Abstract

The storage stability of compounds encapsulated in emulsions is strongly influenced by the properties of the droplet interfacial membrane. To evaluate the effect of emulsion droplet interface thickness on the degradation of citral, emulsions were prepared using polyoxyethylene alkyl ether-type emulsifiers with hydrophilic and hydrophobic groups of various sizes. Acid cyclization of citral at pH 3 promoted faster degradation than that at pH 7. Ferrous irons accelerated citral degradation in the emulsions at pH 3 but not at pH 7, because they decomposed the products of the acid-catalyzed cyclization of citral through redox reactions rather than direct degradation. Water-soluble radicals dramatically increased the rate of citral degradation, irrespective of pH. Notably, at low pH, the rate of citral degradation by ferrous irons was higher than that by radicals. These findings suggest that the thickness and density of emulsion droplet surfaces are not important factors for inhibiting citral degradation in emulsions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Citral is a widely used food flavoring agent, as it comprises two geometric isomers, neral (cis-citral) and geranial (trans-citral) (Schieberle and Grosch, 1998) and has a strong lemon odor. Citral decomposition generally occurs through a series of cyclization and oxidation reactions. Citral degradation decreases the ‘fresh’ aroma and is accompanied by the generation of several off-odor compounds, mainly p-methylacetophenone and p-cresol (Kimura et al., 1983; Schieberle and Grosch, 1998; Ueno et al., 2004). Citral decomposition is promoted in acidic environments (Peacock and Kuneman, 1985). Because the majority of commercially available beverages are acidic, the chemical degradation of citral in such beverages should be prevented to maintain quality. The chemical stability of labile food flavors, including citral, could be improved by isolating them from harsh environments. One of the most effective ways of isolating labile food flavors from harsh environments is by incorporating them into colloidal dispersions, such as emulsions, micelles, and microcapsules. Particularly in emulsions, labile food flavors are isolated from environments that promote their chemical degradation by the interfacial membrane of the emulsion droplets. This can effectively improve the stability of these food flavors, resulting in a reduced degradation rate (Decker and McClements, 2001; Given Jr., 2009).

Generally, emulsions consist of two immiscible liquids (oil and water in food systems), where one liquid is dispersed as small spherical droplets in the other liquid (McClements, 2005). When a pure oil and pure water are combined and homogenized, the two phases generally separate into a system that consists of layers of oil and water within a few minutes (McClements, 2005). This rapid phase separation occurs due to the thermodynamically unstable contact between oil and water molecules (Israelachvili, 2011). The surface activity of emulsifiers gives them the ability to create kinetically stable emulsions by absorbing to the surface of freshly formed droplets during homogenization. By forming an interfacial membrane, emulsifiers act as a barrier that can enhance the physical stability (by preventing coalescence, Ostwald ripening, etc.,) of emulsions and improve their chemical stability by delaying reactions such as lipid oxidation (Faraji et al., 2004; Lee et al., 2018; Qian et al., 2012). It has been suggested that emulsifier properties play a significant role in the determination of the characteristics of the interfacial membrane. When lipophilic functional compounds are encapsulated by emulsion droplets, the interfacial membrane (as a protective barrier) can increase their stability. Through interfacial engineering using mixed emulsifier systems (Mao et al., 2013) and using multilayer coatings (Evans et al., 2013), the ability of emulsions to retard lipid oxidation and to enhance the stability of encapsulated compounds can be improved. Thus, emulsifiers are important for enhancing the stability of emulsions against physical and chemical destabilization processes and improving the storage stability of functional compounds encapsulated in emulsion droplets (McClements, 2013).

Over the past few years, several studies have shown that the stability of citral in acidic environments can be greatly improved by incorporating it into colloidal dispersions (Choi et al., 2010; Djordjevic et al., 2008; Yang et al., 2012). Because citral is fairly water-insoluble, it may be predominantly partitioned into non-polar environments such as oil droplets and inner micelles. Thus, as mentioned above, the incorporation of citral into emulsions and micelles is a good way to alter its stability against chemical degradation. For example, because whey protein isolate can repel prooxidant metals, and the amino acids of whey protein isolate have the ability to scavenge free radicals and to chelate prooxidant metals, the emulsion droplet interface created with whey protein isolate at pH 3 inhibits the degradation of citral in emulsions (Djordjevic et al., 2008). The chemical stability of citral in emulsions was improved by controlling the electrical characteristics of the oil droplets, where the positively charged emulsion interface could repel prooxidant metals from the emulsion droplets by electrostatic repulsion (Choi et al., 2010). The thick emulsion interface, formed by coating the positively charged biopolymers on the negatively charged emulsion droplets, is very helpful for the enhancement of the stability of citral in emulsions during storage. Because transition metals are repelled from emulsion droplets having a positively charged biopolymer layer as the outermost layer, electrostatic repulsion between transition metals and emulsion droplets is also an important factor for improving the stability of citral in these multilayer emulsions (Yang et al., 2012).

However, most studies on the influence of interfacial membrane properties on the stability of citral in emulsions have shown that the charge of the emulsion droplets is one of the most important factors influencing the chemical stability of the encapsulated citral. Although multilayer emulsions have a relatively thick interfacial membrane, the charge of the outermost layer of the oil droplets is still a key factor in controlling the stability of citral in these droplets. However, very few studies have examined the impact of other properties of interfacial membranes, besides the charge, on the stability of labile food flavors in emulsions. Therefore, in the present study, we prepared citral-containing emulsions having various interfacial properties and evaluated the effect of the characteristics of the emulsion interface, especially its thickness, on the stability of encapsulated citral when exposed to environmental stresses (pH, transition metals, and free radicals). Thus, the results of this study can deepen our understanding of the influence of the thickness of emulsion droplet interfaces on the chemical stability of labile food flavors in emulsions.

Materials and methods

Materials

Citral (mixture of 55% geranial and 45% neral, 95% pure), polyoxyethylene alkyl ether-type emulsifiers (polyoxyethylene 10 lauryl ether (P10LE), polyoxyethylene 10 stearyl ether (P10SE), polyoxyethylene 20 stearyl ether (P20SE), polyoxyethylene 23 lauryl ether (P23LE), and polyoxyethylene 100 stearyl ether (P100SE)), and 2,2′-azobis(2-methylpropionamidine) dihydrochloride (AAPH) were purchased from Sigma-Aldrich (St. Louis, MO, USA). Polyoxyethylene alkyl ether-type emulsifiers are nonionic surfactants containing polyethylene oxide chains as hydrophilic groups and n-alkyl chains as hydrophobic groups. Medium chain triglyceride (Delios S, 70% caprylic and 30% capric acids) was obtained from BASF (Ludwigshafen, Germany). Other chemicals used in this study were of analytical grade.

Emulsion preparation

Emulsions were prepared by homogenizing 5% (w/w) oil phase (MCT) with 95% (w/w) aqueous phase containing polyoxyethylene alkyl ether-type emulsifiers in 10 mM phosphate buffer (pH 7) to a predetermined concentration. Coarse emulsions were prepared by homogenization of the oil and aqueous phases using a high-speed blender (T18 Basic Ultra-Turrax, Ika, Staufen, Germany) for 2 min at room temperature. For droplet size reduction, the premixed emulsions were homogenized with five passes through a microfluidizer (MN400BF, Micronox, Seongnam, Korea) at 100 MPa. The pH of the emulsion sample was adjusted to a predetermined value using 0.1 and 1.0 N hydrochloric acid solutions. All emulsions were stirred at the desired pH for at least 30 min under nitrogen before the subsequent step. After emulsion preparation, pure citral was directly added to the emulsion to obtain a final citral concentration of 10 mmol/kg-emulsion and dissolved by stirring for 1 h at room temperature. To determine the effect of iron ions on the stability of citral in emulsions, a ferrous sulfate (FeSO4) stock solution was added to the emulsion samples at a final concentration of 5 mmol/kg-emulsion. Furthermore, to determine the effect of free radicals on the stability of citral in emulsions, AAPH stock solutions were added to the emulsion samples at a final concentration of 5 mmol/kg-emulsion. An emulsion (10 g) was transferred into 12 mL of a glass vial fitted with an airtight screw cap and a sample vial was stored in the dark at 25 °C to prevent potential photodegradation of citral.

Interfacial tension measurement

Interfacial tensions between MCT and emulsifier solutions were determined using SDT spinning-drop tensiometer (Krüss, Hamburg, Germany). The emulsifier solution was injected into the capillary tube as the bulk phase, and 2 μL of MCT were injected into the middle of the tube as the drop phase. Interfacial tensions were measured at rotating velocities ≈ 15,000 rpm and at 30 °C.

Droplet size measurement

Emulsions were diluted to an emulsion droplet concentration of 0.005% (w/w) using a buffer solution with a same pH to emulsions and stirred continuously throughout the measurements to ensure homogeneity. The oil droplet sizes of emulsions were measured using a laser diffraction particle size analyzer (BT-9300ST; Bettersize Instruments, Dandong, China). The refractive indexes of MCT and buffer solution were set at 1.47 and 1.33, respectively, provided by the supplier of a laser diffraction particle size analyzer. The particle size data are reported as either the volume-weighted mean diameter, \(d_{43} = \sum n_{i} \cdot d_{i}^{4} /\sum n_{i} \cdot d_{i}^{3}\), where \(n_{i}\) is the number of particles with diameter \(d_{i}\).

Citral concentration measurement

Citral concentration was measured according to the method described by Park et al. (2015) with slight modification. The emulsion (2 g) was placed in a conical tube, and to it 4 g of dichloromethane was added. The sample was vortexed vigorously for 1 min and the upper organic phase was collected after centrifugation at 1800×g at 25 °C for 30 min. One microliter of extract was injected into an HP-5 column (Agilent Technologies, Santa Clara, CA, USA; 30 m × 0.32 mm i.d., 0.25-μm film thickness) with a splitless glass injection using a gas chromatograph (7890A, Agilent Technologies) with a flame ionizing detector. An oven temperature program was applied by starting at 100 °C, increasing to 140 °C at a rate of 3 °C/min, and ramping to a final temperature of 300 °C at a rate of 10 °C/min. Finally, the temperature was maintained at 300 °C for 5 min. The injector and flame ionization detector were set at 220 and 350 °C, respectively. Nitrogen was used as the carrier gas at a column flow rate of 1.3 mL/min.

The rate of citral degradation was modeled by assuming 1st-order kinetics as follows (Eq. 1):

where C0 is the initial citral concentration in the emulsion and Ct is the citral concentration remaining in the emulsion at time t. The degradation rate constant (k) was determined by linear regression of the plots of \(\ln \left( {C_{t} /C_{0} } \right)\) versus t.

Statistical analysis

All the experiments were performed in triplicate, and the data are expressed as mean ± standard deviation. The equality of coefficients of different linear regressions was analyzed by Chow test (Chow, 1960). All statistical analyses were performed using SPSS Statistics (Version 23; IBM, Armonk, NY, USA).

Results and discussion

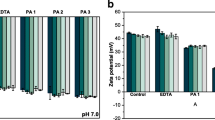

If the micelles formed with unabsorbed emulsifiers in an emulsion system exceed a particular concentration, they may induce destabilization of the emulsions in several cases (Wulff-Pérez et al., 2009). Therefore, to minimize the effect of micelles formed with unabsorbed emulsifiers on the stability of emulsions and encapsulated citral, the minimum emulsifier concentration (MEC) required for the preparation of high-stability emulsions with the smallest droplet size (if appropriate) was determined in our previous study (Han et al., 2018). The MECs of P10LE, P10SE, P20SE, P23LE, and P100SE were 2.90, 3.17, 2.93, 1.78, and 0.99 mM, respectively. The initial droplet diameters (d43) of the emulsions were all fairly similar (0.31, 0.31, 0.32, 0.38, and 0.34 μm for P10LE-, P10SE-, P20SE-, P23LE-, and P100SE-stabilized emulsions, respectively) at the MEC of the emulsifiers, irrespective of the emulsifier type, pH of emulsion, or the presence of iron and AAPH in the emulsions, and the diameters did not change significantly (p > 0.05) during a 14-day storage period. Because all prepared emulsions had a similar droplet diameter, they should have a similar specific surface area. Therefore, any significant difference in the degree and rate of citral decomposition in the various emulsions could not be attributed to the difference in specific surface area.

Because the solubility of citral in water is 1340 mg/L based on the chemical specifications of the supplier, when citral is added to an emulsion, most of the citral molecules are partitioned into emulsion droplets, but some amount of citral may remain in the aqueous phase. Therefore, citral in the aqueous phase could be easily decomposed by water-soluble substances that promote its degradation. In order for the citral located in the core of the emulsion droplets to decompose, it must move to the interfacial membrane. Thereafter, citral must react with water-soluble substances that promote its degradation at the emulsion interface, or it must diffuse to the aqueous phase across the emulsion droplet interface. This means that the interfacial membrane plays an important role in controlling the stability of citral in emulsions.

Influence of pH on decomposition of citral in emulsions

According to the proposed mechanism for degradation of citral, decomposition under acidic conditions is initiated by geranial to neral isomerization, followed by further degradation through cyclization of the neral to form monoterpene alcohols (Weerawatanakorn et al., 2015). It is important to understand the influence of pH on the chemical stability of citral in emulsions because the commercially available soft drinks and nutritional beverages that employ emulsions generally have an acidic pH (Tan, 2004). Therefore, to examine how the properties of the droplet interfacial membrane impact the decomposition of citral at an acidic pH, the emulsions were stored at pH 3 and 7. The effects of the emulsifier and pH on the stability of citral in the emulsions is summarized in Fig. 1. At pH 7, citral underwent little degradation, independent of the number of oxyethylene groups in the hydrophilic heads of the emulsifiers, which could be attributed to the thickness of the emulsion droplet interface (Fig. 1A). To determine the physical location of citral in the emulsions, the citral concentration in the aqueous phase was measured. A trace amount (< 1 μmol/L water) of citral was found in the aqueous phase of the immediately prepared emulsions, regardless of the emulsifier used (data not shown). Considering the logP (≈ 3.0) of citral, it is likely that its concentration in the aqueous phase would be very low; thus, citral could spontaneously diffuse from the oil droplets to the aqueous phase over time. However, the concentration of citral in the aqueous phase hardly changed during storage. Ostwald ripening is the growth of large droplets at the expense of small droplets by diffusion of the solute material across the continuous phase (McClements, 2005). Therefore, when emulsions contain lipids with a relatively high water solubility, such as flavor oils, or when emulsion droplets contain highly water-soluble components at a certain concentration, the growth of droplets with time due to Ostwald ripening is generally observed. Because the components diffuse across the interfacial membrane, the high interfacial tension generally results in an increase in the rate of Ostwald ripening. Considering this fact, citral in emulsions having a higher surface tension at the oil–water interface can diffuse from the droplets to the aqueous phase across the interfacial membrane more easily than citral in emulsions having a lower surface tension. The surface tension at the oil–water interfaces of the P10LE-, P10SE-, P20SE-, P23LE-, and P100SE-stabilized emulsions was 3.4, 5.8, 4.0, 5.7, and 10.1 mN/m, respectively. However, as described above, because no change in the citral concentration in the aqueous phase with time was observed, the surface tension at the oil–water interfaces of the emulsions could not affect the diffusion of citral from the droplets to the aqueous phase, and this was not a critical factor for controlling the stability of citral in the emulsions. Therefore, if a reduction in the citral concentration in an emulsion is observed after a certain period of storage, most of the citral is decomposed at the emulsion droplet interface rather than in the aqueous phase.

As shown in Fig. 1A and B, after 14 days of storage, the amount of citral remaining in the P10LE-, P10SE-, P20SE-, P23LE-, and P100SE-stabilized emulsions stored at pH 3 was 81.9, 80.0, 83.2, 82.2, and 82.3%, respectively. The amount of citral remaining in the emulsions stored at pH 3 was lower than that in the emulsions stored at pH 7. One possible reason for the rapid decomposition of citral is the acid-catalyzed cyclization of citral in acidic environment (Kimura et al., 1983). However, our findings suggest that the stability of citral in emulsions against acid-promoted degradation did not depend on the thickness of the droplet interface or its denseness. Regardless of the thickness and denseness of the emulsion droplet interface, the ability to interrupt the interaction between citral in the emulsion droplets and water-soluble substances that promote citral degradation is similar.

Influence of transition metals on the stability of citral in emulsions

As noted above, because citral rarely diffuses from emulsion droplets into the aqueous phase, if citral degradation is observed in the presence of iron, it may be a result of an interaction of iron with citral at the droplet surfaces. Although nonionic emulsifiers were used to prepare the emulsions in this work, the charges of the droplet surfaces ranged from −9.4 to −1.7 mV at pH 7, and the charge was almost zero at pH 3. This means that the negative surface charge density of the emulsion droplets at pH 7 could attract iron molecules to the droplet surfaces where they could accelerate the degradation of citral. Therefore, it was expected that at a neutral pH, citral encapsulated in the emulsion droplets would degrade faster in the emulsions containing iron than in those containing no iron. However, as shown in Figs. 1 and 2 and Table 1, iron did not increase the rate of degradation of citral in the emulsions at pH 7. In addition, there was no relationship between the k values of citral and the interfacial characteristics such as the thickness and density. It has been suggested that iron molecules that accumulate around negatively charged emulsion droplet surfaces at pH 7 are not directly responsible for the degradation of citral in emulsions containing iron (Hong et al., 2016). Although there was no correlation between the thickness and density of the emulsion droplet surfaces and the rate of degradation of citral, here, iron was found to increase the rate of citral degradation in emulsions at pH 3. In fact, iron did not initiate the degradation of citral, but ferrous iron accelerated the oxidative degradation of citral by decomposing 8-hydroperoxy-p-cymene, which is a product of the acid-catalyzed cyclization of citral, or by the decomposition of p-menthadien-8-ol, a product of the acid-catalyzed cyclization of citral, to give p-cymene, p-cymene-8-ol, and α,p-dimethylstyrene through redox reaction (Weerawatanakorn et al., 2015). According to the proposed hypothesis (Ueno et al., 2004), the degradation of 8-hydroperoxy-p-cymene by ferrous iron mostly occurs in proton-rich environments (i.e., under acidic conditions) but not in a proton-deficient environment (under neutral or alkaline conditions). Another possible reason for the lower stability of citral at pH 3 than at pH 7 in the presence of ferrous iron is the production of reactive oxygen species such as hydroxyl radicals (HO·) and superoxide ions (O ·−2 ). Although the oxygen dissolved in the aqueous phase of the emulsion was removed by nitrogen purging to minimize the effect of oxygen on citral decomposition, it appears that the removal of dissolved oxygen from the aqueous phase was not complete. These strong oxidants may be generated by ferrous iron but their generation is more active under acidic conditions than under neutral conditions (Hayyan et al., 2016). Therefore, because the amount of reactive oxygen species in the emulsions stored at pH 3 may be relatively greater than in those stored at pH 7, citral decomposed faster at pH 3 than at pH 7. In addition, the ability of the emulsion droplet surfaces to inhibit citral degradation via attack by radicals such as the reactive oxygen species did not depend on the thickness and density of the droplet surfaces.

Influence of free radicals on the stability of citral in emulsions

When already-oxidized food components such as lipid peroxides are present in a system, several interactions between citral and these species are possible. Therefore, citral decomposition may be accelerated by several free radicals generated during food processing and storage (Choe and Min, 2006). In the current study, the effect of free radicals on citral decomposition was evaluated using AAPH, which is decomposed to free radicals in aqueous solutions (Fig. 3).

At pH 7, compared with emulsions with and without ferrous iron, AAPH dramatically accelerated citral degradation (Fig. 3A and Table 1). The effect of interfacial density on the rate of citral degradation was unclear, but it appeared that thicker emulsion droplet surfaces induced faster degradation of the encapsulated citral. Considering possible reasons for why ferrous iron accelerates citral degradation under acidic conditions rather than neutral conditions, it was proposed that the mechanism by which radicals degrade citral could be very different from the acid-cyclization mechanism of citral degradation. In addition, even if ferrous iron did not initiate citral degradation, it is apparent that radicals can initiate citral decomposition. When radicals generated during food processing and storage are present in a citral-containing food system, several mechanisms of interaction between citral and the radicals are possible: electron transfer, hydrogen abstraction, and addition of radicals to form citral-radical adducts. The interactions listed are common mechanisms by which radicals destroy food ingredients, particularly carotenoids belonging to the class of terpenoids like citral (Boon et al., 2010). Therefore, although citral could be decomposed rapidly by such interactions in the presence of radicals, it is unclear which interaction plays a major role in citral degradation.

Independent of the thickness and density of the emulsion droplet surface, at pH 3, the emulsions exhibited a loss of over 20% of citral after 14 days of storage. In the P10LE-stabilized emulsion, the degradation of citral at pH 3 was faster than that at pH 7 (Fig. 3 and Table 1). However, there was no significant difference in the rate of citral degradation in the emulsions at pH 7 and 3 (p > 0.05), except in the case of the P10LE-stabilized emulsion. Interestingly, the rate of degradation of citral by radicals was slower than that by ferrous iron at a low pH. A possible reason for this observation is the formation of phenolic compounds as a result of acid-cyclization and oxidation of citral. As noted above, α,p-dimethylstyrene, p-cymene, p-methylacetophenone, and p-cresol are the main products of citral degradation. Among these products, p-cresol is one of the most potent off-flavor compounds (Weerawatanakorn et al., 2015), having a phenolic group in its structure. It is well-known that phenolic compounds exhibit good radial-scavenging activity (Chimi et al., 1991). Therefore, p-cresol generated by acid-cyclization and oxidation of citral could scavenge free radicals generated from AAPH by acting as an antioxidant. Similar to the findings for emulsions containing free radicals at pH 7, no significant difference in the rate of citral degradation for the emulsions having droplet surfaces with various thicknesses and densities was observed (p > 0.05). Therefore, it was concluded that the interfacial thickness and density of droplet surfaces did not affect the ability of the emulsions to protect the encapsulated citral from free radicals in the aqueous phase.

Influence of micelles on the stability of citral in emulsions

According to a previous study (Choi et al., 2010), 7-day storage at acidic pH decomposed about 40% of citral in cationic or nonionic emulsifier-stabilized emulsions; thus, it was expected that a considerable amount of citral would be degraded during 14-day storage at pH 3 in this study. However, in this work, more than 80% of the initial citral remained after 14 days of storage (Fig. 1B). One possible reason for this observation is the general presence of micelles in emulsion systems. As described above, because all the emulsions studied here were prepared at the MEC of the emulsifiers, almost no micelles were present in the emulsions. However, an emulsion evaluated in a previous study (Choi et al., 2010) contained a large amount of micelles, compared to the lack of these species in the present study. Because the micelles formed with the unabsorbed emulsifiers in the aqueous medium have hydrophobic cores that can trap hydrophobic compounds, the micelles could capture lipophilic compounds having relatively high water solubilities and release them into the aqueous phase, and also transport those compounds from one oil droplet to another (Ariyaprakai and Dungan, 2010). Although at acidic pH, the stability of citral incorporated into the hydrophobic interiors of the micelles was improved compared with that of citral in the aqueous phase (Hong et al., 2016), the ability of the micelles to stabilize citral would not be as great as that of the emulsions. However, when micelles are present in emulsions, some citral located in the oil droplets may be transported into the micelles, and the concentration of citral in the aqueous phase of the micelle-containing emulsions would be higher than that in the emulsions containing no micelles. Therefore, in the previous study (Choi et al., 2010), citral in the oil droplets could be transported to the micelles and citral in the micelles could be degraded more easily than in the oil droplets. To confirm this hypothesis, emulsions containing micelles were prepared at 4× MEC, and the change in the concentration of citral with time was monitored (Figs. 1C, D, 2C, D, 3C, and D, and Table 2). Because the critical micelle concentration of P10SE, P20SE, P23LE, and P100SE are 3, 5, 60, and 20 × 10−3 mM, respectively (Kumar and Moulik, 2001; Rosen and Kunjappu, 2012), emulsions prepared at 4× MEC could contain a considerable amount of micelles.

Similar to the findings for emulsions prepared at 1× MEC, the rate of citral degradation was not affected by the thickness and density of emulsion droplet surfaces. Comparison of the results in Tables 1 and 2 shows that the presence of micelles induced a dramatic alteration in the ability of the emulsions to improve the stability of the encapsulated citral. As shown in Table 2, the micelles accelerated the degradation of encapsulated citral in emulsions in the absence of ferrous iron and AAPH, irrespective of the pH. Thus, this result indicates that micelles by themselves could accelerate the degradation of citral in emulsions. However, when the emulsions contained ferrous iron in their aqueous phases, the effect of micelles on the stability of citral in the emulsions was difficult to explain. The presence of the micelles seemed to accelerate the degradation of citral at pH 7; however, they increased the stability of citral in emulsions at pH 3. Further, contrary to our expectations, when the emulsions contained AAPH, the presence of micelles did not critically influence citral degradation. Unfortunately, it is currently unclear why the presence of micelles had no effect on the rate of citral degradation in the presence of AAPH.

References

Ariyaprakai S, Dungan SR. Influence of surfactant structure on the contribution of micelles to Ostwald ripening in oil-in-water emulsions. J. Colloid Interface Sci. 343: 102–108 (2010)

Boon CS, McClements DJ, Weiss J, Decker EA. Factors influencing the chemical stability of carotenoids in foods. Crit. Rev. Food Sci. Nutr. 50: 515–532 (2010)

Chimi H, Chillard J, Cillard P, Rahmani M. Peroxyl and hydroxyl radical scavenging activity of some natural phenolic antioxidants. J. Am. Oil Chem. Soc. 68: 307–312 (1991)

Choe E, Min DB. Mechanisms and factors for edible oil oxidation. Compr. Rev. Food. Sci. Food Saf. 5: 169–186 (2006)

Choi SJ, Decker EA, Henson L, Popplewell LM, McClements DJ. Influence of droplet charge on the chemical stability of citral in oil-in-water emulsions. J. Food Sci. 75: C536–C540 (2010)

Chow GC. Tests of equality between sets of coefficients in two linear regressions. Econometrica 28: 591–605 (1960)

Decker EA, McClements DJ. Transition metal and hydroperoxide interactions: an important determinant in the oxidative stability of lipid dispersions. Inform 12: 215–255 (2001)

Djordjevic D, Cercaci L, Alamed J, McClements DJ, Decker EA. Stability of citral in protein- and gum arabic-stabilized oil-in-water emulsions. Food Chem. 106: 698–705 (2008)

Evans M, Ratcliffe I, Williams PA. Emulsion stabilisation using polysaccharide-protein complexes. Curr. Opin. Colloid Interface Sci. 18: 272–282 (2013)

Faraji H, McClements DJ, Decker EA. Role of continuous phase protein on the oxidative stability of fish oil-in-water emulsions. J. Agric. Food Chem. 52: 4558–4564 (2004)

Given Jr. PS. Encapsulation of flavors in emulsions for beverages. Curr. Opin. Colloid Interface Sci. 14: 43–47 (2009)

Han SW, Song HY, Moon TW, Choi SJ. Influence of emulsion interfacial membrane characteristics on Ostwald ripening in a model emulsion. Food Chem. 242: 91–97 (2018)

Hayyan M, Hashim MA, AlNashef IM. Superoxide ion: generation and chemical implications. Chem. Rev. 116: 3029–3085 (2016)

Hong CR, Park SJ, Choi SJ. Influence of the hydrophilic head size and hydrophobic tail length of surfactants on the ability of micelles to stabilize citral. J. Sci. Food Agric. 96: 3227–3232 (2016)

Israelachvili J. Intermolecular and Surface Forces, 3rd ed. Academic Press, London, UK (2011)

Kimura K, Nishimura H, Iwata I, Mizutani J. Deterioration mechanism of lemon flavor. 2. Formation mechanism of off-odor substances arising form citral. J. Agric. Food Chem. 31: 801–804 (1983)

Kumar S, Moulik SP. Determination of critical micelle concentration (CMC) of nonionic surfactants by donor–acceptor interaction with iodine and correlation of CMC with hydrophile–lipophile balance and other parameters of the surfactants. J. Surfactants Deterg. 4: 303–309 (2001)

Lee HY, Song HY, Choi SJ. Lipid hydroperoxide decomposition in model emulsions stabilized with emulsifiers having various sizes of hydrophilic heads. Food Sci. Biotechnol. https://doi.org/10.1007/s10068-018-0465-3 (2018)

Mao Y, Dubot M, Xiao H, McClements DJ. Interfacial engineering using mixed protein systems: Emulsion-based delivery systems for encapsulation and stabilization of β-carotene. J. Agric. Food Chem. 61: 5163–5169 (2013)

McClements DJ. Food Emulsions: Principles, Practices, and Techniques. CRC Press, Boca Raton, FL (2005)

McClements DJ. Nanoemulsion-based oral delivery systems for lipophilic bioactive components: nutraceuticals and pharmaceuticals. Ther. Deliv. 4: 841–857 (2013)

Park SJ, Hong CR, Choi SJ. Citral degradation in micellar structures formed with polyoxyethylene-type surfactants. Food Chem. 170: 443–447 (2015)

Peacock VE, Kuneman DW. Inhibition of the formation of α-p-dimethylstyrene and p-cymen-8-ol in a carbonated citral-containing beverage system. J. Agric. Food Chem. 33: 330–335 (1985)

Qian C, Decker EA, Xiao H, McClements DJ. Physical and chemical stability of β-carotene-enriched nanoemulsions: Influence of pH, ionic strength, temperature, and emulsifier type. Food Chem. 132: 1221–1229 (2012)

Rosen MJ, Kunjappu JT. Micelle Formation by Surfactants. pp. 123–201. In: Surfactants and interfacial phenomena. Rosen MJ, Kunjappu JT (eds). John Wiley & Sons, Inc., Hoboken, NJ (2012)

Schieberle P, Grosch W. Identification of potent flavor compounds formed in an aqueous lemon oil/citral acid emulsion. J. Agric. Food Chem. 36: 797–800 (1998)

Tan C-T. Beverage emulsions. pp. 485–524. In: Food Emulsions. Friberg SE, Larsson K, Sjöblom J (eds). Marcel Dekker, New York (2004)

Ueno T, Masuda H, Ho C-T. Formation mechanism of p-methylacetophenone from citral via a tert-alkoxy radical intermediate. J. Agric. Food Chem. 52: 5677–5684 (2004)

Weerawatanakorn M, Wu J-C, Pan M-H, Ho C-T. Reactivity and stability of selected flavor compounds. J. Food Drug Anal. 23: 176–190 (2015)

Wulff-Pérez M, Torcello-Gómez A, Gálvez-Ruíz MJ, Martín-Rodríguez A. Stability of emulsions for parenteral feeding: Preparation and characterization of o/w nanoemulsions with natural oils and Pluronic f68 as surfactant. Food Hydrocolloids 23: 1096–1102 (2009)

Yang X, Tian H, Ho C-T, Huang Q. Stability of citral in emulsions coated with cationic biopolymer layers. J. Agric. Food Chem. 60: 402–409 (2012)

Acknowledgements

This work was supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (NRF-2016R1D1A1B03930215), Republic of Korea.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kim, S.H., Song, H.Y. & Choi, S.J. Influence of structural properties of emulsifiers on citral degradation in model emulsions. Food Sci Biotechnol 28, 701–710 (2019). https://doi.org/10.1007/s10068-018-0532-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10068-018-0532-9