Abstract

The nitrilase gene of Rhodococcus rhodochrous J1 was expressed in Escherichia coli using the expression vector, pKK223-3. The recombinant E. coli JM109 cells hydrolyzed enantioselectively 2-methyl-2-propylmalononitrile to form (S)-2-cyano-2-methylpentanoic acid (CMPA) with 96 % e.e. Under optimized conditions, 80 g (S)-CMPA l−1 was produced with a molar yield of 97 % at 30 °C after a 24 h without any by-products.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

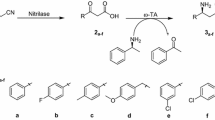

Nitrile-converting enzymes have attracted interest as biocatalysts in preparative organic chemistry due to their capability to convert readily available nitriles into the corresponding higher-value amides and acids (Nagasawa and Yamada 1989). Nitrilases have significant potential as biocatalysts for the direct hydrolysis of nitriles to the corresponding carboxylic acids, and also exhibit advantages over chemical hydrolysis in several points such as mild pH and temperature conditions, and the absence of by-products. Rhodococcus rhodochrous J1 nitrilase was previously purified and characterized (Kobayashi et al. 1989). Nitrilase is inactive as a dimer but active as oligomers (Nagasawa et al. 2000; Thuku et al. 2007). It hydrolyzes a wide range of aromatic nitriles. In the present study, 2-methyl-2-propylmalononitrile (MPMN) was used as the substrate for R. rhodochrous J1 nitrilase (Fig. 1). If nitrilases enantioselectively catalyze the hydrolysis of only a single cyano group of malononitrile derivatives, such as MPMN, optically active cyanoacetic acid derivatives can be obtained. The subsequent chemical reduction of cyanoacetic acid derivatives leads to the formation of β-amino acids, which are available as the building blocks for the synthesis of a variety of biologically active compounds.

There have been many reports on the bioconversion of dinitrile compounds using whole cells or purified enzymes of nitrile-degrading microorganisms. Bayer et al. (2011) reported a nitrilase from a metagenomic library acted regioselectively on aliphatic dinitriles, such as 2-methylglutaronitrile. Vejvoda et al. (2007) described the regioselective hydrolysis of 2,4- and 2,6-pyridinedicarbonitriles by a fungal nitrilase. With respect to malononitrile derivatives, Wu and Li (2003) studied an enantioselective biotransformation of 2-benzyl-2-methylmalononitrile, using a nitrile hydratase and amidase of Rhodococcus sp. cells, resulting in the formation of a complex mixture of hydrolysis intermediates. Therefore, in the present study, we used recombinant Escherichia coli cells expressing an R. rhodochrous J1 nitrilase gene for the hydrolysis of MPMN to evade activity of nitrile hydratase.

Materials and methods

Materials

2-Methyl-2-propylmalononitrile (MPMN), 2-benzyl-2-methylmalononitrile and rac-CMPA were obtained from ChemGenesis Inc. All other reagents were of analytical grade and available from commercial sources.

Microorganisms and culture conditions

Rhodococcus rhodochrous J1 (see Nagasawa et al. 1988) was cultivated in 4 ml medium A at 28 °C for 2 days. The medium A contained 10 g fructose, 13 g Casamino acids, 0.25 % (v/v) isovaleronitrile, 3 g polypeptone, 2 g yeast extract, 10 g sodium glutamate, 0.5 g MgSO4·7H2O and 2 g KH2PO4 in 1 l distilled water at pH 7.

Expression of R. rhodochrous J1 nitrilase gene in E. coli

The cloning and expression of R. rhodochrous J1 nitrilase gene were performed based on the results by Kobayashi et al. (1992). A recognition site of EcoRI was located in the nitrilase gene of R. rhodochrous. The recognition site, GAATTC, was substituted for AAATTC using a QuickChange Site-Directed Mutagenesis Kit (Agilent Technologies), and the resulting nitrilase gene was inserted into the EcoRI/HindIII gap of pKK223-3. E. coli JM109 was transformed with the resulting plasmid, pKKJ1nit. The recombinant E. coli/pKKJ1nit was pre-cultured in 100 ml Luria–Bertani medium containing 50 μg ampicillin ml−1 at 28 °C for 14 h with reciprocal shaking at 90 rpm in a 500 ml Erlenmeyer flask. For expression of the nitrilase gene, 0.5 mM IPTG was added to the culture broth, and cultivation was continued at 28 °C for a further 4 h. The E. coli cells, harvested by centrifugation at 12,000×g for 20 min, were washed twice with 0.15 M NaCl. The washed cells were suspended in the same solution and used as whole cells.

Enzyme assay using whole cells

The reaction mixture contained 10 mM benzonitrile, 100 mM potassium phosphate buffer (pH 7.5) and whole cells in 1 ml. The reaction was carried out at 25 °C for 10 min and stopped by the removal of cells through centrifugation. The supernatant was analyzed by HPLC based on the method of Nagasawa et al. (1988). Nitrilase activity was defined as the amount of benzoic acid formed per minute by 1 mg dry wt whole cells.

Hydrolysis of MPMN using whole cells

The reaction mixture contained 30 mM MPMN, 50 mM potassium phosphate buffer (pH 7.5) and 250 mg dry wt cells of E. coli/pKKJ1nit in 200 ml. The reaction was carried out at 25 °C, and stopped by removing cells through centrifugation at 12,000×g for 10 min. The supernatant was analyzed by HPLC equipped with a YMC-Pack FA column (4.6 × 250 mm). Acetonitrile/10 mM sodium phosphate (pH 2.8) (1:4, v/v) was used for elution at 1 ml min−1 and the eluate was monitored at 210 nm.

Identification of reaction product

After the reaction mixture was acidified to pH 4 by adding solid citric acid, the CMPA produced was extracted with ethyl acetate. The resulting extract was evaporated at 40 °C to dryness, dissolved in a small amount of ethyl acetate, and applied to a Florisil column. CMPA was eluted with ethyl acetate/hexane (1:1, v/v). The eluted fractions were evaporated at 40 °C. CMPA was a colorless viscous liquid identified by 1H NMR, 13C NMR and infrared spectroscopy: 1H NMR (600 MHz, CD3OD): δ 0.98 (3H, t, J = 7.5 Hz), 1.42–1.49 (1H, m), 1.50 (3H, s), 1.51–1.58 (1H, m), 1.60 (2H, dt, J = 4.1, 13.0 Hz), 1.86 (2H, dt, J = 4.8, 12.4); 13C NMR (600 MHz, CD3OD): δ 14.3, 20.3, 24.7, 44.0, 48.0, 124 and 176; IR v max (KBr) cm−1: 3,393, 2,964, 2,833, 2,243, 1,604.

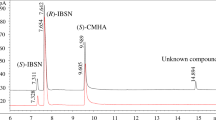

The reaction product was esterified with methanol for chiral GC analysis. The isolated CMPA was dissolved in 50 μl methanol, and 50 μl ~6 M trimethylsilyldiazomethane in 10 % (v/v) hexane was then added. Authentic rac-CMPA was also transformed into the corresponding methyl ester. Chiral GC analysis was performed using a chiral GC column (RT-BDEXM, 0.25 mm × 30 m, Interchim) on GC equipped with an FID detector set at 250 °C and a split injector set at 230 °C, using He as a carrier gas and a program of 2 min at 100 °C, 100–230 °C at 5 °C min−1 and 4 min at 230 °C.

Analytical methods

Optical rotation was measured on an automatic polarimeter SEPA-300 (Horiba). Infrared spectroscopy was performed on a FTIR-8400S, and NMR spectroscopy on a JEOL ECA-600 system with CD3OD as the solvent. The amount of ammonia was colorimetrically estimated by the phenol/hypochlorite method (Fawcett and Scott 1960) using a Conway micro-diffusion apparatus (Conway and Berne 1933).

Results and discussion

Hydrolysis of MPMN using E. coli cells expressing R. rhodochrous J1 nitrilase gene

Nitrilase activity of E. coli/pKKJ1nit cells for benzonitrile, 870 nmol min−1 mg−1, was 18-fold higher than that of R. rhodochrous J1 cells at 48 nmol min−1 mg−1. The activity for MPMN at 20 mM was 2.1 % of that with benzonitrile. CMPA produced from MPMN was isolated and identified, as described in “Materials and methods”. The specific rotation [α] 24D of the isolated CMPA was −9.3 (c 0.5, chloroform), corresponding with the value of (S)-form: [α] 20D −8.0 (c 0.5 chloroform) (Moretto et al. 2000). Chiral GC analysis of the produced CMPA revealed that the enantiomeric excess was 96.2 % e.e. Thus, R. rhodochrous J1 nitrilase catalyzed enantioselectively the hydrolysis of only a single cyano group of MPMN to form (S)-CMPA.

When 2-benzyl-2-methylmalononitrile was used instead of MPMN, as the substrate for E. coli/pKKJ1nit nitrilase, no reaction products were detected by HPLC analysis. 2-Benzyl-2-methylmalononirile is probably an inappropriate substrate for nitrilases. In our preliminary experiment (Wu and Li 2003) on biotransformation using R. rhodochrous J1 cells, in which nitrilase was induced by adding isovaleronitrile in the culture medium, 2-benzyl-2-methylmalononitrile was converted mainly into 2-benzyl-2-methylmalonamide and 2-benzyl-2-methylmalonamic acid. This suggests that incubation of R. rhodochrous J1 cells with MPMN results in the induction of nitrile hydratase and amidase in the cells.

Conditions for hydrolysis of MPMN

The reaction conditions for the hydrolysis of MPMN by whole cells of E. coli/pKKJ1nit were examined. The effect of various buffers at different pHs was examined. Potassium phosphate buffer (pH 8) was effective; its optimum concentration was 50 mM. The hydrolyzing activity was stable during the incubation in a pH range of 6–8 at 30 °C for 20 min. The thermal stability of the hydrolyzing activity was investigated. After the whole cells of E. coli/pKKJ1nit had been incubated up to 35 °C for 20 min, no loss of activity was observed. Treatments of 40, 45 and 50 °C for 30 min caused respective losses of 52, 92 and 100 %.

Synthesis of CMPA from MPMN

The time course of CMPA formation was examined under the optimized reaction conditions (Fig. 2). After a 24 h at 30 °C in 50 mM potassium phosphate buffer (pH 8), 563 mM CMPA (80 g CMPA l−1) accumulated with a molar conversion yield of 97 %. During accumulation, the enantiomeric excess of CMPA was maintained from 96 to 97 % e.e. At 20 °C in potassium phosphate buffer (pH 7), CMPA productivity was lower than that at 20 °C and pH 7. In both cases, stoichiometric amounts of ammonia were formed in the reaction mixtures in accordance with the accumulation of CMPA. We therefore examined the effects of ammonia and CMPA on nitrilase activity. Nitrilase activity for benzonitrile was not inhibited even in the presence of NH4Cl or CMPA at 600 mM. Addition of 300 mM NH4Cl together with 300 mM CMPA inhibited nitrilase activity by 16 %. When both were at 600 mM, activity was inhibited by >99 %. Therefore, CMPA formation from MPMN was inhibited only in the presence of high concentrations of ammonia and CMPA, (Fig. 2).

Time course of CMPA formation using E. coli/pKKJ1nit cells. The reaction mixtures initially contained 20 mM MPMN, 50 mM potassium phosphate buffer and 63 mg dry wt whole cells in 25 ml. Feeding of MPMN was conducted according to its consumption to maintain its concentration at 20 mM. Circles reaction at 30 °C in potassium phosphate buffer (pH 8); squares reaction at 20 °C in potassium phosphate buffer (pH 7)

When CMPA was used as a substrate instead of MPMN, CMPA was not converted into the corresponding dicarboxylic acid by whole cells of E. coli/pKKJ1nit. Thus, in the conversion of MPMN into CMPA, no other products than CMPA were formed.

References

Bayer S, Birkemeyer C, Ballschmiter M (2011) A nitrilase from a metagenomic library acts regioselectively on aliphatic dinitriles. Appl Microbiol Biotechnol 89:91–98

Conway EJ, Berne A (1933) An absorption apparatus for the micro-determination of certain volatile substances. Biochem J 27:419–429

Fawcett JK, Scott JE (1960) A rapid and precise method for the determination of urea. J Clin Pathol 13:156–159

Kobayashi M, Nagasawa T, Yamada H (1989) Nitrilase of Rhodococcus rhodochrous J1: purification and characterization. Eur J Biochem 182:349–356

Kobayashi M, Komeda H, Yanaka N, Nagasawa T, Yamada H (1992) Nitrilase from Rhodococcus rhodochrous J1: sequencing and overexpression of the gene and identification of an essential cysteine residue. J Biol Chem 267:20746–20751

Moretto A, Peggion C, Formaggio F, Crisma M, Toniolo C, Piazza C, Kaptein B, Broxterman QB, Ruiz I, Díaz-de-Villegas MD, Galvez JA, Cativiela C (2000) (αMe)Nva: stereoselective syntheses and preferred conformation of selected model peptides. J Peptide Res 56:283–297

Nagasawa T, Yamada H (1989) Microbial transformation of nitriles. Trends Biotechnol 7:153–158

Nagasawa T, Kobayashi M, Yamada H (1988) Optimum culture conditions for the production of benzonitrilase by Rhodococcus rhodochrous J1. Arch Microbiol 150:89–94

Nagasawa T, Wieser M, Nakamura T, Iwahara H, Yoshida T, Gekko K (2000) Nitrilase of Rhodococcus rhodochrous J1: conversion into the active form by subunit association. Eur J Biochem 267:138–144

Thuku RN, Weber BW, Varsani A, Sewell BT (2007) Post-translational cleavage of recombinantly expressed nitrilase from Rhodococcus rhodochrous J1 yields a stable, active helical form. FEBS J 274:2099–2108

Vejttech V, Sveda O, Kaplan O, Prikrylová V, Elisáková V, Himl M, Kubác D, Pelantová H, Kuzma M, Kren V, Martínková L (2007) Biotransformation of heterocyclic dinitriles by Rhodococcus erythropolis and fungal nitrilases. Biotechnol Lett 29:1119–1124

Wu ZL, Li ZY (2003) Enantioselective biotransformation of α,α-disubstituted dinitriles to the corresponding 2-cyanoacetamides using Rhodococcus sp. CGMCC0497. Tetrahedron Asymm 14:2133–2142

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yoshida, T., Mitsukura, K., Mizutani, T. et al. Enantioselective synthesis of (S)-2-cyano-2-methylpentanoic acid by nitrilase. Biotechnol Lett 35, 685–688 (2013). https://doi.org/10.1007/s10529-012-1131-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-012-1131-0