Abstract

Although association colloidal structures are believed as major oxidation places, relationship of oxygen molecules with association colloids have not been evaluated in oil-in-water (O/W) emulsion. Oxygen solubility was determined in O/W emulsion containing dispersed phases with different charges of emulsifiers, numbers of dispersed droplets, and surface areas of dispersed droplets. The rates of lipid oxidation were also examined. O/W emulsion made of positively charged emulsifier had higher oxygen solubility than negatively charged and neutral emulsifiers. As number and surface area of oil droplet in O/W emulsion increased, higher oxygen solubility was observed, implying that dispersed phases could be places for oxygen molecules. O/W emulsion made of positively charged emulsifier had higher lipid oxidation than neutral emulsifier. O/W emulsion with more interfaces had lower oxidative stability, implying interfaces of association colloids could affect rates of lipid oxidation. Dispersed phase in O/W emulsion can be places for oxygen molecules.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Depending on the matrix including bulk oil and oil-in-water (O/W) emulsion, major factors affecting oxidative stability are different. The most important factor is the degree of unsaturation of fatty acids irrespective of matrix type. For O/W emulsion matrix, transition metal iron plays important prooxidative roles whereas others including types of emulsifiers, pH, and concentrations of salts affect oxidative stability (Budilarto and Kamal-Eldin, 2015; Chen et al., 2012; Laguerre et al., 2015). For bulk oil matrix, minor compounds including phospholipids, moisture, free fatty acids, and even oxidation products are involved in oxidative stability (Budilarto and Kamal-Eldin, 2015; Chaiyasit et al. 2007; Kim et al., 2018a; Kim et al., 2018b). Interfaces among oil and moisture of association colloids in bulk oils and those of dispersed phases in O/W emulsion have been regarded as lipid oxidation places (Budilarto and Kamal-Eldin, 2015; Chen et al., 2011; Laguerre et al., 2015).

Although lipid oxidation is a chemical reaction among unsaturated lipids and oxygen molecules, properties of oxygen molecules have been less elucidated than those of lipids (Johnson and Decker, 2015). Oxygen solubility in bulk oil is about four to five times higher than that in water (Cuvelier et al., 2017). The oxidative stability of O/W emulsion is generally different from that of a bulk oil matrix (Chaiyasit et al., 2005).

In this study, we hypothesized that dispersed phased in O/W emulsions could affect mobility or solubility of oxygen molecules. The importance of these association colloids is supported by studies of phenolipids with different numbers of alkyl chains conjugated to phenolic antioxidants. Antioxidants with 4 to 12 alkyl chains had higher antioxidant properties than those without an alkyl chain or more than 16 alkyl chains (Laguerre et al., 2015). The so called ‘cut-off’ theory can explain antioxidant activities of phenolipids. It states that proper hydrophobic alkyl chain may help position phenolipids near interfaces of association colloids (Laguerre et al., 2015). To evaluate relations of oxygen molecules with association colloids, oxygen solubility was determined in O/W emulsion at diverse conditions including charges of emulsifiers, droplet sizes, and surface areas of dispersed phase. Higher surface areas and/or numbers of association colloidal structures might help solubilize oxygen molecules in O/W emulsion.

Determining oxygen content in bulk oil or O/W emulsion is a challenging task. Gravimetry, chemical titration, gas chromatography (GC), electron paramagnetic resonance, and luminescence techniques have been tried to determine oxygen solubility in lipid matrices (Andersson and Lingnert, 1997; Banerjee et al., 2016; Cuvelier et al., 2017; Kozak and Samotyja, 2013). Recently, Kim et al. (2022) have developed a method to determine oxygen content in oil by GC with a thermal conductivity detector (TCD). However, their method can only determine the effects of amphiphilic lecithin and monoacylglycerols on oxygen solubility in bulk oil matrix. (Kim et al., 2022). Relationships of oxygen solubility with association colloids in O/W emulsions have not been elucidated in the literature, although oxygen solubility in O/W emulsion could be a major factor affecting rates of lipid oxidation.

Thus, the objectives of this study were to determine factors affecting oxygen solubility in O/W emulsion and to evaluate relationship between oxygen solubility and oxidative stability of O/W emulsion matrix.

Materials and methods

Materials

Polyoxyethylene sorbitan monooleate (Tween 80), sorbitan monooleate (Span 80), sodium dodecyl sulfate (SDS), and dodecyl trimethylammonium bromide (DTAB) were purchased from Sigma-Aldrich (St. Louis, MO, USA). Corn oil was purchased from a local grocery market (Suwon, Korea). HPLC-grade n-hexane was purchased from J.T. Baker (Avantor, PA, USA). Isooctane and other reagent grade chemicals were obtained from Samchun Chemical Co. (Seoul, Korea).

Sample preparation

Oxygen solubility in bulk oil and O/W emulsion matrices

Tween 80, Span 80, SDS, and DTAB were selected as representative neutral, neutral, anionic, and cationic emulsifiers, respectively. The hydrophile–lipophile balance value of Tween 80, Span 80, SDS, and DTAB were 15, 4.3, 40.0, and 17, respectively (Liao et al., 2021). The emulsifier was added to deionized water and then combined with 2.5% of corn oil (w/w). The concentration of emulsifier was 0.25% (w/w), which was 10% of dispersed oil content. A coarse emulsion was prepared by homogenizing the mixture for 3 min using an HB501 (Tefal, Haute-Savoie, France). The coarse emulsion was then passed through a high-pressure homogenizer (APV-1000, SPX Flow, NC, USA) operated at a pressure of 40 MPa with three times. The final concentration of the emulsifier in the O/W emulsion was 2500 ppm. To observe effect of the matrix, each emulsifier was added to corn oil at 0.25% (w/w), which was the amount for O/W emulsion. Corn oil and O/W emulsion samples were put in a 10-mL vial with saturated headspace oxygen gas condition. Samples were prepared in triplicate at each sampling point.

Emulsion with different surface areas and numbers of association colloids

The O/W emulsions with different surface areas, numbers of association colloidal structures, and concentrations of emulsifier were prepared as described previously (Kim et al., 2021). The O/W emulsion containing 5% corn oil (w/w) and 0.5% DTAB (w/w) was prepared according to the above procedure. Final O/W emulsions were serially diluted with continuous phase to have 1.0 and 2.5% oil contents (w/w). Sizes of droplets remained similar while number of droplets decreased in O/W emulsion containing 1.0% oil (w/w) compared to that in O/W emulsion containing 5.0% oil content (w/w). Therefore, O/W emulsion should have different surface areas of oil droplet due to the difference in the number of droplets although the sizes of oil droplets in O/W emulsion were similar each other.

To prepare O/W emulsions with different paths of homogenization for generating different size of droplets, the coarse emulsion made of 5% corn oil (w/w) and 0.5% DTAB (w/w) was treated with a high pressure homogenizer (APV-1000, SPX Flow, NC, USA) with 0, 1, and 4 paths so that O/W emulsions had the same oil content with different droplet sizes due to the different treatment number of high pressure homogenization.

Next, O/W emulsions with 5.0% oil (w/w) and 0.5% of DTAB (w/w) were prepared according to the above procedures and then additional 1% and 2% DTAB contents (w/w) were mixed to the prepared O/W emulsion. Therefore, O/W emulsions had the same oil content and droplet size with different emulsifier contents in the continuous phase, which could affect the stability of association colloidal structures during storage.

Autoxidation of O/W emulsion

The samples, which were a different number of homogenization paths and different concentration of emulsifier using DTAB were selected for oxidation stability. O/W emulsions were stored at 37 °C in a water bath for 3 days. Samples were prepared in triplicate and analyzed at 0, 1, 2, and 3 days.

Oxygen solubility analysis using a gas chromatography-thermal conductivity detector (GC-TCD)

The oxygen solubility in bulk oil or O/W emulsion was determined based on a previous report (Kim et al., 2022). Briefly, 14-mL vials containing 10 mL O/W emulsion or bulk oil were prepared and sealed air-tight using rubber septa and aluminium caps. The headspace in the vial was replaced with oxygen molecules for 2 min at rate of 0.5 L/min.

Headspace oxygen contents in air-tight sample vials of corn oil or O/W emulsions were analyzed according to the method described by Kim et al. (2022) using a Hewlett-Packard 7890 GC (Agilent Technologies, Inc., Santa Clara, CA, USA) equipped with a 60/80 packed column (3.0 m × 2 mm ID, Restek Ltd., USA) and a TCD. Forty microliters of headspace were injected to GC-TCD using an air-tight syringe. The flow rate of helium gas was 200 mL/min. Temperatures of an oven, an injector, and the TCD were 60, 180, and 180 °C, respectively. Response of TCD was converted to oxygen solubility according to a previous report (Kim et al., 2022).

Surface area, particle size, and zeta potential analysis of O/W emulsion

Zeta-potential, droplet size, and calculated surface area (CS) of O/W emulsions were analyzed using a zeta-potential and size analyzer (Nanotrac Wave, Microtrac, PA, USA). Total surface area was calculated using CS and oil content. The instrument can determine droplet sizes in O/W emulsion based on dynamic light scattering phenomenon.

Lipid hydroperoxide analysis

Lipid hydroperoxides of O/W emulsions were determined according to the method of Kwon et al. (2020) and Lee and Decker (2011) with some modifications. Briefly, 0.3 mL of emulsion sample was mixed with 1.5 mL of isooctane/2-propanol (3:1, v:v), vortex-mixed for 1 min, and then centrifuged at 13,000×g for 3 min. After centrifugation, 0.2 mL of the upper layer was collected and mixed with 2.8 mL of methanol/1-butanol (2:1, v:v). The mixture (1 mL) was then added to 10 μL of a thiocyanate/Fe2+ solution which was prepared by mixing an equal volume of 3.94 M thiocyanate solution with 0.072 M Fe2+ solution (obtained from the supernatant of a mixture of 0.144 M FeSO4 and 0.132 M BaCl2 in 0.4 M HCl) and vortex-mixed for 10 s. Samples were incubated at room temperature for 20 min. The absorbance of the incubated sample was measured at 510 nm using an UV/VIS-spectrometer (Model UV-1650PC, Shimadzu, Kyoto, Japan). Concentration of lipid hydroperoxide was determined using a cumene hydroperoxide standard curve (1–20 μM).

Conjugated diene analysis

Conjugated dienes in samples were determined using a method of Kwon et al. (2020). Briefly, 120 μL of each sample was mixed with 2.7 mL of methanol/1-butanol (2:1, v/v) and vortex-mixed three times for 10 s each. Absorbance at 233 nm was then measured using a UV/VIS-spectrometer (UH5300, Hitachi, Tokyo, Japan). If the range of absorbance was not within 0.2 to 0.8, samples were diluted using a solution of methanol and 1-buthanol.

Statistical analysis

Data of oxygen solubility, physicochemical properties, and oxidation parameters were statistically analysed using analysis of variance (ANOVA) and Duncan’s multiple-range test of SPSS software version 22 (SPSS Inc., Chicago, IL, USA). A p-value of less than 0.05 was considered significant.

Results and discussion

Oxygen solubility of bulk oil and oil-in-water emulsion matrices

Effects of Tween 80 (a), Span 80 (b), DTAB (c), and SDS (d) on oxygen solubility in corn oil and oil-in-water emulsion are shown in Fig. 1. Depending on types of emulsifiers, slightly different results of oxygen stability were observed. O/W emulsions made of Tween 80 and Span 80 known to be neutral emulsifiers had insignificant differences in oxygen solubility compared to corn oil containing Tween 80 or Span 80 after 5 h storage (Fig. 1A, B). However, when DTAB, a cationic emulsifier, was used for the formation of O/W emulsions, oxygen solubility differed depending on matrices (O/W emulsion or bulk oil). O/W emulsion containing DTAB had significantly higher oxygen solubility, followed by corn oil without DTAB and corn oil containing DTAB at 2 h sampling (p < 0.05) (Fig. 1C). This trend was also observed for SDS anionic emulsifier. O/W emulsion with SDS had significantly higher oxygen solubility than corn oil with SDS (Fig. 1D). DTAB emulsifier made a clearer difference in oxygen solubility than SDS emulsifier in bulk oil and O/W emulsion matrices. Interestingly, DTAB had higher oxygen solubility than other emulsifiers in O/W emulsions after 6 h whereas this effect was not observed for corn oil matrix.

Effect of Tween 80 (A), Span 80 (B), DTAB (C), and SDS (D) on oxygen solubility in corn oil and oil-in-water emulsion. ‘Corn oil’, ‘emulsifier/oil’, and ‘emulsifier/emulsion’ are samples of corn oil, corn oil added with emulsifier, O/W emulsion made of emulsifier, respectively. Different letters at the same sampling time are significant at 0.05

The decrease of oxygen solubility in edible oils with additional amphiphilic compounds including lecithin were reported by Kim et al. (2022), which agrees with the results of current study. According to the study of Chen et al. (2011), addition of phospholipids can form reverse micelle structures in bulk oil matrix which affected performance of antioxidant activities of lipophilic and hydrophilic antioxidants. Therefore, added emulsifiers should form reverse micelles in bulk oil. Charged emulsifier like DTAB and SDS may need more moisture to form reverse micelle structures compared to neutral emulsifiers, which may change the size of reverse micelles and low oxygen solubility as shown in Fig. 1. In addition, the oxygen solubility in bulk oil was increased when the surface tension was decreased. Generally, amphiphilic compounds can decrease surface tension, which may modify association colloidal structures and affect oxygen solubility in edible oil. However, effects of amphiphilic compounds were not compared among edible oil and O/W emulsion matrices.

Surface tension of O/W emulsions is higher than that of conventional edible oil but lower than that of water (data not shown). Increased oxygen solubility in O/W emulsion made of charged emulsifier could be due to creation of more places for oxygen molecules in the O/W emulsion matrix. Emulsifier should affect surface integrity of dispersed droplets in O/W emulsion and dispersed phase made of charged emulsifiers like DTAB and SDS may have more spaces on the surfaces of dispersed phase than neutral emulsifier due to the repulsion among emulsifiers. Therefore, dispersed phase made of DTAB and SDS may have higher oxygen solubility in O/W emulsion than those of Tween 80 and Span 80 (Fig. 1).

Physical properties of oil-in-water emulsion matrix

Droplet sizes, calculated surface areas, total surface areas, and zeta potential of corn oil-in-water emulsion are shown in Table 1. When the oil concentration was controlled by diluting the emulsion using continuous phase, zeta potential was not significantly different from each other (p > 0.05) whereas total surface area was significantly increased by 4.5 times as oil content increased from 1 to 5% (p < 0.05). Dilution of O/W emulsion caused a decrease in mean diameter of volume and an increase in calculated surface area (Table 1).

As paths of homogenization increased from 0 to 4, the mean diameter of volume decreased while calculated surface area and total surface area increased significantly (p < 0.05), implying that the size of dispersed phase decreased while the number of dispersed phase increased in O/W emulsion made of 4 paths of homogenization compared to that made of 0 path of homogenization (Table 1).

Addition of DTAB from 0.5 to 2.0% did not cause significant changes in mean diameter of volume (p > 0.05), implying that added DTAB did not alter the size or the number of dispersed phases in O/W emulsions (Table 1). However, zeta potential and calculated surface area showed an increasing trend while total surface area showed a decreasing trend when the added DTAB content was increased from 0.5 to 2.0% in O/W emulsion. Added DTAB might migrate to surfaces of dispersed phases and participate as emulsifiers without destroying structures, causing changes in zeta potential, calculated surface area, and total surface area. In general, droplet size is decreased with increased emulsifier concentration (Ataeian et al., 2022) and the decreased droplet size of the emulsion implies better emulsion stability (Li et al., 2020). On the other hand, in this study, surplus DTAB might form micelle structures in the continuous phase of O/W emulsion, which might not be detected by the instrument.

Zeta potential, the electrostatic potential at the vicinity of the particle’s surface, provide the information of electrostatic repulsion and separation distance among particles in the emulsion system (Thaiphanit and Anprung, 2016). A zeta potential of higher than 30 mV or lower than − 30 mV considered as a stability threshold. Since the zeta potentials of all samples were higher than 30 mV (Ma et al., 2022), all emulsions prepared were considered as stabilized emulsions. Overall, droplet size, surface area, zeta potential, and calculated surface areas of O/W emulsions were within ranges of expectation.

Oxygen solubility of O/W emulsion made of different surface areas, numbers of droplets, and emulsifier contents

Oxygen solubility in corn oil-in-water emulsions made of different oil contents using serial dilution (a), made of different droplets size according to the number of high-pressure homogenization paths, (b) and made of different concentration of emulsifier (c) are shown in Fig. 2. Oxygen solubilities in O/W emulsions made of 1.0 and 5.0% oil contents were 3.0 and 4.3 μmol/mL, respectively, after 8 h. At 8 h, the difference in oxygen solubility was greater according to the difference in total surface area. The O/W emulsion made of serial dilution had similar sizes of droplets but different numbers of droplets as shown in Table 1. As the number of dispersed phases and total surface area increased, more oxygen was dissolved in O/W emulsion, which was a unique and interesting observation.

Oxygen solubility in corn oil-in-water emulsion made of different oil contents using serial dilution (A), made of different droplets size according to the number of high-pressure homogenization paths (B) and made of different concentration of emulsifier (C). ‘5.0%’, ‘2.5%’, and ‘1.0%’ in (A) are O/W emulsion made of 5.0, 2.5, and 1.0% of oil, respectively. ‘0 time’, ‘1 time’, and ‘4 times’ in (B) are O/W emulsion treated paths using a high pressure homogenizer, respectively. ‘0.5%’, ‘1%’, and ‘2%’ in (C) are O/W emulsion added with 0, 1, and 2% of DTAB, respectively. Different letters represent significant differences (p < 0.05) at the same sampling time

The absolute number of dispersed phases in O/W emulsion made of 1% corn oil was decreased compared to that in O/W emulsion made of 5% corn oil through dilution while the size and zeta potential of dispersed phases were similar to each other.

As homogenization paths in O/W emulsion increased from 0 to 4, more oxygen was soluble (Fig. 2). Oxygen solubilities in O/W emulsions made of 0 and 4 homogenization paths were 1.7 and 2.8 μmol/mL, respectively, after 8 h. As the size and number of dispersed phases and total surface area increased, more oxygen was dissolved in O/W emulsion, in agreement with results shown in Fig. 2. Similar to samples with different oil contents, there was a large difference in oxygen solubility when the difference in total surface area was large. The more surface area of droplets, the more oxygen can be dissolved in O/W emulsions.

When the concentration of added emulsifier was increased from 0.5 to 2.0%, oxygen was less soluble in O/W emulsion (Fig. 2). Oxygen solubilities in O/W emulsions added with emulsifier at 0.5 and 2.0% were 3.4 and 2.8 μmol/mL, respectively, after 8 h. Added emulsifier may locate at the surface of dispersed phases without substantial changing the size or the number of droplets in O/W emulsion. The surplus emulsifier on association colloids increased zeta potential, while decreased empty space of the surface area, which could be locations of oxygen molecules. This might lead better oxidative stability. According to Pan et al. (2013), the antioxidant activity of emulsifiers could affect the permeation of free radicals, as a result, delay the oxidation in O/W emulsion. The permeation of the interfacial layer can be influenced by size of pore and the type of molecules, which can bind or repel the pro-oxidants (Dai et al., 2018; Keramat et al., 2022). The oxidative stability of emulsion is greatly influenced by the interfacial layer properties (physical properties, chemical properties, and electrical charge), droplet size, and pH (Keramat et al., 2022). Among these factors, permeability of the interfacial layer plays a crucial role on oxidative stability of emulsion.

Oxidative stability of oil-in-water emulsion matrix

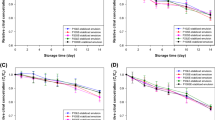

Changes of oxygen consumption (a), lipid hydroperoxides (b), and conjugated dienes (c) in 37 °C stored oil-in-water emulsion made of different droplets size according to the number of high-pressure homogenization paths are shown in Fig. 3. After 3 days of storage, oxygen consumption of O/W emulsion from 4 paths of homogenization was the highest, followed by those from 1 and 0 path in a decreasing manner (Fig. 3A). This implies that the higher the homogenization path, the more the degree of lipid oxidation in O/W emulsion. This trend can be observed in contents of oxidation products. Both conjugated dienes and lipid hydroperoxides in O/W emulsion from 4 paths of homogenization had higher values than those from 0 and 1 paths of homogenization (Fig. 3B, C).

Changes of oxygen consumption (A), lipid hydroperoxides (B), and conjugated dienes (C) in 37 °C stored oil-in-water emulsion made of different droplets size according to the number of high-pressure homogenization paths. ‘0 time’, ‘1 time’, and ‘4 times’ in Fig. 2B are O/W emulsion treated paths using a high pressure homogenizer, respectively. Different letters represent significant differences (p < 0.05) at the same sampling time

Oxygen solubility/concentration is closely related to the oxidative stability because it is a key factor for lipid oxidation (McClements and Decker, 2000). O/W emulsions are more vulnerable to lipid oxidation than bulk oil or bulk oil with water. Droplet size can affect the rate of lipid oxidation in O/W emulsion (Lethuaut et al., 2002). Although oxygen solubility shown in Fig. 3A might not be the major factor, it is inevitable to claim that oxygen molecules play important roles in rates of lipid oxidation in O/W emulsion from different paths of homogenization.

Oxygen consumption (a), lipid hydroperoxides (b), and conjugated dienes (c) in corn oil-in-water emulsion made of different concentrations of DTAB after storage for 3 days at 37 °C are shown in Fig. 4. The lowest concentration of DTAB (0.5%) showed a better oxidative stability than other concentrations (1 and 2%). A similar pattern was observed in oxygen consumption, lipid hydroperoxide, and conjugated dienes (Fig. 4). However, the oxidative stability exhibited different trend depending on emulsifier type (data not shown). O/W emulsion made of DTAB was higher than that made of Tween 80 irrespective of emulsifier concentration in both conjugated dienes and lipid hydroperoxides. This might imply that oxidative stability in O/W emulsion made of DTAB was lower than that in O/W emulsion made of Tween 80. The addition of DTAB increased oxygen consumption and formation of conjugated dienes and lipid hydroperoxides than the addition of other emulsifiers, implying that addition of DTAB might promote the formation of oxidation products in O/W emulsion (data not shown). O/W emulsions made of a cationic emulsifier have lower oxidative stability than those made of a neutral emulsifier (Yi et al., 2016). Although cationic emulsifier can promote oxidation, neutral emulsifier has no significant effect on lipid oxidation of O/W emulsion matrix (Yi et al., 2016). Another study compared headspace oxygen content using different types of emulsifiers such as sodium dodecyl sulfate (SDS, anionic emulsifier), polyoxyethylene sorbitan monolaurate (Tween 20, non-ionic emulsifier), and cetyltrimethylammonium bromide (CTAB, cationic emulsifier) in O/W emulsion during photooxidation. They reported that the emulsion using CTAB (18.27%) showed significantly lower headspace content than emulsions containing SDS (20.02%) and Tween 20 (20.84%). Charged chemicals such as lecithin, SDS, and DTAB play some roles in the oxygen solubility, although their roles are different depending on bulk oil and O/W emulsion. The charged chemicals decreased oxygen solubility in bulk oil, whereas these increased oxygen solubility in O/W emulsion matrix as shown in Fig. 4.

Oxygen consumption (A), lipid hydroperoxides (B), and conjugated dienes (C) in corn oil-in-water emulsion made of different concentration of DTAB stored for 3 days at 37 °C. ‘0.5%’, ‘1%’, and ‘2%’ in Fig. 2C are O/W emulsion added with 0, 1, and 2% of DTAB, respectively. Different letters represent significant differences (p < 0.05) at the same sampling time

Suggested scheme for the correlation among association colloidal structures and oxygen solubility is shown in Fig. 5. As the number of droplets decreased, oxygen solubility decreased (Fig. 3A), implying that dispersed phases were closely related to oxygen solubility (Fig. 5A). This speculation could be supported by results of Fig. 3B. As droplet size decreased, surface areas of droplets increased, resulting in increased oxygen solubility (Fig. 5B). Therefore, dispersed phases could be main places for oxygen molecules in the O/W emulsion matrix. As surplus emulsifier added, surface areas of dispersed phase could be lower due to packing of emulsifier and lowering oxygen solubility (Fig. 5C).

Charged chemicals such as lecithin, SDS, and DTAB play some roles in the oxygen solubility, although their roles are different depending on bulk oil and O/W emulsion. In bulk oil, charged chemicals decreased oxygen solubility as shown in the study of Kim et al. (2022), but increased oxygen solubility in the O/W emulsion matrix. Surface tension of O/W emulsion is higher than that of bulk oil but lower than that of water.

Currently, the exact mechanisms involved in the effect of charged chemicals on oxygen solubility in lipid matrices remain unclear. Contradictory effects of DTAB on bulk oil and O/W emulsion might give some clues (Yi et al., 2018). Oxygen solubility may indicate available space in lipids irrespective of bulk oil or O/W emulsion. High oxygen solubility implies more room or space for small sized molecules like oxygen in matrix. Added compounds may fill the room efficiently with less room for oxygen molecules left in bulk oil. Chemicals possessing high amphiphilicity may incorporate efficiently to association colloidal structures in lipids and occupy space, thus decreasing rooms for oxygen molecules. In case of emulsion matrix, oil droplets covered with charged SDS or DTAB may repel each other better than neutral emulsifiers such as Tween 80 and Span 80, which creates more space among dispersed droplets in an O/W emulsion.

In conclusion, relationships of oxygen molecules with association colloidal structures in bulk oil and O/W emulsion matrices were investigated. Added charged emulsifiers affect the oxygen solubility more than neutral emulsifier irrespective of lipid matrices. The O/W emulsions possessing higher number of droplets or larger surface areas can harvest more oxygen molecules, which implies that dispersed phase or association colloidal structure in O/W emulsions are places for oxygen molecules. Although oxygen solubility partly affects oxidative stability, other factors should also be considered to understand rates of lipid oxidation in an O/W emulsion matrix.

Change history

01 November 2023

A Correction to this paper has been published: https://doi.org/10.1007/s10068-023-01470-3

References

Andersson K, Lingnert H. Influence of oxygen concentration on the storage stability of cream powder. LWT - Food Science and Technology. 30:147-154 (1997)

Ataeian P, Aroyan L, Parwez W, Tam KC. Emulsions undergoing phase transition: Effect of emulsifier type and concentration. Journal of Colloid and Interface Science. 617:214-223 (2022)

Banerjee S, Kelly C, Kerry JP, Papkovsky DB. High throughput non-destructive assessment of quality and safety of packaged food products using phosphorescent oxygen sensors. Trends in Food Science and Technology. 50:85-102 (2016)

Budilarto ES, Kamal-Eldin A. The supramolecular chemistry of lipid oxidation and antioxidation in bulk oils. European Journal of Lipid Science and Technology. 117:1095-1137 (2015)

Chaiyasit W, McClements DJ, Decker EA. The Relationship between the physicochemical properties of antioxidants and their ability to inhibit lipid oxidation in bulk oil and oil-in-water emulsions. Journal of Agricultural and Food Chemistry. 53:4982-4988 (2005)

Chaiyasit W, Elias RJ, McClements DJ, Decker EA. Role of physical structures in bulk oils on lipid oxidation. Critical Reviews in Food Science and Nutrition. 47:299-317 (2007)

Chen B, Han A, Laguerre M, McClements DJ, Decker EA. Role of reverse micelles on lipid oxidation in bulk oils: impact of phospholipids on antioxidant activity of α-tocopherol and Trolox. Food and Function. 2:302-309 (2011)

Chen B, Panya A, McClements DJ, Decker EA. New insights into the role of iron in the promotion of lipid oxidation in bulk oils containing reverse micelles. Journal of Agricultural and Food Chemistry. 60:3524-3532(2012)

Cuvelier ME, Soto P, Courtois F, Broyart B, Bonazzi C. Oxygen solubility measured in aqueous or oily media by a method using a non-invasive sensor. Food Control. 73:1466-1473 (2017)

Dai L, Zhan X, Wei Y, Sun C, Mao L, McClements DJ, Gao Y. Composite zein-propylene glycol alginate particles prepared using solvent evaporation: Characterization and application as Pickering emulsion stabilizers. Food Hydrocolloids. 85:281-290 (2018)

Johnson DR, Decker EA. The role of oxygen in lipid oxidation reactions: A review. Annual Review of Food Science and Technology. 6:171-190 (2015)

Keramat M, Kheynoor N, Golmakani MT. Oxidative stability of pickering emulsions. Food Chemistry: X. 14:100279 (2022)

Kim JS, Kim MJ, Lee JH. The critical micelle concentration of lecithin in bulk oils and medium chain triacylglycerol is influenced by moisture content and total polar materials. Food Chemistry. 261:194-200 (2018a)

Kim JS, Woo YS, Ryu JW, Kim MJ, Lee JH. Lecithin near its critical micelle concentration increases oxidative stability of non-stripped corn oil but not stripped corn oil. European Journal of Lipid Science and Technology. 121:1800219 (2018b)

Kim CH, Jo SB, Yoo KC, Kim MJ, Lee JH. Distribution of aldehydes and comparison of aldehydes with other oxidation parameters in oil matrices during autoxidation. Food Science and Biotechnology. 30:1195-1203 (2021)

Kim SH, Kim SH, Oh WY, Lee YH, Lee JH. Evaluation of the effects of amphiphilic compounds on oxygen solubility in bulk oil. International Journal of Food Science and Technology. 57:6082-6089 (2022)

Kozak W, Samotyja U. The use of oxygen content determination method based on fluorescence quenching for rapeseed oil shelf-life assessment. Food Control 33(1):162-165 (2013)

Kwon YJ, Jo SB, Na HS, Kim SH, Kim MJ, Lee JH. Effects of 1,2-dioleoyl-sn-glycero-3-phosphocholine on moisture content and oxidative stability in soybean oil–water system at different interfaces. Food Science and Biotechnology. 29:479-486 (2020)

Laguerre M, Bayrasy C, Panya A, Weiss J, McClements DJ, Lecomte J, Decker EA, Villeneuve P. What makes good antioxidants in lipidbased systems? The next theories beyond the polar paradox. Critical Reviews in Food Science and Nutrition. 55:183-201 (2015)

Lee JH, Decker E. Effects of metal chelators, sodium azide, and superoxide dismutase (SOD) on the oxidative stability in riboflavin photosensitized O/W emulsion systems. Journal of Agricultural and Food Chemistry. 59:6271-6276 (2011)

Lethuaut L, Métro F, Genot C. Effect of droplet size on lipid oxidation rates of oil-in-water emulsions stabilized by protein. Journal of the American Oil Chemists’ Society. 79:425-430 (2002)

Li D, Zhao Y, Wang X, Tang H, Wu N, Wu F, Yu D, Elfalleh W. Effects of (+)-catechin on a rice bran protein oil-in-water emulsion: Droplet size, zeta-potential, emulsifying properties, and rheological behavior. Food Hydrocolloids. 98:105306 (2020)

Liao X, Wang Y, Liao Y, You X, Yao L, Razaqpur AG. Effects of different surfactant properties on anti-wetting behaviours of an omniphobic membrane in membrane distillation. Journal of Membrane Science. 634:119433 (2021)

Ma J, Chen H, Chen W, Wu J, Li Z, Zhang M, Zhong Q, Chen W. Effects of heat treatment and pH on the physicochemical and emulsifying properties of coconut (Cocos nucifera L.) globulins. Food Chemistry. 388:133031 (2022)

McClements DJ, Decker EA. Lipid oxidation in oil-in-water emulsions: Impact of molecular environment on chemical reactions in heterogeneous food systems. Journal of Food Science. 65:1270-1282 (2000)

Pan Y, Tikekar RV, Nitin N. Effect of antioxidant properties of lecithin emulsifier on oxidative stability of encapsulated bioactive compounds. International Journal of Pharmaceutics. 450(1-2):129-137 (2013)

Thaiphanit S, Anprung P. Physicochemical and emulsion properties of edible protein concentrate from coconut (Cocos nucifera L.) processing by-products and the influence of heat treatment. Food Hydrocolloids. 52:756-765 (2016)

Yi BR, Kim MJ, Lee JH. Effects of emulsifier charges on the oxidative stability in oil-in-water emulsions under riboflavin photosensitization. Food Science and Biotechnology. 25(4):1003-1009 (2016)

Yi BR, Kim MJ, Lee JH. Oxidative stability of oil-in-water emulsions with a-tocopherol, charged emulsifier, and different oxidative stress. Food Science and Biotechnology. 27(6):1571-1578 (2018)

Acknowledgements

This research was supported by a Grant (NRF-2020R1A2C2006600) of the Basic Science Research Program through the National Research Foundation of Korea, Republic of Korea.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors have declared no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yoo, K., Kim, S., Kim, MJ. et al. Effects of association colloidal structures on the oxygen solubility in oil-in-water emulsion matrix. Food Sci Biotechnol 33, 569–577 (2024). https://doi.org/10.1007/s10068-023-01338-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10068-023-01338-6