Ilieva, G. Munteanu, D.C. Andreeva (1998) Bulg. Chem. Comm. 30:378

H. Sakurai, A. Ueda, T. Kobayashi and M. Haruta, Chem. Commun. (1997) 271

F. Boccuzzi, A. Chiorino, M. Manzoli, D. Andreeva, T. Tabakova (1999) J. Catal. 188:176

D. Andreeva, V. Idakiev, T. Tabakova, A. Andreev, R. Giovanoli (1996) Appl. Catal. A 134:275

D. Andreeva, V. Idakiev, T. Tabakova, A. Andreev (1996) J. Catal. 158:354

D. Andreeva, T. Tabakova, V. Idakiev, P. Christov, R. Giovanoli (1998) Appl. Catal. A 169:9

A. Luengnaruemitchai, S. Osuwan, E. Gulari (2003) Catal. Commun. 4:215

Q. Fu, A. Weber, M. Flytzani-Stephanopoulos (2001) Catal. Lett. 77:87

H. Sakurai, T. Akita, S. Tsubota, M. Kiuchi, M. Haruta (2005) Appl. Catal. A 291:179

W. Deng, J. De Jesus, H. Saltsburg, M. Flytzani-Stephanopoulos (2005) Appl. Catal. A 291:126

T. Tabakova, F. Boccuzzi, M. Manzoli, D. Andreeva (2003) Appl. Catal. A 252:385

Q. Fu, H. Saltsburg, M. Flytzani-Stephanopoulos (2003) Science 301:935

Q. Fu, W. Deng, H. Saltsburg, M. Flytzani-Stephanopoulos (2005) Appl. Catal. B 56:57

B. Schumacher, V. Plzak, M. Kinne, R.J. Behm (2003) Catal. Lett. 89:109

V. Plzak, J. Garche, R.J. Behm (2003) Eur. Fuel Cell News 10:16

R. Leppelt, B. Schumacher, V. Plzak, M. Kinne, R.J. Behm (2006) J. Catal. 244:137

Y. Denkwitz, A. Karpenko, V. Plzak, R. Leppelt, B. Schumacher, R.J. Behm (2007) J. Catal. 246:74

A. Karpenko, R. Leppelt, V. Plzak, J. Cai, A. Chuvilin, B. Schumacher, U. Kaiser and R.J. Behm, Topics Catal. (in press)

D. Andreeva, V. Idakiev, T. Tabakova, L. Ilieva, P. Falaras, A. Bourlinos, A. Travlos (2002) Catal. Today 72:51

C.H. Kim, L.T. Thompson (2005) J. Catal. 230:66

T. Tabakova, F. Boccuzzi, M. Manzoli, J.W. Sobczak, V. Idakiev, D. Andreeva (2004) Appl. Catal. B 49:73

A.M. Visco, F. Neri, G. Neri, A. Donato, C. Milone, S. Galvagno (1999) Phys. Chem. Chem. Phys. 1:2869

S.T. Daniells, A.R. Overweg, M. Makkee, J.A. Moulijn (2005) J. Catal. 230:52

N.A. Hodge, C.J. Kiely, R. Whyman, M.R.H. Siddiqui, G.J. Hutchings, Q.A. Pankhurst, F.E. Wagner, R.R. Rajaram, S.E. Golunski (2002) Catal. Today 72:133

M. Romeo, K. Bak, J. El Fallah, F. Le Normand, L. Hilaire (1993) Surf. Interf. Anal. 20:508

D. Briggs and M.P. Seah, Practical Surface Analysis – Auger and X-Ray Photoelectron Spectroscopy, 2nd ed. (John Wiley & Sons, Chichester, 1990)

F. Zhang, P. Wang, J. Koberstein, S. Khalid, S.-W. Chan (2004) Surf. Sci. 563:74

P.B. Weisz (1992) Chem. Eng. Progr. Symp. Ser. 55:29

M.J. Kahlich, H.A. Gasteiger, R.J. Behm (1997) J. Catal. 171:93

I.M. Hamadeh, P.R. Griffiths (1987) Appl. Spec. 41:682

M.M. Schubert, M.J. Kahlich, H.A. Gasteiger, R.J. Behm (1999) J. Power Sources 84:175

J.-J. Pireaux, M. Liehr, P.A. Thiry, J.P. Delrue, R. Caudano (1984) Surf. Sci. 141:21

J.F. Moulder, W.F. Stickle, P.E. Sobol and K.D. Bomben, Handbook of X-ray Photoelectron Spectroscopy (Perkin Elmer Corp., Eden Prairie/USA, 1992)

H.-G. Boyen, G. Kästle, F. Weigl, B. Koslowski, C. Dietrich, P. Ziemann, J.P. Spatz, S. Riethmüller, C. Hartmann, M. Möller, G. Schmid, M.G. Garnier, P. Oelhafen (2002) Science 297:1533

Q. Fu, S. Kudriavtseva, H. Saltsburg, M. Flytzani-Stephanopoulos (2003) Chem. Eng. J. 93:41

G. Jacobs, P.M. Patterson, L. Williams, E. Chenu, D. Sparks, G. Thomas, B.H. Davis (2004) Appl. Catal. A 262:177

J.W. Niemantsverdriet, Spectroscopy in Catalysis – An Introduction (VCH)

T. Dickinson, A.F. Povey, P.M.A. Sherwood (1974) J. Chem. Soc. Faraday Trans. 71:298

A. Laachir, V. Perrichon, A. Badri, J. Lamotte, E. Catherine, J.C. Lavalley (1991) J. Chem. Soc. Faraday Trans. 87:1601

G.S. Herman, Y.J. Kim, S.A. Chambers, C.H.F. Peden (1999) Langmuir 15:3993

Lj. Kundakovic, D.R. Mullins, S.H. Overbury (2000) Surf. Sci. 457:51

M.M. Natile, G. Boccaletti, A. Glisenti (2005) Chem. Mater. 17:6272

D.R. Mullins, S.H. Overbury, D.R. Huntley (1998) Surf. Sci. 409:307

T. Shido, Y. Iwasawa (1992) J. Catal. 136:493

T. Shido, Y. Iwasawa (1993) J. Catal. 141:71

C. Binet, A. Badri, J.C. Lavalley (1994) J. Phys. Chem. 98:6392

C. Binet, M. Daturi, J.-C. Lavalley (1999) Catal. Today 50:207

F. Bozon-Verduraz, A. Bensalem (1994) J. Chem. Soc. Faraday Trans. 90:653

E. Finocchio, M. Daturi, C. Binet, J.C. Lavalley, G. Blanchard (1999) Catal. Today 52:53

C. Li, Y. Sakata, T. Arai, K. Domen, K. Maruya, T. Onishi (1989) J. Chem. Soc. Faraday Trans. 85:929

T. Mokkelbost, I. Kaus, T. Grande, M.A. Einarsrud (2004) Chem. Mater. 16:5489

A. Bumajdad, M.I. Zaki, J. Eastoe, L. Pasupulety (2004) Langmuir 20:11223

A. Trovarelli (1996) Catal. Rev. Sci. Eng. 38:439

A. Venugopal, M.S. Scurrell (2003) Appl. Catal. A 245:137

A. Venugopal, J. Aluha, D. Mogano, M.S. Scurrell (2003) Appl. Catal. A 245:149

C. Li, Y. Sakata, T. Arai, K. Domen, K. Maruya, T. Onishi (1989) J. Chem. Soc. Faraday Trans. 85:1451

G. Jacobs, L. Williams, U. Graham, D. Sparks, B.H. Davis (2003) J. Phys. Chem. B 107:10398

G. Jacobs, L. Williams, U. Graham, G.A. Thomas, D.E. Sparks, B.H. Davis (2003) Appl. Catal. 252:107

Z.-W. Liu, Q.-H. Wei, X. Zhang (2005) Nano Lett. 5:957

Acknowledgments

We gratefully acknowledge financial support by the Deutsche Forschungsgemeinschaft, via Research Training Group 328 (“Molecular Organization and Dynamics at Interfaces and Surfaces”) and via project Be 1201/9-4.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Karpenko, A., Denkwitz, Y., Plzak, V. et al. Low-temperature water-gas shift reaction on Au/CeO2 catalysts – the influence of catalyst pre-treatment on the activity and deactivation in idealized reformate. Catal Lett 116, 105–115 (2007). https://doi.org/10.1007/s10562-007-9111-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-007-9111-z