Abstract

A method of analysis of silver nanoparticles (AgNPs) in chicken meat was developed. The homogenized chicken meat sample, which was spiked with AgNPs, was subjected to enzymolysis by Proteinase K for 40 min at 37 °C. Transmission electron microscopy and inductively coupled plasma mass spectrometry (ICP-MS) in single particle mode were used to characterize the number-based size distribution of AgNPs in the meat digestate. Because similar size distributions were found in the meat digestate and in the aqueous suspension of AgNPs used for spiking the meat, it was shown that no detectable dissolution of the AgNPs took place during the sample preparation stage. The digestate was injected into the asymmetric flow field flow fractionation (AF4) -ICP-MS system, which enabled fractionation of nanoparticles from the remaining meat matrix, and resulted in one large peak in the fractograms as well as two smaller peaks eluting close to the void volume. The recovery of silver contained in the large AgNP peak was around 80 %. Size determination of AgNPs in the meat matrix, based on external size calibration of the AF4 channel, was hampered by non-ideal (early elution) behavior of the AgNPs. Single particle ICP-MS was applied for determination of the number-based particle size distribution of AgNPs in collected fractions. The presented work describes for the first time the coupling of AF4 and ICP-MS for AgNP separation in a food matrix.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

With the increasing use of nanotechnology in food and consumer products, there is a need for reliable detection and characterization methods for nanoparticles (NPs) in complex matrices. Asymmetric flow field flow fractionation (AF4) coupled to inductively coupled plasma mass spectrometry (ICP-MS) is a highly promising method for this purpose [1, 2]. For separation of NPs by AF4, the sample needs to be in liquid suspension and should not contain any large particles which could lead to clogging of the AF4 system. Therefore, when dealing with NPs contained in a complex matrix like food, suitable sample preparation is necessary. In the simplest case, this could be based on dilution and filtration or centrifugation [1]. However, if NPs have a strong affinity to the matrix, decomposition of the matrix by strong acids, bases or enzymes can be necessary to liberate the NPs into liquid suspension. The chemical stability of the NPs limits the applicability of these methods: AgNPs can for example dissolve at low pH [3], which in most cases excludes acid digestion as a sample preparation method.

The number of publications regarding sample preparation of NPs in organic matrices including food stuffs, tissues and cells for AF4-ICP-MS is still limited. Silver (Ag) NPs were extracted from freshwater worms by sonication, followed by centrifugation and analyzed by symmetrical FFF coupled to ICP-MS [4]. A size increase from 31 to 46 nm was observed, but was not further discussed. Neither recovery nor blank samples were determined or analyzed. Other reported sample preparation approaches include acid digestion with nitric acid followed by filtration for silica NPs spiked to tissue homogenates and cell lysates [5, 6] and solvent extraction for analysis of titania NPs in sun screen [7, 8]. Summarizing from the above, there is a need for the development of sample preparation techniques for NPs in complex matrices to allow detection and characterization by AF4-ICP-MS.

For samples which mainly consist of protein, enzymatic digestion with the broad spectrum protease, Proteinase K, is a promising sample preparation method. So far, the use of Proteinase K has only been reported once in the context of releasing nanoparticles from tissues for AF4 [5]. Silica NPs were spiked to lung tissue homogenate and consequently treated with collagenase, hyaluronidase, and finally Proteinase K. The achieved recoveries after sedimentation FFF coupled to light scattering detection were however, poor (22 to 30 %) [5]. Further reports of the application of Proteinase K for tissue digestion are in the context of diatom detection in the diagnosis of drowning in putrified corpses [9]. Furthermore, enzymatic tissue digestion with Proteinase K was suggested as an alternative sample preparation approach for analysis of small-molecule drugs in brain tissues by liquid chromatography coupled to mass spectrometry [10].

AgNPs are presently one of the most frequently used nanomaterials in consumer products related to food, such as food storage containers and dietary supplements [11]. In a previous report, the development and optimization of an AF4 method for separation of an aqueous suspension of AgNPs stabilized with polyvinylpyrrolidone (PVP) was described [12] using a variety of detection systems including ICP-MS for particle characterization, sizing and quantification. In the present paper the same type of AgNPs as previously studied were incorporated into the more complex chicken meat matrix to illustrate a possible scenario where AgNPs may migrate from an antibacterial food contact material into meat. A recent study has for example shown that around 12 % of silver was released from food storage containers in the form of AgNPs [13]. The aims of this work were to demonstrate which methodological steps were necessary, and to highlight the challenges that had to be addressed, in order to develop an appropriate sample preparation method for AgNPs in meat. Separation of AgNPs from the matrix and fractionation by size of AgNPs was investigated by AF4 using on-line detection by ICP-MS in conventional mode or using off-line characterization of their number-based size distribution in single particle mode. ICP-MS used in single particle mode has been shown to be a powerful method for determination of size distribution of AgNPs at concentrations in the nanogram per liter range [14–16].

Materials and methods

Materials

Ultrapure water (18.2 mΩ/cm) was obtained from a Millipore Element apparatus (Millipore, Milford, MA, USA) and used throughout the work.

PVP-stabilized AgNPs in aqueous suspension (NGAP NP Ag-2103) were purchased from Nanogap (Milladoiro, Spain) and characterized by the Institute for Reference Materials and Measurements (IRMM) as detailed elsewhere [12]. Briefly, the nominal size stated by the supplier was 42 ± 10 nm. The mass concentration of Ag determined by inductively coupled plasma optical emission spectrometry was 197.4 ± 0.6 μg/g. The Ag concentration in filtrates obtained by ultrafiltration (cut-off 5 kDa) was 0.38 ± 0.04 μg/g. PVP K10 was used as stabilizer with at a concentration of 3 μg/g. The zeta potential of the AgNPs was −37.9 ± 1.0 mV (pH 7). Lean chicken meat paste was produced by IRMM on the basis of 40 kg of fresh chicken breast filet obtained from a local butcher (Geel, Belgium). After cutting, freezing with liquid nitrogen, and cryo-milling, the material was allowed to thaw. The obtained paste was filled into 25-ml glass jars and stored at 4 °C. After 24 h, the material was sterilized using gamma irradiation (10.0 kGy Avg, SynergyHealth, Etten Leur, NL) and stored at −20 °C.

For sample filtration Minisart® high flow syringe filters (VWR, Bie & Berntsen, Herlev, Denmark) with a pore size of 0.45 μm were used. ReagentPlus sodium dodecyl sulfate (SDS) with ≥ 98.5 % purity and sodium azide with ≥98 % purity were purchased from Sigma-Aldrich (St. Louis, MO, USA). For the enzymatic digestion the commercial protease Proteinase K from Engyodontium album was used (Sigma-Aldrich St. Louis, MO, USA). Proteinase K is a serine protease with a molecular mass 28 930 Da, a broad pH range of 7.5-12 and a temperature optimum of 37 °C regarding the enzyme activity.

Nitric acid (67–69 %) of PlasmaPURE quality and single element PlasmaCAL standards of Ag and rhodium (Rh) at 1 mg/ml were obtained from Science (Quebec, Canada). AF4 carrier liquid was produced by dissolving ammonium bicarbonate NH4HCO3 (ReagentPlus, Sigma-Aldrich, St. Louis, MO, USA) in ultrapure water. Before usage, the pH of the NH4HCO3 solution was reduced from 8 to 7.4 by adding nitric acid. As accumulation wall in the AF4 cell PES membranes (Nadir®, Lot no. 213150) with a molecular weight cut-off of 10 kDa were purchased from Wyatt Technology (Dernbach, Germany). For determination of the transport efficiency for single particle ICP-MS a reference AuNP suspension at 60 nm in nominal diameter (RM8013) was obtained from the National Institute for Science and Technology, NIST (Gaithersburg, MD, USA).

Instrumentation

For sample preparation a MS2 minishaker (IKA Works, Inc., Wilmington, NC, USA), a Sigma 3-18K centrifuge (Buch & Holm, Herlev, Denmark) and a water bath with a Heto HMT 200 RS thermostat and a Telesystem HP15 magnetic stirrer (Holm & Halby, Allerød, Denmark) were used. For indirect sonication of the AgNP suspensions a Branson 5510 sonication bath (VWR International, Leicester, UK) was used at a frequency of 42 kHz and an input power of 185 W. Direct sonication of enzymatically digested meat with AgNPs was performed using a Qsonica LLC Misonix XL-2000 probe sonicator with an operating frequency of 22.5 kHz and a P-4 probe with a tip diameter of 6.4 mm and a 60 μm amplitude (Buch & Holm, Herlev, Denmark). The pH value was measured with a PHM 240 pH/ION meter (Radiometer, Copenhagen, Denmark). The AF4 system used in this study consisted of an Agilent 1200 series autosampler (G1329A), a high-performance liquid chromatography pump (G1311A) (Agilent Technologies, Santa Clara, CA, USA), an EclipseTM 3 AF4 flow control module, and a short channel-type AF4 separation channel (Wyatt Technology Europe GmbH, Dernbach, Germany). The channel had a trapezoid shape with a length from inlet to outlet of 172 mm, a length from inject port to outlet of 152 mm and a width of 24.0 mm at the inlet and 3 mm at the outlet port. The width at the sample inject port was 21.5 mm. The area of the accumulation wall was 2,363 mm2. The AF4 separation program used is listed in Table 1.

Following separation by AF4 various detectors were used to collect information about the eluting fractions. A series 1200 diode array detector (Agilent G1315A, DAD) was used to record the absorbance signal at pre-defined wavelengths. Additionally, absorption spectra were recorded in the wavelength range of 191 to 949 nm (steps of 10 nm) during the separation every 2 s. A DAWN® HELEOSTM (Wyatt Technology Europe GmbH, Dernbach, Germany) multi angle light scattering (MALS) detector with 17 + 1 observation angles operated with a linear polarized laser light at 658 nm was used to record the light scattering signal. The MALS detector was set to a sampling time interval of 1 s per data point. A dynamic light scattering (DLS) detector positioned at the 99° angle of the DAWN® HELEOSTM MALS detector was used for on-line determination of the hydrodynamic diameter of the AgNPs. Data from the light scattering detectors was processed using the ASTRA V software (version 5.3.2.15, Wyatt Technology Corporation, Santa Barbara, CA, USA). As the final detector in the hyphenated system an ICP-MS instrument (ICP-MS 7500ce, Agilent Technologies, Japan) was used to record the 107Ag and 103Rh signal intensities. The silver mass quantification by ICP-MS is described in detail as Electronic Supplementary Material S1. The instrumental settings are presented in Table 2. Aqueous silver standards were introduced off-line using a peristaltic pump.

For ICP-MS used in single particle mode a Thermo Scientific iCAP Q ICP-MS (Thermo Fisher Scientific GmbH, Bremen, Germany) was used. The instrumental settings for single particle ICP-MS are presented in Table 3.

Sample preparation strategies prior to analysis by AF4-ICP-MS

The general scope of the sample preparation work was to enable quantitative detection of AgNPs in a candidate reference material based on chicken meat containing 0.01 % m/m AgNPs. The strategy was to apply a step by step approach towards larger degree of complexity of the procedures.

Centrifugation and filtration

Bearing in mind that AF4 is a technique well-suited for separation of nanoparticles in liquid suspension, one of the least complex sample preparation methods would be extraction of the AgNP containing chicken meat by water. A portion of 1 g of meat paste was transferred into a 13 ml polypropylene tube and 1 ml of AgNP suspension was added to obtain a sample with a concentration of AgNPs of 0.01 % m/m. The sample was vortex-mixed for 1 min at 2,500 rpm and subsequently 2 ml of 0.5 mM ammonium carbonate buffer (pH ∼ 9) was added. The buffer had the same composition as the carrier liquid which was found to be optimum for the separation of the pristine AgNPs [12]. Afterwards, the samples were centrifuged. The centrifugation speed and time, which was necessary to spin down the meat residues, was chosen based on visual inspection bearing in mind the risk of co-precipitation of the AgNP with the meat slurry. A volume of 0.5 ml of the supernatant was removed and 2 ml of the 0.5 mM ammonium carbonate buffer was added. The diluted supernatant was passed through syringe filters with a pore size of 0.45 μm and 100 μl of the filtrate were injected into the AF4 channel.

Enzymatic digestion

The enzyme solution was prepared by dissolving Proteinase K to a final concentration of 3 mg/ml in 50 mM ammonium bicarbonate buffer (pH 7.4) containing 5 mg/ml SDS and 0.2 mg/ml sodium azide used as antimicrobial agent. A portion of 0.25 g meat paste was spiked with 0.25 g of the AgNP suspension. The mixture was vortexed for 1 min at 2,500 rpm and 5 ml of the Proteinase K solution were added. The mixture was incubated at 37 °C in a water bath using continuous stirring until no meat fibers were visible in the sample, which took approximately 40 min as described later. A volume of 10 μl was injected into the AF4 channel corresponding to an injected mass of Ag of m inj = 90 ng. Additionally, injected volumes of 50 or 100 μl of the same digestate were analyzed separately.

As a blank sample, meat without AgNPs was treated using the same procedure. Furthermore, AgNPs were spiked to the enzyme solution and then incubated for 40 min at 37 °C under continuous stirring in the water bath to investigate the influence of the enzyme on the AgNPs and their separation.

Particle size determination by single particle ICP-MS

The theory of ICP-MS used in single particle mode for characterization of colloids in water has been introduced by Degueldre et al. [17]. Data processing was performed using a spread sheet routine [18]. The peristaltic pump was set to 40 rpm for all experiments, which corresponds to a sample flow rate of approximately 0.4 ml/min, which was accurately determined daily by weighing the amount of water that was delivered by the peristaltic pump for 1 min. Instrument calibration was achieved by analysis of a blank and five Ag standards ranging from 0.2 to 5.0 ng/l diluted from a certified solution. The 107Ag intensity for each solution was then averaged from the entire length of the analysis (180 s). To correct for possible instrumental drift over time the standards were analyzed at the beginning and the end of the analysis sequence. The transport efficiency was determined according to the “particle frequency” method described in [18] by measuring a NIST AuNP suspension with a known average particle diameter (56.0 ± 0.5 nm as determined by transmission electron microscopy (TEM)) and gold mass concentration (51.86 ± 0.64 μg/g) diluted 106-times with ultrapure water. The transport efficiency, which was determined daily, was calculated as the percentage of detected particles by single particle ICP-MS versus the theoretical (calculated) particle number.

Samples were diluted to target concentrations of 50 ng/l with ultrapure water. To achieve approximately the target dilution for fractions collected from AF4, the following procedure was followed: Before collection of the fractions, the enzymatically digested meat sample containing AgNPs was first analyzed by conventional AF4-ICP-MS coupling. The collection interval for each fraction was defined and the corresponding Ag concentration in the fractions calculated based on integration of the ICP-MS signal combined with the volume of the eluted fraction. The sample was then injected a second time without ICP-MS-coupling and the pre-defined fractions collected. This approach was possible because no noticeable variation in retention times of the fractogram peaks occurred during repeated injections of the same sample. The collected fractions were then further diluted to the target concentration of 50 ng/l.

For each sample the 107Ag signal intensity was recorded for 180 s which corresponded to 60,000 data points when using 3 ms dwell time. Following the analysis of each sample, ultrapure water was analyzed to illustrate if carry-over from the previous measurement could be excluded. For all analyses, raw signal intensity data were plotted (in counts per second) versus number of events to create a signal distribution histogram using OriginPro 8.1 (OriginLab Corporation, MA, USA). Very low signal intensities were considered to be instrument background or for slightly higher intensity values dissolved silver or silver clusters. An iterative algorithm was applied where particle events were distinguished as outliers from the background/dissolved ion signal if the measured intensity was more than five times the standard deviation of the whole data set as described in [16] (see Electronic Supplementary Material Fig. S2 as an example).

Transmission electron microscopy

The pristine AgNP suspension as well as the enzymatically digested meat sample containing AgNPs was diluted twice with ultrapure water. A volume of 10 μl of the diluted suspension was applied to a 200 mesh Formvar/carbon-coated copper grid. The particle size and shape were observed by TEM using a CM 100 BioTwin instrument (Philips, Eindhoven, The Netherlands) operated at 80 kV accelerating voltage. The analysis is based on images of at least 250 NPs for each sample type. Analysis was done using ImageJ particle analysis to determine the projected area of the particles which was used to calculate an equivalent particle diameter.

Results and discussion

AF4-ICP-MS following centrifugation and filtration

As a first approach a simple extraction and centrifugation procedure was tested in order to isolate AgNPs from the meat matrix. The extracts resulting from aqueous extraction appeared as crude mixtures of semi-solid pieces of meat and aqueous phase and therefore required phase separation before injection into the AF4 was possible. As a first choice, centrifugation was chosen because filtration could result in a loss of nanoparticles [19]. An initial relative centrifugal force (RCF) of 3,077×g was applied for 20 min, but with this force a large fraction of AgNPs was spun down with the meat matrix, which was visible as a black precipitate. Therefore, the force was reduced and at an RCF = 192×g applied for 5 min AgNPs still precipitated at the bottom but at an RCF = 48×g for 10 min no precipitation of AgNPs was noticeable. When using this force however, a few meat residues were still present in the supernatant. The large density difference between AgNPs and meat did not allow a separation based on centrifugation despite the small size of AgNPs in comparison to the visible meat residues. An additional filtration step was therefore necessary before injection of the sample into the AF4 channel was possible. A 0.45-μm cut-off filter was chosen to remove meat residues, which could otherwise clog the AF4 system, and at the same time allow AgNPs to pass through the filter.

The AF4-ICP-MS fractogram of the aqueous extract of a meat sample containing AgNPs showed an early eluting 107Ag peak at t r = 1.6 min, which was not separated from the void peak (Electronic Supplementary Material Fig. S3a). At the same retention time a peak maximum, based on the light scattering signal was observed. The parallel on-line DLS measurements showed that light scattering matter with hydrodynamic diameters of 5 to 10 nm eluted at t r = 1.6 min, both for the blank meat and the meat samples containing AgNPs (Electronic Supplementary Material Fig. S3b). These light scattering entities were probably proteins. The total Ag recovery based on ICP-MS detection of 107Ag from meat samples containing AgNPs was low (<15 %). AgNPs are most likely removed together with the meat constituents during centrifugation and filtration because of the strong affinity between nanoparticles and organic molecules. No further effort was therefore devoted to improve the sample preparation method based on aqueous extraction of AgNPs from meat.

AF4-ICP-MS following enzymatic digestion

To improve the liberation of AgNPs from the meat matrix further degradation of the meat matrix was necessary prior to separation and quantification. Therefore, an enzymatic digestion procedure was chosen to degrade protein to peptides and amino acids. Because the meat samples mainly consisted of protein, the enzymatic digestion relied on the use of the broad spectrum protease, Proteinase K. The described methods in the literature use relatively long treatment times and elevated temperatures: 2 h at 65 °C [5], several hours (overnight plus additional 8 h) at 50 °C [9] and 5 h at 55 °C [10]. The amount of Proteinase K per milligram tissue was between 1 μg [9] and 3.3 μg (calculated from the reported values using a specific activity of Proteinase K of 30 units/mg protein) [10]. For our work, a decrease of the temperature and a reduction of the duration of the enzymatic digestion were favorable to minimize a possible dissolution of AgNPs. To achieve a higher efficiency of the digestion, the amount of enzyme per milligram tissue was increased by 20 to 60 times to 60 μg in comparison to the before described methods. A temperature of 37 °C was chosen based on the information from the supplier (Sigma-Aldrich) that the maximum activity of Proteinase K was achieved at 37 °C. The supplier further recommended addition of 1 to 5 mM Ca2+ for activation of the enzyme. However, no difference in the digestion efficiency was observed with and without Ca2+ based on visual inspection of samples digested for 40 min at 37 °C and no Ca2+ was added in the final method. SDS was added with a concentration of 0.5 % (w/v) according to the supplier’s recommendation for denaturation of the protein substrate which is supposed to result in increased digestion rate. Based on visual inspection the absence of SDS led to a less efficient digestion of the meat after 40 min at 37 °C. Sodium azide was added after observing a black coloration of the samples in combination with a strong smell after 18 h at 37 °C during the pre-studies which indicated bacterial decomposition. To avoid any bacterial growth also during the shorter digestion procedures, a small amount of sodium azide (200 μg/ml in the enzyme solution) was added to all samples before enzymatic digestion.

A treatment of 40 min was necessary for degradation of the sample when using 60 μg of Proteinase K per milligram of meat which corresponded to an enzyme concentration of 3 mg/ml in the method described in Enzymatic digestion. After 40 min, no meat residues were visible in the digestate. Further, the digestate had a yellow color resulting from the surface plasmon resonance (SPR) of the AgNPs.

Reduction of the enzyme concentration from 3 to 1/0.2 mg/ml (corresponding to 60, 20, and 4 μg enzyme per milligram meat) resulted in incomplete digestion of the meat matrix after 40 min. Keeping the sample preparation time as short as possible was important to minimize time-dependent changes of the AgNPs, and consequently an enzyme concentration of 3 mg/ml chosen. It is interesting to note that for the lowest enzyme concentration (0.2 mg/ml), after 24 h the non-digested meat residues had settled as a reddish precipitate and the supernatant appeared transparent and colorless, which indicated the absence of AgNPs in the supernatant (Electronic Supplementary Material Fig. S4). This observation confirms the strong interaction between AgNPs and non-digested meat constituents. The formation of the red precipitate and the influence of enzymatic treatment for longer time on AgNPs dissolution are part of ongoing research.

In Fig. 1, fractograms corresponding to the enzymatically digested meat sample containing AgNPs and to pristine AgNPs have been overlaid. The fractogram of the diluted pristine AgNP suspension (black line) showed an incompletely separated double peak as described and discussed previously [12] with retention times of t r = 11.3 ± 0.1 min (peak 1) and of t r = 14.6 ± 0.2 min (peak 2) (N = 3), respectively. For the enzymatically digested meat sample (light gray line) containing AgNPs, however the double peak was less pronounced with the second peak appearing only as a shoulder on the first peak. Furthermore, the main peak eluted approximately 2 min earlier (t r = 9.6 ± 0.1 min (N = 6)) in comparison to the first peak of the pristine AgNP suspension.

The peak of the enzymatically digested meat sample which was eluting at t r = 9.6 min was assumed to contain AgNPs because of the similar retention time range as the pristine AgNPs. This peak is from now on referred to as “nanoparticle peak”. Additionally, three peaks, which were not detected for the pristine AgNP suspension, were detected at retention times below 5 min. The first of these peaks (referred to as “void peak”) was an unknown species of Ag, which was not retained during separation and thus eluted at the void time t 0. The retention times of the other two peaks were t r = 1.4 ± 0.1 min (referred to as “extra peak 1”) and t r = 2.7 ± 0.1 min (referred to as “extra peak 2”), respectively.

For the enzymatically digested meat sample the recovery of Ag in the nanoparticle peak was 89 ± 4 % (N = 6) and 10 ± 1 % of the Ag was recovered in the peaks eluting before t r = 5.0 min. During the six injections of the same digestate within a time span of about 9 h the elution profile and the recovery did not change. This showed that the enzymatic extract was stable at room temperature for a minimum of a few hours. For the pristine AgNP the recovery in the nanoparticle peak was 83 ± 3 % (N = 3). The significantly lower recovery (p < 0.05) for the pristine AgNP suspension could be caused by the previous runs of the enzymatically digested samples. It was observed throughout the experimental work that lower recoveries of the pristine AgNP suspension were obtained when enzymatically digested samples (with and without AgNPs) were analyzed before on the same membrane. On the other hand carry-over was observed when enzymatically digested samples were analyzed after separation of pristine AgNPs on the same membrane. These observations possibly result from the strong affinity of AgNPs to some of the constituents present in the enzymatic digests.

The UV/Vis spectra recorded at the apex of the nanoparticle peak of the enzymatically digested sample showed a pronounced additional absorbance maximum at 400 nm (data not presented), which is characteristic to the SPR of the AgNPs. This proves that this indeed corresponded to AgNPs originating from the enzymatically digested meat sample. At the peak shoulder, a spectrum with absorbance maxima at 400 and 500 nm possibly caused by larger particle doublets was recorded as previously described also for the pristine AgNP suspension [12]. The less pronounced appearance of the double peak as a shoulder in the fractogram corresponding to the meat sample could be caused by disaggregation of the doublets to primary particles during enzymatic digestion. An attempt was made for determination of the hydrodynamic diameter of AgNPs by the on-line DLS detector. The signal intensity recorded by this detector was however too weak for the injected mass of Ag and no direct size information during AF4 separation could be obtained. This shows the limitation of on-line DLS for samples that only contain a relatively low concentration of AgNPs which is the realistic scenario in case of migration of AgNPs from a food packaging material into food.

To test if the presence of the enzymatically digested meat matrix itself caused the observed peak shift, AgNPs were spiked to enzymatically digested meat (blanks) and the mixture was immediately injected into the AF4 system (Fig. 2a). The elution profile and retention time of the nanoparticle peak in the obtained fractogram was similar to the fractogram of samples where AgNPs were present in the meat during enzymatic digestion (Fig. 1). In both cases, Ag eluted in a void peak, extra peak 1, and extra peak 2 and the nanoparticle peak was shifted by approximately 2 min to lower retention times in comparison to the pristine AgNP suspension. The results of the experiment shows that, in comparison to the diluted pristine AgNP suspension, even for a very short contact time between the enzymatically digested meat matrix and the AgNPs a shift in retention times and the formation of extra peak 1 and 2 occurred. Thus, the altered separation behavior of the AgNPs can most likely be attributed to the presence of the digested meat matrix.

AF4-ICP-MS fractograms obtained for a a 40-min enzymatically digested meat sample where AgNPs were spiked after enzymatic digestion and b of AgNPs spiked to the enzyme solution. Further, the fractogram of an enzymatically digested blank meat sample is presented. For comparison a fractogram of the diluted pristine AgNP suspension is given in both figures. The injected mass of Ag for the Ag-containing samples was m inj = 90 ng

The lower retention times of the AgNPs in enzymatically digested meat could be caused by a modification of the charge of the NP surface and/or membrane surface, which resulted in enhanced electrostatic repulsion between NPs and membrane. This additional force drives the NPs away from the accumulation wall (the membrane) and closer to the channel center, which results in reduced retention times. Another explanation could be a disturbance of the relaxation of the AgNPs during focusing due to the presence of the organic matrix. Peptides and amino acids that do not leave the channel through the 10 kDa PES membrane could create a concentrated sample zone during focusing, which could prevent the AgNPs from relaxing to the right equilibrium level above the membrane.

Because of the relatively high Proteinase K concentration of 3 mg/ml during enzymatic digestion several microgram of enzyme are injected into the AF4 system together with the sample. To investigate the influence of the enzyme on the obtained fractograms, AgNPs were mixed with Proteinase K in the same concentration as in the enzymatically digested meat samples and incubated at 37 °C for 40 min. In contrast to the meat samples containing AgNPs, extra peak 1 or 2 were not observed (Fig. 2b). Furthermore, the presence of only enzyme did not lead to a shift of the retention time of the major nanoparticle peak in comparison to the diluted pristine AgNP suspension. It was concluded that the enzyme had no or only a minor effect on the separation of AgNPs and that the formation of peak 1 and 2 and the larger shift of the retention time of the nanoparticle peak mainly occurred in the presence of enzymatically digested meat.

Separation of blank meat samples showed some carry-over of Ag from previous analyses even when a new membrane was used (Fig. 2b). This carry-over was visible in the fractograms as one small void peak, one peak eluting at a similar retention time as extra peak 2, and one peak eluting at the retention time of the nanoparticle peak. Total carry-over was in the range of 1 to 5 ng of Ag (1 to 6 % of the injected mass) and decreased during consecutive injections of the blank meat. This was attributed to gradual removal of Ag and/or AgNPs associated with surfaces in the analytical system. The scattered light signal for the meat blank was very low in contrast to the findings described in AF4-ICP-MS following centrifugation and filtration. This indicated the absence of scattering entities like, for example, proteins. This showed that the enzymatic digestion was effective in degrading the meat.

To investigate if further degradation of the organic matrix would reduce the influence of the organic matrix on the separation and retention of AgNPs, the duration of the enzymatic digestion procedure was increased from 40 min to 5 h. For an enzymatic digestion procedure of 5 h no large differences in comparison to a 40 min digestion procedure were observed and the elution profile of the nanoparticle peak was similar. The nanoparticle peak eluted 2 min earlier than the one of the diluted pristine AgNP suspension as before and it represented 81 ± 1 % of the total fractogram area (N = 2). About 15 ± 1 % of the fractogram area was associated with the peaks eluting before t r = 5.0 min (semi-quantitative results, no fractogram presented). It was concluded that an increase of the duration of the enzymatic digestion procedure did not improve the separation of AgNPs from meat.

Determination of the size distribution of AgNPs in enzymatic digestate by single particle ICP-MS and TEM

Bulk samples

Alternative methods for particle size determination were necessary to find out if the observed shift of the retention time after enzymatic digestion was caused by a decrease of the AgNP size or if it was caused by non-ideal elution. Single particle ICP-MS and TEM were applied which both determine the number-based size distribution of NPs. The determination of a size distribution based on particle number is relevant for future regulatory purposes because of the European Commission’s recommendation of the definition of a nanomaterial as a “natural, incidental or manufactured material containing particles, in an unbound state or as an aggregate or as an agglomerate and where, for 50 % or more of the particles in the number size distribution, one or more external dimensions is in the size range 1 nm–100 nm” [20]. AF4-ICP-MS results in a mass concentration-based size distribution which could theoretically be converted into a particle number-based size distribution by dividing the mass concentration by the material density and the NP volume. The latter can only be calculated based on the determined NP diameters if all NPs of the size distribution have the same basic geometry. Additionally, the conversion from mass to number distributions employs large conversion factors, especially for the very small particles, which easily can lead to erroneous results. Hence, a combination of AF4-ICP-MS with methods that can determine a number-based size distribution will be interesting for regulatory purposes in the future.

To determine a useful concentration level for single particle ICP-MS, the pristine AgNPs were analyzed at three concentration levels ranging from 25 to 100 ng/l. The number of detected events was between 3,500 and 12,100 particles per 180 s. The resulting number-based size distributions were similar for the three studied concentrations (results not presented). In the following experiments a concentration of 50 ng/l was used as the target concentration for all analyzed samples. Our previous work had shown that the mass concentration-based size distribution of the pristine AgNPs covered a range of hydrodynamic diameters from approximately 20 to 200 nm based on AF4-ICP-MS [12]. Because of the broad size distribution of the studied AgNPs, the dwell time and the dilution level used for single particle ICP-MS were considered as a compromise to minimize the occurrence both of partial and multiple particle events. For direct comparison of pristine AgNPs and AgNPs after enzymatic digestion the samples were diluted to the same concentration and analyzed in one sequence to keep instrumental parameters like sample flow rate, transport efficiency, sensitivity, etc., constant.

Figure 3 shows the number-based particle size distributions determined by single particle ICP-MS (Fig. 3a) and TEM (Fig. 3b) as well as representative TEM images (Fig. 3c) for the pristine AgNPs and for AgNPs in meat after enzymatic digestion. The size distributions for pristine AgNPs and AgNPs after enzymatic digestion of the meat showed no differences with both methods: TEM and single particle ICP-MS.

The maximum of the size distribution was between 30 and 35 nm for the pristine AgNPs and the AgNPs after enzymatic digestion with both methods. In our previous work, TEM of collected AF4-fractions from the pristine AgNPs had shown primary particles ranging in size from 30 to 45 nm in the first eluting peak of the double peak [12], which was in agreement with the TEM results shown. The apparent differences in the size distributions obtained by TEM and single particle ICP-MS (Fig. 3) had two reasons. The lower number of larger particles (>40 nm) in the TEM-based size distribution in comparison to single particle ICP-MS was caused by the fact that there only the diameters of the primary particles could be analyzed. Because samples were prepared by drying a drop of the suspension on a TEM grid it was not possible to distinguish between aggregates/agglomerates that were present in the suspension or aggregates/agglomerates formed during drying. In contrast, single particle ICP-MS measures AgNPs diluted in a liquid.

The differences between single particle ICP-MS and TEM-based size distribution in the lower particle size range (left side of the distribution) could be explained with the larger limit of detection regarding particle size for single particle ICP-MS which was approximately 15 nm in our measurements. In contrast, TEM allowed the detection of particles down to the range of a few nanometers. The slight differences in the particle size range below 10 nm between pristine AgNPs and the AgNPs after enzymatic digestion were caused by the uncertainty of the size determination for very small particles in the images.

AF4-ICP-MS analysis of pristine AgNPs and AgNPs in meat after enzymatic digestion showed a shift of the nanoparticle peak after enzymatic digestion to lower retention times by about 2 min (Fig. 1). According to an external size calibration curve using polystyrene nanospheres [12], this shift would correspond to a theoretical change in the hydrodynamic diameter of the particles of about 10 nm for the applied separation conditions. TEM and single particle ICP-MS analysis, however, showed that no change of the particle size distribution had occurred. This confirmed the assumption that the observed shift in the retention times was rather caused by non-ideal behavior of AgNPs in the AF4 channel in the presence of the enzymatically digested meat than by an actual change of the NP size distribution. Because of this non-ideal eluting of the AgNPs a size determination based on conversion of retention times into hydrodynamic diameters either based on AF4 theory or size calibration with polystyrene nanospheres as described in [12] for the pristine AgNPs was not possible.

Fractions collected after AF4 separation

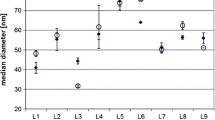

To obtain further information on the separation of AgNPs from enzymatically digested meat, AF4 fractions at different time intervals were collected (Fig. 4a) and analyzed by single particle ICP-MS. Because of the low concentrations in the fractions, it was not possible to determine a size distribution based on TEM. Attempts to inject larger sample volumes into the AF4 system resulted in channel overloading. Figure 4b presents the number-based particle size distributions obtained for the collected fractions. The corresponding 107Ag time scans can be found in the Electronic Supplementary Material (Fig. S5). No carry-over between the samples was observed based on analysis of ultrapure water between samples. Table 4 presents the number of detected particles, the determined median particle diameters as well as the calculated total Ag concentration and the measured Ag concentration of AgNPs and of the background.

a Presentation of the time intervals for collected fractions of the AF4-ICP-MS eluate for off-line single particle ICP-MS analysis (conditions: 40 min enzymatically digested meat sample containing AgNPs; m inj = 90 ng) and, b number-based particle size distributions for all fractions and for the enzymatic digested (bulk) sample. For the sake of clarity histograms (bin width 5 nm) are presented as curves with each point representing a bin center

Fraction 1 which corresponded to the void peak and the enzymatic digestate (bulk) contained a similar number of particles of 4,033 and 5,042, respectively, and had a similar size distribution (Fig. 4b) which suggested that the void peak contained unretained AgNPs with a broad size range. The number of detected particles in fraction 2 which corresponded to extra peak 2 was very low (180). The background Ag concentration was 24 ± 7 ng/l which corresponded to 75 ± 22 % of the total Ag concentration in this fraction. This indicated that the early eluting peak was not caused by non-ideal eluting AgNPs but probably by association of dissolved Ag with organic constituents of the enzymatic meat digestate. Ionic Ag is known to have a strong affinity to thiol groups [21] and thiol-containing biomolecules are abundant in tissues. The occurrence of dissolved Ag can be explained by its presence as a small fraction in the pristine AgNP suspension and by a possible further release of Ag ions during enzymatic digestion.

Fractions 3 and 4, which corresponded to the left and the right side of the nanoparticle peak, showed a narrower particle size distribution than the enzymatic digestate before separation but with a maximum of the size distribution at a similar position at around 30 nm. Figure 5 compares the normalized particle size distribution of the enzymatically digested meat sample with AgNPs before separation by AF4 and the size distributions of the collected fractions 3 and 4. Despite the rather broad nanoparticle peak in the AF4-ICP-MS fractogram (Fig. 4a), no difference in the median particle diameter of fraction 3 and 4 was detectable. Previous work had shown that the broad peak obtained by AF4 separation of the pristine AgNPs contained primary particles and agglomerates or aggregates of these primary particles of increasing size [12]. It is possible that the agglomeration/aggregation state of the AgNPs is different during AF4 separation and after high dilution for single particle ICP-MS analysis. As a result, mainly primary particles are measured by single particle ICP-MS in fraction 3 and 4. In fraction 6, which was collected at relative high retention times, particle diameters from 20 to 80 nm were determined. It cannot be excluded that the presence of the AgNPs down to 20 nm was caused by disaggregation of larger agglomerates by dilution for single particle ICP-MS.

A possible reason for the observed low recoveries (68 ± 13 %) resulting from single particle ICP-MS (Table 4) was that an unknown number of small AgNPs was below the size detection limit (approximately 15 nm). Accordingly, the signal distribution histogram showed that the signals originating from AgNPs and from background signals were overlapping (Electronic Supplementary Material Fig. S2).

Conclusion

AgNPs could be separated from meat and separated by size by AF4 following appropriate enzymatic sample preparation that released AgNPs from the meat matrix into liquid suspension. Recoveries of AgNPs around 80 % were achieved. This finding makes enzymatic digestion a promising sample preparation method for inorganic NPs in protein-based sample matrices. Work is in progress towards validation of the AF4-ICP-MS method for AgNPs in meat and includes metrics such as limit of mass detection, linearity, precision, reproducibility and accuracy. The presence of the partially degraded meat matrix, had an influence on the elution behavior of the AgNPs following AF4 separation. Earlier elution was observed in comparison to the pristine AgNPs, which precluded determination of the particle size distribution based on retention times either based on AF4 theory or against an external size calibration curve. Obtaining size information therefore has to be handled with care and application of additional sizing methods such as TEM or single particle ICP-MS in combination with fraction collection is recommended. The applicability of TEM is limited by the possibly low NP concentration in the collected fractions and interpretation of the NP aggregation/agglomeration state is difficult because conventional TEM requires dried samples. Single particle ICP-MS is a method which is well-suited for determination of the number-based particle size distribution of AgNPs at low number concentration occurring in collected fractions from AF4. The method is restricted by the limit of detection regarding NP size which was in the range of 15 nm for AgNPs in our study. Further, the required high dilution level of the samples could influence the NP agglomeration state. Single particle ICP-MS after AF4 separation identified one fraction as non-nano Ag which was most likely ionic Ag bound to organic constituents of the enzymatic meat digestate. This demonstrated that additional information can be obtained by combination of single particle ICP-MS with a separation method like AF4 in comparison to bulk analysis, especially for NP analysis in complex matrices. Further work is necessary to optimize and combine these powerful detection methods to be able to determine the correct number-based size distribution of a real NP sample.

References

von der Kammer F, Legros S, Larsen EH, Loeschner K, Hofmann T (2011) Trends Anal Chem 30:425–436

Dubascoux S, Le Hecho I, Hassellöv M, Von Der Kammer F, Potin Gautier M, Lespes G (2010) J Anal At Spectrom 25:613–623

Elzey S, Grassian V (2010) J Nanoparticle Res 12:1945–1958

Poda AR, Bednar AJ, Kennedy AJ, Harmon A, Hull M, Mitrano DM, Ranville JF, Steevens J (2011) J Chromatogr 1218:4219–4225

Deering C, Tadjiki S, Assemi S, Miller J, Yost G, Veranth J (2008) Particle Fibre Toxicol 5:18

Tadjiki S, Assemi S, Deering CE, Veranth JM, Miller JD (2009) J Nanoparticle Res 11:981–988

Contado C, Pagnoni A (2008) Anal Chem 80:7594–7608

Nischwitz V, Goenaga-Infante H (2012) J Anal At Spectrom 27:1084–1092

Ludes B, Quantin S, Coste M, Mangin P (1994) Int J Leg Med 107:37–41

Yu C, Penn LD, Hollembaek J, Li W, Cohen LH (2004) Anal Chem 76:1761–1767

Nanotechproject.org. Woodrow Wilson International Centre for Scholars, Project on Emerging Nanotechnologies, Consumer Products Inventory of Nanotechnology Products. http://www.nanotechproject.org/inventories/consumer/. 10-3-2011

Loeschner K, Navratilova J, Legros S, Wagner S, Grombe R, Snell J, von der Kammer F, Larsen EH (2013) J Chromatogr A 1272:116–125

Goetz NV, Fabricius L, Glaus R, Weitbrecht V, Guenther D, Hungerbuehler K (2013) Food Addit Contam: Part A Chem Anal Control Expo Risk Assess 30:612–620

Laborda F, Jiménez-Lamana J, Bolea E, Castillo JR (2011) J Anal At Spectrom 26:1362–1371

Mitrano DM, Barber A, Bednar A, Westerhoff P, Higgins CP, Ranville JF (2012) J Anal At Spectrom 27:1131–1142

Tuoriniemi J, Cornelis G, Hassellöv M (2012) Anal Chem 84:3965–3972

Degueldre C, Favarger PY (2003) Colloids Surf A Physicochem Eng Asp 217:137–142

Pace HE, Rogers NJ, Jarolimek C, Coleman VA, Higgins CP, Ranville JF (2012) Anal Chem 84:4633

Gimbert LJ, Haygarth PM, Beckett R, Worsfold PJ (2005) Environ Sci Technol 39:1731–1735

EC (European Commission) (2011) Off J Eur Union 275:38–40

Liu J, Wang Z, Liu FD, Kane AB, Hurt RH (2012) ACS Nano 6:9887–9899

Acknowledgments

We thank the Core Facility for Integrated Microscopy (CFIM) at the University of Copenhagen for providing access to the electron microscopes. Further, we thank Thermo Fisher Scientific for providing the iCAP Q instrument. The work leading to these results has received funding from the European Union Seventh Framework Programme (FP7/2007-2013) under grant agreement no. 245162.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 1402 kb)

Rights and permissions

About this article

Cite this article

Loeschner, K., Navratilova, J., Købler, C. et al. Detection and characterization of silver nanoparticles in chicken meat by asymmetric flow field flow fractionation with detection by conventional or single particle ICP-MS. Anal Bioanal Chem 405, 8185–8195 (2013). https://doi.org/10.1007/s00216-013-7228-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-013-7228-z