Abstract

We have prepared a sol–gel that incorporates Prussian Blue (PB) as a redox mediator. It is shown that the PB in the pores of the sol–gel retains its electrochemical activity and is protected from degradation at acidic and neutral pH values. TEM and EDX studies revealed the PB nanoparticles to possess a cubic crystal structure and to be well entrapped and uniformly dispersed in the pores of the matrix. The electrocatalytic activity of the materials toward hydrogen peroxide (H2O2) was studied by cyclic voltammetry and amperometry. The modified electrode displays good sensitivity for the electrocatalytic reduction of H2O2 both in acidic (pH 1.4) and neutral media. The sensor has a dynamic range from 3 to 210 μM of H2O2, and the detection limit is 0.6 μM (at an SNR of 3).

TEM micrograph of the Sol-gel–PB composite showing a large quantity of crystalline cubic nanoparticles uniformly distributed in the sol-gel matrix and electrocatalytic response of the Sol-gel–PB electrode for hydrogen peroxide.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Hydrogen peroxide (H2O2) is an important chemical to be monitored in various fields, such as food, medicine, clinical, industrial and environmental analysis. H2O2 is a very reactive byproduct of many metabolic pathways, is an essential mediator in pharmaceutical and clinical research and an important contaminant in some industrial products and wastes. Therefore, a quick and reliable analysis technique for this compound is very important. Horseradish peroxidase (HRP), which can catalyze the oxidation of various substrates by hydrogen peroxide, is one of the most commonly used metalloenzymes for the construction of electrochemical biosensors for H2O2 [1]. Although HRP can catalyze the electrochemical reduction of H2O2, direct electron transfer between HRP and electrode is a difficult process due to their deeply located redox centers. For a faster electron transfer, mediated electrochemical biosensors are typically used [1].

Even though enzyme based biosensors might achieve higher sensitivity and selectivity for H2O2 detection, still there are many disadvantages that limit their universal applications. Firstly, the optimal immobilization of enzyme so as to ensure a good stability of the biosensor is a very complicated process. Secondly, the activity of enzyme can be easily affected by the small changes in operational conditions such as temperature, pH, toxic reaction products, leading thus to the poor stability and low reproducibility of enzymatic sensors. Moreover, enzymes are expensive reagents and thus increase the costs of the analysis. Considering these aspects, the development of novel non-enzymatic sensor for H2O2 still involve an intensive research interest.

Comprehensive reviews concerning the H2O2 electrochemical sensing based on metal nanoparticles have been reported [2–4]. A large variety of electrodes modified by redox mediators and electrocatalysts have been reported in the literature for promoting the oxidation/reduction and detection of H2O2 [5, 6]. Among them, Prussian blue (ferric hexacyanoferrate) has been extensively used and studied for its catalytic activity towards hydrogen peroxide reduction. Huge number of studies has investigated different methods for preparation of Prussian blue (PB) modified electrodes with good sensitivity toward H2O2 detection [7–11].

Almost all procedures adopted for PB deposition are based on chemical method which involves the simple chemical reaction between ferric chloride and ferricyanide and resulting sometimes in a large excess of deposited PB layer with low stability [10, 12]. Another approach for PB synthesis involves an electrochemical driving force which consists in a constant applied potential [8, 11, 13] or potential cycling [14–16] in a solution of ferric and ferricyanide ions. Self-assembling is another common approach for production of PB-modified electrodes by alternating electrostatic adsorption of charged components [17, 18].

The incorporation of Prussian blue mediator into polymeric matrix has been scarcely explored. Karyakin et al. [19] studied the electrodeposition of polypyrrole-PB films under different cyclic voltammetric conditions, showing that various mixed anodic-cathodic polypyrrole-PB films can be grown by changing the electrochemical conditions. Li et al. [7] reported the integration of Prussian blue together with multiwalled carbon nanotubes (MWNT) in a polymeric matrix of poly(4-vinylpyridine) for constructing electrochemical sensors with improved sensitivity towards electroreduction of H2O2. A Prussian blue/polyaniline/MWNTs composite film was fabricated through step-by-step electrodeposition on glassy carbon electrode by Zou et al. [20], while a composite consisting of graphene oxide, Prussian blue and chitosan was prepared by a single-step process [21].

Important advances in inorganic materials obtained by sol–gel method and their applications in electrochemistry were described in remarkable review articles [22–26]. These materials offer several advantages over organic polymers including physical rigidity, chemical inertness, negligible swelling in aqueous or organic solutions, photochemical and thermal stability and optical transparency [22]. Relatively few papers appear in the literature combining sol–gel matrices and PB mediator. These reports were generally based on the chemical synthesis of PB supported on graphite powder and subsequently dispersed into methyltrimethoxysilane-derived gels [27] or electrochemical deposition of PB follow by additional cover with sol–gel as a membrane on the top of PB-modified electrode [28]. Miecznikowski et al. [29] investigated the iron-hexacyanoferrate as a dopant in silica under conditions of a solid state voltammetric experiment, demonstrating that encapsulated iron hexacyanoferrate redox centers seem to be in the dispersed colloidal state rather than in the form of a rigid polymeric film.

In this work, PB is incorporated into the structure of a silica sol–gel network. In an earlier work [30], we reported the synthesis of a hybrid nanocomposite, combining sol–gel matrix with a phenoxazine redox mediator (Meldola’s blue) and carbon nanotubes, obtaining a material with enhanced redox properties and electrocatalytic activity toward NADH compared to individual components by themself. Starting from this system, it was of interest to study the fabrication and electroanalytical application of Prussian blue mediator–doped sol–gel matrix towards H2O2 reduction. The composite preparation involves a simple procedure, which does not require any purification, separation, centrifugation or sedimentation steps. Also, the modification of the electrode is a simple method, by drop-coating followed by a short time of drying. Moreover, the good stability and electrocatalytic activity at neutral pH show a good promise for the fabrication of enzyme-based biosensors in which the enzyme could be immobilized together with the redox mediator in a simple one-step method.

Experimental

Reagents

Analytical grade FeCl3 · 6H2O, K3Fe(CN)6, tetramethoxysilane (TMOS), trimethoxymethylsilane (MTMOS), HCl, KCl, NaCl, sodium phosphate, potassium phosphate, potassium acetate and hydrogen peroxide 30 % were purchased from Sigma-Aldrich (http://www.sigmaaldrich.com). All solutions were prepared with doubly distilled water.

Instrumentation and Methods

Cyclic voltammetry and amperometry measurements were carried out using a multipotentiostat AUTOLAB PGSTAT302N electrochemical system from ECO CHEMIE Utrecht, The Netherlands (http://www.ecochemie.nl) connected to a PC. All experiments were carried out in 3 mL supporting electrolyte in a conventional electrochemical cell, at room temperature, using a three-electrode system. Glassy carbon electrodes purchased from BASi – Bioanalytical Systems, Inc., USA (http://www.basinc.com) were used as working electrode; an Ag/AgCl electrode and a platinum wire were used as reference and auxiliary electrodes.

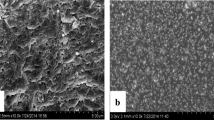

Morphological studies of Sol–gel–PB composite were performed using Hitachi HT7700 transmission electron microscope (TEM) (http://www.hitachi-hta.com) with cryo holder operating at 100 kv in High Resolution and Diffraction mode, allowing obtaining particle sizes, shapes, and their crystallinity character. Sample preparation: one drop of the Sol–gel–PB sonicated sample was placed on a carbon-coated grid.

Quanta 200-FEI scanning electron microscope equipped with energy dispersive X-ray system (EDX) (http://www.fei.com/) permits to determine the elemental composition and the distribution of each element in the sample. Samples preparation: a drop of Sol–gel–PB composite was deposited on microscope lamellae and then dried for 48 hours in oven. Double-sided carbon tape was used to mount the samples on aluminum stubs.

Preparation of Sol–gel–PB composites

The Sol–gel–PB composites are prepared by two-step hydrolysis process:

-

(i)

The sol–gel matrix was prepared according to procedure described elsewhere [30]. Shortly, 100 μL TMOS, 100 μL MTMOS, 400 μL distilled water and 440 μL HCl 1 mM were stirred and sonicated for 10 min obtaining a transparent sol, which is aged in a sealed vial at 4 °C until use for the combination with Prussian blue.

-

(ii)

The synthesis of PB was accomplished by chemical reaction of an equimolar mixture of ferric and ferricyanide ions. The Prussian blue precursors were prepared as solutions of 10 mM FeCl3 and 10 mM K3Fe(CN)6 in HCl 10 mM. In order to attain a higher sensitivity for H2O2 detection, solutions of 20 mM concentrations have been also tested in the formation of PB.

Prior to electrode modification, the Sol–gel–PB composites have been freshly prepared by mixing the components, Sol–gel and PB, in different ratio, such as 1:1, 1:2 and 1:3 (v/v). Mixtures were vigorously stirred for 5 min, kept at 4 °C, and used throughout one day. In order to avoid changes due to the continuous grow of PB particles as well as changes of sol–gel pores due to the condensation process, the Sol–gel–PB mixtures were prepared daily by mixing the already prepared solutions Sol–gel and PB. A volume of 2 μL from the composite was deposited on the glassy carbon electrode surface, previously polished with alumina slurries. The modified electrodes were dried at room temperature for at least 1 h.

For comparison, the PB alone was deposited as a thick layer adsorbed onto the glassy carbon electrode by mixing 1 μL FeCl3 10 mM with 1 μL K3Fe(CN)6 10 mM directly onto electrode surface and dried at room temperature for 1 h.

Results and discussions

Characterization of Sol–gel–PB composites

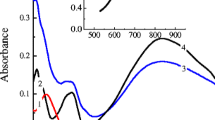

The effectiveness of the PB formation into the sol–gel matrix pores was verified by cycling the modified electrodes from −0.3 to 0.6 V in 0.1 M HCl + KCl supporting electrolyte. Figure 1, curve a shows the voltammogram of the Sol–gel–PB (1:1) modified electrode, revealing the well-known form of the reversible redox peaks of Prussian blue: at 0.17/0.14 V corresponding to the Prussian blue/Prussian white transition and 0.98/0.8 V attributed to Prussian blue/Berlin green transition [7, 8]. Comparatively, the cyclic voltammogram obtained for glassy carbon electrode modified by an adsorbed layer of PB is presented in Fig. 1, curve b. When PB is encapsulated in the sol–gel matrix, the shape of the second redox peaks is slightly distorted and peaks currents are lower, indicating that the second transition PB/BG is not facilitated in such conditions.

Considerable efforts have been undertaken to elucidate the electrochemistry of Prussian blue [9, 16, 31, 32]. According to the mechanism suggested by Itaya et al. [32], the electrochemical reactions of Prussian blue at the electrode interface are the following:

corresponding to the transfer of electrons involved in the reduction of Prussian blue to Prussian white, which is compensated by the entrapment of cations in the film.

where A- is the anion supplied by the electrolyte (Cl- in our case). At high anodic potentials Prussian blue converts to its fully oxidized form Berlin green. Since the presence of alkali metal ions is doubtful in the Prussian blue redox state [9], the only possible mechanism for charge compensation in Prussian blue/Berlin green redox activity is the entrapment of anions in course of oxidative reaction.

On the other hand, according to sol–gel chemistry [28, 33] the surface of the pore walls of silica sol–gel material is negatively charged at pH around 4, which will obstruct the diffusion of chloride anions from the electrolyte to the Prussian blue. This may be the reason of the weak oxidation PB/BG process in case of sol–gel entrapment.

The dependence of the peak current with the scan rate has been studied for Sol–gel–PB (1:1) modified electrode at various scan rates (Fig. 2a). In 0.1 M HCl + KCl solution, the peak currents changed linearly with the square root of sweep rate in the range from 20 to 350 mV/s (Fig. 2b) showing that the process is governed by ion diffusion between support electrolyte and the electrode to ensure the electroneutrality rule.

Once shown that the modified electrode exhibit the redox behavior characteristic for PB, next attempt was to optimize the ratio of Sol–gel and PB obtained from FeCl3 and K3[Fe(CN)6] solutions. Three combinations were tested as explained in the Experimental section, namely 1:1, 1:2 and 1:3 Sol–gel/PB (v/v) and the subsequent voltammetric responses were then evaluated. The redox peaks currents characteristic to PB increased with increasing the mass of PB immobilized in the sol–gel matrix (Fig. 3) and the voltammetric signal was stable for 50 verified scans. When trying to further increase the volume of PB, by using a 1:4 ratio, resulted in brittle and fragile film that loses stability for successive scans (data not shown). Because protons are required for catalysis in silica gel formation, the pH of the reaction medium is an important factor that affects the stoichiometry of the final gel. As the volume of PB precursors is higher, the pH is higher (since the solutions are in HCl 10 mM) which makes the hydrolysis and gelation process faster, explaining thus the formation of the brittle film when decreasing the Sol–gel/PB ratio.

Despite the advantages described for all the PB modified electrodes reported in the literature, their use as sensors for H2O2 reduction is still a matter of concern because of the poor electrochemical stability of the PB layer, limited to few scans or because of its poor operational stability, limited to a range of hours. Moreover, the decrease of sensitivity at neutral and alkaline pH is also a matter of investigation.

To investigate the stability of Sol–gel–PB composite in different electrolytes of different composition and pH, repetitive cyclic voltammetry measurements were performed. Figure 4a shows 10 cycles picked from a set of 50 consecutive cyclic voltammograms (from 5 to 5) of Sol–gel–PB electrode in 0.1 M HCl + KCl, pH 1.4 at a scan rate of 100 mV · s−1, demonstrating a high electrochemical stability of the deposited layer (no degradation after 50 cycles). The same activity and stability was exhibited in KCl, pH 7 used as electrolyte, with a slightly larger difference of potential (ΔE) between redox peaks (Fig. 4b), probably due to the difference of medium pH.

It has been reported many times that not all cations promote Prussian blue/Prussian white electroactivity [9, 10, 16, 34]. Except for potassium, only ammonium (NH+ 4), cesium (Cs+) and rubidium (Rb+) were found able to penetrate the Prussian blue lattice [9, 10], while other mono and divalent cations are considered as blocking ones. In order to demonstrate the beneficial effect of Sol–gel matrix encapsulating the PB, the influence of Na+ in the electrochemical activity and stability of PB was investigated. Figure 4c presents the multiple scans of Sol–gel–PB in 0.1 M NaCl, pH 7 electrolyte. Although a minor current decrease and a negative shift of peaks potential occurred when composite electrodes were cycled in the presence of Na+, still the degradation of PB is not so important. These data indicate that the damage due to the insertion of hydrated Na+ ions in the lattice of PB is attenuated by the Sol–gel matrix surrounding the PB particles. Moreover, when cycling again the electrode in a solution containing both cations Na+ and K+, the PB practically recovered its initial current (Fig. 4d). We obtained a very good stability not only at acidic pH but also at neutral pH, which indicate that there is no degradation of PB as long as K+ is present in the medium.

When operated in a solution of 0.1 M phosphate buffer with 0.1 M KCl, pH 9, the Sol–gel–PB electrode shows a slow decrease of peaks currents during electrochemical cycling. After 50 cycles, the decrease of the signal was about 15 % of the initial value, which suggests a gradual degradation of PB (Fig. 4e). The reason for this behavior is probably due to the strong interaction between ferric ions and hydroxyl ions (OH−) which forms Fe(OH)3 at pH higher than 6.4 [35], thus leading to the destruction of the Fe–CN–Fe bond, therefore solubilizing PB [8, 9]. Moreover, in solutions with pH > about 9, the silicate network starts to break down at its interface with the solution and the rate of breakdown increases sharply with increasing the pH [36, 37]. The silicate decomposition in alkaline media would contribute to the Sol–gel–PB composite degradation, explaining thus the decrease of the signal.

Anyway, at pH 7.5, in potassium acetate buffer, the PB particles are still well protected by the sol–gel matrix and just a slight decrease of the peak current values after 50 cycles can be observed (Fig. 4f), demonstrating the very stable behavior of the composite in physiological pH media.

The formation of PB in sol–gel matrix was proved by TEM and EDX analysis (Fig. 5). TEM images of the sol–gel–PB show that a large quantity of crystalline cubic nanoparticles with average edge of around 35 nm is formed (insets of Fig. 5a), uniformly distributed in the sol–gel matrix (Fig. 5a). These findings show good deposition efficiency of PB when the sol–gel matrix is present. This fact is sustained by another independent study when the authors demonstrated that the crystallinity degree of PB is much higher when its formation occurred in the presence of surfactant [38]. Moreover, it can be observed from EDX results (Fig. 5b) that the Fe, Si and K are present and uniformly distributed throughout the composite.

Accordingly, the greatly increased stability of PB particles make possible the practical application of these sensors at acidic and neutral pH, and for better redox peaks shape and more convenient measurements, we selected K+ containing supporting electrolytes for further experiments.

Electrocatalytic activity of Sol–gel–PB towards reduction of Hydrogen Peroxide

After establishing the excellent stability of the Sol–gel–PB composite in HCl + KCl medium, it is worthwhile to consider this film for application in electroanalytical reduction of hydrogen peroxide, as its detection is of great concern. GC electrodes modified with Sol–gel–PB (1:2) composite films were studied by cyclic voltammetry in 0.1 M HCl + KCl electrolyte solution in absence and in presence of different H2O2 concentrations. The potential was cycled between −0.3 to 0.35 V vs. Ag/AgCl in the blank electrolyte and in the sample solutions with a scan rate of 0.1 V · s−1. The cathodic current increased when the H2O2 was added in the solution as 1.3 mM concentration and further increased when raising the concentration to 3.96 mM (Fig. 6). Therefore, the Sol–gel–PB composite electrode exhibits good electrocatalytic performance for reduction of hydrogen peroxide.

The stability properties of the Sol-ge1–PB modified electrode toward H2O2 reduction were tested by evaluating the profile of electrocatalytic reduction current for 1.3 mM H2O2 in 0.1 M HCl + KCl during successive potential cycling. There was no decrease of the current for 50 cycles (data not shown), indicating that the PB is advantageously encapsulated in the Sol–gel matrix and protected against degradation.

On the basis of the voltammetric results described above, it appears that amperometric detection of H2O2 by Sol-ge1–PB composite is effectively possible. Typical hydrodynamic amperometry (Fig. 7) was acquired by successively adding H2O2 to continuously stirred 0.1 M HCl + KCl electrolyte solution, applying a +0.0 V potential vs. Ag/AgCl. A very fast current response was obtained within a few seconds (4 s) upon each addition, indicating that the composite electrode has a fast response to H2O2.

Amperometric response of the Sol-ge1–PB modified electrode to successive additions of H2O2 in stirred 0.1 M HCl + KCl by applying a 0.0 V potential: a for PB 10 mM and b for PB 20 mM entrapped in the sol–gel matrix. Insets: the linear relationships between the current response and H2O2 concentration for the two composites-modified electrodes

Since PB plays the crucial role in the electron transfer and catalyzing of H2O2 reduction, the content of redox mediator in the composite material is an important factor influencing the response of Sol–gel–PB electrodes. Consequently, the amperometric response to H2O2 was compared at Sol–gel–PB electrodes constructed with 10 mM and 20 mM concentration of PB entrapped in the sol–gel matrix, keeping the same ratio of 1:2 Sol–gel/PB (v/v). As presented in Fig. 7, a higher concentration of PB amplifies the amperometric response of modified electrodes. When PB 20 mM was entrapped in the sol–gel matrix, the cathodic current of the modified electrode was four times higher (Fig. 7, curve b) compared to composite with 10 mM PB (Fig. 7, curve a). The calibration plots and the corresponding equations are presented as insets in Fig. 7, indicating a specific sensitivity of 19.55 mA · M-1 · cm-2 for a linear range between 8 and 210 μM for composite with 10 mM PB. As expected, composite with 20 mM PB show a higher specific sensitivity of 82.95 mA · M-1 · cm−2 for a linear range between 3 and 210 μM H2O2.

The limit of detection was lowered more than 4 times: from 2.6 μM for composite with 10 mM PB to 0.6 μM in case of 20 mM PB, which is comparable or even better than for other sensors utilizing PB redox mediator (Table 1).

Much attention has been paid to the stability of the amperometric response of the Sol–gel–PB electrode to H2O2 reduction. The current response of the composite electrode with 20 mM PB measured for 0.12 mM H2O2 over about 30 min was stable and only current decrease of 5 % was observed. We consider that the high stability of the Sol–gel–PB is related to the chemical and mechanical stability of the silicate matrix, which allows a controlled diffusion of H2O2 to the PB particles into the matrix pores.

The electrode-to-electrode reproducibility was evaluated using five electrodes prepared independently in the same conditions and a RSD of 2.9 % (response to 0.12 mM H2O2, in 0.1 M HCl + KCl, pH 1.4) was obtained.

This acidic pH used in aforementioned experiments could represent a problem for the processability of this material together with pH-sensitive biomolecules such as enzymes in the fabrication of biosensors. A new study was thus performed in order to investigate the electrocatalytic properties of developed composite towards hydrogen peroxide at neutral pH. The Sol–gel–PB modified electrodes prepared with 20 mM PB were calibrated in KCl 0.1 M solution, pH 7 (not shown), keeping the same conditions as for experiment presented in Fig. 7. The sensitivity obtained for 3 electrodes was 5835 ± 52 nA · mM−1 (specific sensitivity of 83.35 mA · M−1 · cm−2) indicating that there is no altering of the catalytic response of the sensor in neutral pH. A practical consequence of this is the possibility to use the developed composite in combination with an enzyme, in the construction of a biosensor, working at neutral pH which is optimal for biomolecules.

The operational stability of the developed sensor toward hydrogen peroxide detection was examined using amperometric measurement at both pHs, by applying a potential of 0 V. Amperometric responses of the Sol–gel–PB electrode to 10 repetitive measurements of 0.12 mM H2O2 in 0.1 M HCl + KCl, pH 1.4 and 0.1 M KCl, pH 7 were recorded. The response of sensor reduced to 95 % of its initial value after 10 repetitive assays in HCl + KCl, pH 1.4 and to 93 % in KCl, pH 7. The percentages of the decrease of amperometric responses (compared to their initial responses) are not significant showing a good stability of the sensor in both media.

Conclusions

The Prussian blue–Sol–gel composite material modified electrode was fabricated for hydrogen peroxide sensing. The porous structure of Sol–gel matrix can provide a protective environment to improve the electrochemical stability of Prussian blue in different electrolytes of different pH, especially in acidic and neutral media. Also, the TEM and EDX studies show that the PB crystalline cubic particles, with dimension of around 35 nm, are protected perfectly by the Sol–gel matrix and the pores of the sol–gel matrix allows H2O2 easily go-through and be reduced by Prussian blue at the electrode surface. Electrochemical experiments demonstrated that the Sol–gel-PB composite exhibited good electrochemical properties and electroanalytical activity for H2O2 reduction, depending on the content of redox mediator immobilized in the sol–gel matrix. The amperometric detection of H2O2 was performed by applying a 0.0 V potential in HCl + KCl, pH 1.4 and KCl pH 7 used as electrolytes, with suitable sensitivities of 82.95 mA · M−1 · cm−2, respectively 83.35 mA · M−1 · cm−2. The stability of the catalytic response of the sensor in neutral pH show promising application for fabrication of biosensors, in which the enzymes could be immobilized together with the redox mediator in the sol–gel matrix, in a simple method without supplementary and complicated steps.

References

Saleh Ahammad AJ (2013) Hydrogen peroxide biosensors based on horseradish peroxidase and hemoglobin. Biosens Bioelectron S9:001. doi:10.4172/2155-6210.S9-001

Pingarrón JM, Yáñez-Sedeño P, González-Cortés A (2008) Gold nanoparticle-based electrochemical biosensors. Electrochim Acta 53:5848–5866

Rad AS, Mirabi A, Binaian E, Tayebi H (2011) A review on glucose and hydrogen peroxide biosensor based on modified electrode included silver nanoparticles. Int J Electrochem Sci 6:3671–3683

Chen S, Yuan R, Chai Y, Hu F (2013) Electrochemical sensing of hydrogen peroxide using metal nanoparticles: A review. Microchim Acta 180:15–32

Chaubey A, Malhorta BD (2002) Mediated biosensors. Biosens Bioelectron 17:441–456

Zen JM, Kumar AS, Tsai DM (2003) Recent updates of chemically modified electrodes in analytical chemistry. Electroanalysis 15:1073–1087

Li J, Qiu JD, Xu JJ, Chen HY, Xia XH (2007) The synergistic effect of Prussian-blue-grafted carbon nanotube/poly(4-vinylpyridine) composites for amperometric sensing. Adv Funct Mater 17:1574–1580

Karyakin AA, Karyakina EE, Gorton L (1998) The electrocatalytic activity of Prussian blue in hydrogen peroxide reduction studied using a wall-jet electrode with continuous flow. J Electroanal Chem 456:97–104

Karyakin AA (2001) Prussian blue and its analogues: Electrochemistry and analytical applications. Electroanalysis 13:813–819

Ricci F, Amine A, Palleschi G, Moscone D (2003) Prussian blue based screen printed biosensors with improved characteristics of long-term lifetime and pH stability. Biosens Bioelectron 18:165–174

Karyakin AA, Karyakina EE, Gorton L (2000) Amperometric biosensor for glutamate using Prussian blue-based “artificial peroxidase” as a transducer for hydrogen peroxide. Anal Chem 72:1720–1723

Ricci F, Amine A, Tuta CC, Ciucu AA, Lucarelli F, Palleschi G, Moscone D (2003) Prussian blue and enzyme bulk-modified screen-printed electrodes for hydrogen peroxide and glucose determination with improved storage and operational stability. Anal Chim Acta 485:111–120

Garjonyte R, Malinauskas A (2000) Glucose biosensor based on glucose oxidase immobilized in electropolymerized polypyrrole and poly(o-phenylenediamine) films on a Prussian Blue-modified electrode. Sens Actuators B 63:122–128

Chi Q, Dong S (1995) Amperometric biosensors based on the immobilization of oxidases in a Prussian blue film by electrochemical codeposition. Anal Chim Acta 310:429–436

Zeng J, Wei W, Liu X, Wang Y, Luo G (2008) A simple method to fabricate a Prussian blue nanoparticles/carbon nanotubes/poly(1,2-diaminobenzene) based glucose biosensor. Microchimica Acta 160:261–267

Itaya K, Ataka T, Toshima S (1982) Spectroelectrochemistry and electrochemical preparation method of Prussian blue modified electrodes. J Am Chem Soc 104:4767–4772

Millward RC, Madden CE, Sutherland I, Mortimer RJ, Fletcher S, Marken F (2001) Directed assembly of multilayers—the case of Prussian blue. Chem Commun 19:1994–1995

Pyrasch M, Tieke B (2001) Electro- and photoresponsive films of Prussian blue prepared upon multiple sequential adsorption. Langmuir 17:7706–7709

Karyakin AA, Chaplin M (1994) Polypyrrole-prussian blue films with controlled level of doping: Codeposition of polypyrrole and Prussian blue. J Electroanal Chem 370:301–303

Zou Y, Sun L, Xu F (2007) Prussian blue electrodeposited on MWNTs-PANI hybrid composites for H2O2 detection. Talanta 72:437–442

Gong H, Sun M, Fan R, Qian L (2013) One-step preparation of a composite consisting of graphene oxide, Prussian blue and chitosan for electrochemical sensing of hydrogen peroxide. Microchim Acta 180:295–301

Lev O, Wu Z, Bharathi S, Glezer V, Modestov A, Gun J, Rabinovich L, Sampath S (1997) Sol–gel materials in electrochemistry. Chem Mater 9:2354–2375

Alber KS, Cox JA (1997) Electrochemistry in solids prepared by Sol–gel processes. Mikrochim Acta 127:131–147

Walcarius A (1998) Analytical applications of silica-modified electrodes—a comprehensive review. Electroanalysis 10:1217–1235

Wang J (1999) Sol–gel materials for electrochemical biosensors. Anal Chim Acta 399:21–27

Opallo M (2002) Electrochemical redox reactions in solvated silica sol–gel glass. Materials Science 20:8–14

Wang P, Yuan Y, Wang X, Zhu G (2000) Renewable three-dimensional Prussian blue modified carbon ceramic electrode. J Electroanal Chem 493:130–134

Lukachova LV, Kotel’nikova EA, Shkerin EA, Karyakina EE, Karyakin AA, D’Ottavi D, Moscone D, Palleschi G, Curulli A (2003) Nonconducting polymers on Prussian blue modified electrodes: Improvement of selectivity and stability of the advanced H2O2 transducer. IEEE Sensors Journal 03:326–332

Miecznikowski K, Cox JA, Lewera A, Kulesza PJ (2000) Solid state voltammetric characterization of iron hexacyanoferrate encapsulated in silica. J Solid State Electrochem 4:199–204

Arvinte A, Sesay AM, Virtanen V, Bala C (2008) Evaluation of meldola blue-carbon nanotube-sol–gel composite for electrochemical NADH sensors and their application for lactate dehydrogenase-based biosensors. Electroanalysis 20:2355–2362

Ellis D, Eckhoff M, Neff VD (1981) Electrochromism in the mixed-valence hexacyanides. 1. Voltammetric and spectral studies of the oxidation and reduction of thin films of Prussian blue. J Phys Chem 85:1225–1231

Itaya K, Uchida I, Neff VD (1986) Electrochemistry of polynuclear transition metal cyanides: Prussian blue and its analogues. Acc Chem Res 19:162–168

Bhatia RB, Brinker C, Gupta AK, Singh AK (2000) Aqueous sol–gel process for protein encapsulation. Chem Mater 12:2434–2441

Garcia-Jareno JJ, Sanmatias A, Navarro-Laboulais J, Vicente F (1998) The role of potassium and hydrogen ions in the Prussian blue–Everitt’s salt process. Electrochim Acta 44:395–405

Feldman BJ, Murray RW (1987) Electron diffusion in wet and dry Prussian blue films on interdigitated array electrodes. Inorg Chem 26:1702–1708

El-Shamy TM, Pantano CG (1977) Decomposition of silicate glasses in alkaline solutions. Nature 266:704–706

Shul G, McKenzie KJ, Niedziolka J, Rozniecka E, Palys B, Marken F, Hayman CM, Buckley BR, Bulman Page PC, Opallo M (2005) Characterisation of biphasic electrodes based on the liquid N, N-didodecyl-N′N′-diethylphenylenediamine redox system immobilised on porous hydrophobic silicates and immersed in aqueous media. J Electroanal Chem 582:202–208

Vittal R, Kim KJ, Gomathi H, Yegnaraman V (2008) CTAB-promoted prussian blue-modified electrode and its cation transport characteristics for K+, Na+, Li+, and NH4 + ions. J Phys Chem B 112:1149–1156

Jin E, Lu X, Cui L, Chao D, Wang C (2010) Fabrication of graphene/prussian blue composite nanosheets and their electrocatalytic reduction of H2O2. Electrochim Acta 55:7230–7234

Haghighi B, Hamidi H, Gorton L (2010) Electrochemical behavior and application of Prussian blue nanoparticle modified graphite electrode. Sensors and Actuators B: Chemical 147:270–276

Acknowledgments

The authors acknowledges the financial support of European Social Fund—“Cristofor I. Simionescu” Postdoctoral Fellowship Programme (ID POSDRU/89/1.5/S/55216), Sectoral Operational Programme Human Resources Development 2007–2013.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Doroftei, F., Pinteala, T. & Arvinte, A. Enhanced stability of a Prussian blue/sol-gel composite for electrochemical determination of hydrogen peroxide. Microchim Acta 181, 111–120 (2014). https://doi.org/10.1007/s00604-013-1076-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00604-013-1076-6