Abstract

In this research work we investigated changes in volatile aroma composition associated with four commercial Oenococcus oeni malolactic fermentation (MLF) starter cultures in South African Shiraz and Pinotage red wines. A control wine in which MLF was suppressed was included. The MLF progress was monitored by use of infrared spectroscopy. Gas chromatographic analysis and capillary electrophoresis were used to evaluate the volatile aroma composition and organic acid profiles, respectively. Significant strain-specific variations were observed in the degradation of citric acid and production of lactic acid during MLF. Subsequently, compounds directly and indirectly resulting from citric acid metabolism, namely diacetyl, acetic acid, acetoin, and ethyl lactate, were also affected depending on the bacterial strain used for MLF. Bacterial metabolic activity increased concentrations of the higher alcohols, fatty acids, and total esters, with a larger increase in ethyl esters than in acetate esters. Ethyl lactate, diethyl succinate, ethyl octanoate, ethyl 2-methylpropanoate, and ethyl propionate concentrations were increased by MLF. In contrast, levels of hexyl acetate, isoamyl acetate, 2-phenylethyl acetate, and ethyl acetate were reduced or remained unchanged, depending on the strain and cultivar evaluated. Formation of ethyl butyrate, ethyl propionate, ethyl 2-methylbutryate, and ethyl isovalerate was related to specific bacterial strains used, indicating possible differences in esterase activity. A strain-specific tendency to reduce total aldehyde concentrations was found at the completion of MLF, although further investigation is needed in this regard. This study provided insight into metabolism in O. oeni starter cultures during MLF in red wine.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Wine production involves a succession of biological processes including alcoholic fermentation by yeast and malolactic fermentation (MLF) by lactic acid bacteria (LAB). MLF in wine is performed, preferably by inoculation with Oenococcus oeni in order to reduce wine acidity by biotransformation of the dicarboxylic l-malic acid to the monocarboxylic l-lactic acid by the malolactic enzyme [9, 15, 33, 36]. MLF improves biological stability and affects wine organoleptic properties such as aroma, flavour, and mouthfeel [4, 9, 29]. O. oeni is recognised as the species most tolerant to the harsh wine conditions of low pH, high sulfur dioxide (SO2), and high alcohol content. For this reason, in addition to its favourable flavour profile, O. oeni is mostly selected as starter culture [33].

The complexity and diversity of the metabolic activity associated with the growth of LAB suggest that MLF may affect wine quality both positively and negatively [15, 35]. Wine aroma and flavour could be affected by LAB via several mechanisms including:

-

1

reduction of flavour compounds by metabolism and adsorption on the bacterial cell wall;

-

2

production of new volatiles by metabolism of grape sugars, amino acids, and other nutrient compounds; and

-

3

metabolism or extracellular modification of grape and yeast secondary metabolites to either more or less flavour and aroma-active metabolites [2].

Wine-associated LAB have been shown to induce a variety of enzymatic activity which has the potential to affect or produce a range of volatile compounds [35, 42–44]. Different enzymatic activity has been observed among the LAB genera and strains evaluated [43]. The use of different bacterial strains in starter cultures during winemaking could, therefore, substantially affect the volatile composition and possibly the resulting sensory properties in a strain-dependant manner.

One of the most important aroma compounds synthesized during MLF, and the most frequently reported cause of aroma modification associated with LAB, is diacetyl (2,3-butanedione), which, when present at concentrations above its sensory threshold, contributes a buttery, nutty, and/or toasty aroma to wine [2, 9, 18, 32, 41]. It is well-known that diacetyl, acetic acid, acetoin, and 2,3-butanediol are formed by citric acid catabolism by LAB; these have been discussed in several comprehensive reviews [3–5, 37, 58]. According to previous reports, modification of wine aroma induced by MLF is far more complex and often involves changes in fruity, flowery, and nutty attributes, and reduction of vegetative, green, grassy, and herbaceous aromas [2, 28]. A significant increase in the concentration of several esters produced by bacterial metabolism has been reported [11, 39], whereas other studies reported reduced ester concentrations [24]. The catabolism of acetaldehyde by wine LAB was reported by Osborne et al. [48]. This illustrates the potential of LAB to metabolise aldehydes [35] and, consequently, reduce the associated herbaceous aroma; reports on these changes during MLF are few, however. Additional compounds such as higher alcohols, fatty acids, lactones, and sulfur and nitrogen-containing compounds may also be produced and could potentially contribute to or alter the wine aroma profile [56].

Different analytical procedures have been described for quantification of volatile compounds in wine, and comprehensive reviews are available [16, 47]. Gas chromatography (GC) in combination with a variety of extraction and detection techniques have been most extensively used for quantification of wine volatile compounds. Headspace SPME (HS-SPME) [1, 61] is an effective and solventless sampling technique especially suitable for quantification of volatile analytes, because it reduces interferences from other, non-volatile, wine constituents. Hayasaka et al. [26] described a simple and effective method for quantification of diacetyl by use of HS-SPME coupled to GC–MS. Other workers have described methods for the quantification of diacetyl and other dicarbonyl compounds [14], and several aldehydes [20, 21, 59], by use of derivatisation procedures before chromatographic analysis. Because the effects of MLF on aldehydes have not yet been characterised, mainly because of a lack of analytical data, a robust method for simultaneous determination of diacetyl and aldehydes in wine would provide insight into changes associated with LAB during MLF.

The purpose of this study was to investigate the effect of MLF on the chemical composition, in terms of volatile aroma compounds and organic acids, of Pinotage and Shiraz wine from South Africa by using four commercial O. oeni starter cultures. The results would provide a better understanding of the contribution of MLF to the composition of wine and its potential contribution to wine aroma.

Materials and methods

Chemical standards and reagents

All standards (Table 1) were of analytical grade (purity 95–99.9%) and purchased from Fluka (Buchs, Switzerland), Sigma-Aldrich (Steinheim, Germany), Riedel-de-Häen (Seelze, Germany), and Merck (Darmstadt, Germany). Sodium chloride (HPLC quality) and diethyl ether (99.5%) were purchased from Merck (Darmstadt, Germany) and pure water was obtained from a Milli-Q purification system (Millipore, Bedford, MA, USA). The internal standards (2-pentanone and 4-methyl-2-pentanol, Fluka) and volatile standards were dissolved in a wine simulant (12% v/v ethanol) prepared according to Louw et al. [38] and used for the respective calibration curves and subsequent validation procedures as reported in the supplementary material.

Bacterial strains

The four commercial starter cultures used for this study are listed in Table 2. These cultures were selected because they are frequently used in the South African wine industry.

Experimental design of winemaking

The experimental design for the winemaking experiments was the same for both years (2008, 2009) and cultivars (Pinotage, Shiraz). Alcoholic fermentation (1,000 l) was followed by MLF performed in triplicate (4.5 l × 3) for each of the different treatments, namely control (no MLF), spontaneous (spon), Enoferm alpha® (A), Lalvin VP41® (V), Viniflora oenos® (O), and Viniflora CH16® (C). The control wine treatment (no MLF; lysozyme added to inhibit LAB growth) and spontaneous treatment (no MLF inoculation) were subjected to the same experimental design and included for comparative purposes. Subsequent chemical analysis of each of the biological triplicates was performed in duplicate or triplicate, depending on the method of analysis.

One-hundred and seventy kilograms of Shiraz grapes were harvested at 25.0°B during the 2008 season from the Wellington region, Western Cape, South Africa. Pinotage grapes were harvested from the same region in South Africa at 28.4°B (170 kg) and 22.0°B (175 kg) during the 2008 and 2009 seasons, respectively. After crushing and destemming, 30 mg/l sulfur dioxide (SO2) was added to the must to reduce possible growth of natural flora present on the grapes and to prevent oxidation. Alcoholic fermentation was performed in a 1,000 l stainless-steel tank at 25°C. A commercial strain of actively dried Saccharomyces cerevisiae, WE372 (Anchor Yeast, South Africa) was inoculated for alcoholic fermentation at 0.3 g/l after rehydration, in accordance with the manufacturer’s specifications. Lysozyme (DSM Food Specialties, Oenology, France) was added at 0.25 g/l to inhibit indigenous LAB microflora. During alcoholic fermentation the skins were punched down manually twice a day. At 3°B the wine was removed from the skins by light pressing, using only the free-flow wine, to reduce hard tannins present in the wine. After completion of alcoholic fermentation (residual sugar less than 5 g/l) the wine was divided into 4.5-l glass bottles for MLF. MLF was performed at 20°C in triplicate for each of the respective treatments, namely spontaneous MLF, four commercial starter cultures, and a control treatment. The spontaneous MLF treatment was not inoculated with a starter culture and no SO2 was added. This treatment was included to evaluate whether any natural flora could have potentially contributed to the MLF process and whether the lysozyme treatment was effective. Commercial starter cultures were rehydrated and inoculated, in accordance with the manufacturers’ specifications, at 0.01 g/l. For the control treatment, three of the 4.5-l glass bottles were racked and 50 mg/l SO2 was added directly after alcoholic fermentation to inhibit microbial growth and enable capture of the chemical composition of the wines before MLF. Bacterial complex nutrients were added in accordance with each manufacturer’s instructions: 0.2 g/l Optimalo (Lallemand, Stellenbosch, South Africa) for the Lalvin VP41 and Enoferm alpha cultures and 0.1 g/l Bactiv-aid (Chr Hansen, Hørsholm, Denmark) for the Viniflora oenos and Viniflora CH16 cultures. MLF was regarded as complete at malic acid concentrations less than 0.3 g/l. After MLF, all wines were racked, SO2 levels adjusted to 50 mg/l, and the wines were bottled. Wines were stored at 15°C before all chemical analysis.

Microbial enumeration

Microbial populations for LAB were monitored to evaluate the effectiveness of the inoculated commercial cultures and to establish if other LAB species survived and could potentially contribute to MLF. For this purpose, LAB were determined by plating 100 μl of a dilution series of the wines, prepared in sterile distilled water, on selective media. MRST plates contained 50 g/l De Man, Rogosa, and Sharpe (MRS; Biolab, Merck, Wadeville, South Africa), 20 g/l bacteriological agar (Biolab, Merck) supplemented with 10% preservative-free tomato juice (All Gold, South Africa) and pH adjusted to 5.0 with hydrochloric acid (HCl). MRS plates contained 50 g/l MRS broth (Biolab, Merck) and 15 g/l bacteriological agar (Biolab, Merck). All plates contained 50 mg/l Delvocid Instant (DSM Food Specialties, The Netherlands) to prevent yeast growth and 25 mg/l kanamycin sulfate (Roche Diagnostics, Mannheim, Germany) to suppress the growth of acetic acid bacteria. MRST, which favours the growth of O. oeni, was used for enumeration of O. oeni whereas MRS agar was used for enumeration of other wine LAB. Agar plates were incubated at 30°C for 5–7 days after which colony-forming units per ml (cfu/ml) were determined. All LAB were anaerobically cultivated by use of Microbiology Anaerocult pads in anaerobic jars (Merck, Darmstadt, Germany).

Fourier transform mid-infrared spectroscopy (FT-MIR)

FT-MIR spectra acquired by use of a Winescan FT120 instrument (FOSS Analytical software version 2.2.1) equipped with Winescan FT120 2001 version 2.2.1 software, in accordance with the method described elsewhere [38].

Quantified chemical data, including pH, ethanol, titratable acidity (TA), volatile acidity (VA), glycerol, and residual sugar (RS), were predicted from infrared spectra by use of commercial or in-house developed calibrations as described elsewhere [38].

Organic acid analysis

Malic acid, lactic acid, pyruvic acid, gluconic acid, acetic acid, succinic acid, and citric acid were quantified before and after MLF by use of a modified version of the certified OIV reference method [46]. The original OIV method was modified (running buffer containing 5% acetonitrile compared with 10% in the original) to include more analytes for quantification. Samples were diluted 1/25 in the running buffer before injection. A 3D CE instrument (Agilent Technologies, Waldbronn, Germany) equipped with Agilent Chemstation software version B.01.03 (204) was used for the analysis and data processing in accordance with the certified OIV method [46]. Calibration ranges were between 0.04 and 2 g/l for all compounds except pyruvic acid, for which the upper limit was 1 g/l.

Volatile aroma compound analysis

Major volatile aroma compounds

Volatile higher alcohols, esters, fatty acids, and carbonyl compounds were analysed in triplicate with a Hewlett–Packard (Little Falls, USA) 6890 Plus gas chromatograph equipped with a split/splitless injector and flame-ionisation detection (FID), following a newly developed fast GC procedure. In brief, volatile compounds were isolated from 5 ml wine, after addition of 10 mg/l 4-methyl-2-pentanol (≥97%) as internal standard, by liquid–liquid extraction with diethyl ether [38]. Analysis of the different compounds was achieved by separation using a J&W DB-FFAP capillary GC column (Agilent, Little Falls, Wilmington, USA) with dimensions 20 m length × 0.1 mm inside diameter × 0.2 μm film thickness followed by FID. Analyte concentrations were calculated by comparing their respective peak areas with those from calibration standard curves, by use of a data-handling system (HP GC Chemstation, revision A.07.01 (682)).

Carbonyl compounds

A headspace solid-phase microextraction gas chromatography–mass spectrometry (HS-SPME GC–MS) method was developed to quantify the carbonyl compounds diacetyl, acetoin, and 2,3-pentanedione, and a selection of aldehydes including hexanal, E-2-hexenal, decanal, octanal, E-2-octenal, E-2-nonenal, and cis-2, trans-6-nonadienal. A selection of method-validation data is provided in the Supplementary Material available for this paper.

Headspace solid-phase microextraction was performed with a 60-μm poly(ethylene glycol) (PEG) SPME fibre (Supelco, Bellefonte, PA, USA), specific for extraction of polar compounds from the headspace. Glass screw-cap vials with polytetrafluoroethylene (PTFE)/silicone septa (20 mm) (Agilent Technologies, Little Falls, Wilmington, USA) were used. After optimisation, SPME analysis was performed on a mixture of 1 ml wine, 9 ml distilled Milli-Q water (Millipore), and 2 g sodium chloride (NaCl; Sigma) in a 20-ml vial. The internal standard, 2-pentanone, was added at 10 mg/l to each vial. The wine was agitated to ensure that NaCl dissolved completely. Extraction of volatiles from the headspace was performed at 50°C for 10 min. Subsequently, the fibre was desorbed in the hot injection port of the GC–MS at 220°C for 2 min. The injector was operated in pulsed split mode (300 kPa, split ratio 10:1) at 220°C for 2 min and 171 kPa afterwards. Each wine was analysed in duplicate.

Separation was performed on a 60 m length × 0.25 mm i.d. × 0.25 μm f.t. FFAP column (Agilent Technologies, Little Falls, Wilmington, USA) using a 6890 gas chromatograph coupled to a 5975C mass spectrometer (Agilent Technologies) and equipped with Enhanced Chemstation version D.01.02.16 software (Agilent Technologies). For SPME sample preparation and injection, the instrument was equipped with a CTC CombiPal autosampler (CTC Analytics, Switzerland) and used with the SPME option. The carrier gas (helium) flow through the GC column was 1.7 ml/min and the oven was programmed from 35°C (2 min), ramped at 5°/min to 150°C (held for 2 min) and ramped at 15°/min to 240°C (held for 1 min). The mass spectrometer (MS) was operated in electron-impact (EI) mode (70 eV). Data acquisition was performed in SIM mode by monitoring the mass-to-charge (m/z) ratios representing unique ion fragments for the respective compounds: 2-pentanone (IS; 43, 86); diacetyl (43, 86); 2,3-pentanedione (57, 100); E-2-hexenal (69, 83, 98); octanal (69, 84, 110); acetoin (45, 88); nonanal (82, 98, 114); E-2-octenal (70, 83, 97); nonanal (82, 95, 112); decanal (82, 95, 112); E-2-nonenal (83, 70, 96); cis-2,trans-6-nonadienal (69, 70, 81). Peak identification of the volatile components was achieved by comparison of retention times after injection of pure, authentic standards.

Data analysis

Data were subjected to one-way analysis of variance (ANOVA) followed by Fisher’s least significant difference (LSD) test to determine whether differences between samples were significant, using XLStat software version 2009.1.02 (Addinsoft, www.xlstat.com). Differences between samples with a significance level of 5% (P ≤ 0.05) were considered significant [49; SAS, 2002]. To obtain a more comprehensible overview of the volatile aroma compounds and to investigate possible correlations amongst the analytes, multivariate data analysis techniques [45], including principal component analysis (PCA) and partial least-squares discriminant analysis (PLS-DA), were performed with the Unscrambler software (version 9.2.1, Camo ASA, Norway). Data were pretreated by autoscaling to eliminate differences in measurement units.

Results and discussion

Monitoring MLF

Malolactic fermentation in the wines was induced with four different LAB strains, after completion of alcoholic fermentation with S. cerevisiae WE372. The alcohol content, pH, and malic acid concentration after alcoholic fermentation were 13.20% (v/v), 3.95, and 2.50 g/l, respectively. MLF resulted in a decrease in titratable acidity (TA), and increases in pH and volatile acidity (VA), all of which are known to be typically associated with MLF, as reported widely [9, 27].

Organic acid profiles

After completion of MLF in the Pinotage 2008 wine, no statistically significant (95% confidence level) differences were observed among the bacterial starter cultures for the malic, lactic, and citric acid (Fig. 1a) profiles. Citric acid consumption is directly involved in the production of diacetyl via the citric acid pathway [3]. No significant difference was observed among the four commercial starter cultures in terms of the citric acid concentrations left in the wine after MLF. Therefore it is not surprising that the diacetyl concentrations were similar (Table 3). No changes in the tartaric acid concentrations were observed during MLF (data not shown). In terms of acetic acid formation (Fig. 1b), the Enoferm alpha strain produced significantly more acetic acid than the control (in Pinotage 2008), although compared with the other bacterial strains there was no significant difference.

Changes observed in the a citric acid and b acetic acid concentrations as a result of MLF with different starter cultures (A, V, O, C) compared to a spontaneous (S) and control wine (no MLF: indicated by the word “Before”). Enoferm alpha: A; Lalvin VP41: V; Viniflora oenos: O; Viniflora CH16: C. Different alphabetical letters indicate significant differences

In the Pinotage 2009 and Shiraz 2008 wines, the Lalvin VP41 strain consumed significantly less citric acid than the other three strains during MLF (Fig. 1a). This could possibly suggest less metabolic activity towards citric acid and, consequently, lower diacetyl concentrations could be expected for this specific strain [3]. No significant changes in the acetic acid (Fig. 1b) and tartaric acid (data not shown) concentrations were observed in the Pinotage 2009 wine. After MLF in the Shiraz 2008 wine, significant differences were observed among the different bacterial starter cultures in terms of citric acid (Fig. 1a) and acetic acid (Fig. 1b). Viniflora CH16 produced the highest acetic acid concentration and the Enoferm alpha strain produced the lowest acetic acid concentration. The other bacteria, control wine, and spontaneous fermentation did not differ significantly from each other in terms of acetic acid concentration.

Effect of MLF on volatile composition

The concentrations of the 48 volatile compounds determined in the control wine (before MLF) and after MLF are listed in Table 3 for the Pinotage 2008 and 2009 wines and in Table 4 for the Shiraz wine. Analysis of variance (ANOVA) showed concentration differences were significant (P < 0.05) for 30 compounds in the Pinotage 2008 wine (Table 3), 28 compounds in the Pinotage 2009 wine (Table 3), and 34 compounds in the Shiraz wine (Table 4) as a consequence of MLF. Different alphabetical letters indicate significant differences (P < 0.05) among the average values obtained for each of the LAB strains used to perform MLF. This outcome is in agreement with previous studies on other red grape varieties [39, 51].

The odour thresholds (OTH) reported in the literature, aroma descriptor, and supplier information for each compound are listed in Table 1. Odour activity values (OAVs), listed in Tables 3 and 4, were calculated by dividing the mean concentration of a compound by its odour threshold value as reported in the literature [25]. This indicates that the volatile compounds with OAV > 1 could potentially make an contribution to the odour of the wine [25]. Of the 48 volatile compounds quantified, 18 analytes had OAVs > 1 in the Pinotage 2008 wine (Table 3), 20 analytes had OAVs > 1 in the Pinotage 2009 wine (Table 3), and 23 analytes had OAVs > 1 in the Shiraz 2008 wine (Table 4). These compounds include ethyl hexanoate, ethyl butyrate, ethyl octanoate, ethyl 2-methylpropanoate, ethyl 2-methylbutyrate, ethyl isovalerate, ethyl acetate, isoamyl acetate, 2-phenylethanol, isoamyl alcohol, 3-ethoxy-1-propanol, acetic acid, butyric acid, isovaleric acid, hexanoic acid, octanoic acid, diacetyl (2,3-butanedione), 2,3-pentanedione, E-2-hexenal, E-2-octenal, E-2-nonenal, and trans-2,cis-6-nonadienal. However, volatile compounds with high OAVs do not always have an effect on the aroma of wine and this information only shows potential contribution to the aroma [17] by individual analytes.

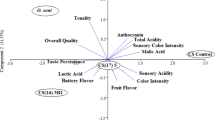

The PCA scores plot and corresponding loadings plot in Fig. 2a, b provide an overview of the volatile profiles associated with the metabolic activity of the four starter cultures during MLF in the Pinotage 2008 wine in terms of esters, alcohols, and acids. Separation along the first principal component (PC1) seems to be driven by the association of the Viniflora CH16 strain (positioned to the left of the scores plot in Fig. 2a) with a selection of ethyl esters, namely ethyl 2-methylpropanoate (fruity), ethyl propionate (fruity), ethyl isovalerate (fruity, anise), and ethyl butyrate (fruity, apple) (Fig. 2b). The Enoferm alpha and Lalvin VP41 strains, and the Viniflora oenos strain to some extent, are positioned toward the right of the scores plot (Fig. 2a) along PC3 and are associated with ethyl hexanoate (fruity, anise), ethyl lactate (butter, cream, fruit), 2-phenylethanol (honey, rose), 3-ethoxy-1-propanol (fruity), and diethyl succinate (berry). Along the second PC, Viniflora oenos, positioned toward the bottom of the scores plot (Fig. 2a), is separated from the other bacteria in terms of its association with acetic acid (vinegar), propionic acid (pungent, rancid, sweat), octanoic acid (sweat, cheese), isovaleric acid (cheese), hexanoic acid (sweat), decanoic acid (rancid, fat), butyric acid (cheese), isobutyric acid (rancid, butter, cheese), isobutanol (wine, solvent), propanol (pungent, harsh), butanol (fusel, spirituous), hexanol (green, grass, resin), 3-methyl-1-pentanol, isoamyl alcohol (fusel, whisky, malt), ethyl acetate (fruit, nail polish), ethyl decanoate (grape, floral, soap), isoamyl acetate (banana, pear), ethylphenyl acetate (rose, floral), and 2-methyl-propyl acetate (solvent). The VP41, CH16, and Enoferm alpha strains are positioned toward the top of the scores plot (Fig. 2a) along the second PC and associated with ethyl octanoate (fruit, fat), 2-phenylethyl acetate (roses), ethyl 2-methylbutyrate (fruity, apple), diethyl succinate (berry), and ethyl 3-hydroxybutanoate (strawberry, burnt marshmallow).

PCA providing a visual overview of changes in the ester, higher alcohol, and acid composition imparted by bacterial metabolism during MLF. a Pinotage 2008 wine scores plot and b the corresponding loadings plot; c Pinotage 2009 wine scores plot and d the corresponding loadings plot; e Shiraz 2008 scores plot and f the corresponding loadings plot. The different starter cultures were: Enoferm alpha (indicated by A); Lalvin VP41 (indicated by V); Viniflora oenos (indicated by O), and Viniflora CH16 (indicated by C) are compared

PCA results (Fig. 2c, d) for the volatile profiles obtained during MLF of the Pinotage 2009 wine illustrate less prominent strain discrimination in terms of the esters, higher alcohols, and acid profiles associated with the four different bacteria. The Enoferm alpha strain is positioned more to the right of the scores plot (Fig. 2c) along PC3 and toward the bottom of the plot along PC2. This position seems to be driven by association with acetoin (butter, cream), diethyl succinate (berry), ethyl propionate (fruity), ethyl decanoate (grape, floral, soap), valeric acid, and ethyl 2-methylbutyrate (fruity, apple) (Fig. 2d). The remaining three strains are positioned more to the left of the scores plot (Fig. 2c) along PC3 and slightly nearer the top of the plot along the second PC. These strains are associated with ethyl butyrate (fruity, apple), 4-methyl-1-pentanol, ethyl hexanoate (fruity, anise), ethyl octanoate (fruit, fat), ethyl 3-hydroxybutyrate (strawberry, burnt marshmallow), hexanol (green, grass), acetic acid (vinegar), isoamyl alcohol (fusel, whisky), isoamyl acetate (banana, pear), octanoic acid (sweat, cheese), hexanoic acid (sweat), decanoic acid (rancid, fat), hexyl acetate (sweet, perfume), and 2-methylpropyl acetate (solvent), with concentrations dependent on the strain used.

PCA results for the Shiraz 2008 wine show clear differentiation amongst the four different bacterial starter cultures (Fig. 2e). Separation along the second PC seems to discriminate VP41 and Viniflora CH16 from Viniflora oenos and Enoferm alpha. Along PC3, the Viniflora CH16 and oenos strains are positioned toward the left of the scores plot whereas the VP41 and Enoferm alpha strains are positioned more to the right (Fig. 2e). The corresponding loadings plot (Fig. 2f) represents the volatile profiles associated with the respective bacteria. The Viniflora oenos strain is positioned toward the bottom of the scores plot (Fig. 2e) and is associated with higher concentrations of acetoin, acetic acid, ethyl lactate, butanol, isobutanol, propanol, ethyl 3-hydroxybutanoate, ethyl 2-methylbutyrate, ethyl 2-methylpropanoate, hexanoic acid, and isoamyl alcohol. The VP41 strain is separated from Viniflora oenos along PC2 as a result of its association with a selection of esters, higher alcohols, and fatty acids including ethyl octanoate, ethyl hexanoate, ethyl isovalerate, 2-methylpropyl acetate, diethyl succinate hexyl acetate isoamyl acetate, 2-phenylethyl acetate, 2-phenylethanol, 4-methyl-1-pentanol, hexanol, 3-ethoxy-1-propanol, isobutyric acid, decanoic acid, and octanoic acid. Enoferm alpha is positioned toward the right of the scores plot along PC3 (Fig. 2e) and is associated with decanoic acid, 2-phenylethyl acetate, hexyl acetate, isoamyl acetate, and ethyl acetate. This strain is positioned in the bottom half of the score plot as a result of higher concentrations of ethyl 2-methylbutyrate, ethyl 2-methylpropanoate, ethyl 3-hydroxybutanoate, and ethyl lactate produced during MLF. The CH16 strain was positioned to the left of the scores plot (Fig. 2e) as a result of increased amounts of isovaleric acid, propionic acid, butyric acid, hexanoic acid, octanoic acid, acetic acid, 3-methyl-1-pentanol, hexanol, acetoin, ethyl lactate, ethyl hexanoate, ethyl decanoate, diethyl succinate, and 2-methylpropyl acetate.

General observations in terms of the changes within the different chemical groups including esters, higher alcohols, volatile fatty acids, and carbonyl compounds are discussed in the following sections.

Esters

Changes observed in ester concentrations after the completion of MLF are illustrated in Fig. 3. Synthesis and hydrolysis of esters during MLF were evident, as the results indicate. Ethyl lactate, diethyl succinate, ethyl octanoate, ethyl 2-methylpropanoate, and ethyl propionate concentrations were increased during MLF in comparison with the control wine, irrespective of the cultivar or bacterial strain evaluated (Fig. 3a, b). For interpretation of the graphs, ethyl lactate is excluded because of its much higher concentration in comparison with the other esters.

In the Pinotage wines, the Viniflora CH16 strain produced consistently lower concentrations of ethyl lactate (Table 3) whereas the Enoferm alpha strain seems to produce consistently higher concentrations of diethyl succinate, irrespective of the cultivar tested (Tables 3, 4). Ethyl lactate and diethyl succinate are the most important esters typically associated with MLF [30, 39, 56]. The increased concentrations are the result of succinic acid and lactic acid produced during O. oeni metabolism followed by subsequent esterification of succinic acid and lactic acid, respectively, with ethanol present in the wine [39]. Although the increase in ethyl lactate concentration was quantitatively the largest, this compound was far below its aroma threshold and is, therefore, not necessarily contributing to wine aroma. Ethyl propionate was consistently produced at higher concentrations by the Lalvin VP41 strain and at lower concentrations by the Viniflora oenos in the Pinotage and Shiraz wines.

Changes of ethyl hexanoate, ethyl decanoate, and ethyl butyrate concentrations depended on both cultivar and bacterial strain used during MLF, although the Viniflora oenos strain tended to produce higher concentrations ethyl butyrate in general. Similarly, ethyl 2-methylbutyrate and ethyl 3-hydroxybutyrate were either increased or reduced with Enoferm alpha producing higher levels of ethyl 2-methylbutryate (fruity, apple) across the wines tested and increased levels of ethyl 3-hydroxybutyrate (strawberry or burnt marshmallow) in the Pinotage 2008 wine. After MLF, ethyl 2-methylbutyrate had an OAV > 1 in all wines, indicative of potential contribution to the resulting fruity wine aroma. Ethyl isovalerate concentrations were reduced in the Shiraz wine whereas a slight increase was observed for VP41. However, in the Pinotage wines characteristic behaviour was observed, with the Viniflora oenos and Viniflora CH16 strains increasing the ethyl isovalerate concentrations, Enoferm alpha resulting in a decrease, and VP41 not affecting the concentration of this compound during both vintages.

The concentrations of hexyl acetate, isoamyl acetate, 2-phenylethyl acetate, and ethyl acetate were generally decreased or remained unchanged, depending on the strain used or the cultivar tested. Ethyl 2-phenylacetate and 2-methylphenyl acetate concentrations were increased or reduced depending on the cultivar tested, although a general trend for the Enoferm alpha strain to produce lower concentrations was observed. Contradictory to previous results [32, 39, 56], the concentration of the powerful odourant isoamyl acetate, characterised by banana attributes, was generally decreased after MLF in all three data sets, with the exception of a strain-specific increase observed in the Pinotage 2009 wine. Isoamyl acetate concentrations found in this study were far above its aroma threshold (0.03 mg/l; [25]) and could, therefore, potentially contribute to the aroma of the wines. 2-Phenylethyl acetate was also decreased or not affected throughout, although the final concentration of this compound was well below its odour threshold (0.25 mg/l; [25]). Pozo-Bayόn et al. [51] also reported no differences in hexyl acetate and 2-phenylethyl acetate concentrations as a result of MLF.

Ethyl hexanoate, ethyl butyrate, ethyl octanoate, ethyl 2-methylpropanoate, ethyl 2-methylbutyrate, ethyl isovalerate, ethyl acetate, and isoamyl acetate were all present at OAVs > 1 and could therefore contribute to the fruity aroma of the wines. Total ester production was increased by the bacterial starter cultures and it seems that two of the cultures (bacteria A and V) produced higher ester concentrations than the other two bacteria (bacteria O and C). The total amounts of esters found in these wines after MLF suggest their beneficial contribution to the wines’ final aroma.

Higher alcohols

Increments in the concentrations of most of the higher alcohols were observed in comparison with control wines in which MLF was suppressed (Tables 3, 4). Higher alcohols are synthesized by yeasts by degradation of amino acids and are considered to affect the aroma and flavour of wine [55]. Isoamyl alcohol, isobutanol, 2-phenylethanol, propanol, butanol, hexanol, 3-methyl-1-pentanol, and 3-ethoxy-1-propanol concentrations were significantly increased by MLF, with characteristic results depending on the strain used to perform MLF. For isoamyl alcohol and isobutanol, the effect of the bacterial strain selected seems to be more profound in the Pinotage wines than in the Shiraz wine. Maicas et al. [39] have also found production of isobutanol, propanol, butanol, and isoamyl alcohol to be strain dependant. In contrast, other studies found no change in the isoamyl alcohol, 2-phenylethanol, isobutanol, and propanol concentration after MLF [30, 32]. Other authors [13, 31] found that MLF had no significant effect on higher alcohol concentrations in wine, except for significant increases in isoamyl alcohol [13] and isobutanol and 2-phenylethanol, respectively [31]. The observed increase in hexanol and 3-methyl-1-pentanol concentrations as a result of MLF is in agreement with a previous report by Ugliano and Moio [56]. Pozo-Bayόn et al. [51] also found MLF to increase the levels of higher alcohols, however, none of these increases was significant.

In general, the concentrations of these alcohols, depending on the specific alcohol, were in agreement with levels found in young red wines [23]. It is interesting to note that only 2-phenylethanol, isoamyl alcohol, and 3-ethoxy-1-propanol, characterised by honey, spice, rose, lilac, fusel, whisky, malt, and fruity aroma notes, had OAVs > 1 after the completion of MLF. This indicates the potential of higher alcohols to contribute to the complexity and fruity aromas of wine; at higher concentrations (above 400 mg/l), however, these compounds are detrimental to wine aroma because of their harsh chemical-like aromas [55].

Volatile fatty acids

All four commercial strains of O. oeni tested in this study caused significant increases in the concentrations of short-chain fatty acids (Tables 3, 4). Volatile short-chain fatty acids are produced by yeast and bacteria as a result of fatty acid metabolism and, despite their low concentrations in wine, these compounds can negatively affect the aroma quality of wine because of their low perception threshold values and odours reminiscent of cheese and rancid cheese [52]. However, in this study, the extent to which these compounds were affected differed significantly from each other and was strain-dependant for some compounds. Hexanoic, decanoic, and octanoic acids were increased by MLF (Fig. 4), although the magnitudes of the concentration changes were more strain-dependant in the Pinotage wine (Fig. 4a) than in the Shiraz wine (Fig. 4b). In agreement with these results, Maicas et al. [39] found increased levels of decanoic and octanoic acid after MLF. Herjavec et al. [30] found significant increases in octanoic, hexanoic, and decanoic acid concentrations, and Pozo-Bayόn et al. [51] found significant differences for octanoic and decanoic acids depending on the MLF culture used.

The other measured fatty acids were either increased or unchanged by MLF (Fig. 4). In a recent metabolic profiling study, Lee et al. [34] reported differentiation between wines according to LAB strain used with regard to, among other compounds, differences observed in isobutyric and octanoic acids. In our study, butyric acid, isovaleric acid, hexanoic acid, and octanoic acid were the only fatty acids present at concentrations above their reported threshold values. This observation is in accordance with previous reports regarding the unlikely contribution of volatile fatty acids to flavour changes or cheesy off-flavours during MLF with O. oeni [52, 56]. It has been proposed that wine LAB have the metabolic capacity to produce volatile fatty acids through lipase activity [10] but lipolytic systems in wine LAB are not well studied and further work on this topic is needed [35, 42].

Carbonyl compounds

Changes related to aldehyde metabolism and citric acid metabolism in terms of the formation of carbonyl compounds in the Pinotage 2008 wine are listed in Table 3 and displayed graphically in Fig. 5a. No significant difference was found between the control and the wines fermented with commercial starter cultures in terms of diacetyl concentration, although the Viniflora CH16 strain produced increased concentrations compared with the other bacteria (Table 3). Similarly, no significant difference was observed in acetoin concentrations, although the Viniflora CH16 strain produced the highest concentration. PCA provides a summary of the changes observed (Fig. 5a). Diacetyl and acetoin were correlated with each other and strongly associated with the Viniflora oenos bacteria and, to a lesser extent, with the Viniflora CH16 and VP41 strains. Enoferm alpha was positioned toward the bottom of the plot and was associated with increased concentrations of E-2-octenal (herbaceous, lemon), decanal (citrus, fruity), nonanal (herbal, floral), and E-2-hexenal (herbaceous, green), all of which are associated with green or herbaceous aromas in wine [12]. However, none of these compounds was present at concentrations above their individual aroma thresholds, but possible contribution to wine aroma should not be excluded, because their cumulative effect might contribute to perceived wine aroma. The presence of trans-2,cis-6-nonadienal and 2,3-pentanedione was associated more with the control and spontaneous treatments during this experiment. It is interesting to note the negative correlation between diacetyl and 2,3-pentanedione. The chemical oxidation of diacetyl results in the formation of 2,3-pentanedione whereas reduction of diacetyl by yeasts and LAB results in the formation of acetoin. Diacetyl was present at concentrations above its range of reported aroma threshold values (0.2–2.3 mg/l; [41]), as was 2,3-pentanedione, whereas acetoin was present at levels below its reported threshold and would be less likely to contribute to wine aroma. All three compounds contribute very similar aroma attributes to wine, therefore the cumulative effect on wine aroma should not be excluded.

PCA illustrating differences among the four strains (indicated by A, V, O, C) in terms of their effect on a selection of carbonyl compounds in the Pinotage 2008 wine (a, b), Pinotage 2009 wine (c, d), and Shiraz 2008 wine (e, f). Bacteria are indicated by A (Enoferm alpha), V (Lalvin VP41), O (Viniflora oenos), and C (Viniflora CH16), and the control wine is indicated by the letter K. The letter S represents the spontaneous MLF treatment included in the study

During MLF of the Pinotage 2009 vintage, separation along the first PC was driven by the strong association of the Enoferm alpha (indicated by A in Fig. 5c and Table 3) strain with diacetyl and acetoin positioned toward the far left of the plot. Viniflora oenos and Viniflora CH16 also produced significant levels of diacetyl and acetoin whereas the VP41 strain (indicated by V in the graph) produced slightly lower levels of these compounds. The control treatment was strongly associated with higher concentrations of the aldehydes and was positioned toward the far right of the plot, and the VP41 strain was also associated with these compounds.

Prominent discrimination, by use of PCA, among the different MLF treatments in terms of carbonyl compounds for the Shiraz 2008 experiment is shown in Fig. 5e. The control, spontaneous, and VP41 treatments were positioned to the left of the PCA scores plot and correlated with each other (Fig. 5e) as a result of their association with higher concentrations of 2,3-pentanedione, E-2-hexenal, and E-2-nonenal (Fig. 5f), and with lower concentrations of diacetyl and acetoin. Conversely, the Enoferm alpha, Viniflora oenos, and Viniflora CH16 strains were positioned to the right of the scores plot and showed strong association with diacetyl and acetoin (Fig. 5f). The Enoferm alpha strain is slightly separated toward the top right of the scores plot (Fig. 5e) as a result of its association with trans-2,cis-6-nonadienal and E-2-octenal. The Viniflora oenos and CH16 strains are more correlated and positioned slightly toward the bottom of the scores plot, because of the presence of decanal. The Enoferm alpha strain produced significantly more diacetyl than the other three bacteria (Table 3) whereas VP41 imparted the smallest increase in diacetyl concentrations. All four strains produced diacetyl concentrations with OAVs > 1, potentially contributing to the buttery aroma of the wine [3]. Acetoin was produced at higher concentrations by Enoferm alpha and Viniflora CH16 strains than by VP41; these concentrations did not exceed the reported threshold level of 150 mg/l, however [18].

In summary, MLF increased diacetyl concentrations significantly with the exception of the Pinotage 2008 wine. Strain-dependant differences were observed with the VP41 strain generally producing lower concentrations of diacetyl, irrespective of the cultivar tested. Acetoin concentrations were always increased.

Significant differences in organic acid profiles corresponding to different bacterial starter cultures were shown to be a useful means of depicting possible differences in terms of specific metabolites such as ethyl lactate and diacetyl. As previously reported [35], differences in lactic acid production and citric acid metabolism could indicate different metabolic requirements and resulting volatile metabolites.

In terms of volatile composition, general increases in the ester, higher alcohol, and volatile fatty acid concentrations of all the wines were observed after the completion of MLF, irrespective of the bacterial strain and grape cultivar used. However, specific strain-dependent differences were observed for some compounds. A large portion of the esters, which are important for the fruity aroma notes of wine, were found to have OAVs > 1, indicating their potential aroma contribution. It could therefore be concluded that MLF using any of these four strains may contribute to wine quality by modifying the concentrations of some of the aroma compounds. However, the effect of chemical changes on perceived aroma should further be investigated by use of sensory evaluation techniques.

Comparative studies of the effect of different commercial MLF bacteria on the concentration of wine volatiles often focus on selected groups of compounds whereas the cultivars and strains tested are often very specific to countries and regions. The effect of MLF activity in Tannat, the most important red wine in Uruguayan viticulture, has been investigated [6], and focussed on comparison of different major volatile compounds. In other studies, the potential of four commercial MLF starter cultures to hydrolyse glycosides and release volatile compounds, and the effect on yeast-derived volatile compounds during MLF in Aglianico grapes from Southern Italy, were evaluated [56, 57]. Pozo-Bayόn et al. [51] found significant differences in the wine volatile and amino acid composition of Tempranillo wine, one of the most important Spanish red grape cultivars, after MLF with O. oeni and Lactobacillus plantarum starter cultures. Recently, metabolic profiling studies revealed significant differences among major volatile compounds after MLF by use of different starter cultures in Meoru wine, made from a wild Korean grape [34, 54]. Some studies have reported the sensory effects of MLF for Chardonnay [52] and Pinot noir [53] by comparing the effect of different bacterial inoculations. However, these studies lack supporting volatile composition data. Volatile aroma constituents including esters, aldehydes, alcohols, ketones, acids, and sulfur-containing compounds in Chancellor wine after MLF have been investigated by use of two commercial starter cultures [11]. De Revel et al. [13] found increased concentrations of wood-derived volatile compounds after MLF performed in barrels with Sauvignon blanc must. Studies specifically focussing on the effect of different MLF conditions on diacetyl concentrations in Chardonnay have also been reported [32].

In conclusion, this research contributes to our current knowledge of malolactic fermentation and, more specifically, the potential contribution to wine composition and aroma. The results therefore illustrate and reiterate that MLF and, specifically, the use of different starter cultures, affects wine aroma and flavour. However, the contribution of these starter cultures was different depending on seasonal variation and precursors present in the wine as a result of the cultivar used. Future studies should include recently developed starter cultures, combination starter cultures, and additional inoculation strategies in order to further expand our current knowledge on MLF and wine aroma under different conditions.

References

Arthur CL, Pawliszyn J (1990) Solid-phase microextraction with thermal desorption using fused silica optical fibers. Anal Chem 62:2145–2148

Bartowsky EJ, Henschke PA (1995) Malolactic fermentation and wine flavour. Aust Grapegrow Winemak 378a:83–94

Bartowsky EJ, Henschke PA (2004) The “buttery” attribute of wine—diacetyl—desirability, spoilage and beyond. Int J Food Microbiol 96:235–252

Bartowsky EJ, Costello PJ, Henschke PA (2002) Management of malolactic fermentation—wine flavour manipulation. Aust NZ Grapegrow Winemak 461a:7–12

Bauer R, Dicks LMT (2004) Control of malolactic fermentation in wine. A review. S Afr J Enol Vitic 25:74–88

Boido E, Medina K, Fariña L, Carrau F, Versini G, Dellacassa E (2009) The effect of bacterial strain and aging on the secondary volatile metabolites produced during malolactic fermentation of Tannat red wine. J Agric Food Chem 57:6271–6278

Chatonnet P, Dubourdieu D (1998) Identification of substances responsible for the sawdust aroma in oak wood. J Sci Food Agric 76:179–183

Culleré L, Cacho J, Ferreira V (2004) Analysis for wine C5–C8 aldehydes through the determination of their O-(2, 3, 4, 5, 6)-pentafluorobenzyl)oximes formed directly in the solid phase extraction cartridge. Anal Chim Acta 524:201–206

Davis CR, Wibowo D, Eschenbruch R, Lee TH, Fleet GH (1985) Practical implication of malolactic fermentation: a review. Am J Enol Vitic 36:290–301

Davis CR, Wibowo D, Fleet GH, Lee TH (1988) Properties of wine lactic acid bacteria: their potential oenological significance. Am J Enol Vitic 39:137–142

Delaquis P, Cliff M, King M, Girard B, Hall J, Reynolds A (2000) Effect of two commercial malolactic cultures on the chemical and sensory properties of Chancellor wines vinified with different yeasts and fermentation temperatures. Am J Enol Vitic 51:42–48

de Revel G, Bertrand A (1994) Dicarbonyl compounds and their reduction products in wine. Identification of wine aldehydes. In: Maarse H, van der Heij DG (eds) Trends in flavour research. Elsevier: Science BV, p 353

de Revel G, Martin N, Pripis-Nicolau L, Lonvaud-Funel A, Bertrand A (1999) Contribution to the knowledge of malolactic fermentation influence on wine aroma. J Agric Food Chem 47:4003–4008

de Revel G, Pripis-Nicolau L, Barbe JC, Bertrand A (2000) The detection of α-dicarbonyl compounds in wine by formation of quinozaline derivatives. J Sci Food Agric 80:102–108

Du Toit M, Engelbrecht L, Lerm E, Krieger-Weber S (2010) Lactobacillus: the next generation of malolactic fermentation starter cultures—an overview. Food Bioprocess Technol 4:876–906

Ebeler SE (2001) Analytical chemistry: unlocking the secrets of wine flavour. Food Rev Int 17:45–64

Escudero A, Campo E, Fariña L, Cacho J, Ferreira V (2007) Analytical characterization of the aroma of five premium red wines. Insights into the role of odor families and the concept of fruitiness of wines. J Agric Food Chem 55:4501–4510

Etiévant P (1991) Wine. In: Maarse H (ed) Volatile compounds in food and beverages. Marcel Dekker, New York, pp 483–546

Ferreira V, Aznar M, Lopez R, Cacho J (2001) Quantitative gas chromatography-olfactometry carried out at different dilutions of an extract. Key differences in the odour profiles of four high-quality Spanish aged red wines. J Agric Food Chem 49:4818–4824

Ferreira V, Culleré L, López R, Cacho J (2004) Determination of important odor-active aldehydes of wine through gas chromatography-mass spectrometry of their O-(2, 3, 4, 5, 6-pentafluorobenzyl)oximes formed directly in the solid phase extraction cartridge used for selective isolation. J Chromatogr A 1028:339–345

Ferreira V, Culleré L, Loscos N, Cacho J (2006) Critical aspects of the determination of pentafluorobenzyl derivatives of aldehydes by gas chromatography with electron-capture or mass spectrometric detection. Validation of an optimized strategy for the determination of oxygen-related odor-active aldehydes in wine. J Chromatogr A 1122:255–265

Ferreira V, Lopez R, Cacho JF (2000) Quantitative determination of the odorants of young red wines from different grape varieties. J Sci Food Agric 80:1659–1667

Francis IL, Newton JL (2005) Determining wine aroma from compositional data. Aust J Grape Wine Res 11:114–126

Gámbaro A, Boido E, Zlotejablko A, Medina K, Lloret A, Dellacassa E, Carrau F (2001) Effect of malolactic fermentation on the aroma properties of Tannat wine. Aust J Grape Wine Res 7:27–32

Guth H (1997) Quantification and sensory studies of character impact odorants of different white wine varieties. J Agric Food Chem 45:3027–3032

Hayasaka Y, Bartowsky EJ (1999) Analysis of diacetyl in wine using solid-phase microextraction combined with gas chromatography-mass spectrometry. J Agric Food Chem 47:612–617

Henschke PA (1993) An overview of malolactic fermentation. Aust NZ Wine Ind J 8:69–79

Henick-Kling T (1995) Control of malolactic fermentation in wine: energetics, flavour modification and methods of starter culture preparation. J Appl Bacteriol 79:29S–37S

Henick-Kling T, Acree T, Gavitt BK, Krieger SA, Laurent MH (1993) Sensory aspects of malolactic fermentation. In: Stockley CS, Johnston RS, Leske PA, Lee TH (eds) Proceedings of the eight Australian wine industry technical conference, 26–28 Oct 1992, Melbourne, Vic. Winetitles, SA, pp 148–152

Herjavec S, Tupajić P, Majdak A (2001) Influence of malolactic fermentation on the quality of Riesling wine. Agric Conspec Sci 66:59–64

Jeromel A, Herjavec S, Orlić S, Redžepović S, Wondra M (2008) Changes in volatile composition of Kraljevina wine by controlled malolactic fermentation. J Cent Eur Agric 9:363–372

Laurent MH, Henick-Kling T, Acree TE (1994) Changes in the aroma and odor of Chardonnay wine due to malolactic fermentation. Vitic Enol Sci 49:3–10

Lerm E, Engelbrecht L, Du Toit M (2010) Malolactic fermentation: the ABC’s of MLF. S Afr J Enol Vitic 31:186–212

Lee JE, Hong YS, Lee CH (2009) Characterisation of fermentative behaviours of lactic acid bacteria in grape wines through 1H-NMR- and GC-based metabolic profiling. J Agric Food Chem 57:4810–4817

Liu SQ (2002) Malolactic fermentation in wine—beyond deacidification. A review. J Appl Microbiol 92:589–601

Lonvaud-Funel A (1995) Microbiology of the malolactic fermentation: molecular aspects. FEMS Microbiol Lett 126:209–214

Lonvaud-Funel A (1999) Lactic acid bacteria in the quality improvement and depreciation of wine. Anton Leeuw Int J G 76:317–331

Louw L, Roux K, Tredoux A, Tomic O, Naes T, Nieuwoudt HH, van Rensburg P (2009) Characterisation of selected South African young cultivar wines using FTMIR spectroscopy, gas chromatography and multivariate data analysis. J Agric Food Chem 57:2623–2632

Maicas S, Gil JV, Pardo I, Ferrer S (1999) Improvement of volatile composition of wines by controlled addition of malolactic bacteria. Food Res Int 32:491–496

Martineau B, Acree TE, Henick-Kling T (1995) Effect of wine type on the detection threshold for diacetyl. Food Res Int 28:139–143

Martineau B, Henick-Kling T, Acree TE (1995) Reassessment of the influence of malolactic fermentation on the concentration of diacetyl in wines. Am J Enol Vitic 46:385–388

Matthews A, Grimaldi A, Walker M, Bartowsky E, Grbin P, Jiranek V (2004) Lactic acid bacteria as a potential source of enzymes for use in vinification. Appl Environ Microbiol 70:5715–5731

Matthews A, Grbin PR, Jiranek V (2006) A survey of lactic acid bacteria for enzymes of interest to oenology. Aust J Grape Wine Res 12:235–244

Mtshali PS, Divol B, van Rensburg P, du Toit M (2010) Genetic screening of wine-related enzymes in Lactobacillus species isolated from South African wines. J Appl Microbiol 108:1389–1397

Naes T, Isaksson T, Fearn T, Davies T (2002) A user-friendly guide to multivariate calibration and classification. NIR Publications, Chichester

Oeno (2006) Determination of the principal organic acids in wine by capillary electrophoresis. Resolutions Oenology. 05 2006. www.oiv.org

Ortega-Heras M, González-SanJosé ML, Beltrán S (2002) Aroma composition of wine studied by different extraction methods. Anal Chim Acta 458:85–93

Osborne JP, Mira de Orduña R, Pilone GJ, Lui SQ (2000) Acetaldehyde metabolism by wine lactic acid bacteria. FEMS Microbiol Lett 191:51–55

Otto RL (1998) An introduction to statistical methods and data analysis. Duxbury Press, Belmont

Peinado RA, Moreno J, Medina M, Mauricio JC (2004) Changes in volatile compounds and aromatic series in sherry wine with high gluconic acid levels subjected to aging by submerged flour yeast cultures. Biotechnol Lett 26:757–762

Pozo-Bayόn MA, Alegría EG, Polo MC, Tenorio C, Martín-Álvarez PJ, Calvo de la Banda MT, Ruiz-Larrea F, Moreno-Arribas MV (2005) Wine volatile and amino acid composition after malolactic fermentation: effect of Oenococcus oeni and Lactobacillus plantarum starter cultures. J Agric Food Chem 53:8729–8735

Rodriguez SB, Amberg E, Thornton RJ (1990) Malolactic fermentation in Chardonnay: growth and sensory effects of commercial strains of Leuconostoc oenos. J Appl Bacteriol 68:139–144

Sauvageot F, Vivier P (1997) Effect of malolactic fermentation on sensory properties of four Burgundy wines. Am J Enol Vitic 48:187–192

Son HS, Hwang GS, Park WM, Hong YS, Lee CH (2009) Metabolomic characterisation of malolactic fermentation and fermentative behaviour of wine yeasts in grape wine. J Agric Food Chem 57:4801–4809

Swiegers JH, Bartowsky EJ, Henschke PA, Pretorius IS (2005) Yeast and bacterial modulation of wine aroma and flavour. Aust J Grape Wine Res 11:139–173

Ugliano M, Moio L (2005) Changes in the concentration of yeast-derived volatile compounds of red wine during malolactic fermentation with four commercial starter cultures of Oenococcus oeni. J Agric Food Chem 53:10134–10139

Ugliano M, Moio L (2006) The influence of malolactic fermentation and Oenococcus oeni strain on glycosidic aroma precursors and related volatile compounds of red wine. J Sci Food Agric 86:2468–2476

Versari A, Parpinello GP, Cattaneo M (1999) Leuconostoc oenos and malolactic fermentation in wine: a review. J Ind Microbiol Biotechnol 23:447–455

Wang Q, O’Reilly J, Pawliszyn J (2005) Determination of low-molecular mass aldehydes by automated headspace solid-phase microextraction with in-fibre derivatisation. J Chromatogr A 1071:147–154

Zea L, Moyano L, Moreno J, Cortes B, Medina M (2001) Discrimination of the aroma fraction of Sherry wines obtained by oxidative and biological ageing. Food Chem 75:79–84

Zhang Z, Pawliszyn J (1993) Headspace solid-phase microextraction. Anal Chem 65:1843–1852

Acknowledgments

Lallemand and Chr Hansen are thanked for providing the starter cultures for the fermentations. Financial support was provided by Winetech, the National Research Foundation, and THRIP.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Malherbe, S., Tredoux, A.G.J., Nieuwoudt, H.H. et al. Comparative metabolic profiling to investigate the contribution of O. oeni MLF starter cultures to red wine composition. J Ind Microbiol Biotechnol 39, 477–494 (2012). https://doi.org/10.1007/s10295-011-1050-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-011-1050-4