Abstract

Seepage in the foundation and abutments of a dam can lead to wasting of the stored water in the reservoir, erosion of the foundation materials and increasing the uplift pressure. It can endanger the long term stability of the dam. Cement grouting is one of the seepage control methods which is generally implemented according to the Lugeon test results. In this study, the grout volume has been examined against Q-value, Lugeon number, SPI (Secondary permeability index) value and joint apertures in the Bakhtiari dam site. In Bakhtiari dam site, the left and the right abutment trial grouting boreholes were drilled up to the final depth of 60 and 100 m, respectively. Limestone of the Sarvak Formation is the dominant rock type in the site. The Q-system parameters have been evaluated by eye-examination of rock cores, the Lugeon numbers and SPI values have been deduced from the water pressure tests and the joint apertures have been calculated based on the permeability of rock mass and the joints spacing. The Q-value, the Lugeon number, the SPI value and the joint aperture have been compared with measured cement take and grout take in the trial grouting boreholes. A general correlation exists, especially when the mentioned parameters have been compared with normalized grout take. Against these general agreements the coefficients of determination for the fitted relations are low or moderate, and it seems that more research has been needed to assessing a reliable predictive relation for the grout and cement takes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cement grouting is a method through which the grout material is injected into the joints and cracks or voids of rock and soil formations, so that the engineering properties of these materials are improved by the decreased permeability, enhanced strength, and reduced deformability of the rock and soil formations. Ground condition and rock and soil properties are the most important factors in grouting process. In the case of the grouting in rocks, the joint conditions (aperture, roughness, spacing, continuity, etc.) are the most important properties which affect the grout penetration and total grout take.

Currently, a considerable share of budget allocated to dam construction processes is spent in cement grouting processes. Cement grouting is carried out for consolidation and improving strength of foundation of the dam and the related structures and water tightening of the foundation and abutment. When we are not certain about the efficiency of grout process in a given site, it is required to perform trial grouting before construction of the dam and applying the grout curtain. In this way, it is possible to measure the permeability, control and adjust the grout mix, assess of the grout penetration and the grout take and finalize the proper spacing of the grouting boreholes.

Due to the anisotropy of the hydraulic paths and various flow properties of water and grout, one cannot always expect a direct relationship between the values of water pressure test (WPT) results and the grout take. In this regard, Ewert (1997) believes that this difference can be explained by the fact that within joints in which water can easily flow grout cannot move, so that the hydraulic failure induced by the grouting pressure results in washout of particles inside the joint. Sadeghiyeh et al. (2013) compared the cement take values with the Lugeon numbers in Ostur dam site and find a general consistency; however they also observed somewhat opposing trends especially where more pressure used for grouting compared to the water pressure test. Generally the crack system and crack apertures are relatively unknown (Fransson 2001) and considering such uncertainties, it is difficult to predict the grouting result and attempts to do this are seldom performed with a more theoretical approach. Some theoretical models have been developed for predicting the take of cement grout in jointed rocks and enable one to estimate the grout penetration length in a single joint. Hässler et al. (1992) presented a theoretical based relationship for determination of maximum grout penetration length in a joint, which is controlled by factors such as pressure, grout properties and the joint aperture. Hässler et al. (1992), Gustafson and Stille (1996) and Funehag and Fransson (2006) assessed the penetration of grout in well characterized fractures and concluded that the hydraulic aperture is a reasonable predictor for penetration length. Recently the critical aperture for field penetrability was investigated and verified by data from some grouting projects (Stille et al. 2012).

In this study relationship between the grout take and some rock mass properties including the Q-values, the Lugeon numbers, the secondary permeability index (SPI) and the joint aperture have been investigated in trial grouting boreholes of Bakhtiari dam site. In this way, rock mass properties and joints parameters as well as the hydro-geological condition, the Lugeon values and the secondary permeability index (SPI) have been evaluated for each 5 m intervals of the trial grouting boreholes. Then the relationships between the grout take and theses parameters have been examined by regression analyses.

Bakhtiari dam site and trial grouting boreholes

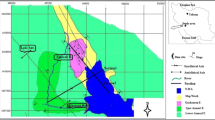

The Bakhtiari dam and hydroelectric power plant project includes the design and construction of a 315 m high, double curvature, concrete dam and an underground powerhouse, with nominal capacity of 1500 MW, in the Zagros mountains in southwest of Iran. Figure 1 shows the Bakhtiari dam site location and Fig. 2 shows the geology map of the dam site. Limestone layers of Sarvak Formation, which are Mid-Cretaceous marine sediments, form the foundation of the dam, powerhouse and other appurtenant structures. These layers are generally tightly folded and an anticline (Siah Kuh anticline) with a sharp axial plane exists in the location of the planned dam axis. The Sarvak Formation is divided into seven geological units, namely Sv1–Sv7, which Sv1 being the oldest unit with no outcrop at the dam site, and Sv7 is the youngest unit.

Location map of the Bakhtiary dam site (after IWPRDC 2009)

Geological map of the Bakhtiary dam site (after IWPRDC 2009)

The instruction for trial grouting at Bakhtiari dam site was prepared in a manner to investigate the effect of grouting on the strength of rock mass on the dam foundation site especially in a weak zone as called the King Band Zone. This zone consists of Sv2 and Sv3 unites, described as an intercalation of marly limestones of black-gray color if fresh and of gray color if moderately weathered and of siliceous limestones. The zone contains frequent cracks, joints, anticline–decline and beddings because of high compression tectonic forces. The trial grouting tests have been performed in the left (TGL panel) and the right (TGR panel) abutments of the planned dam site.

Figure 3 shows the pattern of the trial grouting boreholes panels. In the first stage of the trial grouting test (primary holes), a triangle shape was selected with a borehole distance of 2 m (TGR1 to TGR3 in the TGR panel and TGL1 to TGL3 in the TGL panel). Depth of the boreholes was 100 m in the TGR panel and 60 m in the TGL panel. Distance of the primary boreholes was selected based on the permeability test results of nearby exploratory boreholes. Exploratory boreholes in the site show the medium to low permeability for rock mass, and the distance of the primary boreholes was selected in order that the spacing of the boreholes in the final stage of the trial grouting test will be one meter. The result of primary stage grouted boreholes was controlled by centrally located cored check-holes, which named as CHTGR-A for the TGR panel and CHTGL-A for the TGL panel. Boreholes of the second stage of panels (secondary holes) were originally foreseen with three additional boreholes between the primary holes at one meter spacing. Later, this pattern was modified to two boreholes with a distance of 1 m from the TGR1 in the TGR panel and the TGL1 in the TGL panel, simulating a split spacing method. So the boreholes, TGR4 and TGR5 in the TGR panel as well as TGL4 and TGL5 in the TGL panel were drilled between apexes of the triangle down to the depth of 100 m in the TGR panel and 60 m in the TGL panel and then were grouted after permeability tests. The result of secondary stage grouted boreholes of each panel was controlled by the cored check-holes (CHTGR-B for the TGR panel and CHTGL-B for the TGL panel) by measuring the permeability in 5 m intervals. All boreholes were drilled with 86 mm diameter double core barrel to obtain the core sample continuously and also water pressure test were performed in 5 m intervals.

Materials and methods

Q-system parameters

This system, which is currently used in various applications, was initially presented by (Barton et al. 1974) for selecting a suitable pattern of shotcrete and anchor for ground improvement in the rock mass. Q is calculated using the following equation (Barton et al. 1974):

where RQD is the ratio of healthy cores with length greater than 10 cm in each drilling step (Deere 1989), J n is the relevant ratings for the number of joint sets, J r is the ratings for the joint surface roughness, J a is the ratings for the joint alteration, J w is the rating for the water condition of the joint and SRF is the stress reduction factor.

Permeability

Water pressure test (WPT) or Lugeon test is the most common method applied for determination of rock mass permeability and grout take. In the Lugeon test the steady state rate of flow from the borehole is measured under constant pressure. Generally the tests were carried out with a double packer system. The borehole was drilled to the final depth and the sections were tested from bottom to top. The packers were removed in stages from each position to the next upper position. Double packer systems allow a single test to examine the relationship between pressure, length of borehole and flow over several short sections of the hole, however generally the test section length are constant and considered to be 5 m. The WPT is typically performed in five steps, occasionally with more or less pressure steps. Pressures are increased stepwise up to the maximum pressure and then reduced down to the initial pressure. The Lugeon number for each step can be computed using the following equation (Nonveiller 1989):

where Lu is the Lugeon number, Q is the flow rate (L/min); L is the length of the studied segment (m); and P e is the effective pressure in the tested segment (bar). The pressure–flow rate relationship shown in Fig. 4 provides useful guidance on the properties of the rock mass. In the figure, P is the pressure and Q is the water flow rate. Using the obtained Lugeon values for different pressure steps and comparing them together, it is possible to classify flow behavior in the joints and indicate the representative permeability for the studied segment (Ewert 1985).

The Lugeon number is very useful in assessment of permeability of rock sites, however in the more cases it fails in assessments of the groutability of the site. This is because the results of the Lugeon test are strongly related to the geometric characteristics and weathering degree of the water paths (Ewert 1997), While the groutability of a site not only related to the joint-openings through which water flows, but also related to the rock quality and degree of jointing. Foyo et al. (2005) introduced the secondary permeability index (SPI) as follows:

where the SPI is the secondary permeability index (L/s m2), C is a constant coefficient controlled by fluid viscosity in a rock which is equals to 1.49 × 10−10 in temperature of 10 °C (Snow, 1968), r is the borehole radius (m), Q is the absorbed water (L), H is the total hydraulic head of water column (m), t is the time taken for each pressure step (s) and le is the length of the studied segment (m). The SPI, as a base for the rock mass classification, indicates rock mass permeability and hydraulic conductivity. The SPI express the absorbed water per time, through the surface of the injection camber and the index allows for defining the rock mass quality of the test section. Foyo et al. (2005) classified rock masses based on the SPI values and proposed ground treatment considerations. Table 1 present the rock mass classification based on the SPI values. They also proposed more details of grout characteristics and required actuation based on the SPI tests data. In these details, the jointing degree of the rock mass has been considered rather than hydraulic conductivity and water-absorption.

Joint aperture

The joint aperture is defined as the perpendicular distance between the adjacent rocks walls of a joint which the intervening space is air or water filled (ISRM 1978). For a set of parallel unfilled discontinuities, by modeling the discontinuity as an equivalent parallel plate conductor, the permeability coefficient parallel to the discontinuities can be determined for the laminar flow by (Louis 1974; Zhang 2013):

where K is the hydraulic conductivity of the rock mass (cm/s) which could be calculated based on the Lugeon value; g is the acceleration due to gravity (981 cm/s); e is the average joint aperture (cm); μ is the kinematic viscosity of the fluid (for water equal to 0.0109 cm2/s); b is the average joint spacing (cm) and C is a correction factor representing the discrepancy between the actual physical aperture of the discontinuity and its equivalent hydraulic aperture. This parameter is depended on the joint roughness by following expression:

where m is a constant coefficient and has been reported from 8.8 to 20.5 by different researchers (Barton and Quadros 1997; Zhang 2013) and y is the magnitude of the discontinuity surface roughness. For a smooth parallel joint, y becomes zero and thus C becomes one. By rearrangement of Eq. 3 the average joint apertures could be evaluated as follows (El-Naqa 2001):

Substituting values for the smooth parallel joints result in a simple following relation:

where e is the average joint aperture (cm); b is the average joint spacing (cm) and K is the hydraulic conductivity of the rock mass (cm/s).

Data processing

In this study the data sets of two trial grouting panels have been analyzed. Each panel consists of five grouting boreholes and two check-holes and all data belongs to the 5 m intervals.

The Q-system parameters have been evaluated by use of Q-logging for drilled boreholes (Barton 2002). Eye-examination of rock cores and standard tables of the Q-system is used for evaluation of parameters and rating. Figure 5 shows samples of cores for the drilled trial grouting boreholes. Joint set number is one of the difficult parameters for evaluation which needs considering inclination angle of joint surface. The joint set number for cores of a box has been determined by measuring the surface inclination angle with respect to the drilling axis, as the joints with equal inclination angle make one joint set (Clarck and Budavari 1981). Finally the Q-value has been evaluated for each 5 m interval by use of the Eq. 1.

Permeability in the trial grouting boreholes has been evaluated using water pressure tests. Before performing the test, each interval had been washed by the clear water so that the back water was clear and free of cuttings. After washing, each interval was saturated with water without pressure. Saturation time was between 5 and 10 min. After saturation, The Lugeon tests have been performed in five steps. Pressures have been selected based on the depth of the intervals. At the right abutment the maximum effective water pressures of about 30 bars has been used in the deepest interval of 95–100 m and at the left abutment the maximum effective water pressure of about 12 bars has been used in the depth of 55–60 m interval. Figure 6 shows the categorized Lugeon values based on the Ewert (1985) classification scheme. As can be seen, the Lugeon values within the range of 3–10 and 10–30 are the most frequent for the right and the left abutments, respectively. Figure 7 illustrates a comparison among various types of the joints hydro-mechanical behaviors for the left and the right abutments. The “Laminar” and the “dilation” flow are the most frequent behavior for the left and the right abutments, respectively. Figure 8 shows examples of the pressure–flow rate graphs for the dominant flow types (laminar and dilation) in the abutments of the Bakhtiari dam site. The dilation behavior indicates the elastic state of the rock mass against the applied water pressure. Through this behavior, by increasing the pressure, the joints become wider, flow rate increases and vice versa. Presence of the laminar flow indicates the slow water movement among the joints and cracks (Ewert 1985; Houlsby 1990), in parallel layers, with no disruption between the layers. The “washout” and the “void filling” flows have very low frequency in the Bakhtiari dam site and there is no the “turbulent” flow, indicating absence of the wide joints as well as the lack of the quick flows. Figure 9 represent the plotted Lugeon values against the Q-values in the Bakhtiari dam site. The best fitted regression line from the exponential type has been plotted as well. As expected there is an inverse correlation, where the Lugeon values decreases by increasing the Q-value, however relation is poor and the plotted data are very scattered.

The SPI values have been calculated by use of the Eq. 3 for each 5 m intervals of the trial grouting boreholes and the rock mass classification based on this criterion have been performed based on the Foyo et al. (2005) proposed scheme. In this regards, absorbed water values during water pressure tests have been used for the calculation of the SPI. It should be noted that the results for first boreholes of each trial grouting panels, (TGL1 in the left abutment and TGR1 in the right abutment) and their relevant SPI values, present the natural condition of the dam site. Table 2 represents the SPI classes for the trial grouting boreholes in each 5 m intervals. The SPI classes for the first drilled borehole of the trial grouting panels indicate that there are no intervals with the SPI class of A and all intervals need to be grouted. Also as can be seen, improvement of the permeability condition after grouting is evident. At the first drilled boreholes (TGL1 and TGR1), the SPI class of C is the most frequent and some SPI class of D even can be seen in the left abutment. While in the last drilled boreholes (TGL5 and TGR5), the number of SPI class of C has been reduced and the number of SPI class of B has been increased.

Average joints apertures for each 5 m intervals of the trial grouting boreholes have been calculated based on the permeability and the average joint spacing values in the interval. The permeability values have been evaluated upon the water pressure tests and the average joint spacing deduced from the RQD values and its general relation to the joint spacing (Priest and Hudson 1976). One Lugeon approximately considered being equivalent to the hydraulic conductivity of 1.3 × 10−7 m/s (Nonveiller 1989 and Fell et al. 2005). Smooth joints are the most frequent joint type in the dam site from the joint roughness point of view and in the most cases the joint roughness rating (Jr) for Q-system evaluated to be less than 2. Considering this condition of the joint roughness, the C parameter of Eq. 5 assumed to be 1 and the Eq. 7 has been used for calculation of the average joints aperture. All of the above mentioned data collaborated in a spread sheet data bank which is simple to be handled. Table 3 shows a part of the data bank belongs to the first borehole of the trial grouting panel in the left abutment (TGL1).

Takes and discussion

The grout takes and the cement takes during the trial grout tests had been measured for each 5 m interval of the boreholes and have been cited in the data bank. Figure 10 represent the average grout and cement takes for all of the trial grouting boreholes. As can be seen, both the grout takes and the cement takes generally have been decreased while the test progresses to the last borehole. Also it shows that the both grout takes and cement takes in the left abutment are generally less than the right abutment. Also it shows that generally the lover W:C ratios have been used in the right abutments compared to the left abutment, which is compatible with the higher Lugeon values in the left abutment.

Measured cement and grout takes have been examined by the rock mass parameters including the Q-value, the Lugeon values, the SPI values and the joints aperture. Also the measured grout takes have been normalized by the grouting pressure and then examined by the rock mass parameters including the Q-value, the Lugeon values, the SPI values and the joints aperture.

Figure 11 represents the correlation between the cement take and the Q-value, the Lugeon value, the SPI value and the joint aperture. As can be seen there is a general inverse correlation between the cement takes and the Q-value, where the cement take decreases with increasing the Q-value. This means that less treatment is required when high quality of rock mass exists. Also there is a direct correlation between the cement take and the Lugeon value, the SPI value and the joint aperture, where the cement take increases with increasing the Lugeon value, the SPI value and the joint aperture. The best fitted relations between the cement take and the Q-value, the Lugeon value, the SPI value and the joint aperture have been shown in the figure, too; however plotted data are very high scattered and there is a generally poor relations. Against the generally good correlations, the coefficients of determination are very low, which could be explained that other influencing parameters exist rather than only one parameter and the interaction among all the parameters together influences the results.

Figure 12 represents the relationship between the grout take and the Q-value, the Lugeon value, the SPI value and the joint aperture. As can be seen there are same correlation relationships when compared to the Fig. 11. Against the general agreements, there are poor relations between grout take and the Q-value, the Lugeon value, the SPI value and the joint aperture, too. Considering these poor relations, the grout take values have been normalized by use of the maximum grout pressures in each 5 m intervals. The maximum grout pressure values are provided based on the engineering geological reports (IWPRDC 2009). Figure 13 represents the relationships between the normalized grout take and the Q-value, the Lugeon value, the SPI value and the joint aperture. As can be seen the same correlation relationships exist when compared to the Figs. 11 and 12 while now a little improvement in coefficients of determination is evident.

Table 4 represents the coefficients of determination for the best fitted relations between the take and the Q-value, the Lugeon value, the SPI value and the joint aperture. As can be seen very low coefficients of determination for cement take exist which are increased in grout take and normalized grout take. Only the coefficients of determination for the relation between cement take and Q-value are decreased, which could be explained by different nature of the Q-value in comparison with the Lugeon value, the SPI value and the joint aperture. The Q-value is an engineering property while the Lugeon value, the SPI value and the joint aperture are hydro-geological rock mass properties. The maximum coefficients of determination belong to the normalized grout take, however the relations are poor yet, and it seems that there are other unknown influencing parameters exist rather than only the hydro-geological rock mass properties and the interaction among all the parameters together influences the results.

Conclusions

Grouting as a method for consolidation and water tightening of rock and soil is widely used. The jointed rock mass characteristics are of utmost important to predict the groutability of the rock masses. The left abutment of the Bakhtiari dam site generally showed more groutability than the right abutment in the trial grouting tests. This general condition could be anticipated based on the Lugeon values of the trial grouting boreholes of the left and the right abutments, while there is not precise predictive relation. The measured cement and grout take values have been examined by the Q-value, the Lugeon value, the SPI value and the joint aperture. It has been shown that there is a general correlation between take values and the above mentioned parameters; however the coefficients of determination for the best fitted relations are low. The grout take values were normalized by use of the maximum grout pressures and then examined against the Q-value, the Lugeon value, the SPI value and the joint aperture. The coefficients of determination for the fitted relations have been a little improved, but it seems that more research has been needed to assessing a reliable predictive relation for the grout and cement take.

References

Barton N (2002) Some new Q-value correlations to assist in site characterization and tunnel design. Int. J Rock Mech Min Sci 39:185–216

Barton N, Quadros EF (1997) Joint aperture and roughness in the prediction of flow and groutability of rock masses. Int J Rock Mech Min Sci 34:3–4, Paper No. 252

Barton N, Lien R, Lunde J (1974) Engineering classification of rock masses for the design of tunnel support. Rock Mech 6:189–236

Clarck C, Budavari S (1981) Correation of rock mass classification parameters obtained from borecore and in-situ observation. Eng Geol 17:19–53

Deere DU (1989) Rock quality designation (RQD) after 20 years. US. Army Corps Engrs. Contract Report GL-89-1. Waterways Experimental Station, Vicksburg

El-Naqa A (2001) The hydraulic conductivity of the fractures intersecting Cambrian sandstone rock masses, central Jordan. Environ Geol 40:973–982

Ewert FK (1985) Rock grouting with emphasis on dam sites. Springer, Berlin

Ewert FK (1997) Permeability, groutability and grouting of rocks related to dam sites; part 4. groutability and grouting of rock. Dam Eng 8(4):271–325

Fell R, Mac Gregor P, Stapledon D, Bell G (2005) Geotechnical engineering of dams. Taylor & Francis, London

Foyo A, Sánchez MA, Tomillo C (2005) A proposal for a secondary permeability index obtained from water pressure tests in dam foundations. Eng Geol 77(1):69–82

Fransson A (2001) Characterization of a fractured rock mass for a grouting field test. Tunnel Undergr Sp Technol. 18:321–330

Funehag J, Fransson A (2006) Sealing narrow fractures with a Newtonian fluid: model prediction for grouting verified by field study. Tunn Undergr Sp Technol 21(5):492–498

Gustafson G, Stille H (1996) Prediction of groutability from grout properties and hydrogeological data. Tunn Undergr Sp Technol 11(3):325–332

Hässler L, Håkansson U, Stille H (1992) Classification of jointed rock with emphasis on grouting. Tunn Undergr Sp Technol 7(4):447–452

Houlsby AC (1990) Construction and design of cement grouting: a guide to grouting in rock foundations (Vol. 67). John Wiley & Sons, Hoboken

Iran Water and Power Resources Development Company (IWPRDC) (2009) Engineering geology report phase I feasibility phase Bakhtiari reservoir dam

ISRM (1978) Rock characterization testing and monitoring: suggested methods for quantitative description of fractures in rock masses. Int J Rock Mech Min Sci Geomech Abstr 15:319–368

Louis C (1974) Introduction an l’hydraulique des roches. Bull BRGM 2ième Série Sect III 4:283–356

Nonveiller E (1989) Grouting theory and practice, development of geotechnical engineering. Elsevier, Amsterdam

Priest SD, Hudson JA (1976) Discontinuity spacing in rock. Int J Rock Mech Min Sci 13:135–148

Sadeghiyeh SM, Hashemi M, Ajalloeian R (2013) Comparison of permeability and groutability of ostur dam site rock mass for grout curtain design. Rock Mech Rock Eng 46(2):341–357

Stille H, Gustafson G, Hassler L (2012) Application of new theories and technology for grouting of dams and foundations on rock. Geotech Geol Eng 30:603–624

Zhang L (2013) Aspects of rock permeability. Front Struct Civ Eng 7(2):102–116

Acknowledgments

This research was supported under the School of Geology, University College of the Sciences, University of Tehran, Iran. The authors also would like to thank Iran Water and Power Resources Development Company (IWPRDC) for field test data of the trial grouting boreholes.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sohrabi-Bidar, A., Rastegar-Nia, A. & Zolfaghari, A. Estimation of the grout take using empirical relationships (case study: Bakhtiari dam site). Bull Eng Geol Environ 75, 425–438 (2016). https://doi.org/10.1007/s10064-015-0754-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-015-0754-5