Abstract

Objectives

This study aimed to develop an efficient enzymatic strategy for the industrial production of phenylpyruvate (PPA) from l-phenylpyruvic acid (l-Phe).

Results

l-amino acid deaminase from Proteus mirabilis was expressed in Escherichia coli BL21 (DE3) and modified to release product inhibition by employing conformational dynamics engineering. Based on structural analysis, two residues (E145/L341) were identified for reducing interactions between the product and enzyme and increasing flexibility of the protein, thereby facilitating the product release. The mutant M2E145A/E341A exhibited a 3.84-fold reduction in product inhibition and a 1.35-fold increase in catalytic efficiency in comparison to the wild type. Finally, 81.2 g/L PPA production with a conversion of 99.6% was obtained in a 5-L bioreactor.

Conclusions

The engineered catalyst can significantly reduce product inhibition and facilitate the effective industrial synthesis of PPA.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

PPA is widely used in the pharmaceutical, food and chemical industries (Coban et al. 2014; Song et al. 2016; Zhu and Yuan 2022). It can be synthesized through hydrolysis and acidification of benzylidene hydantoin (des Abbayes and Salaün 2003) with shortages of expensive precursors, multiple chemical steps and harsh conditions. Thus, developing environmentally friendly biocatalytic methods with amino acids as substrates were desirable (Oike and Groger 2020). The production of PPA via the oxidation of d-phenylalanine by d-amino acid oxidase has been reported. However, this reaction produces toxic hydrogen peroxide and requires additional catalase to remove the toxic effects(Yoshimoto et al. 2014).

l-AAD from P. mirabilis exhibited broad substrate specificity toward aliphatic and aromatic-amino acids (Chen et al. 2020, 2021; Mao et al. 2020; Pei et al. 2020; Yuan et al. 2019; Zhu et al. 2020), typically having a high catalytic activity for l-Phe (Hou et al. 2015, 2016a). A two-step bioconversion system was previously developed to produce PPA from l-Phe by metabolically engineered E. coli, and the total maximal production reached 75.1 g/L in a 3-L bioreactor (Hou et al. 2016b). However, product inhibition was the main limiting factor for resting cell bioconversion, and such two-step bioconversion can also result in multiple byproducts, making extraction and purification of PPA potentially problematic.

Many attempts have been made to carry out site-specific mutations or saturation mutations at the binding sites of products to reduce the interaction with products and thus reduce the inhibition of products (Atreya et al. 2016). However, such mutations might result in a decrease in catalytic activity or enzyme stability (Atreya et al. 2016). The conformation of the protein plays a key role in enzyme catalysis, including substrate recognition and binding, allosteric regulation, the formation of an enzyme-substrate complex and product release (Han et al. 2016; Kim et al. 2013; Oyen et al. 2015; Seo et al. 2014). Conformation adjustment is an effective strategy for protein evolution to reduce product inhibition. By site-directed mutation of two key residues on the flaps overlaying of chorimate-pyruvate lyase (CPL), the conformational dynamics of flap increased, thereby enhancing the product release through an opening of the product-binding site and reduced product-binding energy, eventually relieving the product inhibition. The designed mutants exhibited almost an eightfold reduction in product inhibition and a threefold higher catalytic rate in comparison to the wild type (Han et al. 2016).

Herein, we engineered the l-amino acid deaminase from Proteus mirabilis (l-pmAAD) loop structure to reduce product inhibition without decreasing the catalytic efficiency. The best mutant, M2E145A/E341A, was identified to increase the flexible conformation in these regions based on structural analysis, thereby facilitating the product release. Finally, the l-pmAAD mutants were used to synthesize PPA in a 5-L scale fermenter.

Materials and methods

Materials

The expression plasmid pET-20b and the host strain E. coli BL21 (DE3) were obtained from Novagen (Madison, WI). The restriction enzymes, polymerase, plasmid miniprep kit, and agarose gel DNA purification kit were supplied by TaKaRa Biotechnology (Otsu, Japan). Commercial reagents, standards, and solvents were purchased from Sigma-Aldrich, Meryer Chemicals, and Aladdin. Sangon Biotech (Shanghai) Co., Ltd performed the primer synthesis and DNA sequencing. Cultivation for gene manipulation and plasmid construction was performed in Luria-Bertani (LB) broth or on 2% w/v agar plates. Cultivation of E. coli cells and enzyme expression for recombinant were performed in the Terrific Broth (TB) medium.

Construction of the l-pmAAD mutants

The primers used for gene cloning and pET-20b-pmAAD plasmid construction are summarized in Supplementary Table 1. The l-pmAAD encoding gene aad (GenBank ID: U35383) was inserted into the pET-20b(+) using the restriction sites BamHI and XhoI. The variants were constructed by a whole plasmid PCR protocol using plasmid pET-20b-pmAAD as a template. The PCR system (50 µL) was composed of PrimeSTAR polymerase (0.5 µL), 5 × PrimeSTAR Buffer (10 µL), dNTP mix (4 µL), template (40–100 ng), corresponding primers (10 µM with 1 µL), and sterilized water. Next, the PCR products were digested by DpnI and incubated for 3 h at 37 °C to eliminate the template plasmid. Then the PCR product was transformed into E. coli BL21(DE3) cells for the following screening or DNA sequencing.

Determination of kinetic parameters and product inhibition constants

The kinetic parameters (Km and Kcat) were determined by measuring the initial rates of enzymatic reaction at different concentrations of l-Phe (20–200 mM) in Tris-HCl buffer (50 mM, pH 8.0) at 30 °C. Samples were analyzed by high performance liquid chromatography (HPLC) and nonlinear curve fitting of the Michaelis–Menten equation was used for calculating kinetic parameters. The product inhibition constant (KPI) of the wild type and its mutants were determined by measuring the initial reaction rates with respect to substrate concentration in the presence of the product as described in Results (Hou et al. 2015, 2016a). All the experiments were repeated three times and the average values were adopted.

Molecular modeling and molecular dynamics simulations

The 3D structural models of l-pmAAD and its mutants were constructed based on X-ray crystal structures of the l-AAD from P. myxofaciens (PDB ID: 5fjm) by homology modeling. The 3D structure of PPA was downloaded from ChemSpider. Auto Dock Vina 4.0 was used to obtain the staring structure of the l-pmAAD in complex with the substrate PPA. The analysis of the structures was performed by PyMOL 2.2. Missing atoms and hydrogen were added to the enzyme using the GROMACS 4.5.5 simulation package. The protonation state of residues was set according to pH 7.0. Na+ counterions were added to neutralize the system, and the whole system was immersed in a cubic box of TIP3P water molecules, which was extended 10 Å from the dissolved atoms in all three dimensions. Molecular dynamics (MD) simulations were performed with GROMACS 4.5.5 and an AMBER03 force field following the three main steps of energy minimization, system equilibration, and production protocols (Qian et al. 2020). Following steepest-descent energy minimization, 10-ns NVT simulations were run at 300 K in 2-fs. The enzyme and product were assigned to separate energy groups, and the binding energies between them were calculated as total intergroup potential energy (Qian et al. 2020).

Analytical methods

The PPA concentrations were measured by HPLC with an Aminex HPX-87 H column. The mobile phase was a 5 mM H2SO4 solution at a flow rate of 0.6 mL/min (35 °C). l-Phe was determined by automatic pre-column derivatization with o-phthalaldehyde using HPLC equipping an FLD detector and an Agilent Zorbax SB-Aq column. The polar eluent was 10 mM KH2PO4 pH 5.3 (buffer A) and the nonpolar eluent was a 5:3:1 (v/v/v) mixture of acetonitrile, methanol and 10 mM KH2PO4 (buffer B). A flow rate of 1 mL/min was maintained throughout and the column temperature was 40 °C.

Fed-batch fermentation

Conditions for obtaining the whole-cell catalyst were performed as described in previous reports (Yuan et al. 2019).

Bioconversion of PPA from l-Phe

The conversion experiments were carried out in a 250 mL shake flask (20 mL working volume) and a 5-L bioreactor (3-L working volume). The 20 mL reaction mixture was incubated at 30 °C and 200 rpm for 20 h. In a 5-L bioreactor, the wet whole-cell catalysts M2E145A/L341A (30 g/L) were added to initiate the reaction. The reaction mixture was stirred at 500 rpm (30 ℃, pH 8.0).

Results and discussion

Effect of product inhibition on the synthesis of PPA

l-pmAAD was cloned and overexpressed in E. coli BL21(DE3) to produce a recombinant strain M0. However, with 70 g/L l-Phe as substrate and 30 g/L whole-cell as biocatalyst, only 42.1 g/L PPA could be produced with a conversion rate of 60.4%. To confirm the product inhibition on l-pmAAD, different concentrations of PPA (0–200 mM) were added to the reaction system before conversion. The maximum reaction rate Vmax values were unchanged, while the Km values increased along with the PPA concentration, demonstrating a competitive inhibition mode of PPA on the cell bioconversion (Supplementary Table 2). Product inhibition limited the enzymatic synthesis performance, mainly due to the active site of the competitive binding enzyme between products and substrates (Hu et al. 2010) and the slow release rate of products from the active center (Wang et al. 2019).

Directed evolution of l-pmAAD by site-specific mutagenesis

To increase the conformational kinetics of the product binding site and promote the release of the product without perturbing the binding of substrate, the flexible loop regions around the product binding site of l-pmAAD were selected for site-specific mutagenesis. A homology model of l-pmAAD was constructed based on the crystal structure of P. myxofaciens LAAD (93.7% identity). The product PPA and cofactor FAD were then docked into the active site of L-pmAAD. A total of eight loop regions were identified around the product-binding site (Supplementary Fig. 1). Structural analysis revealed that loops 2, 5, 7 and 8 are located at the substrate tunnel entrance. Loop 3 plays an important role in the tunnel, and loop 4 located near the product binding site. Loop 1 and 6 were not the composition of the channels and pockets through the analysis of the structure, and were supposed to have no effects on the release of the product. Seventeen candidate amino acid residues containing five residues in loop 2 (V411/S412/T414/F415/E417), two residues in loop 3 (T436/V437), five residues in loop 4 (Y97/S98/S102/T105/S106), two residues in loop 5 (D144/E145), one residue in loop 7 (V312) and two residues in loop 8 (L336/L341) were selected for site-specific mutagenesis. To avoid a drastic change in the main-chain dynamics and secondary structure distortion, proline and glycine were excluded (Han et al. 2016; Yang et al. 2017).

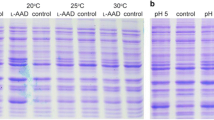

Alanine scanning is a common method in protein evolution engineering. Then, we substituted the aforementioned candidate residues in the wild-type enzyme (M0) with smaller alanine residues and evaluated the transformed ability of these mutants. As shown in Fig. 1, two mutants of M1E145A and M1L341A exhibited 12.1% and 13.3% higher PPA production than the wide type. Then site-directed saturation mutations were performed on E145 and L341 respectively, but it was found that the catalytic performance of the mutants reduced. Therefore, E145A and L341A were combined to construct mutant M2E145A/L341A. The PPA concentration of M2E145A/L341A was 1.41-fold higher than the corresponding value for M0. Furthermore, the activity of M2E145A/L341A increased by 210% compared to that of M0 (Table 1). We speculated that the mutation of two residues affected the conformational kinetics of product binding sites or release channels to a certain extent, promoted the release of PPA, thereby reducing the product inhibition and increasing the yield of PPA.

To investigate the effect of the mutations on enzyme kinetics, the kinetic parameters and product inhibition constants of the parent M0 and its mutants were also determined (Table 2). The Km values of M1E145A, M1L341A, and M2E145A/L341A were 1.05-, 1.17-, and 1.25-fold higher than the corresponding values for M0, respectively. These mutations seemed to affect the substrate-binding site, resulting in a decrease in the substrate-binding affinity. However, the catalytic efficiency (Kcat/Km) of M2E145A/L341A was 1.62 mM−1 min−1, being 1.35-fold higher than that of M0, which was achieved through compensation by the increased Kcat.

*The KPI values were calculated according to the following equation: \({V}_{0}\)=\(\frac{{\text{V}}_{\text{max}}\left[\text{S}\right]}{{\text{K}}_{\text{m}}\left(\text{1+}\frac{\left[\text{P}\right]}{{\text{K}}_{\text{PI}}}\right)\text{+}\left[\text{S}\right]}\) where V0 is the initial reaction rate, Vmax is the maximum reaction rate, Km is the Michaelis constant, [S] is the concentration of l-Phe, [P] is the concentration of PPA and KPI is the product inhibition constant.

Furthermore, the KPI values of M1E145A, M1L341A, and M2E145A/L341A were 1.41-, 1.91-, and 2.84-fold higher than M0, indicating that product inhibition was relieved. In contrast to conventional random mutagenesis (Hegazy et al. 2019; Wang et al. 2019) or rational mutations that focus on engineering the active site (Atreya et al. 2016), herein, we modified the flexible loop regions around the product-binding site to obtain an effective mutant M2E145A/L341A with a 3.84-fold decrease in product inhibition and a 1.35-fold higher catalytic efficiency than the wild-type enzyme.

Computational evaluation of the mutant M2E145A/L341A

To obtain how the mutation significantly relieves the product inhibition, the relationships between the substituted residues and the surrounding residues were investigated using the AutoDock suite. Based on the structural analysis, the E145 carbonyl group formed a hydrogen bond with the NH2 group of D149 on loop 5 (Fig. 2a), and the L341 carbonyl group made a hydrogen bond with the NH2 group of L343 on loop 8 (Fig. 2c). The prolonged distance between E145 and D149 increased from 1.8 to 3.1 Å when the Glu residue at position 145 was replaced with Ala, and the hydrogen bond between them disappeared (Fig. 2b). Similarly, when the Leu residue at position 341 was replaced with Ala, the prolonged distance between L341 and L343 increased from 2.8 to 3.4 Å, and then the hydrogen bonds disappeared (Fig. 2d).

Structural features of M0 and M2E145A/L341A around the mutated residues. a E145 with the surrounding residues in wild-type M0 and the mutated residues. b E145A with the surrounding residues in M2E145A/L341A. c L341 with the surrounding residues in wild-type M0 and the mutated residues. d L341A with the surrounding residues in M2E145A/L341A. Red is oxygen and blue is nitrogen. Hydrogen bonds are presented as yellow dashed lines. The disappeared hydrogen bonds in the mutant M2E145A/L341A are presented as blue dashed lines. e RMSFs for the M0 and M2E145A/L341A were calculated from MD simulations

Furthermore, we determined the PPA binding energy of M0 and its mutants. As shown in Supplementary Tables 3, the product binding energy of M2 E145A/L341A was 5.0, 2.5, and 1.7 kJ mol−1 higher than the corresponding values for M0, ME145A, and M1L341A, respectively, which was in accordance with the product inhibition relief. Consequently, the surrounding amino acids might improve the flexibility owing to the disappearance of hydrogen bonds, thereby enhancing product release. According to previous studies, higher root-mean-square fluctuation (RMSF) values suggested that these two motifs could undergo noticeable movements and were the most likely to influence protein conformation due to their high flexibility (Han et al. 2016; Yang et al. 2017). A remarkable increase in RMSF around region 1 and region 2 was observed from two substitutions of E145 and L341 as a result of modifying the key amino acid residues (Fig. 2e), indicating that the two mutation residues to alanine would thus weaken the structural constraint of the region 1 and region 2, leading to a flexible conformation of l-pmAAD and consequently the opening of the product-binding site. A combination of mutation sites might over-regulate the conformational dynamics and result in low enzyme stability (Han et al. 2016). While the increase in beneficial mutation points was accompanied by an increase in PPA production capacity in this study, probably because single-point regulation had a mild effect on conformation and was within the maximum carrying limit of the conformation.

Synthesis of PPA on a 5-L scale

To provide a better environment for conversion, the bioconversion parameters, including substrate/whole-cell catalyst ratio, bioconversion pH, as well as temperature, were optimized. First, we examined the effect of the substrate/whole-cell catalyst ratio on the PPA titer in a range from 2.4:1 to 3.2:1 with a fixed cell weight of 30 g/L in a 5-L bioreactor within 24 h (l-Phe titer from 72 to 96 g/L). It appeared that as the ratio increased from 2.4:1 to 2.8:1, PPA concentration also increased with a sustaining decrease in conversion rate. A ratio of 2.8:1 provided both a relatively high PPA concentration (76.2 g/L) and conversion rate (91.3%). Subsequently increases in substrate did not significantly improve PPA production, which was attributed to an insufficient supply of whole-cell catalyst (Fig. 3a). Then we investigated the effects of pH on PPA production with 84 g/L of l-Phe. The highest PPA concentration (76.8 g/L) was detected when pH was 8.5 (Fig. 3b). Finally, we evaluated the transformation temperature and selected 30 °C as 25 °C required a longer transformation period (additional 4 h) and 35 °C reduced the conversion rate (Fig. 3c). Under the optimal conditions (the ratio of substrate/whole-cell catalyst was 2.8:1 in pH 8.5 at a conversion temperature of 30 °C), the titer, yield, and productivity of PPA could reach 81.2 g/L, 99.0%, and 5.1 g/L/h within 16 h in a 5-L bioreactor (Fig. 3d), which was the highest titer reported so far (Coban et al. 2016; Hou et al. 2016b).

Optimizations during the conversion process by strain M2E145A/L341A. a Effect of the substrate/whole-cell catalyst ratio on PPA concentration. b Effect of conversion pH on PPA concentration. c Effect of conversion temperature on PPA concentration temperature. d Time course of the optimized conditions at 5-L scale. Values are shown as mean ± SD (n = 3)

Conclusions

An engineered l-pmAAD mutant with relieving product inhibition for the synthesis of PPA was reported in this study. The product inhibition of l-pmAAD was decreased significantly through the enhanced conformational dynamics of the enzyme without a decrease in the catalytic efficiency. The mechanism of relieving product inhibition was discussed based on the analysis of wild-type M0 and its best mutant, M2E145A/L341A. Furthermore, the bioconversion performance of mutant M2E145A/L341A was evaluated and 81.2 g/L PPA was produced within 16 h. This represents a significant improvement in the enzymatic production of PPA.

References

Atreya ME, Strobel KL, Clark DS (2016) Alleviating product inhibition in cellulase enzyme Cel7A. Biotechnol Bioeng 113(2):330–338. https://doi.org/10.1002/bit.25809

Chen Y, Wu P, Ko L-Y, Kao T-Y, Liu L, Zhang Y, Yuan J (2020) High-yielding protocatechuic acid synthesis from l-tyrosine in Escherichia coli. Acs Sustain Chem Eng 8(39):14949–14954. https://doi.org/10.1021/acssuschemeng.0c05165

Chen Y, Chen Y, Liu L, Zhang Y, Yuan J (2021) Microbial synthesis of 4-hydroxybenzoic acid from renewable feedstocks. Food Chem Mol Sci. https://doi.org/10.1016/j.fochms.2021.100059

Coban HB, Demirci A, Patterson PH, Elias RJ (2014) Screening of phenylpyruvic acid producers and optimization of culture conditions in bench scale bioreactors. Bioprocess Biosyst Eng 37(11):2343–2352. https://doi.org/10.1007/s00449-014-1212-7

Coban HB, Demirci A, Patterson PH, Elias RJ (2016) Enhanced phenylpyruvic acid production with Proteus vulgaris in fed-batch and continuous fermentation. Prep Biochem Biotechnol 46(2):157–160. https://doi.org/10.1080/10826068.2014.995813

des Abbayes H, Salaün J-Y (2003) Double carbonylation and beyond: systems at work and their organometallic models. Dalton Trans. https://doi.org/10.1039/b209103h

Han SS, Kyeong HH, Choi JM, Sohn YK, Lee JH, Kim HS (2016) Engineering of the conformational dynamics of an enzyme for relieving the product inhibition. ACS Catalysis 6(12):8440–8445. https://doi.org/10.1021/acscatal.6b02793

Hegazy UM, El-Khonezy MI, Shokeer A, Abdel-Ghany SS, Bassuny RI, Barakat AZ, Salama WH, Azouz RAM, Fahmy AS (2019) Revealing of a novel xylose-binding site of Geobacillus stearothermophilus xylanase by directed evolution. J Biochem 165(2):177–184. https://doi.org/10.1093/jb/mvy092

Hou Y, Hossain GS, Li J, Shin HD, Liu L, Du G (2015) Production of phenylpyruvic acid from l-phenylalanine using an l-amino acid deaminase from Proteus mirabilis: comparison of enzymatic and whole-cell biotransformation approaches. Appl Microbiol Biotechnol 99(20):8391–8402. https://doi.org/10.1007/s00253-015-6757-0

Hou Y, Hossain GS, Li J, Shin HD, Du G, Liu L (2016a) Combination of phenylpyruvic acid (PPA) pathway engineering and molecular engineering of l-amino acid deaminase improves PPA production with an Escherichia coli whole-cell biocatalyst. Appl Microbiol Biotechnol 100(5):2183–2191. https://doi.org/10.1007/s00253-015-7048-5

Hou Y, Hossain GS, Li J, Shin HD, Liu L, Du G, Chen J (2016b) Two-step production of phenylpyruvic acid from l-phenylalanine by growing and resting cells of engineered Escherichia coli: process optimization and kinetics modeling. PLoS ONE 11(11):e0166457. https://doi.org/10.1371/journal.pone.0166457

Hu X, Robin S, O’Connell S, Walsh G, Wall JG (2010) Engineering of a fungal beta-galactosidase to remove product inhibition by galactose. Appl Microbiol Biotechnol 87(5):1773–1782. https://doi.org/10.1007/s00253-010-2662-8

Kim E, Lee S, Jeon A, Choi JM, Lee HS, Hohng S, Kim HS (2013) A single-molecule dissection of ligand binding to a protein with intrinsic dynamics. Nat Chem Biol 9(5):313–318. https://doi.org/10.1038/nchembio.1213

Mao Z, Liu L, Zhang Y, Yuan J (2020) Efficient synthesis of phenylacetate and 2-phenylethanol by modular cascade biocatalysis. ChemBioChem 21(18):2676–2679. https://doi.org/10.1002/cbic.202000182

Oike K, Groger H (2020) Process properties of an l-amino acid oxidase from Hebeloma cylindrosporum for the synthesis of phenylpyruvic acid from l-phenylalanine. J Biotechnol 323:203–207. https://doi.org/10.1016/j.jbiotec.2020.07.005

Oyen D, Fenwick RB, Stanfield RL, Dyson HJ, Wright PE (2015) Cofactor-mediated conformational dynamics promote product release from Escherichia coli dihydrofolate reductase via an allosteric pathway. J Am Chem Soc 137(29):9459–9468. https://doi.org/10.1021/jacs.5b05707

Pei S, Ruan X, Liu J, Song W, Chen X, Luo Q, Liu L, Wu J (2020) Enhancement of α-ketoisovalerate production by relieving the product inhibition of l-amino acid deaminase from Proteus mirabilis. Chin J Chem Eng 28(8):2190–2199. https://doi.org/10.1016/j.cjche.2020.04.009

Qian Y, Lu C, Liu J, Song W, Chen X, Luo Q, Liu L, Wu J (2020) Engineering protonation conformation of l-aspartate-alpha-decarboxylase to relieve mechanism-based inactivation. Biotechnol Bioeng 117(6):1607–1614. https://doi.org/10.1002/bit.27316

Seo MH, Park J, Kim E, Hohng S, Kim HS (2014) Protein conformational dynamics dictate the binding affinity for a ligand. Nat Commun 5:3724. https://doi.org/10.1038/ncomms4724

Song Y, Li J, Shin HD, Liu L, Du G, Chen J (2016) Biotechnological production of alpha-keto acids: current status and perspectives. Bioresour Technol 219:716–724. https://doi.org/10.1016/j.biortech.2016.08.015

Wang X, Jiang Y, Wu M, Zhu L, Yang L, Lin J (2019) Semi-rationally engineered variants of S-adenosylmethionine synthetase from Escherichia coli with reduced product inhibition and improved catalytic activity. Enzyme Microb Technol 129:109355. https://doi.org/10.1016/j.enzmictec.2019.05.012

Yang B, Wang HJ, Song W, Chen XL, Liu J, Luo QL, Liu LM (2017) Engineering of the conformational dynamics of lipase to increase enantioselectivity. ACS Catalysis 7(11):7593–7599. https://doi.org/10.1021/acscatal.7b02404

Yoshimoto M, Okamoto M, Ujihashi K, Okita T (2014) Selective oxidation of d-amino acids catalyzed by oligolamellar liposomes intercalated with d-amino acid oxidase. Langmuir 30(21):6180–6186. https://doi.org/10.1021/la500786m

Yuan Y, Song W, Liu J, Chen X, Luo Q, Liu L (2019) Production of α-Ketoisocaproate and α-Keto-β-methylvalerate by engineered l-amino acid deaminase. ChemCatChem 11(10):2464–2472. https://doi.org/10.1002/cctc.201900259

Zhu Y, Yuan J (2022) A four-step enzymatic cascade for efficient production of l-phenylglycine from biobased l-phenylalanine. Chembiochem. https://doi.org/10.1002/cbic.202100661

Zhu Y, Yang T, Chen Y, Fan C, Yuan J (2020) One-pot synthesis of aromatic amines from renewable feedstocks via whole-cell biocatalysis. ChemistrySelect 5(45):14292–14295. https://doi.org/10.1002/slct.202003807

Funding

This work was financially supported by the National Key R & D Program of China (Grant No. 2021YFC2100100), the National Natural Science Foundation of China (Grant No. 22008089), the National First-class Discipline Program of Light Industry Technology and Engineering (Grant No. LITE2018-08).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with animals performed by any of the authors.

Informed consent

Informed consent was obtained from all individual participants included in the study.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Liu, J., Liu, J., Yang, B. et al. Production of phenylpyruvic acid by engineered l-amino acid deaminase from Proteus mirabilis. Biotechnol Lett 44, 635–642 (2022). https://doi.org/10.1007/s10529-022-03245-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-022-03245-y