Abstract

Modern biomass and organic waste are becoming major, carbon-neutral sources of fine chemicals, biomolecules and fuels to replace fossil fuel products. As a consequence, there is a strong demand for advanced separation techniques to purify biomolecules occurring in complex mixtures, because actual downstream processing accounts for a major part of the overall cost. Here we review the mechanism, methods and applications of three-phase partitioning. Methods include macroaffinity ligand-, metal ion-, enzyme-, ultrasound-, ionic liquid- and microwave-assisted partitioning. Applications to the purification of recombinant and conjugated proteins, enzymes, carbohydrate polymers, lipids and pigment are presented. Three-phase partitioning precipitates biomolecules from aqueous solutions using t-butanol and ammonium sulphate. This technique is applicable for both upstream and downstream with unrefined samples, and downstream, when a simple and scalable step is required. The yield of the biomolecules reaches 90% and higher, and the maximum purification degree is 12–40-fold. Three-phase partitioning allows about 70% of potential savings over standard chromatographic procedures.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Environmental concerns are prominent due to the rising use of fossil fuels and the resulting air pollution. Since fossil fuels have been the primary energy source, a considerable amount of CO2 gases has been released into the atmosphere, resulting in the greenhouse effect and acid rain (Kaloudas et al. 2021). Therefore, finding alternatives to fossil fuels is considered essential. Due to its low cost, renewability, global availability and CO2 cyclability, biomass, a significant industrial commodity and the fourth largest energy source on earth, offers considerable potential to be employed as an efficient and environmentally friendly energy supplement (Xia et al. 2022). The amount of carbon dioxide released by burning biomass is similar to that of burning fossil fuels (Hassan et al. 2020).

Furthermore, an advancement in the heterologous expression of the prokaryotic and eukaryotic systems and fabrication of innovative bioreactors enhances the upstream process of ever-increasing volumes of biomolecules from biomass expressing high product titres. These processes require the proper development of separation techniques at downstream stages to isolate and purify the desired product from scores of other compounds such as metabolic products, precursors, unused substrates and cell debris present in the fermentation broth. Simultaneously, the biological activity of proteins, enzymes, nucleic acids, cell organelles, antibiotics and antigens must be preserved up to the last step. Since many biomolecules have a narrow tolerance range of pH, temperature, osmotic pressure and surface charges, proper selection of extraction and isolation technique is specific and reconcilable to the product. The extraction and separation technique should involve a minimum number of steps because around 80% of the costs of biological processes is spent on downstream processing (Wong et al. 2017).

Due to the developments in molecular biology over the last two decades, growing demand for proteins and enzymes has also emphasized economical, scalable and coherent techniques (Gupta and Roy 2021). The various bioseparation techniques can be classified into chromatographic and non-chromatographic techniques, which outweigh one another in one or more aspects. Chromatographic techniques, which may be based on membrane affinity, hydrophobic interaction or ion exchange, provide more precise resolution, but are often more expensive and difficult to scale up than non-chromatographic approaches. There have recently been several unique approaches in non-chromatographic procedures to aid the increasing requirement for large-scale enzyme and protein production, which are mostly based on affinity separation or precipitation (Rather and Gupta 2013).

Gupta and Roy with their co-workers established the detailed procedure of novel technique three-phase partitioning for the separation and purification of the biological molecules along with applications (Gupta and Roy 2021). They have separated various enzymes and oil from plant and microbial extracts and also developed the extensive of three-phase partitioning technique with macroaffinity ligand. Gupta (2021) elaborates the reasons for the utilization of the three-phase partitioning not only in the separation of proteins also in the extraction of other biological molecules which include enzymes, polysaccaharides, antioxidants, phytochemicals, pigments and also DNA. Rathod and his co-workers also utilized the three-phase partitioning for the extraction of biomolecules such as enzymes and antioxidant from the plant extracts and also integrated three-phase partitioning with another techniques which includes macroaffinity, enzyme-assisted, metal ion-assisted, ionic liquid-, microwave- and ultrasound-assisted three-phase partitioning (Patil & Rathod, 2021). Yan et al. (2018) reported the detailed review for the implementation of three-phase partitioning for the extraction and separation of numerous bioactive compounds, which have been abundantly used in the food and medical industries, and to comprehend the specific partitioning rule.

This review focuses mainly on one such relative technique: three-phase partitioning. The third phase, or middle layer, is formed in systems with water, t-butanol, proteins and ammonium sulphate when shaken and centrifuged. This simple separation technique has immense application in laboratories due to their short processing time. Apart from simplicity, the technique is also less expensive and mild and can be evaluated on the crude solution at room temperature, making the process expedient and compact. This paper also aims to update the application of the three-phase partitioning for the extraction and purification of all the biomolecules which include proteins, enzymes, polysaccaharide, phytochemicals, pigments, oils and antioxidant.

Three-phase partitioning

Three-phase partitioning is a fast-emerging refined bioseparation technique that integrates a biomolecule's concentration and partial purification steps of downstream processing. The methodology depends on the capacity of salt-like ammonium sulphate to partition an apparently miscible t-butanol–water combination into two phases: lower aqueous and upper organic phases. An intermediate protein layer forms when this procedure is performed in the presence of protein, allowing the protein to be removed (Fig. 1). In most cases, three-phase partitioning is used as a 'dewatering' step that is used to concentrate proteins up to 100X from even as low as 0.2 to 1% protein crudes (Yan et al. 2018).

Variants and applications of three-phase partitioning. Conventional three-phase partitioning uses ammonium sulphate and t-butanol for the precipitation of proteins and carbohydrates in the crude solution at the interface. The diverse variants of this conventional technique are the macroaffinity ligand-facilitated three-phase partitioning (MLFTPP), metal ion-assisted three-phase partitioning, enzyme-assisted three-phase partitioning (EATPP), ultrasound-assisted three-phase partitioning (UATPP), ionic liquid-based three-phase partitioning (ILTPP) and microwave-assisted three-phase partitioning (MTPP)

The removal of t-butanol and ammonium sulphate from precipitated proteins in the aqueous two-phase extraction is significantly simpler than the subsequent steps in aqueous two-phase extraction, which are more complex. Additionally, t-butanol is only 10% and 50% of the cost of dextran and polyethylene glycol, respectively, making three-phase partitioning a reliable, inexpensive technique suitable for large-scale applications. Three-phase partitioning has often been described as a combination of salting out and alcoholic precipitation which was generally used as a preliminary step to eliminating a great number of other proteins from the mixture. As outlined by, for the purification of enzymes from crude extract, the influence of this technique has widened to include many other biomolecules (Koyande et al. 2021; Sonar and Rathod 2020).

The application of three-phase partitioning is constrained and prevents the prediction of the behaviour of unknown systems and optimization of compound isolation due to a lack of knowledge of the mechanism of protein separation in the interphase, the driving forces and the controlling factors of the fundamental processes of three-phase partitioning. For example, the results of experiments proved a direct dependence of partitioning and interfacial activity on the hydrophobicity of the protein, assisting one in predicting the efficacy of three-phase partitioning for any protein whose hydrophobic character is completely known. The outcome of studies has shown that in addition to parameters such as pH, isoelectric point (pI), temperature, charge, hydrophobicity, protein concentration, solubility and denaturation of the protein, density differences and interfacial tension in the protein-free, two-phase system also impacts on the amount of protein partitioned from crude extracts (Sarkar et al. 2020).

Another significant feature is the formation of the t-butanol-protein complex, which floats as the central portion contrasting with the sedimentation of protein precipitates in the typical salting out method (Yan et al. 2018; Roy and Gupta 2021). A conceptual understanding of the underlying phenomenon is essential to designing an efficient system. Three-phase partitioning can be seen as a selective interfacial partitioning separation technique, in which separation is effectuated through the partitioning of particles in water/t-butanol/ammonium sulphate two-phase systems, leading to the formation of the third phase (gel-like disc) between the two liquid phases (Roy and Gupta 20212021). According to evaluations, three-phase partitioning is done in the presence of ammonium sulphate for a variety of reasons (Dennison 2012.

Mechanism

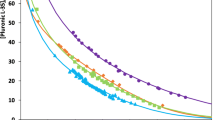

Ternary phase diagrams have been used as a habitual tool to depict the acceptable composition of water, t-butanol and ammonium sulphate in two-phase systems. The effect of partitioning system composition on protein separation was investigated using model systems comprising lysozyme, bovine serum albumin, gelatin and ovalbumin. Both ovalbumin and bovine serum albumin were found to have 70–80% protein yield in the midlayer in systems with decreased tie lines (and lower interfacial tension), whereas those with longer tie lines, which also means an increased interfacial tension, more ammonium sulphate and tert-butanol, resulted in a highest relative amount of protein. Nonetheless, lower interfacial tension (10—0.1 mN.m−1) provides a mild condition for protein precipitation, which may also contribute to the preservation of the enzyme activity (Sonar and Rathod 2020). Sarkar et al. (2020) employed common proteins with established physicochemical qualities to monitor their behaviour under different three-phase partitioning circumstances. The findings demonstrated an inverse connection between the quantity of salt needed to precipitate a protein and their molecular weight.

Another important observation is that the relative amount of protein in the middle phase was unaffected by the initial protein concentration in the system. Even systems with other salts, such as magnesium sulphate or sodium chloride, were found to have the same effect on protein concentration. Additionally, the subsequent application of three-phase partitioning to the lower and upper phases, after the removal of the midlayer, was shown to follow the same partitioning ratio and eventually increase the effectiveness of protein accumulation. These results demonstrate the partitioning character of three-phase partitioning. The experiment also displayed a direct dependency of partitioning and interfacial activity of the proteins on their hydrophobicity, thereby reflecting on the hypothesis of interfacial adsorption as a reason for interface layer formation. Due to a large interfacial area and low interfacial tension (1.0–5.0 mN m−1), increased precipitation might well have created the midlayer of great macroscopic extension (Gupta and Roy 2021).

The protein disc at the interface was evidently a physical gel since no chemical reaction takes place between the added components, which includes tert-butanol and ammonium sulphate at the stable temperature and the mild conditions at which three-phase partitioning is performed, thus giving rise to a network of proteins at the interface from purely physical bonds. The quantitative and mechanical characterization of the gel was performed with bovine serum albumin and ovalbumin as the model proteins. Gels are characterized by the three-dimensional cross-linked network of particles which may be macromolecules or colloids. The protein-stabilized emulsion gel is a type of particle gel that is composed of protein-coated droplets aggregated in a liquid that is immiscible with the interior of the droplets. The middle phase was found to contain about 80–95% liquid and less than 10% protein content. Additionally, the middle phase in the systems with bovine serum albumin underwent a larger compression during centrifugation than those in systems with ovalbumin (Rather and Gupta 2013).

The salt content of the gel phase was correlated with the salt content of the initial system and was seen to be inversely proportional (Okur et al. 2017). On the other hand, precipitated protein concentration seemed to be independent of the initial protein concentration, yet again disproving the established thought and proving the partitioning nature of three-phase partitioning (Sarkar et al. 2020). In addition, in most of the systems investigated, the composition of the middle phase was clearly seen to represent a heterogeneous system, which could indicate the presence of two liquid phases. This was proved by separation and centrifugation of the gel, which led to the separation of the liquid into two phases whose composition, upon analysis, was found to correspond to the lower and upper phases of the partitioning system of three-phase partitioning. This observation served to support the hypothesis that the protein gel was indeed made of particle gel in which the emulsion droplets were wrapped in surface-adsorbed protein.

Three-phase partitioning has been proved to induce subtle structural changes in the proteins during partitioning (Pereira et al. 2022). The network-forming proteins in the emulsion gel thus undergo partial unfolding and conformational changes at the interface, which, in turn, can be detected by the application of stress. The hardening of the gel was seen after compression, and gel was also tougher in systems with increased interfacial tension. As predicted, new interparticle interactions were anticipated to emerge as a result of compression. Further, a reduction in gel reversibility and an increase in viscosity due to structural changes in the gel were also seen with increasing stress. The nature of the protein and the presence of disulphide bonds influenced the elastic behaviour of the gel.

From the analytical and the stress–deformation studies, a probable mechanism that could explain formation of middle phase in three-phase partitioning was designed. According to this, the mixing all the system components leads to forming two immiscible phases at the interface which forms an emulsion. Two processes that simultaneously occur at the interface at this point are the coalescence of emulsion droplets and increasing rigidity of the interfacial layer that prevents coalescence. Equilibrium is attained when the two balance each other, giving a stable middle phase between the two immiscible phases. This mechanism greatly substantiates the hypothesis of emulsion gel. A high value of interfacial visco-elasticity is thought to enhance the two processes that contribute to the stability of the middle phase (Rather and Gupta 2013).

The nature of the middle phase was brought to light by studying the effects of various factors on the interfacial shear rheological behaviour. The system with the highest salt concentration and hence the highest polarity difference between the upper and lower phases, interfacial tension and ionic strength in the aqueous phase showed the longest lag time for the measurement of both elasticity and viscosity. The rate of growth of elasticity and viscosity is another measure of the dynamic changes at the interface, including adsorption, unfolding, cross-linking and rearrangement. As expected, systems with high visco-elastic behaviour and with high salt content showed a constant rate of growth of elasticity in contrast to those with low salt concentration, which exhibited a decreased rate of growth of elasticity after about 5 h.

Protein concentration and nature also seemed to affect the interfacial rheological parameters. Systems with proteins of low molecular weight and high concentration showed less lag time and high values of elasticity and viscosity, which kept increasing with time. On the other hand, the elasticity and viscosity of systems with low protein concentration reached a steady state after some time. Furthermore, when proteins were close to their solubility limit, the visco-elastic behaviour was less than expected, mainly due to the compact conformation of the aggregated molecules, which reduces their tendency to unfold and contribute to the elasticity and viscosity (Yan et al.2018). Interfacial shear rheological behaviour was also found to be depending on the protein's nature itself. Mixing was found to have a large impact on interfacial rheology.

Though the general trend and dependence on protein concentration and salt concentration remained unchanged, mixed systems exhibited a reduced lag time, a higher value of elasticity and viscosity and attainment of quasi-constant values. These were found to be in accordance with the viscosity and elasticity behaviour examined by the uniaxial compression of protein gels. This suggests that emulsification is a crucial stage of three-phase partitioning. A study of the dependence of the interfacial rheology on shear rate or frequency of oscillation revealed that with increasing frequency, the loss modulus decreased, and the deformation was reversible even after the application of the highest possible shear rate.

Microscopic imaging was the next tool used to govern the formation of the middle phase and their relationship with the interfacial properties. Emulsification resulted in the dispersion of droplets from the upper phase to the lower phase. The size distribution of the droplets was found to be independent of the protein concentration. With time, the number of droplets per unit area in the middle layer increased while their mobility decreased. As the aggregation and coalescence of droplets increased further, their shape was distorted owing to the high interfacial visco-elasticity and low interfacial tension, thus leading to form stable emulsion gel in the middle layer of three-phase partitioning.

Structural changes induced by three-phase partitioning

Three-phase partitioning is known for enhancing the catalytic activity of the enzyme that gets separated in the interphase. Though many concepts such as electrostatic forces, conformation tightening, kosmotropy and protein hydration shifts have been put forth to be responsible for the positioning of the proteins in the middle layer (Dennison 2012) and for the subsequent behavioural changes, a substantial contribution is reported to come from the structural changes that the three-phase partitioning induces in the enzyme (Pereira et al. 2022). The determination of crystal structure of three-phase partitioning-treated serine proteinase, proteinase K, by X-ray diffraction at 1.5 Å resolution is a pioneer study towards this (Choonia and Lele et al. 2013). This study revealed several points of importance: the absence/displacement of water molecules from the substrate biding site and the presence of two acetate ions: one at the active site and the other at the surface of the molecule. While the former mimics the job of two water molecules by occupying the oxyanion hole and interacting with histidine 69 and serine 224, thus contributing to enzyme activity and stability, the latter is presumed to be involved in the enzyme's local structure. The higher value of B factor for the three-phase partitioning-treated enzyme indicates their excited state.

Atoms with large B-factors generally indicate greater vibrational motion and resulting flexibility of the part. As a result, the three-phase partitioning-treated proteinase K appears to be more rapid than the crude enzyme. However, the overall structure was maintained, and the hydrogen bonding of the catalytic triad remained intact. This leads to the notion that the structural change in the three-phase partitioning-treated enzyme was not very drastic (Rather and Gupta 2013a). In their research, they investigated the secondary structure contents, thermal stabilities, surface hydrophobicity, hydrodynamic radii and ammonium sulphate solubility.

α-Amylases derived from three different sources were utilized to study the effect of flexibility on enzyme activity. Only a marginal increase was observed in specific activity of the three amylases, thus indicating non-dependency of the activity on the conformational flexibility and nature of the enzyme types. The addition of amylase with protease in the soaking step itself may result in optimal dehairing and fibre opening without any significant damage to collagen (Khambhaty 2020). The decrease in the activity of β-galactosidase was attributed to their oligomeric nature. Due to their shorter half-lives, all of the enzymes became thermolabile due to the three-phase partitioning addition. This could possibly be due to the removal of stabilizing compounds of the enzyme along with other impurities of the crude extract during separation, thus making the interface-partitioned enzymes less stable. No standard pattern was observed in the changes in the secondary structure is generally quenched by neighbouring serine residues. Three-phase partitioning induces a conformational change that moves tryptophan a little farther, thus decreasing quenching partially, resulting in the appearance of absorbance at 360 nm. A decrease in absorbance of porcine α-amylase may be indicative of either burial of tryptophan or their bonding with other residues on the surface. The unfolding of proteins is generally reflected in increased surface hydrophobicity and changes in hydrodynamic radii. Except in subtilisin Carlsberg, no unfolding was indicated in any other protein from changes in surface hydrophobicity. In terms of hydrodynamic radii, porcine α-amylase, β-galactosidase, subtilisin Carlsberg and bovine serum albumin showed marginal decrease while no change was evident in the others. This indicates structural changes of a very subtle nature. Three-phase partitioning-treated enzymes generally showed higher solubility, for instance, α-chymotrypsin at 10% ammonium sulphate.

One possible reason is the exposure of more cationic sites of the three-phase partitioning-treated α-chymotrypsin, thus reducing the ammonium sulphate–water interaction with the simultaneous increase in protein–water interaction. Thus, the solubility curves of untreated and three-phase partitioning-treated enzymes exhibited high differences. In addition, three-phase partitioning has been used earlier for refolding proteins (Pereira et al. 2022). This is clear evidence of a change in the structure of enzymes from their native state. The efficiency of an enzyme is inversely related to its rigidity. Refolding and the subtle structural changes proved here thus may be correlated with the enhanced biological activity of the enzymes.

Variants of three-phase partitioning

Macroaffinity ligand-facilitated three-phase partitioning

Adding an affinity-based phase to three-phase partitioning, which was previously a non-selective procedure, has improved overall selectivity (Roy and Gupta 2021). Macroaffinity ligand-facilitated partitioning was established as a specific protein separation method that integrates the twin resolving power of affinity precipitation with three-phase partitioning, which tends to result in a greater separation and purification of the protein of interest from the crude mixture. This technique that could be viewed as a simultaneous three-phase partitioning of a polymer and a protein consists of two essential steps: binding of the protein with a suitable smart polymer and precipitation of the polymer–protein complex as an interfacial layer after exposure to a t-butanol and ammonium sulphate mixture.

Polymer selected in this case is a water-soluble, three-phase partitioning-separable smart polymer (reversibly soluble–insoluble polymers that are stimuli-responsive and show a specific affinity to the target protein or enzyme) (Goldring 2021). Earlier works with affinity precipitation have shown the possibility of designing water-soluble polymers with specific selectivity by incorporating suitable affinity ligands into three-phase partitioning. Hence, this technique is not limited by the availability of water-soluble polymers with an inherent affinity towards chosen target protein and therefore is quite generic in the application. For direct protein precipitation in macroaffinity ligand-facilitated partitioning, both naturally occurring polymers (e.g. alginate, chitosan and j-carrageenan) and synthetic polymers (e.g. methylmethacrylates) have been utilized. The potential use of chitosan nanoparticles as carriers has paved the way for the development of wide variety of colloidal delivery vehicles. Chitosan nanoparticles can cross biological barriers to protect macromolecules from degrading in biological media (Divya and Jisha 2017).

The main advantages of macroaffinity ligand-facilitated partitioning thus include low cost, high selectivity, ease in scaling up and elimination of preclarification of crude extract. Macroaffinity ligand-facilitated partitioning has also been used in the simultaneous conformational changes and extraction of urea-denatured pectinase and a wide collection of recombinant proteins beginning from solubilized inclusion bodies (Gautam et al. 2012b). The corresponding studies use the point of ignition for the employment of macroaffinity ligand-facilitated partitioning for these applications. Macroaffinity ligand-facilitated partitioning proved to be more efficient than AP in many aspects. In spite of advantages, macroaffinity ligand-facilitated partitioning still continues to be an underexploited bioseparation technique which may be possibly due to the lack of knowledge about smart polymers and their affinity for proteins and enzymes.

Metal ion-assisted three-phase partitioning

Immobilized metal affinity chromatography (IMAC) is a prominent separation approach that takes advantage of natural proteins that contain histidine, cystine and tryptophan residues' affinity for metal ions such as Cu2+, Zn2+ and Ni2+. The presence of surface histidine residues in soybean trypsin inhibitors enables its purification via metal affinity techniques. Conventional three-phase partitioning of soybean trypsin inhibitor from soybean meal gave an interfacial precipitate of only fourfold purification. With the help of the dialyzed aqueous phase of the three-phase partitioning to a second cycle in the presence of suitable volumes of CuSO4 and ZnCl4 instead of ammonium sulphate. This resulted in a 12-fold purification and 66% recovery in the presence of Zn2+ and 13-fold purification and 72% recovery in the presence of Cu2+ions.

A similar protocol was used in evaluating the metal affinity-based three-phase partitioning for the purification of turnip peroxidase in the presence of Cu2+. These works demonstrate that the selectivity of metal ions in pushing proteins out of the aqueous phase operates only in the ‘three-phase partitioning environment’. For example, direct precipitation with 2.0 mM Cu2+ gave only twofold purification of protein. Two major disadvantages of the chromatographic technique are the requirement of a preprocessing step for crude suspensions to avoid column fouling and difficulty in scaling up. This metal affinity-based three-phase partitioning overcomes these disadvantages apart from being more selective than conventional three-phase partitioning, thus demonstrating a high potential for purifying industrially important enzymes in large volumes more conveniently. This strategy will also prove valuable for the purification of recombinant proteins, which are produced as fusion proteins with polyhistidine tags and are currently purified by IMAC (Gagaoua et al.2018).

Enzyme-assisted three-phase partitioning

Three-phase partitioning was first described as an alternative for oil extraction from soybean. The variant of three-phase partitioning in which the oil-bearing seeds are pretreated with enzymes gave rise to a scalable extraction procedure which is novel and simple (Ewunie et al. 2021). The addition of specific enzymes during extraction was considered valid given the well-established fact that oil bodies in plants are found in a meshwork of proteins, cellulose and hemicellulose structures and was found to enhance the oil recovery in the aqueous extraction process. The process was, thus, suitably named enzyme-assisted partitioning and involves the addition of appropriate amounts of t-butanol and ammonium sulphate (w/v) to an aqueous suspension of homogenized oil-bearing seeds pretreated with enzymes. In contrast to the soxhlet extraction approach, which takes roughly 24 h, the protein appears as an interfacial precipitate between the upper t-butanol layer/phase containing oil and the lower aqueous phase within 1–2 h under optimum conditions (Ewunie et al. 2021).

The oil extracted in the organic solvent phase can subsequently be recovered by evaporating the t-butanol in a rotary evaporator at reduced pressure. The various advantages of the enzyme-assisted aqueous extraction approach and their economics are applicable to enzyme-assisted partitioning as well. But enzyme-assisted partitioning involves using a more efficient solvent which is t-butanol. t-Butanol has a greater boiling point of 84 °C than hexane (69 °C), which is also the commonly used solvent for solvent extraction. Thus, even if open systems are used, the addition of volatile organic compounds to the environment would be significantly lower. The latter aspect would allow for easier extraction process design. The higher freezing point of t-butanol compared to hexane also serves in their favour, as cooling uses much less energy than evaporation. Aside from that, both enzyme-based procedures allow for the simultaneous recovery of oil and protein from most oilseeds, and the process generates oil of high quality to satisfy codex standards.

The need for further procedures is minimized since the methods enable the quick removal of some toxins or antinutritional substances from particular oil seeds. Thus, the successful development of enzyme-based processes enables achieving some of the requisites for an efficient oil extraction process, such as being cost-effective, environmental and safety concerns, lower energy consumption and nutrition issues. The economics of enzyme-assisted oil extraction have been previously compared with solvent-based extraction. If market rates for product oil are high, the enzyme-assisted oil extraction process can compete well with the conventional way; furthermore, if immobilized (reusable) versions of the enzyme are utilized, recycling the enzyme can significantly lower the price. Enzyme-assisted partitioning has so far been monitored for oil extraction from Jatropha curcas seeds (Ewunie et al. 2021), mango kernel, soybean, rice bran and Spirogyra sp. (Reddy and Majumder 2014), oleoresin from turmeric (Das et al. 2021) and forskolin from Coleus forskohlii (Marathe et al. 2019).

While the inclusion of the ultrasonication pretreatment step in the enzyme-assisted partitioning protocol was found to enhance the extraction of the oils (Reddy and Majumder 2014; Ewunie et al. 2021), yield of forskolin was observed to improve just minimally when compared to enzymatic treatments alone (Marathe et al. 2019). Currently, enzymes' high cost is a major factor that prevents the acceptance and adoption of these technologies. However, growing environmental concerns, combined with the development of more effective downstream processing technologies for enzymes, are expected to make this a viable technology for oil extraction in the future (Govindarajan et al. 2016).

Ultrasound-assisted three-phase partitioning

A relatively novel and less explored technique is the ultrasound-assisted variant of three-phase partitioning. Ultrasound has long been found to increase the yield and mass transfer in many solid–liquid extraction processes for the extraction of different phytochemicals (Rokhina et al. 2009; Xia et al. 2012), biocatalysis, adsorption and bioremediation processes. Ultrasonic irradiation is unique from other conventional energy sources in exposure, pressure and energy per molecule and duration. The immense local temperatures and pressures, and the extraordinary heating and cooling rates generated by collapse of cavitation bubbles provide an unusual mechanism for generating high-energy chemistry (Gude and Martinez-Guerra 2018). These clearly have demonstrated the advantages of ultrasound irradiation-assisted mass transfer enhancement and as well have summarized the principle. Major works employing this ultrasound-assisted partitioning are the extraction of ursolic acid and oleanolic acid from Ocimum sanctum (Vetal et al. 2013), a fibrinolytic enzyme from Bacillus sphaericus (Avhad et al. 2014), extraction of oil from almond, apricot and rice bran, extraction of oil from Jatropha curcas L. seed kernels, astaxanthin recovery from Paracoccus sp. (Chougle et al. 2014), mangiferin extraction from Mangifera indica leaves palmitic acid (Kulkarni and Rathod 2014) and elaidic acid from Cassia sophera Linn (Mondal et al. 2015) and extraction of algal oil from Spirogyra sp. (Reddy and Majumder 2014).

Of these, ultrasound treatment of an optimized three-phase partitioning system was performed for the extraction of the ursolic acid, oleanolic acid (Vetal et al. 2013), fibrinolytic enzyme (Avhad et al. 2014), mangiferin (Kulkarni and Rathod 2014), palmitic acid and elaidic acid (Mondal et al. 2015). Ultrasonication, in these cases, works on the principle of formation, growth and implosive collapse of vapour cavities or bubbles, the liquid-free zones that work in alternate expansion and compression cycles. Effects of ultrasonication frequency, power, time and duty cycle on the three-phase partitioning system were evident when enhanced % recovery and purity fold were considered (Vetal et al. 2013; Avhad et al. 2014). Increased mass transfer due to ultrasonication implies a reduced process time.

Ultrasonication has also been used as a pretreatment step before three-phase partitioning for oil extraction from almond, apricot and rice bran (Chougle et al. 2014), Jatropha curcas L. seed kernels (Ewunie et al. 2021) and Spirogyra sp. (Reddy and Majumder 2014) and forskolin extraction from the roots of Coleus forskohlii (Marathe et al. 2019). These analyses revealed a considerable impact on overall oil yield. Only 2 min of ultrasonication (in the case of almond) or 4 and 6 min (in the case of apricot and rice bran, respectively) resulted in an improvement through oil yields of 87, 77 and 88 wt% in the case of almond, apricot and rice bran, respectively, and a jatropha oil yield of up to 97%. When extracting oils, it is necessary to be conscious of ultrasonication's impacts, namely heat creation. External characteristics such as vessel base-to-probe distance, vessel volume and shape, and biomass particle size were also investigated. A comparison of ultrasound-assisted partitioning with ultrasound treatment, three-phase partitioning and conventional solvent extraction demonstrated ultrasound-assisted partitioning as the maximum efficient technique (Chougle et al. 2014). Thus, ultrasound-assisted partitioning displays enhanced purity with a higher % recovery of enzymes and other compounds in a short operation time as compared to the conventional three-phase partitioning.

Ion liquid-assisted three-phase partitioning

Ionic liquids possess a large number of extraordinary characteristics such as low vapour pressure, low combustibility, high thermostability, wide liquid temperature regions and solvating properties that can dissolve a number of organic and inorganic compounds (Alvarez-Guerra et al. 2014). Besides these, their thermophysical properties can be tuned to satisfy the nature of the process. Due to all these, they are regarded as the best replacement for organic solvents in many chemical processes, including separation and extraction technologies such as aqueous two-phase extraction. Ionic liquid-based aqueous two-phase extraction works on the same line as conventional aqueous two-phase extraction by an organic salt and is considered an efficient downstream processing method for many biomolecules, including antibiotics, amino acids, proteins and hormones.

Bai et al. (2013) have many advantages such as low-energy requirements, biocompatible environment, short process time and reliable scale-up. But the requirement of a back-extraction step posed a challenge which was overcome by the introduction of ionic liquid-based three-phase partitioning that comprises the advantages of ionic liquids aqueous two-phase extraction by simultaneously eliminating the volatile organic solvents (t-butanol) (Alvarez-Guerra and Irabien 2014). This work demonstrated the potential of 1-methyl-3-butylimidazolium tetrafluoroborate/NaH2PO4 system in lactoferrin recovery. However, the instability of 1-methyl-3-butylimidazolium tetrafluoroborate in the presence of water led to their replacement by BmimTfO in a subsequent work that also studied the effect of pH and protein concentration on the efficiency of the process. The toxicity of 1-methyl-3-butylimidazolium highlighted the importance of their recyclability, which was investigated through the analysis of thermodynamic equilibrium of key components such as ionic liquid, salt and water. 1-Methyl-3-butylimidazolium tetrafluoroborate /(NaH2PO4/Na2HPO4) systems with more than 99% reusable ionic liquid were developed depending on the protein concentration, thereby reducing the economic and environmental impacts of the process. Ionic liquid partitioning thus proves to be a promising technique for protein recovery (Alvarez-Guerra et al. 2014).

Microwave-assisted three-phase partitioning

Among many efforts being made to further enhance the efficiency of three-phase partitioning, the most recent and successful trial has been the usage of microwave radiation to aid the formation of the three layers. So far, the only work employing this variant has been the mangiferin extraction from Mangifera indica leaves (Kulkarni and Rathod 2016). This work reported the use of microwave radiation for the three-phase formation in the presence of t-butanol and ammonium sulphate. As explained in previous works (Veggi et al. 2013; Zou et al. 2013), the principle underlying microwave radiation is the generation of heat via ionic conduction and dipole rotation, which increases molecular movement.

Rotation of molecules at the same frequency eventually causes molecular friction, ultimately resulting in an increased temperature. As the temperature rises, the solvent access to penetrate the matrix more efficiently, enabling extraction and improving the yield. Irradiation time and power affect the final temperature attained and the localization of the heat. When either of these exceeds a particular threshold, the extremely high confined temperature might either cause discolouration of the plant material or solvent evaporation. As a result, microwave may be able to enhance the diffusion of a target molecule in a matrix. Extreme microwave irradiation provides additional energy to the solvent and matrix, which can disrupt molecular connections and hence impair the extraction process. The study of microwave-assisted partitioning on mangiferin extraction further demonstrated the need of operating in pulse mode to reduce wasteful energy use and solvent extraction.

Applications

Three-phase partitioning has been widely researched and used for enzyme purification (Table 1), and its effectiveness as an emerging technique of enzyme purification is obvious from the reported increase in total enzyme activity in various situations (Roy and Gupta, 2021; Ketnawa et al. 2014; Nihan and Burcu 2019; Bayraktar et al. 2013; Shanmugaprakash et al. 2015b) Three-phase partitioning and its variants have been employed for the extraction of different enzyme inhibitors; (Roy and Gupta,2021; Gupta, 2021; Singh and Benjakul 2018; Liu et al. 2016; Araujo et al. 2019), extraction of the recombinant green fluorescent protein (Azevedo et al. 2016; Raghunathan et al. 2014; Senphan and Benjakul, 2014), extraction of antitumour proteins such as trichosanthin (Mondal et al. 2014) and solubilization and refolding of inclusion bodies. The wide range of applications of the three-phase partitioning is shown in Fig. 2.

Three-phase partitioning, as a protein enrichment method have also been demonstrated on various other simple proteins that include meat proteins (Belchior and Freire, 2021), immunoreactive proteins ovalbumin (Rather and Gupta 2013) and whey proteins (Alvarez-Guerra and Irabien, 2014). Three-phase partitioning was also observed when ethanol and ammonium sulphate (Zhao et al. 2018) were added to the broth to simultaneously destabilize the surfactin micelles and salt out the proteins. This order of addition was found to give a better yield and purity than the system with ammonium sulphate addition followed by ethanol.

Three-phase partitioning is also a reliable and efficient method for separating diverse carbohydrate polymers while simultaneously modifying their properties and extracting lipids. Three-phase partitioning was also employed as a deoxyribonucleic acid purification method in preparation of polymerase chain reaction-grade deoxyribonucleic acid and as a tool in the construction of biosensors. A recent application of three-phase partitioning using ethanol and dipotassium hydrogen phosphate was used to concentrate microalgae Cholerlla sp. These microalgae were found to have an increased lipid extraction yield that has implications in biodiesel production (Li et al. 2013).

Three-phase partitioning-purified enzymes have previously demonstrated improved enzyme performance through increased stability over a wide pH and temperature range, as well as tolerance to organic solvents (Bayraktar and Önal 2013a; Niphadkar et al. 2017). Immobilization of three-phase partitioning-purified enzymes was perceived to enhance the operational stability and recyclability of the enzymes, thereby opening a new arena of application for three-phase partitioning ( Kumar et al. 2012; Saikia et al., 2021). Cross-linking enzyme aggregates (CLEAs) are carrier-free immobilized enzymes that have high volumetric productivity and low cost, owing to the exclusion of expensive carrier molecules (Sheldon and van Pelt, 2013). Additionally, they are amenable to easy scale-up. CLEAs methodology, described as combined purification and immobilization strategy, requires a precipitate with highest recovered activity, as provided by interfacial-precipitated enzymes in three-phase partitioning, to undergo cross-linking ( Kumar et al. 2012).

Co-precipitation of laccase and starch in the interfacial layer followed by their cross-linking with glutaraldehyde and subsequent hydrolysis of starch by α-amylase was developed as a breakthrough protocol to produce highly active porous CLEAs of laccase and lipase (Kumar et al. 2012; Saikia et al., 2021). Smooth spherical structure of the immobilized enzyme with numerous large pores as displayed by scanning electron microscope, increased stability under repeated use, higher thermal stability and catalytic efficiency than free laccase made the porous CLEAs produced by this protocol, promising industrial biocatalysts. Three-phase partitioning was found to cause dimerization of serum albumin (Dennison 2012). Three-phase partitioning was also found to be lesser efficient for isolation of immunoglobulin antibodies and of bromelain, than cold acetone precipitation (Dennison 2012). Three-phase partitioning was also found to denature haemoglobin which in turn was made use of in isolating cathepsin D from spleen and many other erythrocyte enzyme (Taniguchi et al. 2016). As a result, using three-phase partitioning in a variety of scenarios is vital to verify the applicability for a specific task.

Enzyme inhibitor proteins

Enzyme inhibitor proteins attach to enzymes and reduce their activity by inhibiting substrate binding to the enzyme's active site and preventing the enzyme from initiating its reaction (Messerli et al. 2018). These inhibitors play major roles in an organism's defence mechanism against pathogens and pests (Rajput et al. 2021), in the therapeutic application (Servidio and Stellacci 2021) and as valuable affinity ligands for bioseparation of industrially important enzymes proteases and amylases (He et al. 2017; Roy and Gupta 2021a). Such proteinaceous inhibitors of proteases and amylases are generally purified by expensive, time-consuming, multistep protocol, including immobilized metal affinity chromatography (Mohammadzadeh et al. 2015). In an effort to develop a simple, scalable and efficient procedure for purifying these inhibitors, three-phase partitioning was tested for purification of several protease and amylase inhibitors from various plant sources such as legume seeds, soybean flour, Gupta and Roy 2021), ragi, wheat germ (Liu et al. 2016) and common bean (Araujo et al. 2019).

Purification of B/B protease inhibitor from soybean with a fourfold purification and 100% activity recovery was the pioneer work in this context. Three-phase partitioning followed by IMAC was developed as an efficient protocol for purification of soybean trypsin inhibitor in an integrated process that resulted in a 90% yield and 26-fold purification (Gupta and Roy 2021). A better protocol that integrates both metal affinity-based step and three-phase partitioning was developed in an earlier work to purify soybean trypsin inhibitor from soybean flour. For this metal affinity-based three-phase partitioning, a two-step procedure was used in which the aqueous phase acquired from a previous three-phase partitioning cycle underwent another in which appropriate quantities of CuSO4 substituted ammonium sulphate and ZnCl2 were used. This resulted in a 13-fold purification and 72% activity recovery, thus demonstrating the increased efficiency of the highly selective metal affinity-based three-phase partitioning. Various proteins which are extracted from different sources are presented in Table 2.

In another study that was aimed at comparing the α-amylase inhibitor protein content, total inhibitory activity and specific inhibitory activity of nine common bean mutants with their wild-type variety, Hwachia and a commercial preparation phase 2, found that three mutant varieties SA-05, SA-27 and SA-11 exhibited higher inhibitory activity than the Hwachia and phase-2 (Wang et al. 2011a). Single-step three-phase partitioning of protein kinase inhibitor from wheat germ with 85% activity recovery and 25-fold purification and a two-step three-phase partitioning of amylase inhibitor and trypsin inhibitor from ragi (Eleusine coracana) with a final purification of 20.1-fold and 16-fold, respectively, and a yield of 39.5% and 32%, respectively, are examples of optimization of three-phase partitioning for purification of bi-functional cereal inhibitors.

Recombinant proteins

Recombinant DNA technology is a science frontier with tremendous applications in medicine, agriculture and animal husbandry. Extraction of the recombinant proteins and solubilization and refolding of inclusion bodies have so far been achieved by three-phase partitioning of the transformed E. coli cells. Recombinant green fluorescent protein was purified by three-phase partitioning with a yield of 78% and 20-fold purification by a two-round three-phase partitioning where the lower aqueous phase of the first round was incorporated to the second round of three-phase partitioning (Messerli et al. 2018). In an attempt to compare the different methods of isolation, extraction and concentration of green fluorescence protein ultraviolent (emits light when expressed to ultraviolet light) expressed in E. coli, a protocol containing freezing/thawing/sonication cycles followed by three-phase partitioning was developed and determined to be the most efficient protocol for recombinant green fluorescence protein ultraviolent purification.

Three-phase partitioning was also evaluated for the refolding capacity of solubilized inclusion bodies, in contrast to the conventional refolding by simple dilution, dialysis or on a column. Ribonuclease A, the first two domains of human CD4 (CD4D12), five insoluble constructs of Drosophila melanogaster protein tyrosine phosphatases and five highly unstable and aggregation-prone mutants of the E. coli proteins controller of cell division or death B, maltose binding protein and thioredoxin were refolded from inclusion bodies using three-phase partitioning.

Other simple proteins

Three-phase partitioning, as a protein enrichment method, has also been demonstrated on various other simple proteins, including proteins, immunoreactive proteins, ovalbumin (Rather and Gupta 2013) and whey proteins (Alvarez‐Guerra and Irabien 2015). Three-phase partitioning was evaluated for the analytical potential in the field of food investigation by subjecting eight raw meat samples of different origins: round of beef, baron of beef, pork chop, legs of pork, chicken and turkey, and breasts of chicken and turkey to compare the middle semi-solid layer formed after centrifugation. The compressibility factor, determined as the ratio of a layer of thickness of the middle layer after centrifugation at two different speeds, was able to distinguish between beef and pork drips. A good correlation was also found between layer thickness and storage time for wild boar samples.

Apart from these, various other proteins such as bovine serum albumin, ovalbumin, lysozyme, gelatine, myoglobulin and haemoglobulin have been studied for structure–activity–aggregation correlation during three-phase partitioning (Rather and Gupta 2013) interfacial behaviour of proteins, shear rheological behaviour, elastic properties of the interface gels, the effect of pH relative to their isoelectric point, protein molecular weight, protein concentration, temperature and proportions of ammonium sulphate and t-butanol on three-phase partitioning. The three-phase partitioning of urea-denatured ovalbumin gave many refolded soluble conformational variants of the protein, which were studied by circular dichroism, fluorescence spectroscopy, scanning electron microscopy and atomic force microscopy. One of the structural variants was also found to possess a specific trypsin inhibitory activity. This study was thus helpful in understanding protein aggregation.

Conjugated proteins

These proteins, formed from the interaction between simple proteins and other chemical groups, have also been purified by three-phase partitioning. Surfactin, a powerful surfactant and antibiotic, is a cyclic lipopeptide and is produced as a secondary metabolite by micro-organisms. Owing to their exceptional ability to reduce the interfacial tension between solids, liquids and gases and strongly affect interfacial rheological phenomena and mass transfer, this valuable biosurfactant has many advantages over chemical surfactants, namely higher biodegradability, lower toxicity and better foaming, which has necessitated the search for an efficient purification technique with high surfactin purity. Three-phase partitioning was observed when ethanol and ammonium sulphate were added to the broth to simultaneously destabilize the surfactin micelles and salt out the proteins. This order of addition was found to give a better yield and purity than the system with ammonium sulphate addition followed by ethanol.

Lactoferrin, a highly added value globular glycoprotein with nutraceutical properties, has been demonstrated to be separated and purified by three-phase partitioning method in 1-methyl-3-butylimidazolium tetrafluoroborate/NaH2PO4 system and BmimTfO/NaH2PO4 system (Alvarez-Guerra and Irabien 2014). These have demonstrated a lactoferrin recovery of about 83%-98%. This has been the only protein recovered by ionic liquid partitioning. Characterization of thermodynamic equilibrium of the latter system and study on the ionic liquid recyclability have also been carried out with lactoferrin as the model protein (Alvarez-Guerra and Irabien 2014).

Enzyme purification

Three-phase partitioning has been widely explored and exploited for purifying enzymes (Table 3). The reported increase in total enzyme activity in some cases demonstrates the efficacy of three-phase partitioning as an emerging technology of enzyme purification (Bayraktar and Önal 2013). Though the mechanism behind this, and the consequent increase in specific activity of the enzymes, is still unclear, major reasons attributed towards this are the removal of inhibitors from enzyme preparations, the higher concentration of B-factor as observed by X-ray diffraction, increased flexibility of the enzyme molecule and the adoption of an increased amount of amino acid residues on the molecule (Rawdkuen et al. 2010).

Peptidases are also prominently implicated in parasite disorders as virulence genes and chemotherapeutic targets (Kangethe et al.2011). Three-phase partitioning has also been employed in demonstrating oligopeptidase B activities in the plasma of Trypanosoma brucei-infected rodents (Bastos et al. 2010). Cathepsins are a group of intracellular proteases that generally occur in animal cell lysosomes. Three-phase partitioning's ability to denature protein was exploited to isolate cathepsin D from the bovine spleen with a 13-fold purification and 27% yield (Goldring 2015).

Protease from dried papaya leaves was extracted at optimized conditions, resulting in 253.5% activity recovery and 15.8-fold purification after the first phase and 89.4% activity recovery and 10.1-fold purification after the second phase of three-phase partitioning. The most recent works on employing three-phase partitioning for purification of proteases include isolation of alkaline protease from fish viscera with a high recovery of 220% and sixfold purification by using sodium citrate and t-butanol (Ketnawa et al. 2014) and ficin from Mediterranean fig latex with 167% recovery and 6.04-fold purification by using conventional three-phase partitioning protocol (Gagaoua et al. 2014). The alkaline protease enzyme process enhances the quantity of natural dye exhausted (Kasiri and Safapour 2014).

Plant protease is a type of enzyme that is utilized in food processing, pharmaceuticals and other industrial activities (Mazorra-Manzano et al. 2018). Plant proteases have a stable commercial enzyme market due to their ability to improve functional qualities in foods such as solubility, foaming and emulsification (Mazorra-Manzano et al. 2018). Three-phase partitioning of latex from one such commercially potential plant source Calotropis procera resulted in purification of 6.92-fold with about 132% activity recovery (Rawdkuen et al. 2010).

Galactosidases are glycoside hydrolase enzymes that catalyse the hydrolysis of terminal glycosyl moieties from various substrates, including lactose and glycoproteins. Commercial production of this enzyme is restricted to generally recognized as safe (Choonia and Lele, 2013). α-Galactosidase has several biotechnological uses, including those in the sugar, pulp and paper industries, soymilk processing, enzymatic synthesis, structural analysis, feed processing, blood group transformation and Fabry's disease treatment (Bayraktar and Önal, 2013). Purification of α-galactosidase from Aspergillus oryzae, by three-phase partitioning with better fold purification of 3.49 and 43.7% yield was also demonstrated (Kuepethkaew et al. 2017). Three-phase partitioning was also utilized to concentrate and purify the galactosidase from pepino (Solanum muricatum) (Şen et al. 2011) and watermelon (Citrullus vulgaris) (Bayraktar and Önal 2013), which gave a yield of 127% and 76.7%, respectively. Similar experiments with chickpea resulted in a β-galactosidase of improved substrate affinity (Choonia and Lele, 2013). Two-step three-phase partitioning of indigenous Lactobacillus acidophilus resulted in 72% recovery and 21-fold purity. This enzyme was also shown to exhibit dual optimum pH, especially when lactose was the substrate (Choonia and Lele, 2013).

Amylase, an enzyme found in mammalian saliva, hydrolyses terminal 1,4-linked D-glucose residues from non-reducing ends of maltooligosyl and polysaccharides to liberate D-glucose. Amylase facilitates starch digestion into glucose. The α-amylases (EC 3.2.1.1) act randomly along the starch chain, breaking them into maltotriose and maltose from amylase or maltose, glucose and limit dextrin from amylopectin. Glucoamylase was purified from Aspergillus niger using alginate in macroaffinity ligand-facilitated partitioning with 20-fold purification and 83% activity recovery (Raghava et al. 2013).

Pectinases are pectolytic enzymes with numerous commercial applications, including retting of flax and vegetable fibres, enhancing fruit juice extraction yield, de-pectinization and clarifying of fruit liquid (Sandri et al. 2011) and wines, extraction of oils from vegetables and lemon peels (Anand et al. 2020), pretreatment of pectic waste water, fermentation of coffee and tea, paper and pulp manufacture, chicken feed production and plant virus purification. Fungal pectinases are extracellular enzymes that, according to a hypothesis, are secreted in low quantities to degrade the pectic polymers that cannot enter the wall. Detection of such low basal activities of fungal pectinase and their purification in a cost-effective manner for industrial purposes have been achieved by employing the three-phase partitioning technique. Three-phase partitioning was also used to purify pectinases from other sources such as Aspergillus niger and tomato extract resulting in yields of 76% and 183% and purification of tenfold and ninefold, respectively (Babagil and Nadaroglu 2022). Pectinase was also purified 13-fold with 96% activity recovery using alginate, from commercial preparation, in a strategy of sequential macroaffinity ligand-facilitated partitioning (Gupta and Roy 2021). Purification of exo-polygalacturonase from Aspergillus sojae ATCC 20,235 resulted in 25.5% recovery and 6.7-fold purification. The enzyme also showed enhanced thermal stability (Ruiz et al. 2017).

Xylanase is a class of hydrolase enzymes that degrade the linear polysaccharide β-1,4-xylan into xylose, thus breaking down hemicelluloses. Xylanase has important biotechnological applications, including chlorine-free bleaching of wood pulp before the papermaking process, as food additives to poultry, for the extraction of coffee and plant oils, clarification of fruit juices in combination with cellulase and pectinase, and so on (Periyasamy et al. 2017). Thus, the three-phase partitioning method is considered to apply cost-effective purification techniques to purify this enzyme. Purification of xylanase by exploiting its affinity to Eudragit S-100, from Aspergillus niger, gave 60% recovery and 95-fold purification (Gautam et al. 2012). This study aided in establishing macroaffinity ligand-facilitated partitioning as a general method of purification. Xylanase from Aspergillus niger was also purified to demonstrate simultaneous renaturation and purification of the enzyme by three-phase partitioning. This efficient integrated approach recovered 93% enzyme activity with 21-fold purification.

Invertase is an enzyme that catalyses the hydrolysis of glycosidic linkage in sucrose to liberate. Much of the biochemistry processes that involve invertase are focused on yeast fermentations and processes for the conversion of starch to sugar (Rodríguez-Restrepo and Orrego 2020). Invertase was purified 12-fold with 54% activity recovery, from the crude extract of Aspergillus oryzae, by three-phase partitioning, along with α-galactosidase (Nihan and Burcu 2019a). Purification of invertase from Baker's yeast (Saccharomyces cerevisiae) in a single-step three-phase partitioning was shown to result in 15-fold purification and 363% recovery (Akardere et al. 2010). Invertase from tomato has also been purified 8.6-fold with 190% recovery (Ozer et al. 2010), thus establishing three-phase partitioning as a simple, quick, economical and efficient technique for the purification of invertases.

Lipases are enzymes that catalyse the breakdown of lipids (fats). They have important roles in the digestion, transport and processing of dietary lipids. They have been used in yogurt and cheese formation and in applications such as baking, laundry detergent and even biocatalysts in processing biodiesel. Phospholipases are naturally occurring lipases that hydrolyse phospholipids into fatty acids and other lipophilic substances. Phospholipase D is a form of phospholipase that cleaves after the phosphate, producing phosphatidic acid and alcohol. For higher systems, lipases has been demonstrated to have a significant role in signalling. Phospholipase D was purified from Dacus carota by three-phase partitioning, leading to 13-fold purification and 72% activity recovery (Nihan and Burcu, 2019).

Chitinases are hydrolytic enzymes that degrade chitin glycosidic linkages. Chitin is a component of the cell wall or exoskeleton. Hence, chitinase is produced by organisms that need to reshape these or dissolve and digest the chitin of fungi or animals (chitinivorous). Chitinivorous organisms include bacteria such as Bacillus and Vibrio that may be pathogenic or detritivorous and some fungi. Chitinases in plants play the role of pathogenesis-related proteins and are induced as part of systemic acquired resistance.

Alkaline phosphatase is a hydrolase enzyme that removes phosphate groups from many types of molecules, including nucleotides, proteins and alkaloids. Alkaline phosphatase is frequently used as a label and signal amplifier in enzyme-linked immunosorbent assays for analytical and preparative purposes in molecular biology research. Three-phase partitioning was used to purify alkaline phosphatase from the chicken intestine from the crude preparation, resulting in a 80-fold purification and activity recovery of 61% (Wati et al. 2009).

Asparaginase has important applications in the medical and industrial fields, including for treating acute lymphoblastic leukaemia and as a processing aid in food-manufacturing to prevent the formation of acrylamide, a potential carcinogen, in starchy foods. Applying three-phase partitioning for the purification of such a valuable enzyme from E. coli K12 fermentation broth, sing iso-octane and ammonium sulphate yielded L-asparaginase with a 36.21% increase in activity and 11-fold purification (Biswas et al. 2014).

Peroxidases are generally utilized in enzyme-linked immunosorbent assay, therapeutic biochemistry, biomedical applications, wastewater treatment containing phenolic chemicals and dye decolourization. Initially used for horseradish peroxidase purification, another methodology combining two procedures, namely purification by column ion exchange chromatography and three-phase partitioning, was developed for extracting high-purity horseradish peroxidase in a relatively few steps (Lavery et al. 2010). Performing partitioning by adding the extra t-butanol to the aqueous solution after the separation of the middle layer created in the first round could result in a 95% yield. This was one of the earlier works that demonstrated the efficiency of subsequent application of two or more three-phase partitioning processes.

Three-phase partitioning was later employed with Turnip roots as the source and Cu2+ as an affinity ligand to purify peroxidase with 80-fold purification and 20% activity recovery (Almaz et al. 2021). Three-phase partitioning was found to be more selective when the metal affinity stage was incorporated into the procedure. Applying two-step, three-phase partitioning for purification of peroxidase from Ipomea palmata leaves resulted in a high degree of purification and activity yield of 18-fold and 81%, respectively, higher than those obtained from conventional techniques (Duman 2021). Three-phase partitioning of peroxidase from orange peels (Citrus sinenses) gave a maximum purity of 18.2-fold purification and 93.96% activity recovery (Vetal and Rathod 2015). According to their source and manner of action, peroxidases are classified into three superfamilies: plant peroxidase, animal peroxidase and catalases.

Laccases (EC 1.10.3.2) are copper-containing oxidase enzymes that have numerous industrial applications, including dye decolourization, biological bleaching in pulp and paper industries, synthesis of new hybrid molecules and biomaterials, detoxification of recalcitrant biochemicals, ethanol production, coal solubilization, and food and beverage industry (Birge et al. 2022). Rajeeva and Lele (2011) conducted research on establishing a downstream methodology for processing laccase from Ganoderma sp. WR-1 fermentation broth by comparing several techniques such as three-phase partitioning, ultrafiltration, diafiltration and chromatography. The three-phase partitioning strategy used in this work was a two-step procedure in which the first stage eliminates all other contaminating proteins, and the second step concentrates on the laccase at the interface (Rajeeva and Lele, 2011).

The subsequent investigation, which was solely focused on developing a three-phase partitioning strategy for the laccase purification from the same strain, yielded a 13.2-fold purification and a yield of 60% (Rajeeva and Lele, 2011). Both of these investigations justified the yield compromises by adopting three-phase partitioning because it avoided all of the shortcomings of the other traditional approaches (Rajeeva and Lele, 2011).

Optimization of parameters of three-phase partitioning is an important aspect required for standardizing yield and purification (Forootanfar and Faramarzi 2015). The partial purification of laccase from was examined as a unique application of microwave-assisted partitioning. Using optimum experimental conditions, including ammonium sulphate concentration (40% w/v), crude to tert-butanol ratio (1:1 v/v), pH 4.5 and temperature 30 °C, the conventional three-phase partitioning method produced 53.9% of Trametes hirsuta MTCC-1171 laccase with 2.4-fold purity. Response surface methodology was used in a Box–Behnken design to optimize microwave-assisted partitioning (Patil and Yadav 2018). The purification of laccase from Pleurotus ostreatus by three-phase partitioning was optimized utilizing a statistical approach that provided information on varying interaction, design specifications and process optimization simultaneously (George et al., 2022). The study purified laccase 7.22-fold with 184% activity recovery. Another study performed for biochemical characterization of the three-phase partitioning-purified laccase demonstrated a 27.8-fold purification and 161% activity recovery (Kumar et al. 2012).

Mannitol dehydrogenase is an enzyme that catalyses the pyridine nucleotide-dependent oxidation of D-mannitol to D-fructose, an intermediate step in the mannitol cycle which is an important NADPH-regenerating system in many imperfect fungi. Three-phase partitioning was employed to isolate this enzyme from the fungal source, Aspergillus parasiticus, with a fourfold purity and a yield of 77% (Ortiz et al. 2017). Preliminary cold acetone extraction was employed to remove the pigments from these mycelia partly.

Aryl alcohol oxidase is a prominent ligninolytic enzyme that has applications in bioethanol production, paper pulp manufacturing and source of renewable fuels (Kumar and Rapheal 2011). With the goal of developing a high-yield low-cost aryl alcohol oxidase from fungi, three-phase partitioning was employed for purification of aryl alcohol oxidase from fermented media of Pleurotus ostreatus that was screened to be the fungi with maximal aryl alcohol oxidase activity among the fungi chosen for the study (Kumar and Rapheal 2011). Three-phase partitioning purified the enzyme 10.19-fold with a yield of 10.95%.

Carbonic anhydrase is a family of enzymes that catalyse the interconversion of carbon dioxide and water to bicarbonate and protons or vice versa. This enzyme was purified 68-fold with 96% activity recovery from human erythrocyte haemolysate, using three-phase partitioning (Ores et al. 2012). This enzyme remains to be the only lyase documented to be purified by three-phase partitioning to date. Industrial application of this enzyme includes replacing methyl diethanolamine in carbon dioxide capture, a technology promoted by Quebec-based company CO2 solutions.

Three-phase partitioning as an emerging alternative for the separation and purification of carbohydrate polymers

Three-phase partitioning continues to be experimented with due to their high efficiency and affordability. This partitioning method has been exploited for the separation and purification of carbohydrate polymers in a yet another dimension that exhibits the versatility of the technique (Table 4). The steps involved in this are essentially the same as that for the purification of proteins. In addition, the three phases formed here are constituted by the upper organic phase and lower aqueous phase and differ from that in proteins at the intermediate polymer precipitate layer. Three-phase partitioning of several water-soluble polymers such as alginate Eudragit S-100 (Gautam et al. 2012), chitosan (Yong et al. 2015) and starch has been demonstrated. These studies have also shown to change their susceptibility to hydrolysis, solubility behaviour and structure.

Levan and smaller fructooligosaccharides are microbial fructose polymers that possess the antitumour activity and are used as non-digestible, calorie-free sweeteners and probiotics, respectively. The diverse applications of these polymers require that they be in a purified form, free of extraneous materials. The existing methods for this purpose tend to be multistep, tedious and often lead to depolymerization. Three-phase partitioning provides a reliable and efficient alternative for their separation with a simultaneous useful modification in their characteristics. Three-phase partitioning of alginate, chitosan (Yong et al. 2015), starch and their derivatives. Eudragit S-100 (Gautam et al. 2012) and Levan (Coimbra et al. 2010) have been demonstrated to recover high amounts of polymer in the interface (around 95%) at optimized conditions.

Oil extraction

Three-phase partitioning also flaunts application in the field of oil extraction (Fig. 3). Oil extracted from seeds has been in use since ancient times and in many cultures. The main use of oil has been in the food industry apart from manufacturing soap, candle, perfume and other personal care and cosmetic products. The very first attempt at three-phase partitioning for oil extraction was performed on soybean flour. Apart from optimizing the conditions, the work also evaluated the efficiency of different solvents for obtaining soybean oil by three-phase partitioning. t-butanol was found to give the maximum yield of 82% within just 1 h. This observation marked three-phase partitioning as a valuable alternative for oil extraction. 85% weight-for-weight oil was recovered in a subsequent attempt at creating an integrated method for extracting lectin, protease inhibitors and soybean flour oil. Soybean oil has also been extracted by three-phase partitioning preceded by treatment of the slurry using commercial preparation of proteases (enzyme-assisted partitioning) (Campbell 2010), resulting in a maximum yield of 98%.

Oil extraction from Jatropha seed kernels (Ewunie et al. 2021) is another example of application of three-phase partitioning. While conventional three-phase partitioning of Jatropha seed slurry yielded 82% oil, enzyme-assisted partitioning increased the oil yield to 92% (Ewunie et al. 2021). According to the study, ultrasound prior to enzyme pretreatment yielded a maximum oil output of 97%. This study also optimized parameters such as ammonium sulphate concentration, pH and slurry ratio to t-butanol for maximum efficiency. Oil from mango kernel has been extracted up to 79% using enzyme-assisted partitioning (Yan et al. 2018). Enzymatic pretreatment (Wang et al. 2011) to a final yield of 88% and 86%, respectively. Ultrasonication-assisted three-phase partitioning was also employed to extract oils from almonds and apricot to a yield of 87 and 77%, respectively. Different types of oils are extracted from various sources by three-phase partitioning, as explained in Table 5.

Other lipid and lipid-soluble extracts obtained by three-phase partitioning and their variants are oleoresin from turmeric (Kurmudle et al. 2011), ursolic acid and oleanolic acid (Vetal et al. 2013). Currently, solvent extraction and supercritical carbon dioxide extraction are used to extract oleoresin and other oleaginous compounds from spices (Kurmudle et al. 2011). But these are costly, time-consuming and cumbersome. Turmeric oleoresin, a common food flavouring agent and cosmetic, was recently extracted by carrying out three-phase partitioning of an α-amylase and glucoamylase pretreated slurry (Kurmudle et al. 2011). Ursolic acid and oleanolic acid are other examples of phytochemicals whose demands are continuously increasing in food, perfumes and pharmaceutical sectors and are also said to possess anti-inflammatory, antiulcer and antitumour properties (Vetal et al. 2013). Such compounds of high biological potential were recently extracted from Octimum sanctum leaves by three-phase partitioning coupled with ultrasound (Vetal et al. 2013). The highest yield of 79.48% and 80.67% of ursolic acid and oleanolic acid, respectively, was obtained at optimized conditions.

Pigment extraction

Astaxanthin, a red-coloured carotenoid, is a commonly found pigment in marine animals. Applications may be found in the pharmaceutical, culinary and cosmetics sectors, respectively. Small amounts of the bacterial source Paracoccus NBRC 101,723 were discovered recently, encouraging research into techniques as three-phase partitioning for its effective extraction. High-intensity, low-frequency ultrasound waves for cell disruption followed by three-phase partitioning (Chougle et al. 2014) have been proved to be one such method. This ultrasound-assisted three-phase partitioning gave a yield that was about 1.35 times that reported from conventional solvent extraction process. Ultrasound-assisted partitioning was also demonstrated to perform better than US treatment and three-phase partitioning separately. Apart from establishing Paracoccus sp. as a potential biosource of astaxanthin with advantages over chemical synthesis, this study widened the application of three-phase partitioning to include pigment recovery from bacterial cells.

Conclusion

As a primary recovery unit operation, a direct comparison between an ion exchange chromatography process and three-phase partitioning reveals that, potentially, a significant cost reduction could be achieved by substituting the chromatography process with three-phase partitioning. Three-phase partitioning has a long-standing reputation for enhancing the activity of purified enzymes. Stabilizing such increased activity at the same time is possible through the incorporation of the immobilization process, resulting in a catalytically active and robust industrial biocatalyst. Cross-linked enzyme aggregates (CLEA) based on three-phase partitioning may become a novel insolubilized enzyme in the laboratory and industry. For instance, examining the viability of utilizing three-phase partitioning-assisted CLEAs biocatalysts in enzyme-assisted partitioning would aid in the development of a substantial cost strategy. Another area that requires investigation is the use of three-phase partitioning to recover biopharmaceuticals. Understanding and exploiting three-phase partitioning to their fullest extent are, therefore, still a few years away and require the extensive application of knowledge and technology. The purified form of an industrial biomolecule allows for increased volumetric activity and prevents undesirable side reactions caused by contaminating by-products. Despite these benefits, three-phase partitioning is mostly restricted to laboratories and has not yet been implemented in industrial applications.

Abbreviations

- MFLTPP:

-

Macroaffinity ligand-facilitated three-phase partitioning

- EATPP:

-

Enzyme-assisted three-phase partitioning

- ILTPP:

-

Ionic liquid-based three-phase partitioning

- UATPP:

-

Ultrasound-assisted three-phase partitioning

- MTPP:

-

Microwave-assisted three-phase partitioning

- CLEAs:

-

Cross-linked enzyme aggregates

References

Ait Kaki El-Hadef El-Okki A, Gagaoua M, Bourekoua H, Hafid K, Bennamoun L, Djekrif-Dakhmouche S, El-Hadef El-Okki M, Meraihi Z (2017). Improving bread quality with the application of a newly purified thermostable α-amylase from Rhizopus oryzae FSIS4. Foods 6(1):1 https://doi.org/10.3390/foods6010001

Akardere E, Özer B, Çelem EB, Önal S (2010) Three-phase partitioning of invertase from Baker’s yeast. Sep Purif Technol. https://doi.org/10.1016/j.seppur.2010.02.025

Alici EH, Arabaci G (2016) Purification of polyphenol oxidase from borage (Trachystemon orientalis L.) by using three-phase partitioning and investigation of kinetic properties. Int J Biol Macromol 93:1051–1056. https://doi.org/10.1016/j.ijbiomac.2016.09.070

Alvarez-Guerra E, Irabien A (2014) Ionic Liquid-based three phase partitioning (ILTPP) for lactoferrin recovery. Sep Sci Technol (philadelphia) 49:957–965. https://doi.org/10.1080/01496395.2013.878722