Abstract

The LaF3 surface-modified LiCr0.05Mn1.95O4 samples were synthesized by co-precipitation method and characterized by high-angle annular dark field scanning transmission electron microscopy (HAADF-STEM) and energy-dispersive X-ray detector (EDX). HAADF-STEM and EDX observations showed that LaF3 deposited on the surface of LiCr0.05Mn1.95O4 particles. When tested as the cathode materials for lithium-ion battery, the LaF3-modified LiCr0.05Mn1.95O4 exhibited significantly improved cyclic and rate performances at high temperature (55 °C). Electrochemical impedance spectrum analyses demonstrated that the surface of LiCr0.05Mn1.95O4 modified by LaF3 was much more stable during the electrochemical process and could greatly facilitate the charge–transfer reaction, which may be attributed to the protection of active material by LaF3 from the HF attack.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

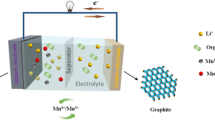

Rechargeable lithium-ion batteries (LIBs) have become very important in electronic devices as well as in electric vehicles and hybrid electric vehicles. Among many cathode materials for LIB, LiMn2O4 spinel has been considered as one of most promising candidates due to its high working voltage, good safety, low cost, abundance and non toxicity [1–4]. However, poor electrochemical performances at high temperature limit its wide application to some extent. The poor high-temperature performances can be ascribed to several possible factors, such as the choice and purity of the electrolyte and the operating voltage window of the cells.

Many experiments showed that Li2Mn2O4 will be formed when the Li x Mn2O4 spinel electrodes' (0 ≤ x ≤ 2) excessive discharge is below 3.0 V, in which a large crystallographic (Jahn–Teller) distortion was responsible for the capacity loss [5–10]. Non-equilibrium localized formation of Li2Mn2O4 at the particle surface has also been observed, particularly under high-rate conditions above 3 V, which can result in subsequent disproportionation reactions to yield Mn(II) and Mn(IV) products. The soluble Mn2+ ions can be transported across the electrolyte to the anode where they are deposited, resulting in capacity fade. At present, cation substitution (Li, Sm, Mg, Al, Cr, etc.) at the Mn site is demonstrated to stabilize the lattice structure and improve electrochemical performances of spinel LiMn2O4 [11–15].

In the electrolyte, a small amount of water can react with fluoride-based electrolyte, generating hydrofluoride acid (HF), which accelerates the decomposition of LiMn2O4 and Mn2+ dissolution, especially at high temperature. In order to overcome these shortcomings, surface coating or modification of LiMn2O4 is suggested to protect Mn3+ from dissolution in the electrolyte. Up to now, many oxides such as Al2O3, ZnO, ZrO2 and TiO2 have been used to modify the surface of spinel LiMn2O4 [16, 17]. However, few researches about the fluorides surface-modified LiMn2O4 have been reported [18]. Considering that those protective oxides will transform into a stable fluoride layer by reacting with HF in the electrolyte during the electrochemical process, a better effect may be achieved if the surface of LiMn2O4 is directly modified by metal fluorides.

In this paper, in order to overcome the structure distortion of LiMn2O4 and assault from the electrolyte, we focus on LaF3 surface-modified LiCr0.05Mn1.95O4 electrode materials. The structural and electrochemical properties of the as-prepared samples were investigated.

Experiment

The pristine LiCr0.05Mn1.95O4 sample is a commercial product of Huilong Technology Co., Ltd., in Yuxi. To prepare the surface-modified materials, La(NO3)3•6H2O and NH4F and LiCr0.05Mn1.95O4 are dissolved in distilled water; the specific process is La(NO3)3•6H2O and LiCr0.05Mn1.95O4 are dissolved in distilled water with continuous stirring for 2 h at 80 °C; 1 mol NH4F is dissolved in 1 L distilled water, added to the mixture at the rate of 3 ml/min and continuously stirred for 2 h at 80 °C; the composition of LaF3 in the modified cathode materials was 0.5, 1.0 and 2.0 wt%, respectively. Subsequently, the mixture was filtered and dried at 90 °C for 5 h; then, the obtained powder was heated at 400 °C for 5 h, and the surface-modified cathode materials are gotten.

The microstructure of the powder was obtained using a high-angle annular dark field scanning transmission electron microscopy (HAADF-STEM). For measuring the electrochemical properties, the electrochemical cells consisting of LiCr0.05Mn1.95O4 as positive electrode, Li metal as the negative electrode and the electrolyte was 1 M LiPF6 dissolved in a 1:1 (volume ratio) mixture of ethylene carbonate and dimethyl carbonate, and Celgard 2400 membrane as the separator between cathode and anode. The cathode was the mixture of 85 wt% active material, 8.0 wt% acetylene black and 7.0 wt% poly-vinylidene fluoride dissolved in 1-methyl-2-pyrolidinone (NMP), which was spread on a 14-mm-diameter aluminium foil and heated to 120 °C for 12 h in vacuum; the electrode thickness is about 20 μm. The cells were assembled in an argon-filled glove box. The constant current constant voltage charge model (CC-CV) cycling was performed between 3.0 and 4.3 V with 1 C (148 mA g−1) rate on the LandCT2001A made in China; the rate performance was performed between 3.0 and 4.3 V with different currents (1 C, 2 C, 5 C, 10 C, 15 C), and electrochemical impedance spectroscopy (EIS) was tested on a PARSTAT 2273 made in the USA. After the cells were at the fully charged state (4.3 V), the impedance spectra were recorded potentiostatistically by applying an AC voltage of 5 mV amplitude over the frequency range from 105 to 0.05 Hz.

Results and discussion

Figure 1 presents the typical HAADF-STEM images of the pristine and LaF3-modified LiCr0.05Mn1.95O4 powders. The pristine particles exhibit a smooth surface, while the surfaces of the modified particles are covered with thin nanolayers, which are determined to be LaF3 on the basis of EDX analysis (Fig. 1d). From the results of the HAADF-STEM and EDX, it can be concluded that the LaF3-modified layer is successfully formed on the surface of LiCr0.05Mn1.95O4.

Figure 2 shows the cyclic performance of pristine and LaF3-modified LiCr0.05Mn1.95O4 electrodes at 55 °C. It is even more important that the cycle ability at high temperature is remarkably improved with the introduction of LaF3-modified layers. For example, the pristine LiCr0.05Mn1.95O4 merely retains 72.2 % of its initial capacity after 600 cycles with 1 C rate. However, the capacity retentions are 81.1, 88.2 and 93.3 % for 0.5, 1.0 and 2.0 wt% LaF3-modified samples, respectively. This great enhancement can be ascribed to the fact that the LaF3-modified layers prevent direct contact between the LiCr0.05Mn1.95O4 active material and the acidic electrolyte, suppressing the tendency for Mn dissolution in the electrolyte.

Figure 3 shows the rate capability of the pristine and LaF3-modified samples at 55 °C. When the moderate rates (1–5 C) are adopted, no obvious difference can be identified between the pristine and LaF3-modified samples. When the rate increases to around and above 10 C, the discharge capacity of the pristine LiCr0.05Mn1.95O4 decreases rapidly as compared to that of the low rates, and only 15.6 % of the 1 C capacity is obtained at 15 C. Meanwhile, the LaF3 surface modification markedly improves the high-rate performance of LiCr0.05Mn1.95O4 since the capacity retentions at 15 C are 38.2, 67.1 and 64.5 % for the 0.5, 1.0 and 2.0 wt% LaF3 samples, respectively.

To further understand the effect of LaF3 modification on the cycle and high-rate performances of LiCr0.05Mn1.95O4 cathode material, EIS analyses are carried out on each cell of 100 % SOC (4.3 V) after the 1st and 100th cycle, respectively. The Nyquist plots of pristine LiCr0.05Mn1.95O4 and LaF3-modified samples are presented in Fig. 4. All the plots in Fig. 4a consist of one semicircle in the high-frequency region, one capacitive arc in the middle frequency and the straight sloping line in the low-frequency region. The high-frequency semicircle is attributed to the charge–transfer reaction, the middle frequency loop is due to the solid electrolyte interface layer, and the inclined line is Warburg impedance (W) which is used to model semi-infinite diffusion in the bulk cathode material [18]. It is clear in Fig. 4a that the LaF3-modified samples have smaller charge–transfer resistance (R ct) values than the pristine LiCr0.05Mn1.95O4, indicating a faster electrochemical reaction on the LaF3-modified spinel electrode. After the 100th cycle, the value of R ct for pristine powders greatly increases from 70 to 128 Ω (Fig. 4b). However, the increase of the R ct value for each LaF3-modified electrode after the 100th cycle is relatively smaller, e.g. the value of R ct for 1 wt% LaF3-modified electrode increases from 40 to 65 Ω. Since the electrochemical reaction happened on the interface between the active material and the electrolyte, the smaller changes in the value of R ct during the cycles imply a more stable surface of the LaF3-modified LiCr0.05Mn1.95O4, suggesting the protection of active material by LaF3 from the HF attack.

Conclusions

The LaF3 surface-modified LiCr0.05Mn1.95O4 samples are synthesized by co-precipitation method. HAADF-STEM and EDX observations illustrate that LaF3 deposited on the surface of LiCr0.05Mn1.95O4 particles. When tested as the cathode materials for LIB, the LaF3-modified LiCr0.05Mn1.95O4 exhibits significantly the improved cyclic and rate performances at a relatively high temperature (55 °C). The capacity retentions are 81.1, 88.2 and 93.3 % for LaF3-modified electrode materials with 0.5, 1.0 and 2.0 wt%, respectively, after 600 cycles, while that of the pristine is only 72.2 %. The capacity retention at the 15 C rate of the pristine powders is only 15.6 % relative to that at 1 C rate. However, the capacity retentions are 38.2, 67.1and 64.5 % for electrode materials with 0.5, 1.0 and 2.0 wt%, respectively. EIS analysis demonstrates that the surface of LiCr0.05Mn1.95O4 modified by LaF3 is much more stable during the electrochemical process and could greatly facilitate the charge–transfer reaction, which may be attributed to the protection of active material by LaF3 from the HF attack.

References

Zhuang QC, Wei T, Du LL (2010) J Phys Chem C 114:8614–8621

Fang CM, Dewijs GA (2006) Chem Mater 18:1169–1173

Thackeray MM, Johnson PJ, Goodenough JB (1984) Mater Res Bull 19:179–187

Liu QS, Yu LH, Wang HH (2009) J Alloys Compd 486:886–889

Takahashi M, Yoshida T, Ichikawa A (2006) Electrochim Acta 51:5508–5514

Xia Y, Wang H, Zhang Q, Nakamura H (2007) J Power Sources 166:485–491

Lee YS, Cho SJ, Yoshio M (2006) Korean J Chem Eng 23:566–569

Yamada A, Tanaka M, Tanaka K (1999) J Power Sources 81–82:73–78

Edstrom K, Gustafsson T, Thomas JO (2004) Electrochim Acta 50:397–403

Shi S, Ouyang C, Wang DS (2003) Solid State Commun 126:531–534

Deng BH, Nakamur H, Yoshio M (2008) J Power Sources 180:864–868

Balaji SRK, Mutharasu D (2010) Ionics 16:351–360

Lee JH, Hong JK, Jang DH (2000) J Power Sources 89:7–14

Xiao LF, Zhao YQ, Yang YY (2008) Electrochim Acta 54:545–550

Thirunakaran R, Sivashanmugama A, Gopukumar S (2008) Mater Res Bull 43:2119–2129

Park SB, Shin HC, Lee WG (2008) J Power Sources 180:597–601

Walza KA, Johnson CS, Genthe J (2010) J Power Sources 195:4943–4951

Lee DJ, Lee KS, Myung ST, Yashiro H (2011) J Power Sources 196:1353–1357

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(JPEG 271 kb)

Rights and permissions

About this article

Cite this article

Sun, H., Zhu, D., Chen, Y. et al. LaF3 surface-modified LiCr0.05Mn1.95O4 cathode material with improved high-temperature performances for lithium-ion batteries. J Solid State Electrochem 16, 2979–2982 (2012). https://doi.org/10.1007/s10008-012-1728-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-012-1728-1