Abstract

Exploration of microbial pool from extremely diversified ecosystem is significantly important for various industrial applications. Bacterial communities from extreme habitats including volcanic vents, hot springs, and industrial sectors are eagerly explored for the isolation of thermophiles. Geobacillus stearothermophilus KIBGE-IB29, isolated from blast furnace site of a steel processing industry, is capable of producing thermostable endo-β-1,4-xylanase. In the current study, this enzyme was immobilized within calcium alginate beads using entrapment technique. Amalgamation of sodium alginate (40.0 gL−1) and calcium chloride (0.4 M) was used for the formation of immobilized beads. It was observed that temperature (50 °C) and pH (7.0) optima of immobilized enzyme remained same, but enzyme–substrate reaction time increased from 5.0 to 30.0 min as compared to free enzyme. Diffusion limit of high molecular weight xylan (corncob) caused a decline in V max of immobilized enzyme from 4773 to 203.7 U min−1, whereas K m value increased from 0.5074 to 0.5722 mg ml−1 with reference to free enzyme. Immobilized endo-β-1,4-xylanase showed its stability even at high temperatures as compared to free enzyme and retained 18 and 9 % residual activity at 70 and 80 °C, respectively. Immobilized enzyme also exhibited sufficient recycling efficiency up to five reaction cycles which indicated that this enzyme can be a plausible candidate in paper and pulp industry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Xylan is a heteropolysaccharide composed of xylose monomers which are linked together by 1,4 linkages within a complex xylan network (Collins et al. 2005). Due to wide applications of xylan hydrolytic products (xylose, xylobiose and xylooligosaccharide) by microbial sources, the researchers are focusing on the development of various strategies for efficient xylan degradation. One of the most important strategies focused is the use of thermophilic biocatalysts which act as strong and specific cleaving agents (Bhalla et al. 2013). Endo-β-1,4-xylanase from thermophilic microbial sources can be used to cleave β-1,4 linkages (Wang et al. 2013a). Recently, interest in this hydrolase has markedly increased because of its various biotechnological applications (Sharma and Kumar 2013). However, with several benefits, the use of enzymes for commercial applications remains limited owing to the fact of losing enzyme activity because of insufficient stability at various temperatures (Quiroga et al. 2011). This obstacle can be overcome using thermophiles for the production of thermozymes and can be explored in diversified ecosystem. Thermophiles from harsh environmental conditions are capable of producing modified enzymes which can withstand various extreme physical conditions during bioprocessing of different metabolites (Elleuche et al. 2014).

Thermostable enzymes isolated from thermophilic microbes of expanded origin have attracted the attention of biotechnological industries, and among them immobilized thermozymes can reduce the cost of the bioprocess (Elleuche et al. 2014; Arya and Srivastava 2006). Immobilization can be used to improve enzyme utilization with chemical and microbiological tools (Elleuche et al. 2014; Fernandez-Lafuente 2009). Thermophilic enzymes exhibit fast hydrolytic rate, generate high yield of product, and are less prone to microbial contamination issues (Yeoman et al. 2010; Viikari et al. 2007). However, the catalytic property of a mesophilic enzyme can be improved using different suitable techniques. Generally, free enzymes show lower thermal and operational stability, and it is also much difficult to separate the free enzyme from reaction mixture after the product formation. These constraints can be overcome by increasing the stability of the enzymes by immobilizing them within various synthetic and non synthetic matrices for continuous production of metabolites (Guzik et al. 2014; Cowan and Fernandez-Lafuente 2011; Mateo et al. 2007). Enzyme immobilization may provide stabilization through multipoint attachment, support in prevention of enzyme dissociation, and can generate favorable environment for enzyme–substrate reaction for the production of different biological molecules (Garcia-Galan et al. 2011; Rodrigues et al. 2011; Mateo et al. 2007; Pedroche et al. 2007). Moreover, immobilization technique may also improve some other enzymatic features such as catalytic activity, specificity, resistance to inhibitors, etc. Selection of appropriate immobilization technique with support is also an important criterion in various bioprocesses. Due to non toxic property of calcium alginate, it is considered as a suitable matrix for the entrapment of biological macromolecules (Kar et al. 2008). Alginate is a natural polysaccharide composed of 1,4 linked β-d mannuronic and α-l-guluronic acid residues, and in presence of calcium ions, alginate produces insoluble gel-like structure (calcium alginate) which is capable of tolerating high temperature and is biocompatible with most of the enzymes (Blandino et al. 1999, 2000).

The stabilization of multimeric enzymes in several bioprocesses is a huge issue which can be resolved by immobilizing the enzymes. In many instances, multimeric enzymes loss their structure assembly or dissociates into their subunits which affects the catalytic efficiency of the enzyme (Eijsink et al. 2004). However, in case of monomeric enzymes, the inactivation occurs by the alteration in the tertiary structure of enzymes (Ahern and Klibanov 1985; Poltorak et al. 1999; Pilipenko et al. 2007). Most of the thermophilic microbes are capable of producing high content of multimeric enzymes with strong subunit association as compared to mesophilic counterpart (Sterner et al. 1996; Tanaka et al. 2001; Ogasahara et al. 2003). Therefore, these multimeric enzymes can be used in biotechnological industries, and they can be further stabilized using immobilization technique (Fernandez-Lafuente 2009). Geobacillus stearothermophilus is an extremophile which has been extensively studied for the production of different enzymes (Wang et al. 2013a; Al-Qodah 2006). Limited data are available for the production of xylanase from G. stearothermophilus, and research is also scarce for the immobilization of this enzyme.

Considering the wide commercial applications of thermostable endo-β-1,4-xylanase, current study was designed to immobilize the partially purified endo-β-1,4-xylanase. Enzyme was produced from an indigenously isolated G. stearothermophilus KIBGE-IB29 and immobilized within calcium alginate beads using entrapment technique. Different reaction parameters were examined for free and immobilized enzyme. Thermal and operational stability of immobilized enzyme was also investigated to fulfill the requirement of different industrial processes. Surface topography of gel beads with and without immobilized enzyme was also examined.

Materials and methods

Production of endo-β-1,4-xylanase from Geobacillus stearothermophilus KIBGE-IB29

A thermophilic bacterium namely G. stearothermophilus KIBGE-IB29 was previously isolated from the soil collected around the blast furnace site of Pakistan Steel Mill, Karachi, Pakistan (Bibi et al. 2014). Bacterium was inoculated into optimized fermentation medium containing (gL−1) corncob xylan, 5.0; peptone, 5.0; yeast extract, 2.0; meat extract, 1.0; K2HPO4, 2.5; KH2PO4, 0.5; (NH4)2SO4, 0.5; and CaCl2, 0.1 with pH-6.0 and incubated at 60 °C for 24 h. Cells were harvested by centrifugation at 40248×g for 15.0 min at 4 °C. The cell-free filtrate (CFF) containing extracellular endo-β-1,4-xylanase was partially purified using 40 % ammonium sulfate saturation. This mixture was kept at 4 °C overnight, and the precipitates formed were collected by centrifugation at 40248×g for 15.0 min at 4 °C. The precipitates were dissolved in sodium phosphate buffer (25.0 mM, pH-7.0) and dialyzed against the same buffer overnight at 4 °C. The dialyzed enzyme sample was used for further analysis.

Enzyme assay for free and immobilized enzyme

Catalytic activity of free and immobilized endo-β-1,4-xylanase was examined by quantification of reducing sugar using 3′5′-dinitrosalicylic acid (DNS) method (Miller 1959). Free enzyme (100.0 μl) was incubated with 1.0 ml of xylan (20.0 gL−1) prepared in sodium phosphate buffer (25.0 mM, pH-7.0) at 50 °C for 5.0 min. DNS solution (1.0 ml) was incorporated to stop the reaction, and the tubes were kept in boiling water bath for 5.0 min. Double-deionized water (9.0 ml) was added in the reaction tubes and mixed thoroughly. Slightly modified protocol was followed for immobilized enzyme. Initially, 0.5 g immobilized beads were mixed with 1.0 ml of xylan (20.0 gL−1) solution and incubated for 30.0 min at 50 °C. From this tube, 1.0 ml reaction mixture was transferred in another tube containing DNS solution (1.0 ml), and rest of the protocol was followed exactly the same as mentioned for free enzyme. Color intensity was measured at 546 nm against a reagent blank, and endo-β-1,4-xylanase activity was calculated using xylose calibration curve. One unit of endo-β-1,4-xylanase is defined as the amount of enzyme required to release 1.0 μmol of reducing sugar (xylose) per minute under standard assay conditions (50 °C, sodium phosphate buffer: 25.0 mM, pH-7.0).

Matrix entrapment of endo-β-1,4-xylanase using calcium alginate beads

Calcium alginate beads were prepared for the matrix entrapment of endo-β-1,4-xylanase. Partially purified enzyme was mixed in equal volume (1:1) of sodium alginate solution (30.0 gL−1) prepared in sodium phosphate buffer (25.0 mM, pH-7.0). This mixture was added drop wise into calcium chloride solution (0.3 M) with continuous stirring on ice bath. Enzyme immobilized beads were formed as insoluble beads. These beads were washed thrice with sodium phosphate buffer (25.0 mM, pH-7.0) to remove any unbound or loosely bound enzyme. Alginate beads with and without immobilized enzyme were weighted and stored at 4 °C for further studies. Calcium alginate beads without enzyme were used as control.

Optimization of sodium alginate and calcium chloride concentration for endo-β-1,4-xylanase entrapment

Different concentrations of sodium alginate (10.0–70.0 gL−1) and calcium chloride (0.1–0.5 M) were analyzed for the preparation of stable calcium alginate bead structure. Sodium alginate solution was prepared in sodium phosphate buffer (25.0 mM, pH-7.0), and calcium chloride solution was prepared in double-deionized water.

Selection of optimum reaction time for free and immobilized endo-β-1,4-xylanase

The effect of different reaction time was investigated by incubating the free and immobilized endo-β-1,4-xylanase for different time intervals (5.0–60.0 min) under standard assay conditions.

Optimization of reaction temperature for free and immobilized endo-β-1,4-xylanase

Influence of incubation temperature on the free and immobilized enzyme was analyzed at various temperatures ranging from 30 to 80 °C.

Effect of pH on the catalytic activity of free and immobilized endo-β-1,4-xylanase

The optimum pH of free and immobilized enzyme was determined by incubating with different pH buffers ranging from 4.0 to 10.0 and keeping same ionic strength (25.0 mM). Different buffers investigated were phosphate–citrate buffer (pH: 4.0–6.0), sodium phosphate buffer (pH: 7.0–8.0), and glycine–NaOH buffer (pH: 9.0–10.0).

Enzyme–substrate kinetics of free and immobilized enzyme

Lineweaver–Burk Plot was constructed to calculate the maximum velocity (V max) and Michaelis–Menten constant (K m) for both free and immobilized endo-β-1,4-xylanase. Xylan was dissolved in sodium phosphate buffer (25.0 mM, pH-7.0) in different concentrations ranging from 10.0 to 30.0 gL−1.

Thermal stability of free and immobilized endo-β-1,4-xylanase

Thermal stability of free and immobilized enzyme was investigated by pre-incubating both at different temperatures (40–80 °C) for 120.0 min. Percent residual activity was measured under standard assay conditions.

Reusability of immobilized endo-β-1,4-xylanase

The catalytic activity of immobilized enzyme was evaluated using a repeated batch process in order to investigate the operational stability of endo-β-1,4-xylanase for continuous processing. Immobilized beads (0.5 g) were incubated with substrate (20.0 gL−1) at 50 °C for 30.0 min, and the resultant reducing sugar was estimated under standard assay conditions. After each batch reaction, beads were washed thrice with sodium phosphate buffer (25.0 mM, pH-7.0). Percent residual activity was calculated with reference to control.

Scanning electron microscopy of calcium alginate beads with and without enzyme

Surface topography of calcium alginate beads with and without immobilized endo-β-1,4-xylanase was examined by scanning electron microscope (SEM) (JSM 6380A Jeol, Japan) at different resolutions. Beads were dried by incubating at 37 °C overnight, and cross-sectional beads were sputter coated with gold by Auto coater (Model JFC-1500 Jeol, Japan) which was used for micrographs to analyze morphological changes.

Results and discussion

Different concentrations of sodium alginate were used for the formation of robust immobilized beads, and it was found that maximum entrapment (10 %) was achieved when sodium alginate (40.0 gL−1) was used (Fig. 1a). Further increased or decreased in sodium alginate concentration declined the enzyme entrapment. It is due to the fact that the lower concentration of sodium alginate produced fragile calcium alginate beads having large pore size which ultimately causes the leaching of enzyme molecules from beads. However, higher concentration would have led towards lower penetration of high molecular weight substrate into the beads for the product formation (Quiroga et al. 2011; Kumar et al. 2009). Concentration of calcium chloride was also varied for the formation of stable bead structure, and it was found that maximum entrapment was achieved at 0.4 M (Fig. 1b). Further increased or decreased concentration beyond optimum level (0.4 M) declined the entrapment of endo-β-1,4-xylanase. Different concentrations of sodium alginate and calcium chloride have been reported by various research groups for the entrapment of pectinase (Rehman et al. 2013), protease (Anwar et al. 2009), and Glucose oxidase (Blandine et al. 2001).

In order to investigate the optimum reaction time of free and immobilized endo-β-1,4-xylanase, enzyme activity was conducted by varying the time of enzyme–substrate incubation (5.0–60.0 min). Immobilized endo-β-1,4-xylanase showed maximum hydrolytic activity at 30.0 min as compared to the free enzyme which was achieved at 5.0 min (Fig. 2). The shift in the reaction time from 5.0 to 30.0 min could be due to the time required by xylan to penetrate into the complex calcium alginate beads structure. Similar result has also been reported for the immobilization of dextransucrase where reaction time was increased from 15.0 to 60.0 min (Qader et al. 2007).

To observe the optimum temperature for maximum enzyme–substrate reaction, free and immobilized endo-β-1,4-xylanase was incubated at various temperatures (30–80 °C). The optimum temperature for maximum catalysis of free and immobilized endo-β-1,4-xylanase was observed at 50 °C (Fig. 3). At high temperature gradual decline in percent relative activity was observed in both cases. Immobilized enzyme showed 82 and 63 % relative activity at 70 and 80 °C as compared to free enzyme which was around 70 and 47 %, respectively. The literature which is available about the immobilization of different enzymes suggests that the catalytic behavior of an enzyme in terms of pH optima, temperature optima, and thermal stability varies with the change in the type of the matrix used because some of the supports are reported as microporous while, others are mesoporous materials. Like in a previously reported study, catechol 2,3-dioxygenase showed maximum specific activity at 30 °C using same matrix support (Wojcieszyńska et al. 2012). However, xylanase immobilization on functionalized polyaniline support by covalent attachment revealed maximum relative activity at 60 °C (Madakbaş et al. 2013).

A wide range of pH from 4.0 to 10.0 was investigated to observe maximum enzyme–substrate reaction of free and immobilized endo-β-1,4-xylanase. Entrapment within calcium alginate does not cause any significant effect on pH maxima, and maximum percent relative activity of both free and immobilized endo-β-1,4-xylanase was achieved at pH-7.0 (Fig. 4). After pH 7.0, both free and immobilized enzyme showed a gradual decline indicating that the enzyme activity within calcium alginate matrix is also affected by alkaline nature of the reaction. When other immobilization supports were observed for the pH optima change, it was noticed that the maximum relative activity of free and immobilized laccase on various TiO2–Montmorillonite complexes was same (pH-3.0) (Wang et al. 2013b), whereas in case of manganese superoxide dismutase immobilization on supermagnetic 3-APTES-modified SiO2-coated Fe3O4 nanoparticles, pH optima was shifted remarkably from pH-6.0 to 10.0 (Song et al. 2012). Therefore, it is suggested that the catalytic behavior of an immobilized enzyme may be shifted towards a higher or a lower pH value depending upon the surface charges present on the support used. As this is correlated with the unwanted opening of the surface loop, which acts as an active site tunnel for enzyme–substrate reaction, and hence results in the reduction of catalytic efficiency of an enzyme (Shah et al. 2008).

Lineweaver–Burk plot was used to calculate the kinetics parameters of free and immobilized endo-β-1,4-xylanase by varying the substrate concentration and keeping other enzymatic conditions constant. For this purpose, maximum reaction rate and Michaelis–Menten constant for free and immobilized enzyme were determined. V max and K m values of free enzyme were 4773 U min−1 and 0.5074 mg ml−1, with a standard error of 175.3 U min−1 and 0.067 mg ml−1, respectively. However, for immobilized endo-β-1,4-xylanase, V max and K m values were 203.7 U min−1 and 0.5722 mg ml−1 with standard error of 7.4 U min−1 and 0.071 mg ml−1, respectively. Around 23 times decline was noticed in V max of immobilized enzyme as compared to free enzyme, whereas a slight increase was observed for K m value. This could be due to lower diffusion of high molecular mass substrate into immobilized beads. A similar effect was also noticed when high molecular weight substrates were used including xylan (Gouda and Abdel-Naby 2002; Dalal et al. 2007). It is also reported earlier that both kinetic parameters were increased after immobilization of xylanase when adsorption technique was employed. However, at the same time, a decline was noticed in V max value when the same enzyme was immobilized using reticulation procedure (Romo-Sánchez et al. 2014). These studies suggest that the kinetic parameters may vary from technique to technique when xylanase is immobilized.

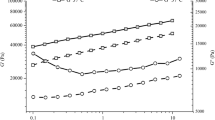

Stability of enzyme at higher temperatures remains a noteworthy requirement for different industries in order to reuse the catalyst more efficiently. The thermal stability of free and immobilized endo-β-1,4-xylanase was investigated by pre-incubating both at different temperatures. Enzyme samples were retrieved from each temperature vial with 30.0 min time interval, and percent residual activity was determined with reference to free enzyme. The free enzyme was completely stable at 40 °C, whereas at 50 °C, it exhibited 64 % residual activity up to 120.0 min of incubation (Fig. 5a, b). At 60 °C, only 32 % residual activity was observed, and unfortunately at 70 and 80 °C, the free enzyme completely lost its activity just in 30.0 min. It was noted that immobilized endo-β-1,4-xylanase is capable to stand a wide range of temperatures for relatively longer time period in comparison with free enzyme. Whereas at 50 and 60 °C, immobilized endo-β-1,4-xylanase showed around 80 and 35 % residual activity (Fig. 5b, c) as compared to 70 and 80 °C where it exhibited only 18 and 9 % residual activity, respectively, within 60.0 min (Fig. 5d, e). Thermal stability can be improved if endo-β-1,4-xylanase is immobilized on different matrices. Endo-β-1,4-xylanase from the same strain was immobilized within agar–agar matrix previously, and it relatively showed improved thermal stability as compared to calcium alginate environment (Bibi et al. 2015). It is possible that elevated temperature may denature the catalytic function of an enzyme in the micro environment of the matrix used. Enhanced thermal stability can be attributed to the nature and type of the matrix which could prevent the conformational changes and in return stabilize the enzyme activity against different temperature levels (Shah et al. 2008).

Thermal stability of free and immobilized endo-β-1,4-xylanase from Geobacillus stearothermophilus KIBGEIB29 (mean ± SE, n = 6). Samples were retrieved with time intervals of 30.0 min. a 40 °C; b 50 °C; c 60 °C; d 70 °C; e 80 °C. Reaction temperature: 50 °C, pH: 7.0, substrate concentration: 20.0 gL−1. 254 × 203 mm (96 × 96 DPI)

The reusability of calcium alginate immobilized beads was also performed. Immobilized endo-β-1,4-xylanase beads showed around 80 and 60 % residual activity after second and third reaction cycle, respectively. After fourth and fifth cycle, only 49 and 18 % residual activity was noticed (Fig. 6). Similar effect was also observed when xylanase from B. pumilus SV-205 MTCC 9862 was immobilized on aluminum oxide pellets (Nagar et al. 2012). Excessive washing at every step prior to next reaction cycle may be responsible for enzyme leaching from gel beads, and therefore decrease in residual activity was noticed (Rehman et al. 2013). Accumulation and/or adsorption of product synthesized during the catalytic reaction could have also contributed in the reduction of residual activity as reported earlier (Adham et al. 2010). However, cycling efficiency of this immobilized endo-β-1,4-xylanase was found to be better with those reported previously when calcium alginate matrix was used for immobilization of cellulase from Bacillus subtilis TD6 (Andriani et al. 2012). However, manganese superoxide dismutase retained more than 70 % of its initial activity after 10.0 reaction cycles when immobilized on supermagnetic 3-APTES-modified SiO2-coated Fe3O4 nanoparticles (Song et al. 2012).

Surface morphology of the cross-sectional calcium alginate beads in the presence and absence of enzyme was examined under scanning electron microscope. Irregular surface morphology of the cross-sectional control beads was observed (Fig. 7a, c, e), whereas small irregular particles were observed on the surface of immobilized beads (Fig. 7b, d, f). Significant change on the surface morphology of immobilized laccase on TiO2–Montmorillonite complexes was also observed where TiO2–MMT complex showed a compact and continuous structure after enzyme immobilization (Wang et al. 2013b).

Conclusion

Endo-β-1,4-xylanase produced from a thermophilic strain of G. stearothermophilus KIBGE-IB29 was immobilized within calcium alginate support. The enzyme showed better immobilization yield and operational stability in order to hydrolyze the high molecular mass xylan. However, the enzyme immobilization properties can be improved further by immobilizing it on different supports for industrial purpose.

References

Adham NZ, Ahmed HM, Naim N (2010) Immobilization and stability of lipase from Mucor racemosus NRRL 3631. J Microbiol Biotechnol 20:332–339

Ahern TJ, Klibanov AM (1985) The mechanism of irreversible enzyme inactivation at 100 °C. Science 228:1280–1284

Al-Qodah Z (2006) Production and characterization of thermostable α-amylase by thermophilic Geobacillus stearothermophilus. Biotechnol J 1:850–857

Andriani D, Sunwoo C, Ryu HW, Prasetya B, Park DH (2012) Immobilization of cellulase from newly isolated strain Bacillus subtilis TD6 using calcium alginate as a support material. Bioprocess Biosyst Eng 35:29–33

Anwar A, Qader SAU, Raiz A, Iqbal S, Azhar A (2009) Calcium alginate: a support material for immobilization of proteases from newly isolated strain of Bacillus subtilis KIBGE-HAS. World Appl Sci 7:1281–1286

Arya SK, Srivastava SK (2006) Kinetics of immobilized cyclodextrin gluconotransferase produced by Bacillus macerans ATCC 8244. Enzyme Microb Technol 39:507–510

Bhalla A, Bansal N, Kumar S, Bischoff KM, Sani RK (2013) Improved lignocellulose conversion to biofuels with thermophilic bacteria and thermostable enzymes. Bioresour Technol 128:751–759

Bibi Z, Ansari A, Zohra RR, Aman A, Qader SAU (2014) Production of xylan degrading endo-1,4-β-xylanase from thermophilic Geobacillus stearothermophilus KIBGE-IB29. J Radiat Res Appl Sci 7:478–485

Bibi Z, Shahid F, Qader SAU, Aman A (2015) Agar-agar entrapment increases the stability of endo-β-1,4-xylanase for repeated biodegradation of xylan. Int J Biol Macromol 75:121–127

Blandine A, Macías M, Cantero D (2001) Immobilization of glucose oxidase within calcium alginate gel capsules. Process Biochem 36:601–606

Blandino A, Macías M, Cantero D (1999) Formation of calcium alginate gel capsules: influence of sodium alginate and CaCl2 concentration on gelation kinetics. J Biosci Bioeng 88:686–689

Blandino A, Macías M, Cantero D (2000) Glucose oxidase release from calcium alginate gel capsules. Enzyme Microb Technol 27:319–324

Collins T, Gerday C, Feller G (2005) Xylanases, xylanase families and extremophilic xylanases. FEMS Microbiol Rev 29:3–23

Cowan DA, Fernandez-Lafuente R (2011) Enhancing the functional properties of thermophilic enzymes by chemical modification and immobilization. Enzyme Microb Technol 49:326–346

Dalal S, Sharma A, Gupta MN (2007) A multipurpose immobilized biocatalyst with pectinase, xylanase and cellulase activities. Chem Cent J 1:16–20

Eijsink VGH, Bjørk A, Gåseidnes S, Sirevåg R, Synstad B, van den Burg B, Vriend G (2004) Rational engineering of enzyme stability. J Biotechnol 113:105–120

Elleuche S, Schröder C, Sahm K, Antranikian G (2014) Extremozymes-biocatalysts with unique properties from extremophilic microorganisms. Curr Opin Biotechnol 29:116–123

Fernandez-Lafuente R (2009) Stabilization of multimeric enzymes: strategies to prevent subunit dissociation. Enzyme Microb Technol 45:405–418

Garcia-Galan C, Berenguer-Murcia Á, Fernandez-Lafuente R, Rodrigues RC (2011) Potential of different enzyme immobilization strategies to improve enzyme performance. Adv Synth Catal 353:2885–2904

Gouda MK, Abdel-Naby MA (2002) Catalytic properties of the immobilized Aspergillus tamarii xylanase. Microbiol Res 157:275–281

Guzik U, Hupert-Kocurek K, Wojcieszyńska D (2014) Immobilization as a strategy for improving enzyme properties-application to oxidoreductases. Molecules 19:8995–9018

Kar S, Mandal A, Mohapatra PKD, Samanta S, Pati BR, Mondal KC (2008) Production of xylanase by immobilized Trichoderma reesei SAF3 in Ca-alginate beads. J Ind Microbiol Biotechnol 35:245–249

Kumar S, Dwevedi A, Kayastha AM (2009) Immobilization of soybean (Glycine Max) urease on alginate and chitosan beads showing improved stability: analytical applications. J Mol Catal B Enzym 58:138–145

Madakbaş S, Daniş Ӧ, Demir S, Kahraman VM (2013) Xylanase immobilization on functionalized polyaniline support by covalent attachment. Starch/Stärke 65:146–150

Mateo C, Palomo JM, Fernandez-Lorente G, Guisan JM, Fernandez-Lafuente R (2007) Improvement of enzyme activity, stability and selectivity via immobilization techniques. Enzyme Microb Technol 40:1451–1463

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugars. Anal Chem 31:426–428

Nagar S, Mittal A, Kumar D, Kumar L, Gupta VK (2012) Immobilization of xylanase on glutaraldehyde activated aluminum oxide pellets for increasing digestibility of poultry feed. Process Biochem 47:1402–1410

Ogasahara K, Ishida M, Yutani K (2003) Stimulated interaction between α and β subunits of tryptophan synthase from hyperthermophile enhances its thermal stability. J Biol Chem 278:8922–8928

Pedroche J, del Mar Yust M, Mateo C, Fernandez-Lafuente R, Girón-Calle J, Alaiz M, Vioque J, Guisán JM, Millán F (2007) Effect of the support and experimental conditions in the intensity of the multipoint covalent attachment of proteins on glyoxyl-agarose supports: correction between enzyme-support linkages and thermal stability. Enzyme Microb Technol 40:1160–1166

Pilipenko OS, Atyaksheva LF, Poltorak OM, Chukhrai ES (2007) Dissociation and catalytic activity of oligomer forms of β-galactosidases. Russ J Phys Chem A 81:990–994

Poltorak OM, Chukhrai ES, Kozlenkov AA, Chaplin MF, Trevan MD (1999) The putative common mechanism for inactivation of alkaline phosphatase isoenzymes. J Mol Catal B Enzym 7:157–163

Qader SAU, Aman A, Syed N, Bano S, Azhar A (2007) Characterization of dextransucrase immobilized on calcium alginate beads from Leuconostoc mesenteroides PCSIR-4. Ital J Biochem 56:158–162

Quiroga E, Illanes CO, Ochoa NA, Barberis S (2011) Performance improvement of araujiain, a cystein phytoprotease, by immobilization within calcium alginate beads. Process Biochem 46:1029–1034

Rehman HU, Aman A, Silipo A, Qader SAU, Molinaro A, Ansari A (2013) Degradation of complex carbohydrate: immobilization of pectinase from Bacillus licheniformis KIBGE-IB21 using calcium alginate as a support. Food Chem 139:1081–1086

Rodrigues RC, Berenguer-Murcia Á, Fernandez-Lafuente R (2011) Coupling chemical modification and immobilization to improve the catalytic performance of enzymes. Adv Synth Catal 353:2216–2238

Romo-Sánchez S, Camacho C, Ramirez HL, Arévalo-Villena M (2014) Immobilization of commercial cellulase and xylanase by different methods using two polymeric supports. Adv Biosci Biotechnol 5:517–526

Shah P, Sridevi N, Prabhune A, Ramaswamy V (2008) Structural features of penicillin acylase adsorption on APTES fuctionalized SBA-15. Micropor Mesopor Mat 116:157–165

Sharma M, Kumar A (2013) Xylanase: an overview. Br Biotechnol J 3:1–28

Song C, Sheng L, Zhang X (2012) Preparation and characterization of a thermostable enzyme (Mn-SOD) immobilized on supermagnetic nanoparticles. Appl Microbiol Biotechnol 96:123–132

Sterner R, Kleemann GR, Szadkowski H, Lustig A, Hennig M, Kirschner K (1996) Phosphoribosyl anthranilate isomerase from Thermotoga maritima is an extremely stable and active homodimer. Protein Sci 5:2000–2008

Tanaka H, Chinami M, Mizushima T, Ogasahara K, Ota M, Tsukihara T, Yutani K (2001) X-ray crystalline structures of pyrrolidone carboxyl peptidase from a hyperthermophile, Pyrococcus furiosus, and its Cys-free mutant. J Biochem 130:107–118

Viikari L, Alapuranen M, Puranen T, Vehmaanpera J, Siika-Aho M (2007) Thermostable enzymes in lignocellulose hydrolysis. Adv Biochem Eng Biotechnol 108:121–145

Wang Q, Peng L, Li G, Zhang P, Li D, Huang F, Wei Q (2013a) Activity of laccase immobilized on TiO2-montmorillonite complexes. Int J Mol Sci 14:12520–12532

Wang Y, Feng S, Zhan T, Huang Z, Wu G, Liu Z (2013b) Improving catalytic efficiency of endo-β-1,4-xylanase from Geobacillus stearothermophilus by directed evolution and H179 saturation mutagenesis. J Biotechnol 168:341–347

Wojcieszyńska D, Hupert-Kocurek K, Jankowska A, Guzik U (2012) Properties of catechol 2,3-dioxygenase from crude extract of Stenotrophomonas maltophilia strain KB2 immobilized in calcium alginate hydrogels. Biochem Eng J 66:1–7

Yeoman CJ, Han Y, Dodd D, Schroeder CM, Mackie RI, Cann IK (2010) Thermostable enzymes as biocatalysts in the biofuel industry. Adv Appl Microbiol 70:1–55

Acknowledgments

This research was funded and supported by The Karachi Institute of Biotechnology and Genetic Engineering (KIBGE), University of Karachi, Pakistan.

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by F. Robb.

Rights and permissions

About this article

Cite this article

Bibi, Z., Qader, S.A.U. & Aman, A. Calcium alginate matrix increases the stability and recycling capability of immobilized endo-β-1,4-xylanase from Geobacillus stearothermophilus KIBGE-IB29. Extremophiles 19, 819–827 (2015). https://doi.org/10.1007/s00792-015-0757-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00792-015-0757-y