Abstract

Evidence of bacterial involvement in precipitation of calcium carbonates has brought a revolution in the field of applied microbiology, geotechnical sciences, environmental and civil engineering with its marked success in restoration of various building materials. For applications of these calcite binder-producing bacterial cultures, different expensive carrier materials have been used but their high costs have come in the way of their successful commercialization. In the present study, we have explored the potential of cheap industrial by-product fly ash as a carrier material for bacterial cells and investigated the viability of calcifying bacterial isolates: Bacillus megaterium, Bacillus cereus, and Lysinibacillus fusiformis in fly ash carrier at varying temperatures and moisture conditions along with biomineralization efficacy of these formulations. We used laser scanning confocal microscopy to analyze the viability of bacteria by florescent dye 5-cyano-2,3-ditolyl tetrazolium chloride (CTC) along with the plate count method. Results revealed that fly ash successfully served as an effective carrier material and bacterial formulations stored at 4 °C provided longer shelf life than those stored at higher temperatures. Up to 106 cfu/g was found to sustain in all formulations at 4 °C compared to 104-105 cfu/g in case of higher temperatures up to 1 year. For 4 °C, higher moistures (50 %) were found to provide better survivability while for higher temperatures, lower moistures (30 %) favored higher viability. The biomineralization capability of fresh and formulated bacterial cells was compared on the basis of precipitation of carbonates and it was found that carbonate precipitation efficacy of formulated bacterial cells was comparable to fresh bacterial cells.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The application of calcifying bacterial cells for production of biogenic carbonate minerals has brought a revolution in various fields of applied microbiology, geotechnical sciences, environmental and civil engineering [1]. The ability of certain bacteria to precipitate calcium carbonate crystals is being explored by a large number of researchers around the world [2]. The coherent carbonate polymorphs formed as a metabolic by-product of several bacteria have found applications in the remediation and restoration of many building materials [3–5]. Stocks-Fischer et al. [6] reported that most of the bacterial species are able to precipitate carbonates given the right conditions, namely, an alkaline environment rich in Ca2+ ions. Though there are several mechanisms for precipitation of carbonates by bacteria, formation of calcium carbonate crystals via urea hydrolysis is the most widely used method for studying microbially induced calcium carbonate precipitation (MICCP) in the laboratory [7]. The precipitated calcium carbonates act as binders between loose substrate particles and reduce the pores inside the substrate particles, thereby consolidating them. This capability of bacterial cells to produce coherent calcite binders has made them useful tools nowadays for dealing with problems related to consolidation of building materials.

Although fresh cell preparations of bacterial cells are suitable for research studies, such preparations are not applicable for commercial purposes where these calcifying agents need to be applied in a simplified manner. To be acceptable, there must be suitable formulations of bacterial cells that can be easily handled and used. Formulations contain one or more beneficial bacterial strains (or species) in an easy-to-use carrier material. Use of a suitable carrier capable of supporting a highly viable microbial population for a prolonged duration is of utmost importance along with the nature of bacterial isolate and optimum conditions for storage. Until now, successful commercialization of calcifying bacterial isolates has not been achieved because of the high cost of carrier materials like sepiolite, high-density poly ethylene sheets (costs around 3 $ m−2) and Carbogel (costs around 39 $ kg−1) [7]. The commercial success of any technology is dependent upon its cost-effectiveness. Hence, there is a need for economical carrier materials that can successfully support the survival of bacterial cells and have an acceptable shelf life. Also, the conditions for maintaining survival and efficacy of bacterial isolates need to be developed. Along with the above parameters, the size of bacterial inoculum and survival of bacterial cells inside the formulations could have serious implications for the use of bacterial calcification as a method of consolidation. Most of the studies of bacterial cell survival have been carried by plate count method since long but now a days bacterial cell viability has also been accomplished by staining with florescent dyes. CTC (5-cyano-2,3-ditolyl tetrazolium chloride), which is a monotetrazolium redox dye that produces red fluorescent formazan (CTF) when biologically reduced by actively respiring bacteria, has been used by many researchers [8–11]. It has also been successfully used for detecting viable bacteria along with nucleic acid counter stains like DAPI and SYTO green which stain total bacteria, making viable and non viable counts very distinguishable. The sensitivity of this dye facilitates the visualization of even a small number of bacteria.

Fly ash (FA) generated during the combustion of coal for energy production is one of the industrial by-products that is recognized as an environmental pollutant. The addition of FA to concrete has become a common practice in recent years. Reports have been published concerning the effect of FA on concrete porosity and resistivity, pore solution chemistry, oxygen and chloride ion diffusivity, carbonation rates and passivation [12, 13]. The utilization of FA as a carrier material for calcifying bacteria can serve important economical, environmental, and technical benefits. Utilization of FA as a carrier material for developments of biofertilizers has been done by many researchers [14, 15], however no studies have been reported on the use of FA carrier material in biodeposition studies. In order to develop efficient formulations, it is crucial to optimize temperature and moisture conditions for maximum survival of bacterial cells. To the best of our knowledge, there is not enough information concerning optimum parameters for viability of bacterial formulations in different carriers. In the present investigation, utilization of FA as a carrier material for calcifying bacteria has been proposed along with optimization of moisture and temperature parameters for long-term stability of inoculum formulations. The viability of bacterial cells within the formulations has been evaluated for 1 year. Efficacy of bacterial formulations for precipitation of carbonates in comparison to fresh bacterial cells is also checked.

Materials and methods

Bacterial isolates

Three calcifying bacteria, Bacillus megaterium SS3, Bacillus cereus SS5, and Lysinibacillus fusiformis SS18 isolated from alkaline soils (pH 11.0), were used in this study. Characterization of these bacterial isolates and detailed analysis of carbonate polymorphs formed by these isolates were reported in Dhami et al. [16]. All the strains were maintained in Nutrient broth media (5.0 g peptone, 1.5 g beef extract, 1.5 g yeast extract, and 5.0 g sodium chloride per liter, pH 8.0).

Preparation of bacterial cells for formulations

Pure cultures of all the three bacterial isolates were cultivated in nutrient broth by incubating at 37 °C in a rotating shaker at 120 rpm for 3 days. The bacterial cultures were then centrifuged at 5,000 rpm for 10 min to obtain the bacterial pellet. The pellet was washed twice with phosphate buffer saline. The bacterial pellets of all the cultures were resuspended in 20 % sterilized distilled water to make bacterial slurry. Fly ash used in the present study was procured from Orissa, India, and autoclaved for 20 min prior to use. The physicochemical composition and elemental analysis of FA used in this study is presented in Table 1. Bacterial formulations were prepared by adding bacterial slurry of Bacillus megaterium SS3, Bacillus cereus SS5 and Lysinibacillus fusiformis SS18 to 250 g FA and mixed thoroughly to obtain uniformity. The initial cfu was kept at 5 × 108 cells/g and final moisture content was adjusted to 30, 40, and 50 % (w/v) in different sets by adding a known volume of sterilized distilled water calculated from moisture content of the carrier before packing into separate bags. The formulations were packed in sterile polythene bags (Hi Media, India) that were sealed to retain the moisture and stored at different temperatures (4, 25, and 37 °C).

Stability of bacteria in formulations at various moisture content and temperatures

The stability of the bacterial inoculants was determined monthly during storage. The formulation (1.0 g) was sampled monthly from all the packets incubated at different temperatures and was processed separately. Before sampling, the packets were shaken carefully and thoroughly to attain uniform distribution. One gram of the formulation (equivalent to 1.0 g of fly ash) was suspended in 10 ml of sterile distilled water and serial dilutions were made. Then, a 100-μl aliquot was plated onto nutrient agar plates and incubated at 37 °C for 48 h. The plate count was carried out in triplicate and the final value of colony-forming units (cfu/ml) was expressed as log cfu/g FA. The formulations were also investigated regularly to check for any contamination. The metabolic activity of bacterial cells within the formulations initially and after 1 year of storage was measured by directly assessing the urease activity as per the method of McGarity and Myers [17].

The viability of bacterial formulations was also checked by florescent dye CTC (5-cyano-2, 3-ditolyl tetrazolium chloride; Polysciences Inc.). The formulated cells were inoculated into nutrient broth for 2 h and then fixed on microscopic slides for 30 min with 4 % paraformaldehyde 2-phosphate-buffered saline. The slides were flooded with freshly prepared 1.5 mM (final concentration) CTC solution. The stain solution was left to react overnight at room temperature in the dark, and the slides were stored at −20 °C for 30 min to stop the reaction. Counter-staining was done with 2 μm SYTO 24 nucleic acid stain. Before visualization with a confocal scanning laser microscope (LSM 510 Meta; Carl Zeiss), the slides were covered with a coverslip and fixed with DPX mountant (Hi Media, India). The stain was excited at 453 nm by the use of a 590-nm long-pass filter. The slides were visualized at 400× magnification under immersion oil.

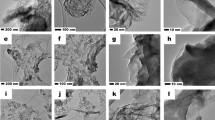

The bacterial formulations were also observed by scanning electron microscope 1 year after storage. One gram from each formulation was randomly sampled and analyzed using SEM. For SEM analysis, the samples were fixed overnight in 2.5 % glutaraldehyde in 0.1 M sodium phosphate buffer at 4 °C, rinsed in 0.2 M phosphate buffer saline (pH 7.4) for 1 h, and dehydrated through a graded series of ethyl alcohol. The SEM observation was done under the following analytical conditions: EHT = 20.00 kV, WD = 10–11 mm.

Calcium carbonate precipitation

In order to check the efficacy of bacterial formulations, 1 g inoculum formulation (106 cfu/g) of B. cereus (as it had maximum viability after 1 year) was inoculated into 50 ml of nutrient broth media supplemented with 2 % urea and 25 mM CaCl2 (NBU) as described by Achal et al. [18]. In another set, fresh bacterial cells (106 cfu/ml) were inoculated into NBU media along with a control where there was no bacterial inoculum. All three sets were incubated at 37 °C in a rotating shaker at 120 rpm for 72 h for precipitation of CaCO3. The aliquots from flasks were taken at regular time intervals and centrifuged. Soluble Ca2+ in the supernatant and insoluble Ca2+ in the pellet were estimated by EDTA titration method [19] as described in Stocks-Fisher et al. [6].

Microbial calcification of sand plugs

For studying the efficacy of formulated bacterial cells, columns were prepared as described in Reddy and Gupta [20] with little modification. Soil : sand : formulated FA (1:1:0.5) was mixed with 7 % cement and 10 % nutrient broth containing 2 % urea along 25 mM CaCl2 (NBU) was added. These columns were labeled as formulated bacterial sand columns (For-BSC). Sand, soil, FA, and cement were sterilized prior to use to eliminate the indigenous microflora by autoclaving at 121 °C for 1 h. The columns were packed as cylinders with a diameter of 3.8 cm and height of 7.6 cm. In the second set, similar columns as described above were prepared along with addition of fresh bacterial cells (5 × 106 cfu/g) to FA and mixed with 10 % NBU media, labeled as fresh bacterial sand columns (F-BSC). In the control set, the columns were prepared with only NBU media and designated as control sand columns (C-SC). All the columns were left at room temperature for 24 h and cured for 28 days by spraying 30 ml NBU/day onto the columns as described in Reddy and Gupta [20]. After 28 days, the columns were allowed to dry at room temperature and CaCO3 precipitated on the columns was determined as described in Achal et al. [21].

Micrographic and chemical characterization of the carbonates formed was done through scanning electron microscope, energy dispersive X-ray, and X-ray diffraction studies. For SEM analysis, samples were fixed with 2 % glutaraldehyde and processed as mentioned above. An energy dispersive X-ray analyzer (Bruker AXS, QuanTax 200) for elemental analysis was equipped with SEM. XRD spectra were obtained using an X’ Pert PRO diffractometer with a Cu anode (40 kV and 30 mA) and scanning from 3 ° to 60 ° 2θ. The components of the sample were identified by comparing them with standards established by the International Centre for Diffraction Data.

Characterization of sand columns

In order to test the efficacy of bacterial columns, it is imperative to study the consolidating effect of biodeposition on porosity of the substrate material. For this characterization, water absorption and mercury intrusion porosimetry analysis was done.

For studying water absorption, For-BSC, F-BSC, and C-BC columns were dried in an oven at 50 °C and dry weight was measured (W oven dried) as described in Dhami et al. [22]. The columns were then saturated overnight in water and weighed again (W saturation).

Water absorption was calculated by using the following formula:

Changes in porosity and pore size determination in case of For-BSC, F-BSC, and C-BC specimens were studied using mercury intrusion porosimetry (MIP) (with a Micromeritics Autopore 5510 device); 1 cm3 geometric volume from each type of column was dried overnight in an oven at 80 °C prior to MIP analysis. The samples were degassed under vacuum under pressure of 50 μmHg. Mercury surface tension value of 485 dynes/cm and contact angle of 130° was used, respectively. Mean pore size in the range of 0.006 to 338 μm was determined. Porosity (% total porosity) was then determined as weight normalized volume of mercury intruded in the sample.

All chemicals used in the experiments were purchased from Himedia, India, and used without any additional purification. All experiments were performed in triplicate. The data were analyzed by analysis of variance (ANOVA) and the means were compared with Tukey’s test. All the analyses were performed using GraphPad Prism software version 5.0 (GraphPad Software Inc. La Jolla, CA, USA).

Results and discussion

Viability of different inoculum formulations

The survival of all the three bacterial isolates at varying temperature and moisture over a period of 1 year showed a similar trend. The viability of bacterial formulations showed a somewhat upward trend during the first month in case of 25 and 37 °C at all moisture contents, which indicated the optimum environment and nutrients in the formulation-supported bacterial multiplication (Fig. 1). The multiplication rate was higher at 37 °C compared to 25 °C while there was no increase in the bacterial population at 4 °C. However, after the 2nd month, the microbial load declined sharply in samples stored at 37 and 25 °C (all moisture conditions). The increase in the bacterial population at initial stages might be due to the presence of some of the mineral nutrients along with low levels of organic carbon in FA (Table 1). Similar results were reported by Gaind and Gaur [23] in diazotrophs and phosphobacteria when FA was used as a carrier material. There was a significant difference in the viability of bacterial cells at three moisture levels. The viability of cells was significantly higher at 4 °C compared to 25 and 37 °C. Fly ash formulations were capable of sustaining viable cells of all bacterial isolates up to log of 107 cfug−1 for at least 6 months at 4 °C while in case of 25 and 37 °C, the viability reached log 106 cfu g−1 after 6 months in various isolates. After 12 months, the viable cells at 4 °C were still found to be in the range of 106 cfu g−1, while in case of 25 and 37 °C, the viability reached 104–105 cfu g−1. Moisture content of 50 % was found to be optimum for all bacterial formulations stored at 4 °C, as there was maximum bacterial viability here while 30 % moisture content favored higher viability of bacterial cells at 25 and 37 °C.

The high viability of all the isolates might be attributed to the formation of endospores by these isolates under unfavorable conditions. Decline in the cfu at 25 and 37 °C might be due to toxicity of metabolites produced by bacteria and/scarcity or exhaust of nutrients, moisture, and autolysis of cells [24]. The increased viability of all isolates at lower temperatures is in agreement with previous studies [25–27]. So from this study, it has been further confirmed that formulations stored at 4 °C had a longer shelf life as compared to higher temperatures. The purity of bacterial cells within all the formulations was also investigated from time to time and it was found that all formulations are free from any other bacterial contamination.

Viability of bacterial cells in FA formulations was also tested by CTC dye. The results showed the presence of both viable (red) and dead (green) cells in the formulations (Fig. 2). Both live and dead cells exhibited green florescence but intracellular accumulation of CTC in viable cells produced strong red florescence as visible by confocal laser scanning microscopy. As healthy cells respiring via the electron transport chain absorb and reduce CTC into an insoluble, red fluorescent formazan product while cells not respiring do not reduce CTC and are counter-stained by SYTO 24 green—fluorescent nucleic acid stain. The advantage of using fluorescent dyes over plate count is that at times certain bacterial cells not capable of forming colonies actively reduce these dyes and give fluorescence [28]. CTC has been successfully used to determine respiratory activity of many complex microbial systems [29] and in our study also we have demonstrated the feasibility of its usage in case of inoculum formulations.

Confocal laser scanning microscopy of bacterial formulations after staining with CTC and SYTO green where the red color indicates CTC reduction and the green color indicates total count. Different panels depict different spectra (green channel, red channel and superimposed green and red channels) a B. cereus SS5, b B. megaterium SS3, c L. fusiformis SS18

The urease activity of bacterial formulations at the beginning of the experiment was found to be in the range of 74.3 ± 2.5 μM/g/h while after 1 year, the urease activity declined to 53.6 ± 2.9 μM/g/h. Though the urease activity declined with time, a considerable amount of activity was still noticed. The moisture content in all the formulations was also investigated after a year and it was found that the moisture loss varied from 4.5 to 5.6 %. In case of pH, the drop varied from 0.18 to 0.23 in bags stored at 4 °C, 0.34–0.41 in case of 25 °C formulations and 0.56–0.63 in case of formulations stored at 37 °C.

SEM of formulations containing SS3, SS5, and SS18 revealed various sizes of the particles after 1 year (Fig. 3). Smooth, rugged, and porous surfaces were seen (3a, b, c, d, e, f). Particles of bacterial formulations containing B. megaterium were larger compared to others (3e, f). At higher magnifications, bacterial cells were clearly detected on the rugged areas.

Though Carbogel has also been devised as an effective carrier material for the application of bacterial cells in biodeposition of limestone and it offers higher retention of viable bacteria but, it adds heavily to the cost of biodeposition treatment [30]. For the formation of a gel, 10 g/l of Carbogel is required. Considering the thickness of the gel of about 1 cm, this brings the cost per m2 to about 2.8 € per m2, which is further added by using Japanese paper used along with Carbogel bringing an extra cost of about 12.3 € m−2. High-density polyethylene sheets used on external wall assemblies also amount to about 2.3 € m−2. Hence, these factors favor the use of FA as a carrier material for calcifying bacterial inoculum formulations in biodeposition studies. Though the composition FA do vary to some extent from one source to another, most of them are a good source of mineral nutrients, have optimum pH, and have good water-holding capacity. These properties have made FA a highly favorable carrier for bacterial formulations [23].

Efficacy of the viable bacterial cells

Figure 4 represents the pattern of insoluble Ca2+ in formulated cells, fresh bacterial cells, and control NBU media. Although addition of urea adds to the total cost of the media, it has been found to be the most efficient and simple mechanism for precipitation of carbonates by bacterial cells [7]. It was seen that calcium carbonate precipitation was about 75 % completed in 12 h in case of formulated cells while it was 90 % completed in case of fresh bacterial cells in same amount of time. In case of the control, there was a very small change in the concentration of Ca2+, which proves the involvement of bacteria in carbonate precipitation. CaCO3 precipitation is dependent on the concentration of Ca2+ and CO3 2− in solution. Hydrolysis of urea by bacterial urease is the major player in creating alkaline conditions in the surrounding medium due to production of ammonium ions and additional release of CO2 [6, 31]. An increase in CO3 2− concentration occurs under alkaline conditions abundant in calcium (Ca2+) and carbonate (CO3 2−) ions [32]. Bacterial presence and activity are prerequisite for the precipitation of calcium carbonate as bacterial metabolic activity produces the necessary increase in supersaturation to induce the heterogeneous crystallization of calcium carbonate on the surface of bacterial cells [2]. The reduction in efficiency of carbonate precipitation in case of formulated cells compared to fresh bacterial cells is observed, which might be due to poor accessibility of bacterial cells due to entrapment in FA particles or due to decreased metabolic activity, which leads to lesser precipitation. It is also possible that the cells within the formulations that had a larger particle size are entrapped inside the particles of FA and are therefore not effective in precipitation process. Although the precipitation of carbonates by formulated cells decreased in comparison to fresh cells but formulated cells still had promising precipitation capability, which offered the possibility of using them for commercial applications, however more research is needed to work on the characteristics of FA, for example its particle size.

Microbial calcification in sand plugs

The application of formulated cells and fresh bacterial cells on the surface of sand columns brought interesting results. The calcified layer on the surface of the columns was checked for the amount of carbonate precipitation. In case of formulations, the amount of precipitated calcium carbonate was found to be 24 % compared to 32 % in case of fresh bacterial cells whereas in the case of control, the carbonate content was merely 6 % (Fig. 5). The higher amount of precipitates in case of formulated cells as well as fresh cells depicts active bacterial carbonate precipitation. Inoculation of bacterial formulations consolidated the surface of sand columns due to formation of CaCO3 precipitates efficiently. The success of biodeposition treatment also depends upon the pore structure of the material used [33, 39]. Precipitation of CaCO3 was predominantly observed on the surface of the columns compared to inside the column. This may be due the facultatively anaerobic nature of Bacillus spp. that grow at a higher rate in the presence of oxygen and consequently induce active precipitation of CaCO3 around the surface area [6, 34].

XRD analysis of the three types of columns revealed that carbonate deposits were present as calcite and vaterite in case of F-BSC as well as For-BSC while in case of control sand column, no calcium carbonate peak was noticeable (Fig. 6 a, b, c). The formation of coherent durable calcite in our study has ensured high physicochemical resistance because of its high chemical and mechanical stability. Though extensive studies on bacterial carbonatogenesis have been carried out, little is known about the causes of polymorph selection during bacterial calcium carbonate mineralization [2, 35]. EDX analysis further revealed the mineral constituents of sand columns. A high amount of calcium was seen in case of fresh as well as inoculum-treated sand columns while the control sand column was seen to have very low calcium content.

The percentage of water absorption by formulated bacterial cell columns was found to be 8.84 % while in the case of fresh bacterial cell-treated columns, it was found to be 7.35 % (Fig. 7). Water absorption in the case of control specimens was 12.15 %. This showed that formulated cells reduced the absorption level to a significantly low level. Achal et al. [21] and De Muynck et al. [36] also reported a significant decrease in water absorption in cement mortar cubes upon treatment with bacteria as compared to the control. Lowering of water absorption is attributed to the deposition of biogenic carbonate crystals leading to reduction of pores on the surface of bacterial cylinders. This leads to decreased permeation due to plugging of pores and hence the porosity decreases.

Mercury intrusion porosimetry data (Table 2) of formulated bacterial cells, fresh bacterial cells, and control specimens also reflected sufficient efficacy of formulated bacterial cells on reduction of total porosity. The total porosity of control specimens was found to be 25.3 % while upon calcification by formulated cells it was estimated to be 19.2 %, which showed 24 % reduction. In case of fresh bacterial cells application, the porosity was found to be 17.4 %, which was 31 % reduction. The porosity of the samples was calculated using cumulative intrusion volume and relevant mass measurements. Whiffin et al. [37] also observed a 90 % decrease in porosity of sand column upon bacterial calcite formation. The reduction in porosity is attributed to the filling of the voids and clogging of pores due to precipitated carbonate crystals. Entrapped bacterial biomass and extrapolymeric substances also leads to a reduction in porosity [22]. Though there was again some reduction in the extent of carbonate precipitation by formulated cells compared to bacterial cells, the application of formulated cells still successfully reduced the porosity of sand columns to a good extent and hence proved its efficacy. Zamarreno et al. [38] also reported that biodeposition treatment resulted in a decrease in pore size of about 50 % in limestone.

Conclusions

Development of stable formulations for application of MICCP in commercial purposes is of great importance as this technology offers an eco-friendly, novel, and convenient solution to various problems of building materials. The results of the present study suggest that FA as a carrier for bacterial isolates is stable not only in sustaining viability but also the efficacy of calcifying bacteria. Use of FA as a carrier in these formulations is an effective way of utilizing problematic FA waste in a useful manner and the present study has undoubtedly proved the potential of bacterial FA formulations for commercial purposes. Further studies need to be done on optimization of particle sizes in FA, nutrient content of FA and testing of other industrial by products that can be effective bacterial carrier materials for application of MICCP in building materials.

References

De Jong JT, Soga K, Kavazanjian E, Burns S, Van Paassen LA, Al Qabany A, Aydilek A, Bang SS, Burbank M, Caslake LF, Chen CY, Cheng X, Chu J, Ciurli S, Esnault-Filet A, Fauriel S, Hamdan N, Hata T, Inagaki Y, Jefferis S, Kuo M, Laloui L, Larrahondo J, Manning DAC, Martinez B, Montoya BM, Nelson DC, Palomino A, Renforth P, Santamarina JC, Seagren EA, Tanyu B, Tsesarsky M, Weaver T (2013) Biogeochemical processes and geotechnical applications: progress, opportunities and challenges. Geotechnique 63:287–301

Rodriguez-Navarro C, Jroundi F, Schiro M, Ruiz-Agudo E, González –Muñoz MT (2012) Influence of substrate mineralogy on bacterial mineralization of calcium carbonate: Implications in stone conservation. Appl Environ Microbiol 78:4017–4029

Dhami NK, Mukherjee A, Reddy MS (2012) Biofilm and microbial applications in biomineralized concrete. In: Jong Seto (ed) Advanced topics in biomineralization, InTech, New York, pp 137–164

Dick J, De Windt W, De Graef B, Saveyn H, Van der Meeren P, De Belie N, Verstraete W (2006) Bio-deposition of a calcium carbonate layer on degraded limestone by Bacillus species. Biodegradation 17:357–367

Rodriguez-Navarro C, Rodriguez-Gallego M, Ben Chekroun K, Gonzalez-Muñoz MT (2003) Conservation of ornamental stone by Myxococcus xanthus induced carbonate biomineralization. Appl Environ Microbiol 69:2182–2193

Stocks-Fischer S, Galinat JK, Bang SS (1999) Microbiological precipitation of CaCO3. Soil Biol Biochem 31:1563–1571

De Muynck W, Belie N, Verstraete W (2010) Microbial carbonate precipitation in construction materials: a review. Ecol Eng 36:118–136

Adams BL, Bates TC, Oliver JD (2003) Survival of Helicobacter pylori in a natural freshwater environment. Appl Environ Microbiol 69:7462–7466

Créach V, Baudoux AC, Bertru G, Rouzic BL (2003) Direct estimate of active bacteria: CTC use and limitations. J Microbiol Methods 52:19–28

Richardson RE, James CA, Bhupathiraju VK, Cohen LA (2002) Microbial activity in soils following steam treatment. Biodegradation 13:285–295

Winding A, Binnerup SJ, Sorense J (1994) Viability of indigenous soil bacteria assayed by respiratory activity and growth. Appl Environ Microbiol 60:2869–2875

Montemor MF, Simoes AMP, Salta MM (2000) Effect of fly ash on concrete reinforcement corrosion studied by EIS. Cem Concr Comp 22:175–185

Thomas MDA, Matthews JC (1992) The permeability of fly ash concrete. Mater Struct 25:388–396

Khan MJ, Majid S, Mohidin FA, Khan N (2011) A new bioprocess to produce low cost powder formulations of biocontrol bacteria and fungi to control fusarial wilt and root-knot nematode of pulses. Biol Control 59:130–140

Kumar V, Gupta P (2010) Studies on shelf-life of fly-ash based Azotobacter chroococcum formulation and its bio-efficacy in wheat. Res J Agric Biol Sci 6:280–282

Dhami NK, Mukherjee A, Reddy MS (2013) Biomineralization of calcium carbonate polymorphs by the bacterial strains isolated from calcareous sites. J Microbiol Biotechnol 23:707–714

McGarity JW, Myers MG (1967) A survey of urease activity in soils of northern New South Wales. Plant Soil 27:217–238

Achal V, Mukherjee A, Reddy MS (2009) Strain improvement of Sporosarcina pasteurii for enhanced urease and calcite production. J Ind Microbiol Biotechnol 36:981–988

APHA (American Public Health Association) (1989) Standard methods for the examination of water and wastewater. In: 7th edn. American Public Health Association, Washington, DC

Reddy BVV, Gupta A (2005) Characteristics of soil-cement blocks using highly sandy soils. Material Struct 38:651–658

Achal V, Mukherjee A, Reddy MS (2011) Effect of calcifying bacteria on permeation properties of concrete structures. J Ind Microbiol Biotechnol 38:1229–1234

Dhami NK, Mukherjee A, Reddy MS (2012) Improvement in strength properties of ash bricks by bacterial calcite. Ecol Eng 39:31–35

Gaind S, Gaur AC (2004) Evaluation of fly ash as carrier material for diazotrophs and phosphobacteria. Bioresour Technol 95:187–190

Gaind S, Gaur AC (1990) Influence of temperature on the efficiency of phosphate solubilizing microorganisms. Indian J Microbiol 30:305–310

Cigdem K, Merih K (2005) Effect of formulation on the viability of biocontrol agent, Trichoderma harzianum conidia. Afr J Biotechnol 85:483–486

Daza A, Santamaria C, Rodrigues-Navarro DN, Camach M, Orive R, Temprano F (2000) Perlite as a carrier for bacterial inoculants. Soil Biol Biochem 32:567–572

Walker R, Rossall S, Asher MJC (2004) Comparison of application methods to prolong the survival of potential biocontrol bacteria on stored sugar-beet seed. J Appl Microbiol 97:293–305

Sherr BF, Giorgio PD, Sherr EB (1999) Estimating abundance and single-cell characteristics of respiring bacteria via the redox dye CTC. Aquat Microb Ecol 18:117–131

Nielsen JL, de Muro MA, Nielsen PH (2003) Evaluation of the Redox Dye 5-Cyano-2,3-Tolyl-Tetrazolium chloride for activity studies by simultaneous use of microautoradiography and fluorescence in situ hybridization. Appl Environ Microbiol 69:641–643

Cappitelli F, Toniolo L, Sansonetti A, Gulotta D, Ranalli G, Zanardini E, Sorlini C (2007) Advantages of using microbial technology over traditional chemical technology in removal of black crusts from stone surfaces of historical monuments. Appl Environ Microbiol 73:5671–5675

Bachmeier KL, Williams AE, Warmington JR, Bang SS (2002) Urease activity in microbiologically induced calcite precipitation. J Biotechnol 93:171–181

Qian C, Wang R, Cheng L, Wang J (2010) Theory of microbial carbonate precipitation and its application in restoration of cement-based materials defects. Chin J Chem 28:847–857

De Muynck W, Leuridan S, Loo DV, Verbeken K, Cnudde V, De Belie N, Verstraete W (2011) Influence of pore structure on the effectiveness of a biogenic carbonate surface treatment for limestone conservation. Appl Environ Microbiol 77:6808–6820

Achal V, Mukherjee A, Reddy MS (2010) Biocalcification by Sporosarcina pasteurii using corn steep liquor as nutrient source. J Ind Microbiol Biotechnol 6:170–174

Rivadeneyra MA, Parraga J, Delgado R, Ramos-Cormenzana A, Delgado G (1998) Biomineralisation of carbonates by Halomonas eurihalina in solid and liquid media with different salinities: crystal formation sequence. Res Microbiol 149:277–287

De Muynck W, Cox K, De Belie N, Verstraete W (2008) Bacterial carbonate precipitation as an alternative surface treatment for concrete. Constr Build Mater 22:875–885

Whiffin VS, van Paassen L, Harkes MP (2007) Microbial carbonate precipitation as a soil improvement technique. Geomicrobiol J 24:417–423

Zamarreno DV, Inkpen R, May E (2009) Carbonate crystals precipitated by freshwater bacteria and their use as a limestone consolidant. Appl Env Microbiol 75:5981–5990

Samonin VV, Elikova EE (2004) A study on the absorption of bacterial cells on porous materials. Microbiol 73:696–701

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dhami, N.K., Mukherjee, A. & Reddy, M.S. Viability of calcifying bacterial formulations in fly ash for applications in building materials. J Ind Microbiol Biotechnol 40, 1403–1413 (2013). https://doi.org/10.1007/s10295-013-1338-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-013-1338-7