Abstract

Uniaxial compressive strength (UCS), Brazilian tensile strength (BTS), and brittleness are widely used in rock engineering applications. However, preparing the test samples for the standard tests may not always be possible for weak or soft rocks. On the other hand, only rock fragments may be available to estimate the rock strength in some cases such as drilling. Therefore, developing some models for estimating the rock strength and brittleness from rock fragments will be useful. In this study, a crushability index (CI) was described from the crushing test, and the possibility of predicting UCS, BTS, and brittleness from this index was investigated. Strong and significant linear correlations were found between the CI and UCS, BTS, and one of the brittleness concepts. It was concluded that the UCS, BTS, and some brittleness concepts of rock could be estimated from the CI. The suggested method is especially useful for the drilling industry and for the cases where there are not enough samples for the standard tests. However, the study is a preliminary study on limited rock types and further study is required by including the number of different rock types.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The uniaxial compressive strength (UCS) and the Brazilian tensile strength (BTS) of rocks are commonly used in civil and mining engineering projects performed in rock environment. However, the direct determination of rock strength is time consuming and expensive and requires well-prepared and high quality core samples. For this reason, point load index, block punch index, Schmidt hammer, and ultrasonic velocity tests have been frequently used to predict rock strength for preliminary studies (Broch and Franklin 1972; Gunsallus and Kulhawy 1984; Gaviglio 1989; Sachapazis 1990; Katz et al. 2000; Kahraman 2001; Ulusay et al. 2001; Yasar and Erdogan 2004; Fener et al. 2005; Basu and Kamran 2010; Kohno and Maeda 2011 etc.). However, even preparing specimens for indirect testing may not always be possible for weak or soft rocks. On the other hand, there may be only rock fragments to estimate the rock strength in some cases such as drilling. For these reasons, estimating the rock strength from rock fragments will be useful.

Brittleness is also an important rock property. It has been used for the assessment of the cutability of coal, the drillability and borability of rocks, the sawability of rocks, and the estimation of fracture toughness (Evans and Pomeroy 1966; Singh 1986, 1987; Kahraman 2002; Kahraman and Altindag 2004; Gunaydin et al. 2004). On the other hand, the brittleness of rock has an important role for the development of tight oil gas reservoirs where it provides an indication of the potential for hydraulic fracturing.

There is no agreement between the different authors as to definition, concept, or measurement of brittleness (Morley 1944; Hetényi 1966; Obert and Duvall 1967; Ramsay 1967). Suggested brittleness methods depends on laboratory mechanical testing (Hucka and Das 1974; Altindag 2002), mineral contents (Jarvie et al. 2007; Wang and Gale 2009), and elastic parameters (Goodway et al. 2007; Rickman et al. 2008; Guo et al. 2012). The two brittleness definition evaluated in this study are given following (Hucka and Das 1974; Altindag 2002):

where B 1 and B 2 are brittleness, σ c is the uniaxial compressive strength (MPa), and σ t is the tensile strength (MPa).

Kahraman and Toraman (2008) investigated the possibility of predicting the Los Angeles abrasion loss from a crushability index (CI). They found a strong exponential correlation between the Los Angeles abrasion loss and the CI values. Toraman et al. (2010) also studied the predictability of the CI from impact strength index and established a strong inverse linear relation between the crushability index and the impact strength index. They concluded that the crushability of rocks could practically be estimated from the impact strength index using the simple regression model.

In this study, a CI, slightly different from the CI previously defined in the literature, was described and the predictability of UCS, BTS, and brittleness from this CI was studied. The sample preparation and testing method are easy in the crushability test. A small amount (500 g) of crushed rock is enough for testing. This is an advantage when there are limited rock samples. That the crushability test can be applied on the drill cuttings is another important advantage.

Because the aim of this study is to reveal the predictability of strength and brittleness of rocks from the CI, limited rock types were tested. The study will be expanded by including the number of different rock types in future.

Crushability index

Crushed samples are prepared from the rock to be tested and sieved to obtain 500 g test samples in the selected charging size range of 19.00–9.52 mm. After these samples are oven dried at a temperature of 110 °C for 48 h, they are charged to a laboratory jaw crusher with an outlet gap of 8–12 mm. Crushed materials are passed through the 9.52 mm mesh and the percentage of oversized material is described as the crushability index (CI). This description is a bit different from the previous definitions. Kahraman and Toraman (2008) and Toraman et al. (2010) performed the same testing method, but they described the CI as the percentage of undersized material. If the percentage of undersized material was used as CI in this study, inverse correlations would obtained between the CI and both the UCS and BTS.

Sampling

A total of 24 different rock types were sampled, eight of which were igneous, eight of which were metamorphic, and eight of which were sedimentary. Quarries, marble factories, and natural outcrops in Nigde, Kayseri, Konya, and Afyon areas of Turkey were visited and rock blocks were collected for the laboratory testing. The locations and the names of the rocks are given in Table 1.

Experimental studies

A jaw crusher was used in the crushability tests (Fig. 1). The vertical and horizontal cross sections of the jaw plates of the crusher are shown in Fig. 2. The open side discharge setting (OSS) and the closed side discharge setting (CSS) of the jaw plates are 12 and 8 mm, respectively (Fig. 2a, b). Therefore, the eccentricity is 4 mm. The crusher has corrugated jaw plates as shown in Fig. 2c. The plates were a bit worn, but the all tests were carried out at the same wear condition. The speed of the jaw crusher is 200 rpm.

The samples were fed inside the jaw crusher chamber in twos and threes by hand. Because the test specimens were prepared by using the same crusher at a large outlet gap, some of them (about 15%) were elongated.

The energy applied during the crushing tests was not measured. Measuring the energy applied in crushability test will be useful for the evaluation of the test results in future studies.

First block samples of rocks were cored to get specimens for the USC and BTS tests. Then, the remaining rock blocks were used for the crushing tests. Crushed rock samples in the size range of 19.00–9.52 mm were prepared for each rock type to be tested (Fig. 3) and then crushability tests were carried out. The tests were repeated three times for each rock type and the average value was recorded as the CI (Table 1).

The USC and BTS tests were also performed on the each rock type according to ISRM (2007) suggested methods. At least five core samples were tested for each rock type in the strength tests and the results were averaged. The average values of strength test are given in Table 1. The calculated B 1 and B 2 brittleness values are also given in Table 1.

Evaluation of the results

The correlations between crushability index and strength values

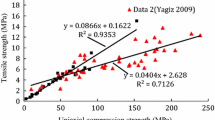

The data given in Table 1 were analysed using the method of least squares regression. The CI values were correlated to the corresponding the UCS and BTS values. Linear, logarithmic, exponential and power curve fitting approximations were tried and the best approximation equation with highest correlation coefficient was determined. The CI values strongly correlated to both the UCS and BTS values (Figs. 4, 5). Both the UCS and BTS values linearly increase with increasing the CI values. The equations of the lines are

where, σ c is the uniaxial compressive strength (MPa), σ t is the tensile strength (MPa), and CI is the crushability index (%).

It was stated in the literature (Farmer 1983; Budavari 1983; Jumikis 1983) that most of rocks have a compressive strength that is approximately 10 times greater than the tensile strength. In other words, the ratio between UCS and BTS is approximately 10. It is interesting to note that the ratio of the coefficients of Eqs. (3) and (4) is 11.4, which fairly close to 10. This result may be an indicator of the validity of the derived correlations.

To see how the correlations vary with the rock class, regression analysis was performed for igneous rocks, metamorphic rocks, and sedimentary rocks, respectively. As shown in Figs. 6 and 7, the correlations between the CI and both the UCS and BTS are moderate for igneous rocks. It is clear that these correlations are controlled by a single data point at approximately a CI of 40%. These correlations should be checked by including more data points in future investigations. On the other hand, the CI is strongly correlated to both the UCS and BTS for sedimentary rocks (Figs. 8, 9). On the other hand, the correlations between the CI and both the UCS and BTS are very strong for metamorphic rocks (Figs. 10, 11) and relatively higher than that of Eqs. (3) and (4). The porosity value of migmatite 1.33% and the other metamorphic rocks tested have porosity value lower than 1%. That the correlations between the CI and both the UCS and BTS are very strong for metamorphic rocks may be because their porosity values are very close to each other. For Figs. 10, 11, there are no data between a CI of approximately 20–50%. Including more data points to these correlations will probably increase their significance in future studies.

The correlations between crushability index and brittleness values

The brittleness B 1 and B 2 values were correlated to the CI values. There is no correlation between the brittleness B 1 and the CI values (Fig. 12). However, the brittleness B 2 was strongly correlated to the CI values (Fig. 13).

Validation of the derived equations

The correlation coefficients of Eqs. (3) and (4) are good, but they do not necessarily identify a valid model. Validation of the models should be further analyzed by using statistical tests such as t test and F test. The significance of r values can be determined by the t test, assuming that both variables are normally distributed and the observations are chosen randomly. The distribution of the data was checked by histogram analysis and it was seen that the data didn’t show normal distribution. For this reason, t test was not performed.

The significance of regressions was determined by the analysis of variance. In this test, a 95% level of confidence was chosen. If the computed F value is greater than tabulated F value, the null hypothesis is rejected that there is a real relation between the dependent and independent variables. The computed F values are greater than the tabulated F value as shown in Table 2. Therefore, it is concluded that the derived equations are valid according to the F test.

Areas for further work

CSS, OSS, and eccentricity control the CI in a crushing test by using a jaw crusher. Other factors affecting the CI are the speed of the jaw crusher, the type, and wear condition of the jaw plates and the level of feed inside the jaw crusher chamber. The natural shape of particles used as the feed also influences the CI. It is known that if the rock fragments to be crushed are slabby or elongated in shape, larger size fragments can pass through. After carrying out extensive tests, a standard method may be suggested by taking into account the factors influencing the CI in the future. In addition, a large number of different rock types should be further tested in order to develop more reliable correlations between the CI and rock properties.

Some other form of test using rock fragments may be used as an alternative to CI test for the estimation of rock properties. For example, 10% fines test used in the aggregates industry can be a choice. This test is carried out under more controlled conditions than that used in a jaw crusher. Bearman (1991) found a good correlation between the 10% fines and the crusher performance. The correlations between the 10% fines and rock properties should be further investigated.

Conclusions

Twenty-four different rock types including sedimentary, igneous, and metamorphic rocks were tested to investigate the predictability of UCS, BTS, and brittleness from the CI. Strong linear correlations were found between the CI and both the UCS and BTS. Increasing the CI increases linearly the UCS and BTS values. The significance of the derived correlations was shown by the statistical test. Strong linear correlations were also found between the CI and a brittleness concept. Concluding remark is that the UCS, BTS, and some brittleness concepts of rock can be estimated from the CI. The suggested method is especially useful for the drilling industry and for the cases where there are not enough samples for the standard tests.

This study is a preliminary study and the data are a bit scattered. Further study is required to investigate deeply the topic by increasing the number of rock and rock types.

References

Altindag R (2002) The evaluation of rock brittleness concept on rotary blast hole drills. J S Afr Inst Min Metall 102:61–66

Basu A, Kamran M (2010) Point load test on schistose rocks and its applicability in predicting uniaxial compressive strength. Int J Rock Mech Min Sci 47:823–828

Bearman RA (1991) The application of rock mechanics parameters to the prediction of crusher performance, Ph.D. Thesis, Camborne School of Mines

Broch E, Franklin JA (1972) Point-load strength test. Int J Rock Mech Min Sci 9:669–697

Budavari S (1983) Rock mechanics in mining practice. The South African Institute of Mining and Metallurgy, Johannesburg

Evans I, Pomeroy CD (1966) The strength fracture and workability of coal, Pergamon Press

Farmer IW (1983) Engineering behavior of rocks. Chapman and Hall, London

Fener M, Kahraman S, Bilgil A, Gunaydin O (2005) A comparative evaluation of indirect methods to estimate the compressive strength of rocks. Rock Mech Rock Eng 38(4):329–343

Gaviglio P (1989) Longitudinal wave propagation in a limestone: the relationship between velocity and density. Rock Mech Rock Eng 22:299–306

Goodway B, Varsek J, Abaco C (2007) Isotropic AVO methods to detect fracture prone zones in tight gas resource plays. CSPG CSEG Conv 2007:585–589

Gunaydin O, Kahraman S, Fener M (2004) Sawability prediction of carbonate rocks from brittleness indexes. J S Afr Inst Min Metall 104:239–243

Gunsallus KL, Kulhawy FH (1984) A comparative evaluation of rock strength measures. Int J Rock Mech Min Sci 21:233–248

Guo ZQ, Li XY, Chapman M (2012) Correlation of brittleness index with fractures and microstructure in the Barnett Shale. 74th EAGE Conf. and Exhibition Extended Abstracts F022

Hetényi M (1966) Handbook of experimental stress analysis. Wiley, New York

Hucka V, Das B (1974) Brittleness determination of rocks by different methods. Int J Rock Mech Min Sci Geomech Abstr 11:389–392

ISRM (2007) The complete ISRM suggested methods for rock characterization, testing and monitoring: 1974–2006. Ulusay R, Hudson JA (Eds). Commission on Testing Methods ISRM. International Society for Rock Mechanics (ISRM), Turkish National Group, Ankara, Turkey. ISBN: 9789759367541. p 628

Jarvie DM, Hill RJ, Ruble TE, Pollastro RM (2007) Unconventional shale-gas systems: the Mississippian Barnett Shale of north-central Texas as one model for thermogenic shale–gas assessment. AAPG Bull 91(4):475–499

Jumikis AR (1983) Rock mechanics.second edition. Trans Tech Publications

Kahraman S (2001) Evaluation of simple methods for assessing the uniaxial compressive strength of rock. Int J Rock Mech Min Sci 38:981–994

Kahraman S (2002) Correlation of TBM and drilling machine performances with rock brittleness. Eng Geol 65:269–283

Kahraman S, Altindag R (2004) A brittleness index to estimate fracture toughness. Int J Rock Mech Min Sci 40:343–348

Kahraman S, Toraman OY (2008) Predicting the Los Angeles abrasion loss of rock aggregates from crushability index. Bull Mater Sci 31:173–177

Katz O, Reches Z, Roegiers JC (2000) Evaluation of mechanical rock properties using a Schmidt hammer. Int J Rock Mech Min Sci 37:723–728

Kohno M, Maeda H (2011) Estimate of uniaxial compressive strength of hydrothermally altered rocks from northeastern Hokkaido, Japan, based on axial point load strength test results. Int J Jpn Comm Rock Mech (JCRM) 7:17–23

Morley A (1944) Strength of materials, Longman

Obert L, Duvall WI (1967) Rock mechanics and the design of structures in rock. Wiley, New York

Ramsay JG (1967) Folding and fracturing of rocks. McGraw-Hill, London

Rickman R, Mullen MJ, Petre JE, Grieser WV, Kundert D (2008) A practical use of shale petrophysics for stimulation design optimization: All shale plays are not clones of the Barnett Shale: SPE Annual Technical Conference and Exhibition, SPE-115258-MS

Sachapazis CI (1990) Correlating Schmidt hardness with compressive strength and Young’s modulus of carbonate rocks. Bull Int Assoc Eng Geol 42:75–83

Singh SP (1986) Brittleness and the mechanical winning of coal. Min Sci Technol 3:173–180

Singh SP (1987) Criterion for the assessment of the cuttability of coal. In: Szwilski AB, Richards MJ (eds) Underground mining methods and technology. Elsevier, Amsterdam, pp 225–239

Toraman OY, Kahraman S, Cayirli S (2010) Predicting the crushability of rocks from the impact strength index. Miner Eng 23:752–754

Ulusay R, Gokceoglu C, Sulukcu S (2001) Draft ISRM suggested method for determining block punch strength index (BPI). Int J Rock Mech Min Sci 38:1113–1119

Wang FP, Gale JFW (2009) Screening criteria for shale-gas systems. Gulf Coast Assoc Geol Soc Trans 59:779–793

Yasar E, Erdogan Y (2004) Correlating sound velocity with density, compressive strength and Young’s modulus of carbonate rocks. Int J Rock Mech Min Sci 41:871–875

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kahraman, S., Toraman, O.Y. & Cayirli, S. Predicting the strength and brittleness of rocks from a crushability index. Bull Eng Geol Environ 77, 1639–1645 (2018). https://doi.org/10.1007/s10064-017-1012-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-017-1012-9