Abstract

This study aimed to reveal the effects of different concentrations (0, 5, 10, and 20%) of Aloe vera gel (AV) coating on the quality-related characteristics of table grapes (‘Alphonse Lavallée’ and ‘Red Globe’) during cold storage at 1.0 ± 0.5 °C with 90 ± 5.0% relative humidity for 75 days. Sulphur dioxide (SO2) was also used as a common chemical-based postharvest application to compare the effectiveness of the treatments. During the cold storage, AV treatments were remarkably effective in delaying the loss in fresh weight of grapes with greater effects than both the control and SO2. Postharvest changes in biochemical features such as the soluble solid contents (SSC), titratable acidity (TA), and maturity index (MI) of both grape cultivars were significantly delayed by AV concentrations. Higher concentrations of AV displayed better protection in the physical, biochemical, and visual quality-related properties of the grape cultivars. Considering the general findings, the use of 10% AV treatment could be recommended as a natural, safe, and healthy alternative strategy to chemicals as it provided better conservation of the fresh grapes in long-term cold storage.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Turkey is one of the most important grape-growing countries in the world with an annual fresh grape production of 4,208,908 t (FAO 2020). More than 30% of the total grapes produced in Turkey are consumed as fresh table grapes. ‘Alphonse Lavallée’ and ‘Red Globe’ table grape cultivars are cultivated widely throughout the world due to their high market value. Some of the important characteristics of these grape cultivars include high yield and quality with attractive berry colours, as well as high antioxidant and anthocyanin properties. However, table grapes are non-climacteric and easily perishable produce with their succulent berry tissue and thin pericarp (Lang and During 1990). Therefore, they are exposed to significant water loss and pathogen infections, which result in a high decay rate (Meng et al. 2010) and low storability (Mirdehghan and Rahimi 2016). Sulphur dioxide (SO2) has been used widely as one generator per 6 kg grape to extend the postharvest quality of table grapes since it effectively controls postharvest pathogens and reduces the incidence of berry decay. With its excellent effect on the protection of fresh grapes, the use of SO2 generators for cold storage of table grapes has become an integral part of the preservation of table grapes intended for medium- or longer-term storage around the world (Droby and Lichter 2004). However, SO2 residues are harmful to human health and frequently give the grapes a sulphurous flavour. Besides, SO2 is highly injurious to most fresh produce and causes phytotoxicity symptoms such as bleaching of berries and browning of the rachis (Meng et al. 2008). In earlier studies, in fact, Nelson and Tomlinson (1958) stated that SO2 fumigation causes microscopic injuries to the berry surface that may facilitate pathogenic infection as well as water loss. Hairline cracks, which are invisible, small, fine, longitudinal, cracking lines on the berry skin, develop when table grapes are subjected to high dose of gaseous SO2 (Zoffoli et al. 2008). In addition, organic growers are prohibited from using SO2. Such problems have prompted researchers to focus on alternative means for decay control and quality maintenance of fresh table grapes (Sabir et al. 2021a).

Edible coatings, as a semi-permeable organic barrier on the surface of the berry, restrict the movement of gasses as well as the rate of respiration and water loss, and they modify the atmosphere thereupon and delay the senescence in a range of horticultural commodities (Alberio et al. 2015; Liguori et al. 2021). Coating matters consist of lipids, proteins, or various compounds which can effectively protect the produce (Vieira et al. 2016; Xing et al. 2020; Avcı et al. 2022; Islam et al. 2022). Recently, Aloe vera gel (AV), composed of polysaccharides and compounds including vitamins, antioxidants such as phenolic compounds, and antimicrobials, has received considerable attention as an edible coating for quality maintenance of produce (Vieira et al. 2016) due to its human health benefits and antimicrobial properties (Parven et al. 2020). The AV coating in a variety of easily perishable produce such as mango (Shah and Hashmi 2020), strawberry (Sogvar et al. 2016), peach, and plum (Guillen et al. 2013) reduced respiration rates, softening, moisture loss, and microbial decay, and it conserved overall quality properties. Alberio et al. (2015) reported that dipping into AV made it possible to decrease the respiration rate of minimally processed ‘Victoria’ and ‘Black Magic’ table grape cultivars and was effective at reducing the enzymatic activities commonly responsible for postharvest quality decay. Their general findings confirmed that by coating the table grapes with AV it was possible to maintain better quality compared to untreated table grapes. Dipping into AV is proposed as a natural tool for the quality maintenance of perishable horticultural produces like table grapes as it improves the nutritional value of the produce and helps reduce the recourse to synthetic additives. Although there are many studies on the use of AV in postharvest quality maintenance of various agricultural products, experimental studies regarding the response of commonly stored grapes to different AV concentration and, in particular, comparison of AV with SO2, are surprisingly lacking in the literature. Therefore, the present study was conducted to assess the effect of different doses of postharvest AV coating on the physicochemical properties, biochemical characteristics, antioxidant activity, and postharvest quality of table grapes during cold storage.

Material and Methods

Plant Materials

Clusters of ‘Alphonse Lavallée’ and ‘Red Globe’ table grape cultivars were harvested from vineyards at commercial maturity stages (at around 16.1 °Brix). Grapes were then immediately transported to laboratories with a cold vehicle in the early morning (at around 10 °C temperature). Grape samples were selected to be a uniform size and free from any diseases and damage. Aloe vera extract contains a wide range of bioactive compounds such as essential oils, amino acids, fatty acids, vitamins, minerals, enzymes, flavonoids, polysaccharides, phenolics, and glycoproteins (Shelton 1991; Andrea et al. 2020). A worldwide commonly used gel product of Aloe vera was purchased from a commercial company (NaturLex, Scottsdale, AZ, USA).

Treatments and Packaging

The fresh clusters belonging to each cultivar were sorted into five equal groups: (a) control (no treatment); (b) SO2 fumigation as commonly applied with one SO2 generator per ca. 6 kg grape (Lichter et al. 2008); (c) dipping the clusters for 10 min in 5% AV, (d) dipping the clusters for 10 min in 10% AV; and (e) dipping the clusters for 10 min in 20% AV. Attention was paid to ensure that the complete clusters were submerged into the AV solution. After AV treatments, the grapes were air-dried for 30 min to let the dew on berries evaporate under room conditions (Ozturk et al. 2022). For each experiment, 15 packages (five storage period × three replications) were prepared by placing about 400 g of table grapes inside the polyamide/polyethylene plastic bags. A total of 75 bags were stored for up to 75 days in a cold room at 1.0 ± 0.5 °C with 90 ± 5.0% relative humidity. For logical comparisons of the treatment effects on grape quality, three package samples (replicates) per treatment were taken at harvest, and on the 15th, 30th, 45th, 60th and 75th day of storage.

Biochemical Analyses

Grape juice (must) from the randomly collected berries was extracted with a hand press and filtered through cheesecloth and the supernatants were collected for biochemical analysis. The soluble solid content (SSC) of grape must (juice) was quantified by a manual refractometer (ATAGO Company, Fukuoka, Japan) according to 932.12 AOAC methods at 25 °C and the results were reported as the degree of Brix. Titratable acidity (TA) was determined by titration of 5 mL of grape extract dissolved in 45 mL distilled water with the addition of NaOH (0.1 N) solution to reach a pH of 8.1. The numerical value was expressed in terms of the predominant acid (tartaric). The pH of the must was obtained using direct immersion of the electrode (Hanna Instruments Inc., Cluj-Napoca, Romania). The maturity index (MI) was obtained as SSC/TA.

Berry Skin Colour

The skin colour of 30 berries for each treatment was read using a colorimeter (Minolta® CR-400) to obtain the following variables from two equatorial points of berries: L* (lightness), C (chroma), and h° (hue). Lightness values can vary from 0 (black) 100 (white). Chroma refers to the intensity or purity of colour, the distance from grey (achromatic) towards a pure chromatic colour. Hue angle reflects the colour wheel and is measured in degrees; green, yellow and red correspond to 180, 90 and 0°, respectively (McGuire 1992; Peppi et al. 2006).

Weight Loss and Visual Quality Assessments

During postharvest storage, the loss in weight (%) was quantified by periodical weighing and calculated by dividing the mass change along with the storage by the original mass: weight loss (%) = ([Mi − Ms] / Mi) × 100, where Mi = initial weight and Ms = weight at examined time (Mattiuz et al. 2009).

Berry visual quality was determined by nine panellists with knowledge of the grape quality together with the assessment team to assess the berry appearance index using the Delphi method (Ma et al. 2016). The experts were assigned to make a multiple evaluation regarding the relative importance of the visual quality of the berries. The 9‑point Hedonic scale based on previous research performed by Ma et al. (2016) was employed for the evaluation experiment on grape storage. The criteria were as follows: 1 = dislike extremely; 2 = dislike very much; 3 = dislike moderately; 4 = dislike slightly; 5 = neither like nor dislike (marketability threshold value); 6 = like slightly; 7 = like moderately; 8 = like very much; 9 = like extremely.

Rachis visual quality was evaluated to quantify symptoms of dehydration and browning for primary and secondary branches on a ranked scale of 1 to 5, where 1 = absence of these symptoms, 2 = slight occurrence, 3 = moderate, 4 = severe, and 5 = extremely severe browning and dehydration (Liguori et al. 2021). A score of 3 was considered to be the limit of marketability.

Skin Rupture and Berry Detachment Force

A force gauge (DPS-11; Imada, Northbrook, IL, USA) was used to quantify the berry skin rupture force (SRF) and the berry detachment force (BDF) as described by Fidelibus et al. (2007) using 60 berries randomly collected from the middle of the clusters per treatment. To obtain the SRF, the berry from the equatorial point was cradled in a jig attached to a force gauge and the gauge was gently pulled away from the berry until the skin puncture. For BDF (attachment strength of berry to rachis and/or pedicel) determination, the hook apparatus of the force gauge was fixated around the berry pedicel and the gauge was gently pulled away from the cluster until the berry detached. The forces required for skin rupturing and berry detachment were recorded in Newton (N).

Total Antioxidant Capacity and Total Phenols

For antioxidant and phenol analyses, grape berry extracts were prepared as described by Thaipong et al. (2006) with slight modifications. After removing the stem caps of berries, 5 g grape tissue from a mixture of 15 berries excluding seeds was homogenized in methanol using an Ultra-Turrax homogenizer (IKA, T18 digital, Staufen, Germany) for 1 min and then centrifuged at 4000 × g for 30 min at 5 °C. The supernatants were recovered and stored at −20 °C in dark-coloured bottles until analysis. The antioxidant capacity of the sample was determined using a ferric reducing antioxidant potential (FRAP) assay following the method described by Benzie and Strain (1996). The FRAP reagent was a mixture of 25 mL of acetate buffer pH 3.0, 2.5 mL of 10 mM 2,4,6-trioyridyl‑1,3,5-triazine and 2.5 mL of 20 mM ferric chloride hexahydrate. The mixture reaction was commenced when 0.5 mL of the supernatant was added in 5 mL of FRAP solution. The reaction solution was incubated at ambient temperature for 30 min and then the absorbance was read at 630 nm. The antioxidant capacity was expressed as micromoles of Trolox equivalents (TE) per gram fresh weight (μmole TE/g FW). Total phenols were quantified using the method of Singleton et al. (1999). A 100-μL aliquot of each extract was mixed with 1.58 mL of water, 100 μL of Folin-Ciocalteu’s reagent and 300 μL of sodium carbonate solution (200 g L−1). The absorbance at 760 nm was read after 2 h. The content of total phenols was calculated on the basis of the calibration curve of gallic acid and was expressed as milligram gallic acid equivalent (GAE) 100 g−1 FW.

Statistical Analysis

Data sets of each cultivar from analysed parameters were subjected to analysis of variance. Sources of variation were storage time, treatments, and their interactions. Comparisons of means were performed by Tukey’s multiple range tests at a significance level of p < 0.05. Analyses were performed with SPSS software package v. 15.0 for windows.

Results and Discussion

The effect of SO2 and AV gel coating treatments on SSC, TA and maturity index (MI) of ‘Alphonse Lavallée’ and ‘Red Globe’ grapes throughout the storage period of 75 days is presented in Tables 1 and 2 respectively. The overall SSC content in grapes of both cultivars increased gradually until the end of storage. Such increment physiology after harvest indicates progressive ripening of grapes during storage, as reported by various researchers for different cultivars (Sabir and Sabir 2013), although the grape is classified as a non-climacteric commodity (Kader 2002). Physiologically, SSC increase is generally thee result of water loss (Pretel et al. 2006) and gluconeogenesis (a pathway in which organic acids are converted irreversibly back to sugars in cell vacuoles; Hui et al. 2006). In the present study, SO2 and AV treatments were significantly effective in delaying the postharvest increase in SSC in both cultivars. At the final analyses, the highest SSC levels were determined in the control grapes. Higher doses of AV displayed similar effects to those of SO2 treatments in cultivars. Physiologically, it has been well documented that the treatments with the AV slow down the respiration rate of fresh produce during the storage period (Rehman et al. 2020). In contrast to SSC, TA levels in both cultivars decreased progressively during storage. From the beginning of storage until the end, all the treatments were significantly effective in delaying the decrease in TA. A gradual increase in SSC and a decrease in TA resulted in remarkable increases in MI across the stored grapes. Such biochemical changes occur in grapes as the berries remain metabolically active and react to internal and environmental factors for a certain period. However, the treatments significantly slowed down the increase in MI with the highest effect of 10% AV for both cultivars. MI is one of the most commonly accepted indicators for senescence level of the horticultural commodities. Hence, overall findings on biochemical features of the grapes indicated that all doses of AV treatment were capable of delaying grape senescence during cold storage. In particular, 10% AV displayed similar positive effects to those of SO2 in maintaining the biochemical features of grape must during storage.

L*, C* and hue angle values of ‘Alphonse Lavallée’ grapes were not significantly influenced by SO2 or AV treatments (see Table 3). This is most probably because the berry skin colour was uniformly developed in the grape samples as they were harvested from the vineyard located at higher altitudes that induce anthocyanin biosynthesis in grapes. However, in ‘Red Globe’ there were significant changes in C* and hue angle values of the berries in response to the treatments (see Table 4). Such differential response may be due to the skin colour distinctness of the cultivars. The C* value of ‘Red Globe’ cultivar significantly decreased along with the storage duration as previously reported for different grape cultivars (Sabir et al. 2021a). At the end of the storage, the greatest decrease occurred in control grapes while SO2 treatment provided the lowest change. Among the AV treatments, the most effective dose was 20% in delaying the decrease in C* value of ‘Red Globe’ grapes. Berry colour is one of the most important genetic features of the table grape cultivars, which has a significant effect on the consumer’s preference as it is directly related to visual quality (Sabir et al. 2021b). This morphological character is greatly variable and not consistently uniform within a grape cultivar or even a bunch. Between harvest and consumption fruits are stored for several weeks which time is influencing the color of the berry.

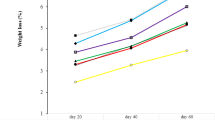

Weight loss was found for both grape cultivars during the storage period (Fig. 1). However, coating of grapes with AV was effective in creating a physical barrier to moisture loss; hence, reduced weight loss was observed for the treated grapes than for the non-treated samples. All the AV treatments were significantly effective in reducing the loss in weight for both cultivars. Control grapes suffered as high as 4.5% and 8.4% losses in weight at the end of the 75-day storage for ‘Alphonse Lavallée’ and ‘Red Globe’, respectively. During this period, the lowest losses in weight were from 10% AV treatment with values of 3.6% and 4.6% for ‘Alphonse Lavallée’ and ‘Red Globe’, respectively. Preventing the postharvest loss in weight of produce is one of the prime considerations determining the success level of cold storage since weight loss has a direct influence on storage cost. Weight loss in horticultural commodities is the result of water loss and increases due to desiccation and metabolic activities such as respiration and transpiration (Zhu et al. 2008). Ali et al. (2011) demonstrated that loss of water from papaya fruit was reduced by coating with chitosan. Besides, coating cherry, peach and other fruits with AV gel has been effective in restricting weight loss during cold storage (Guillen et al. 2013; Ozturk et al. 2019). Moreover, AV gel also been shown to be beneficial for the maintenance of the postharvest life of grapes at 20% concentration during cold storage by reducing water loss (Ali et al. 2016). Overall results of studies indicated that the most probable reason for the reduced weight loss of AV-treated commodities is the inhibition of desiccation during their postharvest life. The desiccation-inhibitory effect of AV is most probably due to latex and gel substances found in AV.

Variation in weight loss values of ‘Alphonse Lavallée’ (a) and ‘Red Globe’ (b) as influenced by SO2 and Aloe vera gel (AV) treatments. Standard error is shown by vertical bars and each value is the mean of three replicates. Different letters on top of the bars indicate significant differences at p < 0.05. d days, LSD least significant difference

The visual qualities of the grape berries did not change up to the 30th day of storage although it changed remarkably after this date in both cultivars (Fig. 2). On the 30th day, only control grapes displayed a significant loss in visual quality of the berry. The grapes of both cultivars presented similar changes with the greatest degradations in control grapes up to the end of the storage. On the 75th day, the highest loss in visual quality was determined in control grapes and followed by 5% AV treatment. However, the lowest changes were obtained from SO2 and higher doses (10% and 20%) of AV treatments with similar effects. Rachis visual quality was the same as the beginning condition during the first 15 days of storage for both cultivars (Fig. 3). However, on the 30th day, there was an abrupt change in nontreated control grapes of both cultivars. During the remaining timespan, control grapes always had the greatest values with remarkable damages, probably due to faster desiccation from the rachis. At the end of the storage, significantly lower changes were found in grapes of both cultivars treated with SO2 and AV treatments at higher doses (10% and 20%). The greenness of the cluster rachis provides an essential indication of the freshness of the table grapes after storage. Crisosto et al. (2001) stated that extensive rachis browning occurs beyond a certain water-loss threshold (beyond 3%). The current investigation on weight loss and subsequent rachis visual quality indicated AV (10 and 20%) was effective for sustainable maintenance of cluster rachis quality.

Variation in berry visual quality values of ‘Alphonse Lavallée’ (a) and ‘Red Globe’ (b) as influenced by SO2 and Aloe vera gel (AV) treatments. Standard error is shown by vertical bars and each value is the mean of three replicates. Different letters on top of the bars indicate significant differences at p < 0.05. d days, LSD least significant difference

Variation in rachis visual quality values of ‘Alphonse Lavallée’ (a) and ‘Red Globe’ (b) as influenced by SO2 and Aloe vera gel (AV) treatments. Standard error is shown by vertical bars and each value is the mean of three replicates. Different letters on top of the bars indicate significant differences at p < 0.05. d days, LSD least significant difference

Expectedly, SRF values of both cultivars displayed gradual and treatment-dependent decreases during the storage (Fig. 4), as previously reported in similar studies on various grape cultivars (Sabir et al. 2021). The lowest SRF values were always determined in control grapes for both cultivars. At the end of the storage, the greatest SRF values were obtained from 10% AV treatment for both cultivars while 20% AV had a similar effect on SRF. All of the treatments were significantly effective in maintaining the berry SRF. After harvest, berry skin consistency is inevitable decreased (Cagnasso et al. 2005), although it has a significant effect on consumer acceptance and the market value of table grapes. Therefore, maintaining the berry skin hardness is one of prime considerations determining the success of postharvest cold storage (Sabir et al. 2021a).

Variation in skin rupture force values of ‘Alphonse Lavallée’ (a) and ‘Red Globe’ (b) as influenced by SO2 and Aloe vera gel (AV) treatments. Standard error is shown by vertical bars and each value is the mean of three replicates. Different letters on top of the bars indicate significant differences at p < 0.05 d days, LSD least significant difference

As expected, berry detachment force (BDF) progressively decreased for both cultivars during the storage (Fig. 5). However, postharvest treatments significantly delayed the changes in BDF from the beginning of the storage until the end of the study. The BDF (adherence power of berry to pedicel and/or rachis) determines the shatter (berry drop from the cluster stalk) incidence, an important physiological disorder directly affecting the marketability of table grapes. The BDF changes during the storage were remarkably lower in ‘Alphonse Lavallée’ than in ‘Red Globe’ although both of the cultivars displayed significant losses in BDF. As a natural postharvest physiology, berry shatter increases along with the prolonged grape senescence during postharvest life. Water loss, pathogen inoculations and improper handling operations accelerate the shatter incidence that results in considerable loss in market value of table grapes (Zoffoli et al. 2009). However, the treatments in the present study significantly delayed the loss in BDF for both cultivars with the greatest effect of 10% AV treatment, similar to the findings for SRF.

Variation in berry detachment force values of ‘Alphonse Lavallée’ (a) and ‘Red Globe’ (b) as influenced by SO2 and Aloe vera gel (AV) treatments. Standard error is shown by vertical bars and each value is the mean of three replicates. Different letters on top of the bars indicate significant differences at p < 0.05. d days, LSD least significant difference

Total phenol contents of the grape cultivars gradually increased from the first day of storage until the 45th day and slowly decreased until the 75th day (Fig. 6). In both cultivars, the highest increases generally occurred in control grapes while the overall treatments remarkably delayed the changes in phenols. The phenolic compounds have antioxidant activity since they trap free radicals (Sreenivas et al. 2011) and grapes possess high antioxidant activity as they are rich in total phenols (Tyagi et al. 2022). Thus, maintaining the phenolic content level during storage is desired so as to prolong the freshness and functionality of table grapes after harvest. However, a decrease in total phenol after a certain period is inevitable due to breakdown of the cellular structure caused by produce aging and tissue degradation, resulting in phenolic acid depletion during senescence (Palafox-Carlos et al. 2012).

Variation in total phenol values of ‘Alphonse Lavallée’ (a) and ‘Red Globe’ (b) as influenced by SO2 and Aloe vera gel (AV) treatments. Standard error is shown by vertical bars and each value is the mean of three replicates. Different letters on top of the bars indicate significant differences at p < 0.05. d days, LSD least significant difference

Antioxidant activity levels of the grapes displayed gradual decrease along with the storge duration although the cultivars greatly differed in terms of antioxidant level (Fig. 7). The greatest changes were found in control grapes of both cultivars, except for the 15th day for ‘Alphonse Lavallée’. Generally, treatments had similar effects in preventing the decrease in antioxidant activity levels during the storage. Consumer demand for fresh grapes has been increasing recently due to their rich phenolic compounds, giving them a great functionality value with high antioxidant activity (Solari-Godiño et al. 2017). Therefore, maintenance of antioxidants during storage is one of the features determining the successful storage.

Variation in antioxidant activity values of ‘Alphonse Lavallée’ (a) and ‘Red Globe’ (b) as influenced by SO2 and Aloe vera gel (AV) treatments. Standard error is shown by vertical bars and each value is the mean of three replicates. Different letters on top of the bars indicate significant differences at p < 0.05. d days, LSD least significant difference

Conclusion

Postharvest handling strategies aim at delaying physiological activities to maintain the physicochemical and visual attributes of fresh commodities. Among such physiologies, berry water loss is a principal postharvest physiological disorder largely responsible for changes in biochemical composition, metabolism and market quality of grapes as revealed in the present and previous studies. Aloe vera gel (AV) treatments were remarkably effective in preventing the weight loss with higher effects than both control and SO2. Such beneficial effects of AV treatments were also found in the soluble solid contents, titratable acidity and maturity index features of the grape cultivars. Higher doses of AV resulted in better protection of the berry and rachis visual qualities for both cultivars, similar to the effects of SO2. Higher doses of AV were also effective in extending the physical parameters such as berry pedicel strength and skin hardness. Losses in antioxidant activity and total phenols of the grapes were retarded by all the treatments. To sum up, overall findings revealed that the AV treatments significantly maintained the postharvest physical, physiological, and biochemical quality-related features of ‘Alphonse Lavallée’ and ‘Red Globe’ table grape cultivars. Among the doses used, an application of 10% AV could be recommended for long-term cold storage of table grapes since its effects on general parameters were similar to those of SO2.

References

Alberio GRA, Muratore G, Licciardello F, Giardina G, Spagna G (2015) Aloe vera extract as a promising treatment for the quality maintenance of minimally-processed table grapes. Food Sci Technol 35:299–306

Ali A, Muhammad MTM, Sijam K, Siddiqui Y (2011) Effect of chitosan coatings on the physicochemical characteristics of Eksotika II papaya (Carica papaya L.) fruit during cold storage. Food Chem 124:620–626

Ali J, Pandey S, Singh V, Joshi P (2016) Effect of coating of Aloe vera gel on shelf life of grapes. Curr Res Nutr Food Sci J 4:58–68

Andrea B, Dumitrița R, Florina C, Francisc D, Anastasia V, Socaci S, Adela P (2020) Comparative analysis of some bioactive compounds in leaves of different Aloe species. Bmc Chem 14:67

Avcı V, Islam A, Ozturk B, Aglar E (2022) Effects of Aloe vera gel and modified atmosphere packaging treatments on quality properties and bioactive compounds of plum (Prunus salicina L.) fruit throughout cold storage and shelf life. Erwerbs-Obstbau. https://doi.org/10.1007/s10341-022-00694-7

Benzie IFF, Strain JJ (1996) The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”, The FRAP assay. Anal Biochem 239:70–76

Cagnasso E, Caudana A, Rolle L, Gerbi V (2005) Profili di maturazione e scelta di vinificazione per la valorizzazione varietale. Inf Agrar Suppl 1–14:23–26

Crisosto CH, Smilanick JL, Dokoozlian N (2001) Table grapes suffer water loss, stem browning during cooling delays. Calif Agric (berkeley) 55:39–42

Droby S, Lichter A (2004) Postharvest Botrytis Infection: Etiology, Development and Management. In: Elad Y, Williamson B, Tudzynski P (eds) Botrytis: Biology, Pathology and Control. Dordrecht: Kluwer Academic Publishers, N. Delen), pp 349–367

FAO 2020. Food and Agriculture Organization of the United Nations, http://www.fao.org/faostat/en/. Accessed 24 May 2022

Fidelibus MW, Cathline KA, Burns J (2007) Potential abscission agents for raisin, table, and wine grapes. Hort Sci 42:1626–1630

Guillen F, Diaz-Mula HM, Zapata PJ, Valero D, Serrano M, Castillo S, Martinez-Romero D (2013) Aloe arborescens and Aloe vera gels as coatings in delaying postharvest ripening in peach and plum fruit. Postharvest Biol. Tecnol, vol 83, pp 54–57

Hui YH, Nip WK, Nollet LML, Paliyath G, Simpson BK (2006) Food Biochemistry and Food. Processing, vol 769. Blackwell Publishing, Ames, IA, USA, p 769

Islam A, Acıkalın R, Ozturk B, Aglar E, Kaiser C (2022) Combined effects of Aloe vera gel and modified atmosphere packaging treatments on fruit quality traits and bioactive compounds of jujube (Ziziphus jujuba Mill.) fruit during cold storage and shelf life. Postharvest Biol Technol 187:111855

Kader AA (2002) Postharvest biology and technology: an overview. In: Kader AA (ed) Postharvest Technology of Horticultural Crops (Publication 3311), 535p., pp 145–148. University of California and Agricultural and Natural Resources, Berkeley

Lang A, During H (1990) Grape berry splitting and some mechanical properties of the skin. Vitis 29:61–70

Lichter A, Zutahy Y, Kaplunov T, Lurie S (2008) Evaluation of table grape storage in boxes with sulfur dioxide-releasing pads with either an internal plastic liner or external wrap. Hort Tech 18:206–214

Liguori G, Sortino G, Gullo G, Inglese P (2021) Effects of modified atmosphere packaging and chitosan treatment on quality and sensorial parameters of minimally processed cv. ‘Italia’ table grapes. Agronomy 11:328

Ma C, Fu Z, Xu M, Trebar M, Zhang X (2016) Evaluation on home storage performance of table grape based on sensory quality and consumers’ satisfaction. J Food Sci Technol 53:1363–1370

Mattiuz B, Miguel ACA, Galati VC, Nachtigal JC (2009) Efeito da temperatura no armazenamento de uvas apirênicas minimamente processadas. Rev Bras Frutic 31:44–52

McGuire R (1992) Reporting of objective color measurements. Hort Sci 27:1254–1255

Meng X, Li B, Liu J, Tia S (2008) Physiological responses and quality attributes of table grape fruit to chitosan preharvest spray and postharvest coating during storage. Food Chem 106:501–508

Meng XH, Qin GZ, Tian SP (2010) Influences of preharvest spraying Cryptococcus laurentii combined with postharvest chitosan coating on postharvest diseases and quality of table grapes in storage. LWT–Food Sci. Technol, vol 43, pp 596–601

Mirdehghan SH, Rahimi S (2016) Pre-harvest application of polyamines enhances antioxidants and table grape (Vitis vinifera L.) quality during postharvest period. Food Chem 196:1040–1047

Nelson KE, Tomlinson FE (1958) Some factors influencing bleaching and wetness of Emperor and Tokay grapes. Proc Am Soc. Hortic Sci 71:190–198

Ozturk A, Ozturk B, Karakaya O, Gun S, Ates U, Yildiz K, Siddiqui MW, Gundogdu M (2022) Preliminary results: Combination of MAP and Aloe vera gel in Medlar fruit. Erwerbs-Obstbau 64:37–45

Ozturk B, Karakaya O, Yıldız K, Saracoglu O (2019) Effects of Aloe vera gel and MAP on bioactive compounds and quality attributes of cherry laurel fruit during cold storage. Sci Hortic 249:31–37

Palafox-Carlos H, Yahia EM, González-Aguilar GA (2012) Identification and quantification of major phenolic compounds from mango (Mangifera indica, cv. Ataulfo) fruit by HPLC–DAD–MS/MS-ESI and their individual contribution to the antioxidant activity during ripening. Food Chem 135:105–111

Parven A, Sarker MR, Megharaj M, Meftaul IM (2020) Prolonging the shelf life of Papaya (Carica papaya L.) using Aloe vera gel at ambient temperature. Sci Hortic 265:109228. https://doi.org/10.1016/j.scienta.2020.109228

Peppi MC, Fidelibus MW, Dokoozlian N (2006) Abscisic acid application timing and concentration affect firmness, pigmentation and color of ‘Flame Seedless’ grapes. Hort Sci 41:1440–1445

Pretel MT, Martinez-Madrid MC, Martinez JR, Carreno JC, Romojaro F (2006) Prolonged storage of ‘Aledo’ table grapes in a slightly CO2 enriched atmosphere in combination with generators of SO2. LWT-Food Sci Technol 39:1109–1116

Rehman MA, Asi MR, Hameed A, Bourquin LD (2020) Effect of Postharvest Application of Aloe vera gel on shelf life, activities of anti-oxidative enzymes, and quality of ‘Gola’ guava fruit. Foods 9:1361

Sabir FK, Sabir A (2013) Quality response of table grapes (Vitis vinifera L.) during cold storage to postharvest cap stem excision and hot water treatments. Int J Food Sci Technol 48:999–1006

Sabir F, Sabir A, Unal S (2021a) Quality response of minimally processed ‘Alphonse Lavallée’ table grapes during cold storage as influenced by preharvest sustained deficit irrigation and postharvest UV‑C irradiation. Erwerbs-Obstbau 63(Suppl 1):S141–S148

Sabir FK, Sabir A, Unal S (2021b) Maintaining the grape quality on organically grown vines (Vitis vinifera L.) at vineyard condition under temperate climate of Konya Province. Erwerbs-Obstbau 63 (Suppl 1):S71–S76

Shah S, Hashmi MS (2020) Chitosan-Aloe vera gel coating delays postharvest decay of mango fruit. Hortic Environ Biotechnol 61:279–289

Shelton M (1991) Aloe vera, its chemical and therapeutic properties. Int J Dermatol 30:679–683

Singleton VL, Orthofer R, Lamuela-Raventos RM (1999) Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin-Ciocalteu reagent. Meth Enzymol 299:152–178

Solari-Godiño A, Lindo-Rojas I, Pandia-Estrada S (2017). Determination of phenolic compounds and evaluation of antioxidant capacity of two grapes residues (Vitis vinifera) of varieties dried: Quebranta (red) and Torontel (white). Cogent Food Agriculture. https://doi.org/10.1080/23311932.2017.1361599

Sogvar OB, Koushesh SM, Emamifar A (2016) Aloe vera and ascorbic acid coatings maintain postharvest quality and reduce microbial load of strawberry fruit. Postharvest Biol Technol 114:29–35

Sreenivas KM, Singhal RS, Lele SS (2011) Chemical pretreatments and partial dehydration of ash gourd (Benincasa hispida) pieces for preservation of its quality attributes. LWT–Food Sci. Technol, vol 44, pp 2281–2284

Thaipong K, Boonprakob U, Crosby K, Cisneros-Zevallos L, Hawkins Byrne D (2006) Comparison of ABTS, DPPH, FRAP, and ORAC assays for estimating antioxidant activity from guava fruit extracts. J Food Compost Anal 19:669–675

Tyagi K, Maoz I, Lapidot O, Kochanek B, Butnaro Y, Shlisel M, Lerno L, Ebeler SE, Lichter A (2022) Effects of gibberellin and cytokinin on phenolic and volatile composition of Sangiovese grapes. Sci Hortic 295:110860

Vieira JM, Flores-Lopez ML, Jasso D, Rodriguez D, Sousa MC, Vicente AA, Martins JT (2016) Effect of chitosan Aloe vera coating on postharvest quality of blueberry (Vaccinium corymbosum) fruit. Postharvest Biol Technol 116:88–97

Xing Y, Yang H, Guo X, Bi X, Liu X, Xu Q, Wang Q, Li W, Li X, Shui Y, Chen C, Zheng YI (2020) Effect of chitosan/Nano-TiO2 composite coatings on the postharvest quality and physicochemical characteristics of mango fruits. Sci Hort 263:109135

Zhu X, Wang Q, Cao J, Jiang W (2008) Effects of chitosan coating on postharvest quality of mango (Mangifera indica L. cv. Tainong) fruits. J Food Process Preserv 32:770–784

Zoffoli JP, Latorre BA, Naranjo P (2008) Hairline, a postharvest cracking disorder in table grapes induced by sulfur dioxide. Postharvest Biol Technol 47:90–97

Zoffoli JP, Latorre BA, Naranjo P (2009) Preharvestapplications of growth regulators and their effect on postharvest quality of table grapes during cold storage. Postharvest Biol Technol 51:183–192

Acknowledgements

The authors wish to thank the Scientific Research Project Coordination Unit (BAP) of Selcuk University (Turkey) for supporting the study (Project no: 20401130).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

F.K. Sabir, S. Unal and A. Sabir declare that they have no competing interests.

Rights and permissions

Springer Nature oder sein Lizenzgeber hält die ausschließlichen Nutzungsrechte an diesem Artikel kraft eines Verlagsvertrags mit dem/den Autor*in(nen) oder anderen Rechteinhaber*in(nen); die Selbstarchivierung der akzeptierten Manuskriptversion dieses Artikels durch Autor*in(nen) unterliegt ausschließlich den Bedingungen dieses Verlagsvertrags und dem geltenden Recht.

About this article

Cite this article

Sabir, F.K., Unal, S. & Sabir, A. Postharvest Aloe vera Gel Coatings Delay the Physiological Senescence of ‘Alphonse Lavallée’ and ‘Red Globe’ Grapes During Cold Storage as an Alternative to SO2. Erwerbs-Obstbau 65, 1889–1898 (2023). https://doi.org/10.1007/s10341-022-00761-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10341-022-00761-z