Abstract

A specific, robust, and rapid UV-HPLC method was developed for the assay of daclatasvir (DCV) in pharmaceutical formulation in the presence of potential degradation products using quality-by-design approach. The impurity profile of DCV was studied via forced degradation procedures with subsequent characterization of the resultant degradation products using LC–MS. Central composite design with response surface methodology was utilized to simultaneously optimize four chromatographic factors: pH, elution temperature, flow rate, and organic modifier %. The first order, interaction, and quadratic effects of those four factors were evaluated for 16 responses of eight peaks “resolution (7), number of theoretical plates (8), run time (1)”. Optimum separation was achieved using Eclipse plus RP C18 column, mobile phase consisting of methanol: 0.025 M phosphate buffer pH 7.0 (58: 42 v/v), flow rate of 1.5 mL min−1at 40 °C, and detection at 303 nm. The optimized method was validated according to ICH guidelines and applied to determine DCV in pharmaceutical formulation. DCV response was linear (r = 0.9999) in the range 1.5–90 µg mL−1; inter-day and intra-day precisions were 0.28% and 0.25%, respectively, and independent t test indicated non-significant difference between inter- and intra-day means; accuracy was 100.49 ± 0.92%.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

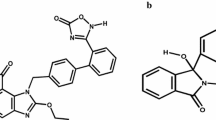

Approximately 170 million people worldwide are chronically infected with the hepatitis C virus (HCV) [1] which can lead to cirrhosis, liver failure, hepatocellular carcinoma, and liver transplantation [2]. HCV is a small, enveloped, single-stranded RNA virus belonging to the Flaviviridae family, while, NS5A, a zinc-binding and proline-rich hydrophilic phosphoprotein, plays a crucial role in HCV RNA replication [3, 4]. Daclatasvir (DCV) is a potent NS5A replication complex inhibitor with demonstrated antiviral activity in HCV genotype 1 patients when co-administered with peginterferon and ribavirin [5]; fortunately, its pharmacokinetic profile supports one-daily dose [6]. DCV is commercially supplied as daclatasvir dihydrochloride salt which is a white-to-yellow powder, slightly hygroscopic with poor solubility in water; aqueous solubility is inversely proportional with pH. According to IUPAC system, DCV (Fig. 1) is methyl ((1S)-1-(((2S)-2-(5-(4′-(2-((2S)-1-((2S)-2-((methoxycarbonyl)amino)-3-methylbutanoyl)-2-pyrrolidinyl)-1H-imidazol-5-yl)-4-biphenylyl)-1H-imidazol-2-yl)-1-pyrrolidinyl) carbonyl)-2-methylpropyl) carbamate dihydrochloride.

Although DCV is non-pharmacopoeial, several LC methods were developed for its determination using conventional leave-one-out method development approach. Literature contains several HPLC methods for determination of DCV: non-stability indicating methods [7,8,9], stability indicating methods (SIM) [10,11,12,13], and methods for application in plasma [2, 14,15,16,17]. Here, we discuss brief examples of published SIM that claim specificity and robustness. Baker et al., have developed a stability indicating method (SIM) for DCV in the presence of forced degradation products; however, DCV was slightly retained to 5 min, specificity and robustness of peak area, and retention time were indicated through peak purity and by change in peak area, retention time (≤ 3.85%), respectively [11]. However, development of UV-HPLC method with DCV retention of 2.6 min, 2.3 min, and 1.8 min. Sumathi et al. [10], Othman et al. [12], and Ashok et al. [7] have declared specificity and robustness. However, Ashok et al. declared insensitivity of DCV to forced degradation [7]; Kekan et al., Othman et al. [12], and Sumathi et al. [10] indicated the significant degradation toward forced degradation with relatively similar conditions. Although Gholve et al. [18] indicated photo instability of DCV, its photolytic stability was repeatedly reported in rest of literature [7, 11]. The most of previously published works share one or more of major drawbacks. First, they had indicated specificity only via decrease in peak area of DCV for forced degradation solutions compared to equi-molar standard solution without insight on degradation products resolution. Second, robustness of those methods is minimally discussed or studied. Third, retention of DCV in most of the published methods including stability indicating ones was too short which alert questions about specificity of those methods. Fourth, optimization via leave-one-out approach does not account for interaction between factors, it provides limited information about responses in a given experimental domain, and it is a non-structured framework which leads to large number of experiments needed to optimize such multivariate processes.

Literature contains redundant publications utilizing quality-by-design and experimental design approaches in diverse applications [19,20,21,22,23]. Analytical quality-by-design (AQbD) was applied in development of chromatographic [24,25,26,27,28,29,30], spectrophotometric, mass spectrometric [21, 22], and capillary electrophoretic [31] methods. The major advantage in using a multivariate approach to optimize an analytical method is maximization of knowledge gained with respect to number of experiments done. Furthermore, interactions between parameters can be investigated with multivariate experiments, which would be impossible to do with a leave-one-out approach [32]. Response surface methodology (RSM) was developed by Box and Collaborators in the 50s [33]. This term was originated from the graphical perspective generated after fitness of the mathematical model [34]. As one of the popular response surface designs, central composite design (CCD) can be used to investigate the relationship between one or more responses from one side and experimental factors from other side, it permits estimation of the coefficients of the main factors, interactions, and second-order terms, i.e., it can model polynomial response surfaces up to second order.

As the chromatographic process is a multi-response technique with conflicting goals, Derringer’s desirability function (DDF) for multi-criterion optimization (an objective function ranges from zero outside limits to one at the target) can be employed to optimize such process. This function searches for a combination of factor levels that jointly optimize a set of responses by satisfying the requirements for each response in the set. To do so, it transforms the measured properties to a dimensionless desirability scale for each response, so that values of several responses, obtained from different scales of measurement, may be combined [35]. The desirability scale ranges between d = 0, corresponding to a completely undesirable level of quality, to d = 1, which indicates an ultimate level of quality beyond which further improvements would have no value [36]. Concisely, the optimization is accomplished via calculating the individual desirability for each response; define the geometric mean of the individual desirability to obtain the composite desirability (D), and finally by maximizing the composite desirability and identifying the optimal factor settings [32].

The main objective of this work was to develop and validate a specific and robust stability indicating HPLC method for determination of DCV in the presence of potential degradation products inferred from forced degradation studies. To achieve this objective, a CCD combined with RSM and DDF were utilized to study the experimental domain and to simultaneously optimize 16 dependent variables using four independent chromatographic variables.

Experimental

Materials

Daclatasvir dihydrochloride (99.69%) was supplied by Orchid Pharmaceuticals, (Orchid Pharma Ltd., Tamil Nadu, India). All reagents used were of analytical grade, solvents were of HPLC gradient grade. Methanol (Labscan analytical sciences, Gliwice, Poland); Potassium dihydrogen phosphate and sodium hydroxide (E. Merck, Darmstadt,Germany); purified water, ≤ 17.3 MΩ cm [Milli-Q purification system (Branstead, USA)].

Instruments

An Agilent 1200 HPLC system (Agilent technologies, Santa Clara, California, USA) equipped with Quaternary Pump (Agilent LC 1200, model G1311A); UV-DAD (Agilent LC 1200, model G1315); Autosampler (Agilent LC 1200, model G1329A); Eclipse plus RP C18 column 100 × 4.6 mm, 3.5 µm particle size (Agilent technologies, Santa Clara, California, USA); 0.45 μm nylon Millipore membrane filter. Chemstation software for LC systems: Rev B.03.01. Experimental design, data analysis, modeling, and desirability calculations were performed by Design expert software package Version 9.0.0 (Stat-Ease Inc., Minneapolis, Minnesota, USA).

Standard Solutions

A stock standard solution 600 µg mL−1 of DCV was prepared by dissolving 60 mg of DCV in solvent mixture (methanol:water, 1:1, v/v). A working standard solution 60 µg mL−1 of DCV was prepared by dilution of stock standard solution in the same solvent.

Pharmaceutical Formulation

A pharmaceutical formulation of daclatasvir 30 mg tablet, Andodacla BN.17102015 (Al-andalous pharmaceuticals, Egypt).

Preparation of Degradation Products

Into a series of 50 mL conical flask, 15 mL from 10 mg mL−1 DCV in solvent, was diluted to 30 mL using; 0.1 M sodium hydroxide; 0.1 M hydrochloric acid; 5% hydrogen peroxide, and then, each solution was refluxed for 2 h at 80 °C. The resultant degradation solutions were neutralized with suitable solvent, if any, and injected in HPLC in semi-preparative way; where fractions were collected to obtain the major degradation products in pure form. Photodegradation was assessed by exposing similar solution of DCV to UV chamber equipped with 254/365 nm lamps for 6 h. Finally, a development mixture was made via mixing different aliquots according to concentration of previously separated degradation products with DCV to prepare a single solution containing well-detected amounts of each compound.

Chromatographic Conditions

Chromatographic separation was conducted, using Eclipse plus RP C-18 column (100 mm × 4.6 mm, 3.5 µm), using methanol:phosphate buffer 0.025 M, pH 7.0 (58:42, v/v) as a mobile phase which was degassed and filtered through a 0.45 mm nylon membrane filter. Detection wavelength was 303 nm; elution was operated with flow rate 1.5 mL min−1 at 40 °C.

Experimental Design and Derringer’s Desirability Function

A typical analytical quality-by-design (AQbD) methodology was employed. During optimization step, a CCD with six replicates at center point and total 30 runs was used to optimize four chromatographic factors “methanol %, pH, flow rate, elution temperature” by mapping the response surface of multi-criteria chromatographic responses of “retention time of last eluted peak, number of theoretical plates (N), and resolution of each chromatographic peak”. The core of optimization process is the definition of individual desirability function for each individual attribute of the chromatographic response according to the predefined analytical target profile as described earlier in introduction section, followed by definition of composite desirability as a function of method factors that can be easily maximized, Design expert software was utilized to handle mathematical modeling and desirability optimization.

Method Validation

The optimized method was validated as per the ICH Q2 (R) guidelines for following parameters: Specificity, linearity, accuracy, precision, limit of detection (LOD), and limit of quantitation (LOQ) [37]. After robustness has been built in method through development, it has been assessed within the design space.

Specificity and System Suitability

Specificity has been indicated through injection of placebo solution (blank formula extracted in methanol:water, 1:1, v/v), DCV fortified degradation mixture in the same solvent. For system suitability determination, a solution consists of DCV and seven degradation products were used. Six replicate injections of this solution were analyzed. From these replicate injections, the asymmetry factor, resolution, number of theoretical plate, and retention time of last eluted peak were studied.

Linearity

Stock standard solution (600 µg mL−1) of DCV was further diluted with solvent mixture to obtain seven solutions in the ranges of 1.5–90 µg mL−1. Column was equilibrated with mobile phase before injection, 10.0 µL injections on duplicate base were chromatographed for each solution. The peak areas were regressed against the corresponding concentrations and the regression parameters for DCV were calculated.

Precision

Precision of the developed method was evaluated by performing repeatability, six replicate sample preparations (60 µg mL−1 of DCV); whereas the intermediate precision study was performed by repeating another six different sample preparations with similar concentration on different day by different analyst. For each data set, the recoveries were calculated and percent relative standard deviation (% RSD) was calculated. In addition, a statistical testing of significant difference in mean recovery of the two data sets was evaluated using independent t test, via comparing calculated t value with critical t value0.05 2.228. Statistical comparison of significant difference in variance between data set was assessed by F test and the calculated F value was compared to critical F value0.05 (5.05 at df1 = 5, df2 = 5).

Accuracy

The DCV standard in the range of 50%, 100%, and 150% of the sample’s concentration (60 µg mL−1) was separately mixed with placebo solution to prepare three final concentrations of 30, 60, and 90 µg mL−1, the same process has been performed in triplicate and the resulting solutions were chromatographed using the optimized method and then recoveries were calculated. One-sample t test was used to test significance of difference between the grand mean and 100%, via comparing calculated t value with critical t value0.05 2.306.

Assay of Pharmaceutical Formulation

Ten tablets were grinded into fine powder, mix, and then, an amount of the powder equivalent to 60 mg DCV was transferred into 100-mL volumetric flask, and dissolved in solvent. A 5.0 mL aliquot of the previous solution was transferred into 50-mL volumetric flask, and the volume was made up using the solvent, and then chromatographed.

Results and Discussion

The pharmaceutical industry is constantly facing increasing expectations of taking suitable measures to ensure the specificity and robustness of the analytical procedures. Therefore, the current work will illustrate and discuss the successive use of statistical and mathematical tools to develop specific and robust analytical HPLC method for DCV in presence of possible degradation products.

Specificity is one of the most crucial properties of any analytical procedure, yet it is the hardest to be achieved. In development phase, very limited amount of information is always available including stability related part. Unfortunately, it is hard to claim knowledge of exact real degradation pathways for a pharmaceutical product unless accelerated and long-term stability studies have been conducted. Therefore, forced degradation studies were presented as an alternative to gain some knowledge about possible degradation pathways; however, the space of degradation products (DPs) resulted from such studies is very large and may or may not include the real degradation products, but it still widely acceptable approach. Although realistic degradation products is more likely to be obtained with relatively mild degradation conditions; it is hard to define mild degradation conditions as it depends on the drug. However, we acclaim that mild degradation procedure is the one that produces minor detachment/alteration of terminal groups. Mild degradation could be inferred practically from spectral characteristics of DP relative to that of parent drug, where the more similar the spectral profile, the more probable the DP to fall in the space of realistic DPs and vice versa.

Robustness is another fatal property of a given analytical procedure, and it requires great awareness during development of the procedure. Unless response is affected by on factor or interactions of underlying factors are not suspected; robustness is not achievable with ordinary univariate method development and optimization especially, when factor interaction is suspected as the case in chromatographic process. From chromatographic point of view, robustness should be built for crucial responses like resolution between different peaks, efficiency of separation rather than peak area or retention time which we think about as of less importance. We acclaim that development of specific and robust method by definition infers precision and if linearity of response is assured; confidently, successful validation could be expected.

Forced Degradation Study

A mild degradation process for DCV was performed to generate realistic degradation products. A forced degradation study using photolytic, alkaline, acid, and oxidative conditions was applied to DCV, with fractions of major degradation products (DPs) for each stress pathway collected chromatographically in a semi-preparative way. However, the studies revealed photolytic stability of DCV; seven major DPs were observed: Two alkaline, one acid, and four oxidative degradation products. Previous DPs were outsourced for external facility to suggest an identity using LC–MS for these compounds. The suggested degradation products are summarized in Table 1; for more information, please refer to supplementary data.

For an alkaline hydrolytic pathway, two different major degradation products were observed with m/z of 681.3 and 581.9, respectively. Figure 2 illustrates a proposed degradation pathway, appearance of m/z 681.3 suggested the loss of –CH2 (− 14) followed by loss of CO2 (− 44). This can be achieved by hydrolysis of one of the terminal ester bonds followed by decarboxylation of the resulted carboxylic acid producing degradation product OH2 (C38H48N8O4). The second degradation product (581.9) may indicate the hydrolysis of one of the amide bonds where three amide bonds exist in OH2, the only possible hydrolysis to yield loss of a fragment whose mass is 99 is the hydrolysis of the amide bond linked to a pyrrolidine ring resulting in second alkaline degradation product OH1.

In the acid hydrolysis process, a single degradation product with molecular mass of 452.6 was observed. This suggested that the two amide bonds linked to the pyrrolidine rings were hydrolyzed resulting in the core structure (C26H28N6). This hydrolysis was followed by condensation reaction with residual methanol, resulting in an observed mass of 452.6 corresponding to the acid degradation product (H-1). A proposed acid hydrolytic pathway was illustrated in Fig. 3.

The highly water soluble n-oxides are possible products of the reaction between H2O2 and tertiary amino moieties in DCV; n-oxides may further undergo n-dealkylation reaction. Due to the presence of primary and secondary amine moieties in DCV hydroxyl amines, products may be another possible products of the reaction. The process of oxidative degradation resulted in four major products OX-1–OX-4 with molecular mass of 479, 513, 490, and 560, respectively. In general, the oxidative degradation products were the least chromatographically retained among all degradation products indicating high aqueous solubility relative to hydrolytic degradation products. The product of the mass 479 (OX-1) was the least retained, which may be explained by the formation of n-oxide. The other three products (OX-2, OX-3, and OX-4) were of moderate retention suggesting the lack of n-oxides. Figure 4 illustrates the suggested chemical structures of the oxidative degradation products.

According to the captured online spectra Fig. 5, obviously UV spectral profiles of DPs are very close to that of DCV which means according to our definition for mild degradation that those DPs are highly probable to be realistic degradation products. Unfortunately, unless specificity is chromatographically built through method development; method may be still nonspecific due to the fact that peak purity calculations may conclude erroneous purity due to the high spectral similarity between degradation products and DCV. Previous issue becomes of major concern if DCV is not chromatographically retained enough or if the resolution robustness was not considered enough in method development as the case in most of previously published works.

Chromatographic Optimization

For optimizing a chromatographic method for separation of DCV and its degradation products, typical quality-by-design procedure was implemented where an analytical target profile and critical quality attributes (CQAs) were initially defined. Next, a central composite design (CCD) was implemented to model different responses and then identifying a design space followed by desirability mapping of the previously identified design space and finally define optimum parameters and control space. The analytical target profile was made to maximize specificity, accuracy, sensitivity, reproducibility, and robustness for the analytical method. The studied chromatographic CQAs were resolution, number of theoretical plates, and run time with predefined values of NLT 1.5, NLT 2000, and NMT 15 min, respectively.

In the current work, factors like chromatographic column and organic modifier types were studied in univariate mode. Preliminary experiments reveled that C-18 column type was superior to C-8 and phenyl columns in terms of efficiency and selectivity, methanol was superior to acetonitrile as organic modifier in terms of efficiency; therefore, we concluded to use C-18 column and methanol. Detection wavelength optimization was based on chromatographing the solution of degradation products using diode array detector (DAD), where λ = 303 was optimum for DCV and most DPs.

On the other hand, method parameters like methanol percentage (MeOH %), buffer pH, flow rate, and elution temperature were studied in multivariate way using four-factor CCD as described in Table 2. Analysis of the chromatographic responses resulted from application of the proposed CCD experiments resulted in construction of 16 four-dimensional (4D) response polygons in 5D space, one for each response. The common intersection space of those 4D-response polygons at which all CQAs are satisfied constituted a 4D design space (4D-DS). In general, some responses were mathematically transformed before modeling to meet the normality assumption of residuals. The quality of the fitted models were evaluated by applying the analysis of variance (ANOVA) [34], p values of all fitted models were below 0.05 indicating significant models, adjusted R2 were between 0.999 and 0.801, and finally, the obtained high adequate precision values indicate good signal-to-noise ratio.

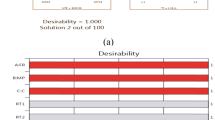

The chromatographic optimization is a multi-criterion problem, in which a compromise between conflicting goals should be found such as maximizing resolution, number of theoretical plates while minimizing the run time [36]. Desirability function is a beneficial tool to optimize such multi-criterion response, where different importance and weight values were assigned to each response according to the relative importance from chromatographic point of view. The desirability of the 4D-DS was mapped by applying the desirability function; Fig. 6 depicts six different perspectives of the 4D design space polygon.

The inspection of the design space results in selection of the highest desirability region to be the control space of the method; the normal operation values of chromatographic factors were methanol: phosphate buffer 0.025 M, pH 7.0 (58:42, v/v) at elution temperature of 40 °C, and flow rate of 1.5 mL min−1. Application of the optimum parameters illustrated in Table 3 resulted in base line well-resolved peaks with appropriate peak asymmetry, and number of theoretical plates in a reasonable run time of about 12 min, as shown in Fig. 7.

Regarding instantaneous and convenient troubleshooting purposes of such complex relationship between method parameters and different responses, we have used perturbation plots to fully and rapidly describe the system. However, for building deeper knowledge, readers are encouraged to review graphs in supplementary data. Perturbation plots are a beneficial tool to compare the effect of all factors at a particular point in the design space, and it is plotted by changing only one factor over its range while holding of the other factors constant. The sign and magnitude of the slope for lines or curves in perturbation plots determine the relation between different factors and given response. High positive slope indicates strong direct effect of studied factor on the response; low negative slope indicates minor inverse effect of studied factor on the response. The effects of method parameters on some selected critical responses at optimum parameters are illustrated in perturbation plots Fig. 8. In general, an inverse proportionality between N and flow rate for all analytes was observed (Fig. 8a–d) indicating mass transfer-controlled chromatographic behavior. Figure 8e shows that resolution of OH-1 was inversely proportional to methanol % and flow rate which could be counteracted by the effect of pH and elution temperature, while Fig. 8f demonstrates that pH and elution temperature to less extent poses a directly effect on resolution of H-1 which may be opposed by the effect of flow rate. Figure 8g indicates that methanol % and pH were found to have predominant inverse relationship with resolution of OH-2, while elution temperature and flow rate were of minor effects on resolution of OH-2. Finally, in Fig. 8h, retention time (tR) of DCV as an indicator of total runtime was found to be inversely related to methanol %, pH and to less extent to elution temperature.

The objective of this work was achieved by development of an optimized method that satisfies the predefined values for CQA regarding DCV and DPs. The method was then validated according to the ICH guidelines [37]. Validation and robustness assessment results are summarized in Tables 4, 5, and 6 which indicate that previous objective was successfully achieved. The method was successfully applied for determination of DCV in pharmaceutical formulation; where the results are summarized in Table 7.

Conclusion

AQbD approach was successfully implemented and resulted in specific, robust analytical method that could confidently deliver the intended performance. The HPLC method was capable to simultaneously determine DCV in the presence of seven potential degradation products, and it was validated according to ICH guidelines in addition to robustness assessment within the design space. AQbD is useful, especially in a multi-factor chromatographic process with multi-criterion multi-response outcomes. The construction of hyper-dimensional design space in addition to definition of control space ensures the robustness of the proposed method in addition to flexible method transfer and troubleshooting. The perturbation plots and gif type animations presented in supplementary data illustrating the hyper-dimensional design space afford a straight forward but deep troubleshooting guidance for method performance.

References

Mohamed AA et al (2015) Hepatitis C virus: a global view. World J Hepatol 7(26):2676

Jiang H, Kandoussi H, Zeng J, Wang J, Demers R, Eley T et al (2015) Multiplexed LC-MS/MS method for the simultaneous quantitation of three novel hepatitis C antivirals, daclatasvir, asunaprevir, and beclabuvir in human plasma. J Pharm Biomed Anal 107:409–418

Tellinghuisen TL, Marcotrigiano J, Gorbalenya AE, Rice CM (2004) The NS5A protein of hepatitis C virus is a zinc metalloprotein. J Biol Chem 279(47):48576–48587

He Y, Staschke KA, Tan SL (2006) HCV NS5A: a multifunctional regulator of cellular pathways and virus replication. In: Tan SL (ed) Hepatitis C viruses: genomes and molecular biology, chap 9. Horizon Bioscience, Norfolk

Fontana R, Hughes E, Bifano M, Appelman H, Dimitrova D, Hindes R et al (2013) Sofosbuvir and daclatasvir combination therapy in a liver transplant recipient with severe recurrent cholestatic hepatitis C. Am J Transplant 13(6):1601–1605

Pol S, Ghalib RH, Rustgi VK, Martorell C, Everson GT, Tatum HA et al (2012) Daclatasvir for previously untreated chronic hepatitis C genotype-1 infection: a randomised, parallel-group, double-blind, placebo-controlled, dose-finding, phase 2a trial. Lancet Infect Dis 12(9):671–677

Chakravarthy VA, Sailaja B (2016) Method development and validation of assay and dissolution methods for the estimation of daclatasvir in tablet dosage forms by reverse phase HPLC. Eur J Pharm Med Res 3:356–364

Satyanarayana L, Sandeepthi N (2018) The estimation of daclatasvir in tablet dosage form by RP-HPLC. Int J Pharma Res Health Sci 6(1):2212–2215

Dandamudi SP, Battineni JK, Bakshi V, Peddapalli H, Boggula N (2018) Validated RP-HPLC method for estimation of daclatasvir in tablet dosage form. Int J Adv Res Dev 3(2):1170–1174

Sumathi K, Thamizhvanan K, Vijayraj S (2016) Development and validation of stability indicating RP-HPLC method for the estimation of daclatasvir in bulk and formulation. Pharm Lett 8(15):107–113

Baker M, El-Kafrawy D, Mahrous M, Belal T (2017) Validated stability-indicating HPLC-DAD method for determination of the recently approved hepatitis C antiviral agent daclatasvir. Elsevier, Amsterdam, pp 176–184

Ragab GHA, Saleh H, Othman MA (2017) Stability indicating HPLC method development and validation for determination of daclatasvir in pure and tablets dosage forms. INDO Am J Pharm Sci 3:1565–1572

Zaman B, Hassan W (2018) Development of stability indicating HPLC–UV method for determination of daclatasvir and characterization of forced degradation products. Chromatographia 81(5):785–797

Nannetti G, Messa L, Celegato M, Pagni S, Basso M, Parisi SG et al (2017) Development and validation of a simple and robust HPLC method with UV detection for quantification of the hepatitis C virus inhibitor daclatasvir in human plasma. J Pharm Biomed Anal 134:275–281

Aboshabana R, Shalan S, Eid M, El-Enany N (2018) Two validated spectrofluorimeteric and high performance liquid chromatography (HPLC) methods with fluorescence detection for the analysis of a new anti-hepatitis C drug, daclatasvir hydrochloride, in raw material or tablet form and in biological fluids. Luminescence 33(8):1333–1345

Atia NN, El-Shaboury SR, El-Gizawy SM, Abo-Zeid MN (2018) Simultaneous quantitation of two direct acting hepatitis C antivirals (sofosbuvir and daclatasvir) by an HPLC-UV method designated for their pharmacokinetic study in rabbits. J Pharm Biomed Anal 158:88–93

Abdallah OM, Abdel-Megied AM, Gouda AS (2018) Development and validation of LC-MS/MS method for simultaneous determination of sofosbuvir and daclatasvir in human plasma: application to pharmacokinetic study. Biomed Chromatogr 32(6):e4186

Kekan V, Gholve S, Bhusnure O (2017) Development, validation and stability study of UV spectrophotometric method for determination of daclatasvir in bulk and pharmaceutical dosage forms. Int J Chemtech Res 10:281–287

Schweitzer M, Pohl M, Hanna-Brown M, Nethercote P, Borman P, Hansen G et al (2010) Implications and opportunities of applying QbD principles to analytical measurements. Pharm Technol 34(2):52–59

Huang J, Goolcharran C, Ghosh K (2011) A quality by design approach to investigate tablet dissolution shift upon accelerated stability by multivariate methods. Eur J Pharm Biopharm 78(1):141–150

Jadhav ML, Tambe SR, Girase MV. Analytical quality by design approach for development of uv spectrophotometric methods in the estimation of trospium chloride from capsule dosage form. Int J Pharm Pharm Sci. 2014;6(10)

Wang L, Chen T, Zeng S, Qu H (2014) Quality by design study of the direct analysis in real time mass spectrometry response. J Am Soc Mass Spectrom 25(2):278–285

Raman N, Mallu UR, Bapatu HR (2015) Analytical quality by design approach to test method development and validation in drug substance manufacturing. J Chem 2015:1–8

Krull I, Swartz M, Turpin J, Lukulay PH, Verseput R (2008) A quality-by-design methodology for rapid LC method development, part I. LCGC N Am 26:1190–1197

Krull I, Swartz M, Turpin J, Lukulay PH, Verseput R (2009) A quality-by-design methodology for rapid LC method development, part II. LCGC N Am 27:48–61

Ling V, McBrien MM (2011) A quality by design approach to chromatographic method development. LCGC Column 7:16–20

Vogt FG, Kord AS (2011) Development of quality-by-design analytical methods. J Pharm Sci 100(3):797–812

Karmarkar S, Garber R, Genchanok Y, George S, Yang X, Hammond R (2011) Quality by design (QbD) based development of a stability indicating HPLC method for drug and impurities. J Chromatogr Sci 49(6):439–446

Ayre A, Mane P, Ghude K, Nemade M, Gide P (2014) Implementing quality by design—a methodical approach in the RP-HPLC method development process. Int J Adv Pharm Anal 4(1):01–06

Gad M, Zaazaa HE, Amer SM, Korany MA (2017) Quality by design approach for establishment of stability indicating method for determination of Cefditoren Pivoxil. J Pharm Anal Insights 2(1)

Lin Y-H, Yang Y-H, Wu S-M (2007) Experimental design and capillary electrophoresis for simultaneous analysis of arbutin, kojic acid and hydroquinone in cosmetics. J Pharm Biomed Anal 44(1):279–282

Ragonese R, Macka M, Hughes J, Petocz P (2002) The use of the Box–Behnken experimental design in the optimisation and robustness testing of a capillary electrophoresis method for the analysis of ethambutol hydrochloride in a pharmaceutical formulation. J Pharm Biomed Anal 27(6):995–1007

Gilmour SG (2006) Response surface designs for experiments in bioprocessing. Biometrics 62(2):323–331

Bezerra MA, Santelli RE, Oliveira EP, Villar LS, Escaleira LA (2008) Response surface methodology (RSM) as a tool for optimization in analytical chemistry. Talanta 76(5):965–977

Derringer G (1980) Simultaneous optimization of several response variables. J Qual Technol 12:214–219

Bourguignon B, Massart D (1991) Simultaneous optimization of several chromatographic performance goals using Derringer’s desirability function. J Chromatogr A 586(1):11–20

ICH Harmonized Tripartite Guideline (2005) Q2B validation of analytical procedures: methodology. Switzerland, Geneva

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Gad, M., Hassan, S.A., Zaazaa, H.E. et al. Multivariate Development and Optimization of Stability Indicating Method for Determination of Daclatasvir in Presence of Potential Degradation Products. Chromatographia 82, 1641–1652 (2019). https://doi.org/10.1007/s10337-019-03793-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10337-019-03793-y