Abstract

The degradation and utilization of solid waste (SW) from anaerobic digestion of poultry litter by Agrocybe aegerita was evaluated through mushroom production, loss of organic matter (LOM), lignocellulolytic enzymes activity, lignocellulose degradation and mushroom nutrients content. Among the substrate combinations (SCs) tested, substrates composed of 10–20% SW, 70–80% wheat straw and 10% millet was found to produce the highest mushroom yield (770.5 and 642.9 g per 1.5 kg of substrate). LOM in all SCs tested varied between 8.8 and 48.2%. A. aegerita appears to degrade macromolecule components (0.6–21.8% lignin, 33.1–55.2% cellulose and 14–53.9% hemicellulose) during cultivation on the different SCs. Among the seven extracellular enzymes monitored, laccase, peroxidase and CMCase activities were higher before fruiting; while xylanase showed higher activities after fruiting. A source of carbohydrates (e.g., millet) in the substrate is needed in order to obtain yield and biological efficiency comparable to other commercially cultivated exotic mushrooms.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Agro-industrial residues are generally considered the best substrates for the cultivation of many edible white rot fungi because such fungi can utilize a variety of lignocellulosic residues as substrate to produce mushrooms that can serve as human food (Madan et al. 1987). However, in the cultivation of saprophytic fungi to produce mushrooms, nutrient supplements, usually high in organic nitrogen, phosphorus, calcium, etc., are added to lignocellulosic materials like sawdust and cereals straw, in order to increase substrate degradation and mushroom yield (Royse and Sanchez-Vazquez 2003; Royse et al. 2004; Royse and Sanchez 2007). Animal beddings and residues, which are naturally high in nutrients, have been used for mushroom cultivation (Rangaswami et al. 1975; Noble et al. 2002). Poultry litter is naturally high in nutrients and has been used as supplements in the cultivation of different mushroom. Banik and Nandi (2004) reported that supplementation of rice substrate with poultry litter is effective in increasing oyster mushrooms yield. However, very low amounts of poultry litter can be added to substrate for mushroom cultivation (Savoie and Libmond 1994; Isikhuemhen and Ivey 2005) and its application to agricultural fields is also limited (Sharpley and Smith 1993; Sharpley 1997). Therefore alternative uses for poultry litter are needed for the recycling of this abundant waste from the poultry industry.

Anaerobic digestion has been used for many decades to recover energy from organic matter (Erickson 2000). Broiler litter, resulting from commercial production of broiler chickens on wood chips bedding, when subjected to anaerobic digestion, produces a liquid effluent as well as a nutrient rich lignocellulosics solid waste (SW) (Stafford et al. 1980). Chung Po and Wong (1975) reported on such digester effluents use for crops and fruit production in Taiwan. Although not much reports exists in research for the use of anaerobic digester effluent in crop production, Liedl et al. (2006) have successfully utilized such liquid effluent in hydroponic cultivation of tomatoes and lettuce. However, the lingocellulose rich solid waste from anaerobic digester has limited use in crop production as fertilizers and transportation cost from point of production to point of application to fields.

Agrocybe aegerita mushrooms have a unique flavor, are highly nutritious food and are of medicinal value (Zhao et al. 2003). Fruit bodies have been produced on several lignocellulosic based substrates consisting of barley, maize and wheat straw, cotton seed shells and sawdust, orange peel, grape stalk, reed, sunflower, cotton waste, peanut shells (Nicolini et al. 1987; Wang et al. 2000; Zervakis et al. 2001; Philippoussis et al. 2001). However, mushroom yields in A. aegerita are generally lower than yields reported for many other cultivated mushrooms; hence its large scale or commercial cultivation is not widespread (Wang et al. 2000).

Agrocybe aegerita is relatively understudied for its cultivation and biotechnological applications when compared to other mushrooms species of similar organoleptic properties. Ullrich and Hofrichter (2005) reported that during vegetative growth, A. aegerita produces a peroxidase which catalyzes the oxidation of 2,6-dimethoxyphenol or 2,2′-azinobis-(3-ethylbenzothiazoline-6-sulfonate). Laccase, peroxidase and carboxylmethyl cellulase enzymes were also detected at different stages of fruit body development, during cultivation on cotton seed and sawdust substrate (Wang et al. 2000). Various authors have tried to establish correlations between mushrooms production, lignocellulolytic enzyme synthesis and lignocellulose degradation (Eriksson et al. 1990; Valmaseda et al. 1991).

There is no clear understanding how different substrates content affects lignocellulose utilization vis-a-vis enzyme production and mushrooms yield in A. aegerita. Preliminary studies (Isikhuemhen and Shulga, unpublished) indicated that although 100% SW could support mycelia colonization by A. aegerita, the growth was significantly lower than in wheat straw supplemented with SW. However, there is little known about the yield potential, lignocellulolytic enzyme production and substrate utilization when A. aegerita is cultivated on wheat straw substrate amended with SW. The aim of this study was to investigate the utilization of SW from poultry litter either as a complete substrate, or as a supplement of wheat straw and millet based substrates. We were also interested in determining the relationships between fruit body production and ligninolytic enzyme activities.

Materials and methods

Organism and inoculum preparation

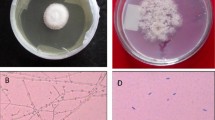

Agrocybe aegerita 156 from the Mushroom Biology and Fungal Biotechnology Laboratory (MBFBL) culture collection at North Carolina A&T University was used in this study. Stock culture of this fungus is maintained on potato-dextrose agar at 4°C until used for experiment.

To make grain spawn, we soaked wheat grains in water for 6 h, drained the water, and mixed with 3 g kg−1 CaCO3. The resulting substrate contained about 70% H2O by weight. We loaded 300 g of grain into 47 × 17 cm polyethylene bags (Unicorn bag Type 4), which were autoclaved for 3 h at 121°C, and allowed to cool for 4 h under a laminar flow hood. Each bag was inoculated with agar blocks (120 g) of actively growing mycelia, sealed and incubated at 25°C. The grain spawn was colonized within 14 days of incubation, and was then used to inoculate the different substrate combinations (SCs) tested.

Preparation of substrates and experimental design

Solid waste from digester effluent was collected from a thermophilic (56.6°C) anaerobic biodigester located on the campus of West Virginia State University. The feedstock for the anaerobic digester was broiler litter from wood chip based bedding (Liedl et al. 2006). Prior to use, the solid waste was air dried, during which time excess ammonia was volatilized (as indicated by smell). Wheat straw was obtained from the North Carolina A&T State University farm, and millet was obtained from a local grain supply store. The wheat straw was chopped to 5 cm pieces before use.

The different combinations of solid waste, wheat straw and millet used as cultivation substrates are shown in Table 1. The experimental design for this study was a single factor randomized design, with ten levels of the factor Substrate Combinations (SCs). The ten factor levels were stratified into two groups: substrates without millet (SC1–SC6, with SC1: wheat straw 100% serving as the control for group 1) and substrates with millet (SC7–SC10, with SC7: Wheat straw 80%, millet 20% serving as control for group 2). Substrates within each group had an increasing proportion of solid waste (SW) from 0 to 100% for group 1, whereas, group 2 had SW increments of 0–20%. Each substrate combination was replicated in four bags and a random sample was taken from each bag for a total of 40 experimental units. Cultivation bags 93 × 36 cm (Unicorn bag Type 422-l A) containing 1.5 kg each (dry weight) of the SCs were prepared. Each substrate combination was mixed and moisture content adjusted to 70% before use. Substrate bags were autoclaved at 121°C for 3 h and allowed to cool. Each bag was inoculated with approximately 5% (w/w) grain spawn described above. Inoculated bags were incubated at 25 ± 2°C. Upon full colonization, holes (15 mm) were punched into the bags and they were transferred to a fruiting room (80–85% relative humidity and 22–25°C). Mushroom fruit bodies in each bag were manually harvested from the substrate and weighed. After two flushes, the total mushroom yield was calculated. Collected mushrooms were dried at 50°C and used for elemental content analyses. Biological efficiency was calculated as percent of fresh weight of mushrooms harvested/dry weight of substrate. A repeat experiment using one of the best performing substrate combinations (SC9) was conducted to determine extended fruit body yield during five flushes.

Samples of substrate (50 g each) were taken from the cultivation bags before and after fruiting. Each sample was soaked in 300 ml sodium acetate buffer (50 mM, pH 5.0) and extracted for 2 h at 4°C, and filtered through Whatman paper to obtain an extract used for enzyme activity determination. The solid biomass (spent mushroom substrate) that remained after filtration was dried at 50°C until a constant mass was achieved, and then weighed and analyzed for protein and macromolecular contents (lignin, cellulose and hemicellulose).

Dry mushrooms were analyzed for water soluble carbohydrate and crude fat content. The crude protein and fat were detected by official methods of analysis (AOAC 1990). The conversion factor of total nitrogen to protein in the mushroom samples was 4.38 (Bernas et al. 2006). The C/N ratio in SCs was analyzed with Perkin Elmer 2400 Elemental Analyzer. Lignin, cellulose and hemicellulose components were analyzed by the Van Soest et al. (1991) method for dietary fiber. Determination of water soluble carbohydrates involved reacting extracts from test samples with 1 N Sulfuric acid for 20 min in a boiling water bath, followed by cooling and neutralizing (Derias 1961). The amount of reducing sugars was determined spectrophotometrically with potassium ferricyanide. LOM was calculated as the percent difference in weight between the test substrate and the control (uninoculated substrate). Analysis for lignocellulose, protein, fat and water soluble carbohydrates described above was conducted at the Rumen Fermentation Profiling Lab, West Virginia University, WV, USA.

Enzyme activities assay

Laccase activity was determined following the oxidation of 2,2-azino-bis-ethylbenthiazoline (ABTS) as a substrate at 420 nm in 100 mM sodium acetate buffer (pH 5.0) (Isikhuemhen and Nerud 1999). Peroxidase activity was assayed by the oxidation of Phenol Red in sodium lactate-succinate buffer (pH 4.5) (Glenn and Gold 1985). Absorbance was read at 610 nm. One unit of enzyme activity is defined as the amount of enzyme required to oxidize 1 μmol of substrates at 24–25°C.

Carboxylmethylcellulase (CMCase) activity was assayed with 1% solution of carboxymethyl cellulose as an enzyme substrate in 0.05 M citrate buffer (pH 5.0) according to IUPAC recommendations (Ghose 1987). The reaction mixture was incubated for 10 min in a buffer at a temperature of 50°C. Xylanase activity was assayed using a 1% solution of xylan from birch wood (Roth 7500) as a substrate in 0.05 M citrate buffer (pH 5.0). The release of glucose and xylose, respectively, in 10 min at 50°C were measured using the dinitrosalicylic acid method (Bailey et al. 1992). One unit of enzyme activity is defined as 1 μmol of glucose or xylose equivalents released per minute under the given conditions.

The activities of exo-1, 4-β-glucanase (EC 3.2.1.4), 1,4-β-glucosidase (EC 3.2.1.2), and 1,4-β-xylosidase (EC 3.2.1.37) were determined by measuring the rate of hydrolysis of p-nitrophenyl-β-d-cellobioside, p-nitrophenyl-β-d-glucopyranoside and p-nitrophenyl-β-d-xylopyranoside as described by Poutanen and Puls (1988). The reaction mixture containing 1.8 ml of 2.5 mM substrate and 0.2 ml of the culture extract filtrate was incubated at 50°C for 10 min. The reaction was stopped by the addition of 1 ml of 1 M Na2CO3 into the reaction mixture. The enzyme quantity catalyzing the release of 1 μmol of p-nitrophenol per min under these conditions was considered to be a unit of enzymes activities.

Statistical analysis of experimental data

The following variables were measured in the cultivation of the A. aegerita 156 strain, under the 10 treatment conditions (Substrate Combinations of wheat straw, SW, and millet): total mushroom yield, loss of organic matter and enzymes activity in the substrates before and after fruiting.

Statistical analyses of data were conducted using SPSS (v14). The general linear models procedure was used to perform a one-way analysis of variance to test the equality of treatment means in each group (with and without millet) under the 10 fixed factor treatment conditions. The overall F-ratio was found to be statistically significant (α = 0.05, P < 0.05) for both groups, only then were multiple comparison t-tests (Fisher’s Protected LSD) conducted within each group to compare each treatment mean with the control for that respective group. The best (high mushroom yields) substrates in both groups were compared to identify the overall better performing substrate combination (Neter et al. 1996; Dallal 2001).

Results and discussion

Mushroom production, biological efficiency, loss of organic matter and C/N ratio

The content of different SCs tested, mushroom yield, biological efficiency, loss of organic matter and C/N are presented in Table 1. Mycelial colonization on all SCs was 42 ± 1 days, except SC5 and SC6 which were 46 ± 2 days. During 78 days of cultivation, the combined results of two flushes showed that in Group 1, where substrate combinations of wheat straw and solid waste (SW) were compared, on the average, mushroom yield increased as the proportion of SW increased until the wheat straw:SW ratio reached 50:50 where yield was highest for group 1 (SC4; 232.2 g per 1.5 kg). After that, increasing the proportion of SW resulted in inhibition of mycelium growth and reduced mushroom yield, with the lowest yield observed for SC6 (100% SW; 95.0 g per 1.5 kg). Banik and Nandi (2004) also reported that high dosages of biogas residual slurry manure in cultivation substrates of Pleurotus sajor-caju resulted in low mushroom production. Yield for Group 2 SCs (wheat straw, SW, and millet combinations) were consistently higher than most of the Group 1 SCs, suggesting that inclusion of millet is clearly advantageous for production of A. aegerita. Among Group 2 SCs the lowest yield was observed in the control, (wheat straw and millet without SW; 159.1 g per 1.5 kg), and subsequently, even a 10% addition of SW seemed to double the yield (SC8; 372.0 g per 1.5 kg). Substrate combination 9 with a 20% proportion of SW increased mushroom production by almost five times (SC9; 770.5 g per 1.5 kg; P < 0.05) that of the control (SC7); and SC10 gave similar high yield (642.9 g; P < 0.05), although lower than SC9. As can be seen from Table 1, addition of SW in proportions ranging 10–50% increased mushroom yield, especially in 10% millet combinations, with SC9 and SC10 clearly being the best of all the 10 SCs tested.

Philippoussis et al. (2001) reported that A. aegerita produced equally high yield of mushrooms in wheat straw and cotton waste (150.5 and 136.6 g per 1.2 kg, respectively). However, according to our results, A. aegerita 156 produced significantly higher mushroom yield in two flushes for the best performing SCs.

Biological efficiency obtained in two flushes was observed to be much higher for most of Group 2 SCs, than those observed for Group 1 SCs. Again biological efficiency was highest for SC9 (51.4%), followed by that for SC10 (42.9%). Loss of organic matter before fruiting varied from 4.6 to 34.8% and after fruiting from 8.8 to 48.2% for Group 1 compared to uninoculated substrate (Table 1). A higher LOM was observed for Group 2, before fruiting ranging from 23.8 to 39.2% and after fruiting from 35.8 to 46.9%. The maximum after fruiting loss was observed in SC1, followed by SC2. Substrate combinations 9 and 10, which supported the two highest mushroom yields, had 36.8 and 39.2% values of LOM. The matter degradation in our results is higher than reported by Zadražil (1977) who found 20% degradation of wheat straw by A. aegerita, and concluded that 20% LOM was not satisfactory for conversion of plant residues (wheat straw) to feed.

Adequate C/N ratio is critical to the rate of lignocellulose degradation and mushroom production (Madelin 1956). Solid Waste consists of 3.1% nitrogen, and its combinations with other substrate materials maintained between 13/1 and 96/1 C/N ratio in the 10 SCs tested. All Group 2 SCs had higher C/N ratios than most of those in Group 1. Substrate combinations 1 and 2 had the highest at 96/1 and 88/1, respectively. The SCs that produced the highest mushroom yields had C/N ratio of 72/1 and 81/1, respectively (Table 1). Whereas, Philippoussis et al. (2001) observed best C/N values, 59/1, for fruiting A. aegerita.

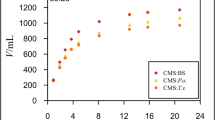

Degradation of lignin, cellulose and hemicellulose

Degradation of macromolecules composition in uninoculated and inoculated (before and after fruiting) substrates combinations is shown in Table 2. In the uninoculated SCs, increasing SW supplementation resulted in increasing lignin content among all SCs tested. However, our results indicated negative correlation between increasing SW and lignin degradation in treated SCs (r 2 = 0.86). Considering the dry weight loss of the SCs, lignin degradation varied widely among the SCs tested, and results indicated values ranging from 0.6 to 21.8% as shown in Fig. 1. Group 1 SCs showed higher lignin degradation rates (from 16.7 to 21.8%) with control (SC1) showing highest value. Increasing SW percent decreases lignin utilization. Substrate Combinations 5 and 6 with 75–100% SW did not degrade lignin component (0.6–0.7%). Supplementation of substrates with millet (Group 2) showed even lower lignin degradation compared to SCs containing SW and wheat straw only. Substrate Combinations 8–10, showed half the lignin degradation (8.1–9.8%) than control substrate (SC7). Nicolini et al. (1987) also observed that A. aegerita decomposed lignin in orange peel and grape stalks substrates only to a small (20–30%) extent for producing fruit body.

Cellulose and hemicellulose degradation varied from 27.7 to 55.2% and from 14.0 to 53.9%, respectively, in Group 1 (Fig. 1), the highest degradation rate was for SC2. Group 2 SCs showed cellulose degradation rates from 39.2 to 48.6% and hemicellulose degradation from 33.8 to 46.4%, however, control substrate degradation values were superior for both groups. Similar to lignin, least cellulose and hemicellulose degradation was observed in SC6 (27.7 and 14%, respectively). Correlation between percent of SW and loss of cellulose and hemicellulose were negative (r 2 = 0.63 and r 2 = 0.81, respectively). Cellulose appears to be easily utilized by A. aegerita compared to hemicellulose. Kempken (2002) reported that A. aegerita decompose cellulose and hemicellulose selectively. Nicolini et al. (1987) reported 20–55% loss of cellulose during degradation of wheat straw, orange peel and grape stalk substrates by A. aegerita. This species has been reported to utilized preferably other sugar polymers before cellulose, with minimal degradation of lignin (Wang et al. 2000).

Extracellular enzyme activities

Low laccase activities were detected in both groups SCs tested; they varied between 0.1 and 6.2 U g−1 reaching peak in SC6 before fruiting (Table 3). Substrate Combination 8, SC9 and SC10 (Group 2) showed significantly lower laccase activities as compared to the control SC7 (P < 0.05). In Group 1 (SCs containing wheat straw and SW only), SW content was positively correlated to laccase activity after fruiting (r 2 = 0.91), and significantly higher than the control but there was no significant difference in activities among SC2 through SC4. Peroxidase enzyme activity was much lower in all substrates (0.3–0.9 U g−1; Table 3). Maximum activity was observed in SC8 and SC9 (P < 0.05). Beyond 78 days (after fruiting) laccase and peroxidases activities decreased. Wang et al. (2000) observed that three strains of A. aegerita presented different levels of laccase activities during fructification; in addition, this species produced very low amounts of peroxidases.

CMCase activity is shown in Table 4. Increased supplementations of SW (10–75%) resulted in higher enzyme production in Group 1. CMCase activities were highest in group 2 SCs (11.45–15.26 U g−1); enzyme activity in SC8 and SC9 showed significantly different result than control SC (P < 0.05). CMCase activities decreased after fruiting, showing values that are 0.9–2.0 times lower than before fruiting in all SCs tested. Wang et al. (2000) have also reported decreased CMCase activities in three strains of A. aegerita grown on cotton seed shell and sawdust.

In the case of exo-1, 4-β-glucanase (Table 4), high enzyme activity before fruiting, was observed in group 1; SC 2 had highest enzyme activity (11.38 U g−1). However, the control (SC1) from Group 1 demonstrated much higher enzyme activity (8.76 U g−1) than control SC7 from Group 2 (2.52 U g−1). It seems that in the presence of millet exo-1, 4-β-glucanase activity decreases. Enzyme activities gradually increased after fruiting in Group 2 SCs and in Group 1 SC4-SC6 (Table 4). SC9 (20% SW) presented the highest 1,4-β-glucosidase activities. Generally it appears that 1,4-β-Glucosidase activities increased after fruiting (Table 5).

Xylanase activities in Group 1 increased from SC2 to SC6 and values ranged between 2.8 and 11.6 U ml−1 (Table 5). Furthermore, enzyme activities increased after fruiting in all SCs; especially in Group 2 substrates (SC7-SC10), where 2.0–3.0 times higher increases were observed. 1,4-β-Xylosidase activity values ranged between 2.5 and 6.4 U g−1 before fruiting, and increased further by the end of the second flush. Our results are similar to the findings of Terashita et al. (1998), who showed that xylanase activity increased significantly during fruit body formation in Hypsizygus marmoreus. Changes in xylanase and CMCase activities correlates with SW content (r 2 = 0.87, r 2 = 0.61, respectively) but the results of statistical analysis in the different SCs were not significantly different from control (P = 0.05).

The chemical composition of fruit bodies

Results of crude protein, carbohydrates and total fat analyses are presented in Table 6. The crude protein in non-inoculated substrates correlate positively with SW content, and it was highest in SC6 (13.63%; Table 6). In addition, protein content in the SCs tested increased after fruiting with values that ranged from 1.04 to 1.51 times higher (except SC6) compared to values obtained before fruiting. Similarly, results from nutritional analyses of mushrooms indicated that supplementation of SW increased the crude protein content in mushrooms (Table 6). Crude protein amounts in the mushrooms varied from 27.1 to 37.6% dry weight. Judging by mushroom production, the best SCs (9 and 10) had 32.1 and 27.8% protein, respectively. Wild A. aegerita mushrooms collected in Turkey had 41.0–46.8% of protein content (Yildiz et al. 2004).

Water soluble carbohydrates content increased with SW content; highest values were obtained for SC6 (20.3%) and lowest for SC3 (9.3%). Solid waste content did not affect significantly the lipid content of mushrooms harvested from different SCs (Table 6). Mushrooms from SC 9 showed highest value of lipid (2.28%).

Results presented clearly indicate that solid waste from anaerobic digestion of poultry litter was effective in increasing mushroom yield. Productivity of A. aegerita was found to be highest in this experiment when wheat straw (the basic component for most mushroom production substrates) was supplemented with 10–20% SW and millet. Solid waste content above 50% affected mushroom yield negatively, and this could be due to very high content of readily available nutrients, and especially due to the low C/N ratio (which is a result of the increased SW supplementation). Furthermore, the high lignin content introduced by SW may be difficult for A. aegerita to degrade, since correlation analysis showed that increase of SW concentration in the substrates negatively affected fruit body production (r 2 = 0.08) and degradation of lignocellulose. It is reported that A. aegerita is sensitive to high lignin content in substrates consisting of peanut shells (Philippoussis et al. 2001). The low lignin degradation could deprive access to the other macromolecules (cellulose and hemicellulose) needed as carbon source (Freer and Detroy 1982) for growth, development and fructification. Underutilization of substrate as indicated in the lowest degradation and mushroom yield results in SC6 (Table 1, Fig. 1), could be attributed among others to the low C/N ratio (13/1).

Patra and Pani (1995) observed that substrates for the cultivation of oyster mushroom could produce biological efficiency values of at least 50%. Philippoussis et al. (2001) reported that wheat straw and cotton waste supported satisfactory yields for A. aegerita (49.8%). In this context, our best substrate produced satisfactory yields, which in two flushes gave biological efficiency of 51.4%. It is clear that the addition of millet in the substrate is critical to obtaining high yield in substrates formulated with wheat straw and SW.

Our results suggest that SC9 was superior to other substrate combinations in most of the studied parameters; therefore, further experiment with SC9 was repeated over a 115 days fruiting cycle. A total yield of 1593.5 g (per 1.5 kg substrate) was obtained in five flushes. In addition, it is the first time that such a high biological efficiency (106.2%) has been reported for A. aegerita. Therefore, the combination of SW with wheat straw could serve as a better substrate for commercial cultivation of A. aegerita. Furthermore, BE obtained in SCs containing wheat straw, SW, and millet in two flushes (51.4%) is higher than 33.8% reported for Volvariella volvacea (Salmones et al. 1996), but lower than the 86.4% reported for Lentinula edodes and the 93% reported for Pleurotus ostreatus (Hernández et al. 2003; Royse and Sanchez-Vazquez 2003). Therefore, major obstacle (low BE) which limits commercial cultivation of A. aegerita could be eliminated through the use of suitable substrate materials like those we tested. A new cultivated mushroom species, Oudemansiella tanzanica, when grown on a 5% chicken manure supplemented sawdust substrate produced 900 g of fresh mushrooms per kg of substrate and BE of 140% (Magingo et al. 2004). The 106.2% BE (as demonstrated by our results) achieved through the use of SW (a waste of limited value) in combination with millet to produce A. aegerita mushrooms is an interesting development that elevate A. aegerita to the status of emerging exotic mushrooms for commercial cultivation. Similarly, our findings open up new avenues for the utilization of solid waste from anaerobic digester solids to generate financial gains in the overall economy of anaerobic digester plants.

References

AOAC (1990) Official method of analysis. Association of official analytical chemists, 15th edn

Bailey MJ, Biely P, Poutanen K (1992) Interlaboratory testing of methods for assay of xylanase activity. J Biotechnol 2:257–270. doi:10.1016/0168-1656(92)90074-J

Banik S, Nandi R (2004) Effect of supplementation of rice straw with biogas residual slurry manure on the yield, protein and mineral contents of oyster mushroom. Ind Crops Prod 20:311–319. doi:10.1016/j.indcrop.2003.11.003

Bernas E, Jaworska G, Kmiecik W (2006) Storage and processing of edible mushrooms. Acta Sci Pol Technol Aliment 5:5–23

Chung Po HH, Wong SK (1975) Small methane generator for waste disposal. In: Proceeding of 3rd International Symposium Livestock Wastes. Urbana, pp 21–24

Dallal GE (2001) Multiple comparison procedures. (http://www.StatisticalPractice.com)

Derias RE (1961) Method for determination water soluble carbohydrates. J Sci Food Agri 12:152. doi:10.1002/jsfa.2740120210

Erickson LE (2000) Bioreactors. In: Lederberg. J (ed) Encyclopedia of Microbiology, vol 1, 2nd edn. Academic Press, New York, pp 579–586

Eriksson KE, Blanchette RA, Ander P (1990) Microbial and enzymatic degradation of wood and wood components. Springer Series Wood Sci, p. 407

Freer S, Detroy R (1982) Biological delignification of 14C labeled lignocelluloses by basidiomycetes, degradation and solubilisation of lignin and cellulose components. Mycologia 74:943–951. doi:10.2307/3792724

Ghose TK (1987) Measurement of cellulase activities. Pure Appl Chem 59:257–268. doi:10.1351/pac198759020257

Glenn JK, Gold MH (1985) Purification and characterization of an extracellular Mn(II)-dependent peroxidase from the lignin degrading basidiomycete Phanerochaete chrysosporium. Arch Biochem Biophys 242:329–341. doi:10.1016/0003-9861(85)90217-6

Hernández D, Sánchez JE, Yamasaki K (2003) A simple procedure for preparing substrate for Pleurotus ostreatus cultivation. Bioresour Technol 90:145–150. doi:10.1016/S0960-8524(03)00118-4

Isikhuemhen OS, Ivey C (2005) Effect of Substrate Composition and Heat Pretreatment on Vegetative Growth of Agaricus brasiliensis S. Wasser et al. and A. subrufescens Peck. Int J Med Mushrooms 7(3):413

Isikhuemhen OS, Nerud F (1999) Preliminary studies on the ligninolytic enzymes produced by the tropical fungus Pleurotus tuberregium (Fr.) Sing Antonie Van Leeuwenhoek 75:257–260. doi:10.1023/A:1001871101604

Kempken F (2002) Agricultural Applications (The Mycota). Springer, New York, p 20

Liedl BE, Bombardiere J, Chatfield JM (2006) Fertilizer potential of liquid and solid effluent from thermophilic anaerobic digestion of poultry waste. Water Sci Technol 53:69–79. doi:10.2166/wst.2006.237

Madan M, Vasudevan P, Sharma S (1987) Cultivation of Pleurotus sajor-caju on different wastes. Biol Wastes 22:241–250. doi:10.1016/0269-7483(87)90110-8

Madelin MF (1956) Studies on the nutrition of Coprinus lagopus Fr., especially as affecting fruiting. Ann Bot (Lond) 20:467–480

Magingo FS, Oriyo NM, Kivasi AK, Danell E (2004) Cultivation of Oudemansiella tanzanica nom. prov. on agricultural solid wastes in Tanzania. Mycologia 96(2):197–204. doi:10.2307/3762053

Neter J, Kutner MH, Nachtsheim CJ, Wasserman W (1996) Applied linear statistical models. 4th edn. WCB/McGraw-Hill

Nicolini L, Hunolstein V, Carilli A (1987) Solid state fermentation of orange peel and grape stalks by Pleurotus ostreatus, Agrocybe aegerita and Armillariella mellea. Appl Microbiol Biotechnol 26:95–98. doi:10.1007/BF00282155

Noble R, Hobbs PJ, Mead A, Dobrovin-Pennington A (2002) Influence of straw types and nitrogen sources on mushroom composting emissions and compost productivity. J Ind Microbiol Biotechnol 29:99–110. doi:10.1038/sj.jim.7000292

Patra AK, Pani BK (1995) Evaluation of banana leaf as a new alternate substrate to paddy straw for oyster mushroom cultivation. J Phytol Res 8:145–148

Philippoussis A, Zervakis G, Diamantopoulou P (2001) Bioconversion of agricultural lignocellulosic wastes through the cultivation of the edible mushroom Agrocybe aegerita, Volvariella volvacea and Pleurotus spp. World J Microbiol Biotechnol 17:191–200. doi:10.1023/A:1016685530312

Poutanen K, Puls J (1988) Characteristics of Trichoderma reeseiß-xylosidase and its use in the hydrolysis of solubilized xylans. Appl Microbiol Biotechnol 28:425–432. doi:10.1007/BF00268208

Rangaswami F, Kandaswami TK, Ramasamy K (1975) Pleurotus sajor-saju (Fr.) Singer, a protein rich nitrogen fixing mushroom fungus. Curr Sci 44:403–404

Royse DJ, Sanchez JE (2007) Ground wheat straw as a substitute for portions of oak wood chips used in shiitake (Lentinula edodes) substrate formulae. Bioresour Technol 98(11):2137–2141. doi:10.1016/j.biortech.2006.08.023

Royse DJ, Sanchez-Vazquez JE (2003) Influence of precipitated calcium carbonate (CaCO3) on shiitake (Lentinula edodes) yield and mushroom size. Bioresour Technol 90:225–228. doi:10.1016/S0960-8524(03)00119-6

Royse DJ, Rhodes TW, Ohga S, Sanchez JE (2004) Yield, mushroom size and time to production of Pleurotus cornucopiae (oyster mushroom) grown on switch grass substrate spawned and supplemented at various rates. Bioresour Technol 91(1):85–91. doi:10.1016/S0960-8524(03)00151-2

Salmones D, Waliszewskiz KN, Guzman G (1996) Use of some agro-industrial lignocellulose by-products for edible mushroom Volvariella volvacea cultivation. Rev Int Contam Ambient 12(2):69–74

Savoie J-M, Libmond S (1994) Stimulation of environmentally controlled mushroom composting by polysaccharidases. World J Microbiol Biotechnol 10(3):313–319. doi:10.1007/BF00414871

Sharpley AN (1997) Rainfall frequency and nitrogen and phosphorus runoff from soil amended with poultry litter. J Environ Qual 26:1127–1132

Sharpley AN, Smith SJ (1993) Nitrogen and phosphorus fate from long-term poultry litter applications to Oklahoma soils. Soil Sci Soc Am J 57:1131–1137

Stafford DA, Hawkes DL, Horton RH (1980) Methane production from waste organic matter. CRC Press, Boca Raton

Terashita T, Murao R, Yoshikawa K, Shishiyama J (1998) Changes in carbohydrase activities during vegetative growth and development of fruit-bodies of Hypsizygus marmoreus grown in sawdust-based culture. J Wood Sci 44:234–236. doi:10.1007/BF00521969

Ullrich R, Hofrichter M (2005) The haloperoxidase of the agaric fungus Agrocybe aegerita hydroxylates toluene and naphthalene. FEBS Lett 19:16253244

van Soest PJ, Pobertsonm JB, Lewism BA (1991) Methods for dietary fiber, neutral detergent fiber and nonstarch polysaccharides in relation to animal nutrition. J Dairy Sci 74:3583–3597

Valmaseda M, Martínez MJ, Martínez A (1991) Kinetics of wheat straw solid-state fermentation with Trametes versicolor and Pleurotus ostreatus—lignin and polysaccharide alteration and production of related enzymatic activities. Appl Micro Biotech 35:817–823

Wang N, Shen F, Tan Q, Chen M, Pan Y (2000) Detecting in 9 extracellular enzyme activities of Agrocybe aegerita strains. Mycosystema 19:540–546

Yildiz A, Yeil OF, Yesil O, Karakaplan M (2004) Organic elements and protein in some macrofungi of South East Anatolia in Turkey. Food Chem 89:605–609. doi:10.1016/j.foodchem.2004.03.015

Zadražil F (1977) The conversion of straw into feed by basidiomycetes. Eur J Appl Microbiol Biotechnol 4:273–281

Zervakis G, Pillippoussis A, Ioannidou S, Diamantopoulou P (2001) Mycelium growth kinetics and optimal temperature conditions for the cultivation of edible mushroom species on lignocellulosic substrates. Folia Microbiol (Praha) 46:231–234. doi:10.1007/BF02818539

Zhao C, Sun H, Tong X, Ql Y (2003) An antitumour lectin from the edible mushroom Agrocybe aegerita. Biochem J 374:321–327. doi:10.1042/BJ20030300

Acknowledgments

This research was supported by USDA grants entitled “Organic Waste Treatment Using Thermophilic Anaerobic Digestion (Bioplex) Phase 5 (Grant #2005-38850-02292) and the WVSU Gus R. Douglass Land-Grant Institute of Agricultural, Consumer, Environmental and Outreach Programs. We are grateful to Eric Lopez for help with the experimental work. We are thankful for the editorial help received from the Agricultural Research Program and Ag Communications at the School of Agriculture and Environmental Science, North Carolina A&T State University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Isikhuemhen, O.S., Mikiashvili, N.A. & Kelkar, V. Application of solid waste from anaerobic digestion of poultry litter in Agrocybe aegerita cultivation: mushroom production, lignocellulolytic enzymes activity and substrate utilization. Biodegradation 20, 351–361 (2009). https://doi.org/10.1007/s10532-008-9226-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10532-008-9226-y