Abstract

Rising crude oil prices and environmental concerns have renewed interest in renewable energy. Cellulosic ethanol promises to deliver a renewable fuel from non-food feedstocks. One technical challenge producing cellulosic ethanol economically is a robust organism to utilize the different sugars present in cellulosic biomass. Unlike starch where glucose is the only sugar present, cellulosic biomass has other sugars such as xylose and arabinose, usually called C5 sugars. This review examines the most promising naturally occurring C5 fermenting organism, Pichia stipitis. In this work, the properties that make P. stipitis unique from other organisms, its physiology and fermentation results on lignocellulosic substrates have been reviewed. P. stipitis can produce 41 g ethanol/l with a potential to cleanup some of the most concentrated toxins. These results coupled with the less stringent nutritional requirements, great resistance to contamination and its thick cell walls makes P. stipitis a viable organism for scale-up. However, P. stipitis has a slower sugar consumption rate compared to Saccharomyces cerevisiae and requires microaerophilic condition for ethanol production. Finally, future studies to enhance fermentation capabilities of this yeast have been discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Increase in global energy demand has caused oil prices to reach record levels in recent times. High oil prices together with concerns over CO2 emissions have resulted in renewed interests in renewable energy. In using a renewable energy source such as ethanol, the carbon is recycled through photosynthesis. Ethanol is a renewable fuel which can be used in cars either as neat alcohol (100% ethanol) or in different combinations with gasoline (E10, E15, E85). The US and Brazil are the leading producers of fuel ethanol in the world. Most of the ethanol produced in the US, currently over 7 billion gallons, is made from corn grown mostly in the Midwest regions of the US. However, studies predict only 15 billion gallons can be produced from corn at a sustainable level (http://www.ncga.com/ethanol/pdfs/2006/HowMuchEthanolCan%20ComeFromCorn.v.2.pdf). The recent doubling in corn prices without an increase in the ethanol price has reduced profit margins for producing ethanol from corn. The need for nonfood feedstock makes cellulosic substrates attractive for producing ethanol.

Cellulosic biomass refers to agricultural residues such as corn stover, wheat straw, bagasse, plant residues, municipal solid wastes, and manure. These are waste materials or low value feedstock with enormous potential for ethanol production. Recently, the US government passed an energy bill mandating 36 billion gallons of ethanol by 2022, of which 21 billion gallons will be produced from cellulosic biomass. Developing an efficient technology to convert the sugars in cellulose to ethanol in an economical process is a challenge currently worked on by industry, research institutions and academia.

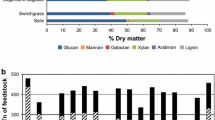

Although there are different processes for producing ethanol from biomass, the most common approach is shown in Fig. 1. The feedstock is milled and pretreated to open up the biomass structure. Cellulosic biomass is a recalcitrant substrate consisting mainly of cellulose, hemicellulose and lignin (Mosier 2005). Pretreatment may involve high temperatures and chemicals to make the cellulose and hemicellulose susceptible to enzymatic action. Enzymes are added to hydrolyze the biomass to simple sugars such as glucose and xylose. Fermentation is then performed where the sugars are converted to ethanol. Fermentation is followed by distillation where ethanol is recovered and the waste water is treated for reuse.

Some technical challenges in developing an economical process for ethanol from cellulosic biomass include the requirement for a high yield feedstock (tons/acre), storage and transport of feedstock, pretreatment cost, reducing or eliminating chemicals in pretreatment, lowering the cost and quantity of enzymes, an efficient organism for using the available sugars (DOE/SC-0095). Other challenges include developing an efficient ethanol recovery system and cleanup of the waste water stream. Unlike corn where glucose constitutes all the sugars present, glucose constitutes ∼60% of the total sugars available in cellulosic biomass (Lee 1997). Fermentation of the available sugars in cellulosic biomass presents a unique challenge because of the presence of other sugars such as xylose and arabinose (C5 sugars). In addition, pretreatment chemicals and toxins generated during pretreatment presents additional problems that are not seen in the current corn to ethanol process.

Developing an efficient organism to ferment the C5 sugars has been pursued for the past few decades. Organisms to ferment the C5 sugars in cellulosic biomass can be divided into two subgroups, namely naturally occurring and genetically engineered microorganisms. The naturally-occurring microorganisms include Pichia stipitis, Candida shehatae, and Pachysolen tannophilus. Genetically-engineered organisms with C5 fermenting capabilities include Saccharomyces cerevisiae, E. coli, Zymomonas mobilis (Skoog and Hahn-Hagerdal 1988). There are other reviews on C5 organisms in general (Skoog and Hahn-Hagerdal 1988; Jeffries and Jin 2000). This review looks at the most promising naturally occurring C5 fermenting organism, P. stipitis. In this work, the unique properties of P. stipitis compared to other naturally occurring C5 organisms, its physiology and fermentation results on pretreated cellulosic biomass has been reviewed.

Nature of the yeast

Pichia stipitis belongs to a group of yeasts isolated from decaying wood and the larvae of wood inhabiting insects (Toiviola et al. 1984). The ecological niche of this yeast provides it with capabilities to utilize most of the sugars present in wood. P. stipitis has developed various cellulases and hemicellulases to break down wood into monomeric sugars (Jeffries et al. 2007). One of those enzymes is β-glucosidase which breaks down cellobiose into glucose monomers; therefore P. stipitis has the ability to ferment cellobiose. In yeasts, such as S. cerevisiae, ethanol is produced when sugar concentrations are relatively low, even under aerobic conditions. This phenomenon is known as the Crabtree effect. Unlike S. cerevisiae, P. stipitis is a respiratory yeast, which does not produce ethanol under aerobic conditions, even in the presence of excess sugars (Klinner et al. 2005). The choice to produce ethanol or cell mass by P. stipitis depends on the O2 supply to the cells. At high aeration rates, only cell mass is produced and at low aeration rates, ethanol is produced (du Preez 1994).

P. stipitis is able to ferment glucose, xylose, mannose, galactose and cellobiose (Parekh and Wayman 1986). It also has the ability to produce cell mass from l-arabinose but not ethanol (Nigam 2002). P. stipitis exhibits both low-affinity and high-affinity proton symport systems that operate simultaneously (Kilian and Uden 1988). The low-affinity transport system is shared between glucose and xylose for sugar transport. Glucose inhibits xylose transport by noncompetitive inhibition in the low-affinity proton symport system (Kilian and Uden 1988). The low-affinity transport is used when sugar concentrations are high and the high affinity systems are used when sugar concentrations are low. Repression of xylose uptake occurs in fermentation media containing glucose and xylose (Chandra et al. 1988). Therefore, glucose is the preferred sugar by P. stipitis in ethanol production. The rate of glucose consumption is higher than xylose under similar growth conditions (Agbogbo et al. 2006). The transport of sugars into the cells is the rate limiting step in the utilization of sugars for ethanol production in P. stipitis (Ligthelm et al. 1988).

In most bacteria, d-xylose conversion proceeds via direct isomerization to d-xylulose using xylose isomerase (Fig. 2a). In yeasts and most fungi, the conversion is carried out by two oxidoreductases, xylose reductase (XR) and xylitol dehydrogenase (XDH). XR is NADPH cofactor specific whereas XDH is NAD+ cofactor specific. The difference in cofactor preference of XR and XDH leads to the formation of xylitol under anaerobic conditions (Fig. 2b). Xylitol is therefore a byproduct in ethanol fermentation and its production reduces the final ethanol yield. P. stipitis is one of the few types of yeast that is able to ferment xylose to ethanol under anaerobic conditions because it possesses both NADH and NADPH specific XR cofactor. The benefit of XR using NADH is that there is a total cofactor balance when this cofactor is used, and therefore no xylitol is produced (Fig. 2c). Kinetic studies indicate that NADPH is the preferred coenzyme because its affinity is about double the value for NADH (Verduyn et al. 1985). Under anaerobic conditions, xylose fermentation by P. stipitis must proceed by NADH-linked XR for a total cofactor balance. The ability of P. stipitis and P. tannophilus to use NADH for XR provides these yeasts with the ability to produce less xylitol in xylose conversion compared to other xylose fermenting yeasts under anaerobic conditions (Verduyn et al. 1985).

Studies on P. stipitis and P. tannophilus suggest that P. stipitis produces less xylitol than P. tannophilus even though they both have the ability to use NADH as a cofactor for XR (Debus et al. 1983). The reason for this difference is because P. stipitis has a complex oxidative respiratory system that contains cytochrome and non-cytochrome electron transport chains in the mitochondria. The non-cytochrome electron transport chain is the salicyl hydroxamic acid (SHAM) sensitive pathway. The existence of the SHAM sensitive pathway in P. stipitis provides a redox sink for coping with cofactor in-balance, and therefore results in less xylitol production by P. stipitis (Jeppsson et al. 1995) compared to other yeasts lacking this pathway. It is for the same reason that XR and XDH genes cloned from P. stipitis into recombinant S. cerevisiae produce considerable amounts of xylitol, although transformants expressed the same level of XR and XDH enzyme activities as in P. stipitis (Hahn-Hagerdal et al. 1994). Deletion of the cytochrome c gene from P. stipitis resulted in a mutant that uses the SHAM-sensitive respiratory pathway for aerobic energy production. The mutant produced had 50% lower growth rates than the parent strain on fermentable sugars, and had a 21% higher yield on ethanol compared to parental strains (Shi et al. 1999). Further work showed that the non-proton translocating NAD(P)H dehydrogenase are linked to the SHAM-sensitive terminal oxidase in xylose metabolizing cells and serves a regulatory function in the complex redox network of P. stipitis (Shi et al. 2002).

Recently, the genome sequence for P. stipitis has been published (http://www.jgi.doe.gov/pichia) (Jeffries et al. 2007). The genome sequence shows that P. stipitis uses an alternative nuclear codon that substitutes serine for leucine when CUG is specified (Laplaza et al. 2006). The sequence showed numerous genes for bioconversion such as xylanase, endo-1,4-β-glucanase, exo-1,3-β-glucosidase, β-mannosidase and α-glucosidase (Jeffries et al. 2007). The presence of these genes in P. stipitis offers very useful traits for simultaneous saccharification and fermentation of cellulose and hemicellulose. Amino acid supplementation, controlled oxygen limitation and sequential double induction have been found to improve xylanase production in P. stipitis (Gorgens et al. 2005). Colocation of genes with related functions has been found to occur with a high frequency in P. stipitis. This suggests that proximal relationships evolved through selective pressure in P. stipitis (Jeffries et al. 2007). The colocation of genes for related functions may enhance the gene activities and their mutual function (Jeffries et al. 2007).

The physiology of the yeast

The optimal temperature for P. stipitis fermentation is between 25 and 33°C and the optimal pH is 4.5–5.5 (du Preez et al. 1986). Nutrients in fermentation media play an important part in the growth and ethanol production in P. stipitis. Studies on P stipitis NRRL Y-7124 using a defined medium provided with nitrogen, vitamin, amino acids, purines and pyrimidines shows that some of these components could enhance growth and ethanol production in P. stipitis (Slininger et al. 2006). Ethanol production increased with addition of amino acids and nitrogen was required for non-growth associated ethanol production (Slininger et al. 2006). Ammonium salts increased the ethanol productivity and the ethanol to biomass yield in P. stipitis (Guebel et al. 1992; Agbogbo and Wenger 2006). Magnesium has also been shown to play an important role in redox balance and therefore has an effect on xylitol production (Mahler and Nudel 2000). Low levels of Mg resulted in xylitol accumulation and a high intracellular NADH content (Mahler and Nudel 2000). Corn steep liquor is a viable nutrient source for P. stipitis fermentation when used as a sole nitrogen source compared to amino acids, vitamins and other nutrients (Amartey and Jeffries 1994). A summary of the effect of various nutrients on growth and ethanol production is shown in Table 1.

Oxygen plays an important role in cell growth, redox balance, functioning of the mitochondria and generation of energy for xylose transport in P. stipitis (Skoog et al. 1990). Fermentation in P. stipitis is not induced by high sugar concentrations, but inactivated by aerobic conditions (Passoth et al. 1996). The investigation by Passoth et al. revealed that the branching point between respirative and fermentative metabolism which includes enzymes such as pyruvate decarboxylase, alcohol dehydrogenase and aldehyde dehydrogenase were induced by a reduction in oxygen tension (Passoth et al. 1996). Some studies have shown that P. stipitis produces ethanol under anaerobic conditions (Delgenes et al. 1986), but microaerobic conditions are optimal for ethanol production (Grootjen et al. 1990). The different measurements used to quantify the level of oxygenation are rev/min in shake-flasks whilst vvm (volume/volume min), OTR (O2 transfer rate) and DO (dissolved O2) are used in fermentor experiments (Skoog and Hahn-Hagerdahl 1987). These differences make it difficult to compare data from different O2 transfer systems. The optimal DOT values are well below 1% of saturation, which is below the sensitivity limit for dissolved O2 electrodes suitable for use in microbial fermentation (du Preez 1989).

The initial xylose concentration has an effect on the fermentation parameters of P. stipitis with maximum ethanol productivities occurring at a xylose concentration of 50 g/l (du Preez et al. 1985). Sugar inhibition studies show that volumetric ethanol productivity is inhibited at initial xylose concentrations of between 76 and 99 g/l and ethanol yield decreased when xylose concentration was above 145 g/l (Roberto et al. 1991). Chamy and coworkers found no evidence of xylose inhibition when xylose concentration was 200 g/l (Chamy et al. 1994). High sugar concentrations increase osmotic stress on organisms and therefore reduces growth and fermentation rate. Therefore, the observation by Chamy and coworkers on xylose inhibition may be due to experimental conditions which reduce the sugar stress.

Delgenes et al. (1988) showed that P. stipitis produces ethanol initially at 50 g/l, even though this totally inhibits the strains activity under microaerobic conditions. Ethanol can damage the cell membrane by altering the cell membrane organization and permeability. Ethanol is known to dissipate the proton-motive force across the plasma membrane leading to cytoplasmic acidification and cell death. The ethanol tolerance of P. stipitis was shown to have a correlation with the ATPase activity of the plasma membrane (Meyrial et al. 1995). The ATPase is used for proton transport across the cell membrane to reduce cytoplasmic acidification. Glucose grown cells of P. stipitis showed higher specific ATPase activity compared to xylose grown cells, and therefore the ethanol tolerance of glucose grown cells were higher than xylose grown cells (Meyrial et al. 1995).

Fermentation of lignocellulosic substrates

P. stipitis has been used as an ethanologen to ferment various types of pretreated biomass such as red oaks, wheat straw, sugarcane bagasse, rice straw, corn cob, corn stover, aspen wood, pine wood and poplar wood (Table 2). Fermentations using these hydrolyzates have been performed using mainly shake flasks and bioreactors ranging from 125 ml to 5 l (Table 2). The ethanol produced ranged from 6 to 41 g/l, at a yield of 0.31–0.48 g ethanol/g sugars consumed (Table 2). The percentage of sugars consumed was in the range of 78–100% and fermentation times between 5 and 100 h. In most of these studies, the pretreated substrate was detoxified by methods such as steam stripping (Parekh et al. 1987), overliming (Amartey and Jeffries 1996; Eken-Saracoglu and Eden 2000), molecular sieves and mixed bed of resins (Tran and Chambers 1985). In other cases, the hydrolyzate was used without detoxification by adjusting the pH to around 6.0 (van Zyl et al. 1988; Agbogbo and Wenger 2007).

The effect of different inhibitor concentrations on P. stipitis has been studied (Tran and Chambers 1986; Delgenes et al. 1996; Liu et al. 2004, 2005). In all these studies, model compounds of inhibitors generated in acid prehydrolysis hindered fermentation in P. stipitis (Tran and Chambers 1986). Some compounds in pretreated lignocellulosic substrates such as vanillin (Delgenes et al. 1988), and syringaldehyde (Tran and Chambers 1986) were identified as some of the most toxic components. Recently it was demonstrated that P. stipitis reduces the aldehyde group in the furan ring of HMF and furfural (Liu et al. 2004, 2005). These results together with the observation of a decrease in acetic acid concentration during fermentation on P. stipitis (Agbogbo et al. 2007), presents a potential for in situ detoxification of the inhibitors generated during pretreatment.

Conclusion and future prospects

P. stipitis has certain unique qualities that make it the most promising naturally occurring organism to utilize the sugars present in lignocellulosic substrates. One of these qualities is the enzyme systems developed for breaking down and using wood sugars. P. stipitis has developed two mechanisms to minimize xylitol production. The first mechanism is the ability to use two XR cofactors (NADH, NADPH), which P. stipitis shares with other organisms such as P. tannophilus. The second mechanism, which is unique to only P. stipitis is the existence of the SHAM sensitive pathway which provides a redox sink for coping with cofactor imbalance. Recently, the genome of P. stipitis has been sequenced and this provides the blueprints for making genetic manipulations.

P. stipitis has a slower sugar consumption rate compared to S. cerevisiae. Understanding the limitations for sugar transport in P. stipitis will help improve the fermentation rate. Moreover, understanding the sugar repression systems in P. stipitis will help improve sugar utilization rates. Further work should also focus on increasing the ethanol tolerance and concentrations in P. stipitis at industrial relevant conditions. More work on understanding ATPase activity could help increase the ethanol tolerance in P. stipitis. Evolution towards higher promoter strength for higher transcript levels could be advantageous in enhancing fermentation rates. Searching for other xylose fermenting organisms from woody environments could potentially lead to the discovery of new and potent organisms. Finally, determining how other inhibitor compounds change during fermentation in P. stipitis could potentially reveal new insights.

Fermentation results on P. stipitis show that 61 g ethanol/l can be produced in synthetic media (Slininger et al. 2006), and 41 g/l (Parekh et al. 1987) in pretreated aspen wood. These results, coupled with the fact that P. stipitis can utilize corn steep liquor as a nutrient source (Amartey and Jeffries 1994), provides unique opportunities for looking at the capabilities of this yeast in cellulosic ethanol production. The ability of P. stipitis to consume acetic acid, reduce the furan ring in HMF and furfural creates an opportunity for this yeast to cleanup some of the most concentrated toxins in cellulosic biomass conversion. This could be very beneficial in waste water treatment since there will be a reduction in the quantity of toxins to be treated. Fermentation of lignocellulosic substrates using P. stipitis at pilot scale could potentially reveal new insights on using this organism in industrial applications.

References

Agbogbo FK, Wenger KS (2006) Effect of pretreatment chemicals on xylose fermentation by P. stipitis. Biotechnol Lett 28(24):2065–2069

Agbogbo FK, Wenger KS (2007) Production of ethanol from corn stover hemicellulose hydrolyzate using P. stipitis. J Ind Microbiol Biotechnol 34(11):723–727

Agbogbo FK, Coward-Kelly G, Torry-Smith M, Wenger KS (2006) Fermentation of glucose/xylose mixtures using P. stipitis. Process Biochem 41(11):2333–2336

Agbogbo FK, Haagensen FD, Milam D, Wenger KS (2007) Fermentation of acid pretreated corn stover to ethanol without detoxification using P. stipitis. Appl Biochem Biotechnol (in press)

Amartey SA, Jeffries TW (1994) Comparison of corn steep liquor with other nutrients in the fermentation of d-xylose by Pichia stipitis CBS 6054. Biotechnol Lett 16(2):211–214

Debus D, Methner H, Shulze D, Dellweg H (1983) Fermentation of xylose with the yeast Pachysolen tannophilus. Eur J Appl Microbiol Biotechnol 17:287–291

Delgenes JP, Moletta R, Navarro JM (1986) The effect of aeration on d-xylose fermentation by P. tannophilus, P. stipitis, K. marxianus and C. shehatae. Biotechnol Lett 8(12):897–900

Delgenes JP, Moletta R, Navarro JM (1988) The ethanol tolerance of Pichia stipitis Y 7124 grown on a d-xylose, d-glucose and l-arabinose mixture. J Ferment Technol 66(4):417–422

Delgenes JP, Moletta R, Navarro JM (1996) Effects of lignocellulosic degradation products on ethanol fermentations of glucose and xylose by Saccharomyces cerevisiae, Zymomonas mobilis, Pichia stipitis and Candida shehatae. Enzyme Microb Technol 19:220–225

DOE/SC-0095 (2006) Breaking the biological barriers to cellulosic ethanol. US Department of Energy Office of Science and Office of Energy Efficiency and Renewable Energy

du Preez JC (1994) Process parameters and environmental factors affecting d-xylose fermentation by yeasts. Enzyme Microb Technol 16:944–956

du Preez JC, Bosch M, Prior BA (1985) Xylose fermentation by Candida shehatae and Pichia stipitis: effects of pH, temperature and substrate concentration. Enzyme Microb Technol 8:360–364

Eken-Saracoglu N, Arslan Y (2000) Comparison of different pretreatments in ethanol fermentation using corn cob hemicellulose hydrolysate with Pichia stipitis and Candida shehatae. Biotechnol Lett 22:855–858

Fenske JJ, Hashimoto A, Penner MH (1993) Relative fermentability of lignocellulosic dilute-acid prehydrolyzates-application of a Pichia-based toxicity assay. Appl Biochem Biotechnol 73:145–157

Gorgens JF, Passoth V, van Zyl WH, Knoetze JH, Hahn-Hagerdahl B (2005) Amino acid supplementation, controlled oxygen limitation and sequential double induction improve heterologous xylanase production by Pichia stipitis. FEMS Yeast Res 5:677–683

Grootjen DRJ, van der Lans RGJM, Luyben KChA (1990) Effects of the aeration rate on the fermentation of glucose and xylose by Pichia stipitis CBS 5773. Enzyme Microb Technol 12:20–23

Guebel DV, Cordenons A, Cascone O, Guilietti AM, Nudel C (1992) Influence of the nitrogen source on growth and ethanol production by Pichia stipitis NRRL Y-7124. Biotechnol Lett 14(12):1193–1198

Hahn-Hagerdal B, Jeppsson H, Olsson L, Mohagheghi A (1994) An interlaboratory comparison of the performance of ethanol-producing microorganisms in a xylose-rich acid hydrolysate. Appl Microbiol Biotechnol 41:62–72

Jeffries TW, Jin Y-S (2000) Ethanol and thermotolerance in the bioconversion of xylose by yeasts. Adv Appl Microbiol 47:221–268

Jeffries TW, Grigoriev IV, Grimwood J, Laplaza JM, Aerts A, Salamov A, Schmutz J, Lindquist E, Dehal P, Shapiro H., Jin Y-S, Passoth V, Richardson PM (2007) Genome sequence of the lignocellulose-bioconverting and xylose-fermenting yeast Pichia stipitis. Nat Biotechnol 25(3):319–326

Jeppsson H, Alexander NJ, Hahn-Hagerdahl B (1995) Existence of cyanide-insensitive respiration in the yeast P.stipitis and its possible influence on product formation during xylose utilization. Appl Environ Microbiol 61(7):2596–2600

Kilian SG, van Uden N (1988) Transport of xylose and glucose in the xylose fermenting yeast Pichia stipitis. Appl Microb Biotechnol 27:545–548

Klinner U, Fluthgraf S, Freese S, Passoth V (2005) Aerobic induction of respire-fermentative growth by decreasing oxygen tensions in the respiratory yeast Pichia stipitis. Appl Microbial Cell Physiol 67:247–253

Laplaza JM, Torres BR, Jin YS, Jeffries TW (2006) Sh ble and Cre adapted for functional genomics and metabolic engineering of Pichia stipitis. Enzyme Microb Technol 38:741–747

Lee J (1997) Biological conversion of lignocellulosic biomass to ethanol. J Biotechnol 56:1–24

Legthelm ME, Prior JC, du Preez JC, Brandt V (1988) An investigation of d-xylose metabolism in Pichia stipitis under aerobic and anaerobic conditions. Appl Microb Biotechnol 28:293–296

Liu ZL, Slininger PJ, Dien BS, Berhow MA, Kurtzman CP, Gorsick SW (2004) Adaptive response of yeasts to furfural and 5-hydroxyfurfural and new chemical evidence for HMF conversion to 2,5-bis-hydroxymethylfuran. J Ind Microbiol Biotechnol 31:345–352

Liu ZL, Slininger PJ, Gorsick SW (2005) Enhanced biotransformation of furfural and hydroxymethylfurfural by newly developed ethanologenic yeast strains. Appl Biochem Biotechnol 121–124:451–460

Mahler G, Nudel C (2000) Effect of magnesium ions on the fermentative and respirative functions in Pichia stipitis under oxygen-restricted growth. Microbiol Res 155:31–35

Meyrial V, Delgenes JP, Romieu C, Molleta R, Gounot AM (1995) Ethanol tolerance and activity of plasma membrane ATPase in Pichia stipitis grown d-xylose or d-glucose. Enzyme Microb Technol 17:535–540

Moniruzzaman M (1995) Alcohol fermentation of enzymatic hydrolysate of exploded rice straw by Pichia stipitis. World J Microbiol Biotechnol 11:646–648

Mosier N, Wyamn C, Dale B, Elander R, Lee YY, Holtzapple M, Ladisch M (2005) Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour Technol 96:673–686

Nigam JN (2001a) Development of xylose-fermenting yeast Pichia stipitis for ethanol production through adaptation on hardwood hemicellulose acid prehydrolysate. J Appl Microbiol 90:208–215

Nigam JN (2001b) Ethanol production from hardwood spent sulfite liquor using an adapted strain of Pichia stipitis. J Ind Microbiol Biotechnol 26:145–150

Nigam JN (2001c) Ethanol production from wheat straw hemicellulose hydrolysate by Pichia stipitis. J Biotechnol 87:17–27

Nigam JN (2002) Bioconversion of water-hyacinth (Eichhornia crassipes) hemicellulose acid hydrolysate to motor fuel ethanol by xylose-fermenting yeast. J Biotechnol 97(2):107–116

Panchal CJ, Bast L, Russell I, Stewart GG (1988) Repression of xylose utilization by glucose in xylose-fermenting yeasts. Can J Microbiol 34:1316–1320

Passoth V, Zimmermann M, Klinner U (1996) Peculiarities of the regulation of fermentation and respiration in the crabtree-negative, xylose-fermenting yeast Pichia stipitis. Appl Biochem Biotechnol 57/58:201–212

Parekh S, Wayman M (1986) Fermentation of cellobiose and wood sugars to ethanol by Candida shehatae and Pichia stipitis. Biotechnol Lett 8(8):597–600

Parekh SR, Parekh RS, Wayman M (1987) Fermentation of wood-derived acid hydrolyzates in a batch bioreactor and in a continuous dynamic immobilized cell bioreactor by Pichia stipitis R. Process Biochem 22(3):85–91

Parekh SR, Parekh RS, Wayman M (1988) Fermentation of xylose and cellobiose by Pichia stipitis and Brettanomycetes clausenii. Appl Biochem Biotechnol 18:325–338

Shi N-Q, Davis B, Sherman F, Cruz J, Jeffries TW (1999) Disruption of the cytochrome c gene in xylose-utilizing yeast Pichia stipitis leads to higher ethanol production. Yeast 15:1021–1030

Shi N-Q, Cruz J, Sherman F, Jeffries TW (2002) SHAM-sensitive alternative respiration in the xylose-metabolizing yeast Pichia stipitis. Yeast 19:1203–1220

Skoog K, Hahn-Hagerdal B (1988) Xylose fermentation. Enzyme Microb Technol 10:66–80

Skoog K, Hahn-Hagerdahl B (1990) Effect of oxygenation on xylose fermentation by Pichia stipitis. Appl Environ Microbiol 56(11):3389–3394

Slininger PJ, Dien BS, Gorsick SW, Liu ZL (2006) Nitrogen source and mineral optimization enhances d-xylose conversion to ethanol by the yeast Pichia stipitis NRRL Y-7124. Appl Microbial Cell Physiol 72(6):1285–1296

Tran AV, Chambers RP (1986) Ethanol fermentation of red oak acid prehydrolysate by the yeast Pichia stipitis CBS 5776, 1986. Enzyme Microb Technol 8:439–444

Toivola A, Yarrow D, van den Bosch E, van Diijken JP, Scheffers WA (1984) Alcoholic fermentation of d-Xylose by yeasts. Appl Environ Microbiol 47(6):1221–1223

Van Zyl C, Prior BA, du Preez JC (1988) Production of ethanol from sugar cane bagasse hemicellulose hydrolyzate by Pichia stipitis. Appl Biochem Biotechnol 17:357–369

Veduyn C, Van Kleef R, Frank J, Schreuder H, van Dijken JP, Scheffers WA (1985) Properties of the NAD(P)H-dependent xylose reductase from the xylose-fermenting yeast Pichia stipitis. Biochem J 226(3):669–677

Acknowledgements

We would like to thank Dr. Thomas Jeffries who provided a lot of guidance in our work with P. stipitis. We will like to thank our colleagues Dr. Kevin Wenger, Dr. Mads Torry-Smith, Dr. Frank Haagensen and David Milam for their support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Agbogbo, F.K., Coward-Kelly, G. Cellulosic ethanol production using the naturally occurring xylose-fermenting yeast, Pichia stipitis . Biotechnol Lett 30, 1515–1524 (2008). https://doi.org/10.1007/s10529-008-9728-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-008-9728-z