Abstract

Due to the continuous development of underground mining methods, technical equipment, the Internet and intelligent technology, a new energy revolution will be of great significance in years to come. Meanwhile, the high-intensity mining (HIM) of thick coal seams has become an important development direction of China’s underground coal mining technology. By summarizing the current situation and analyzing the characteristics of underground HIM using the analytic hierarchy process (AHP) method in thick coal seams in China, negative externalities are proposed, which are mainly reflected in the three aspects of overlying strata, ground surface, and ecological environment under the premise of standard operating procedures and underground mining safety. Considering the negative externalities of overlying strata and surface damage in HIM, geological disasters under HIM are divided into mine production disasters and ecological environment disasters, which have cluster, suddenness, and chain characteristics. Based on the types and characteristics of geological disasters caused by HIM, coal mining technology for preventing major geological hazards and environmental damage has been formed, providing a theoretical guidance and technical support for the development goals of HIM and environmental protection in China.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

At present, the competitive pattern of global industries is undergoing a major adjustment, and China is facing great challenges in a new round of development. With the gradual depletion of coal resources in central and eastern China, the strategic focus of coal mining has shifted to the northwestern region, where the coal resources are abundant, and the occurrence condition is simple. Moreover, it is appropriate for high-intensity mining (HIM). The Shendong mining area is the first coal production base of over a billion tons and will become the main energy supply base in China (Guo et al. 2018). Meanwhile, not only has the “Silk Road Economic Belt” brought new opportunities for coal enterprises going global, but also the proposed key construction of 14 billion tons of coal bases (as shown in Fig. 1) by the “13th Five-Year” plan (2016–2020) has further promoted the coal mines to intensive, large-scale, and modern development.

With the healthy development of China’s coal industries in the direction of “high yield, high efficiency, safety, and cleanliness”, HIM has become the main development direction for thick coal seams (Wang 2013). Through the innovation of theory, technology, and equipment, China has made great progress in the exploitation of thick coal seams: Meng et al. (2009) analyzed three methods of HIM in thick coal seams and determined the focus and development direction from the aspects of mining technology and safety production. Gao and He (2010) determined the large mining height (LMH) by comparing and analyzing the mining method of thick coal seams in the Shendong mining area. Meanwhile, field application verifies the effect of the supporting system in the 6.3-m fully mechanized face, and the recovery rate of the working face was above 96%. A few key technologies with independent intellectual property rights have been formed by studying the safe and efficient mining of an 8-m-thick coal seam, such as heavy equipment matching technology, surrounding rock control technology, mining technology, mining informatization, and environmental protection technology. A capacity of more than 15.5 Mt./a through field applications has been achieved (Yang 2017). In 2017, the production of 14 large coal bases accounted for 94.3% of the national volume, among which the coal production in the Shanxi, Shaanxi, and Inner Mongolia provinces accounted for 66.82%. Meanwhile, according to the China Coal Market Climate Index (as shown in Fig. 2), the index for December 2017 was 7.7, which is in the normal range, indicating that the coal industry in China has basically recovered, and high efficiency and green mining have become the current theme.

However, due to the northwest area being an arid and semi-arid climate, it has unique characteristics, such as strong evaporation, low vegetation coverage, poor ability to resist disturbance, and a fragile ecological environment. Therefore, HIM not only causes the coal mine disasters, such as roof cutting and water and sand inrush of the working face during the mining process, but also causes the loss of groundwater resources (in ecologically fragile areas), surface damage, grassland desertification, and ecological environment pollution (Shi and Li 2012; Zhang et al. 2016; Guo et al. 2017; Bai et al. 2018a; Yang et al. 2018). Meanwhile, coal waste rock deposited on the surface not only causes the deterioration of land resources and changes topography and landforms, but also pollutes the mining area and the atmosphere. The destruction of water resources has caused groundwater pollution and water level decline, which has caused serious damage to vegetation and the living environment of residents.

At present, due to the characteristics of the ecological environment described above in western China, many geological disasters and much environmental damage caused by HIM have occurred, which restricted the sustainable development of coal mines and has drawn the attention of researchers. For the definition of HIM, Fan (2014) indicated that the coal mining intensity had an obvious relationship with geological disaster development and defined HIM from the aspects of the proportion of the mining area, the panel size, and the mining rate. After that, Guo (2017) pointed out that HIM not only correlates well with geological and technical mining parameters, but also the destruction degrees caused by mining. Therefore, a new definition of HIM was proposed based on the green mining theory. Although the definition of HIM is redefined from the perspective of the ecological environment, the technical characteristics of HIM need to be clear, and it is necessary to study the negative externalities of HIM and disaster prevention technology to raise awareness of environmental protection.

Therefore, based on the definition of HIM, this paper systematically summarizes the mining methods and technical equipment of HIM in China, and its technical characteristics are obtained. Followed by the negative externalities analysis of HIM, the main types and characteristics of geological disasters are given. Then, prevention and control technology of geological disasters under HIM is proposed, which provides a theoretical and technical basis for safe, efficient, and green mining, focusing on mining damage and protection in HIM coal mines.

Current status of HIM

With the continuous development of coal mining technology, the improvement of machinery and equipment manufacturing, HIM [that is defined as full-height (top-coal caving or large mining height) of a thick coal seam (M ≥ 3.5 m), large panel sizes (L ≥ 200 m), fast face advance (V ≥ 5 m/d), large panel yield (minimum 3 million t/a, generally 5~10 million t/a), small ratio of mining depth to thickness (H/M < 100), high yield, and high-efficiency mining methods with serious overlying strata and surface damage; Guo and Wang 2017] has become an important development direction of thick coal seams in the western mining area. The following is described in terms of the technology, equipment, and characteristics of HIM.

Technology of HIM

Large mining height (LMH) and fully mechanized top-coal caving (FMTCC) are widely used in thick coal seams and have become the main mining technologies of thick coal seams in China. HIM means the above two mining methods are used with high production and high efficiency, large panel sizes, and fast face advance. On this basis, intelligent mining technology has also become an interesting research topic in the coal field.

LMH technology has developed rapidly since it was first introduced into China in 1978. Due to its high efficiency, less coal resources loss, safety, and reliability advantages, the LMH technology has become one of the most advanced technologies of modern coal mining in China. Generally, LMH means extracting a total seam of over 3.5 m (this is the demarcation line between thick seam and medium seam) at one time, which has been widely adopted in China, especially in western regions. At present, the maximum mining height has reached 8.8 m (in Shangwan coalmine), far ahead of other developed countries. Among them, using the LMH technique with mining heights of 7~8 m has been popular in most of China’s mining areas (Ju and Xu 2013; Wang et al. 2014), which has made outstanding contributions to the modernization of coal mining in China.

FMTCC technology is where a longwall face with proper mining height is arranged along the bottom of the thick coal seam and mined using the conventional method. The top coal above the hydraulic support is broken into a loose body by the action of mine pressure or assisted by an artificial loosening method, and is discharged from the back of the hydraulic support and transported by scraper conveyor. FMTCC has the advantage of a low rock roadway development ratio, good adaptability to undulate the coal seam, and high productivity, and it has quickly become a technical means for thick and extra-thick coal mining in China (Wang et al. 2016). Meanwhile, in Australia with approximately 17.5 billion tons of thick coal seams (thin: < 1.3 m, medium: 1.3 m ~ 3.5 m, thick: > 3.5 m), previous studies (Simsir and Ozfirat 2008; Vakili and Hebblewhite 2010) show that FMTCC not only improves the recovery rate of coal resources but also decreases the spontaneous combustion risk. Therefore, it has been a major method for mining thick or extra-thick coal seams around the world (Kumar et al. 2015; Li et al. 2017a). The production of the working face is constantly refreshed with the application of longwall top-coal caving (LTCC), and the unique pattern is formed by combining it with China’s actual coal mining. For example, a coal seam of 14–20 m was extracted successfully due to a combination of LMH and FMTCC in the Tashan coalmine in 2013 (Wang 2013).

Intelligent mining technology adds an autonomous decision-making function to the automation system under the premise of mining safety, so that it can recognize the changes of the surrounding rock and external environment in real time and adjust the mining parameters automatically. It is the core strategy and key technical support for “precision mining” and “scientific mining” (Wang and Huang 2017). The realization of automatic mining on the working face has a great correlation with geological conditions and mining technology. Because a 2~5-m coal seam has relatively stable geological conditions, simple mining processes, and small mining disturbance, it is less difficult to utilize automatic and intelligent technology. These parameters have been applied in 15 mining areas in China, and basically achieve normal mining of an “unmanned working face, manned roadway.” The 8.2-m fully mechanized mining technology and intelligent control system were first developed in China and have achieved more than 1.5 Mt. per month on a working face in the Jinjitan coalmine as of 2016 (Wang and Pang 2017). In intelligent LTCC, the intelligent control method for caving the coal and hydraulic support was used to obtain self-adaptive control, sequential control, and memory coal caving. However, due to the complexity of the caving process and conditions, there are still many problems that need to be solved to fully realize intelligent FMTCC technology (Wang and Huang 2017).

Equipment of HIM

Technology is the guarantee for HIM, while equipment is the foundation of HIM. Through the unremitting efforts of professional and technical personnel, China has made great achievements in the modernization of coal mining equipment, and independently developed several types of coal mining equipment that can meet geological conditions in different mining areas.

First, several types of coal machine equipment were developed, including an electric traction shearer, serial hydraulic support, scraper conveyor, emulsion pump, and chain conveyor. For example, the electric traction shearer is designed with the application of a mechatronics system; the hydraulic support can reach 8.8-m height (Gao 2017). The following are also utilized: a super-large-capacity SGZ1400/3 × 1600 scraper conveyor (transport capacity 6000 t/h, total power 4800 kW); BRW (630/40) high-pressure and large flow emulsion pump; and a belt conveyor (belt width 1.6 m, speed 4.0 m/s, 3200 m long, power 4 × 500 kW; Guo et al. 2018). By using domestic equipment, the Tashan coalmine was the first to use the system with a target of 10 Mt./a of an FMTCC face in 2013 (Wang 2013).

Second, for face end support, the previous support is mainly supported by a single hydraulic prop with a steel articulated roof beam, but the mechanization of the advance support cannot be realized. In view of this problem, a support system for the face end support and advance hydraulic support is developed, which overcomes the limitation of traditional support methods and realizes the automation of roadway advance support (Wang 2016). In addition, an advance support group is developed for the large section roadway with a mining height of 8.2 m. The application shows that its adaptability to surrounding rock is strong, propulsion efficiency is high, the top of the roadway is complete, and it has good adaptability (Wang and Pang 2017).

Finally, the successful development of the support truck and its technical system meet the needs of different mining areas. The development of the support truck is within the world’s leading level. For example, the maximum load of trailer-mounted trucks is far greater than that of other developed countries (W. KG 2017). With the continuous improvement of modern mining technology, an excavator with a greater dig ability or cut ability was developed for roadway tunneling, which met the mining requirements of various geological conditions.

Characteristics of HIM

According to the statistical analysis of 25 main coalmines in the northwest mining area, the production parameters of a working face under HIM are shown in Table 1 (Guo et al. 2018).

Based on the analysis of the present HIM development status and working face parameters, focusing on geological mining technology, it has been observed that the characteristics of HIM are mainly due to simple geological and mining conditions, large panel sizes, advanced equipment and mining technology, fast face advance speed, high production and efficiency, large mining thickness, and small H/M ratio (the ratio of mining depth to mining thickness). The parameters of the geological and mining factors are shown in Table 2.

According to the field monitoring analysis of HIM, characteristics 4 and 6 on Table 2 are closely related to the HIM characteristics in terms of mining and damage. Li et al. (2017b) pointed out that the advance speed is directly proportional to the strain energy density in the surrounding rock and the peak value of strain energy in the coal seam. With the increase of the advance rate, a large-range caving accident will be induced under HIM. Thus, it is a factor that induces roof collapse. Additionally, H/M is a parameter that measures the damage degree of surface buildings or structures, which is negatively correlated with the strength of the surface movement and deformation (Guo and Wang 2017). Therefore, these two characteristics are the connection points of the two aspects (geological and mining technology, mining, and damage) of HIM.

According to the concept of HIM based on green mining theory, due to the ecological environment, HIM characteristics mainly include serious overburden strata destruction, and severe surface movement and deformation (mainly refers to surface subsidence and other phenomena caused by it). In order to verify the rationality of the HIM characteristics that is considered to be the mining damage factors, the analytic hierarchy process (AHP) method is used to analyze the weight of the indices based on the principle of fuzzy mathematics. Based on the established multi-level structure model and 9-scale method (shown in Table 3), the judgment matrix is constructed and presented in Table 4. However, the consistency of the judgment matrix must be checked, and the consistency ratio CR can be calculated from the following formula:

where CR is the consistency ratio of the judgment matrix, CI is the consistency index, and RI is an average random consistency index with dimension n. Values are shown in Table 3.

From the above table, it can be seen that the judgment matrix A of HIM technical characteristics is shown in formula (2) as follows:

By calculating and normalizing the judgment matrix A, the eigenvector ω and the maximum eigenvalue λmax of the matrix are shown in the following formula:

The consistency test results from the above formula and Table 3 show that CI = 0.039 and CR = 0.028 < 0.1. Therefore, the obtained judgment matrix is consistent with the consistency condition; i.e., it is reasonable to assign each component of the eigenvector ω as the weight of each technical characteristic. The mining damage factors occupy the same important position as the geological and mining factors, and the weight coefficient reliably reflects the actual situation. Meanwhile, it verifies that the definition of HIM based on green mining is reasonable.

Through the analysis and classification of the above technical characteristics, the HIM characteristics can be divided into geological and mining factors, and mining damage factors. The geological and mining factors mainly include simple geological and mining conditions, large panel sizes, advanced equipment and mining technology, fast face advance speed, high production and efficiency, large mining thickness, and small H/M ratios. The mining damage factors mainly include serious destruction of overburden strata, and severe surface movement and deformation. The geological and mining factors show whether a mine is capable of high production and high efficiency, and the mining and damage factors indicate the mining impact on the ecological system. The geological and mining factors are the basis of the mining and damage factors. In general, both of them is symbiotic. From the point of view of logical order, the relationship of HIM characteristics is shown in Fig. 3, and the negative externalities are also included in its technical characteristics.

Negative externalities of HIM

An externality is the behavior influence of an economic subject to the welfare of another, and the subject that exerts this effect does not pay or compensate for it. Generally, externalities can be divided into positive externalities and negative externalities. Under HIM, positive externalities refer to the infrastructure, such as roads, railways, and wharves, and the driving effect on local employment. Similarly, negative externalities mainly mean damage to the ecological and geological environments. The negative externalities of HIM are consistent with its mining-induced damage characteristics. Therefore, its negative externalities mainly become apparent in the destruction of the overlying strata, surface, and ecological environment, and its evaluation indexes are mainly divided into building damage, surface movement and deformation, surface discontinuous deformation, overlying strata damage, hydrogeological impact, and ecological environment damage. The purpose of that is to judge whether the longwall mining face in the coal mine is HIM or not, or to judge and analyze the damage to buildings, overburden, and surface caused by HIM and the ecological environment in the mining area.

Movement and destruction of overlying strata

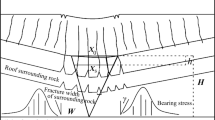

During mining, overburden failure is the direct manifestation of the mining driving force to the environment, and it is also the internal cause for the dynamic instability in the goaf. Due to the large panel sizes and fast advance rate of the HIM face, the overburden is severely damaged. It is mainly embodied in two aspects: First, the height of the “two-zone”(caved and fractured zones) caused by mining is high, causing evolution of the groundwater seepage field and groundwater level decline, which worsens the underground environment in arid and semi-arid areas. Second, the failure mode of overlying strata in partial samples is changed from a “three-zone” model to a “two-zone” model (as shown in Fig. 4), and it is easy to cause water inrush and air leakage passages, which threaten the safety of coal mine production. For example, because shallow water and quicksand entered the mine from the roof of the Buertai coal mine in the Shendong mining area, the 60 hydraulic supports of the working face were buried, and the direct economic loss was nearly 100 million yuan (Yang et al., 2016).

Compared with traditional mining (mining height: 2~3 m), the mining height increase will lead to the decrease of the step pressure-arch distance, the increase of the roof step subsidence, and the disaster of a large range of the roof falling along the coal wall (Wang and Wang 2015). For example, due to the small rated working resistance of the hydraulic support for the working face in the Wulanmulun mining area (9000 kN), the hydraulic support was seriously damaged when the first weighting occurred, the shield beam of hydraulic support was broken, and the balance cylinder was damaged.

Destruction of surface buildings

The stability of the lower strata determines the development of the upper strata. When the lower strata breaks, the upper will also be affected. Therefore, in the process of HIM, the upward transfer of overburden failure causes surface movement and deformation, including vertical movement and deformation (subsidence, slope, and curvature) and horizontal movement and deformation (horizontal movement, stretching, and compression; Guo et al. 2017; Zhou et al. 2018). It destroys cultivated land, water environments, transportation facilities, and ground buildings (structures) in the surface mining area. In general, for the surface buildings, the resistance to tensile deformation is relatively small, and cracks appear in weak areas of the building, such as near doors or windows. Under the influence of HIM, parts with strong tensile strength (such as walls) will be seriously damaged (as shown in Fig. 5), resulting in a series of social problems, which threaten lives, property, and the sustainable development of the mining area.

Destruction of ecological environment

In addition to the process of overlying strata breaking and surface subsidence, there is the process of land use change and the succession of the ecosystem with time. For the ecological environment, it is in a dynamic equilibrium state; however, the overburden and surface damage caused by HIM exceeds the self-regulation ability of the ecosystem, resulting in the destruction of its structure and function. It mainly brings about three issues: geological disasters, water resource loss, and surface soil and vegetation.

-

1)

Geological disasters: With the increase of the coal mining intensity in China, the geological disasters caused by HIM have gradually become an interesting issue. On the ground surface, HIM mainly occurs in the form of cracks, collapse pits, landslides, and debris flows. At present, the area of surface subsidence caused by coal mining has reached 2.06 × 104 km2 and has increase by 4.66 × 102 km2 per year. Based on the geological and mining factors of HIM, surface subsidence has characteristics of serious discontinuous ground surface destruction (Fig. 6a), as well as rapid subsidence (Fig. 6b), which present a remarkable disturbance to the surface environment.

-

2)

Water resources: The surface cracks or ground collapse caused by HIM always lead to the decrease of groundwater recharge. They do not only change the landform shape, which results in a directional change of the surface water flow and the original spatial pattern of water confluence, but also accelerate the conversion of surface water to groundwater and the infiltration rate of precipitation. For the surface phreatic water, surface cracks are a main factor affecting the submersible transport. Because of surface subsidence, the non-capillary voids increase, which promotes the vertical water evaporation, while cracks promote the lateral water evaporation (Bai et al. 2018a). In summary, the surface cracks and collapses induced by HIM have caused surface water seepage and groundwater level decline, which affects the growth environment of soil and vegetation on the surface.

-

3)

Surface soil and vegetation: The influence of HIM on geological disasters and water resource has destroyed soil structure, promoted soil leaching and erosion, reduced the biodiversity in the soil, reduced the ability of soil conservation and fertilizer, and reduced the soil quality year by year (Lei and Bian 2014). Meanwhile, surface cracks and collapse cause plant root fracture, resulting in the decrease of soil nutrients and water retention in the root area, thereby inhibiting the growth of plants and leading to vegetation degradation and land desertification (as shown in Fig. 7), which seriously constrains the sustainable development of the mining area economy and exacerbates the deterioration of the eco-environment.

In summary, the negative externalities of HIM show that the influence on overlying strata and surface is more serious, causing serious harm to the living environment of residents. By studying the negative externalities of HIM, people can focus on the ecological damage and environmental protection awareness caused by HIM, reducing the impact on agricultural economic development and the harm to quality of life and health. It also urges coal enterprises to adopt mining methods that can not only improve the recovery rate of resources but also do not destroy the natural ecological environment, and take the road of sustainable development of coal, on the premise of fully considering the requirements of environmental protection. This will greatly promote the construction of a resource-friendly and environmentally concerned society. However, in view of mining and damage characteristics (i.e., a mining area has caused damage), it is necessary to study the theory and technology of geological disaster prevention under HIM to achieve the goal of coordinated development of coal resources and environmental protection.

Types and characteristics of major disasters induced by HIM

As large-scale HIM destroys the internal balance of overburden, a series of serious geological disasters occurring during the mining process, such as the crack passage formed by roof failure leading to water inrush or air leakage; large scale roof cutting caused by the large working face and mining height; the ecological environment problems, such as vegetation death and grassland desertification induced by groundwater loss. According to the characteristics of typical geological disasters under HIM, disasters can be divided into mine production disasters and ecological environment disasters, as shown in Fig. 8.

Mine production disasters

Mine production disasters mainly include water and sand inrush, roof cutting and water-sand inrush, rock burst and coal and gas outburst. The various types of disasters are described as follows:

-

(1)

Water and sand inrush refers to a type of mine geological disaster where a water-sand mixture with high sand content breaks into the underground working face when mining under thick alluvium and thin bedrock. It is mainly related to overlying strata, overburden fissures, mining space, and aquifers. The overlying strata (thickness and material composition of the loose layer) is the host material for the occurrence of water and sand inrush. Overburden fissures (form, number, and penetration degree of mining fissures) are the direct cause of water and sand inrush, whereby mining space (the space under excavation and the gob below) is a key factor in the severity of water and sand inrush, and an aquifer (water pressure height, water abundance, and recharge) is the source.

-

(2)

Roof cutting and water-sand inrush refers to the chain reaction of water and sand inrush and roof cutting, which poses a serious threat to the safe and efficient production of the panel. In the HIM area of Northwest China, due to its unique geological structure and fragile ecological environment, the roof of the working face has difficulty in forming a voussoir beam structure during the HIM process. Subsequently, roof step subsidence occurs, resulting in serious damage to the hydraulic support and other strong dynamic disasters. At the same time, the “two-zone” model of overlying strata will cause water and sand inrush. Therefore, for the northwest mining area, the geological disasters under HIM are mainly caused by roof cutting and water-sand inrush.

-

(3)

Rock burst: Under the influence of rock mass properties and mining activity, the mine dynamic phenomenon or rock burst is created by the release of a certain of energy that has been accumulated. The rock burst can be found quite often in deep HIM. At present, the maximum mining depth of China’s coal mine is 1502 m at the Suncun coal mine. According to statistics, as of 2015, there were 187 rock burst mines, and 17 of the 26 coal-producing provinces had experienced rock burst (Yuan et al. 2018). The sudden and severe destruction poses a great threat to mine safety.

Under the influence of the high in situ stresses, intact rock elasticity, and rock mass conditions, the mine dynamic phenomenon or rock burst is created by the release of a certain of energy that has been accumulated. The rock burst can be found quite often in deep HIM

-

(4)

Coal and gas outbursts are typical dynamic disasters of coal mines with sudden, sharp, violent outbursts, and other characteristics, which not only have a large damage degree and wide influence, but also easily induce other major accidents. It mainly occurs in highly gaseous HIM coal mines. China’s highly gaseous coal mines account for about 70% of the total mines, and there are 1192 coal and gas outburst coal mines. Up to now, gas accidents have accounted for 27% of 20,000 outburst accidents in coalmines (Yuan et al. 2018). Frequent occurrence of dynamic disasters has brought serious challenges to China’s coal safety and green mining.

Ecological environment disaster

The ecological environment disaster is a “side effect” caused by HIM, which mainly includes surface cracks, the decrease of groundwater level, and the variation of land use structure.

-

1)

Surface cracks are a typical nonlinear mechanical disaster in a coal mine, which result due to the coupling between overlying strata movement and topsoil deformation after coal mining. For a shallow buried coal seam with HIM in Northwest China, the sand inrush or air leakage on the working face caused by a transfixion crack is harmful to safety production. According to the field measurement of Halagou coal mine (Bai et al, 2018), there have been three characteristics of surface cracks. First, the surface discontinuity is serious. The surface cracks are dense, wide, and often accompanied by a step crack and even collapse pit in some areas. The cracks generally develop to the outer edge of the gob with the shape of “C” or “O” type. Second, the surface subsidence rate is fast and can reach up to 700.5 mm/d, which is larger than that of longwall mining. In the short term after mining, the ground surface has obvious deformation and is of short duration. In the active stage, the surface subsidence value is large and has mutation characteristics. Third, surface movement and deformation are severe. The influence range is relatively small and the subsidence curve is steep (as shown in Fig. 9), which is caused by the smaller main influence radius.

-

2)

Groundwater level decline: The fissure evolution caused by coal mining is closely related to the occurrence state of groundwater resources. Under a shallow buried coal seam with HIM, a water-conducting fractured zone will develop at the bottom of the Quaternary aquifer and even to the ground surface, resulting in the decrease of surface water, attenuation or depletion of river water, and water-sand burst. In the northwest mining area, the damage and disturbance caused to the underground water seepage field by HIM have caused the groundwater level to decline greatly (more than 15 m), resulting in the death of surface vegetation and land desertification, as shown in Table 5, which has a serious impact on the surface life and ecological environment (Fan et al. 2016).

-

3)

Variation of land use structure: In the process of “two-integration” (promoting industrialization with information and promoting informatization with industrialization), the mining intensity is strengthened, and the degree of land use is increasing. In the HIM area, the variation of land use is mainly reflected in the increase of industrial and mining land, and the gangue land area occupied. Meanwhile, the cultivated land area is reduced due to surface collapse. However, the vegetation coverage has been increasing year by year due to the vigorous implementation of ecological management projects. Taking the Daliuta coalmine as an example (Fan et al. 2016), the change in the farmland area and occupied area was obtained through remote sensing, as shown in Fig. 10.

The variation of land use structure makes land desertification in the state of reversal-development. On one hand, various engineering activities in the mining area reduce vegetation coverage and aggravate the development of desertification; on the other hand, the recovery and control measures of the mine geological environment reduce the speed of desertification development and play an important role in its reversal.

Characteristics of disasters induced by HIM

According to the comprehensive investigation and analysis of geological disasters and the geological environment, the development characteristics of geological disasters can be summarized as follows.

-

(1)

The term cluster suggests that geological disasters usually occur simultaneously over a certain period and area. This is mainly determined by two important factors, namely the geological environment and HIM. Due to similar geological conditions (topography, geomorphology, and geotechnical types), the formation mechanism of the same type of geological disasters is basically the same, such as the surface cracks caused by HIM and accidents caused by water-sand inrush in the working face.

-

(2)

Suddenness means that geological disasters are short, and early warning signs are not obvious. This is related to the steady-state accumulation and unstable state release of energy in the coal and rock mass system during mining. The geological disaster is often strongly destructive, causing great harm with a wide range of influence, and makes it easy to induce other accidents, threatening safe production of the mining area, such as dynamic disasters occurring during coal mining (rock burst, coal and gas outburst, surface step cracks, etc.).

-

(3)

Chain: There is a certain correlation between different types of geological disasters under certain conditions, i.e., a disaster may induce another. For example, a roof-cutting disaster causes the overlying strata fissures to develop into loose aquifers or ground surface, causing water and sand burst and the decline of groundwater level. At the same time, it induces step cracks or crack groups on the ground surface, resulting in soil erosion, landslides, and other geological disasters. All kinds of geological disasters interact and act together, which further aggravates the degree of environmental damage.

Prevention technology of geological disasters under HIM

Due to HIM characteristics in China, large-scale HIM will inevitably cause serious geological disasters. Therefore, the prevention of geological disaster should be the first priority. That is, the proper coal mining method and scientific planning are adopted for scientific mining to prevent geological disasters in coal mines. Water and sand inrush and roof cutting and water-sand inrush disasters, rock burst and coal and gas outburst disasters can be prevented by overall optimization of the mining process. In order to carry out the overall optimization, a new concept and key technologies of precise risk identification and early warning monitoring of typical dynamic disasters in coal mines are proposed, and a research system is established. By applying the new concept, surface cracks and variation of land use structure can be improved by reclamation measures to increase vegetation coverage, and groundwater level decline can be prevented by water protection mining technology.

Optimization of mining technology

As the present requirements for mining continue to increase, the mining target has shifted from economic benefits to safety production and environmental protection. With the increase of targets, the corresponding constraints also increase. Thus, a multilevel optimization technique needs to be adopted, and a hierarchical model including the system layer, distribution layer 1, distribution layer 2, distribution layer 3 and so on is established. For HIM areas under different environmental conditions in the northwest, different protective mining schemes should be studied to optimize mining technology and reduce geological disasters and environmental damage. The multilevel optimization model of mining technology is shown in Fig. 11. According to reasonable optimization of the influencing factors, a safer and greener mine production mode can be achieved.

Prevention and monitoring of dynamic disasters

Rock burst and coal and gas outburst are the typical nonlinear dynamic disasters in underground coal mines, involving the occurrence mechanism of geological disasters, the deformation and failure characteristics of rock mass, the mining stress distribution, the temporal-spatial evolution of the energy field, and the multi-factor coupling process (Zhao and Wen 2018). In view of the present status of typical dynamic disasters in China’s coal mines, the conception of green mining combined with mining, separating, and backfilling in deep coal resources is proposed (Sun et al. 2017; Zhang et al. 2018). Namely, an integrated production system is directly constructed underground for coal mining, coal waste rock separation, and gangue filling, and the cooperative production mode of “mining-dressing-gas draining-backfilling-protecting” is formed for deep coal mining. The theoretical research and technical system of the concept are basically formed, as shown in Fig. 12 (Zhang et al. 2018), which has been carried out in typical mines such as the 12th Coal Mine of the Pingdingshan Group and Tangshan Coal Mine of the Kailuan Group, realizing safe, efficient, and green mining for deep coal and associated resources. To focus on effective development and control of coalbed methane, the new technology of an electrically pulsed perforated coal seam has been developed with controllable intensity, action area, and frequency of action (Zhang et al. 2017). The field application proves its effectiveness in gas drainage and control, ensuring safe mining practices.

Concept of green mining integrating mining, separating, and backfilling in deep coal resources (Zhang et al. 2017)

In terms of dynamic disaster monitoring, based on the concept of precise coal mining, the basic principles and methods of precise risk identification and monitoring early warning are expounded upon, and four key scientific problems are proposed. The scientific problems include a) evolution mechanism of a multiphase, multi-field coupling catastrophe; b) theory and technology of multi-parameter precursory information for intelligent recognition and early warning; c) new sensing and multi-network fusion transmission method and its technical equipment for precursor information; and d) early warning methods and technology of typical dynamic disasters based on big data and cloud technology. It pointed out the major research direction for precise risk identification and monitoring early warning (Yuan et al. 2018). Meanwhile, it also directs the technology route for online monitoring, intelligent identification, and real-time precision warning for coal bursts and coal and gas outbursts.

Ground collapse and crack management

For recurring geological disasters, corresponding measures should be taken to govern them. Generally, ground collapse and crack management adopt measures such as grouting and backfilling. Coal mines can use waste materials, while taking engineering measures to control it, making it necessary to perform drainage work in the subsidence area. If rain enters the collapse area, it may lead to the occurrence of secondary collapse. According to the damage degree of the ground subsidence and the economic conditions of the mine, it is possible to reinforce the house foundations or relocate the residents in the subsidence area, avoiding the casualties caused by collapse. For the cultivated land in the subsidence area, the backfilling of cracks is the main methodology used when subsidence is in the unstable stage. Once stabilized, large-scale mechanical management measures will be adopted for unified governance.

In addition, Chen and Hu (2018) classified ground cracks regarding the formation mechanism into three categories, 1) reviewed their research advances, 2) analyzed the impact factors and research methods of ground cracks, and 3) discussed the key issues for related research. In addition, they explored future challenges of formation mechanisms for ground crack, including: 1) The progress of rock failure and soil deformation, especially the stress and strain mechanism of the interface between bedrock and unconsolidated layers; 2) the formation mechanism of multi-cycle of dynamic ground crack; 3) construction of the mechanical model considering multiple factors; 4) comprehensive application of multi-technical means; and 5) the formation mechanism of ground cracks due to deep coal mining, HIM in the western ecological fragile region, and new coal mining technology, etc.

Water protection mining technology

The essence of groundwater level decline caused by HIM is the flowing of the water seeps out of the fracture zone and aquifer. To effectively protect and develop groundwater resources in the damaged area of Western China, the concept of water protection mining is proposed, which includes four levels: prevention of water inrush disaster in roofs, in-situ protection of the underground aquifer, regeneration of the mining-destroyed aquifer, and storage of the mining-lost groundwater and recycle utilization. Meanwhile, the technical system with the protection of the ecological water level is established as the core. Based on different geological and mining conditions, the following water-protection mining methods have been formed.

-

(1)

Backfilling mining replaces coal with backfilling material. Currently, solid backfilling mining is more often applied (Zhang et al. 2014). Due to the northwestern mining area covering a large amount of aeolian sand and its good anti-deformation ability, a rapid backfilling mining method is proposed based on aeolian sand. This method can effectively solve the problem of overburden failure and surface subsidence, alleviate water inrush, improve the mining area environment in the west, and avoid secondary pollution of groundwater resources (Liu et al. 2017). At the same time, it has the characteristics of high production efficiency, low input equipment and low backfilling cost, providing a new technical way for green mining in the desert area of Western China. For example, Yuyang coalmine (Bai et al. 2018b) adopted mechanized backfilling mining with paste-like aeolian sand for water-protection mining practices. The damage degree of the overlying strata is slight, and the aquifer has been effectively protected in ecologically fragile areas. In addition, combined with the advantages of strip pillar mining, coal reserve is divided into regular strips that are mined in every other strip. The strips left behind, called strip pillars, are designed to support the overburden, prevent surface subsidence, and protect the surface structures, ecological environment, and backfilling mining. A coordinated mining method of partial filling with “strip mining, roadway backfilling” is proposed, as shown in Fig. 13 (Bai et al. 2018c).

Schematic diagram of harmonic mining with strip mining and roadway backfilling (Bai et al. 2018c)

-

(2)

Strip-backfilling mining is an effective way to control the loss of groundwater in a relatively thin section of bedrock, which is less than 18 times of the mining height. By adding several strip-backfilling bodies in the middle of the working face to support the overlying strata, the height of the “upward cracks” (water-flowing fracture of overlying strata developed from bottom to top) can be controlled. Meanwhile, due to the decrease of overburden subsidence, the depth of the “downward cracks” (downward tensile fracture due to strata subsidence on the surface of the water-resisting layer) at the edge of the surface subsidence basin will decrease correspondingly. Thus, this guarantees the safety of the overburden aquifer, as shown in Fig. 14 (Huang 2017).

Upward crack zone and downward crack zone of overburden strata induced by mining (Huang 2017)

-

(3)

Limited coal height mining: By limiting the mining height, the sliding or rotating space after roof breaking and the height of the water seeps out of the fracture zone can be reduced. Due to the great waste of coal resources, it is generally less used. For example, Daliuta coalmine has about 1 billion tons of recoverable coal reserves, and the average abandoned coal rate will reach 46.7% if adopting this mining method, which means that 0.46 billion tons of coal resources cannot be mined, causing huge coal resource losses.

-

(4)

Longwall mechanized rapid advance mining: For different advance speeds of the working face, the stope roof shows different intensity, and the faster the working face advances, the stronger the ability of the roof is to resist breaking. Therefore, the advance rate of the working face directly affects the periodic weighting distance of the basic roof. That is, an appropriate increase in the rate of the working face can effectively extend the period weighting distance of the working face and reduce roof subsidence, which is conducive to roadway stability and the safe production of the working face.

In addition, in view of the unique ecological environment in the northwestern mining area, the concept of storing mine water in the gob is first proposed (Gu 2015). It overcomes the technical problems of water source prediction, reservoir location, reservoir capacity calculation, dam construction, safety control, and water quality assurance and establishes the technical system of the underground reservoir of the coal mine, as shown in Fig. 15 (Gu et al. 2016). In the full implementation of the Shendong mining area, 35 underground reservoirs were built with a water storage capacity of 25 million m3, which supplies more than 95% of the water for the mining area and the surrounding industries. It has opened an effective technical approach and reference for protection and utilization of water resources in HIM areas.

Structural diagram of an underground reservoir in a coal mine (Gu et al. 2016)

Discussion

Based on the definition of HIM, the technical characteristics of high-strength mining were obtained, and the negative externalities of HIM and its evaluation index were proposed. Although the negative externality is a part of the technical characteristics of HIM, it is necessary to discuss the negative impact of HIM from the perspective of ecological environmental protection. Based on the types and characteristics of disasters in the damaged mining areas in Northwest China, prevention and control techniques of geological disasters were given.

According to Eq. (1), AHP is used to verify the rationality of HIM characteristics, and similar results can be obtained by other fuzzy comprehensive evaluation methods. For the mining damage factors, only two are included to achieve the “human” shape in Fig. 3, and six evaluation indices are supplemented in the negative externalities.

The mining damage factors are consistent with the negative externalities. The evaluation indices are divided into six, which are used to judge whether the longwall mining face is HIM, or evaluates, analyzes, and warns of the building (structure), overburden and surface, and ecological environment damage of the mining area caused by the HIM face after mining. However, due to the fact that the failure index of the mining impact has not been quantified, the government and enterprise applications need to be summarized by more engineering measurement, which is also the next step requiring study.

Because Northwest China is a typical mining area with HIM and the mountain landslide and debris flow disasters caused by mining in the southwest mountain areas are not HIM areas, only the HIM areas in Northwest China are taken as an example to classify the disaster types. Similarly, disaster prevention and control technology not only consider the damage to the ecological environment, but also include the safety of underground mining. Therefore, it is necessary to study the negative externalities of HIM as people focus on the ecological damage caused by HIM and improve their awareness of environmental protection.

Conclusions

-

(1)

Based on the analysis of the present status and definition of HIM for thick coal seams in China, analysis of its characteristics using AHP is done. The geological and mining characteristics demonstrate whether a mine is capable of high production and high efficiency, while the mining and damage characteristics indicate the mining impact on the ecological system. Meanwhile, the relationship between these two aspects is determined, and the negative externalities of HIM are consistent with its mining and damage factors, which mainly manifest in the destruction of overlying strata, ground surface, and the ecological environment.

-

(2)

From the eco-environment characteristics in China’s HIM area, the geological disasters caused by HIM can be divided into two aspects: mine production disaster and ecological environment disaster. Mine production disasters mainly include water and sand inrush, roof cutting and water-sand inrush, rock burst, and coal and gas outburst; ecological environment disasters mainly include surface cracks, decrease of groundwater level, and variation of farmland or grassland use structure.

-

(3)

According to the study of typical geological disasters caused by large-scale HIM, coal mining technologies have been developed to prevent major geological disasters, such as optimization of coal mining technology to avoid roof cutting and water-sand inrush disasters; green mining techniques combined with mining, separating, and backfilling in deep coal resources, and precise risk identification and monitoring early warning on typical dynamic disasters in coal mines; water protection mining technology for prevention and control of aquifer and ground surface and underground water storage technology for underground water resources protection. These technologies provide scientific and technological support for prevention and control of geological disasters caused by HIM, which are of great significance for coal mine safety, high efficiency, green production, mining damage, and protection for the eco-environment, etc.

References

Bai EH, Guo WB, Tan Y, Yang DM (2018a) Special features and mechanism of the surface response to the high-intensity mining in the thick seam mining activities. J Saf Environ 18(2):503–508

Bai EH, Guo WB, Tan Y, Yang DM (2018b) The analysis and application of granular backfill material to reduce surface subsidence in China’s northwest coal mining area. PLoS One 13(7):e0201112

Bai EH, Guo WB, Tan Y, Yang DM (2018c) Green coordinated mining technology of strip mining roadway backfilling method. J China Coal Soc 43(S1):21–27

Chen C, Hu ZQ (2018) Research advances in formation mechanism of ground crack due to coal mining subsidence in China. J China Coal Soc 43(3):810–823

Fan LM (2014) On coal mining intensity and geo-hazard in Yulin-Shenmu-Fugu mining area. China Coal 40(5):52–55

Fan LM, Xiang MX, Peng J, Li C, Li YH, Wu BY, Bian HY, Gao S, Qiao XY (2016) Groundwater response to intensive mining in ecologically fragile area. J China Coal Soc 41(11):2672–2678

Gao J, He HT (2010) Application of fully mechanized full seam one passing mining technology to thick seam in Shendong mining area. J China Coal Soc 35(11):1888–1892

Gao YJ (2017) Study on design and manufacturing key technology of 8.8 m hydraulic powered support. Coal. Sci Technol 45(11):15–20

Gu DZ (2015) Theory framework and technological system of coal mine underground reservoir. J China Coal Soc 40(2):239–246

Gu DZ, Yan YG, Zhang Y, Wang EZ, Cao ZG (2016) Experimental study and numerical simulation for dynamic response of coal pillars in coal mine underground reservoir. J China Coal Soc 41(7):1589–1597

Guo WB, Bai EH, Tan Y, Yang DM (2017) Surface movement characteristics caused by fully-mechanized top coal caving mining under thick collapsible loess. Electron J Geotech Eng 22(3):1107–1116

Guo WB, Bai EH, Yang DM (2018) Study on the technical characteristics and index of thick coal seam high-intensity mining in coalmine. J China Coal Soc 43(8):2117–2125

Guo WB, Wang YG (2017) The definition of high-intensity mining based on green coal mining and its index system. J Mining Saf Eng 34(4):616–623

Huang QX (2017) Research on roof control of water conservation mining in shallow seam. J China Coal Soc 42(1):50–55

Ju JF, Xu JL (2013) Structural characteristics of key strata and strata behaviour of a fully mechanized longwall face with 7.0 m height chocks. Int J Rock Mech Min Sci 58:46–54

Kumar R, Singh AK, Mishra AK, Singh R (2015) Underground mining of thick coal seams. Int J Min Sci Technol 25:885–896

Lei SG, Bian ZF (2014) Research progress on the environment impacts from underground coal mining in arid western area of China. Acta Ecol Sin 34(11):2837–2843

Li M, Zhang JX, Huang YL, Gao R (2017a) Measurement and numerical analysis of influence of key stratum breakage on mine pressure in top-coal caving face with super great mining height. J Cent South Univ 24(8):1881–1888

Li Y, Yang TH, Liu HL, Hou XG, Wang H (2017b) Effect of mining rate on the working face with high-intensity mining based on micro seismic monitoring: a case study. J Geophys Eng 14(2):350–358

Liu PL, Zhang HX, Cui F, Sun KH, Sun WM (2017) Technology and practice of mechanized backfill mining for water protection with aeolian sand paste-like. J China Coal Soc 42(1):118–126

Meng XR, Wang HP, Liu CH, Zhang Y (2009) Selection principle and development status of thick seam mining methods in China. Coal Sci Technol 37(1):39–44

Shi XX, Li L (2012) A study on prevention measures against water and sand inrush and their application in Shendong mining area. Dis Adv 5(4):1129–1135

Simsir F, Ozfirat MK (2008) Determination of the most effective long wall equipment combination in long wall top coal caving (LTCC) method by simulation modelling. Int J Rock Mech Mining Sci 45:1015–1023

Sun Q, Zhang JX, Zhang Q, Zhao X (2017) Analysis and prevention of geo-environmental hazards with high-intensive coal mining: a case study in China’s western eco-environment frangible area. Energies 10(6):786

Vakili A, Hebblewhite BK (2010) A new capability assessment criterion for longwall top-coal caving. Int J Rock Mech Mining Sci 47:1317–1329

Wang GF (2016) Longwall mining technology & equipment system integration. China Coal Industry Publishing House, Beijing

Wang GF, Pang YH (2017) Development and application of complete equipment for fully mechanized mining with 8.2m super-large mining height. Coal Eng 49(11):1–5

Wang JC, Wang ZH (2015) Stability of main roof structure during the first weighting in shallow high-intensity mining face with thin bedrock. J Mining Saf Eng 32(2):175–181

Wang JC, Yang SL, Li Y, Wei LK, Liu HH (2014) Caving mechanisms of loose top-coal in longwall top-coal caving mining method. Int J Rock Mech Mining Sci 71:160–170

Wang JC, Zhang JW, Li ZL (2016) A new research system for caving mechanism analysis and its application to sublevel top-coal caving mining. Int J Rock Mech Mining Sci 88:273–285

Wang JH (2013) Key technology for fully-mechanized top coal caving with large mining height in extra-thick coal seam. J China Coal Soc 38(12):2089–2098

Wang JH, Huang ZH (2017) The recent technological development of intelligent mining in China. Engineering 3:439–444

W. KG (2017) Aerospace science and technology group successfully developed the world’s largest explosion-proof carrier truck. Dual Use Technol Prod 23:22

Yang JZ (2017) Research on key mining technology of fully-mechanized working face with 8 m large mining height. Coal Sci Technol 45(11):9–14

Yang Z, Li WP, Pei YB, Wu YL (2018) Classification of the type of eco-geological environment of a coal mine district: a case study of an ecologically fragile region in Western China. J Clean Prod 174(10):1513–1526

Yuan L, Jiang YD, He XQ, Dou LM, Zhao YX, Zhao XS, Wang K, Yu Q, Lu XM, Li HC (2018) Research progress of precise risk accurate identification and monitoring early warning on typical dynamic disasters in coal mine. J China Coal Soc 43(2):306–318

Zhang JX, Jiang HQ, Deng XJ, Ju F (2014) Prediction of the height of water-conducting zone above the mined panel in solid backfill mining. Mine Water Environ 33(4):317–326

Zhang JX, Li BY, Zhou N (2016) Application of solid backfilling to reduce hard-roof caving and longwall coal face burst potential. Int J Rock Mech Min Sci 88:197–205

Zhang JX, Zhang Q, Ju F, Zhou N, Li M, Sun Q (2018) Theory and technique of greening mining integrating mining, separating and backfilling in deep coal resources. J China Coal Soc 43(2):377–389

Zhang YM, Qiu AC, Qin Y (2017) Principle and engineering practices on coal reservoir permeability improved with electric pulse controllable shock waves. Coal Sci Technol 45(9):79–85

Zhao ZL, Wen ZJ (2018) Design and application of a mining-induced stress testing system. Geotech Geol Eng 36(3):1587–1596

Zhou DW, Wu K, Miao XX (2018) Combined prediction model for mining subsidence in coal mining areas covered with thick alluvial soil layer. Bull Eng Geol Environ 77(1):283–304

Acknowledgements

The authors gratefully acknowledge the financial support for this work provided by the National Natural Science Foundation of China (grant no. 51374092, 51774111), the Key Project of the National Natural Science Foundation of China (grant no. U1261206), and the Innovation and Outstanding Talent Project of Henan Province Science and Technology (grant no. 184200510003). The authors are also grateful to the reviewers for their helpful comments and constructive suggestions in improving this paper.

Author information

Authors and Affiliations

Contributions

Erhu Bai and Wenbing Guo conceived and designed the layout; Erhu Bai analyzed the data; Yi Tan established the observation station and monitored the subsidence; Erhu Bai and Wenbing Guo wrote the paper. Erhu Bai and Mingjie Guo revised the paper.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Bai, E., Guo, W. & Tan, Y. Negative externalities of high-intensity mining and disaster prevention technology in China. Bull Eng Geol Environ 78, 5219–5235 (2019). https://doi.org/10.1007/s10064-019-01468-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-019-01468-4