Abstract

Stereoselective synthesis of unsaturated α-amino acids was performed by asymmetric alkylation. Two methods were investigated and their enantiomeric excess measured and compared. The first route consisted of an enantioselective approach induced by the Corey–Lygo catalyst under chiral phase transfer conditions while the second one involved the hydroxypinanone chiral auxiliary, both implicating Schiff bases as substrate. In all cases, the use of a prochiral Schiff base gave higher enantiomeric excess and yield in the final desired amino acid.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Unnatural amino acids constitute more and more attractive targets for drug design, and their asymmetric synthesis has been increasingly developed over the last decades. It is well known that non-proteinogenic amino acids incorporation in peptide sequences increases resistance to enzymatic proteolysis. Moreover, disposing of a wide variety of unnatural amino acids allows the modulation of physical and chemical properties of the resulting peptide depending on the selected side chains (Gentilucci et al. 2010).

In this domain, unsaturated amino acids represent very interesting building blocks. Indeed, alkenyl- or alkynyl- side chains can be functionalized by many chemical functions and offer a wide range of possible transformations (Gorges and Ullrich 2013; Marchand and Martinez 2008; Cavelier et al. 2008; Kazmaier et al. 2000b, 2001). Particularly, unsaturated α-amino acids give access to many synthetic applications in all fields of chemistry (Kaiser et al. 2005). Among them, metal catalysed cross-coupling reactions and cross metathesis are commonly used to generate peptide modifications (Kazmaier et al. 2013; Kazmaier et al. 2000a) and cyclization (Brik 2008). They can also be substrates of biological interest for fluorination for example as PET radiotracers (Höfling et al. 2008). They are very interesting and useful tools for « click » chemistry (Rostovtsev et al. 2002; Demko and Sharpless 2002) in peptidomimetic drug design or covalent modification of proteins (Chalker et al. 2011). They can also be incorporated in compounds as beta-turn inducer to promote secondary structures (Kaul et al. 2005). Finally they can be used for the preparation of stapled peptides. Stapled peptides were first designed by Verdine as a hydrocarbon staple that ‘locked’ a flexible peptide into the shape of an alpha-helix by reaction of two α,α-disubstituted non-natural amino acids bearing an olefin side chain (Schafmeister et al. 2000). In recent years a great number of papers have appeared on stapled pepides (Walensky and Bird 2014; De Araujo et al. 2014; Phillips et al. 2011) and it has been demonstrated that also monosubstituted alkenyl amino acids are suitable for their preparation (Aillard et al. 2014; Yeo et al. 2013).

Different synthetic approaches have been developed to obtain chiral unsaturated α-amino acids. They have been prepared by chiral induction with auxiliaries as Sulfinyl imino acetate (Kong et al. 2005) or bislactime ether (Bucuroaia et al. 2009). Kinetic resolution using cinchona alkaloids has also been employed (Hang and Deng 2009). Furthermore they have been synthesized by thioclaisen rearrangement, which further led to β-substituted-γ-δ unsaturated amino acids (Liu et al. 2008). Synthetic routes starting from boron derivatives through Petasis reaction (Li and Xu 2012) and phosphor derivatives through Wittig reactions (Rémond et al. 2012; Kokotos et al. 1998) also proved their efficiency.

Here, we present two stereoselective approaches to synthesize unsaturated α-amino acids in optically active form. The first method involved the Corey–Lygo chiral phase transfer catalyst (PTC), which enabled enantioselective alkylation of benzophenone Schiff base of glycine with unsaturated bromides (C–L induction). The second route implicated the use of (1R,2R,5R) hydroxypinan-3-one as chiral auxiliary affording a prochiral glycine Schiff base and dealt with diastereoselective alkylation (HP induction). We compared yields and stereoselectivity of each method with the same bromide derivatives.

Materials and methods

All solvents were purchased from Sigma Aldrich in gradient grade or reagent quality. All reactions involving air-sensitive reagents were performed under nitrogen or argon. Purifications were performed with column chromatography using silica gel (Merck 60, 230–400 mesh) or with a Biotage instrument Isolera 4 using SNAP KP-SIL flash cartridges. Proton nuclear magnetic resonance 1H-NMR and carbon nuclear magnetic resonance 13C-NMR spectra were recorded on a Bruker spectrometer avance 300 at 300 and 75 MHz, respectively. Chemicals shifts (δ) are reported from tetramethylsilane with the solvent resonance as the internal standard. Data are reported as follows: chemical shift (δ in ppm), multiplicity (s = singlet, d = doublet, t = triplet, q = quartet, br = broad, m = multiplet), integration, coupling constants (J = Hz) and assignment. Low resolution electrospray ionization (ESI) mass spectra were recorded on a micromass platform electrospray mass spectrometer. Spectra were recorded in the positive mode (ESI+). The analytical chiral HPLC experiments were performed on a Beckman System Gold 126 instrument with variable detector using Chiracel OD (Diacel Chemical industries) (4.6 × 250 mm, 10 µm), with a flow of 1 mL/min, and hexane/2-propanol: 90/10 as eluent.

Synthesis of tert-butyl 2-(diphenylmethylene amino)acetate 2

Benzophenone imine (1.81 g, 10 mmol) was added to a suspension of glycine tert-butylester hydrochloride 1 (1.68 g, 1 eq) in dichloromethane (40 mL). The mixture was stirred for 24 h at room temperature. The organic layer was then washed with water (20 mL), dried over MgSO4 and concentrated. The Schiff base 2 was obtained in quantitative yield.

MS–ESI: [M+H]+ = 296.4.

1HNMR (CDCl3, 300 MHz): δ (ppm) 1.44 (s, 9H, tBu); 4.10 (s, 2H, NCH 2 CO2tBu); 7.18–7.63 (m, 10H, HPh).

Alkylation procedure under Corey–Lygo catalysis conditions (procedure A)

To a solution of tert-butyl 2-(diphenylmethylene amino)acetate 2 (200 mg, 0.68 mmol) in toluene 7/dichloromethane 3 (3.4 mL) Corey–Lygo catalyst (41 mg, 0.1 eq) and a solution of potassium hydroxide 9 M (1.96 mL, 26 eq) were added. The mixture was cooled to 0 °C and alk(en)yl bromide (0.82 mmol, 1.2 eq) was slowly added. The reaction mixture was vigorously stirred for 24 h at room temperature. After concentration, the residue was diluted in water (30 mL) and ether (30 mL). The aqueous layer was then extracted with ether (3 × 45 mL), and the organic layer was washed with water (2 × 45 mL), dried over MgSO4 and concentrated.

Compound 3a

Yield: 92 % colourless oil.

1HNMR (CDCl3, 300 MHz): δ (ppm) 1.42 (s, 9H, tBu), 2.61–2.65 (m, 2H, CHCH 2 CHCH2), 3.95–4.01 (m, 1H, NCHCO2tBu), 4.97–5.09 (m, 2H, CHCH2CHCH 2 ), 5.64–5.77 (m, 1H, CHCH2 CHCH2), 7.14–7.80 (m, 10H, HPh).

Compound 3d

Yield: 100 % colourless oil.

1HNMR (CDCl3, 300 MHz): δ (ppm) 1.42 (s, 9H, tBu), 1.56–1.61 (m, 3H, CHCHCH 3 ), 2.34–2.54 (m, 2H, CHCH 2 CHCHCH3), 3.92–3.97 (m, 1H, NCHCO2tBu), 5.27–5.34 (m, 2H, CH2CHCHCH3), 7.25–7.82 (m, 10H, HPh).

Compound 3e

Yield: 93 % colourless oil.

1HNMR (CDCl3, 300 MHz): δ (ppm) 1.38 (s, 9H, OC(CH 3 ) 3 ), 1.45 (s, 3H, CH3), 2.45–2.58 (m, 2H, CHCH 2 C=CH2), 3.98–4.03 (m, 1H, CHCH2C=CH2), 4.64–4.67 (m, 2H, CH 2 =CH), 7.09–7.76 (m, 10H, HPh).

Compound 3f

Yield: 100 % colourless oil.

1HNMR (CDCl3, 300 MHz): δ (ppm) 1.43 (s, 9H, tBu), 1.71 (s, 3H, CH2C≡CCH 3 ), 2.63–2.77 (m, 2H, NCHCH 2 C≡CCH3), 4.07–4.12 (m, 1H, NCHCO2tBu), 7.20–7.80 (m, 10H, HPh).

Synthesis of (+)-(1R,2R,5R)-2-hydroxy-3-pinanone Schiff base 5.

A suspension of glycine tert-butylester hydrochloride 1 (0.17 g, 1.5 eq) in dry toluene (5 mL) was stirred in the presence of triethylamine (209 µL, 1.5 eq) for one hour. After triethylammonium chloride filtration, (1R,2R,5R)-2-hydroxy-3-pinanone (0.112 g, 0.67 mmol) was added to the free amine. The mixture was heated to reflux for 4 hour in the presence of boron trifluoride diethyl ether (10 μL). Water, formed during the reaction, was removed with a Dean–Stark trap. After cooling, the mixture was concentrated. The crude product was purified by chromatography separation on silica flash (cyclohexane 7/ethyl acetate 3; 1 % TEA). The Schiff base 5 (0.17 g) was obtained in 94 % yield as pale yellow oil.

R f = 0.3 (cyclohexane 7/ethylacetate 3).

MS–ESI [M+H]+ = 282.4.

1HNMR (CDCl3, 300 MHz): δ (ppm) 0.85 (s, 3H, CH 3bridge), 1.30 (s, 3H, CH 3bridge), 1.46 (s, 9H, tBu), 1.5 (s, 3H, C(OH)CH 3 ), 2.02–2.06 (m, 3H, CH 2 CHC(OH)CH3), 2.25–2.35 (m, 1H, CHCH2CN), 2.40–2.45 (m, 2H, CH 2 CN), 4.07 (s, 2H, CNCH 2 ).

Alkylation procedure in (+)-(1R,2R,5R)-2-hydroxy-3-pinanone induction (procedure B)

To a solution of diisopropylamine (0.35 mL, 2.5 eq) in dry THF (6 mL) was added very slowly a solution of n-butyllithium 2, 5 M in hexane (0, 96 mL, 2.4 eq) at −10 °C. After 30 min, the mixture was cooled to −78 °C and the Schiff base 5 (0.28 g, 1 mmol) dissolved in THF (1 mL) was added. After 40 min, the alk(en)yl bromide (1.8 eq) was added. The mixture was stirred at −78 °C for 8 h, then it was allowed to cool to −10 °C overnight. The reaction was quenched with a saturated solution of ammonium chloride (10 mL). THF was concentrated and the aqueous phase was extracted three times with ethyl acetate (3 × 20 mL). The organic phase was dried over MgSO4. After concentration, the crude product was purified on silica flash (cyclohexane/ethyl acetate; 1 % TEA) affording compounds 6a–f.

Compound 6a

Yield: 54 % pale yellow oil.

1HNMR (CDCl3, 300 MHz): δ (ppm) 0.81 (s, 3H, CH 3bridge), 1.22–1.28 (m, 4H, CH2 CHCH2 and CH 3bridge), 1.41 (s, 9H, tBu), 1.44 (s, 3H, C(OH)CH 3 ), 1.98–2.05 (m, 2H, C(OH)CHCH 2 ), 2.18–2.22 (m, 1H, C(OH)CH), 2.48–2.63 (m, 4H, NCCH 2 and CH2=CHCH 2 ), 4.08–4.12 (m, 1H, NCHCO2tBu), 4.98–5.09 (m, 2H, CH 2 =CH), 5.63–5.75 (m, 1H, CH2=CH).

Compound 6b

Yield: 14 % pale yellow oil.

1HNMR (CDCl3, 300 MHz): δ (ppm) 0.80 (s, 3H, CH3bridge), 1.26–1.30 (m, 4H, CH2 CHCH and CH 3bridge), 1.41 (s, 9H, tBu), 1.50 (s, 3H, C(OH)CH 3 ), 1.90–2.15 (m, 5H, C(OH)CHCH 2 , CH2=CHCH 2 and CH2=CHCH2 CH 2 ), 2.24–2.39 (m, 1H, C(OH)CH), 2.40–2.55 (m, 2H, NCCH 2 ), 4.01–4.08 (m, 1H, NCHCO2tBu), 4.93–5.01 (m, 2H, CH 2 =CH), 5.71–5.83 (m, 1H, CH2=CH).

Compound 6c

Yield: 41 % pale yellow oil.

1HNMR (CDCl3, 300 MHz): δ (ppm) 0.84 (s, 3H, CH 3bridge), 1.23–1.30 (m, 2H, CH 2 CHCH2), 1.31 (s, 3H, CH 3bridge), 1.37–1.39 (m, 2H, CH2=CHCH2 CH 2 ), 1.41 (s, 9H, tBu), 1.48 (s, 3H, C(OH)CH 3 ), 1.75–1.95 (m, 2H, CH2=CHCH2CH2 CH 2 ), 1.95–2.30 (m, 4H, C(OH)CHCH 2 and CH2=CHCH 2 ), 2.30–2.33 (m, 1H, C(OH)CH), 2.45–2.60 (m, 2H, NCCH 2 ), 4.01–4.08 (m, 1H, NCHCO2tBu), 4.93–5.01 (m, 2H, CH 2 =CH), 5.71–5.83 (m, 1H, CH2=CH).

Compound 6d

Yield: 45 % pale yellow oil.

1HNMR (CDCl3, 300 MHz): δ (ppm) 0.82 (s, 3H, CH 3bridge), 1.31 (s, 3H, CH 3bridge), 1.41 (s, 9H, tBu), 1.47 (s, 3H, C(OH)CH 3 ), 1.78–1.94 (m, 3H, CH 2 CHCO7tBu and CH=CHCH 3 ), 1.97–2.11 (m, 2H, HOCCHCH 2 ), 2.26–2.40 (m, 1H, C(OH)CH), 2.50–2.61 (m, 2H, NCCH 2 ), 4.00–4.11 (m, 1H, NCHCO2tBu), 4.88–5.05 (m, 1H, CH=CH), 5.68–5.87 (m, 1H, CH=CH).

Compound 6e

Yield: 42 % pale yellow oil.

1HNMR (CDCl3, 300 MHz): δ (ppm) 0.82 (s, 3H, CH 3bridge), 1.25 (s, 3H, CH 3bridge), 1.37 (s, 9H, OC(CH 3 ) 3 ), 1.42 (s, 3H, C(OH)CH 3 ), 1.67 (s, 3H, CH 3 ), 1.97–2.02 (m. 2H, HOCCHCH 2 ), 2.23–2.27 (m, 1H, C(OH)CH), 2.38–2.64 (m, 4H, NCCH 2 and CHCH 2 ), 4.16 (dd, 1H, J = 5.4, 8.2 Hz, CHCH2), 4.65–4.72 (m, 2H, CH 2 =CH).

Compound 6f

Yield: 85 % pale yellow oil.

1HNMR (CDCl3, 300 MHz): δ (ppm) 0.89 (s, 3H, CH 3bridge), 1.31 (s, 3H, CH 3bridge), 1.42 (s, 9H, tBu), 1.48 (s, 3H, C(OH)CH 3 ), 1.68 (s, 3H, C≡CCH 3 ), 2.00–2.07 (m, 2H, HOCCHCH 2 ), 2.26–2.39 (m, 1H, C(OH)CH), 2.50–2.76 (m, 4H, NCCH 2 and CH3C≡CCH 2 ), 4.22–4.27 (m, 1H, NCHCO2tBu).

Compound 6g

Yield: 10 % pale yellow oil

1HNMR (CDCl3, 300 MHz): δ (ppm) 0.86 (s, 3H, CH3bridge), 1.15–1.22 (m, 3H, CH 3 C≡CH), 1.34 (s, 3H, CH3bridge), 1,39 (s, 9H, tBu), 1.42 (s, 3H, C(OH)CH 3 ), 2.00–2.07 (m, 2H, HOCCHCH 2 ), 2.29–2.40 (m, 3H, NCCH 2 and C(OH)CH); 3.09–3.21 (m, 1H, CH2CHC≡CH), 3.84–4.00 (m, 1H, CH2CHC≡CH), 4.11–4.25 (m, 1H, NCHCO2tBu), 4.49 (br s, 1H, OH).

Cleavage procedure of alkylated Schiff bases 3 and 6 and amine function protection

To a solution of the alkylated Schiff base 3 (or 6) (1 eq) in THF (2 mL/mmol) was added a solution of citric acid 15 % (6 mL/mmol). The mixture was stirred at room temperature for 6 h for compounds 3a–d–f (for 3 days for compounds 6a–g). After removing THF in vacuo, the aqueous layer was extracted with diethylether (10 mL/mmol) in order to remove the ketone. Then, the pH was increased to 8–9 with potassium carbonate addition. The free amine was then extracted with ethyl acetate (3 × 15 mL/mmol). The organic layer was concentrated at room temperature due to the amine volatility. The tert-butylester was then dissolved in ethyl acetate (5 mL/mmol) and Fmoc-OSu (1.3 eq.) was added. The pH was adjusted to 8–9 with triethylamine addition and the mixture was stirred overnight. The organic layer was washed with a solution of potassium hydrogenosulphate (3 × 15 mL/mmol) and a saturated solution of sodium hydrogenocarbonate (3 × 15 mL/mmol). Then, organic layer was dried over MgSO4, concentrated and the crude product was purified on silica flash (cyclohexane/ethyl acetate).

Compound 4a

Our data are coherent with those reported in literature (Jakopin et al. 2013).

Yield over two steps: 67 % (procedure A); 66 % (procedure B) colourless oil.

1HNMR (CDCl3, 300 MHz): δ (ppm) 1.40 (s, 9H, OC(CH 3 ) 3 ), 2.38–2.50 (m, 2H, CH2=CHCH 2 ), 4.13–4.27 (m, 1H, NHCHCO2tBu), 4.30–4.35 (m, 3H, CHCH 2Fmoc), 5.05–5.09 (m, 2H, CH 2 =CH), 5.29 (br d, 1H, NH), 5.57–5.71 (m, 1H, CH2=CH), 7.27–7.76 (m, 8H, HFmoc).

13CNMR (CDCl3, 75 MHz): δ (ppm) 170.8, 155.6, 143.9, 143.8, 141.3, 132.2, 127.7, 127.0, 125.1, 119.9, 119.0, 82.3, 66.9, 53.6, 47.2, 37.0, 28.0.

ee = 83 % (procedure A).

ee = 90 % (procedure B).

Compound 4b

Our data are coherent with those reported in literature (Deboves et al. 2001).

Yield over two steps: 61 % (procedure B) colourless oil.

1HNMR (CDCl3, 300 MHz): δ (ppm) 1.46 (s, 9H, OC(CH 3 ) 3 ), 1.80–1.99 (m, 2H, CH2=CHCH2CH 2 ), 2.10–2.17 (m, 2H, CH2=CHCH 2 ), 4.19–4.31 (m, 1H, NHCHCO2tBu), 4.36–4.44 (m, 3H, CHCH 2Fmoc), 4.98–5.07 (m, 2H, CH 2 =CH) 5.25–5,36 (br d, 1H, NH), 5.73–5.90 (m, 1H, CH2=CH), 7.27–7.76 (m, 8H, HFmoc).

13CNMR (CDCl3, 75 MHz): δ (ppm) 172.1, 156.3, 144.5, 144.3, 141.8, 137.7, 128.2, 127.6, 125.6, 120.5, 116.1, 82.7, 67.4, 54.4, 47.7, 32.7, 30.2, 29.9, 28.6.

ee = 96 %.

Compound 4c

Yield over two steps: 63 % (procedure B) colourless oil.

1HNMR (CDCl3, 300 MHz): δ (ppm) 1.43 (s, 9H, OC(CH 3 ) 3 ), 1.61–1.92 (m, 2H, CH2=CHCH2CH2CH 2 ), 1.94–2.16 (m, 2H, CH2=CHCH 2 CH2CH2), 4.25–4.31 (m, 2H, CHCH2Fmoc and NHCHCO2tBu), 4.36–4.48 (m, 2H, CHCH 2Fmoc), 4.96–5.05 (m, 2H, CH 2 =CH), 5.36–5.39 (br d, 1H, NH), 5.71–5.84 (m, 1H, CH2=CH), 7.24–7.76 (m, 8H, HFmoc).

13CNMR (CDCl3, 75 MHz): δ (ppm) 171.8, 155.9, 144.1, 143.9, 141.4, 138.1, 127.8, 127.2, 125.2, 120.1, 115.2, 82.2, 67.0, 54.3, 47.3, 33.3, 32.4, 28.1, 24.4.

ee = 94 %.

Compound 4d

Yield over two steps: 65 % (procedure A); 59 % (procedure B) colourless oil.

1HNMR (CDCl3, 300 MHz): δ (ppm) 1.45 (s, 9H, OC(CH 3 ) 3 ), 1.60–1.67 (m, 3H, CH=CHCH 3 ), 2.35–2.52 (m, 2H, CH3CH=CHCH 2 ), 4.20–4.24 (m, 1H, NHCHCO2tBu), 4.32–4.42 (m, 3H, CHCH 2Fmoc), 5.20–5.69 (m, 3H, CH2 CH=CHCH3), 5.66–5.69 (br d, 1H, NH), 7.24–7.76 (m, 8H, HFmoc).

13CNMR (CDCl3, 75 MHz): δ (ppm) 172.5, 156.7, 144.8, 144.6, 142.1, 138.8, 128.5, 127.9, 125.9, 120.8, 115.9, 82.9, 67.7, 55.0, 48.0, 34.0, 33.1, 28.9, 25.1.

ee = 92 % (procedure A).

ee = 98 % (procedure B).

Compound 4e

Yield: 69 % over two steps (procedure A), 62 % over two steps (procedure B) colourless oil.

1HNMR (CDCl3, 300 MHz): δ (ppm) 1.50 (s, 9H, OC(CH 3 ) 3 ), 1.81 (s, 3H, CH3), 2.39–2.61 (m, 2H, CHCH 2 C=CH2), 4.23–4.28 (m, 1H, CHCH2C=CH2), 4.34–4.47 (m, 3H, CHCH 2Fmoc), 4.81 (s, 1H, CH 2 =CH), 4.89 (s, 1H CH 2 =CH), 5.32 (d, J = 8.07 Hz, 1H, NH), 7.30–7.79 (m, 8H, HFmoc).

13CNMR (CDCl3, 75 MHz): δ (ppm) 171.4, 155.7, 144.0, 143.9, 141.3, 140.7, 127.7, 127.0, 125.2, 119.9, 114.5, 82.2, 66.9, 52.6, 47.2, 41.1, 28.0, 26.9, 21.9.

ee = 94 % (procedure A).

ee = 94 % (procedure B).

Compound 4f

Yield over two steps: 39 % (procedure A); 50 % (procedure B) colourless oil.

1HNMR (CDCl3, 300 MHz): δ (ppm) 1.43 (s, 9H, OC(CH 3 ) 3 ), 1.78 (s, 3H, CH 3alkyne), 2.63–2.75 (m, 2H, CH3C≡CCH 2 ), 4.17–4.26 (m, 1H, NHCHCO2tBu), 4.37–4.39 (m, 3H, CHCH 2Fmoc), 5.66–5.69 (br d, 1H, NH), 7.28–7.77 (m, 8H, HFmoc).

13CNMR (CDCl3, 75 MHz): δ (ppm) 169.6, 155.5, 143.7, 141.1, 127.5, 126.9, 125.0, 119.8, 82.2, 78.8, 73.0, 66.9, 53.0, 47.0, 27.8, 23.1 3.29.

ee = 88 % (procedure A).

ee = 94 % (procedure B).

Compound 4g

Yield over two steps: 96 % colourless oil.

1HNMR (CDCl3, 300 MHz): δ (ppm) 1.20 (d, 3H, J = 7.13 Hz, CHCH 3 ), 1.42 (s, 9H, OC(CH 3 ) 3 ), 2.08–2.09 (d, 1H, J = 2.42 Hz, C≡CH), 3.06–3.15 (m, 1H, CH(CH3)C≡C), 4.16–4.21 (m, 1H, NHCHCO2tBu), 4.25–4.34 (m, 3H, CHCH 2Fmoc), 5.40 (br d, 1H, NH), 7.22–7.71 (m, 8H, HFmoc).

13CNMR (CDCl3, 75 MHz): δ (ppm) 170.0, 155.9, 144.1, 141.5, 127.9, 127.3, 125.4, 120.2, 82.6, 79.2, 77.6, 73.4, 67.3, 53.3, 47.4, 29.9, 28.2, 23.5, 3.7.

ee = 93 %.

Compound 7

1HNMR (CDCl3, 300 MHz): δ (ppm) 1.37 (s, 9H, OC(CH 3 ) 3 ), 1.39 (s, 9H, CH3Boc), 1.52–1.65 (m, 2H CH 2 ), 1.67–1.75 (m, 2H, CH 2 CH=CH2), 1.96–2.03 (m, 2H, CHCH 2 ), 4.07–4.13 (m, 1H, CHCH2), 4.88–4.98 (m, 3H, NH and CH=CH 2 ), 5.64–5.77 (m, 1H, CH=CH2).

13CNMR (CDCl3, 75 MHz): δ (ppm) 172.0, 155.3, 138.1, 114.9, 81.7, 79.5, 53.8, 33.2, 32.3, 28.3, 28.0, 24.3.

Compound 8

Compound 7 (59 mg, 0.19 mmol) was dissolved in dry dichloromethane (0.6 mL) under argon followed by addition of the catalyst (Bu4N)2PtCl6 (8.8 mg, 0.01 mmol) and HSi(CH3)2Ph (48 mg, 0.34 mmol). The stirred mixture was heated to reflux for 2 h. The solvent was removed and the product purified by silica gel chromatography to give compound 8 as a colourless oil in 70 % yield.

1HNMR (CDCl3, 300 MHz): δ (ppm) 0.25 (s, 6H, CH 3 Si), 0.71–0.75 (m, 2H, CH 2 Si), 1.28–1.33 (m, 8H, CH 2 ), 1.45 (s, 9H, OC(CH 3 ) 3 ), 1.46 (s, 9H, CH3Boc), 4.12–4.18 (m, 1H, CHCH2), 4.99 (br, 1H, NH), 7.34–7.36 (m, 3H, Ar), 7.49–7.52 (m, 2H, Ar).

13CNMR (CDCl3, 75 MHz): δ (ppm) 171.8, 155.0, 139.2, 133.0, 128.3, 127.5, 81.2, 79.1, 53.6, 32.6, 32.3, 28.0, 27.5, 24.3, 23.3, 15.2, −3.4.

Compound 9

Iron(III) oxalate hexahydrate (275 mg, 0.56 mmol) was stirred in H2O (11.4 mL) until completely dissolved (t ~ 2 h). The solution was cooled to 0 °C and degassed for 10 min. Selectfluor (201 mg, 0.56 mmol) and MeCN (5.7 mL) were added to the reaction mixture. A solution of 7 (85 mg, 0.28 mmol) in MeCN (5.7 mL) was transferred to the reaction mixture and NaBH4 (32 mg, 0.85 mmol) was added to the mixture at 0 °C. After 2 min, the reaction mixture was treated with an additional portion of NaBH4 (32 mg, 0.85 mmol). The resulting mixture was stirred for 30 min before being quenched by addition of 28–30 % aqueous NH4OH (5.7 mL). The mixture was extracted with 10 % MeOH in CH2Cl2 and the organic layer was dried over MgSO4 and concentrated under reduced pressure. Flash chromatography (SiO2, cyclohexane/ethyl acetate 95:5) provided 9 as colourless oil (70 mg, 77 %).

1HNMR (CDCl3, 300 MHz): δ (ppm) 1.19–1.29 (m, 3H, CH 3 ), 1.29–1.57 (m, 2H, CH3CFCH2CH2CH 2 ), 1.37 (s, 9H, OC(CH 3 ) 3 ), 1.40 (s, 9H, CH3Boc), 1.58–1.66 (m, 2H, CH3CFCH2CH 2 CH2), 1.70–1.77 (m, 2H, CH3CFCH 2 CH2CH2), 4.08–4.14 (m, 1H, CHCH2), 4.46–4.67 (m, 1H, CHF), 4.96 (d, 1H, J = 7.1 Hz, NH).

13CNMR (CDCl3, 75 MHz): δ (ppm) 171.9, 155.3, 90.6 (d, J = 166 Hz), 90.4 (d, J = 166 Hz), 81.8, 79.5, 53.7, 36.4 (d, J = 21 Hz), 36.3 (d, J = 21 Hz), 32.8, 32.6, 30.1, 28.3, 27.9, 23.6, 21.1, 21.0, 20.9, 20.8, 20.7. 19FNMR (CDCl3, 376 MHz) δ (ppm) −172.9, −173.16.

Results and discussion

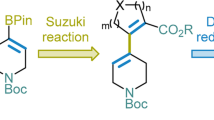

To synthesize unnatural amino acids with an unsaturated side chain, we firstly prepared benzophenone Schiff base 2 starting from glycinate tert-butylester hydrochloride 1 and benzophenone imine in quantitative yield (O’Donnell and Polt 1982). Different types of reactions applied under phase transfer conditions and different classes of catalysts were described a few years ago and gave an overview of this chemical process scope (Ooi and Maruoka 2007). We chose to use a quaternary ammonium ion as a catalyst, which was a cinchonidine derivative named Corey–Lygo (Lygo and Andrews 2004; Corey et al. 1997). This catalyst already proved its efficiency for enantioselective induction on glycine derivative as substrates (Denmark et al. 2011). We investigated several alkylation conditions described in literature (Respondek et al. 2011; Lygo and Andrews 2004; Corey et al. 1997). The best and mildest method of PTC alkylation was performed using a 9 M potassium hydroxide solution as a base, at 0 °C in a mixture of toluene/dichloromethane (7:3) (Benohoud et al. 2009). The result-affording compounds 3a–g are gathered in Table 1. (S)-Fmoc amino acids 4a–g were obtained after Schiff base hydrolysis under acidic conditions followed by N-protection (Table 2). The enantiomeric excess as well as the stereochemistry of the compounds obtained via Corey–Lygo PTC condition was determined using chiral HPLC and by comparison of the retention time with the respective compound obtained via HP condition. It is well known that depending on the chirality of the hydroxypinanone moiety it is possible to control the stereochemistry of the final product. Thus starting from (1R,2R,5R)hydroxypinan-3-one, S amino esters are obtained (Tabcheh et al. 1991; El Achqar et al. 1988) (Scheme 1).

In parallel, (1R,2R,5R)hydroxypinan-3-one was used for the preparation of shiff base 5. The use of this chiral auxiliary showed its ability to promote excellent diastereoselectivity in α-amino acid synthesis, as we recently reported (René et al. 2013). We applied this route to our new targets (Scheme 2), and alkylation yields are reported in Table 1. Alkylation was then carried out using Lithium diisopropylamide (LDA) affording compounds 6a–g. The Schiff base was then hydrolysed under acidic conditions and Fmoc N-protected affording S amino acids 4a–g (Table 2).

When comparing both methods, we were facing two opposite situations: either alkylation yields of benzophenone Schiff base under phase transfer conditions were higher than the alkylation yields with hydroxypinanone induction (entries 1, 4, 5 and 6), or the introduction of an unsaturated chain did not occur at all (entries 2, 3 and 7). We can observe that if the substitution site is not an activated position, alkylation is not possible under PTC conditions (entries 2, 3). We can rationally hypothesize that the high basic aqueous conditions degrade bromide derivatives by an elimination mechanism. Indeed, hydrogen atoms, which are situated in α-position of the bromine atom, can easily be wrested in basic medium. Alkylations with alkenyl bromide derivatives can be performed in quantitative yield (entry 6) but only when the substitution site is not branched (entry 7). Concerning hydroxypinanone induction, alkylation yields are low to moderate (entries 1, 2, 3, 5 and 7) excepted for linear alkenyl chains (entries 4 and 6). These results are probably due to the relative ability of bromide atom to be a good leaving group. A basic medium can indeed easily promote the elimination of bromide especially when the elimination product leads to the formation of a stable conjugated compound such as the case of electrophiles b and g (entries 2 and 7).

After Schiff base hydrolysis to release the free amine function, Fmoc derivatives were obtained in moderate to good yields according to side chains polarity (Table 2).

Both routes when they are comparable induced excellent enantiomeric excess higher than 90 %. The best result concerned the compound 4d, which was obtained in 98 % ee with hydroxypinanone as chiral auxiliary and in a good overall yield.

In order to confirm the potential of unsaturated amino acids as tools for amino acid diversification we prepared, starting from the Boc protected compound 7, two different amino acids derivatives containing a silica atom and a fluorine atom, respectively (Scheme 3). The Boc protection was chosen in this case in order to differentiate the protecting group pattern exploitable in our synthetic pathway. Thus silicon-containing derivative 8 was prepared by hydrosilylation reaction previously optimized in our research group (Marchand and Martinez 2008) and provides an alternative synthetic procedure for the preparation of long side chain silylated compounds. The presence of a silicon-containing amino acid has been proved to influence the stability, conformation and bioactivity of silicon-containing peptides (Martin et al. 2014; Cavelier et al. 2002). The presence of fluorine in pharmaceutical products (Müller et al. 2007) and the use of labelled 18F compounds for positron emission tomography (PET) molecular imaging (Wu et al. 2014) prompted us to prepare fluorinated amino acid 9. The application of a method developed by Boger resulted in exclusive Markovnikov addition and obtainment of fluorinated compound 9 (Barker and Boger 2012). Both methods work with excellent yields providing an easy access to heteroatom-containing amino acids.

Conclusion

In summary, we performed stereoselective synthesis of seven unsaturated α-amino acids via two methods of asymmetric alkylation. On one hand, when the synthesis was carried out under chiral phase transfer conditions with the Corey–Lygo catalyst, the desired amino acid was obtained in good yields and rather good ee, but failed in a few cases. On the other hand, exploitation of the hydroxypinanone-induced asymmetric alkylation afforded all the α-amino acids desired with slightly lower alkylation yields and with an excellent final ee. Finally, we prepared an example of fluorinated a silylated amino acid to prove the extended versatility of unsaturated amino acids as chiral building blocks for amino acids diversification.

References

Aillard B, Robertson NS, Baldwin AR, Robins S, Jamieson AG (2014) Robust asymmetric synthesis of unnatural alkenyl amino acids for conformationally constrained α-helix peptides. Org Biomol Chem 12(43):8775–8782

Barker TJ, Boger DL (2012) Fe(III)/NaBH4-mediated free radical hydrofluorination of unactivated alkenes. J Am Chem Soc 134(33):13588–13591

Benohoud M, Leman L, Cardoso SH, Retailleau P, Dauban P, Thierry J, Dodd RH (2009) Total synthesis and absolute configuration of the natural amino acid tetrahydrolathyrine. J Org Chem 74(15):5331–5336

Brik A (2008) Metathesis in peptides and peptidomimetics. Adv Synth Catal 350(11–12):1661–1675

Bucuroaia C, Groth U, Huhn T, Klinge M (2009) Asymmetric synthesis of α-allenylglycines. Eur J Org Chem 21:3605–3612

Cavelier F, Vivet B, Martinez J, Aubry A, Didierjean C, Vicherat A, Marraud M (2002) Influence of silaproline on peptide conformation and bioactivity. J Am Chem Soc 124(12):2917–2923

Cavelier F, Marchand D, Martinez J (2008) α, α ‘-disubstituted amino acids with silylated side chains as lipophilic building blocks for the synthesis of peptaibol analogues. Chem Biodiv 5(7):1279–1287

Chalker JM, Bernardes GJL, Davis BG (2011) A “tag-and-modify” approach to site-selective protein modification. Acc Chem Res 44(9):730–741

Corey EJ, Xu F, Noe MC (1997) A rational approach to catalytic enantioselective enolate alkylation using a structurally rigidified and defined chiral quaternary ammonium salt under phase transfer conditions. J Am Chem Soc 119(50):12414–12415

De Araujo AD, Hoang HN, Kok WM, Diness F, Gupta P, Hill TA, Driver RW, Price DA, Liras S, Fairlie DP (2014) Comparative α-helicity of cyclic pentapeptides in water. Angew Chem Int Ed Engl 53(27):6965–6969

Deboves HJC, Montalbetti CAGN, Jackson RFW (2001) Direct synthesis of Fmoc-protected amino acids using organozinc chemistry: application to polymethoxylated phenylalanines and 4-oxoamino acids. J Chem Soc Perkin Trans 1(16):1876–1884

Demko ZP, Sharpless KB (2002) A click chemistry approach to tetrazoles by huisgen 1,3-dipolar cycloaddition: synthesis of 5-acyltetrazoles from azides and acyl cyanides. Angew Chem Int Ed Engl 41(12):2113–2116

Denmark SE, Gould ND, Wolf LM (2011) A systematic investigation of quaternary ammonium ions as asymmetric phase-transfer catalysts. Synthesis of catalyst libraries and evaluation of catalyst activity. J Org Chem 76(11):4260–4336

El Achqar A, Boumzebra M, Roumestant M-L, Viallefont P (1988) 2-Hydroxy-3-pinamone as chiral auxiliary in the asymmetric synthesis of α-amino acids. Tetrahedron 44(17):5319–5332

Gentilucci L, De Marco R, Cerisoli L (2010) Chemical modifications designed to improve peptide stability: incorporation of non-natural amino acids, pseudo-peptide bonds, and cyclization. Curr Pharm Des 16(28):3185–3203

Gorges J, Ullrich A, Kazmaier U (2013) Straightforward approach to ferrocenyl amino acids and peptides by allylic Alkylation. Eur J Org Chem 20:4372–4378

Hang J, Deng L (2009) Asymmetric synthesis of β, γ-unsaturated α-amino acids via efficient kinetic resolution with cinchona alkaloids. Bioorg Med Chem Lett 19(14):3856–3858

Höfling SB, Hultsch C, Wester H-J, Heinrich MR (2008) Radiochemical 18F-fluoroarylation of unsaturated α-, β- and γ-amino acids, application to a radiolabelled analogue of baclofen. Tetrahedron 64(52):11846–11851

Jakopin Ž, Gobec M, Kodela J, Hazdovac T, Mlinarič-Raščan I, Sollner Dolenc M (2013) Synthesis of conformationally constrained γ-d-glutamyl-meso-diaminopimelic acid derivatives as ligands of nucleotide-binding oligomerization domain protein 1 (Nod1). Eur J Med Chem 69:232–243

Kaiser J, Kinderman SS, van Esseveldt BCJ, van Delft FL, Schoemaker HE, Blaauw RH, Rutjes FPJT (2005) Synthetic applications of aliphatic unsaturated α-H-α-amino acids. Org Biomol Chem 3(19):3435–3467

Kaul R, Surprenant S, Lubell WD (2005) Systematic study of the synthesis of macrocyclic dipeptide β-turn mimics possessing 8-, 9-, and 10- membered rings by ring-closing metathesis. J Org Chem 70(10):3838–3844

Kazmaier U, Maier S, Zumpe FL (2000a) A journey from amino acid and peptide chemistry to palladium and back. Synlett 11:1523–1535

Kazmaier U, Schauß D, Pohlman M, Raddatz S (2000b) Application of the molybdenum-catalysed hydrostannation towards a flexible synthesis of substituted unsaturated amino acids. Synthesis 07:914–916

Kazmaier U, Schauß D, Raddatz S, Pohlman M (2001) Preparation and reactions of stannylated amino acids. Chem Eur J 7(2):456–464

Kazmaier U, Bayer A, Deska J (2013) Palladium-catalyzed allylic alkylations as versatile tool for amino acid and peptide modifications. Synthesis 45(11):1462–1468

Kokotos G, Padrón JM, Martín T, Gibbons WA, Martín VS (1998) A general approach to the asymmetric synthesis of unsaturated lipidic α-amino acids. The first synthesis of α-aminoarachidonic acid. J Org Chem 63(11):3741–3744

Kong J-R, Cho C-W, Krische MJ (2005) Hydrogen-mediated reductive coupling of conjugated alkynes with ethyl (N-Sulfinyl)iminoacetates: synthesis of unnatural α-amino acids via rhodium-catalyzed C–C bond forming hydrogenation. J Am Chem Soc 127(32):11269–11276

Li Y, Xu M-H (2012) Lewis acid promoted highly diastereoselective petasis borono-mannich reaction: efficient synthesis of optically active β, γ-unsaturated α-amino acids. Org Lett 14(8):2062–2065

Liu Z, Qu H, Gu X, Min BJ, Nyberg J, Hruby VJ (2008) Enantioselective synthesis of anti-β-substituted γ, δ-unsaturated amino acids: a highly selective asymmetric thio-claisen rearrangement. Org Lett 10(18):4105–4108

Lygo B, Andrews BI (2004) Asymmetric phase-transfer catalysis utilizing chiral quaternary ammonium salts: asymmetric alkylation of glycine imines. Acc Chem Res 37(8):518–525

Marchand D, Martinez J, Cavelier F (2008) Straightforward synthesis of chiral silylated amino acids through hydrosilylation. Eur J Org Chem 18:3107–3112

Martin C, Legrand B, Lebrun A, Berthomieu D, Martinez J, Cavelier F (2014) Silaproline helical mimetics selectively form an all-trans PPII helix. Chem Eur J 20(44):14240–14244

Müller K, Faeh C, Diederich F (2007) Fluorine in pharmaceuticals: looking beyond intuition. Science 317(5846):1881–1886

O’Donnell MJ, Polt RL (1982) A mild and efficient route to Schiff base derivatives of amino acids. J Org Chem 47(13):2663–2666

Ooi T, Maruoka K (2007) Recent advances in asymmetric phase-transfer catalysis. Angew Chem Int Ed Engl 46(23):4222–4266

Phillips C, Roberts LR, Schade M, Bazin R, Bent A, Davies NL, Moore R, Pannifer AD, Pickford AR, Prior SH, Read CM, Scott A, Brown DG, Xu B, Irving SL (2011) Design and structure of stapled peptides binding to estrogen receptors. J Am Chem Soc 133(25):9696–9699

Rémond E, Bayardon J, Ondel-Eymin M-J, Jugé S (2012) Stereoselective synthesis of unsaturated and functionalized l-NHBoc amino acids, using Wittig reaction under mild phase-transfer conditions. J Org Chem 77(17):7579–7587

René A, Vanthuyne N, Martinez J, Cavelier F (2013) (L)-(Trimethylsilyl)alanine synthesis exploiting hydroxypinanone-induced diastereoselective alkylation. Amino Acids 45(2):301–307

Respondek T, Cueny E, Kodanko JJ (2011) Cumyl ester as the C-terminal protecting group in the enantioselective alkylation of glycine benzophenone imine. Org Lett 14(1):150–153

Rostovtsev VV, Green LG, Fokin VV, Sharpless KB (2002) A stepwise huisgen cycloaddition process: copper(I)-catalyzed regioselective “ligation” of azides and terminal alkynes. Angew Chem Int Ed Engl 114(14):2708–2711

Schafmeister CE, Po J, Verdine GL (2000) An all-hydrocarbon cross-linking system for enhancing the helicity and metabolic stability of peptides. J Am Chem Soc 122(24):5891–5892

Tabcheh M, El Achqar A, Pappalardo L, Roumestant M-L, Viallefont P (1991) Alkylation and protonation of chiral schiff bases: diastereoselectivity as a function of the nature of reactants. Tetrahedron 47(26):4611–4618

Walensky LD, Bird GH (2014) Hydrocarbon-stapled peptides: principles, practice, and progress. J Med Chem 57(15):6275–6288

Wu Z, Li L, Liu S, Yakushijin F, Yakushijin K, Horne D, Conti PS, Li Z, Kandeel F, Shively JE (2014) Facile preparation of a thiol-reactive 18F-labeling agent and synthesis of 18F-DEG-VS-NT for PET imaging of a neurotensin receptor-positive tumor. J Nucl Med 55(7):1178–1184

Yeo DJ, Warriner SL, Wilson AJ (2013) Monosubstituted alkenyl amino acids for peptide “stapling”. Chem Commun (Camb) 49(80):9131–9133

Acknowledgments

We thank Géraldine Masson and Yan chao from ICSN for giving the Corey–Lygo catalyst and Medincell S.A for financial support (Cifre Grant of Adeline René).

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Handling Editor: J. Leban.

Rights and permissions

About this article

Cite this article

Fanelli, R., Jeanne-Julien, L., René, A. et al. Stereoselective synthesis of unsaturated α-amino acids. Amino Acids 47, 1107–1115 (2015). https://doi.org/10.1007/s00726-015-1934-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00726-015-1934-0