Abstract

The feasibility of producing colloidal silver nanoparticle reference materials and silver nanoparticle spiked reference matrix materials was investigated. Two concentrations of PVP-coated silver nanoparticle dispersions were evaluated and used to spike chicken meat, with the aim of producing a set of reference materials to support the development of analytical methods for the detection and quantification of nanoparticles in food. Aqueous silver nanoparticle (AgNP) dispersions were evaluated for their homogeneity of mass fraction and particle size and found sufficiently homogeneous to be used as reference materials. Stability studies at 4 °C, 18 °C and 60 °C demonstrated sufficient short- and long-term stability, although particle size decreases in a linear fashion at 60 °C. The AgNP dispersions were characterized for total Ag mass fraction by ICP-OES, dissolved Ag content by ultrafiltration-ICP-MS, as well as AgNP particle size by dynamic light scattering, transmission electron microscopy (TEM) and gas-phase electrophoretic molecular mobility analysis. Chicken breasts were homogenized by cryo-milling and spiked with aqueous AgNP dispersions. Rapid freezing over liquid nitrogen resulted in homogeneous and stable materials. The spiked chicken materials were characterized for their total Ag mass fraction by neutron activation analysis and for the AgNP particle size by TEM and single-particle inductively coupled plasma mass spectrometry. The observed differences in particle sizes between the spiked chicken samples and the original silver dispersions indicate relevant matrix effects. The materials demonstrate that production and characterization of reference materials for the detection and quantification of silver nanoparticles in meat are feasible, but challenges especially in assessing stability and having sufficiently precise methods for assessment of homogeneity and stability remain.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Recent regulation in the European Union requires food ingredients to be identified when they are present in nano-form [1]. Enforcement of this directive will, eventually, also require checking prepared foodstuff for the presence of nanoparticles (NPs), but no validated methods are currently available to this end.

Reliable detection of nanoparticle content in complex matrices such as food is a daunting task given the multiscale structured nature of most foodstuffs. Providing proof of principle of the feasibility to detect and quantify NPs in complex matrices is hence urgently needed to support the legislation and further improve consumer confidence. Along with method development and validation of detection methods, demonstration of the feasibility of the development of reference materials (RMs) is another essential goal, to enable food agencies to perform valid measurements. These two objectives were pursued by the project NanoLyse of the European Commission’s 7th Framework Program for Research and Development (www.nanolyse.eu).

Silver nanoparticle (AgNPs)-impregnated cutting boards, refrigerators and storage boxes for food are already marketed, allegedly rendering the materials antimicrobial and improving durability of food stored in such materials [2]. Migration of these AgNPs into foodstuffs has been demonstrated [3, 4].

Therefore, AgNPs were chosen as one model particle in this study. Chicken breast was chosen as matrix simulating the transfer of AgNPs from impregnated cutting boards or food packaging to food. The leanness of this meat was expected to minimize problems in homogenization and mixing.

Production of a reference material (RM) comprises the following steps. [5]:

-

(a)

production planning

-

(b)

processing, i.e., the physical manufacturing and bottling of the material

-

(c)

homogeneity assessment

-

(d)

assessment of stability during transport

-

(e)

assessment of stability during storage

-

(f)

performing tests for assigning property values

It is important that the degree of homogeneity and stability to be achieved depends on the precision and accuracy of the methods used. Variations due to inhomogeneity and stability should not contribute to the overall variation of results. As no general, absolute degree of homogeneity can be stated, the definitions of “reference material” and “certified reference material” require “sufficient homogeneity and stability” [5]. While any RM needs to be sufficiently homogeneous and stable, only certified reference materials (CRMs) need to have values assigned using a metrologically valid procedure, which are then documented on a certificate of analysis. This means that any homogeneous and stable material can serve as an RM, but only those with assigned values can be CRMs.

This list of steps highlights the inherent problem in developing completely novel reference materials: Processing control, homogeneity testing, stability testing and characterization require validated analytical methods, but method validation requires reference materials. Therefore, specific challenges exist for “first of its kind” RMs, which mean that not in all cases all production steps can be performed in an optimal way. Subsequent materials can build upon that, leading to a stepwise improvement of analytical methods as well as RMs.

At the start of the project, no methods for the detection and quantification of nanoparticles in food were available. Partly as a result of the project, several methods have been published, including single-particle (sp) inductively coupled plasma mass spectrometry (ICP-MS) [6], solid-sampling atomic absorption spectrometry (ss-AAS) [7] and field-flow fractionation coupled with single-particle or conventional ICP-MS [8]. In addition, variation of atomization temperature was reported to allow a screening for Ag nanoparticles in fish [9].

Currently, no RMs for the detection and quantification of nanoparticles in food are commercially available, although two certified reference materials consisting of Ag dispersions have been released [10, 11]. Stability is one of the critical steps, as AgNPs are known to be susceptible to dissolution [12, 13], but all other steps are of no less importance. The feasibility of producing RMs consisting of silicon dioxide NP dispersion and silicon dioxide NP spiked tomato soup was described in an earlier paper [14]. This paper describes processing and characterization of two aqueous Ag dispersions and two AgNP-spiked chicken meat RMs, together with the challenges caused by the fact that methods were developed simultaneously with the RM.

Concept

Similar to the materials containing silica particles [14], two kinds of AgNP materials were developed. AgNPs in dispersion would act as training samples for initial method development and calibration and determination of recovery rates. These dispersions would also act as a reference for results obtained on the food materials to identify biases of the methods determining AgNPs in meat. Ideally, the particle size distribution in the neat suspensions would match the one found in the meat, thus simultaneously demonstrating the absence of method bias and changes during processing. In case of differences, additional efforts in method development are necessary to confirm that the differences are not a method bias. Changes of AgNPs during processing would not make the production of an RM impossible: Any value assignment has in this case to rely on measurements alone without the additional confirmation from the spike.

Ag mass fractions far above of what can be expected to migrate from contact materials (0.1 g/kg and 0.5 g/kg) were used. The reason for these high concentrations was that the main focus of the project was to develop methods that are also able to extract the AgNPs from the sample without any change in particle size distributions. Potential changes in size distribution are easier detectable at higher concentrations than close to the limit of detection. This rather high Ag mass fraction also had the effect that potential contamination in blanks in the methods for total Ag is rendered irrelevant compared with the Ag contained in the sample.

Processing

AgNP dispersions

Two batches of 15 L AgNP suspensions with silver mass fractions of 0.2 g/kg and 1 g/kg and a nominal AgNP diameter in the range of (42 ± 10) nm were purchased from NanoGap (Milladoiro, Spain), catalogue number NP Ag-2103 (note: the catalogue number refers to PVP-stabilized Ag and is used by the company for several Ag concentrations). The silver particles are dispersed in water and stabilized with polyvinylpyrrolidone (PVP; average molar mass 10000 kg/mol; mass ratio PVP/Ag 0.05–0.06). Each suspension was mixed by stirring and ampouled into 25 mL, pre-cleaned and dried amber glass ampoules using an automated ampouling machine (ROTA, Wehr, Germany). Ampoules were flushed with argon and flame-sealed after filling.

About 600 ampoules of 25 mL of each concentration level were produced and labeled NanoLyse03 (0.2 g/kg) and NanoLyse04 (1 g/kg). As light may cause material alteration, care was taken to minimize exposure to light throughout the process, e.g., by covering glass vessels with aluminum foil.

AgNP-spiked chicken meat

Preservation issues

Homogenized chicken meat is prone to be metabolized by bacteria and degraded by enzymes. Additionally, the level of oxygen in the meat increases as well as the specific surface of the material upon milling. Thus, preservation is a prerequisite to prevent degradation of matrix and particles. Four different strategies were considered:

-

Steam water spray sterilization: Preliminary tests treating the chicken paste with 121 °C for 20 min in an autoclave (AR 092, JBTC, Sint Niklaas, Belgium) led to denaturation of the meat and phase separation, resulting in a solid piece of meat and water. In addition, it was deemed possible that Ag nanoparticles dissolve at high temperatures as indicated by data obtained for dispersions at 60 °C as presented in section “Assessment of stability”. Autoclaving was hence found unsuitable for the stabilization of the materials.

-

AgNP addition (in situ sterilization): As AgNPs have antimicrobial effects, the action of spiking itself might prevent bacterial growth. Although the colloidal silver chosen has a reduced antimicrobial activity compared with other products (NanoGap, personal communication), microbial testing (plating of Escherichia coli CIP 106878) showed no propagation of bacteria upon incubation for 96 h at 37 °C. Nevertheless, even the biocidal activity of the silver did not prevent the enzymatic hydrolysis causing matrix deterioration and foul smell. Therefore, this method was deemed insufficient to ensure stabilization of the material.

-

γ-irradiation: A test batch was irradiated on a GS6000 pallet irradiator at Synergy Health Ede (Etten-Leur, The Netherlands) with an average dose of 10.8 kGy. Possible bacterial contamination was deactivated, but nevertheless, a distinct fouling smell developed after a short time, as also γ-irradiation (10.8 kGy) is unable to stop the enzymatic hydrolysis. The production of organic radicals produced by the γ-irradiation may even have accelerated the degradation. Therefore, γ-irradiation was found unsuitable as means of preservation, too.

-

Freezing: freezing the sample does not kill bacteria nor does it completely denature enzymes, but it slows down any metabolic activity. The downside is potential agglomeration/aggregation upon freezing, as collapse of the suspension was observed for AgNP dispersions upon freezing (see section “Assessment of stability”). However, it was expected that the viscosity of the meat paste, the stabilization of the AgNPs by the proteins and the fast freezing would prevent agglomeration of Ag particles. This expectation was confirmed experimentally (see section “Assessment of stability”). Therefore, shock-freezing was chosen for stabilization of the materials.

-

Lyophilization: Although lyophilization is a common form of preservation, it was not considered for this project as it offers few advantages over freezing. If freezing itself leads to agglomeration, lyophilization would be as affected as freezing without lyophilization. Dissolution of AgNPs requires diffusion, so dissolution in frozen samples is already very much reduced. Additional problem of reconstitution, which again may lead to dissolution of AgNPs, was believed to more than compensate the advantage of milder storage temperatures for lyophilized samples, although recent work demonstrated the feasibility of producing lyophilized AgNP dispersions [11].

Processing steps

6 kg fresh chicken breast filets were obtained from a local butcher. The meat was delivered in 1-kg batches in polystyrene trays and a polyethylene wrap as packaging and was processed at the day of delivery. The meat was cut manually in cubes of approximately 1–2 cm3 using ceramic knifes and polyethylene cutting boards to prevent metal contamination. The meat cubes were dropped into liquid nitrogen and then milled on a titanium vibrating cryo-mill (PALLA VM-KT, Humboldt-Wedag, Cologne, Germany) to obtain a powder-like product. Temperature in the mill was monitored, and when the mill reached −100 °C, milling was stopped and the mill was cooled down again to −196 °C to ensure freezing conditions until all material was milled. This process resulted in a paste with a homogeneous texture without lumps upon thawing. This paste was also used as blank material for control purposes for several methods.

Water uptake capacity of the chicken homogenate was tested to prevent phase segregation after adding of the aqueous silver dispersion. Addition of 1 part of water to 2 parts of chicken paste turned out to be feasible.

A PVP-stabilized AgNP dispersion with an Ag mass fraction of 15 % was obtained from NanoGap (Milladoiro, Spain; catalogue number Ag-2103), and the particle size distribution was confirmed to match the particle size distributions of NanoLyse03 (mean diameter of 70 nm) and NanoLyse04 (mean diameter of 65 nm) by dynamic light scattering (DLS). The dispersion was diluted with deionized water (Millipore, Molsheim, France) to mass fractions of 0.3 g/kg and 1.5 g/kg, respectively, for the processing of the two batches of spiked chicken material. The appropriate amount of silver dispersions were added in five steps to the chicken paste while continuously stirring using a kitchen robot (Kenwood, Havant, United Kingdom), resulting in nominal Ag mass fractions of 0.1 g/kg and 0.5 g/kg. Total amounts used were 479 g of 0.3-g/kg dispersion to 963 g chicken paste (NanoLyse13) and 621 g of 1.5-g/kg dispersion to 1243 g chicken paste (NanoLyse14). Addition of the AgNP dispersion changed the color of the meat from yellowish into a green-brownish color. After addition of the AgNP dispersions, mixing continued until no differences in paste consistency and color could be observed anymore, which was achieved after mixing for additional 15 min at 5 revolutions per minute (rpm). The homogeneous paste was filled into 2-mL Nunc™ plastic cryo-vials (VWR, Leuven, Belgium) by means of a 100-mL syringe. The materials were labeled as NanoLyse13 and NanoLyse14, respectively. Each vial contains about 2 mL spiked chicken homogenate. A flowchart of the processing of NanoLyse13 paste is given in Fig. 1.

Samples were placed into racks and shock-frozen above liquid nitrogen in large Dewar vessels (temperature below −130 °C) to avoid segregation and agglomeration. Samples were stored above liquid nitrogen (temperature below −130 °C) until dispatch to the project partners. Dispatch was done on dry ice.

Measurement and statistical methods

More instrument parameters and sample preparation are given in the electronic supplementary material.

Ultrafiltration-ICP-MS on the silver dispersions

Ultrafiltration was chosen for the determination of dissolved Ag in NanoLyse03 and NanoLyse04. The determination of the silver ion concentration in the respective dispersions was done in two steps:

-

Separation of solute from colloids using ultrafiltration: For the separation of Ag ions, three samples of each of the two dispersions were randomly chosen and aliquoted (5 mL, two of each sample) into ultrafiltration spin columns (molecular weight cut-off of 5000 u; VS0611, PES, Sartorius, Göttingen, Germany). The tubes were centrifuged at 5000 rpm at 20 °C for 15 min.

-

Filters were not rinsed to avoid dissolution of AgNPs.

-

Analysis of the filtrate by ICP-MS (see section “ICP-MS on ultrafiltrates”).

Dynamic Light Scattering on the Silver Dispersions

The DLS measurements for homogeneity and stability testing of the Ag suspensions were performed using a Malvern Zetasizer Nano ZS (Malvern Instruments Ltd, Malvern, UK). The scattering angle was 173°, the measuring position was 4.65 mm inside the cuvette, and the measuring temperature was set to 25 °C. The nonnegative least square, general purpose method (NNLS) was used for the determination of the particle diameter (x NNLS), as the dispersions contain the stabilizing PVP causing a bimodal size distribution.

DLS measurements at three different laboratories using different instruments were performed for the characterization study. Different signal evaluation algorithms (correlation analysis, frequency analysis, cross-correlation) were used ensuring a robust mean value. Instruments used were two Malvern Zetasizer Nano ZS (Malvern Instruments Ltd, Malvern, UK), a Horiba LB-550 (Horiba, Longjumeau, France), a Malvern 41700C (Malvern Instruments Ltd, Malvern, UK) and an LS Instruments 3D (LS Instruments, Fribourg, Switzerland) using NMR as well as Pyrex tubes. On each of 3 days, one ampoule of NanoLyse03 and NanoLyse04 were measured in duplicate. A certified reference material for particle size (ERM-FD100; IRMM, Geel, Belgium) was measured on the first day to assure proper instrument performance.

Inductively coupled plasma optical emission spectrometry (ICP-OES) on the silver dispersions

The total Ag mass fraction of the silver dispersions was determined by ICP-OES. A Thermo Iris Intrepid II XDL ICP-OES was fitted with a 2-mL/min micro-concentric nebulizer and cyclonic spray chamber (Thermo Scientific, Franklin, MA, USA); 1350 W RF power was applied, and nebulizer and auxiliary gas flows were 0.65 mL/min and 0.5 mL/min, respectively. The plasma was viewed axially, with the Ag emission line at 328.068 nm used for measurement, and the line at 338.289 nm monitored to check for potential interferences.

ICP-MS on ultrafiltrates

The Ag concentration of the ultrafiltrates was determined by ICP-MS. An Agilent 7500ce ICP-MS (Agilent Corp, Santa Clara, US) was fitted with 400 µL/min micro-concentric nebulizer (Glass Expansion, Melbourne, Australia), and Scott jacketed spray chamber maintained at 10 ºC. Nebulizer argon gas flow was 0.89 L/min with 0.20 L/min makeup, and 1350 W plasma RF power was applied. Six replicate measurements were performed on 107Ag and 109Ag, with 2 s dwell time. Measurements were performed using external calibration with 3 standards in the range 1–5 µg/L.

ICP-MS on spiked chicken meat

Homogeneity testing of the total Ag mass fraction of the chicken samples was outsourced to ALS Czech Republic (Prague, Czech Republic). Samples were homogenized and mineralized by an acid/hydrogen peroxide mixture prior to quantification with ICP-MS. Measurements were performed under the laboratory’s scope of accreditation to ISO 17025.

k0-Neutron activation analysis (k0-NAA) on spiked chicken meat

The k0-NAA method avoids potential problems of digestion and precipitation, which makes it a very suitable method for the determination of total mass fractions of elements. Determination of the total Ag mass fractions of the spiked chicken homogenates (NanoLyse13 and NanoLyse14) was outsourced to the Institut Jozef Stefan (Ljubljana, Slovenia). Single measurements on two ampoules per material were performed. Aliquots were sealed into a pure polyethylene ampoule (Kartell, Noviglio Italy) and irradiated together with a standard Al-0.1%Au (IRMM-530R, IRMM, Belgium) for 180 min with a thermal neutron flux of 1.1 × 1012 cm−2 s−1 and measured after 1 day and 6–8 days cooling time using an absolutely calibrated HPGe detector with 45 % relative efficiency. For element concentrations and effective solid angle calculations, the software package Kayzero (www.kayzero.com) for Windows was applied.

Transmission Electron Microscopy (TEM) on dispersions and spiked chicken meat

TEM data on the silver dispersions were obtained at the University of York, JEOL Nanocentre using JEOL JEM 2011 TEM operating at 200 kV. The microscope was equipped with a digital camera (Gatan 794) and an energy dispersive x-ray spectroscopy (EDX) system (Thermo Fisher NS7 system operated by NSS112E NORAN).

Object-based image analysis software (eCognition Architect, version 8.7.2, Trimble, www.ecognition.com) with a specially designed application facilitating the measurement of NPs in complex matrices (Centre for GeoInformatics, Paris-Lodron-University, Salzburg, Austria) was used for sizing of the particles. Measurements were performed in the scope of the validation study reported in [15].

The TEM experiments were conducted analyzing images of uniform area (1.6 µm × 1.6 µm) in each test. A relatively large area was chosen to capture as many particles as possible. All the size values are reported as median of the equivalent circle diameter (ECD), i.e., the diameter of a circle with the same area. The cut-off value for the particle size was estimated as 80 pixels based on background noise during the image analysis, which was an equivalent of 16 nm ECD. For the particle numbers in the sample, mean values are given (in particles per replicate).

Gas-phase electrophoretic molecular mobility analysis (GEMMA) on dispersions

Measurements on the neat AgNP dispersions were performed by GEMMA using a nano electrospray unit type 3480, coupled to a nano differential mobility analyzer (DMA) unit type 3080 and a condensation particle counter type 3025A (TSI, Shoreview, MN, USA).

Three measurement series consisting of 10 measurements each were performed for material NanoLyse03, and two measurement series consisting of 5 measurements each were performed for material NanoLyse04.

Single-particle ICP-MS (sp-ICP-MS) on spiked chicken meat

sp-ICP-MS measurements were performed in two laboratories. The method developed by Peters et al. [6] was used by one laboratory.

The second laboratory used a slightly modified protocol as described by Loeschner et al. [8].

Study designs and statistical methods

Approach for the assessment of homogeneity

The data obtained for the homogeneity of the particle diameter by one method were subsequently used as estimate of the between-unit variation for the particle diameter for all methods (note: the term “unit” refers in this case to one packaging unit, be it an ampoule or vial).

Ten ampoules each of NanoLyse03 and NanoLyse04 (neat dispersions) were selected from the stock using a random stratified sampling scheme covering the whole batch. Each ampoule was analyzed in triplicate for particle size by DLS and for total Ag content by ICP-MS.

Ten vials of NanoLyse13 and NanoLyse14 were selected using a random stratified scheme, and two measurements of the total Ag content were performed on each sample.

For the assessment of between-unit standard deviation, results were evaluated using one-way analysis of variance as described in [16]. Within-unit standard deviations (s wb, equal to the method repeatability) and between-unit standard deviation (s bb) were calculated. In addition, the maximum heterogeneity that could be hidden by method repeatability (\(u^{*}_{\text{bb}}\)), the “limit of detection of the homogeneity study,” was calculated as described in [17].

Number-based concentration values and the particle size distribution in NanoLyse13 and NanoLyse14 were obtained by TEM on only two vials per material. Three subsamples per vial and 10 TEM images per subsample were taken under repeatability conditions. The number of vials (2) is clearly insufficient for confirming the homogeneity of the particle number concentration, but given the time required for sample preparation and image evaluation by TEM, performing more measurements was not feasible.

Approach for the assessment of stability

For the aqueous silver nanoparticle systems (NanoLyse03, NanoLyse04), potential degradation during transport was assessed using an isochronous scheme [18] with testing after 0, 1, 2 and 4 weeks of storage at 4 °C or 60 °C.

Stability of the dispersions during storage at 18 °C (reference temperature 4 °C) was tested using an isochronous scheme with time points of 0, 2, 6, 8, 16, 24, 32 and 46 weeks. On each time point, 2–4 measurements were performed.

The stability assessment had a different setup for NanoLyse13 and NanoLyse14 as the samples are stored above liquid nitrogen and are shipped on dry ice. These are already the safest conditions, and no reference conditions exist, precluding the use of isochronous stability studies. The materials were inspected by TEM on two occasions within 6 months. The first set of experiments was conducted on 10 different days spread over 20 working days. Ten vials per material were investigated in duplicate and 10 TEM images recorded per vial taken. The second set of experiments was performed 6 months after the first. Two vials per material were measured in duplicate. All sample preparation and imaging for the measurements of the second set of results were carried out on 1 day each, and 3 images were taken per replicate.

Assessment of homogeneity

Aqueous AgNP dispersions

The homogeneity of the Ag mass fractions was determined by ICP-OES. The procedure would in principle also measure dissolved Ag, but as shown in section Total and ionic Ag mass fraction, virtually all silver is present in particulate form. All within-unit as well the between-unit standard deviations are smaller than 1 %. For NanoLyse04, the mean square value of the between-unit standard deviation is smaller than the one of the within-unit standard deviation, preventing a calculation of the between-unit standard deviation, but the good repeatability demonstrates that also this material is sufficiently homogeneous to serve as reference material.

The homogeneity of particle size was determined by DLS. All results of the homogeneity assessment are shown in Table 1. The variations for NanoLyse04 are about 5 times higher than for NanoLyse03, but the between-unit standard deviations are sufficiently small to make NanoLyse03 and NanoLyse04 suitable as reference materials.

AgNP-spiked chicken meat

Total Ag mass fraction was determined by ICP-MS. s wb, s bb and \(u^{*}_{\text{bb}}\) were calculated as described for the neat suspensions, and the results are shown in Table 1. For both materials, the method repeatability limits the detectable inhomogeneity at about 2 %, with the calculated between-unit standard deviation for NanoLyse13 below this value (0.8 %) and for NanoLyse14 slightly above this value (2.3 %). The results of the homogeneity study show that the mixing was sufficient to distribute the AgNPs sufficiently homogeneous in the meat matrix. Unless de-mixing of smaller and larger particles or agglomeration of particles occurred, the particle diameters should therefore be sufficiently homogeneous as well.

Because of the relatively low number of particles per image, the numbers of particle per image should, for a perfectly homogeneous material, follow a Poisson distribution. Major deviations from this would indicate significant unexpected effects in the samples. The data obtained by TEM follow approximately a Poisson distribution, indicating the absence of major differences between the two vials. Due to the low number of vials and the low power of tests assessing distributions, this test could only find major inhomogeneity. So it is mainly the homogeneity of the Ag mass fractions that indicates the suitability of the materials as reference materials.

Assessment of stability

Aqueous AgNP dispersions

The materials were analyzed by DLS using NNLS. The relative standard deviations of the equivalent hydrodynamic diameter of NanoLyse03 and NanoLyse04 were below 3 % for the materials stored at 4 °C, thus showing that the data are of sufficient quality to make meaningful assessments about the stability of the materials. Both slopes were statistically different from zero at a 99 % confidence level for the studies at 60 °C. Thus, the materials are not stable at 60 °C over longer periods of time, but the change at 60 °C (−2.4 nm/week for NanoLyse03 and 1.3 nm/week for NanoLyse04) is relatively small. Dispatch, the only occasion when the materials could be exposed to 60 °C, takes usually 1–2 days, so potential change of the particle sizes during dispatch is technically insignificant. The change at 60 °C also indicates that an autoclaving step (121 °C, 20 min) of the spiked chicken is not appropriate. Freezing of selected samples of the neat dispersions at −70 °C for 10 min and resulted in irreversible sedimentation, showing that the neat dispersions should not be frozen at all.

The slope of the regression line of the particle diameter of the long-term stability was not statistically different from zero on a 99 % confidence interval, demonstrating sufficient stability for storage at room temperature. Uncertainties of stability for the particle diameter for storage of 2 years were estimated as 0.5 % (NanoLyse03) and 0.7 % (NanoLyse04), respectively.

AgNP-spiked chicken meat

No significant difference was observed between the measurements at the different time points within the standard deviation of the measurement (5 nm). Also, the particle number values obtained by TEM were constant with about 1 particle per µm2 and 5 particles per µm2 for NanoLyse13 and NanoLyse14, respectively. The relatively high variation of the results does not allow a very accurate assessment, but the results demonstrate that the variation introduced to a potential change is negligible compared with the method precision. The materials are therefore sufficiently stable under the chosen storage conditions over the period of nearly 1 year.

Characterization

Aqueous silver suspensions NanoLyse03 and NanoLyse04

Total and ionic Ag mass fractions

For the aqueous silver nanoparticle systems (NanoLyse03, NanoLyse04), characterization of the total silver mass fraction is based on data from the homogeneity study.

Ultrafiltration resulted in clear and colorless filtrates, which were analyzed by ICP-MS for Ag, obtaining Ag concentrations of (0.38 ± 0.04) mg/L for NanoLyse03 and (1.73 ± 0.21) mg/L for NanoLyse04. These concentrations are negligible compared with the total Ag mass fractions, demonstrating that virtually all silver is present in (nano)particulate form. Filter techniques always come with the compromise of material adsorption to the filter, so material loss can be anticipated, leading to potential underestimation of the amount of ionic silver. Another reason for potential underestimation of the ionic silver content is the decision not to rinse the filters, which may lead to incomplete elution. On the other hand, the filters taken had a molecular weight cut-off of 5000 g/mol and may also permit the migration of Ag clusters (Ag2–10) and particles (Ag25–50) through the filters, potentially leading to an overestimation of the amount of ionic silver. Considering the low level found (one 1000th of the total mass fraction), these potential errors are not expected to change the assessment of negligible ionic silver in the samples.

Particle size by DLS

Representative particle size distribution graphs for silver dispersions by DLS are shown in Fig. 2. A bimodal size distribution is clearly visible for the silver dispersions. The first peak is attributed to the stabilizing PVP, as measurement results on the PVP used provided by NanoGap show one mode at 4.7 nm in the volume-weighted distribution, whereas the second is attributed to the Ag particles covered by the stabilizing polymer. If the first peak is indeed PVP, this implies a significant excess of PVP in the sample.

The characterization results are shown in Table 2. The variation among instruments and methods is considerable. Although the different evaluation algorithms (correlation analysis, cross-correlation analysis, frequency analysis) certainly contribute to this variation, it is interesting that for NanoLyse03, the highest and the lowest results were obtained on the same type of instrument (Malvern Zetasizer NanoZS). Instrument settings and sample preparation therefore still contribute significantly to the variation of results.

Particle size of the materials as determined by field-flow fractionation (FFF) was reported by Loeschner et al. [19]. They found a particle diameter for single particles between 30 nm and 45 nm, with doublets, triplets and quadruples and some larger clusters contributing to the tailing in the size distribution toward higher sizes. The significantly lower particle size obtained for singlets by FFF compared with the aggregate results by DLS suggests that the DLS data mainly reflect the doublets/triplets observed in the samples.

Particle size by TEM

Particle size defined as median ECD was taken from the method validation study [15]. Measurements were spread over 10 different days, performing two replicate analyses per day consisting of evaluation of 10 images each. Average number of particles per image was 4.6 (NanoLyse03) and 17.6 (NanoLyse04). Representative images are shown in Fig. 3. No particles were found in the blank material.

The results by TEM are in agreement with the results by FFF as reported for singlets in [19], even if the size of the latter was calibrated with polystyrene latex particles.

Particle size by GEMMA

The two results for NanoLyse03 and NanoLyse04 are not statistically significantly different on a 95 % confidence level. The diameters as determined by GEMMA are about 30 % larger than those obtained by TEM, possibly due to incomplete desorption of the stabilizing PVP and that the sizing was done at atmospheric pressure. Representative GEMMA spectra of NanoLyse03 and NanoLyse04 can be seen in Fig. 4, showing also the width of the particle size distribution.

Small nonvolatile sample components like the stabilizing agent PVP can interfere with the measurement in the nano DMA (PVP-encrusted AgNPs appear larger). This is found particular if the number of particles per volume is relatively low. For NanoLyse04, the situation is unbiased, while for NanoLyse03, the peak shape is clearly altered and shifted toward a higher particle size with very low signal-to-noise ratio. An evaluation of the blank signal did not show any significant response in the size range of interest.

Chicken material NanoLyse13 and NanoLyse14

Total Ag mass fraction

Natural Ag concentration in meat is generally below 1 mg/kg [20], which is negligible compared with the content in the spiked material. As the meat was from a local butcher, i.e., fit for consumption, there was no risk of significantly increased Ag mass fractions in the blank meat, and no measurements on the blank meat were performed. The total silver mass fraction of NanoLyse13 and NanoLyse14 was determined by k0-neutron activation analysis. The obtained values agree with the concentrations of the added spike.

Agglomeration state and particle size by TEM

The degree of agglomeration of Ag nanoparticles was investigated using TEM; representative images are given in Fig. 5. The images show individual particles rather than large aggregates or agglomerates, confirming that the meat matrix protects against agglomeration. However, the results must be taken with caution, as a selection bias in the sample preparation might lead to an underrepresentation of agglomerates in the images. The material was also checked against silver nanoparticle dissolution by means of TEM-EDX. Spectra taken in close vicinity to the nanoparticles matched the EDX of the blank, demonstrating the absence of severe dissolution within the limits of detection of the method.

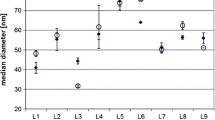

Particle size defined as median ECD was taken from the method validation study [15]. Measurements were spread over 10 different days. On each day, two measurements, each consisting of 10 images, were performed, on one vial each of NanoLyse13 and NanoLyse 14 (in total, 10 vials each of NanoLyse13 and NanoLyse14). Each image contained on average 3.3 particles (NanoLyse13) and 8.8 particles (NanoLyse14), respectively. The particle sizes in meat were slightly smaller than observed for the aqueous suspensions. The difference was caused by a change in the particle distribution curve: Whereas the pure suspensions show a nearly triangular particle size distribution (with a tail at higher particle sizes), the size distribution of particles in meat is characterized by a sharp peak and a significant tailing, see Fig. 6.

The difference between the neat AgNPs and the food spikes might be caused by a partial dissolution of the AgNP surface, maybe triggered by the high affinity between the sulfur/amine compounds of the meat proteins and the silver of the particles. As the surface can be expected to be oxidized, an instant release of silver ions may result in the decrease in the particle size. Such ion release was, however, not confirmed by dedicated EDX measurements (see section “Assessment of stability”). This may be due to the detection limit of the method being typically at 1 g/kg. Another explanation for the difference might be a selection bias in the sample preparation procedure for the meat samples. No preference can currently be given for any of these explanations. A third possibility is that there seems to be a low-size cut-off for the measurements in chicken, which may distort the distributions. All characterization data are summarized in Table 3.

Particle size by sp-ICP-MS

Median particle diameters for NanoLyse13 and NanoLyse14 as measured by one laboratory using the method described in [6] were (51.0 ± 2.6) nm (NanoLyse13) and (50.3 ± 1.5) nm (NanoLyse14) (averages and standard deviations of 6 measurements each). Size standard deviations of the underlying distributions were rather broad (22 nm) and asymmetric with a long tail of particles of up to 150 nm. The second laboratory using the method described in [8] reported a median particle diameter of 35 nm from two measurements on NanoLyse13. This difference of 15 nm is equivalent to the between-laboratory standard deviation for sp-ICP-MS found in a recent intercomparison [21].

Mass fraction of particulate silver was determined simultaneously with the particle size. These were (0.026 ± 0.005) g/kg (NanoLyse13) and (0.12 ± 0.04) g/kg (NanoLyse14), which is about 25 % of the added amount. This low recovery of total Ag is confirmed by the results of the second laboratory, which reported 0.019 g/kg, i.e., about 20 % recovery. This low finding is not due to inhomogeneity, as digestion by aqua regia and subsequent quantification by ICP-MS yielded the target values of 0.1 g/kg and 0.5 g/kg. A part of the explanation can be dissolution of the particle, as one laboratory reported a higher background, indicating the presence of ionic silver in the spiked samples. Another hypothesis is that a part of the silver nanoparticles is no longer available for sp-ICP-MS analyses after some time. One hypothesis is that a part of the silver reacts with chloride or sulfur and forms an insoluble deposit of AgCl or Ag2S, which grow together to form AgCl aggregates [6].

Simulated value assignment

The materials are not certified reference materials (CRMs), so in principle, no value assignment is necessary. However, to assess the feasibility of producing (C)RMs, a tentative value assignment was performed to get an idea about the uncertainties that could be expected in the production of a CRM.

As is common practice for certified reference materials [22], uncertainty contributions of homogeneity (u bb), long-term stability (u lts) and characterization (u char) were combined and multiplied with a coverage factor of k = 2 to obtain an idea of which uncertainties could be achieved for a value assigned to a CRM. Uncertainties were estimated as follows:

All uncertainties of homogeneity (u bb) were based on the larger value of s bb or \(u^{*}_{\text{bb}}\) for each of the suspensions. The homogeneity data determined from DLS for NanoLyse03 and NanoLyse04 were also used as contributions for GEMMA and TEM. Uncertainty of homogeneity for the AgNP mass fractions in the meat was also used as uncertainty contribution for the particle diameter.

Uncertainty of long-term stability for particle diameter in the dispersions was in all cases based on the u lts estimated for DLS for a storage period of 2 years. These uncertainties were also used as u lts for the two meat materials. This maybe an underestimation, but given the current storage at below −130 °C, dissolution and diffusion of Ag ions and AgNPs can be regarded negligible.

Uncertainties of characterization were in all cases estimated as the standard error of the mean of results, with the exception of the Ag mass fraction in meat: k0NAA is metrologically sufficiently developed, and the laboratory demonstrated its competence repeatedly in proficiency tests organized by the Consultative Committee on the Amount of Substance (CCQM) to use the expanded uncertainty submitted by the laboratory.

The uncertainty budgets and assigned values are shown in Table 4. It should be highlighted that especially the characterization data for NanoLyse13 and NanoLyse14 are tentative, as for each method, they were obtained by one laboratory only. As no CRM is available for such measurements, a significant laboratory bias is still possible.

As expected, values by DLS, TEM and GEMMA differ significantly, as the physical properties measured differ. Interestingly enough, also the data for TEM and sp-ICP-MS for the two chicken materials differ significantly, although both methods report number-based diameters. A possible reason for this difference is that sp-ICP-MS does not count particles below 20 nm, as they are below the size limit of detection for this method. An alternative explanation is that the nature of the image analysis used for TEM aims to size the constituent particles of agglomerates (as far as discernible), whereas sp-ICP-MS regards agglomerates and aggregates as single particles.

Conclusions

The work presented in this paper demonstrated that the production of RMs based on a polydisperse AgNP dispersion is feasible: Materials obtained were found sufficiently homogeneous and stable for the methods employed, and the data obtained indicate that even assigning a value needed for a CRM should be feasible.

The work also demonstrates one scenario for the production of reference materials for AgNPs in a meat matrix. Spiking aqueous suspensions to a fine meat homogenate proved to be a suitable way of obtaining samples with a homogeneous distribution of Ag. Rapid freezing resulted in apparently stable materials without leading to excessive agglomeration. While processing of such a material is possible, the results also highlight the greater challenges faced when working with AgNPs compared to working with silica NPs: AgNPs are chemically reactive and can dissolve. While freezing definitely slowed down the process sufficiently to make the materials suitable for this project, further studies are necessary to check whether the change is slow enough to allow production of suitable reference materials, which need to be stable for several years. Using more stable metal oxide systems like TiO2 would certainly make ensuring stability easier.

The reactivity of AgNPs is also one factor that is causing difficulties in the development of efficient methods for the detection and quantification of AgNPs. Specifically, the influence of sample preparation on the AgNPs is not completely understood. However, efficient methods, which allow numerous replicate measurements to be performed on one sample, are required for processing control and a rigorous assessment of homogeneity and stability. Availability of such methods becomes absolutely vital for the processing of materials at a lower concentration, where the color of the spiked mixture can no longer serve as an indicator for homogeneity.

Further studies are also necessary to investigate the difference in the particle size distributions observed between the suspensions and the meat materials. Availability of independent methods would allow deciding whether this difference is due to real changes of the particles or of an unidentified method bias. At the current stage, any tentative value assignment could only yield method-specific values obtained by intercomparison among different laboratories.

Despite these challenges, which are common to any emerging field, the materials described in this work are suitable to serve as first step in the iterative process of improving analytical methods and reference materials.

The materials described in this paper are available from JRC-IRMM at the cost of distribution.

References

EC Regulation 1169/2011 on the provision of food information to consumers

Chaudhry Q, Scotter M, Blackburn J, Ross B, Boxall A, Castle L et al (2008) Applications and implications of nanotechnologies for the food sector. Food Addit Contam Part A 25:241–258

von Goetz N, Fabricius L, Glaus R, Weitbrecht V, Günther D, Hungerbühler K (2013) Migration of silver from commercial plastic food containers and implications for consumer exposure assessment. Food Addit Contam Part A Chem Anal Control Expo Risk Assess 30:612–620

Echegoyen Y, Nerín C (2013) Nanoparticle release from nano-silver antimicrobial food containers. Food Chem Toxicol. 62:16–22

ISO Guide 34, General requirements for the competence of reference materials producers, International Organization for Standardization, Geneva, Switzerland, 2009

Peters RJB, Rivera ZH, van Bemmel H, Marvin HJP, Weigel S, Bouwmeester H (2014) Development and validation of single particle ICP-MS for sizing and quantitative determination of nano-silver in chicken meat. Anal Bioanal Chem. 406:3875–3885 doi:10.1007/s00216-013-7571-0

Feichtmeier NS, Leopold K (2014) Detection of silver nanoparticles in parsley by solid sampling high-resolution-continuum source atomic absorption spectrometry. Anal Bioanal Chem 406:3887-3894. doi: 10.1007/s00216-013-7510-0

Loeschner K, Navratilova J, Købler C, Mølhave K, Wagner S, von der Kammer F, Larsen EH (2013) Detection and characterization of silver nanoparticles in chicken meat by asymmetric flow field flow fractionation with detection by conventional or single particle ICP-MS. Anal Bioanal Chem 405:8185–8195

Gagné F, Turcotte P, Gagnon C (2012) Screening test of silver nanoparticles in biological samples by graphite furnace-atomic absorption spectrometry. Anal Bioanal Chem 404:2067–2072

Menzel M, Bienert R, Bremser W, Girod M, Rolf S, Thünemann AF, Emmerling F (2013) Certification Report Certified Reference Material BAM-N001 Particle Size Parameters of Nano Silver, BAM Federal Institute for Materials Research and Testing, http://www.rm-certificates.bam.de/de/rm-certificates_media/rm_cert_particle_size/bam_n001repe.pdf

MacCuspie RI, Allen AJ, Martin MN, Hackley VA (2013) Just add water: reproducible singly dispersed silver nanoparticle suspensions on-demand. J Nanopart Res 15:1760

Harmon AR, Kennedy AJ, Poda AR, Bednar AJ, Chappel MA, Steevens JA (2014) Determination of nanosilver dissolution kinetics and toxicity in an environmentally relevant aqueous medium. Environ Toxicol Chem 33:1783–1791

Peretyazhko TS, Zhang Q, Colvin VL (2014) Size-Controlled Dissolution of Silver Nanoparticles at Neutral and Acidic pH Conditions: kinetics and Size Changes. Environ Sci Technol 48:11954–11961

Grombe R, Allmaier G, Charoud-Got J, Dudkiewicz A, Emteborg H, Hofmann T, Lehner A, Llinas M, Seghers J, Solans C, von der Kammer F, Wagner S, Linsinger TPJ (2014) Production of reference materials for the detection and size determination of silica nanoparticles in tomato soup. Anal Bioanal Chem 406: 3895–3907. doi: 10.1007/s00216-013-7554-1

Dudkiewicz A, Boxall ABA, Chaudhry Q, Mølhave K, Tiede K, Hofmann P, Linsinger TPJ (2014) Uncertainties of size measurements in electron microscopy characterization of nanomaterials in foods. Food Chem. doi:10.1016/j.foodchem.2014.12.071 (in press)

van der Veen AMH, Linsinger TPJ, Pauwels J (2001) Uncertainty calculations in the certification of reference materials. 2. Homogeneity study. Accred Qual Assur 6:26–30

Linsinger TPJ, Pauwels J, van der Veen AMH, Schimmel H, Lamberty A (2001) Homogeneity and stability of reference materials. Accred Qual Assur 6:20–25

Lamberty A, Schimmel H, Pauwels J (1998) The study of the stability of reference materials by isochronous measurements. Fres J Anal Chem 360:359–361

Loeschner K, Navratilova J, Legros S, Wagner S, Grombe R, Snell S, von der Kammer F, Larsen EH (2013) Optimisation and evaluation of asymmetric flow field-flow fractionation of silver nanoparticles. J Chrom A 1272:116–125

Cunningham WC, Stroube WB (1987) Application of an instrumental neutron activation analysis procedure to analysis of food. Sci Total Environ 63:29–43

Linsinger TPJ, Peters R, Weigel S (2014) International interlaboratory study for sizing and quantification of Ag nanoparticles in food simulants by single-particle ICPMS. Anal Bioanal Chem 406:3835–3843

ISO Guide 35, Reference materials—General and statistical principles for certification, International Organization for Standardization, Geneva, Switzerland, 2006

Acknowledgments

The work leading to these results has received funding from the European Union Seventh Framework Programme (FP7/2007–2013) under grant agreement no 245162. The authors thank Mrs. Meeus (EC JRC-IRMM) for conducting the microbiology tests.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Grombe, R., Allmaier, G., Charoud-Got, J. et al. Feasibility of the development of reference materials for the detection of Ag nanoparticles in food: neat dispersions and spiked chicken meat. Accred Qual Assur 20, 3–16 (2015). https://doi.org/10.1007/s00769-014-1100-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00769-014-1100-5