Abstract

Strawberry (Fragaria ananassa) is rich in bioactive compounds with high antioxidant activity. High pressure processing (HPP) is an efficient alternative to preserve these bioactive compounds in terms of microbial inactivation and shelf-life stability. This review compares the effects of pasteurization methods using high pressure or thermal pasteurization (TP) on the quality parameters of various strawberry-based products. To summarize, most of the high pressure-treated products are microbiologically stable and showed minimum degradation of thermolabile compounds than TP-treated ones. However, some studies reported that high pressure did not have an advantage over TP especially in the preservation of phenolic phytochemicals during storage. The insufficient enzyme inactivation and high residual activity of enzymes after high pressure treatment could cause anthocyanins degradation thus affecting the product quality. Overall, this review could be valuable to potential processors in evaluating the effective commercialization of high pressure-treated strawberry products.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The production of strawberries (Fragaria ananassa) exceeded more than 8.8 million tons in 2020 (FAOSTAT, 2021). It is one of the most economically vital berry fruits consumed for its nutrient content and pleasant flavor (Padmanabhan et al., 2015). Phenolic compounds including anthocyanins, flavonoids, phenolic acids and ascorbic acids in strawberries contribute to the powerful antioxidant, anti-inflammatory and prevention of various diseases such as cardiovascular diseases, arthritis, type 2 diabetes and even cancer (Bodelon et al., 2013; Ganhão et al., 2019; Marszalek et al., 2016).

Strawberries are perishable; therefore, cooling, freezing and drying are among the most common method to prolong the shelf-life of this fruit (Abouelenein et al., 2021). Besides freshly consuming strawberries, the fruits can be diversified into various products such as juice, puree, jam and mousse. Drying via thermal processing has led to color deterioration due to the anthocyanins degradation, leaving undesirable effects on the strawberry product (Gao et al., 2016). Significant losses of the bioactive compounds during processing and storage need to be minimized. Hence, non-thermal technologies are a useful alternative to enhance product safety by reducing the microorganisms to a safe level, extending the shelf-life and lowering the effect on the sensory and physical properties of the products (Khan et al., 2017; Özkan-Karabacak et al., 2019).

High pressure processing (HPP) uses pressures in the range of 100–600 MPa to process liquid or solid foods (with or without heat). Also, high pressure inactivates spoilage/pathogenic bacteria and enzymes, hence extending food shelf-life (Balasubramaniam et al., 2015; Terefe et al., 2015). In terms of nutritional and sensory qualities, HPP is regarded as a promising method for food preservation (Škegro et al., 2021). High pressure and thermal pasteurization (TP) were applied for different types of fruit juices, either by single or combined treatments. Among other fruits, strawberries were identified to have the highest application of HPP. To date, various high pressure and TP treatments were applied to products such as strawberry juice (Aaby et al., 2018; Yildiz et al., 2019, 2021), puree (Aaby et al., 2018; Salamon et al., 2021; Sulaiman et al., 2017), paste (Verbeyst et al., 2010), mousse (Ferrari et al., 2011) and dried strawberry slices (Zhang et al., 2020b) (Fig. 1).

Therefore, this work aimed to verify and compare the effects of two different pasteurization treatments (high pressure and TP) on the quality parameters of strawberry-based products including microbiological properties, enzymes inactivation, anthocyanins content, total phenolics, antioxidant activity, color and sensory properties.

Thermal pasteurization

Despite being categorized as high-acid foods (pH 3.0–4.5), outbreaks of pathogenic bacteria such as Escherichia coli O157:H7 and Salmonella spp. in berry juices are widely reported and becoming a critical issue (Duan and Zhao, 2009). To be accepted under processing conditions, the Food and Drug Administration (FDA) requires at least a 5-log reduction of the specified microorganism (FDA, 2001). Thermal inactivation of bacteria and enzymes in juice is commonly carried out at 70–121 ℃ for 30–120 s (Aaby et al., 2018; Zhou et al., 2009). It is aimed to achieve two ultimate goals of food safety by (i) inactivating enzymes which responsible for deteriorative reactions and (ii) killing relatively heat-sensitive microorganisms. Non-spore-forming bacteria, yeast, molds, vegetative bacteria, pathogenic and spoilage microorganisms were destroyed to extend the shelf-life depending on the pasteurization method applied (Manyi-Loh et al., 2016). Thermophysical properties such as specific heat, enthalpy, thermal conductivity, thermal diffusivity and heat penetration are dependent upon the chemical composition and structure of a food product. This typical physical thermal process of food processing is still commonly used in the food industry due to its efficiency, environmental friendly and economical price as compared with other technologies (Amit et al., 2017). However, the undesirable impact of heat on fruit tissues resulted in significant changes in the nutritional and unfavorable sensorial including color degradation, tissue softening, unpleasant cooked taste and aroma development, as well as vitamin loss (Marszalek et al., 2017; Yildiz et al., 2019).

High pressure pasteurization

Mild pasteurization and minimal processing have attracted much interest due to the increase in consumer awareness, convenience and healthiness (Vervoort et al., 2011). Non-thermal treatments have become popular in developed countries such as European countries, the USA, China, Japan and Australia focusing especially on the food safety, quality and environmental impacts of fruit and vegetable-based products (Bevilacqua et al., 2018; Liu et al., 2020; Picart-Palmade et al., 2019). High pressure with and without heat reduces the microbial count by conformational changes in cell membranes, cell morphology and perturbs biochemical reactions, as well as the genetic mechanism of the microorganisms (Balasubramaniam et al., 2015; Sehrawat et al., 2021).

Regardless of size, shape or food composition, high pressure transmits isostatic pressure to the product instantaneously, resulting in a highly homogenous product (Deliza et al., 2005). It can alter the structure of high-molecular-weight molecules like proteins and carbohydrates, yet it has little effect on smaller molecules such as volatile compounds, pigments, vitamins and other compounds which contributed to sensory, nutritional and health-promoting functions. As results, better retention of some of the quality parameters including anthocyanins, total phenolics, ascorbic acids and color was obtained (Barrett and Lloyd, 2012; Ijod et al., 2022; Oey et al., 2008).

Effect on microbiological efficacy

According to Tables 1, 2 and 3, both high pressure and TP treatments efficiently inactivate the microbial counts below 5-log CFU/mL in strawberry juice (Aaby et al., 2018; Cao et al., 2014; Yildiz et al., 2019, 2021), puree (Marszalek et al., 2016; Marszalek et al., 2017) and cupped strawberries (Gao et al., 2016). Aaby et al. (2018) found that HPP at elevated pressures (400–600 MPa) was efficient to inactivate microorganisms, where below the detection level was obtained after 500 MPa/1 min, proving that HPP induced changes in the cell morphology and biochemical reactions. These inhibited genetic mechanisms and caused protein denaturation, which eventually led to microbial inactivation. Other potential factors that influenced the treatment effect are the fruit species and cultivar, as well as solute concentrations and pH (Ng et al., 2019).

The shelf-life of fresh strawberry juice can be prolonged for at least 42 days by thermal (72 ℃/15 s) and HPP (300 MPa/1 min) treatments by maintaining the microbial counts around 2-log CFU/mL (Yildiz et al., 2021). In this study, HPP was more efficient than thermal treatment under the specified phytochemical properties in terms of shelf-life extension and enhanced phytochemical properties. According to Cao et al. (2014), the initial count of total aerobic bacteria, coliform bacteria, yeasts and molds in HPP-treated cloudy juice was a 1-log cycle greater than in clear juice. High insoluble solids in cloudy juice contribute to partial inhibition of microorganisms during the enzyme hydrolysis stage (45 °C/60 min). Subsequently, these microorganisms precipitated with the pulps during the centrifugation phase. Also, steam blanching followed by HPP treatment (600 MPa/25 ℃/4 min) inactivated bacteria or endogenous enzymes in cloudy and clear strawberry juices, indicating a good combination treatment in commercial practice.

Mold growth was still observed in strawberry puree even after HPP treatment at 300 MPa/50 ℃/15 min and 500 MPa/50 ℃/15 min (Marszalek et al., 2017). Even though some studies declared the capability of HPP to inactivate the microorganisms, microbial stability is affected by pressure, process time and temperature. Another study by Gao et al. (2016) reported that both HPP and thermal-treated cupped strawberries stored at 4 ℃ and 25 ℃ for 45 days showed the reduction of total aerobic bacteria, yeast and molds to a level below the detection limit. Unexpectedly, total microbial was recovered in HPP-treated samples after 45 days at 25 ℃. This is due to sublethal damage of cells after HPP treatment prevented them from growing until they recovered during storage. However, injured cells could not be restored at 4 ℃, thus this temperature is a better option for preserving cupped strawberries.

Inactivation of enzyme activity

Polyphenol oxidase (PPO), peroxidase (POD), β-d-glucoside (BGL), lipoxygenase (LOX), pectin methylesterase (PME), polygalacturonase (PG), amylase and hydroperoxide lyase are several oxidative and pectic enzymes responsible for the development of brown pigments, deterioration of color, flavor and nutritional value in fruit purees and juices (Chakraborty et al., 2014; Marszalek et al., 2017). Other than phenolic compounds, POD also affects other hydrogen donors such as aromatic amines, ascorbic acid and indoles. Hydrogen peroxide is generated during the degradation reactions of PPO-catalyzed phenolics and BGL-catalyzed anthocyanins, which function as a substrate for POD. Hence, it is necessary to inactivate this enzymatic to enhance product quality.

The incomplete inactivation of these enzymes can affect the stability of chemical constituents and the quality of berry products during storage. Therefore, there is growing concern over HPP that it may not be able to adequately inactivate quality-related enzymes (Terefe et al., 2010, 2013, 2014). For examples, PPO, POD and PME are highly resistant to HPP, which can tolerate pressures up to 600–800 MPa. PG and LOX on the other hand are relatively more pressure sensitive and can be substantially inactivated by HPP (Chakraborty et al., 2014; Terefe et al., 2014). Furthermore, there seems to be some evidence that POD is more vulnerable to HPP inactivation than PPO. Cao et al. (2011) reported that high pressure treatment at 400–600 MPa/25 ℃/5–25 min on the strawberry pulp inactivated 48% PPO and 64% POD activities. Also, the inactivation of 23% PPO and 72% POD in strawberry puree were recorded at 100–690 MPa/24–90 ℃/5–15 min (Terefe et al., 2010).

In the study of different strawberry cultivars by Terefe et al. (2013), Rubygem samples maintained the maximum PPO activity in strawberry puree after HPP treatment, followed by Festival and Camarosa, indicating the sensitivity of enzymes to inactivation was also influenced by the variety of isoenzymes, cultivar, growing condition and degree of ripening. In thermal treatment, however, both POD and PPO were inactivated.

Treatment time and temperature play a key role in PME inactivation in strawberries (Chakraborty et al., 2015); however, pressure affects the inactivation of PPO more compared to processing time. In comparison to TP, structural modifications of enzymes after pressurization are reversible (Aaby et al., 2018; Terefe et al., 2014). Nevertheless, most studies focused on the effects of HPP on the enzyme activity in strawberry products only after processing and not during storage. The presence of PME activity, could drive the demethoxylation reaction and generate a high methoxyl pectin change into low methoxyl pectin, resulting in the stability or increase in viscosity of HPP-treated fruit products. Pectin gel is formed when low methoxyl pectin is cross-linked to calcium ions and other macromolecular compounds like protein to produce a greater viscosity (Corredig and Wicker, 2002). For instance, during HPP, non-covalent bonds, such as hydrophobic bonding, salt bridges, metallic bonds, and intramolecular forces between pectin molecules and other components were disrupted, thus decreasing the viscosity of cloudy strawberry juice (Cao et al., 2014).

Other than that, temperature also plays a major role in PME inactivation. Pressurizing the strawberry puree at 100–400 MPa/50 ℃/15 min sufficiently inhibited PME activity, thus preventing gelation before and after 6 months of storage (Bodelon et al., 2013). Overall, a combination of pressure and temperature treatment at 600 MPa/50 ℃/15 min may be a preferable alternative for inactivating enzymes in strawberry purees rather than applying individual stress in the form of high pressure or temperature (Marszalek et al., 2016). Also, a combination of steam blanching and HPP treatment (600 MPa/4 min/room temperature) inactivated the PME activity to extend the shelf-life and maintain the quality of strawberry juice (Cao et al., 2014).

Effect on the spore inactivation

Due to its efficiency and low processing cost, thermal processing is commonly used to minimize microbiological spoilage. But the quality of the food and consumer acceptance could be impacted by the product’s exposure to heat. To satisfy consumer demand for processed foods with minimal nutrition loss at low temperatures, HPP has been verified for commercial uses (Amsasekar et al., 2022). However, HPP is only effective at killing pathogenic and spoilage vegetative microorganisms to levels that relevant for food safety while bacterial spores are still present (Pinto et al., 2020), yet it only applies to refrigerated storage, restricting preservation at room temperature.

As previously stated, depending on the fungi spores, TP and HPP have little effect on the viability of fungi spores to have significant effects on food safety. Despite being resistant to conventional pasteurization methods and being the cause of food spoilage, bacterial spores are typically more resilient than fungi spores (Black et al., 2007). Since some pathogenic bacteria’s spores cannot be destroyed by HPP, low- or moderate-temperature environments are required to destroy harmful bacteria (Zhang et al., 2022). The FDA approved this method in 2009 for use in commercial sterilization (Bermúdez and Barbosa, 2011).

In general, pressures between 400 and 600 MPa can inactivate pathogenic microorganisms and spoilage bacteria. But pressures up to 1000 MPa are still insufficient to completely inactivate the bacterial spore (Margosch et al., 2004, 2006). Some researchers found that bacterial spores require up to 1200 MPa to be inactivated (Gopal et al., 2017; Tenuta et al., 2023). Silva (2017) studied the inactivation of heat-resistant molds in strawberry puree using high pressure thermal processing (HPTP) (600 MPa, 75 °C). The Byssochlamys nives mold, which frequently causes spoilage in high-acid food, produces heat-resistant molds known as ascospores. No effect was found on B. nivea spores age (4–12 weeks old) for the first 20 min of HPP, however, up to 40 min the spore inactivation was increased from 2.0 to 3.4 log in the 4 week old spores. Higher microbial counts were found where older spores had lower levels of inactivation and more pronounced tails.

A similar study by Timmermans et al. (2020) used a combination of moderate heat and pressure to inactivate the ascospores of the heat-resistant fungi Talaromyces macrosporus and Aspergillus fischeri in fresh strawberry puree after 2 weeks storage at ambient temperature. The result showed that combining moderate heat (85℃/90 °C) at 500 to 700 MPa was extremely effective in the inactivation process for both species. A. fischeri was inactivated after 3 min (600 MPa, 90 °C), while after 13 min of treatment, T. macrosporus had ≤ 1 log10 of surviving spores that were no longer detectable after the storage.

Low-acid foods (pH > 4.6) can likely be spoiled by bacteria when not appropriately inactivated, due to spores that are difficult to kill and always wait for ideal conditions to grow. The pressure-resistant spore cannot be inactivated using HPP at room temperature, but they can be destroyed by applying heat (90–120 °C) (Nema et al., 2022). Daryaei and Balasubramaniam (2013) study on tomato juice revealed that first-order kinetics were suitable to explain TP. Yet the best mathematical model to describe the inactivation spores of Bacillus coagulans 185A using HPTP is the Weibull model. According to some research, at least 6 log reduction in the target microorganism spores are recommended for the design of appropriate pasteurization processes for fruit juices or products (Oliveira et al., 2014; Silva and Gibbs, 2001, 2004). There were some limitations in the spores inactivation, however, combination with other hurdles can reduce it while retaining the quality of the products (Nema et al., 2022).

Effect on anthocyanins

Anthocyanins are responsible for the bright red color of berries with promising health benefits. The major anthocyanins found in strawberries are pelargonidin-3-O-glucoside (P3G) (77–95% of total anthocyanins) followed by pelargonidin-3-O-rutinoside (P3R) and cyanidin-3-O-glucoside (C3G) (Bodelon et al., 2013; Cao et al., 2014; Marszalek et al., 2016; Marszalek et al., 2017). The rate of anthocyanins degradation is influenced by external factors such as processing and storage temperature, oxygen and light (Azman et al., 2022). Internal factors including pH, anthocyanins structure, presence of metallic ions and oxidative enzymes (PPO, POD and BGL) also affected the stability of anthocyanins (Patras et al., 2010; Srivastava et al., 2007).

Anthocyanins in strawberries were rather stable during HPP but degraded during storage (Aaby et al., 2018; Cao et al., 2012; Terefe et al., 2013). According to Marszalek et al. (2016), monomeric anthocyanins are engaged in complex associations such as copigmentation, self-association and polymerization which cause color changes during storage. During storage, anthocyanins were better retained in HPP-treated strawberry juice than in purees. Lower PPO activity increased the stability of anthocyanins in the juice (77%) compared to the puree (61%) (Aaby et al., 2018). PPO cannot oxidize anthocyanins; however, anthocyanidins may be oxidized by PPO after sugar moieties are removed by β-glucosidase (Terefe et al., 2014). Another possible reason explained by Cao et al. (2012) is that less oxygen was trapped in the juice which results in differences in oxygen absorption for the higher stability of anthocyanins in strawberry juice.

In another study by Patras et al. (2009), strawberry puree treated using HPP at 400–600 MPa/10–30 °C/15 min significantly retained more anthocyanins (mg P3G/100 g DW) than TP at 70 °C for 2 min. However, HPP and TP did not affect anthocyanin content (mg C3G equivalent/L), where higher anthocyanin content remained after cold storage at 2 °C (Salamon et al., 2021). In the strawberry paste with HPP treatment (200, 400, 550 and 700 MPa/80, 95 and 110 °C), the temperature effect on anthocyanins (P3G) is greater than the effect of both pressure and temperature (Verbeyst et al., 2010).

During TP, anthocyanins are degraded by non-enzymatic oxidation and cleavage of covalent bonds following the same pathway. These include sugar moiety hydrolysis and aglycone formation, ring-opening and formation of a chalcone, followed by the breakdown into carboxylic acids and carboxy aldehydes in acidic media (Patras et al., 2010; Zhao et al., 2013). Anthocyanin stability is mostly determined by their chemical structure, where a higher degree of glycosylation, acylation and methoxylation improves the stability of anthocyanins (Azman et al., 2022). Meanwhile, higher susceptibility to PPO activity is associated with an increase in the number of OH groups on the anthocyanins phenolic ring. Due to the single OH group in the phenolic ring, P3G and P3R would be less susceptible to PPO activity than C3G (Srivastava et al., 2007).

The HPP-treated strawberry product had a recommended cold shelf-life of 6 weeks at 6℃. Among these, the HPP-treated (500 MPa/50 °C/15 min) puree had a greater level of polyphenols and color parameters than the TP (90 °C/15 min) puree (Marszalek et al., 2017). Although HPP did not cause anthocyanin degradation, these labile compounds were degraded over long-term storage as found in strawberry juice (Aaby et al., 2018), strawberry puree (Aaby et al., 2018; Salamon et al., 2021) and strawberry mousse (Ferrari et al., 2011).

A higher content of L-ascorbic acid may result in faster anthocyanin degradation in the analyzed puree (Oey et al., 2008). During the oxidation of ascorbic acid, hydrogen peroxide is produced, where its presence is required for the enzymatic reaction of POD. The synergistic effect of PPO reaction products as substrates for POD reactions may potentially contribute to higher POD activity (Terefe et al. 2013). Strawberry juice produced by a more complicated and intrusive process had a lower ascorbic acid content than puree. The half-life of anthocyanin pigments was used to determine the puree quality. TP-treated puree had better anthocyanins stability compared to HPP-treated ones (Marszalek et al., 2017). Furthermore, C3G and P3G have better storage stability (86 days) in puree treated at 300 MPa/50 °C/15 min than at 600 MPa. Lower residual PPO activity in puree handled at a lower pressure might account for these occurrences (Marszalek et al., 2016).

Water mobility and drying efficiency of strawberry slices were significantly increased after the HPP pre-treatment (50, 100, 150, 200 and 250 MPa/25℃/5 min). Moisture and anthocyanins were more equally distributed due to the disruption of microstructure and tissue structure, as well as the degradation of cell wall components. As a result, 200 MPa was indicated as the ideal HPP pressure for producing vacuum freeze-dried strawberry slices (Zhang et al., 2020b).

Effect of total phenolics and antioxidant activity

Phenolic compounds such as flavonoids, phenolic acids and anthocyanins are known to be responsible for antioxidant capacities in strawberries rather than ascorbic acid (Guine et al., 2020). HPP-treated strawberry juice at 550 MPa/20 °C/2 min (Predna et al., 2016) and 300 MPa/25 ℃/1 min (Yildiz et al., 2021), strawberry puree at 500 and 600 MPa/10–30 °C/15 min (Patras et al., 2009) and cupped strawberries at 120 MPa/25 °C/1 min (Gao et al., 2016) showed significantly higher total phenolics with higher antioxidant activity than TP. Strawberry and wild strawberry mousses had a significant increase of the total phenolics (9.8%) immediately after HPP at 500 MPa/50 °C/10 min compared to unprocessed purees (Ferrari et al., 2011), demonstrated better extractability of the polyphenol compounds using high pressure.

HPP-treated cloudy juices had higher total phenols than clear juices (Cao et al., 2014). The insolubilization of antioxidant components including anthocyanins, amino acids and protein in cells with a phenolic hydroxyl group increased in the juice after HPP treatment. In the Folin–Ciocalteau method, these oxidizing substances converted molybdenum (Mo6+) and wolfram (W6+) to Mo2+ or W2+. HPP also improve cell permeability by deprotonating charged groups and disrupting salt bridges and hydrophobic interactions in cell membranes, facilitating the polyphenols extraction process from pulp particles (Cao et al., 2014).

In contrast, HPP (600 MPa/20 °C/5 min) did not result in higher preservation of phenolic phytochemicals than TP (88 °C/2 min) in strawberry puree (Terefe et al., 2013). During refrigerated storage (4 ℃/3 months) of HPP-treated samples, a slightly higher loss of total polyphenol content and antioxidant capacity was found. HPP samples have substantially more residual oxidative enzyme activity than thermally treated ones. If the main objective is to retain more phenolic antioxidants, HPP may not be a preferable option to thermal processing for strawberry puree processing.

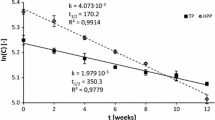

Similarly, total phenolic half-lives in strawberry puree were 350 days for TP (90 °C/15 min) and 170 days for HPP (500 MPa/50 °C/15 min) method (Marszalek et al., 2017). To preserve a higher total phenolic content in HPP-treated strawberry puree than TP, the maximum storage period should not exceed more than 8 weeks. The active enzymatic system in the pressurized puree is linked to the increasing amount of phenolic acids (ellagic acid and quercetin) during storage. In heat treatment, these compounds are released during hydrolysis reactions, especially in the acidic environment of puree (pH 3.3). However, the antioxidant activity of strawberry puree was less affected by HPP (600 MPa/48 ℃/15 min) than by TP (65 ℃/15 min) (Sulaiman et al., 2017). At room temperature, small molecules such as vitamins, flavor, and aroma compounds were unaffected by HPP (Oey et al., 2008). The differences in cultivars or antioxidant activity assays might explain the differences in findings (Terefe et al., 2013).

Furthermore, the total antioxidant capacity in cupped strawberries (combined flesh and syrup) decreased significantly during storage at 25 ℃ for 45 days due to the reduction in total phenolic content during HPP (120 MPa/25 °C/1 min) and TP (75 °C/20 min) (Gao et al., 2016). The level of total phenolics of flesh in TP-treated samples was significantly lower than that in HPP-treated ones after processing, due to more structural damage and the temperature decomposition of these compounds (especially anthocyanins) in TP treatment. This leads to a higher leaching of phenols from flesh to syrup, reducing the total phenolics in flesh.

Effect on ascorbic acid

Ascorbic acid is frequently measured to evaluate nutrient loss during TP. It is water-soluble and prone to leaching from cells, sensitive to heat, pH, metal ions, and light, as well as readily oxidizable by ascorbic acid oxidase (Wang et al., 2018). Strawberry fruit has a relatively high content of ascorbic acid (40–70 mg/100 g) (Sapei and Hwa, 2014). Ascorbic acid in strawberry purees and fruit smoothies containing strawberries is easily degraded and difficult to preserve due to the low stability of ascorbic acid during storage (Aaby et al., 2018; Marszalek et al., 2016; Marszalek et al., 2017). The remarkable effect in ascorbic acid degradation can be observed at 40–60 ℃ and reached the greatest impact at 60–80 ℃ (Herbig and Renard, 2017).

In comparison to TP samples, all high-pressure treated samples had significantly higher ascorbic acid levels. Patras et al. (2009) found that pressurization at 400, 500 and 600 MPa/10–30 °C/15 min preserved up to 94% of the ascorbic acid in the strawberry puree samples compared to TP (70 °C/2 min). The anti-radical power of strawberry puree was positively correlated with ascorbic acid, showing that ascorbic acid plays a key role in strawberry puree’s scavenging activity.

Ascorbic acid in HPP-treated (100, 200, 300 and 400 MPa/20 and 50 °C/15 min) strawberry purees was significantly affected by the temperature than pressure (Bodelon et al., 2013). Pressures do not affect the ascorbic acid content at ambient temperature (20 ℃), but an increase in temperature such as 50 ℃ under pressure produces a slight reduction (around 15%) in comparison to the control. The amount of ascorbic acid is quite high (40–50 mg ascorbic acid/100 g product) and the puree was protected against color degradation after pressurization. Degradation of ascorbic acid rates was not influenced by its initial concentration, but the temperature (40–60 °C) marked the greatest impact on the rate of degradation, following the first-order reaction (Herbig and Renard, 2017).

Ascorbic acid levels in strawberry purees were significantly higher at 300 MPa/50 °C/15 min than at 600 MPa (Marszalek et al. 2016). L-dehydroascorbic acid (DHAA) is a reversible oxidation product of ascorbic acid, and no increase in DHAA content was observed in the sample treated at 600 MPa. During storage, both ascorbic acid and its oxidized form (DHAA) degraded rapidly. Low pH and pressure assist the irreversible hydrolysis of DHAA to 2,3-diketogluconic acid and other break-down products (Wibowo et al., 2015).

In the study on strawberry puree by Marszalek et al. (2017), HPP treatment (500 MPa/50 °C/15 min) showed higher ascorbic acid than TP (90 °C/15 min). However, at 6 °C, the strawberry puree was better kept for 8 weeks after TP (90 °C/15 min) than for just 4 weeks in HPP (500 MPa/50 °C/15 min). Compared to TP, HPP less inactivated several oxidative enzymes such as PPO and ascorbic acid oxidase (Aaby et al., 2018).

On the other hand, no significant difference was discovered between HPP (400, 500 and 600 MPa/20 ℃/3 min) and TP (85 ℃/2 min) on the ascorbic acid in strawberry juice and puree (Aaby et al., 2018). However, significantly lower ascorbic acid was detected in the juice and purees that were pressurized at 600 MPa and 400 MPa, respectively. Moreover, after 35 days of storage, almost no ascorbic acid was detected. Cao et al. (2014) found that ascorbic acid was decreased by 7.82% and 12.60% in cloudy juices and clear juices, respectively after HPP treatment (600 MPa/25 ℃/4 min). This is due to the protection by higher antioxidative compounds such as anthocyanins and total phenols in cloudy juices than in clear juices (Cao et al., 2014).

Effect on color properties

Many factors influence the color and its stability including pH, light, temperature, oxygen, enzymatic and non-enzymatic reactions, and l-ascorbic acid (Bąkowska et al., 2003). The extensive decrease in total monomeric anthocyanins during storage was, however, not reflected in a corresponding color change, but in the formation of polymeric pigments that contribute to the color of the products (Howard et al., 2012, 2014).

Many positive effects of HPP than TP treatment on the color of strawberry purees have been reported. Color retention of a* values (redness) was higher in HPP (400, 500 and 600 MPa/10–30 °C/15 min) samples than TP (70 °C/2 min) (Patras et al., 2009). Also, total color difference (ΔE) of TP sample (90 °C/15 min) for 12 weeks of storage was higher than HPP treatment at 500 MPa/50 °C/15 min (Marszalek et al., 2017). Moreover, slower ΔE within the first 15 days of storage for HPP (600 MPa/48 ℃/15 min) in comparison to thermally (65 ℃/15 min) treated puree was described by Sulaiman et al. (2017).

Gao et al. (2016) reported that the degradation and transfer of anthocyanins from the flesh of samples into the syrup caused the color of the flesh to become brighter, less red and less yellow at the end of storage. Overall, the major cause of the color change in cupped strawberries was due to anthocyanin loss and leaching, where low storage temperature (4 ℃) and HPP treatment efficiently preserved a more attractive color for consumers.

Color of strawberry purees differed significantly between the two temperatures assessed (20 and 50 ℃) at the pressures assessed (100, 200, 300 and 400 MPa/15 min) (Bodelon et al., 2013). The purees become darker (L* decreased) at 20 ℃ and less dark (L* increased) at 50 ℃, indicating the texture alteration of strawberries during pressurization. However, no color changes were detected between either temperature after 6 months at 5 ℃ storages. HPP promotes enzymatic and non-enzymatic reactions via cell rupture. Also, color changes are primarily caused by tissue enzyme activity (PPO and POD) and Maillard non-enzymatic browning reactions generated by increased temperature and low pH (Gössinger et al., 2009; Rodrigo et al., 2007). The color change in the puree after HPP treatment at 50 ℃ was reversible following cold storage, suggesting that the color changes are not due to Maillard reactions. Anthocyanins become paler when heated, as their equilibrium shifts towards the colorless carbinol base and chalcone forms. When sufficiently cooled, the chalcones re-converse and re-store to the original color. Additionally, the formation of blue quinoidal forms is favored at low temperatures which caused color changes in samples (Khoo et al., 2017).

L*, a*, b* and chroma values of strawberry purees tended to rise for both batches at 300 and 600 MPa/50 °C/15 min (Marszalek et al., 2016). This is due to the mechanical extraction of anthocyanins and other pigments from the tissue after HPP treatment. Other than that, browning index values increased by approximately 6.5 and 3.5 units in puree treated at 300 and 600 MPa, respectively. Lower pressure remained the activities of POD, pectin esterase (PE) and polygalacturonase (PG) in the purees. The products of enzymatic oxidation of phenolic compounds enhance anthocyanins degradation, leading to the production of numerous polymeric molecules that may precipitate from the solution (Cao et al. 2011).

The increase in redness in dried strawberry slices when the pressure increased from 0 to 200 MPa/25 ℃/5 min was strongly contributed by high anthocyanin content (Zhang et al., 2020b). The centre section of HPP pre-treated strawberry chips was visibly redder than the control sample. The tissue is damaged by the HPP pre-treatment, causing more anthocyanins to be released into the intercellular space (Zhang et al., 2020a).

The clear juices after HPP treatment had lower ΔE values compared to cloudy juices. A lower concentration of antioxidant compounds in clear juices protects against oxidation discoloration than in cloudy juices. Furthermore, the total inactivation of PPO by blanching before juice extraction was associated with improved color retention in this study (Cao et al., 2014).

Effect on sensory properties

Over 360 volatiles have been discovered in strawberries including esters, ketones, aldehydes, alcohols and acids. The types and concentrations of volatiles that contribute to strawberry aroma vary depending on the cultivar and maturity level of the fruit (Forney et al., 2000). Strawberry volatiles has three types of aroma characteristics which are fruit aroma, sweet aroma and green-grass aroma (Abouelenein et al., 2021). Overall acceptability and liking of strawberries are greatly influenced by their sweetness and flavor intensity (Schwieterman et al., 2014).

Sensory quality is the most significant quality parameter of foods, as long as microbiological safety is ensured. Strawberry purees exposed to the least severe treatments of 400 MPa/20 ℃/3 min than 500 and 600 MPa have lower sensory scores for viscosity, fresh flavor, strawberry flavor and odor. Similar sensory properties between the strawberry puree and the fresh samples were detected in the application sequence of the combined HPP and TP treatments; 600 MPa–75 ℃/75 ℃–600 MPa as compared to 300 MPa–55 ℃/55 ℃–300 MPa, even after 14 days of storage at 15 °C (Salamon et al., 2021).

The pH of the HPP purees decreased after storage and become more acidic. This was confirmed by sensory profiling, where HPP purees were sourer than the control and TP purees. Bacterial growth was minimal during storage, and pH decline was unlikely to be caused by lactic acid production by bacteria (Aaby et al., 2018). The decline in pH, according to Jacobo‐Velázquez and Hernández‐Brenes (2010), might be explained by the gradual migration of organic acids from the intracellular matrix of vegetable cells, which is ruptured by HPP. The sensory assessment demonstrated that freshly produced, untreated strawberry puree and juice had lower color intensity and color saturation (lighter and purer red) than stored samples. Also, the viscosity of the HPP purees was lower than that of the freshly prepared and TP purees. The decrease of viscosity in HPP purees after storage implies pectin degradation, suggesting that pectinases such as PME were not inactivated by pressure treatment (Aaby et al., 2018).

Gao et al. (2016) studied the effects of HPP (120 MPa/25 °C/1 min) and TP (75 °C/20 min) on the hardness of flesh in the cupped strawberries during 45 days of storage. Samples treated with HPP and stored at 4 ℃ showed higher hardness than TP-treated ones. HPP and lower storage temperature were efficient in preserving the quality of cupped strawberries. HPP treatment causes less structural damage than TP treatment, thereby less leaching of cell wall pectin from flesh to syrup. Furthermore, a lower storage temperature may delay the loss of flesh hardness, whereas a high storage temperature accelerates the change of pectin in sample flesh (Zhang et al., 2012).

In contrast, Marszalek et al. (2017) reported that the consistency of TP-treated (90 °C/15 min) strawberry puree remained unchanged over the entire storage period, but the HPP-treated (500 MPa/50 °C/15 min) puree was rapidly deteriorating. The puree preserved with HPP was better than the TP product only until the 4th week of storage at 6℃. Subsequently, enzymatic changes caused the sensory quality of the HPP-treated puree to deteriorate significantly. After 4 weeks of storage, the thick puree turned watery. The activity of tissue enzymes, particularly pectinolytic enzymes, was most likely responsible for the rapid changes in consistency.

As conclusions, as an alternative to heat treatments, high pressure at moderate temperatures and greater pressure (≥ 500 MPa) are the best choices for some strawberry products to offer both shelf-life extension and greater preservation of phytochemicals and nutritional quality. High pressure effectively preserved the quality attributes such as anthocyanins, antioxidant capacity, total phenols, volatile flavors and color than TP. The stability of polyphenols after processing and during storage was also affected by different production technologies, strawberry cultivars, and/or different methods for determining enzyme activity. During storage, less color changes and lower viscosity were detected in high pressure treated purees than TP samples. Also, significant changes in chemical composition and quality occurred during storage rather than processing. Therefore, it is critical to incorporate storage in high pressure studies and to monitor the activity of quality-degrading enzymes during product storage.

However, some studies show that high pressure does not have an advantage over TP in terms of phenolic phytochemical preservation after processing or storage. The activity of pressure-resistant enzymes such as PPO and POD increased in high pressure but remained constant in TP purees during storage. Inadequate inactivation and regeneration of PPO and other degrading enzymes after high pressure are the main reason contributing to the degradation of anthocyanins and ascorbic acids. In commercial applications, hurdle technologies of blanching, high pressure and storage at a lower temperature (2–6 ℃) are the good choice to increase the shelf-life and retain the quality of strawberry products. Also, raw materials with low initial enzyme activity such as juices are more suitable for high pressure treatment, while purees are more effectively preserved using TP.

Processing cost of high pressure and thermal processing

When new technologies emerge, the food industries have expressed concerns about the incremental cost and environmental issues. The preservation of foods with a fresh-like quality and products without additives as an alternative to thermal processing has been a problem in the food industry. Although HPP is regarded as one of the non-thermal processing methods that can produce those qualities, processing costs that are relatively high have raised concerns. Despite having a higher processing cost, HPP has been gaining consumer acceptance, and its widespread use has fueled its growth and market demand. By the end of 2015, the value of the manufacturers annual output had increased gradually and almost reached $ 10 billion (Huang et al., 2017).

The production of HPP equipment is carried out by several companies, including Multivac (Germany), Avure (Middletown, Ohio, USA), and Baotao Kefa High Pressure Technology Co., Ltd. (Baotao, China), with Hiperbaric (Burgos, Spain) serving as the primary global supplier. Depending on the equipment capacity and operating range, a set of HPP equipment can range in price from $ 0.5 to $ 2.5 million. According to Peerun (2015), the market for HPP foods was worth $ 9.8 billion globally in 2015 and is projected to reach $ 54.77 billion in 2025. The original equipment manufacturer (OEM) service is very well-liked in North America and Europe due to the high investment costs of HPP equipment. The market for HPP equipment and OEM services was estimated to be worth $ 330 million, or 3–4% of the gross output value of HPP products, and it will continue to grow by double digits in the future (Huang et al., 2017).

A study by Sampedro et al. (2014) analyzed the cost between HPP and TP with orange juice as an example due to its high consumption and commercialization worldwide. With both HPP and TP having throughput of 3000 L/h, the capital cost for typical commercial pasteurization by TP (88 °C/5 s) was estimated to be $ 66,000 for industrial scale. Meanwhile, HPP (550 MPa/90 s) systems (pumps, plate heat exchangers, and holding tube) were estimated to be $ 2,500,000 with $ 45,000 added as equipment (coolers, supplemental pumps and heat exchangers) cost. Yet, installing the equipment might incur additional costs equal to the pasteurization systems by 200%. For both TP and HPP systems, it was estimated to be $ 132,000 (0.08 ¢/L) and $ 5,090,000 (3.1 ¢/L). This corresponds to 38% increase in capital cost by HPP than TP system.

As for the production cost, TP recorded $ 0.015/L with HPP around $ 0.107/L. This is caused by the electricity usage by HPP ($ 70,000) whereas 1,020,100 kWh/year contributed by the pressure pumps compared to TP ($ 8000) for natural gas and electricity cost. The labor cost also differs by threefold for HPP than TP. Since HPP use batch processes, more operators are needed for the loading and unloading process. Consider installing the automatic line to HPP system, the labor cost can be reduced by 50–67%. Overall, the total production cost estimated to be 1.5 ¢/L for TP and 10.7 ¢/L for HPP, indicating an increase of 7% of the total cost compared to TP.

By offering wholesome and clean-label products (Jamaluddin et al., 2022), HPP is advancing in the food market following the most recent trend. However, the main drawback of HPP is the need for batch or semi-continuous processing of solid foods to generate high pressure safely and repeatedly in a vessel. Additionally, the capital expense of equipment is quite high (Gopal et al., 2017). Therefore, the alternative to increasing the volume of corporate vessels or reducing the cycle time can effectively produce higher outputs and lower processing costs, making HPP more affordable for some industries.

Abbreviations

- BGL:

-

β-d-glucoside

- C3G:

-

Cyanidin-3-O-glucoside

- DHAA:

-

L-Dehydroascorbic acid

- FDA:

-

Food and Drug Administration

- HPP:

-

High pressure processing

- HPTP:

-

High pressure thermal processing

- LOX:

-

Lipoxygenase

- OEM:

-

Original equipment manufacturer

- P3G:

-

Pelargonidin-3-O-glucoside

- P3R:

-

Pelargonidin-3-O-rutinoside

- PE:

-

Pectin esterase

- PG:

-

Polygalacturonase

- PME:

-

Pectin methylesterase

- POD:

-

Peroxidase

- PPO:

-

Polyphenol oxidase

- TP:

-

Thermal pasteurization

References

Aaby K, Grimsbo IH, Hovda MB, Rode TM. Effect of high pressure and thermal processing on shelf life and quality of strawberry puree and juice. Food Chemistry. 260: 115-123. (2018)

Abouelenein D, Mustafa AM, Angeloni S, Borsetta G, Vittori S, Maggi F, Sagratini G, Caprioli G. Influence of freezing and different drying methods on volatile profiles of strawberry and analysis of volatile compounds of strawberry commercial jams. Molecules. 26: 4153 (2021)

Amit SK, Uddin MM, Rahman R, Islam SMR, Khan MS. A review on mechanisms and commercial aspects of food preservation and processing. Agriculture and Food Security. 6: 1-22 (2017)

Amsasekar A, Mor RS, Kishore A, Singh A, Sid S. Impact of high pressure processing on microbiological, nutritional and sensory properties of food: a review. Nutrition and Food Science. (2022)

Azman EM, Yusof N, Chatzifragkou A, Charalampopoulos D. Stability enhancement of anthocyanins from blackcurrant (Ribes nigrum L.) pomace through intermolecular copigmentation. Molecules. 27: 5489 (2022)

Bąkowska A, Kucharska AZ, Oszmiański J. The effects of heating, UV irradiation, and storage on stability of the anthocyanin–polyphenol copigment complex. Food Chemistry. 81: 349-355 (2003)

Balasubramaniam VM, Martinez-Monteagudo SI, Gupta R. Principles and application of high pressure–based technologies in the food industry. Annual Review of Food Science and Technology. 6: 435-462 (2015)

Barrett DM, Lloyd B. Advanced preservation methods and nutrient retention in fruits and vegetables. Journal of the Science of Food and Agriculture. 92: 7-22 (2012)

Bermúdez-Aguirre D, Barbosa-Cánovas GV. An update on high hydrostatic pressure, from the laboratory to industrial applications. Food Engineering Reviews. 3: 44-61 (2011)

Bevilacqua A, Petruzzi L, Perricone M, Speranza B, Campaniello D, Sinigaglia M, Corbo MR. Nonthermal technologies for fruit and vegetable juices and beverages: overview and advances. Comprehensive Reviews in Food Science and Food Safety. 17: 2-62 (2018)

Black EP, Setlow P, Hocking AD, Stewart CM, Kelly AL, Hoover DG. Response of spores to high‐pressure processing. Comprehensive Reviews in Food Science and Food Safety. 6: 103-119 (2007)

Bodelon OG, Avizcuri JM, Fernandez-Zurbano P, Dizy M, Prestamo G. Pressurization and cold storage of strawberry puree: color, anthocyanins, ascorbic acid and pectin methylesterase. LWT-Food Science and Technology. 52: 123-130 (2013)

Cao X, Zhang Y, Zhang F, Wang Y, Yi J, Liao X. Effects of high hydrostatic pressure on enzymes, phenolic compounds, anthocyanins, polymeric color and color of strawberry pulps. Journal of the Science of Food and Agriculture. 91: 877-885 (2011)

Cao X, Bi X, Huang W, Wu J, Hu X, Liao X. Changes of quality of high hydrostatic pressure processed cloudy and clear strawberry juices during storage. Innovative Food Science and Emerging Technologies. 16: 181-190 (2012)

Cao X, Liu F, Wu J, Liao X, Hu X. Effects of high hydrostatic pressure combined with blanching on microorganisms and quality attributes of cloudy and clear strawberry juices. International Journal of Food Properties. 17: 1900-1920 (2014)

Chakraborty S, Kaushik N, Rao PS, Mishra HN. High-pressure inactivation of enzymes: a review on its recent applications on fruit purees and juices. Comprehensive Reviews in Food Science and Food Safety. 13: 578-596 (2014)

Chakraborty S, Baier D, Knorr D, Mishra HN. High pressure inactivation of polygalacturonase, pectinmethylesterase and polyphenoloxidase in strawberry puree mixed with sugar. Food and Bioproducts Processing. 95: 281-291 (2015)

Corredig M, Wicker L. Juice clarification by thermostable fractions of marsh grapefruit pectinmethylesterase. Journal of Food Science. 67: 1668-1671 (2002)

Daryaei H, Balasubramaniam VM. Kinetics of Bacillus coagulans spore inactivation in tomato juice by combined pressure–heat treatment. Food Control. 30: 168-175 (2013)

Deliza R, Rosenthal A, Abadio FBD, Silva CH, Castillo C. Application of high pressure technology in the fruit juice processing: benefits perceived by consumers. Journal of Food Engineering. 67: 241-246 (2005)

Duan J, Zhao Y. Antimicrobial efficiency of essential oil and freeze-thaw treatments against Escherichia coli O157:H7 and Salmonella enterica Ser. Enteritidis in strawberry juice. Journal of Food Science. 74: M131–M137 (2009)

FAOSTAT (2021). Available from http://www.fao.org/faostat/en/#data/QCL. Accessed Oct 17 2022

Food and Drug Administration (FDA). Hazard analysis and critical control point (HACCP); procedures for the safe and sanitary processing and importing of juices: final rule. Vol. 66, pp. 6137–6202. Federal Register, Washington D.C., USA (2001)

Forney CF, Kalt W, Jordan MA. The composition of strawberry aroma is influenced by cultivar, maturity, and storage. HortScience. 35: 1022-1026 (2000)

Ferrari G, Maresca P, Ciccarone R. The effects of high hydrostatic pressure on the polyphenols and anthocyanins in red fruit products. Procedia Food Science. 1: 847-853 (2011)

Gao G, Ren P, Cao X, Yan B, Liao X, Sun Z, Wang Y. Comparing quality changes of cupped strawberry treated by high hydrostatic pressure and thermal processing during storage. Food and Bioproducts Processing. 100: 221-229 (2016)

Ganhão R, Pinheiro J, Tino C, Faria H, Gil MM. Characterization of nutritional, physicochemical, and phytochemical composition and antioxidant capacity of three strawberry “Fragaria×ananassa Duch.” cultivars (“Primoris”,“Endurance”, and “Portola”) from Western Region of Portugal. Foods. 8: 682 (2019)

Gopal KR, Kalla AM, Srikanth K. High Pressure Processing of fruits and vegetable products: a review. International Journal of Pure and Applied Bioscience. 5: 680-692 (2017)

Gössinger M, Moritz S, Hermes M, Wendelin S, Scherbichler H, Halbwirth H., Stich K, Berghofer E. Effects of processing parameters on color stability of strawberry nectar from puree. Journal of Food Engineering. 90: 171-178 (2009)

Guine RPF, Correia PMR, Ferraro AC, Gonçalves F, Lerat C, El-Idrissi T, Rodrigo E. Evaluation of phenolic and antioxidant properties of strawberry as a function of extraction conditions. Brazilian Journal of Food Technology. 23: e2019142 (2020)

Herbig AL, Renard CM. Factors that impact the stability of vitamin C at intermediate temperatures in a food matrix. Food Chemistry. 220: 444-451 (2017)

Howard LR, Prior RL, Liyanage R, Lay JO. Processing and storage effect on berry polyphenols: challenges and implications for bioactive properties. Journal of Agricultural and Food Chemistry. 60: 6678–6693 (2012)

Howard LR, Brownmiller C, Prior RL. Improved color and anthocyanin retention in strawberry puree by oxygen exclusion. Journal of Berry Research. 4: 107–116 (2014)

Huang HW, Wu SJ, Lu JK, Shyu YT, Wang CY. Current status and future trends of high-pressure processing in food industry. Food Control. 72: 1-8 (2017)

Ijod G, Musa FN, Anwar F, Suleiman N, Adzahan NM, Azman, EM. Thermal and nonthermal pretreatment methods for the extraction of anthocyanins: a review. Journal of Food Processing and Preservation. e17255 (2022)

Jacobo‐Velázquez DA, Hernández‐Brenes C. Biochemical changes during the storage of high hydrostatic pressure processed avocado paste. Journal of Food Science. 75: S264-S270 (2010)

Jamaluddin F, Noranizan MA, Azman EM, Yusof NL, Sulaiman A. A review of clean‐label approaches to chilli paste processing. International Journal of Food Science and Technology. 57: 763-773 (2022)

Khan I, Tango CN, Miskeen S, Lee BH, Oh DH. Hurdle technology: a novel approach for enhanced food quality and safety—a review. Food Control. 73: 1426–1444 (2017)

Khoo HE, Azlan A, Tang ST, Lim SM. Anthocyanidins and anthocyanins: colored pigments as food, pharmaceutical ingredients, and the potential health benefits. Food and Nutrition Research. 61: 1361779 (2017)

Liu J, Bi J, McClements DJ, Liu X, Yi J, Lyu J, Liu D. Impacts of thermal and non-thermal processing on structure and functionality of pectin in fruit- and vegetable- based products: a review. Carbohydrate Polymers. 250: 116890 (2020)

Manyi-Loh CE, Mamphweli SN, Meyer EL, Makaka G, Simon M, Okoh AI. An overview of the control of bacterial pathogens in cattle manure. International Journal of Environmental Research and Public Health. 13: 843 (2016)

Margosch D, Ehrmann MA, Gänzle MG, Vogel R. Comparison of pressure and heat resistance of Clostridium botulinum and other endospores in mashed carrots. Journal of Food Protection. 67: 2530-2537 (2004)

Margosch D, Ehrmann MA, Buckow R, Heinz V, Vogel RF, Gänzle MG. High-pressure-mediated survival of Clostridium botulinum and Bacillus amyloliquefaciens endospores at high temperature. Applied and Environmental Microbiology. 72: 3476-3481 (2006)

Marszalek K, Wozniak L, Skąpska S. The application of high pressure––mild temperature processing for prolonging the shelf -life of strawberry puree. High- Pressure Research. 36: 220-234 (2016)

Marszałek K, Woźniak Ł, Skąpska S, Mitek M. High pressure processing and thermal pasteurisation of strawberry purée: quality parameters and shelf life evaluation during cold storage. Journal of Food Science and Technology. 54: 832-841 (2017)

Nema PK, Sehrawat R, Ravichandran C, Kaur BP, Kumar A, Tarafdar A. Inactivating food microbes by high-pressure processing and combined nonthermal and thermal treatment: a review. Journal of Food Quality. (2022)

Ng SK, Tan TB, Tan PF, Chong GH, Tan CP. Effect of high- pressure processing on the microbiological, physicochemical and enzymatic properties of jackfruit (Artocarpus heterophyllus L.) bulb. Food Research. 3: 213-220 (2019)

Oey I, Lille M, Van Loey A, Hendrickx M. Effect of high-pressure processing on color, texture and flavour of fruit-and vegetable-based food products: a review. Trends in Food Science and Technology. 19: 320-328 (2008)

Oliveira M, Gibbs PA, Nunez H, Almonacid S, Simpson R. Thermal processes: pasteurization. Encyclopedia of Food Microbiology. (2014)

Özkan-Karabacak A, İncedayı B, Çopur ÖU. Preservation of beverage nutrients by high hydrostatic pressure. In: Preservatives and Preservation Approaches in Beverages, pp. 309–337. Academic Press (2019)

Padmanabhan P, Mizran A, Sullivan JA, Paliyath G. Strawberries. Encyclopedia of Food and Health, pp. 193–198 (2015)

Patras A, Brunton NP, Da Pieve S, Butler F. Impact of high-pressure processing on total antioxidant activity, phenolic, ascorbic acid, anthocyanin content and color of strawberry and blackberry purees. Innovative Food Science and Emerging Technologies. 10: 308-313 (2009)

Patras A, Brunton NP, O'Donnell C, Tiwari BK. Effect of thermal processing on anthocyanin stability in foods; mechanisms and kinetics of degradation. Trends in Food Science and Technology. 21: 3-11 (2010)

Peerun S. The Food High Pressure Processing (HPP) Technologies Market Forecast 2015–2025: Pascalization and Bridgmanization. Visiongain Ltd. London, UK. (2015)

Picart-Palmade L, Cunault C, Chevalier-Lucia D, Belleville MP, Marchesseau S. Potentialities and limits of some non-thermal technologies to improve sustainability of food processing. Frontiers in Nutrition. 5: 130 (2019)

Pinto CA, Moreira SA, Fidalgo LG, Inácio RS, Barba FJ, Saraiva JA. Effects of high-pressure processing on fungi spores: factors affecting spore germination and inactivation and impact on ultrastructure. Comprehensive Reviews in Food Science and Food Safety. 19: 553–573 (2020)

Predna L, Habanova M, Gazarova M, Mendelova A, Haban M, Saraiva JMA, Queiros R. Effect of thermal pasteurisation and high-pressure processing on bioactive properties in strawberry juice. Potravinarstvo Slovak Journal of Food Sciences. 10: 537-542 (2016)

Rodrigo D, Van Loey A, Hendrickx M. Combined thermal and high pressure color degradation of tomato puree and strawberry juice. Journal of Food Engineering. 79: 553-560 (2007)

Salamon B, Zakarias F, Csehi B, Kisko G, Dalmadi I. Different sequence of high-hydrostatic pressure and mild-heat treatment on the color and sensory characteristics of strawberry puree. Acta Alimentaria. 50: 93-101 (2021)

Sampedro F, McAloon A, Yee W, Fan X, Geveke DJ. Cost analysis and environmental impact of pulsed electric fields and high pressure processing in comparison with thermal pasteurization. Food and Bioprocess Technology. 7: 1928-1937 (2014)

Sapei L, Hwa L. Study on the kinetics of vitamin C degradation in fresh strawberry juices. Procedia Chemistry. 9: 62-68 (2014)

Schwieterman ML, Colquhoun TA, Jaworski EA, Bartoshuk LM, Gilbert JL, Tieman DM, Clark DG. Strawberry flavor: diverse chemical compositions, a seasonal influence, and effects on sensory perception. PloS ONE. 9: e88446 (2014)

Sehrawat R, Kaur BP, Nema PK, Tewari S, Kumar L. Microbial inactivation by high pressure processing: principle, mechanism and factors responsible. Food Science and Biotechnology. 30: 19-35 (2021)

Škegro M, Putnik P, Bursać Kovačević D, Kovač AP, Salkić L, Čanak I, Frece J, Zavadlav S, Ježek D. Chemometric comparison of high-pressure processing and thermal pasteurisation: the nutritive, sensory, and microbial quality of smoothies. Foods. 10: 1167 (2021)

Silva FV, Gibbs P. Alicyclobacillus acidoterrestris spores in fruit products and design of pasteurization processes. Trends in Food Science and Technology. 12: 68-74 (2001)

Silva FV, Gibbs P. Target selection in designing pasteurization processes for shelf-stable high-acid fruit products. Critical Reviews in Food Science and Nutrition. 44: 353-360 (2004)

Silva FV. Resistance of Byssochlamys nivea and Neosartorya fischeri mould spores of different age to high pressure thermal processing and thermosonication. Journal of Food Engineering. 201: 9-16 (2017)

Srivastava A, Akoh CC, Yi W, Fischer J, Krewer G. Effect of storage conditions on the biological activity of phenolic compounds of blueberry extract packed in glass bottles. Journal of Agricultural and Food Chemistry. 55: 2705-2713 (2007)

Sulaiman A, Farid M, Silva FV. Strawberry puree processed by thermal, high pressure, or power ultrasound: process energy requirements and quality modeling during storage. Food Science and Technology International. 23: 293-309 (2017)

Tenuta MC, Artoni E, Fava P, Bignami C, Licciardello F. Shelf life extension and nutritional quality preservation of sour cherries through high pressure processing. Foods. 12: 342 (2023)

Terefe NS, Yang YH, Knoerzer K, Buckow R, Versteeg C. High pressure and thermal inactivation kinetics of polyphenol oxidase and peroxidase in strawberry puree. Innovative Food Science and Emerging Technologies. 11: 52-60 (2010)

Terefe NS, Kleintschek T, Gamage T, Fanning KJ, Netzel G, Versteeg C, Netzel M. Comparative effects of thermal and high-pressure processing on phenolic phytochemicals in different strawberry cultivars. Innovative Food Science and Emerging Technologies. 19: 57-65 (2013)

Terefe NS, Buckow R, Versteeg C. Quality-related enzymes in fruit and vegetable products: Effects of novel food processing technologies, Part 1: high-pressure processing. Critical Reviews in Food Science and Nutrition. 54: 24-63 (2014)

Terefe NS, Buckow R, Versteeg C. Quality-related enzymes in plant-based products: effects of novel food processing technologies, Part 2: pulsed electric field processing. Critical Reviews in Food Science and Nutrition. 55: 1-15 (2015)

Timmermans R, Hayrapetyan H, Vollebregt M, Dijksterhuis J. Comparing thermal inactivation to a combined process of moderate heat and high pressure: effect on ascospores in strawberry puree. International Journal of Food Microbiology. 325: 108629 (2020)

Verbeyst L, Oey I, Van der Plancken I, Hendrickx M, Van Loey A. Kinetic study on the thermal and pressure degradation of anthocyanins in strawberries. Food Chemistry. 123: 269-274 (2010)

Vervoort L, Van der Plancken I, Grauwet T, Timmermans RAH, Mastwijk HC, Matser AM, Van Loey A. Comparing equivalent thermal, high pressure and pulsed electric field processes for mild pasteurisation of orange juice part II: impact on specific chemical and biochemical quality parameters. Innovative Food Science and Emerging Technologies. 12: 466-477 (2011)

Wang J, Law C, Mujumdar A, Xiao HW. The degradation mechanism and kinetics of vitamin C in fruits and vegetables during thermal processing. pp. 227-253. In: Drying Technologies in Foods. Nema PK, Kaur BP, Mujumdar AS (ed). CRC Press, Boca Raton, FL, USA (2018)

Wibowo S, Grauwet T, Santiago JS, Tomic J, Vervoort L, Hendrickx M, Van Loey A. Quality changes of pasteurized orange juice during storage: a kinetic study of specific parameters and their relation to color instability. Food Chemistry. 187: 140-151 (2015)

Yildiz S, Pokhrel PR, Unluturk S, Barbosa-Cánovas GV. (2019). Identification of equivalent processing conditions for pasteurization of strawberry juice by high pressure, ultrasound, and pulsed electric fields processing. Innovative Food Science and Emerging Technologies. 57: 102195 (2019)

Yildiz S, Pokhrel PR, Unluturk S, Barbosa-Canovas GV. Shelf-life extension of strawberry juice by equivalent ultrasound, high pressure, and pulsed electric fields processes. Food Research International. 140: 110040 (2021)

Zhang F, Dong P, Feng L, Chen F, Wu J, Liao X, Hu X. Textural changes of yellow peach in pouches processed by high hydrostatic pressure and thermal processing during storage. Food and Bioprocess Technology. 5: 3170-3180 (2012)

Zhang L, Liao L, Qiao Y, Wang C, Shi D, An K, Hu J. Effects of ultrahigh pressure and ultrasound pretreatments on properties of strawberry chips prepared by vacuum-freeze drying. Food Chemistry. 303: 125386 (2020a)

Zhang L, Qiao Y, Wang C, Liao L, Shi D, An K, Shi L. Influence of high hydrostatic pressure pretreatment on properties of vacuum-freeze dried strawberry slices. Food Chemistry. 331: 127203 (2020b)

Zhang S, Meenu M, Hu L, Ren J, Ramaswamy HS, Yu Y. Recent progress in the synergistic bactericidal effect of high pressure and temperature processing in fruits and vegetables and related kinetics. Foods. 11: 3698 (2022)

Zhao M, Luo Y, Li Y, Liu X, Wu J, Liao X, Chen F. The identification of degradation products and degradation pathway of malvidin-3-glucoside and malvidin-3, 5-diglucoside under microwave treatment. Food Chemistry. 141: 3260-3267 (2013)

Zhou L, Wang Y, Hu X, Wu J, Liao X. Effect of high pressure carbon dioxide on the quality of carrot juice. Innovative Food Science and Emerging Technologies. 10: 321-327 (2009)

Acknowledgements

This work was financially supported by the Ministry of Higher Education, Malaysia under the Fundamental Research Grant Scheme (FRGS) with Project No. FRGS/1/2020/STG04/UPM/02/6.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nawawi, N.I.M., Ijod, G., Senevirathna, S.S.J. et al. Comparison of high pressure and thermal pasteurization on the quality parameters of strawberry products: a review. Food Sci Biotechnol 32, 729–747 (2023). https://doi.org/10.1007/s10068-023-01276-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10068-023-01276-3