Abstract

Mango is an important fruit with worldwide acceptance, extensive marketing, vast production, wide distribution, and benefits to human health. Mango wastes, namely, seed kernel (MSK) and peel, have high functional and nutritional potential. An investigation was undertaken on the mango with molecular analysis of 32 varieties to select genetically diverse genotypes followed by biochemical characterization of seed kernel of 10 varieties to assess the industrial potential of the kernel. Overall, 16 biochemical parameters and eight simple sequence repeat (SSR) primers were used to characterize the varieties of mango. Proximate composition was studied for the different mango varieties. Lipid profile, amino acid profile, and mangiferin profile were also analysed. For molecular analysis, DNA was extracted from leaf tissues. Biochemical analysis of the kernel revealed significant variability for phytochemicals among the genotypes. The kernel was rich in minerals (1.15%), oil (9.235%), starch (50%), and crude protein (10.36%). Amino acid profiling through liquid chromatography–tandem mass spectrometry (LC-MS/MS) suggested that kernels can be a source of eight essential amino acids. Steric and oleic acid represented the main fatty acids. Total phenol was in the range of 0.33–0.54%. Mangiferin content in the seed, analysed by LCMS, varied from 0.27 to 4.88 mg/g. Anti-nutritional factors were also detected in the kernel. The results of the current study suggest that significant varietal differences exist in mango for various phytochemicals. Based on the outcome of this experiment, it can be concluded that mango kernel is an economical source of valued food and nutraceutical components, which can be exploited in various food and feed industries.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Mango (Mangifera indica L.; Anacardiaceae) is an important fruit tree species of tropical and subtropical regions. Its nutritional value, aroma, and pleasant taste make it the king of fruits (Saran et al. 2020). Mango is an essential raw material for various food industries. The processing of fruit results in elevated amounts of waste materials. Dumping of the waste products, such as the peels, stones/seeds, and oilseed meals generated after fruit processing, is one of the major problems associated with mango pulp industries. This “co-product” not only causes environmental issues, viz. mushrooming of insects and rodents, but is also responsible for financial stress due to the transportation to landfill sites. The literature suggests that mango seed kernel (MSK) is a reservoir of useful nutrient components (El-safy et al. 2012). Hence, there is a need to develop strategies for the productive use of the waste generated by mango-processing industries.

Approximately 40–60% of waste in the form of peel and kernel is produced during mango processing. Of this waste, the peel represents 12–15% while the kernel accounts for is 15–20%. Every year, over 107 quintals of MSK as waste results from the food processing sectors, which can be exploited to generate some valuable produce and as a result ecological risks could be reduced (Abdalla et al. 2007). The appropriate use of MSK as raw material and/or a food additive could increase the financial benefits of these industries. The use of MSK by food industries to prepare food supplements will also contribute towards eliminating malnutrition, promoting health and reducing the environmental effects of co-products (Da Silva and Jorge 2014).

Starch, oil and protein are significant components of MSK. The MSK oil comprises both saturated (45 to 48%; majority stearic) and unsaturated fatty acids (52–56%). In comparison with many other vegetable oils, MSK oil has a better stability. With long shelf life, mango oil is safe and is fit for mixing with vegetable oils, stearin, confectionery, and soap. Earlier research indicated that MSK lipid from various mango genotypes is devoid of toxic material such as hydrocyanic acid (Rashwan 1990). The kernel is also rich in starch. The mango seed cakes and meals generally called ‘total waste’ have an adequate volume of starch. However, a kernel is low in protein but encompasses most of the essential amino acids.

Furthermore, MSK is rich in polyphenols, phytosterols such as campesterol, sitosterol and tocopherols polyphenols, sesquiterpenoids and phytosterols and metal chelators and tyrosinase inhibitors (Ashoush and Gadalla 2011; Kittiphoom 2012). Among the various polyphenols present in the mango, mangiferin (C-2-β-D-glucopyranosyl‑1,3,6,7-tetrahydroxyxanthone) is a distinct compound. Mangiferin is a promising biologically active and antioxidant compound that can be used as a remedy against inflammation, diabetes, tumours and for immunomodulation (Luo et al. 2012). The diverse bioactivities of mangiferin are present in the catechol moiety of the B‑ring. Mangiferin promotes the movement of the endothelial cell during the formation of new blood vessels (angiogenesis). Thus, it may ameliorate vascular diseases and have therapeutic potential in the inflammation of blood vessels (Imran et al. 2017).

The contents and concentration of various phytochemicals in mango seed depend on the genetic makeup of the plant. Therefore, characterization of the germplasm is a criterion for protection and utilization in breeding programs. Genetic characterization serves the twin purposes of documentation of the germplasm and determination of their genetic variance (Saran and Kumar 2011). The mango germplasm has been characterized with morphological markers. But the high interaction of morphological markers with environmental conditions affects the characterization of germplasm.

On the contrary, simply inherited DNA/molecular markers are enormous in number and are not affected by environmental conditions and the growth stage of the plant. Depending on the marker of choice, simple sequence repeats (SSRs) have also been used in mango (Mahato et al. 2016). Against this background, the current study was commenced with the objectives to (1) characterize mango varieties by SSR markers and (2) evaluate the nutritional and industrial properties of MSK from selective varieties.

Materials and Methods

Plant Materials and Molecular Characterization

For molecular characterization, leaf samples of 32 mango genotypes were collected from a mango orchard in the Horticulture Farm, Anand Agricultural University, Anand. The DNA was isolated from leaf tissues using cetyltrimethyl ammonium bromide (CTAB) following the protocol of Doyle and Doyle (1990). The genomic DNA was amplified using SSR primers through polymerase chain reaction (PCR). The PCR reaction of 15 μL volume comprised 1.5 μL template DNA, 7.5 μL PCR master mix (2×; EmeraldAmp® GT PCR Master Mix, Takara, Japan), 1.5 μL diluted primer and 3.5 μL distilled water. The PCR reactions were conducted in SensoQuest Thermocycler (Göttingen, Germany) with thermal conditions as per Singh et al. (2012). Of 32 genotypes, a set of ten diverse (at SSR marker level) genotypes were selected from each group for biochemical analysis.

Biochemical Characterization

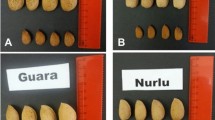

For biochemical analysis, three fully matured fruits of each selected genotype were collected followed by pulp removal to collect the seed. Seeds were washed, the MSK separated, dried at 60 °C for 6 h in a hot-air oven and ground into fine powder manually.

Proximate Analysis

The fine powder was used for biochemical analysis. Moisture and ash content from MSK flour was determined as per the methodology of the Association of Official Analytical Chemists (AOAC; 1965). The micro-Kjeldahl method was deployed to estimate crude protein (AOAC 1965). The Anthrone method of Dubois et al. (1956) was used for estimation of starch. Crude fibre was determined according to the AACC (American Association of Cereal Chemists) guidelines (1983). Total oil from MSK was extracted with a Soxhlet apparatus using hexane (AOAC 1965). Kernel mineral content (Fe, Mn, Zn and Cu) was estimated as per Sadasivam and Manickam (1992). Total phenol was estimated with the procedure described by Bray and Thorpe (1954). The presence of tannin and total phytate was determined following the method of Harborne (1973) and Makkar et al. (1993), respectively. Trypsin inhibitor activity was calculated as per Hammerstrand et al. (1981).

Amino Acid Profiling

A fast and straightforward method for quantification of amino acids without a derivatization approach was standardized as per the protocol described by Lane (2015) with minor modifications. In brief, stock solution (10 mM) of each amino acid standard except cysteine and tryptophan was prepared in 0.1% formic acid. Cysteine and tryptophan were first diluted with a few drops of NaOH and the volume made by 0.1% formic acid. Further serial dilution was made from 10 mM stock, and six series (9.11, 4.88, 2.44, 1.22, 0.61 and 0.305 nmol/µL) were prepared for a standard curve.

Amino acid separation and quantification were carried out using a triple quadrupole-linear ion trap mass spectrometer QTRAP 4500 (AB Sciex LLC,) in conjunction with an Expert LC 100 xl UPLC (Eksigent) system. Mass spectrometry was equipped with a Turbo V™ electrospray ionization (ESI) source. Out of 20, 17 amino acids such as glycine, alanine, serine, proline, valine, threonine, leucine, isoleucine, aspartic acid, lysine, glutamic acid, methionine, histidine, phenylalanine, arginine, tyrosine, and cysteine showed the highest sensitivity in the positive scan mode. At the same time, asparagine, glutamine and tryptophan responded to the negative scan mode. Details on multiple reaction monitoring (MRM) for detection and quantification of amino acids in tandem mass spectrometry are presented in Supplementary Table S1. A 5-µL sample was injected on an ACCQ TAG ULTRA C18 (1.7 µM, length 2.1 × 100 mm; Waters, Framingham, MA, USA) column. The column temperature was adjusted to 40 °C. Elution of amino acids was optimized with an increasing gradient of 1000 ppm formic acid in each water (solution A) and acetonitrile (solution B) sample. A constant flow of 0.3 mL/min was delivered through gradient elution from 2% to 98% of solution B over 5 min and then from 98% to 2% (solution B) for 4 min and the column was re-equilibrated for 1 min. Data were recorded and analysed in Analyst (v. 1.6.2) software (SCIEX, Concord, Canada).

The sample for amino acid extraction was prepared as per the protocol given by Koji et al. (1987) with modification such as 30 mg of kernel powder was first hydrolysed in 3 mL of 1000 ppm phenol in 6 M hydrochloric acid solution and kept in an oven at 110 °C overnight together with blank (no sample). After 12 h, 0.7 mL of the hydrolysed mixture was neutralized with an equal amount of 6 M NaOH and the volume was restored to 2.0 mL with Milli Q water. Centrifugation at 13,000 rpm was carried out for 2 min and the supernatant was sieved through a 0.22-µm PVDF membrane filter. The filtrate of 100 µL was diluted with 900 µL formic acid (0.1%) for further analysis in LC-MS.

Fatty Acid Profiling

Methyl esterification of oil was carried out as per Bazina and He (2018) with minor modifications. In brief, for fatty acid profiling, 300 mg of oil was mixed with 6 mL of 0.5 N methanolic NaOH solution followed by heating of the mixture on a steam bath until the oil/fat globules went into the solution. After cooling to room temperature, the mixture was supplemented with 8 mL of BF3-methanol reagent followed by heating at 80 °C for 5 min. Further, 1 mL of petroleum ether was added in the same flask. At room temperature, adequate saturated NaCl solution was added in the mixture for separation of the methyl esters layer present on top into the narrow neck of the flask. This layer was collected using a syringe and analysed immediately on a gas chromatographer (Trace-1110; Thermo Fisher, Waltham, MA, USA) using a flame ionization detector (FID). The following conditions were fixed for the separation of fatty acid methyl esters: injector and detector temperature—250 °C, oven temperature—120–240 °C with 4 °C/min, hold for further 7 min at 240 °C and carrier gas hydrogen, column head pressure 220 kPa, linear velocity (30–40) cm/s, flow rate 1.0 mL/min.

Mangiferin Quantification

Analytical grade standard of mangiferin was procured from Sigma–Aldrich Fine Chemicals (St. Louis, MO, USA). Standard was first prepared in methanol to maintain a concentration of 1 µg/mL. The standard curve for mangiferin quantification was plotted using concentrations of 1 ng/mL to 1 μg/mL. The sample was prepared as per Luo et al. (2012) with minor modifications. In brief, the MSK fine powder (0.5 g) was mixed with methanol (10 mL) followed by ultrasonication for 30 min at 40 °C. The sample was extracted thrice in 10 mL of methanol in the ultrasonicator for 30 min. All three extracts were combined followed by evaporation to dryness at 50 °C under the stream of nitrogen. The dried residue was dissolved in 5 mL of methanol, filtered through a 0.22-μm nylon filter and diluted 100 times before injection in LC-MS.

For quantification of mangiferin, the ESI probe was operated in negative ion scan mode on then QTRAP 4500 (Sciex) platform. The mass spectrometer parameters were optimized with a capillary temperature of 550 °C, curtain gas at 30 psi, ion source gas 1 (GS1) at 50 psi and GS2 at 50 psi with −4500 v. Nitrogen was used as curtain and collision gas. A standard of 1 μg/mL was infused at the flow rate of 10 μL/min in the mass analyser. The optimized de-clustering potential (DP) and entrance potential (EP) for detection of parent ion (421) was −11.5 and −4.8, respectively. The two most intense fragments (m/z) 421/300.7 (collision energy [CE]: −30 and collision cell exit potential [CXP]: −10) and 421/330.8 (CE: −28.54 and CXP: −30) were selected for MRM.

For chromatographic separation, an expert ultra LC-100xl series UPLC system (Eksigent, Dublin, CA, USA) equipped with a binary solvent pump, an auto-sampler and a column oven was used. Separation of mangiferin was carried out using an ACQUITY UPLC BEH C18 column (2.1 × 150 mm, 130 Å, 1.7-μm particle size; Waters) maintained at 40 °C in the column oven. The sample volume of 5 μL was injected through the UPLC.

Elution of mangiferin was optimized with an increasing gradient of 1000 ppm formic acid in each water (solution A) and methanol (solution B) sample. The mobile phase was delivered through a gradient elution of 20–50% of solution B over 2 min (flow rate = 0.5 mL/min) and then from 50% to 100% of solution B for 8 min (flow rate = 0.6 mL/min) and the column was re-equilibrated for 2 min (flow rate = 0.5 mL/min) with 20% of solution B. Data were recorded and analysed in Analyst (v. 1.6.2) software (AB Sciex, Framingham, MA, USA). A standard curve was obtained with linear regression (y = 2.1e + 007x + 1.88e + 005) and an r value of 0.99 to calculate the concentration of mangiferin in samples.

Data Analysis

To analyse the data, the amplicon size of the SSR marker was calculated manually. The number of alleles per locus, major allele frequency, gene diversity, heterozygosity and polymorphism information content (PIC) were calculated by Power marker v. 3.25. Neighbour-joining (NJ) clustering was carried out with DARwin 6.0 to construct a dendrogram. The biochemical data were analysed as per Chandel (1997). Quantification of amino acids and mangiferin were calculated using Analyst version 1.6.2 data acquisition software. Quantification was done by taking 1/x (x, area) as a weighting factor.

Results and Discussion

Molecular Diversity

Genetic Analysis Using SSR Markers

A reliable methodology for genetic diversity investigations is molecular characterization. The limitations (low polymorphism, few alleles, time-consuming, stressful, and germplasm environment interactions) of phenotypic data-based diversity analysis are overcome with the help of DNA marker data. Among various DNA markers, microsatellites or SSRs are preferred by plant geneticist due to the advantages such as high polymorphism information content (PIC), co-dominance behaviour, automation, single locus, etc. In the present investigation, the diversity in 32 mango varieties was assessed using SSR markers. During the screening step, 15 out of 20 primers were amplified successfully, of which eight were polymorphic (Table 1). Eventually, these polymorphic markers were exploited to evaluate inter-varietal diversity.

The amplicon size ranged from 125 bp (MMCA268) to 345 bp (MMCT138). The amplicon sizes were in the range reported earlier (Nazish et al. 2017). From 32 varieties, a total of 21 alleles were amplified with eight SSR primers. In a previous study, Singh et al. (2012) reported that the average number of alleles per locus is 3.47, which is higher than our results and this may be due to the use of a different set of SSR markers on varieties of more variability. The maximum allele frequency (0.9348) was found for marker MMCA49 and the minimum (0.6053) was found for MMCT5. Mean gene diversity was 0.3122. Maximum gene diversity of 0.4778 was found for MMCT5 and the minimum of 0.1219 was found for MMCA49. The mean PIC was 0.254 and ranged from 0.1145 (MMCA49) to 0.3648 (MMCA268), suggesting that markers of the current study have a low level of polymorphism. A low PIC (0.39) value was also recorded in Pakistani mango germplasm by Nazish et al. (2017). The variability in the germplasm affects the PIC and individual alleles for each marker. The heterozygosity ranged from 0.13 to 0.60 with a mean value of 0.31. Mango is a cross-pollinated tree species and conserves gene flow, which leads to heterozygosity. Gene diversity and heterozygosity had a minor difference and a moderately positive correlation (0.61), indicating that the germplasm is in Hardy–Weinberg equilibrium. Discrimination of mango varieties was possible through the use of SSR primers.

The unweighted neighbour-joining approach was used to calculate the pair-wise dissimilarity indices among mango types. With a mean of 0.49, dissimilarity coefficients ranged from 0.05 to 0.94 among 32 varieties. Minimum dissimilarity (0.05) was between ‘Badam’/‘Alphanso’, ‘Malgoa Lal’/‘Rajapuri’ and ‘Badam’/‘Nastota’. The maximum genetic divergence (0.94) was between the ‘Kesar’/‘Amrutang’, ‘Neelum’/‘Badshah Pasand’ and ‘Doodhpenda’/‘Badshah Pasand’. In their study, Begum et al. (2013) reported that the pair-wise genetic dissimilarities ranged from 0.00 to 0.46 with a mean value of 0.23 in different mango varieties. The clustering revealed three distinct groups among mango varieties at a 0.1 dissimilarity coefficient cut-off value. Cluster A had three varieties (‘Mahudha Gol Keri’, ‘Noorjahan’ and ‘Langro’); cluster B was generated with nine varieties (‘Badshah Pasand’, ‘Navrangi’, ‘Venkalia Aurangabad’, ‘Neelum’, ‘Kailash Rashulabad’, ‘Jujva Gol Keri’, ‘Gorjit Amalsad’, ‘Amrutang’ and ‘Kesar’). The largest group was cluster C, which included 20 varieties. This cluster was further divided into three sub-clusters (C1, C2 and C3). Based on the result obtained from the diversity analysis, the most popular and genetically diverse varieties of fruits available were selected for biochemical analysis (Fig. 1).

Biochemical Characterization

Moisture Content

The quality, taste and appearance of fruits and seeds are influenced by water/moisture content. Therefore, moisture is one of the most frequently evaluated parameters during the phytochemical analysis of seeds and fruits. In the current study, seed moisture varied from 22.24 (‘Badam’) to 24.00% (‘Neelum’; Table 2). Sagar and Singh (2016) reported that moisture content in MSK of Indian mango varieties was 43.22%. The moisture content in kernels depends on the maturity and quality. The moisture content of the seed determines the chemical stability and storage capacity of the seed.

Ash Content and Mineral Content

Compared to wheat flour, MSK flour contains 2–4 times more minerals (Kaur and Brar 2017). In the current study, ash content, an index of total mineral in MSK, varied from 0.87 (‘Langro’) to 1.62% (‘Mallika’) with an average of 1.15% (Table 2). These results are in close agreement with those of Rajan et al. (2011), where ash content in MSK powder was 1.72%. Recent studies suggested that MSK flour can be exploited to prepare mineral-fortified biscuits and cookies (Gumte et al. 2018). Consequently, MSK flour could be a growing source of functional food ingredient for the food/bakery industry, such as for biscuits and bread (Das et al. 2019). The mineral requirements by humans and plant are analogous. In view of the current interest in the mineral composition of MSK due to its influence on MSK flour quality, minerals were also assessed. In MSK of various mango varieties, substantial variability was observed for Fe (20.20–28.70 ppm), Mn (2.30–9.40 ppm), Zn (6.20–31.20 ppm) and Cu (19–106 ppm). ‘Rajapuri’, ‘Alphanso’, ‘Badam’ and ‘Neelum’ were recorded as a rich source of Fe, Mn, Zn and Cu, respectively.

Crude Protein Content and Amino Acid Profiling

Crude protein (CP) refers to the total amount of protein. Although MSK has less protein than cereals, it is of higher quality because it has a high amount of all the important amino acids (Jahurul et al. 2015). With an average value of 10.36%, CP in MSK varied from 8.10% (‘Amrutang’) to 12.07% (‘Neelam’) in the current study (Table 2). Previous studies indicated that MSK contains 5.20–8.10% CP (Lakshminarayana et al. 1983). The results of the current experiment were comparable to the results of Dakare et al. (2014), where CP was between 6.83% and 8.50%.

Amino acid profiling in the current study suggested that 18 amino acids (AAs) are present in mango seed, which are utilized in protein synthesis. Out of 18 AAs, eight were categorized as essential (isoleucine, methionine, phenylalanine, leucine, lysine, threonine, tryptophan and valine). Histidine and arginine are crucial in infants (Table 3; Supplementary Fig. S1). Earlier, Dakare et al. (2014) reported 17 different AAs in MSK with nine essential AAs. In the current study valine, threonine, leucine, isoleucine, and phenylalanine were found in higher amounts, which is in agreement with earlier reports on MSK (Fowomola 2010). The results indicated that variety ‘Mallika’ and ‘Neelum’ were lacking histidine, lysine and serine. This shows that the genetic makeup of genotypes is different. The regression and retention times of 20 amino acids in MSK are given in Supplementary Table S2.

Total Starch Content

Starch is not only a principal carbohydrate constituent of most plant materials but also an essential source of energy for the human body, metabolized into glucose during digestion. Starch has wide applicability in the food, textile, paper and pharmaceutical industries. The growing demand for starch by various sectors can be met by finding new starch sources other than potato and cereals such as corn and rice. In this context, MSK could be a suitable source of starch because it consists of up to 50% starch (Nayak and Rayaguru 2018). With a mean of 36.36%, the starch in MSK in the current study varied between 25.58% (‘Badam’) and 49.99% (‘Neelum’) (Table 2).

Crude Fibre

The crude fibre (CF) varied between 1.09% (‘Amrapali’) and 2.53% (‘Mallika’) among the varieties, although the average value of CF was 1.61% (Table 2). The outcomes of the current study are comparable with those reported by Mutua et al. (2017), where CF ranged between 2.64 and 3.71%. The CF in seed kernel and yellow corn is similar (Omer et al. 2019); hence, seed kernel-based cake can become a cost-effective animal ration for the dairy industry by replacing maize and other feed.

Total Oil Content

The pale yellow MSK oil has promising qualities and is a good source of micronutrients, i.e. sterol, tocopherol, and squalene (Jin et al. 2016). In a dry form, the MSK contains 7.1–15% crude fats (Jahurul et al. 2015). In Indian varieties, MSK oil ranged between 3.7% and 12.6% (Lakshminarayana et al. 1983). In the current study, with a mean of 9.23%, total oil content in MSK was found to vary from 4.16% (‘Amrapali’) to 14.40% (‘Badam’) (Table 2). These results are in agreement with the study by Jin et al. (2016), where MSK oil ranged from 5.65% to 11.14%. There are roughly 4–18 million tonnes of MSK available annually throughout the world, making it a potential raw material for a variety of lipid-based industries (Diarra 2014). The major fatty acids (Table 4) present in MSK were palmitic acid (0.22–2.61%), stearic acid (0.49–17.28%), oleic acid (2.20–33.25%), linoleic acid (0.39–4.5%), linolenic acid (0.03–0.33%), arachidonic acid (0.03–0.85%), behenic acid (0.01–0.22%), and lignoceric acid (0.01–0.4%). Yadav et al. (2017) reported on the optimization and extraction of oil from MSK. According to Yadav et al. (2017), stearic acid (58.08%), palmitic acid (1.33%), oleic acid (17.99%) and linoleic acid (2.86%) were the key fatty acids in MSK oil. MSK oil is rich in unsaponifiable matter; hence, MSK fat can be targeted in the cosmetics industry. As for amino acids, ‘Neelum’ exhibited a lack of behenic acid, lignoceric acid and linoleic acid.

Total Phenol Content

Several studies suggested that kernel is an excellent source of various phenols and antioxidants. Functional food and nutraceutical sectors are becoming more interested in MSK (Abdalla et al. 2007). The literature suggests that total phenolic contents in MSK ranged from 0.12% to 0.44% (Abdel-Aty et al. 2018). In the current study, the total phenol content in mango seed was found to range from 0.33% (‘Neelum’) to 0.54% (‘Badam’) (Table 2). The differences in total phenol among various studies might be due to environmental and edaphic conditions (stress conditions increase phenols) and the genetic makeup of cultivars. Studies indicated that MSK phenol inhibited protease, fibrinogens, haemolytic and haemorrhagic activities as well as the lethality of snake venom. Therefore, MSK phenolic compounds could be used by the pharmaceutical industry to manage viper venom (Abdel-Aty et al. 2018).

Mangiferin Content

Mangiferin, a xanthone, is a promising antioxidant bioactive compound in mango and has antiviral, anticancer, antidiabetic, antioxidative, antiaging, immunomodulatory, hepatoprotective and analgesic effects (Tayana et al. 2019). Mangiferin exists in 12 plant families, but members of the family Anacardiaceae and Anemarrhena are the primary sources of mangiferin. It has been reported that MSK is a good source of mangiferin. Several reports are available for the quantification of mangiferin content on various instrument platforms. The HPLC-based investigation of the mangiferin has been performed (Barreto et al. 2008; Tayana et al. 2019). The LC-MS/MS method is comparatively sensitive, solvent saving and quick to quantify sufficiently at low concentrations (Luo et al. 2012). In the present study, the limits of detection (LOD) and quantification (LOQ) for mangiferin were 5 and 15 ng/mL, respectively. Earlier, the amount of mangiferin in MSK from different cultivars was found to be between 0.05 and 6.5 mg/g (Barreto et al. 2008; Ribeiro et al. 2008). In the current study, total mangiferin content in mango seed varied from 0.27 to 4.88 mg/g DW with a mean of 1.55 mg/g (Table 2). The cultivar ‘Mallika’ had the highest mangiferin, whereas it was minimum in ‘Kesar’ (Supplementary Fig. S2). As a principal secondary metabolite that protects the plants against several (a)biotic stress, higher amounts of mangiferin were noted in the seed kernel. The outcomes of the current study are in agreement with Luo et al. (2012) who found that mangiferin content in MSK ranged from 0.14 to 2.43 mg/g DW.

Anti-Nutritional Factors (Phytate, Tannin and Trypsin Inhibitor)

Phytochemical analysis of MSK indicated that it is a good source of many food ingredients such as oil, protein, starch etc. Therefore, due to its high nutritional value, MSK is consumed as porridge in India. It is also widely known that anti-nutritional factors significantly affect the nutritional value of vegetables and fruits and reduce the usefulness of MSK as food and feed. The amount of anti-nutritional factor in MSK is given in Table 2 where phytic acid, tannin and trypsin inhibitor are 0.24 mg/100 g, 0.32 mg/100 g and 18.45 TIU/mg protein, respectively. The minimum phytic acid value was found in the variety ‘Kesar’ (0.193 mg/100 g), the lowest tannin was in ‘Neelum’ (0.225 mg/100 g) while trypsin inhibitor was the lowest in ‘Alphanso’ (16.986 TIU/mg protein). The smallest amount of anti-nutritional factor is suitable for consumption. Fowomola (2010) reported on nutrient and anti-nutrient contents of the kernel in Nigeria. The results of anti-nutrient analysis showed that MSK contains tannins (1.03 ± 0.01 mg/100 g) and phytate (1.44 ± 0.01 mg/100 g). Its trypsin inhibitor activity was 18.42 ± 2.54 TIU/mg protein. The trypsin inhibitor content was in agreement with that reported by Mishra et al. (2018), i.e. 18.36 TIU. Although tannins are anti-nutritional factors for humans, they play a vital role in plant defence mechanisms, especially against insect attack. Tannin is a potent antioxidant and has anti-carcinogenic and anti-mutagenic effects. According to Dhingra and Kapoor (1985), tannins can be removed by soaking the MSK three times in hot water (80 °C) for 20 min. In the current study, tannin was 20 times lower than in tamarind seeds (20.10 mg/100 g; Mishra et al. 2018).

The current study revealed that the ‘Langro’ variety exhibited the higher amount of histidine, valine, threonine, leucine, lysine, serine and tyrosine. By contrast, the ‘Dashehari’ variety was rich in fatty acids such as palmitic, stearic, linolenic and arachidonic acid as well as amino acids, namely glutamic acid, glutamine and alanine. The highest levels of the bioactive component mangiferin and ash content were recorded in ‘Mallika’. The ‘Badam’ variety can be exploited by industries for edible oil.

Conclusion

Mango is one of the most important tropical fruits in the world. Processing of mango by the food industry generates peel and kernel as waste by-products. Instead of dumping, the seed can be processed to harvest starch, fat, protein, fibres and many other secondary metabolites especially mangiferin. The current study suggested that mango seed kernel (MSK) with high oil and mangiferin content contained in the variety ‘Badama’ and ‘Mallika’, respectively, can be important raw material for many industries. The results of this study support the idea that the growing problem of seed kernel management can be resolved through utilization of MSK by the food, pharmaceutical, and feed industries (livestock and poultry). The MSK flour can be exploited to increase the nutritional value of food supplements.

References

Abdalla AEM, Darwish SM, Ayad EHE, El-hamahmy RM (2007) Egyptian mango by-product 1. compositional quality of mango seed kernel. Food Chem 103:1134–1140

Abdel-Aty AM, Salama WH, Hamed MB et al (2018) Phenolic-antioxidant capacity of mango seed kernels: therapeutic effect against viper venoms. Rev Bras Farmacogn 28:594–601

American Association of Cereal Chemists (AACC) (1983) Approved methods of the AACC, 8th ed., American Association Cereal Chemists, St. Paul, MN, USA

Ashoush IS, Gadallah MGE (2011) Utilization of mango peels and seed kernels powders as sources of phytochemicals in biscuit. World J Dairy Food Sci 6:35–42

Association of Official Analytical Chemists (AOAC) (1965) Official methods of analysis, 10th edn. AOAC, Washington, DC.

Barreto JC, Trevisan MT, Hull WE et al (2008) Characterization and quantitation of polyphenolic compounds in bark, kernel, leaves, and peel of mango (Mangifera indica L.). J Agric Food Chem 56(14):5599–5610

Bazina N, He J (2018) Analysis of fatty acid profiles of free fatty acids generated in deep-frying process. J Food Sci Technol 55(8):3085–3092

Begum H, Reddy MT, Surapaneni M, Narshimulu G, Reddy BP (2013) Microsatellite analysis of intracultivar diversity in ‘Chinnarasam’ mango from Andhra Pradesh, India. Afr Crop Sci J 21(2):109–117

Bray HG, Thorpe WV (1954) Analysis of phenolic compounds of interest in metabolism. Methods Biochem Anal 1(27):52

Chandel SRS (1997) A handbook of agricultural statistics. Achal Prakashan Mandir, Kanpur, India

Da Silva A, Jorge N (2014) Bioactive compounds of the lipid fractions of agroindustrial waste. Food Res Int 66:493–500

Dakare MA, Danladi AA, Agbaji AS, Atawodi SE (2014) Chemical composition and antinutrient contents of yellow maize, raw and processed composite mango (Mangifera indica L.) seed kernel from Zaria, Kaduna State Nigeria. Int J Adv Res 2(7):90–97

Das PC, Khan J, Rahman S, Majumderd S, Islam M (2019) Comparison of the physico-chemical and functional properties of mango kernel flour with wheat flour and development of mango kernel flour based composite cakes. NFS Jl 17:1–7

Dhingra S, Kapoor AC (1985) Nutritive value of mango seed kernel. J Sci Food Agri 36:752–756

Diarra SS (2014) Potential of mango (Mangifera indica L.) seed kernel as a feed ingredient for poultry: a review. Worlds Poult Sci 70:279–288

Doyle JJ, Doyle JL (1990) A rapid DNA isolation procedure for small quantities of fresh leaf tissue. Phytochem Bull 19:11–15

Dubois M, Gills K, Hemilton J, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356

El-safy FS, Salem RH, Abdel-ghany ME (2012) Chemical and nutritional evaluation of different seed flours as novel sources of protein. World J Dairy Food Sci 7(1):59–65

Fowomola MA (2010) Some nutrients and antinutrients contents of mango (Magnifera indica L.) seed. Afr J Food Sci 4(8):472–476

Gumte SV, Taur AT, Sawate AR, Kshirsagar RB (2018) Effect of fortification of mango (Mangifera indica) kernel flour on nutritional, phytochemical and textural properties of biscuits. J Pharmacog Phytochem 7(3):1630–1637

Hammerstrand GE, Black LT, Glover JD (1981) Trypsin inhibitor in soy products: modification of the standard analytical procedure. Cereal Chem 58:42–45

Harborne JB (1973) Phytochemical methods. Chapman and Hall, London, pp 49–188

Imran M, Arshad MS, Butt MS, Kwon JH, Arshad MU, Sulta MT (2017) Mangiferin: a natural miracle bioactive compound against lifestyle related disorders. Lipids Health Dis 16:84

Jahurul M, Zaidul I, Ghafoor K et al (2015) Mango (Mangifera indica L.) by-products and their valuable components: a review. Food Chem 183:173–180

Jin J, Warda P, Mu H, Zhang Y, Jie L et al (2016) Characteristics of mango kernel fats extracted from 11 china-specific varieties and their typically fractionated fractions. J Am Oil Chem Soc 93(8):1115–1125

Kaur A, Brar JK (2017) Use of mango seed kernels for the development of antioxidant rich health foods. Food Sci Res J 8(2):368–374

Kittiphoom S (2012) Utilization of mango seed. Int Food Res J 19(4):1325–1335

Koji M, Satoshi S, Hisao K (1987) Measurement of tryptophan in peptides by acid hydrolysis in the presence of phenol and its application to the amino acid sequence of a sea anemone toxin. Agri Biol Chem 51:1607–1616

Lakshminarayana G, Chandrasekhara RT, Ramalingaswamy PA (1983) Varietal variations in content, characteristics and composition of mango seeds and fat. J Am Oil Chem Soc 60(1):88–89

Lane CS (2015) Rapid LC-MS/MS Analysis of free amino acids in extracellular matrix. biomarkers and omics. Document number: RUO-MKT-02-3777‑A, pp 17–19

Luo F, Lv Q, Zhao Y, Hu G, Huang G, Zhang J, Sun C, Li X, Chen K (2012) Quantification and purification of mangiferin from chinese mango (Mangifera indica L.) cultivars and its protective effect on human umbilical vein endothelial cells under H2O2-induced stress. Int J Mol Sci 13:11260–11274

Mahato AK, Sharma N, Singh A, Srivastav M, Singh SK, Singh AK, Sharma TR, Singh NK (2016) Leaf transcriptome sequencing for identifying genic-SSR markers and SNP heterozygosity in crossbred mango variety Amrapali (Mangifera indica L.). PLoS One 11(10):e164325

Makkar HPS, Blummel M, Boroway NK, Becker K (1993) Gravimetric determination of tannins and their correlations with chemical and protein precipitation methods. J Sci Food Agri 61:161–165

Mishra R, Prasad R, Verma A (2018) Nutritional composition, anti-nutritional factors and antioxidant activity of waste seeds (Mango seeds and Tamarind seeds). J Pharmacog Phytochem 7(3):1078–1080

Mutua JK, Imathiu S, Owino W (2017) Evaluation of the proximate composition, antioxidant potential, and antimicrobial activity of mango seed kernel extracts. Food Sci Nutr 5(2):349–357

Nayak P, Rayaguru K (2018) Studies on extraction of starch from dried and fresh mango seed kernel. J Agric Sci 10(18):7192–7195

Nazish T, Shabbi G, Ali A, Naeem M, Javed M, Batool S, Hussain S, Aslam K, Seher R, Tahir M, Baber M (2017) Molecular diversity of Pakistani mango (Mangifera indica L.) varieties based on microsatellite markers. Genet Mol Res 16(2):gmr16029560

Omer HAA, Tawila MA, Gad SM et al (2019) Mango (Mangifera indica) seed kernels as untraditional source of energy in Rahmani sheep rations. Bull Natl Res Centre 43:176

Rajan S, Surya D, Vijaya P, Prabhu K, Thirunalasundari T (2011). Pharmacognostical and phytochemical studies of Mangifera indica L. seed kernel. J Pharmacy Res 4(11):4272–4275

Rashwan MRA (1990) Fatty acids composition, neutral lipids and phospholipids fractionation in the kernel lipids of the mango varieties. Assiut Jf Agri Sci 21(1):105–117

Ribeiro SMR, Barbosa LCA, Queiroz JH et al (2008) Phenolic compounds and antioxidant capacity of Brazilian mango (Mangifera indica L.) varieties. Food Chem 110:620–626

Sadasivam S, Manickam A (1992) Biochemical methods for agriculture sciences. Wiley Eastern, New Delhi

Sagar A, Singh RP (2016) Biochemical estimation of nutritive parameters in waste seed kernel of mango (Mangifera indica L.). Int J Agril Invent 1(1):113–115

Saran P, Kumar R (2011) Boron deficiency disorders in mango (Mangifera indica): Field screening, nutrient composition and amelioration by boron application. Ind J Agri Sci 81(6):506–510

Saran P, Rajput KS, Meena RP et al (2020) Mango (Mangifera indica L.) germplasm screening against Burl: effect on plant morphology and graft-incompatibility and orchard topography in India. Erwerbs-Obstbau 62:315–325

Singh A, Singh AK, Singh SK (2012) SSR markers reveal genetic diversity in closely related mango hybrids. Ind J Horti 69(3):299–305

Tayana N, Inthakusol W, Duangdee N, Chewchinda S, Pandith H, Kongkiatpaiboon S (2019) Mangiferin content in different parts of mango tree (Mangifera indica L.) in Thailand. Songklanakarin J Sci Tech 41(3):522–528

Yadav K, Garg N, Verma A, Trivedi M (2017) Optimization and extraction of oil from mango seed kernel (Mangifera indica). Indian J Agric Sci 87:943–946

Acknowledgements

The authors would like to thank Anand Agricultural University for providing the laboratory facility during the experiments.

Author information

Authors and Affiliations

Contributions

Conceptualization of the research (NJP, SK); designing of the experiments (SDP, JJD); execution of field/laboratory experiments and data collection (SDP, AAS, SK, NJP); analysis of data and interpretation (SK, AAS, NJP); preparation of manuscript (SDP, SK, AAS).

Corresponding author

Ethics declarations

Conflict of interest

S.D. Patel, N.J. Patel, A.A. Sakure, S. Kumar and J.J. Dhruv declare that they have no competing interests.

Supplementary Information

10341_2022_759_MOESM2_ESM.docx

Supplementary Figures S1–S3. Supplementary Figure S1: LC-MS based amino acid profile of MSK powder, Supplementary Figure S2: LC-MS chromatograms of mangiferin for MSK powder

Rights and permissions

Springer Nature oder sein Lizenzgeber hält die ausschließlichen Nutzungsrechte an diesem Artikel kraft eines Verlagsvertrags mit dem/den Autor*in(nen) oder anderen Rechteinhaber*in(nen); die Selbstarchivierung der akzeptierten Manuskriptversion dieses Artikels durch Autor*in(nen) unterliegt ausschließlich den Bedingungen dieses Verlagsvertrags und dem geltenden Recht.

About this article

Cite this article

Patel, S.D., Patel, N.J., Sakure, A.A. et al. Detection of the Potential of Seed Kernel for Food Industries Through Biochemical Evaluation of Diverse Mango Cultivars. Erwerbs-Obstbau 65, 2427–2436 (2023). https://doi.org/10.1007/s10341-022-00759-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10341-022-00759-7