Abstract

Three high pressure processing (HPP) treatments (350 and 450 MPa for 5 min and 600 MPa for 3 min) at cold temperature (10 °C) were assessed as an alternative to thermal pasteurization (85 °C for 7 min) to obtain multi-fruit smoothies with “fresh-like” properties destined for retailing lines. The effects of the treatments on various sensory, enzymatic, physical-chemical and nutritional properties were determined 48 h post-processing, and microbial quality (total viable and psychrophilic bacteria, coliforms, Escherichia coli, Salmonella spp., Listeria monocytogenes, moulds and yeasts) was checked after 30 days of refrigerated storage. Compared with HPP, the thermal treatment only provided benefits with respect to the inactivation of oxidase and pectic enzymes but had clear disadvantages concerning the development of a cooked-fruit flavour and the loss of vitamin C. The application of 350 MPa did not alter fruit properties and ensured the microbiological quality of smoothies, while using higher pressures involved a higher risk of flavour alteration without providing other benefits. Both HPP treatments retained vitamin C, total phenols and flavonoids but also resulted in a sucrose hydrolysis. However, the antioxidant capacity and the values of lightness, turbidity, transmittance and viscosity indicated that the pressurized smoothies had a higher tendency for clarification and oxidation than the thermally pasteurized smoothies. Thus, the resistance of spoiling enzymes to high pressure is probably the main handicap when pressurizing fruit smoothies, since these enzymes remained active in the HPP-treated smoothies and the potential sensory and nutritional benefits of using HPP could be lost during storage.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

There is a general consensus that the consumption of fruit and vegetables is a key factor in a balanced diet. The Office of Disease Prevention and Health Promotion of the US Government (2015) recommends the consumption of five daily portions of fruits and vegetables. In Europe, fruit and vegetable intake varies between countries (Lobstein et al. 2004), but according to the compiled results of the European Food Safety Authority (EFSA) (2008), the average consumption (386 g per day) is below the 400 g per day recommended by the World Health Organization (WHO). Smoothies are an increasingly popular way of consuming fruit homogenates containing pulp and so may contribute to a healthier diet. Smoothies often consist of a number of ingredients including fruit (or less commonly vegetables), fruit juice, ice, yogurt and milk (Walkling-Ribeiro et al. 2010). In recent years, fruit-based smoothies have gained popularity across the world and are currently one of the major segments of the soft drinks market. This is primarily driven by rising health consciousness among the public, convenience and the taste and “naturalness” offered by smoothies. High pressure processing (HPP) is used by companies, mainly small- and medium-sized ones, to obtain a high-quality product with a good cost/benefit ratio (Sampedro et al. 2010). Industrial installations typically operate discontinuously and can attain pressures of up to 800 MPa (Barba et al. 2012b). As mentioned by several authors (Keenan et al. 2010; Landl et al. 2010; Knockaert et al. 2011; Vervoort et al. 2012), HPP has proven to be an alternative to heat treatment for processing fruit and vegetable juices and is accepted by the majority of consumers (Butz et al. 2003). HPP promotes the destruction of vegetative microorganisms and enzyme inactivation and causes little change in the sensory and nutritional properties of the food. HPP affects the viability of microbial cells (Patterson et al. 2012; Zhao et al. 2014) and the structure of proteins and/or enzymes (López-Malo et al. 1998; Rastogi et al. 2007), while hardly affecting the food compounds of low molecular weight, such as vitamins, pigments, flavouring agents and other compounds that are related to the sensory, nutritional and health properties of food products (Fernández-García et al. 2001; Butz et al. 2003; Nienaber and Shellhammer 2001; Oey et al. 2008; Barba et al. 2012b). Most HPP studies published to date have been carried out in individual fruit products, although some studies on blended fruit mixtures have been developed in recent years. Different pressurizing conditions have been tested in order to obtain products with the sensory and/or nutritional attributes normally associated with “minimally processed” fruit. Keenan et al. (2012a, b) compared two HPP treatments (450 and 600 MPa at 20 °C for 5 min) and an equivalent thermal treatment (P 70 > 10 min) in a similar fruit smoothie containing sterilized apple juice. The study found that HPP provided some advantages concerning colour retention, antioxidant capacity and vitamin C degradation, while its positive effect on flavour was less clear; however, the higher oxidation degree observed in the HPP-treated smoothies after chilled storage led these authors to conclude that enzymatic degradation systems were not inactivated by the pressurizing conditions tested. This finding was confirmed by Barba et al. (2014) in a study on a fruit extract containing orange, mango and papaya sweetened with Stevia rebaudiana. The application of 300–500 MPa for 5–15 min permitted a good retention of fruit properties such as colour, antioxidant capacity and phenol content but only resulted partially effective in inactivating oxidase enzymes. In contrast, HPP would provide a wide margin of microbial security in the blended fruit products. For example, pressurizing at 200 MPa for 5 min allowed a 5-log reduction of Lactobacillus plantarum in an orange juice-milk beverage (Barba et al. 2012a). A preliminary study (Picouet et al. 2015) confirmed that the application of 600 MPa at 10 °C for 5 min widely ensured the microbial quality of a carrot juice for 29 days, which suggests that the use of lower pressures would also be considered effective for pasteurizing similar products such as smoothies.

Besides HPP, alternative methods to thermal pasteurization can be used for preserving fruit products. Walkling-Ribeiro et al. (2010) researched the shelf life and sensory attributes of a fruit smoothie-type beverage processed with moderate heat and pulsed electric fields (PEFs) and concluded that the improvement in microbiological stability obtained and generally comparable attributes obtained meant that the process could be considered a feasible alternative to treatment with mild pasteurization. Zulueta et al. (2013) also reported that alternative methods such as HPP and PEF may give new opportunities to develop an orange juice-milk beverage with an equivalent shelf life to that of thermally treated beverage in terms of microbial, physical-chemical and nutritional characteristics. However, no industrial preservation process involving pulsed electric fields exists. In contrast, food companies have ever more access to HPP equipment, and the number of HPP food products on the market is increasing, particularly blended fruit homogenates that are sold in chilling cabinets. Thus, the growing consumption of fresh-like fruit smoothies and juices requires new specific studies that simultaneously address the different aspects related with their preservation, including the inactivation of pathogens and spoiling microbes, the retention of fresh fruit flavour and colour, the inactivation of the oxidase and pectic enzymes involved in darkening, clarification and off-flavours or the preservation of major nutrients, such as vitamins, antioxidants and sugars. In addition, comparisons with equivalent conventional thermal processes are needed.

The aim of the present study was to assess the effects of three high pressure treatments (ranging from 350 to 600 MPa) on the resulting quality of a multi-fruit smoothie elaborated with fruits in proportions similar to those used in commercial smoothies. Based on the results obtained, one of the three HPP treatments will be chosen for future studies and a further full shelf life experiment will be carried out to monitor spoilage in fruit smoothies kept under refrigeration.

Materials and Methods

Experimental Design

The experimental design was based on the research published by Keenan et al. (2010, 2011, 2012a, b). After preliminary sensory trials (data not shown), a commercial formulation for smoothies containing fresh fruits was chosen. Smoothies from five different treatments (raw, HPP-treated at 350, 450 or 600 MPa and thermally treated at 85 °C) were compared. The quality of smoothies (flavour, oxidase and pectic activities, antioxidant status, different physical properties and major nutrients) was assessed 48 h post-processing. This time period represents the time elapsing from processing (pressurizing or heating) to the beginning of the trading period (including post-processing storage, transport and pre-retailing storage in the supermarket). Next, microbial counts were made after 30 days of chilled storage to determine whether the smoothies complied with microbial standards for a suitable time before retail. Data were analysed by ANOVA using the Statistix 8 package for Windows (Analytical Software, Tallahassee, FL, USA). The statistical model included the treatments as fixed effect and the replica as a random effect. Mean differences between treatments were tested by Tukey test (P ≤ 0.05). Sample size was 45 smoothie units (3 bottles or bags × 5 treatments × 3 manufacturing batches). All measurements and analyses were made in triplicate at least.

Sample Preparation

The smoothie formulation was based on commercial smoothies but selected for its sensory properties. Fruits were purchased from a local wholescale agent. The smoothie composition by weight (g 100 g−1) was apple juice (Pyrus malus v. Golden delicious) (33), orange juice (Citrus sinensis v. Late Navel) (33), strawberry (Fragaria ananassa v. Pájaro) (14), whole apple (10) and banana (Musa cavendishii v. Pequeña enana) (10). Juices were obtained using a juicer (Robot Coupé C40, Bourgogne, France) and blended in a tank to achieve the above-mentioned composition. After mixing, the pH and total soluble solids of the different smoothies were measured in each manufacturing batch. The average values for pH and total soluble solids (°Brix) were 3.8 ± 0.0 and 12.2 ± 0.1, respectively. Untreated smoothies and the smoothies intended for HPP were packaged in 250-ml polyethylene terephthalate (PET) bottles (Sunbox, Madrid, Spain), while specific HT300 pouches (Seal Air Cryovac, Milano, Italy) were used for the thermally treated samples. These packaging types are suitable for high pressure and thermal processing, respectively, and prevent the possible negative effects of packaging materials on smoothie flavour. The packed smoothies were kept at 4 °C in darkness for up to 1 h before processing.

Thermal and High Pressure Processing

HPP consisted of pressurization at an initial temperature of 9–10 °C, a feasible industrial working temperature to prevent smoothie overheating during pressurization and limit the energetic costs derived from water chilling. A 6500/120 industrial apparatus for HPP was used (Hyperbaric, Burgos, Spain), the main characteristics of which were throughput, 555 kg per h; vessel capacity, 120 l; vessel diameter inside, 200 mm and footprint, 37 m2. Pressure measurements were made with an IS-20H pressure transducers (Wika instrument, Lawrenceville, USA) able to measure pressure from 0 to 689.5 MPa (≈100,000 psi). The initial temperature of the water located at the entrance of the vessel was measured by a temperature sensor pt100 (IFM electronic, El Prat de Llobregat, Spain). Three different pressurizing conditions were tested. For Pmax = 350 MPa, the pressure ramp was 200 MPa min−1, holding time 5 min and total processing time 7 min 18 s. For Pmax = 450 MPa, the pressure ramp was 215 MPa min−1, holding time 5 min and total processing time 7 min 40 s, while for Pmax = 600 MPa, the pressure ramp was 230 MPa min−1, holding time 3 min and total processing time 5 min 8 s. With such parameters, the quasi-adiabatic temperature increase was below 3.0 °C at 100 MPa−1 (Patazca et al. 2007), indicating that sample temperature was below 25 °C at 600 MPa. For thermal processing, the samples were introduced into an Ilrpaplus autoclave (Ilpra Systems, Mataró, Spain) and heated to 85 °C for 7 min, including the initial ramp of 5.7 °C min−1, the total heating time being 27 min. After processing, the samples were kept in a Climacell 707 cabinet (MMM Medcenter Einrichtungen, München, Germany) at 4 ± 1 °C under darkness for 48 h.

Sensory Analysis

Sensory analysis was carried out in two steps: first, screening by differences between samples, and then, a triangle test (ISO 4120 2004) between the two most similar treatments was applied for discriminating smoothie flavour. Six assessors were selected and trained according the ISO 8586 2012. Training focused on the possible off-flavours present in smoothies, in particular, cooked-fruit “pressurized-like” flavours. In the triangle test, three samples are presented, two of which are known to be alike and the third different; the probability is 1/3 that the odd sample will be chosen by chance alone. The normal curve approximation with P = 1/3 may be used to obtain approximate probabilities. Samples were coded with three randomized numbers and presented with equal frequency in each of the six possible orders: ABB, BAB, BBA, AAB, ABA and BAA. At all tasting sessions, three triangle tests were presented. At a P < 0.05 level of significance, 18 of the 36 possible correct identifications are required to be regarded as significant. The sensory evaluation was carried out in a standardized sensory test room at 22 ± 1 °C.

Enzymatic Activities

Peroxidase enzyme (POD) was first extracted from the smoothies by mixing 10 ml sample with 10 ml 0.2 M sodium phosphate buffer, pH 6.5. The mixture was centrifuged for 10 min at 15430×g. The supernatant was mixed with 1.1 ml 0.2 M sodium phosphate buffer pH 6.5, 0.5 ml enzyme extract, 1 ml o-phenylenediamine (OPDA) solution (10 g l−1 in 0.2 M sodium phosphate buffer pH 6.5) as substrate and 0.5 ml hydrogen peroxide solution (15 g l−1 in 0.2 M sodium phosphate buffer pH 6.5) as oxidant in a 1-cm path cuvette. The formation of the coloured oxidation product (2,3-diaminophenazine) was measured as the change in absorbance at 485 nm and 25 °C after 20 min (Vervoort et al. 2011).

Polyphenol oxidase (PPO) enzymatic activity was assessed according to the procedure of Wang et al. (2014) with slight modifications. Samples (3 g) were homogenized in 6 ml 0.2 M sodium phosphate buffer, pH 7.0, containing 10 g l−1 insoluble polyvinylpyrrolidone (PVP) and 5 g l−1 Triton X-100 and were then centrifuged at 15,430×g for 10 min. The reaction material containing 2 ml of 7 mM 4-t-butyl catechol solution, 1 ml of distilled water and 0.2 ml of the extract supernatant was measured at 420 nm and 25 °C. The reference cuvette contained only substrate solution and distilled water. PPO activity was defined as the change in absorbance under the assay conditions (Δ absorbance min−1 mol). The final results were expressed as percentage of POD and PPO relative activities and were calculated as the ratio between the treated (HPP and thermal) and the untreated smoothies.

The enzymatic activity of pectin methyl esterase (PME) was determined according to the method of Li et al. (2015) with slight modifications. PME activity was assayed by reacting 5 ml of sample with 50 ml of a 1 % (w/v) citrus pectin solution containing 0.2 M NaCl. During pectin hydrolysis, the pH was maintained constant by the addition of 0.01 N NaOH using a GLP21 pH meter (Crison, Barcelona, Spain). The results of PME activity (expressed as PME units g−1) were calculated using the following formula (1):

Antioxidant Activity Assay

Free radical scavenging activity was determined using the 2,2-diphenyl-2-picryl-hydrazyl (DPPH) method (Vega-Gálvez et al. 2014) with some modifications. The sample was diluted in an 80:20 (v/v) ethanol/water solution to obtain the extract (0.1 g ml−1). Sample extract was diluted at seven different concentrations (from 0.005 to 0.1 g ml−1) in an 80:20 (v/v) ethanol/water solution. Then, an aliquot of 2 ml of 0.15 mM DPPH radical in ethanol was added to a test tube with 1 ml of the sample extract. The control solution was prepared containing the same volume without any extract. The absorbance was measured at 515 nm using a UV2 Series UV⁄Vis spectrophotometer (Unicam, Cambridge, UK) after 20 min in darkness. The spectrophotometer was equilibrated with an 80 % (v/v) ethanol/water solution. Total antioxidant activity (TAA) was expressed as the inhibition percentage of the DPPH radical and was determined by the following formula (2):

where TAA is the total antioxidant activity and Abs is the absorbance.

A polynomial regression equation between the TTA values obtained at different concentrations for each sample was used for quantification. The results (IC50) were expressed as the sample concentration required to scavenge half of the DPPH free radicals.

The reducing power was determined using the ferric ion reducing antioxidant power (FRAP) assay as described by Benzie and Strain (1996) with some modifications. To prepare the FRAP reagent, a mixture of 300 mM acetate buffer (pH 3.6), 10 mM 2,4,6-Tripyridyl-s-triazine (TPTZ) solution in 40 mM HCl and 20 mM ferric chloride (10:1:1; v/v/v) was freshly prepared. Then, 3 ml reagent, 300 μl water and 100 μl sample were added. FRAP reagent was added at 37 °C. The reaction mixture was monitored at 593 nm versus a blank (reaction mixture without sample). Methanolic Fe2+ solutions in a concentration range of 100–1000 μmol (FeSO4) l−1 were used to obtain the calibration curve. The results were expressed as μmol equivalents Fe2+ 100 ml−1 (±3 μmol 100 ml−1).

Density

Density (expressed as g ml−1) was measured in shaken samples kept at 25 °C using a DMA 35N densimeter (Anton Paar, Graz, Austria) with an accuracy of ±0.001 g ml−1 and a measuring range of 0–3 g cm−3.

Viscosity

Absolute viscosity was measured in the supernatant from the centrifuged sample kept at 40 °C, using a No. 300 Ostwald Cannon-Fenske viscometer tube (Sigma-Aldrich, Madrid, Spain). Absolute viscosity was calculated according to the following formula (3):

where V is the absolute viscosity (cP), C is the constant for the viscometer (0.24438 mm2 s−1), T is the holding time (s) and D is the density (g ml−1).

Total Soluble and Insoluble Solids

Total soluble solids (g 100 g−1 or °Brix, ±0.01°Brix) were determined in shaken samples using an ATC-1e hand refractometer (Atago, Minato-ku, Tokyo, Japan) following the method of the Association of Official Analytical Chemists (1990) (AOAC 932.14). Total insoluble solids (g 100 g−1) were calculated as the relative weight difference (g 100 g−1) between the shaken sample and the resulting supernatant after centrifugation.

Turbidity and Transmittance

Turbidity (nephelometric unit (NTU)) was measured in the upper part of the smoothie (bottle or bag kept in vertical position) using a 2100N turbidimeter (Hach, Loveland, USA) with an accuracy of ±0.20 NTU. Transmittance (%) was measured at 660 nm wavelength using pure water as a blank (100 % transmittance). A UV2 Series UV⁄Vis spectrophotometer (UNICAM, Cambridge, UK) was used.

Instrumental Colour

Instrumental colour was measured in shaken samples using a CR-200/08 Chroma Meter II (Minolta Ltd., Milton Keynes, UK) with D65 illuminant, 2° observer angle and 50 mm aperture size. The results were expressed as CIELAB values: lightness (L*), redness (a*), yellowness (b*), chroma (C*) and hue angle (H*) (sexagesimal degrees) values, calculated as follows: C* = √ (a* 2 + b* 2 ); H* = tan −1 (b*/a*).

Browning Index

The browning index (absorbance units) was determined according to the method of Ting and Rouseff (1986). A solution of sample in methanol at 1:1 (v/v) was kept on ice for 15 min, and then, the solution was centrifuged at 15,430×g for 10 min in a 5804 Eppendorf centrifuge. The absorbance of the supernatant was measured at 420 nm in an UV2 Series UV⁄Vis spectrophotometer.

Total Acidity and pH

The total titratable acidity (g citric acid 100 g−1, ±0.01 g 100 g−1) was quantified in shaken samples by potentiometric titration with 0.1 N NaOH (AOAC 924.15; 1990). The pH was measured in shaken samples with a GLP21 pH meter (Crison, Barcelona, Spain) equipped with a combined electrode Cat. No. 52-21 (Ingold Electrodes, Wilmington, USA) (AOAC 981.12; 1990).

Vitamin C

The total vitamin C content (mg 100 ml−1, ±0.5 mg 100 ml−1) was calculated as the sum of ascorbic acid (AA) and dehydroascorbic acid (DHAA) following the method of Gil et al. (1998) with slight modifications. Sample was diluted 3:8 (w/v) in methanol water at 5:95 (v/v) with 0.5 g l−1 citric acid and 0.5 g l−1 ethylendiaminetetracetic acid. The sample solution was centrifuged for 10 min at 15,430×g and then filtered through syringe filter Chromafil Xtra of 0.20 μm pore size (Macherey-Nagel GmbH & Co. KG, Düren, Germany). The filtered sample was injected into HPLC for AA determination. For DHAA determination, 3 ml of dilution was reacted with 1 ml of an OPDA solution in a 5:95 methanol/water solution (v/v) (332.72 mg OPDA 100 ml−1). The mixture was kept at 4 °C in darkness for 40 min before analysis and then filtered through a 0.20 μm pore size filter and injected into the HPLC. The reverse-phase high-performance liquid chromatography (RP-HPLC) system was made up as follows: L-6200 pump (Merck-Hitachi, Darmstadt, Germany), 2050 Plus autosampler (Jasco Inc., Easton, UK), L-7420 UV detector (Merck-Hitachi) and a Gemini C18 column (300 × 4.6 mm, 5 μm) connected to a C18 reverse phase guard column (Phenomenex, Torrance, CA, USA). The mobile phase used was 5:95 methanol water (v/v) containing 5 mM cetrimide and 50 mM KH2PO4 (pH 4.5). The operating conditions were 100 μl injection volume, 260 nm (AA) or 340 nm (DHAA) nm detector wavelength and 0.9 ml min−1 flow rate.

Total Phenols and Flavonoids

Total phenols (mg gallic acid equivalents (GAE), 100 ml−1, ±2.5 mg 100 ml−1) were determined according to Singleton and Rossi (1965). The absorbance of a yellow compound formed from the reaction between a sample of the ethanolic extract and Folin-Ciocalteu reagent was measured at 765 nm. Total flavonoids (mg quercetin equivalents (QE), 100 ml−1, ±0.5 mg 100 ml−1) were determined according to the method of Chang et al. (2002). The absorbance of a yellow compound formed by reacting 0.5 ml of a methanolic sample extract with 0.1 ml of 10 % aluminium chloride, 0.1 ml of 1 M potassium acetate and 2.8 ml of water was measured at 415 nm.

Sugars

Sugars (sucrose, glucose and fructose) were determined by HPLC using the method described by Hellín et al. (2001). A water extract sample was filtered through Chromafil Xtra syringe filters of 0.20 μm pore size (Macherey-Nagel GmbH & Co. KG) and then injected into the HPLC system equipped with a L-7490 Lachrome refractive index detector (Merck-Hitachi) and a Carbosep CHO682 lead column (Transgenomic, Elancourt, France). The mobile phase used was pure water (MilliQ). The operating conditions were 20 μl injection volume, 0.4 ml min−1 flow rate and 80 °C temperature. Results were expressed as g 100 ml−1 (±0.02 g 100 ml−1).

Microbial Analysis

Total viable counts and total psychrophilic bacteria (expressed as log CFU g−1) were determined on a plate count agar (Scharlab, Barcelona, Spain) after incubation at 30 °C for 72 h (ISO 4833 2013) and 4 °C for 7 days, respectively. The detection limit was <0.1 log CFU g−1.

E. coli and total coliforms (log CFU g−1) were determined in a chromogenic E. coli/coliform medium (ChromID Coli, Biomerieux, Madrid, Spain) using pour plating and incubation at 37 °C for 24 h. The detection limit was <0.1 log CFU g−1.

Moulds and yeasts (log CFU g−1) were counted on Yeast Extract Glucose Chloramphenicol Agar (Merck, Madrid, Spain) using pour plating and incubation at 25 °C for 5 days. The detection limit was <0.1 log CFU g−1.

The presence of Salmonella spp. and Listeria monocytogenes was investigated in 25 ml of sample, diluted 1/10 in brain-heart infusion (BD Becton, Dickinson and Company, New Jersey, USA) and enriched for 48 h at 37 °C. The presence of the pathogens was determined as described by Stollewerk (2012). Chromogenic Listeria agar and real-time polymerase chain reaction (HLY gene) was used for L. monocytogenes. In the case of Salmonella, samples were incubated in Rappaport Vasiliadis (Oxoid, Basingstoke, Hampshire, UK) at 41.5 °C for 48 h followed by streaking in CHROMagar™ Salmonella plus (Scharlab Sentmenat, Barcelona, Spain) and confirmation by real-time polymerase chain reaction (ttr gen).

Results and Discussion

Flavour Retention

The results of triangle sensory test are shown in Table 1. Preliminary screening (qualitative evaluation) showed that all the thermally treated samples were unequivocally characterized by a cooked-fruit flavour, while those pressurized at 600 MPa also developed an off-flavour commonly associated with HPP. All the assessors agreed that both the thermally treated samples and those treated at 600 MPa were clearly different from the others and were rejected due to flavour alterations. Then, samples treated at 350 or 450 MPa were compared with the raw samples using different triangle tests. The tasters correctly selected the odd sample six or less times of the 36 possible identifications. At a P< 0.05 level of significance, 18 correct identifications were required, from a total of 36, for differences to be statistically significant between samples. The conclusion was that the sensory panel did not discriminate between smoothie flavours and that the “fresh-like” fruit flavour was maintained in smoothies pressurized at 350 and 450 MPa.

The main differences in flavour between the smoothies subjected to HPP and the thermal treatment concern the development of a cooked-fruit flavour, as a result of thermal degradation of flavouring compounds during fruit heating (Ludikhuyze et al. 2003). Fruit flavour can also be altered by HPP, depending on the intensity of the applied treatments, among other factors. Most available data correspond to individual fruit products. For example, the application of 200–600 MPa at ambient temperature did not alter the flavour of strawberry purée (Lambert et al. 1999), mandarin juice (Takahashi et al. 1993) or orange-lemon-carrot juice (Fernández-García et al. 2001). In contrast, the application of more intense HPP treatments (500–800 MPa for up to 20 min) modified the flavour of strawberry purée (Lambert et al. 1999) and orange juice (Fernández-García et al. 2001). In other studies, the taste of HPP-treated orange juice was judged more favourably than traditional heat-pasteurized orange juice (Parish 1998; Polydera et al. 2003). In contrast, Keenan et al. (2012a) found no clear differences in the flavour profile or in the levels of some related volatiles, such as limonene or trans-2-hexanal, of thermally (P 70 ≥ 10 min) and HPP (450 MPa and 20 °C for 5 min or 600 MPa and 20 °C for 10 min) treated smoothies, containing apple, orange, banana and strawberry. In the above study, the use of HPP led to a partial loss of fresh fruit flavour in smoothies rested during 24 h at 4 °C. The lack of correspondence with our results may be explained by the different ingredients, including thermally treated apple juice, higher temperature and/or the sensory test used by Keenan et al. (2012a). However, our results confirmed that HPP may affect smoothie flavour, although the application of a pressure equal to or below 450 MPa at 10 °C would prevent the development of off-flavours.

Inactivation of Oxidase and Pectic Enzymes

The inactivation of the oxidase and pectic enzymes responsible for oxidation and cloud clarification is another goal in fruit processing. In this respect, there were noticeable differences in the smoothies submitted to the respective treatments. As shown in Table 2, HPP-treated smoothies maintained quite similar PPO, POD and PME enzymatic activities to those presented by raw smoothies, while heating at 85 °C for 7 min was highly effective at inactivating all three enzymes. When the HPP-treated smoothies were compared amongst themselves, no significant differences in the relative activities of POD and PPO were observed, while the application of 600 MPa reduced PME activity by about half, meaning that this enzyme cannot be inactivated without damaging flavour in the HPP-treated smoothies.

The pressure resistance of PME has been reported by others. For example, Bayindirli et al. (2006) needed to apply 450 MPa and 50 °C for 30 min in order to inactivate PME in orange juice, although the sensory quality was not assessed. PME was also partially inactivated in orange juice treated at 400 MPa and 50 °C for 12 min (Nienaber and Shellhammer 2001) and in banana treated at 600 MPa and 10 °C for 2 min (Ly Nguyen et al. 2002), while a slight activation of PME was found by Cano et al. (1997) in orange juice treated at 200 and 400 MPa at 20 °C for 15 min. PME activity in fruit juices is mainly related with cloud stability. PME enzymes hydrolyse methyl esters of galacturonic acid, generating free carboxyl groups and free methanol. The result is the formation of low-methoxyl pectin and even polygalacturonic acid, which can react with Ca+2 ions present in the medium to form calcium pectate and other water-insoluble compounds, whose deposition leads to a gradual loss of turbidity in fruit juices (Wicker et al. 2003). This can negatively affect the appearance and so, fruit smoothies may require to be shaken before consumption.

PPO and POD enzymes were seen to be even more pressure-resistant than PME enzyme in smoothies. There is no consensus on the potential of HPP for inactivating oxidase enzymes in fruit products. Partial PPO inactivation has been reported in a similar multi-fruit smoothie pressurized at 450–600 MPa (Keenan et al. 2012b) and in a fruit extract pressurized at 300–500 MPa for 5–15 min (Barba et al. 2014). González-Cebrino et al. (2012) reported that HPP was insufficient to inactivate the PPO in plum purée, which required antibrowning ingredients or blanching pre-treatments. Similarly, both POD activation (García-Palazón et al. 2004) as partial POD inhibition (Cano et al. 1997; Barba et al. 2014) were observed in different fruit juices and/or extracts processed by HPP. In our study, PPO and POD remained fully active in the HPP-treated smoothies which were therefore exposed to the oxidizing reactions catalysed by these enzymes. Fruit can suffer browning as a result of polyphenol oxidation catalysed by PPO (García-Palazón et al. 2004), while POD oxidizes different substrates (phenols and others) at the expense of hydrogen peroxide, resulting in the formation of different products, which may cause changes in the colour and flavour of fruits (Zhang et al. 2005).

Antioxidant Status

Enzymatic and non-enzymatic oxidation reactions can negatively affect smoothie quality. The antioxidant status results (see Table 2) confirmed that the HPP-treated smoothies had a lower antioxidant capacity (higher IC50 and lower FRAP) than the thermally treated smoothies at 48 h post-processing. As can been seen, these differences between treatments may be due to oxidase activities. Keenan et al. (2010) found that the antioxidant capacity (DPPH and FRAP) in a HPP-treated (450 MPa and 20 °C for 5 min) was lost more rapidly than in thermally treated (P 70 ≥ 10 min) smoothies kept in refrigeration for up to 30 days and concluded that enzymatic degradation systems were not inactivated by the HPP treatment. Other studies reported no changes in antioxidant capacity immediately after processing as a result of HPP or thermal treatments in fruit extract (Barba et al. 2014), orange juice (Fernández-García et al. 2001; Sanchez-Moreno et al. 2005) and orange juice-milk beverage (Zulueta et al. 2013), while Polydera et al. (2005) found that oxidative stability was greater in HPP-treated (600 MPa and 40 °C for 4 min) than in thermally heated (80 °C for 1 min) orange juice during chilled storage. The differences in fruit matrixes and processing conditions may explain this disparity in the results. Whatever the case, the time elapsing from processing may increase the differences observed in the antioxidant capacity of smoothies treated by HPP and heating, since oxidase enzymes would be active in the former. Our data confirmed that the pressurized smoothies had a higher tendency to oxidation and so would be less stable under refrigeration. Oxidizing reactions would be particularly favoured in smoothies compared with intact fruit, because mincing and mixing disrupt fruit structures and facilitate contact between enzymes, occluded oxygen and fruit components, which may help to explain the early loss in the antioxidant capacity of smoothies treated by HPP.

Cloud Stability and Discolouration

Smoothie tendency toward cloud clarification and discolouration was objectively assessed by reference to different physical properties. The results are shown in Tables 3 and 4. In general, the HPP-treated smoothies presented physical characteristics similar to those presented by the raw smoothies, with some exceptions. The density and soluble solid content were similar in all the smoothies after shaking, whereas the values of viscosity and turbidity measured in the supernatant were higher in the thermally treated than in the HPP-treated smoothies, indicating that the clarifying tendency may be greater in the latter. When HPP-treated samples were compared among themselves, the absolute viscosity values increased as the pressure level increased; in contrast, smoothie turbidity was not affected by the different conditions used in HPP. According to the transmittance values, translucency was significantly higher in the smoothies treated at 350 MPa than in the thermally treated smoothies, while the samples from the rest of the treatments had intermediate transmittance values. The insoluble solid content was higher in the HPP-treated and thermally treated smoothies than in the raw smoothies, which suggests a lower tendency to flocculation in the untreated samples.

HPP resulted in a lower consistency and absolute viscosity in orange juices (Parish 1998; Polydera et al. 2005), although no clear differences in transmittance and absolute viscosity were observed in other studies (Bull et al. 2004). The loss of viscosity in cloudy juices may be attributed to pulp precipitation and pectin degradation through enzymatic and non-enzymatic mechanisms (Sila et al. 2009). It is well-known that pectin flocculation is affected by pH in fruit smoothies and juices. As can been seen, the fruit mixture used to elaborate the smoothies in our study resulted in an acidic product, and the values of total titratable acidity and pH were not affected by any preservative treatment. HPP did not result in changes of pH or titratable acidity in orange juice (Bull et al. 2004), blueberry juice (Barba et al. 2013) or an orange juice-milk beverage (Zulueta et al. 2013). Acidification is often associated to differences in the growth rate of lactic acid bacteria, which can be difficult to see at the beginning of storage in pasteurized fruit products. Our physical assessment suggests that the HPP-treated smoothies had a greater tendency towards clarification than the smoothies processed by heating. Parish (1998) reached the same conclusion when assessing cloud stability in orange juice pressurized at 500–700 MPa. In the mentioned study, thermal pasteurization was also more effective than HPP for cloud stabilization. Taking into account the high pressure resistance of PME enzymes, the use of HPP in smoothies should be combined with complementary cloud stabilization strategies. For example, Sun-Waterhouse et al. (2014) proposed the use of carboxymethyl cellulose, a stabilizing agent, to prevent clarification problems in smoothies treated by HPP. In addition, using fruit varieties rich in water-soluble polysaccharides may also help cloud stabilization in the case of fruit smoothies.

As regards colour, the CIELAB coordinates were similar in the raw and HPP-treated smoothies, and so, the “orange” colour was not altered by HPP. In contrast, the application of thermal treatment increased L* value and, to a lesser extent, the H* angle but did not affect the values of a*, b* and C*, resulting in slightly less translucent and browner smoothies. Moreover, the browning index was not affected by thermal treatment or HPP, suggesting that early oxidase activities did not affect colour in the HPP-treated smoothies. Discolouration and non-enzymatic browning following thermal treatment can result from several reactions, including Maillard condensation, caramelisation and the destruction of pigments, such as anthocyanins (Ibarz et al. 2000). Keenan et al. (2011) found the opposite results in a similar smoothie treated by HPP (450 MPa and 20 °C for 5 min) or heating. Unlike our study, HPP led to higher rates of colour change, resulting in a reduction in L*, while L* values were similar in the raw and thermally treated samples. This disparity in the results might be explained by the different raw materials and/or processing conditions used by Keenan et al. (2011). Other studies agree with the results of Keenan et al. (2011). According to Picouet et al. (2015), the use of thermal processing (80 °C for 7 min) provided a carrot juice with a higher browning index and a lower L* than those treated by HPP (600 MPa and 10 °C for 5 min). Similar colour differences were reported in an orange juice-milk beverage (Zulueta et al. 2013). In our study, the reduction in lightness observed in the HPP-treated smoothies may be explained by their greater clarification and translucency after 48 h of storage. Whatever the case, the discolouration induced by processing might be less relevant in blended fruit homogenates than in smoothies elaborated with individual fruits, which need to have a recognizable colour to satisfy consumer expectations.

Vitamin C, Antioxidants and Sugars

Retention of the main nutrients, including vitamins, antioxidants and sugars, is another relevant aspect of fruit processing. Vitamin C degradation is often considered as a handicap for the nutritional quality of fruit derivatives. As shown in Table 4, the ascorbic acid content was low in smoothies regardless of the preservation treatment. RP-HPLC-UV analysis indicated that most of the vitamin C present in smoothies corresponded to dehydroascorbic acid. The conversion of ascorbic acid into dehydroascorbic acid is catalysed by ascorbate oxidase, although direct oxidation may also occur (Greenway and Ongomo 1990). HPP led to better vitamin C retention than thermal processing with the resulting nutritional benefits. Moreover, the total vitamin C content was not affected by any HPP treatment and had similar levels to that observed in raw smoothies. The pressure resistance of vitamin C has also been seen in other studies. Keenan et al. (2012b) reported that HPP allows better retention of vitamin C, as determined by direct titration, compared with thermally treated smoothies. Similarly, the retention of ascorbic acid was slightly higher in an orange juice-milk beverage pressurized at 400 MPa and 15 °C for 5 min than in those heated at 90 °C for 15 s (Zulueta et al. 2013). The resistance of vitamin C to HPP has also been seen in other results. For example, the use of ultra-HPP (1400 MPa and 1 °C for 4 min) did not affect the content of ascorbic acid in an orange-lemon-carrot juice (Butz et al. 2003).

On the other hand, there were no differences between treatments in the total contents of phenols and/or flavonoids, and therefore, the use of HPP did not provide any advantage regarding the retention of these phenolic antioxidants compared with thermal treatment. Similar results have been reported in fruit smoothies (Keenan et al. 2011), fruit extract (Barba et al. 2014) and an orange juice-milk beverage (Zulueta et al. 2013), which may be explained by the different antioxidant property oxidation of ascorbic acid and phenols. Phenols can act either as antioxidants or substrates in browning reactions during fruit oxidation (Robards et al. 1999). In general, phenolic antioxidants are considered more resistant than vitamin C to fruit processing (Kalt 2005). Ascorbic acid is the primary antioxidant involved in the oxidation-reduction reactions occurring in fruit. Ascorbic acid can be oxidized to dehydroascorbic acid in the presence of oxidized phenols, converting quinones into their reduced form and protecting phenols against oxidation. Thus, the oxidation of ascorbic acid would be favoured in fruit products rich in phenolic compounds where oxidase enzymes remain active (Gandía-Herrero et al. 2007), as occurred in the HPP smoothies.

Finally, the use of HPP or heating led to changes in the sugar content. The increase observed in the glucose and fructose contents indicated that sucrose hydrolysis took place in the samples treated by HPP, which suggests that β-fructosidase enzymes followed a similar degradation pattern to that followed by oxidase and pectic enzymes. Sucrose inversion has been reported in other fruit products treated by HPP. For example, the incomplete inactivation of β-fructosidase enzymes resulted in the total disappearance of sucrose during the storage of HPP-treated raspberry purée (Butz et al. 2003). On the other hand, thermal inactivation of fruit β-fructosidase has also been well documented in fruit products (Simpson et al. 2012). Our results show that early sucrose inversion occurred in the smoothies treated by HPP, modifying the sugar profile by increasing glucose and fructose.

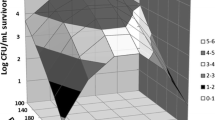

Microbial Quality Evaluated After 30 Days of Chilled Storage

Before being sold for consumption, smoothies must comply with microbial standards during their shelf life. For this reason, microbial quality was checked in smoothies after 30 days of chilled storage. The microbial counts of smoothies stored for 30 days are shown in Table 5. In general, spoiling and pathogenic bacteria were naturally inhibited in the fruit smoothies. Raw smoothies had total viable counts of 4.2 log CFU g−1, which decreased to 2.3 and 1.3 log CFU g−1 in smoothies treated by HPP and heating, respectively. Thus, pasteurizing at 85 °C for 7 min was only slightly more effective than HPP treatments in inactivating microbes. European Commission Regulation No 2073 (2005) establishes maximum total viable counts of 5 log CFU g−1 for smoothies. Moreover, no counts above the detection limit were found for total psychrophilic bacteria or total coliforms, while E. coli, Salmonella spp. and L. monocytogenes were absent in all the smoothie samples, as required by European Commission Regulation No. 2073. All the HPP treatments were also effective against moulds and yeasts, the main microbes involved in the spoilage of fruit juices and purees (Parish and Higgins 1989). Thus, microbial standards can be maintained in smoothies for 30 days without pasteurization, although both HPP and thermal treatment reduced the microbial risk.

Microbial inactivation by HPP has been demonstrated in numerous studies on fruit juices and purees. In general, pressures between 200 and 600 MPa are effective in inactivating most pathogenic and spoilage vegetative microorganisms present in fruit juices over a mild range of temperature (Parish 1998; Bull et al. 2004; Bayindirli et al. 2006; Balasubramaniam and Farkas 2008; Vega-Gálvez et al. 2014). For example, Picouet et al. (2015) reported counts from 0.3 to 3.0 log CFU g−1 for total viable bacteria and counts from <0.1 to 0.8 log CFU g−1 for moulds and yeasts in an HPP-treated (600 MPa and 10 °C for 5 min) carrot juice kept in refrigeration for 29 days. In this study, HPP treatment was surprisingly more effective that mild heating (80 °C for 7 min) in inhibiting microbial growth. Barba et al. (2012a) obtained a 5-log reduction of L. plantarum in an orange juice-milk beverage after pressurization at 200 MPa for 5 min. These authors also reported a reduction of at least 5 log cycles of L. monocytogenes in a buffered fruit extract treated at pressures higher than 300 MPa or for holding times in excess of 5 min (Barba et al. 2014). In a recent study, cold pressurizing at 300 MPa for 5 min inactivated Zygosaccharomyces bailii and L. monocytogenes cultures added to a multi-fruit smoothie elaborated with berries, orange, grape and apple (Scolari et al. 2015). Our results confirmed that it is possible to obtain microbiologically stable smoothies by applying 350 MPa at a cold temperature. The use of higher pressures may alter flavour and/or have no additional antimicrobial effects. As can been seen, microbial quality can be ensured without great difficulty through HPP in acidic smoothies where microbes have little chance to proliferate. It was not necessary to apply HPP, which may alter the flavour to maintain the microbial standards required for smoothies.

Conclusions

The use of “moderate” HPP can be regarded as an alternative to thermal pasteurization for preserving smoothies containing fruits, such as orange, strawberry, apple and banana, whose sensory and nutritional properties can be altered by the pasteurization temperature. Pressurizing at 350 MPa and 10 °C for 5 min retains the fresh-like fruit flavours, ensuring at the same time the microbial quality of smoothies, while the application of more intense pressuring conditions may represent a risk for flavour without providing other quality-related benefits. Moderate HPP treatment also protects vitamin C, does not affect phenol antioxidants, including flavonoids, but results in smoothies with a different sugar profile due to early sucrose hydrolysis. Compared to HPP, thermal processing provides noticeable benefits regarding enzyme inactivation but has clear sensory disadvantages due to the development of cooked-fruit flavours. The high pressure resistance of oxidase and pectic enzymes is probably the main handicap for pressurizing smoothies. These enzymes remained active in the HPP-treated smoothies, and the potential sensory and nutritional benefits of using HPP could be lost because of their potential for clarification and oxidation. Future shelf life studies should be carried out on the possible strategies to decrease the effects of these enzymes on smoothies treated by HPP.

References

AOAC. (1990). Official methods of analysis. Virginia: Association of Official Analytical Chemists.

Balasubramaniam, V. M., & Farkas, D. (2008). High-pressure food processing. Food Science and Technology International, 14(5), 413–418.

Barba, F. J., Cortés, C., Esteve, M. J., & Frigola, A. (2012a). Study of antioxidant capacity and quality parameters in an orange juice-milk beverage after high-pressure processing treatment. Food and Bioprocess Technology, 5, 2222–2232.

Barba, F. J., Esteve, M. J., & Frigola, A. (2012b). High pressure treatment effect on physicochemical and nutritional properties of fluid foods during storage: a review. Comprehensive Reviews in Food Science and Food Safety, 11(3), 307–322.

Barba, F. J., Esteve, M. J., & Frigola, A. (2013). Physicochemical and nutritional characteristics of blueberry juice after high pressure processing. Food Research International, 50, 545–549.

Barba, F. J., Criado, M. N., Belda-Galbis, C. M., Esteve, M. J., & Rodrigo, D. (2014). Stevia rebaudiana Bertoni as a natural antioxidant/antimicrobial for high pressure processed fruit extract: processing parameter optimization. Food Chemistry, 148, 261–267.

Bayindirli, A., Alpas, H., Bozoğlu, F., & Hizal, M. (2006). Efficiency of high pressure treatment on inactivation of pathogenic microorganism and enzymes in apple, orange, apricot and sour cherry juices. Food Control, 17, 52–58.

Benzie, I. F. F., & Strain, J. J. (1996). The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”: the FRAP assay. Analytical Biochemistry, 239(1), 70–76.

Bull, M. K., Zerdin, K., Howe, E., Goicoechea, D., Paramanandhan, P., & Stockman, R. (2004). The effect of high pressure processing on the microbial, physical and chemical properties of Valencia and Navel orange juice. Innovative Food Science and Emerging Technologies, 5, 135–149.

Butz, P., Fernández-García, A., Lindauer, R., Dieterich, S., Bognár, A., & Tauscher, B. (2003). Influence of ultrahigh pressure processing on fruit and vegetable products. Journal of Food Engineering, 56, 233–236.

Cano, M. P., Hernandez, A., & De Ancos, B. (1997). High pressure and temperature effects on enzyme inactivation in strawberry and orange products. Journal of Food Science, 62(1), 85–88.

Chang, C. C., Yang, M.-H., Wen, H. M., & Chern, J. C. (2002). Estimation of total flavonoid content in propolis by two complementary colorimetric methods. Journal of Food and Drug Analysis, 10(3), 178–182.

European Commission Regulation (EC) No 2073/2005 (OJ L338, p1, 22/12/2005) of 15 November 2005 on microbiological criteria for foodstuffs.

European Food Safety Authority (EFSA) (2008). Concise database summary statistics—total population. http://www.efsa.europa.eu/en/datexfoodcdb/datexfooddb.htm Accessed July 2014

Fernández-García, A., Butz, P., Bognér, A., & Tauscher, B. (2001). Antioxidative capacity, nutrient content and sensory quality of orange juice and an orange-lemon-carrot juice product after high pressure treatment and storage in different packaging. European Food Research and Technology, 213(4–5), 290–296.

Gandía-Herrero, F., Escribano, J., & García-Carmona, F. (2007). Characterization of the activity of tyrosinase on betanidin. Journal of Agricultural and Food Chemistry, 55, 1546–1551.

García-Palazón, A., Suthanthangjai, W., Kajda, P., & Zabetakis, I. (2004). The effects of high hydrostatic pressure on β-glucosidase, peroxidase and polyphenoloxidase in red raspberry (Rubus idaeus) and strawberry (Fragaria x ananassa). Food Chemistry, 88, 7–10.

Gil, M. I., Ferreres, F., & Tomas-Barberan, F. A. (1998). Effect of modified atmosphere packaging on the flavonoids and vitamin C content of minimally processed Swiss chard (Beta bulgaris Subspecies cycla). Journal of Agricultural and Food Chemistry, 46, 2007–2012.

González-Cebrino, F., García-Parra, J., Contador, R., Tabla, R., & Ramírez, R. (2012). Effect of high pressure processing and thermal treatment on quality attributes and nutritional compounds of “Songold” plum purée. Journal of Food Science, 77(8), 866–873.

Greenway, G. M., & Ongomo, P. (1990). Determination of L-ascorbic acid in fruit and vegetable juices by flow injection with immobilised ascorbate oxidase. Analyst, 115(10), 1297–1299.

Hellín, P., Ros, J. M., & Laencina, J. (2001). Changes in high and low molecular weight carbohydrates during Rhizopus nigricans cultivation on lemon peel. Carbohydrate Polymers, 45, 169–174.

Ibarz, A., Pagán, J., & Garza, S. (2000). Kinetic models of non-enzymatic browning in apple pureé. Journal of the Science of Food and Agriculture, 80(8), 1162–1168.

ISO 4120 (2004). Sensory analysis. Methodology. Triangle test. http://www.iso.org. Accessed 20 February 2015.

ISO 4833 (2013). Microbiology of the food chain—horizontal method for the enumeration of microorganisms—part 1: colony count al 30 degrees C by the pour plate technique. http://www.iso.org. Accessed 20 February 2015.

ISO 8586 (2012). Sensory analysis. General guidelines for the selection, training and monitoring of selected assessors and expert sensory assessors. http://www.iso.org. Accessed 20 February 2015.

Kalt, W. (2005). Effects of production and processing factors on major fruit and vegetable antioxidants. Journal of Food Science, 70(1), 11–19.

Keenan, D. F., Brunton, N. P., Gormley, T. R., Butler, F., Tiwari, B. K., & Patras, A. (2010). Effect of thermal and high hydrostatic pressure processing on antioxidant activity and colour of fruit smoothies. Innovative Food Science & Emerging Technologies, 11, 551–556.

Keenan, D. F., Brunton, N. P., Gormley, T. R., & Butler, F. (2011). Effect of thermal and high hydrostatic pressure processing and storage on the content of polyphenols and some quality attributes of fruit smoothies. Journal of Agricultural and Food Chemistry, 59, 601–607.

Keenan, D. F., Brunton, N. P., Mitchell, M., Gormley, T. R., & Butler, F. (2012a). Flavour profiling of fresh and processed fruit smoothies by instrumental and sensory analysis. Food Research International, 45, 17–25.

Keenan, D. F., Röβle, C., Gormley, T. R., Butler, F., & Brunton, N. P. (2012b). Effect of high hydrostatic pressure and thermal processing on the nutritional quality and enzyme activity of fruit smoothie. LWT--Food Science and Technology, 45, 50–57.

Knockaert, G., De Roeck, A., Lemmens, L., Van Buggenhout, S., Hendrickx, M., & Van Loey, A. (2011). Effect of thermal and high pressure processes on structural and health-related properties of carrots (Daucus carota). Food Chemistry, 125(3), 903–912.

Lambert, Y., Demazeau, G., Largeteau, A., & Bouvier, J.-M. (1999). Changes in aromatic volatile composition of strawberry after high pressure treatment. Food Chemistry, 67(1), 7–16.

Landl, A., Abadias, M., Sárraga, C., Viñas, I., & Picouet, P. A. (2010). Effect of high pressure processing on the quality of acidified Granny Smith apple purée product. Innovative Food Science & Emerging Technologies, 11, 557–564.

Li, R., Wang, Y., Wang, S., & Liao, X. (2015). A comparative study of changes in microbiological quality and physicochemical properties of N2-infused and N2-degassed banana smoothies after high pressure processing. Food and Bioprocess Technology, 8, 333–342.

Lobstein, T., Baur, L., & Uauy, R. (2004). Obesity in children and young people: a crisis in public health. Obesity Reviews, 5(1), 4–85.

López-Malo, A., Palou, E., Barbosa-Cánovas, G. V., Welti-Chanes, J., & Swanson, B. G. (1998). Polyphenoloxidase activity and colour changes during storage of high hydrostatic pressure treated avocado puree. Food Research International, 31(8), 549–556.

Ludikhuyze, L., Van Loey, A., Indrawati, Smout, C., & Hendrickx, M. (2003). Effects of combined pressure and temperature on enzymes related to quality of fruits and vegetables: from kinetic information to process engineering aspects. CRC Critical Reviews in Food Science and Nutrition, 43(5), 527–586.

Ly Nguyen, B., Van Loey, A., Fachin, D., Verlent, I., & Hendrickx, M. (2002). Purification, characterization, thermal, and high-pressure inactivation of pectin methylesterase from bananas (cv Cavendish). Journal of Biotechnology and Bioengineering, 78(6), 683–690.

Nienaber, U., & Shellhammer, T. H. (2001). High pressure processing of orange juice: kinetics of pectin methylesterase inactivation. Journal of Food Science, 66(2), 328–331.

Oey, I., Lille, M., Van Loey, A., & Hendrickx, M. (2008). Effect of high pressure processing on colour, texture and flavour of fruit and vegetable-based food products: a review. Trends in Food Science and Technology, 19(6), 320–328.

Office of Disease Prevention and Health Promotion. United States Government (2015). Scientific report of the 2015 Dietary Guidelines Advisory Commitee. http://www.health.gov/dietaryguidelines/2015-scientific-report. Accessed 10 july 2015.

Parish, M. E. (1998). Orange juice quality after treatment by thermal pasteurization or isostatic high pressure. LWT--Food Science and Technology, 31, 439–442.

Parish, M. E., & Higgins, D. P. (1989). Extinction of Listeria monocytogenes in single-strength orange juice: comparison of methods for detection in mixed populations. Journal of Food Safety, 9, 267–277.

Patazca, E., Koutchma, T., & Balasubramaniam, V. M. (2007). Quasi-adiabatic temperature increase during high pressure processing of selected foods. Journal of Food Engineering, 80(1), 199–205.

Patterson, M. F., McKay, A. M., Connolly, M., & Linton, M. (2012). The effect of high hydrostatic pressure on the microbiological quality and safety of carrot juice during refrigerated storage. Food Microbiology, 30, 205–212.

Picouet, P. A., Sárraga, C., Cofán, S., Belletti, N., & Guàrdia, M. D. (2015). Effects of thermal and high-pressure treatments on the carotene content, microbiological safety and sensory properties of acidified and of non-acidified carrot juice. LWT--Food Science and Technology, 62, 920–926.

Polydera, A. C., Stoforos, N. G., & Taoukis, P. S. (2003). Comparative shelf life study and vitamin C loss kinetics in pasteurized and high pressure processed reconstitutes orange juice. Journal of Food Engineering, 60, 21–29.

Polydera, A. C., Stoforos, N. G., & Taoukis, P. S. (2005). Effect of high hydrostatic pressure treatment on post processing antioxidant activity of fresh Navel orange juice. Food Chemistry, 91, 495–503.

Rastogi, N. K., Raghavarao, K. S., Balasubramaniam, V. M., Niranjan, K., & Knorr, D. (2007). Opportunities and challenges in high pressure processing of foods. Critical Reviews in Food Science and Nutrition, 47(1), 69–112.

Robards, K., Prenzler, P. D., Tucker, G., Swatsitwang, P., & Glover, W. (1999). Phenolic compounds and their role in oxidative processes in fruits. Food Chemistry, 66(4), 401–436.

Sampedro, F., Rodrigo, D., & Fan, X. (2010). High hydrostatic pressure processing of fruit juices and smoothies: research and commercial application. In C. Donna, K. Kustin, & F. Feeherry (Eds.), Case studies in novel food processing technologies: innovations in processing, packaging, and predictive modelling (pp. 34–72). Cambridge, U.K.: Woodhead Publishing.

Sanchez-Moreno, C., Plaza, L., Elez-Martínez, P., De Ancos, B., Martín-Belloso, O., & Cano, M. P. (2005). Impact of high-pressure and pulsed electric fields on bioactive compounds and antioxidant activity of orange juice and comparison with traditional thermal processing. Journal of Agricultural and Food Chemistry, 53(11), 4403–4409.

Scolari, G., Zacconi, C., Busconi, M., & Lambri, M. (2015). Effect of the combined treatments of high hydrostatic pressure and temperature on Zygosaccharomyces bailii and Listeria monocytogenes in smoothies. Food Control, 47, 166–174.

Sila, D. N., Buggenhout, S. V., Duvetter, T., Fraeye, I., Roeck, D. E., Van Loey, A., & Hendrickx, M. (2009). Pectins in processed fruits and vegetables: part II—structure–function relationships. Comprehensive Reviews in Food Science and Food Safety, 8, 86–104.

Simpson, B. K., Rui, X., & Klomklao, S. (2012). Enzymes in food processing. In B. K. Simpson, L. Nollet, G. Paliyath, S. Benjakul, W. K. Nip, & Y. Hui (Eds.), Food biochemistry and food processing (pp. 181–206). New York: Wiley-Blackwell.

Singleton, V. L., & Rossi, J. A. (1965). Colorimetry of total phenolics with phosphomolibdic-phosphotungstic acid reagent. American Journal of Enology and Viticulture, 16, 144–158.

Stollewerk, K. (2012). Food Safety in fast drying (QDS process®) of dry-cured meat products: high pressure and NaCl-free processing implementation (Ph. D. Thesis). Girona: Universidad de Girona.

Sun-Waterhouse, D., Bekkour, K., Wadhwa, S. S., & Waterhouse, G. I. N. (2014). Rheological and chemical characterization of smoothie beverages containing high concentrations of fibre and polyphenols from apple. Food and Bioprocess Technology, 7, 409–423.

Takahashi, Y., Ohta, H., Yonei, H., & Ifuku, Y. (1993). Microbicidal effect of hydrostatic pressure on Satsuma mandarin juice. International Journal of Food Science and Technology, 28(1), 95–102.

Ting, S. V., & Rouseff, R. L. (1986). Vitamins. In S. V. Ting & R. L. Rousseff (Eds.), Citrus fruits and their products: analysis, technology (pp. 121–136). New York: Marcel Dekker.

Vega-Gálvez, A., López, J., Torres-Ossandón, M. J., Galotto, M. J., Puente-Díaz, L., Quispe-Fuentes, I., & Di Scala, K. (2014). High hydrostatic pressure effect on chemical composition, color, phenolic acids and antioxidant capacity of Cape gooseberry pulp (Physalis peruviana L.). LWT - Food Science and Technology, 58, 519–526.

Vervoort, L., Van der Plancken, J., Graumet, T., Timmermans, R. A. H., Mastwijk, H. C., Matser, A. M., et al. (2011). Comparing equivalent thermal, high pressure and pulsed electric field processes for mild pasteurization of orange juice. Part II: impact on specific chemical and biochemical quality parameters. Innovative Food Science and Emerging Technologies, 12, 466–477.

Vervoort, L., Van der Plancken, I., Grauwet, T., Verlinde, P., Matser, A., Hendrickx, M., & Van Loey, A. V. (2012). Thermal versus high pressure processing of carrots: a comparative pilot-scale study on equivalent basis. Innovative Food Science & Emerging Technologies, 15, 1–13.

Walkling-Ribeiro, M., Noci, F., Cronin, D. A., Lyng, J. G., & Morgan, D. J. (2010). Shelf life and sensory attributes of a fruit smoothie-type beverage processed with moderate heat and pulsed electric fields. LWT--Food Science and Technology, 43, 1067–1073.

Wang, S., Lin, T., Man, G., Li, H., Zhao, L., Wu, J., & Liao, X. (2014). Effects of anti-browning combinations of ascorbic acid, nitrogen and carbon dioxide on the quality of banana smoothies. Food and Bioprocess Technology, 7, 161–173.

Wicker, L., Ackerley, J. L., & Hunter, J. L. (2003). Modification of pectin by pectin methylesterase and the role in stability of juice beverages. Food Hydrocolloids, 17(6), 809–814.

Zhang, Z., Pang, X., Xuewu, D., Ji, Z., & Jiang, Y. (2005). Role of peroxidase in anthocyanin degradation in litchi fruit pericarp. Food Chemistry, 90(1–2), 47–52.

Zhao, L., Wang, Y., Qiu, D., & Liao, X. (2014). Effect of ultrafiltration combined high pressure processing on safety and quality features of fresh apple juice. Food and Bioprocess Technology, 7, 3246–3258.

Zulueta, A., Barba, F. J., Esteve, M. J., & Frígola, A. (2013). Changes in quality and nutritional parameters during refrigerated storage of an orange juice-milk beverage treated by equivalent thermal and non-thermal processes for mild pasteurization. Food and Bioprocess Technology, 6, 2018–2030.

Acknowledgments

The authors gratefully acknowledge the financial participation of INIA through project FRUITECH-RTA2011-00038-C02-02. The authors would also like to acknowledge the contribution of Marta Baret and Jordi Garcia, both from IRTA Monells, Girona (Spain), in the preparation, processing and analysis of the smoothie samples.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hurtado, A., Picouet, P., Jofré, A. et al. Application of High Pressure Processing for Obtaining “Fresh-Like” Fruit Smoothies. Food Bioprocess Technol 8, 2470–2482 (2015). https://doi.org/10.1007/s11947-015-1598-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-015-1598-5