Abstract

In this paper, a facile immobilization of copper hexacyanoferrate nanoparticles (CuHCFNP) on a paraffin wax-impregnated graphite electrode (PIGE) was carried out using the room-temperature ionic liquid (RTIL) 1-ethyl-3-methylimidazolium tetrafluoroborate (EMIMBF4) as an ionic binder. The characteristics of the CuHCFNP/EMIMBF4 gel-modified electrode were investigated by cyclic voltammetry (CV) and electrochemical impedance spectroscopy (EIS) techniques, and the modified electrode morphology was also characterized using field emission scanning electron microscopy (FESEM). The electrocatalytic behavior of butylated hydroxyl anisole (BHA) at the modified electrode has been investigated in 0.1 M KNO3 in static and dynamic conditions. Under the optimum conditions, the oxidation peak current was proportional to the BHA concentration in the range from 1.5 to 1000 μM with a detection limit of 0.5 μM (S/N = 3). The proposed method was applied to determine BHA content in real samples with satisfactory results.

ᅟ

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nanomaterials have fascinated a huge interest in recent years because of the unusual mechanical, electrical, and optical properties endowed by confining the dimensions of such materials and because of the combinations of bulk and surface properties to the overall behavior. One need only consider the staggering developments in electrochemical sensors to appreciate the potential of materials with reduced dimensions. Electrochemical sensors have an increasing demand for determining the low concentration of biological, environmental, and industrial significant samples as simple, inexpensive, and rapid analytical methods [1–3]. Most development in the electrochemical sensors in the recent years has originated from nanomaterial-based modified electrodes for enhanced sensitivity and selectivity [4–6].

Metal hexacyanoferrates, a class of polynuclear mixed-valence compounds, have attracted much attention because of their special properties such as ion-exchange selectivity, electrochromism, solid-state batteries, photoimage formation, magnetism, and electrochemical sensors [7–9]. Among many transition metal hexacyanoferrates, copper hexacyanoferrate (CuHCF) has been studied widely because they exhibit useful applications in catalysis and biosensing determinations [10–12]. CuHCF nanoparticles (CuHCFNP) offer higher catalytic efficiency per gram than the bulk one due to their larger surface-to-volume ratios [13, 14].

Room-temperature ionic liquids (RTILs) are a class of materials which have attracted the attention of many scientists as holding a great promise for green chemistry applications [15]. RTILs have significant characteristics, including a wide electrochemical window, low vapor pressure, high thermal stability, good ionic conductivity, and no hydrogen evolution [15]. The electrochemical applications that involve RTILs comprise the electrochemical devices like in batteries, capacitors, fuel cells, photovoltaics, actuators, and electrochemical sensors [16–18].

Recently, carbon ionic liquid electrodes (CILEs), with the advantages of low cost, ease of preparation, high conductivity, wide electrochemical windows, antifouling effect, and renewable surface, have been widely used in the field of electrochemical sensing [19–22]. CILE can be prepared by substituting a non-conductive organic binder with high conductive ionic liquids, which exhibit superior electrochemical performances over the traditional working electrodes [23]. Numerous electrochemical sensors were reported earlier using CILEs [19–24]. However, only very few reports are available using RTIL as a binder in immobilization of redox mediators [25, 26].

Butylated hydroxyl anisole (BHA) is a commonly used phenolic preservative in commercial products such as vitamin tablets, edible oils, confectionary, food packing, animal feed, cosmetics, and junk food. BHA is added to food products to improve their stability, especially to prevent rancidity in products containing lipids or fats. BHA is exclusively used in food products because of its ability to remain active even at high temperatures while cooking or baking. Even though it is widely used, excessive use of BHA can bring about some physical ailments such as hyperactivity in children [27] and allergy in adults. Furthermore, a large dose of BHA can cause tumors in lab animals. As BHA is an extensively used food preservative and also toxic at higher amounts, it is necessary to develop a fast, accurate, and reproducible method for the determination of BHA [28, 29].

However, to the best of our knowledge, no study has reported yet about the determination of BHA using a CuHCFNP/EMIMBF4 gel-modified electrode. In the present work, an RTIL (EMIMBF4) is used as the binder for immobilization of a CuHCFNP in a paraffin wax-impregnated graphite electrode (PIGE). From our earlier reports [25, 26], the nanocomposite was based on the idea that the CuHCFNP with EMIMBF4 could enhance the electron transfer rate and also exhibit increased sensitivity and stability for BHA determination.

Experimental

Chemicals

A spectroscopic-grade graphite rod (3 mm diameter) was used as received from Aldrich. 1-Ethyl-3-methylimidazolium tetrafluoroborate (EMIMBF4) was purchased from Alfa Aesar. BHA was obtained from HIMEDIA Laboratories Pvt. Ltd., India. Potassium hexacyanoferrate, copper chloride, and potassium chloride were of analytical grade. pH was varied using 0.1 M HNO3 and 0.1 M NaOH solutions. All other reagents were of analytical grade and used without further purification. All aqueous solutions were prepared with double-distilled water.

Instrumentation

UV-vis was obtained with a fiber-optic spectrometer (Ocean Optics, Inc., FL, USA) with a DT lamp. XRD analysis was performed on a Bruker model D8 using Cu Kα radiation. A field emission scanning electron microscopy (FESEM) image of the electrode surface was obtained on SU6600 field emission scanning electron microscopy (Hitachi, Japan). TEM images were obtained using a Hitachi H7650 Microscope.

Electrochemical measurements were performed with a CHI 660B electrochemical workstation (CH Instruments, USA) controlled by a personal computer. A three-electrode system was employed in this study. A platinum wire and a saturated calomel electrode (SCE) were used as auxiliary and reference electrodes, respectively. All potentials were referred to the latter. The modified electrode employed as the working electrode was prepared according to the procedure described below. A magnetic Teflon stirrer was provided for the convective transport during the amperometric measurements. All the experiments were performed at room temperature.

Synthesis of CuHCFNP

In a typical procedure, 70 mL of 0.01 M aqueous solution of CuCl2 was added slowly to 70 mL solution of 0.05 M K3Fe(CN)6 containing 0.05 M KCl under stirring [14]. After complete addition, the mixture was vigorously agitated for 15 min and then directly subjected to centrifugation. The retentate was continuously washed with double-distilled water several times and then collected after centrifugation and dried overnight in vacuum to get a light-green-colored powdered substance. The CuHCFNP could be redispersed in distilled water and ethanol, which were suitable for further characterization.

Construction of the CuHCFNP/EMIMBF4 gel-modified electrode

About 10 mg of CuHCFNP mixed with 5 μL EMIMBF4 was ground with an agate mortar for about 10 min, and a fine gel was obtained. PIGE with a circular surface diameter of 3 mm prepared as reported [30] was used for electrode modification. One end of the electrode was carefully polished on a smooth surface and with emery paper, washed with distilled water, and dried in air. Then, the polished surface was coated with CuHCFNP/EMIMBF4 gel by mechanical transfer. Finally, the gel on the electrode surface was spread with a spatula to have a thin gel film on the PIGE surface, which was used as the working electrode. For comparison, a CuHCFNP/paraffin oil gel-modified electrode was also prepared using paraffin oil as a non-ionic binder with CuHCFNP and the same procedure was followed. A CuHCFNP-modified electrode was also prepared through mechanical immobilization of CuHCFNP (without RTIL).

Determination of BHA commercial samples

BHA in spiked samples of commercially available dry potato flakes was investigated. The potato flakes were crushed in an agate mortar. About 500 mg of the powdered sample was spiked with a known amount of the standard solution of BHA and placed into a 10-mL centrifuge tube. The extraction was carried out with 5 mL of a 10 % methanol–water solution. The mixture was mechanically shaken for 20 min, and after centrifugation at 3000 rpm for 30 min, the supernatant extract was collected. The supernatant extract was added to 0.1 M KNO3 in the electrochemical cell and BHA were analyzed by a standard addition method.

Results and discussion

UV-vis and XRD of the potassium-copper hexacyanoferrate nanoparticles

The UV-vis spectrum of CuHCFNP exhibits a strong absorbance at 305 nm and a broad absorption around 420 nm (Fig. 1a). The absorption at 305 nm can be assigned to the ligand to metal charge transfer (LMCT) band of [FeIII(CN)6], and that at 420 nm due to the d-d transitions of CuII. This observation is consistent with an earlier report [31], which indicates the formation of CuHCFNP. XRD analysis has been applied to determine the structure and average size of the CuHCFNP. CuHCFNP showed broad peaks, which can be indexed as a face-centered-cubic (fcc) structure (Fig. 1b), where the peak positions are identical to CuHCF pattern (JCPDS card, file no. 86-0513). It can be observed that the peaks are broader, indicating the existence of crystallites of nanometer in size. The average crystalline size, which was determined from the half-width of the diffraction peaks by using the Debye–Scherrer equation, was approximately 32 nm in diameter.

HRTEM, FESEM, and EDS analysis

Figure 2a shows the typical HRTEM image of the synthesized CuHCFNP, where a fairly uniform particle size is clearly seen. The particles are dispersed in the aqueous solution with no evidence of aggregation. The particle shape is spherical and the size distribution is ranging from 20 to 60 nm. The EDS pattern reveals that the CuHCFNP is composed of K, C, N, Fe, and Cu which are the elements present. The EDS spectra showed peaks for Cu and Fe at 8.1 and 6.4 keV, respectively, confirming the presence of these elements in the CuHCFNP. The amount of the Cu is almost equal to the amount of Fe atoms. The proposed empirical formula of the CuHCFNP may be given as KCu[Fe(CN)6] (figure not shown). The morphology of the CuHCFNP/EMIMBF4 gel-modified electrode was characterized using FESEM (Fig. 2b). The CuHCFNP was homogenously dispersed in the EMIMBF4 IL and evenly coated in the electrode surface without any aggregation owing to the highly conductive IL. In the case of the CuHCFNP/paraffin oil gel-modified electrode, the CuHCFNP was sparingly distributed in severe aggregation (Fig. 2c).

Cyclic voltammetric studies of the modified electrodes

The cyclic voltammograms of the different modified electrodes such as bare electrode, CuHCFNP-modified electrode, CuHCFNP/paraffin oil gel-modified electrode, and CuHCFNP/EMIMBF4 gel-modified electrode in 0.1 M KNO3 at the scan rate of 20 mV s−1 are shown in Fig. 3a. It was found that there was no electrochemical response for the bare electrode (curve a). The CV of the CuHCFNP-modified electrode was studied under the same condition (curve c), and it has shown a pair of well-defined redox peaks with the anodic and cathodic peak potentials of 0.68 and 0.61 V, respectively, which is due to the redox reaction of Fe[(CN)6]3−/Fe[(CN)6]4− present in CuHCF. The paraffin oil-CuHCFNP-modified electrode (curve b) has shown a pair of redox peaks but the anodic and cathodic potentials were observed at 0.72 and 0.57 V, with the peak-to-peak separation (ΔE p) of 0.15 V, which indicates that the electron transfer rate in the CuHCFNP is decreased due to the non-conductive liquid paraffin binder enhancing the ohmic resistance of the cell, resulting in a distorted voltammogram. On the other hand, for the CuHCFNP/EMIMBF4 gel-modified electrode, a pair of well-defined redox peaks appeared (curve d) with enhanced peak currents and lesser anodic and cathodic peak potentials (0.67 and 0.62 V) and the ΔE p has decreased to a greater extent (50 mV). The results indicate that the CuHCFNP/EMIMBF4 gel-modified electrode has shown better reversibility than the CuHCFNP/paraffin oil gel-modified electrode and the CuHCFNP-modified electrode, suggesting that the presence of RTIL (EMIMBF4) promotes the rate of the electron transfer of the modified electrode.

a CVs of the (a) bare, (b) CuHCFNP/paraffin oil gel-modified, (c) CuHCFNP-modified electrodes and (d) CuHCFNP/EMIMBF4 gel-modified electrode. b EIS of the (a) bare, (b) CuHCFNP/paraffin oil gel-modified, (c) CuHCFNP-modified electrodes and (d) CuHCFNP/EMIMBF4 gel-modified electrode in 0.1 M KNO3, with the frequency swept from 1 Hz to 0.1 MHz. Inset: modified Randles equivalent circuit diagram and enlarged view of the CuHCFNP/EMIMBF4 gel-modified electrode

Electrochemical impedance spectroscopy of the modified electrodes

Electrochemical impedance spectroscopy (EIS) was employed to investigate the charge transfer behavior at the modified electrodes (Fig. 3b) and was also compared with that of the bare electrode. The electrode was scanned in the range of 1 Hz to 0.1 MHz. All experimental plots could be well described theoretically with the generalized Randles model. The modified Randles equivalent circuit model was chosen to fit the measurement results (Fig. 3b inset circuit). The charge transfer of the cations between the solution and the CuHCFNP/EMIMBF4 gel-modified electrode and the transport of these ions within the composite can be described well with the suggested model. Figure 3b shows the Nyquist plot for the four different modified electrodes. It was observed that the CuHCFNP/EMIMBF4 gel-modified electrode offered the least resistance to charge transfer at the formal potential of the electrode when compared to the other modified electrodes.

The electron transfer resistance (R ct) of a CuHCFNP-modified electrode (without RTIL) was estimated to be 339.5 Ω (curve b). With the CuHCFNP/paraffin oil gel-modified electrode, an R ct value of 8.1 KΩ (curve c) was obtained, which could be due to the interface effect obtained by presence of the non-conductive liquid paraffin binder enhancing the ohmic resistance. When the CuHCFNP/EMIMBF4 gel was coated on the electrode surface, the charge transfer resistance was reduced to 96.0 Ω (curve d). The enlarged EIS plot of the CuHCFNP/EMIMBF4 gel-modified electrode is shown in curve d of Fig. 3b. The result indicates that the electron transfer was accelerated on the CuHCFNP/EMIMBF4 gel-modified electrode, which was attributed to the high ionic conductivity of the RTIL present with the CuHCFNP.

Effect of scan rates

The cyclic voltammograms of the CuHCFNP/EMIMBF4 gel-modified electrode were recorded at different scan rates in the range 5–150 mV s−1. Both the anodic and cathodic peak currents were found to increase upon increasing the scan rates. Also, at lower scan rates (ν ≤ 40 mV s−1), the peak currents are linearly proportional to the scan rate, confirming that the redox reaction is a surface-confined process (Fig. 4a). However, at higher scan rates (ν ≥ 50 mV s−1), the peak currents were proportional to the square root of the scan rate, which indicates that the redox process is a diffusion-controlled process (Fig. 4b) [32, 33].

The electrochemical rugosity (Γ) or surface concentration of the electroactive species was also estimated [20]. The Γ of the modified electrode was calculated to be 9.1 × 10−9 mol/cm2 at a scan rate of 20 mV s−1.

Electrocatalytic oxidation of BHA at the modified electrode

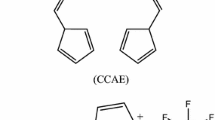

The modified electrode was employed for the electrocatalytic oxidation of BHA and the CVs obtained are shown in Fig. 5a. Curves a and c correspond to the voltammograms of the bare electrode and modified electrode, respectively, in 0.1 M KNO3 in the absence of BHA, and curves b and d correspond to those obtained in the presence of 1.42 × 10−3 M BHA, respectively. The response of the bare electrode to the oxidation of BHA (curve b) was much less pronounced than that obtained with the modified electrode (curve d). As could be seen, the modified electrode exhibited an enhanced anodic current at a lower potential in the presence of BHA, which is indicative of the electrocatalytic process occurring at the modified electrode surface. For each addition of BHA, a corresponding increase in anodic current was observed. The modified electrode showed a linear response for the catalytic oxidation of BHA. The linear range for the determination of BHA is from 1.5 × 10−6 to 1.0 × 10−3 M with a correlation coefficient of 0.9923 (Fig. 5b). The electrocatalytic oxidation mechanism of BHA to t-butyl quinone (TBQ) at the CuHCFNP/EMIMBF4 gel-modified electrode is given in Scheme 1.

a Cyclic voltammograms of the (a) bare electrode, (b) bare electrode in the presence of 2.4 × 10−4 M BHA, (c) CuHCFNP/EMIMBF4 gel-modified electrode, and (d) CuHCFNP/EMIMBF4 gel-modified electrode in the presence of 2.4 × 10−4 M BHA; electrolyte, 0.1 M KNO3; scan rate, 20 mV s−1. b Plot of the catalytic current versus concentration of BHA

Effect of pH and long-term stability of the modified electrode to BHA determination

The impact of pH on the electrocatalytic activity of the modified electrode in the pH range from 2 to 9 was studied. Figure 6a depicts the variation of the anodic peak current for the oxidation of 2.75 × 10−4 M BHA at different pH values. The maximum current response for oxidation was obtained at pH 7.0, and a decrease in current at higher pH values was observed which is due to the hydroxylation of the mediator. Hence, pH 7.0 was chosen as the optimum pH for the determination of BHA. The pH of the supporting electrolyte was maintained using 0.05 M phosphate buffer for subsequent experiments of electrocatalytic oxidation of BHA.

The electrocatalytic activity of the CuHCFNP/EMIMBF4 gel-modified electrode was studied for a period of 60 days in the presence of 3.2 × 10−4 M BHA, and the results showed that the modified electrode retained 96.1 % response at the end of the period. For studying the stability of the modified electrode for amperometric determination of BHA over a longer time period, current measurements were made for a 5-h duration at a time interval of 30 min. Figure 6b shows that the modified electrode responded almost equally in the entire time scale under hydrodynamic conditions, showing the remarkable stability of the modified electrode for electrocatalysis. It can be noticed from the figure that the modified electrode exhibits an almost constant response, suggesting the stable immobilization of the CuHCFNP in the electrode surface with the aid of RTIL.

Linear sweep voltammetry and chronoamperometric studies

In order to study the applicability of the CuHCFNP/EMIMBF4 gel-modified electrode for the determination of BHA in flow systems, linear sweep voltammograms have been recorded by measuring the current for different fixed potentials as shown in Fig. 7. The catalytic current observed with the modified electrode (curve b) was much higher and also at a lower potential for the detection compared to the bare electrode (curve a). The electrocatalytic current at the modified electrode was found to be maximum at 0.68 V (Fig. 7). This behavior illustrates that the oxidation of BHA is greatly enhanced at the CuHCFNP/EMIMBF4 gel-modified electrode due to electrocatalysis which is effectively assisted by the highly conductive RTIL. Hence, a potential of 0.7 V was selected as the working potential for amperometric determination of BHA using the CuHCFNP/EMIMBF4 gel-modified electrode.

The amperometric response of the CuHCFNP/EMIMBF4 gel-modified electrode towards the oxidation of BHA was tested by the successive addition of 0.5 mL of 2 mM BHA to the stirring supporting electrolyte solution of 0.1 M KNO3 (0.05 M phosphate buffer, pH 7) at an operating potential of 0.7 V, and a part of the measurement is shown in Fig. 8a. Each addition of BHA caused a rapid change in the current which attained a constant value in a fairly short time (less than 5 s). The catalytic currents exhibited quite good reproducibility and a good linear relationship for BHA was obtained as shown in Fig. 8b. Such a good response of the CuHCFNP/EMIMBF4 gel-modified electrode to oxidation of BHA under dynamic conditions justifies its viable application in flow systems.

Interference studies

The specificity of the CuHCFNP/EMIMBF4 gel-modified electrode to BHA determination in the presence of some possible interfering substances like butylated hydroxyl toluene (BHT), ascorbic acid (AA), citric acid, lactic acid, propyl gallate, and various cations and anions was examined for their influence on the determination of 30 μM BHA. It is well known that AA and BHT coexist with BHA in many samples, which may affect the determination of BHA. It was observed from CV studies that the oxidation of BHT at the modified electrode took place at a higher potential when compared to BHA. The results exhibit that it is sufficient to allow the determination of one of the compounds in the presence of another. The experiment showed that a 500-fold excess of BHT, citric acid, lactic acid, and propyl gallate did not interfere with the determination of BHA. The cations and anions such as Ca2+, Ba2+, Mg2+, NO3 −, and SO4 2− had negligible effects in the determination of BHA. However, AA is significantly interfering with the BHA determination. The interference from AA can be easily eliminated by coating the surface of the modified electrode with Nafion as reported elsewhere [34]. Thus, the results reveal that this CuHCFNP/EMIMBF4 gel-modified electrode has reasonable selectivity for BHA determination.

Commercial sample analysis

The practical utilization of the CuHCFNP/EMIMBF4 gel-modified electrode for the determination of BHA in real samples was tested by measuring the concentration of BHA in potato flake samples using the CV technique. The results are summarized in Table 1. The recovery ranged from 97.04 to 99.20 %, which showed that the proposed method is a reliable one for the estimation of BHA using three different potato flake samples.

Conclusion

In summary, the main feature of this work is enhancing the electron transfer rate of the redox mediator CuHCFNP using RTIL (EMIMBF4) as an ionic binder. The CuHCFNP/EMIMBF4 gel-modified electrode showed an excellent electrocatalytic performance towards oxidation of BHA, which was due to the presence of ionic liquid in the CuHCFNP in the electrode surface. Finally, the proposed method was successfully applied to the commercially available dry potato flake samples. Also, the application of this modified electrode to determine some biological and environmental analytes is under progress.

References

Privett BJ, Shin JH, Schoenfisch MH (2008) Electrochemical sensors. Anal Chem 80:4499–4517

Brett CMA, Brett AMO (2011) Electrochemical sensing in solution-origins, applications and future perspectives. J Solid State Electrochem 15:1487–1494

Jacobs CB, Peairs MJ, Venton BJ (2010) Review: carbon nanotube based electrochemical sensors for biomolecules. Anal Chim Acta 662:105–127

Yi W, Liu J, Chen H, Gao Y, Li H (2015) Copper/nickel nanoparticle decorated carbon nanotubes for nonenzymatic glucose biosensor. J Solid State Electrochem 19:1511–1521

Prabhu P, Babu RS, Narayanan SS (2014) Synergetic effect of Prussian blue film with gold nanoparticle graphite–wax composite electrode for the enzyme-free ultrasensitive hydrogen peroxide sensor. J Solid State Electrochem 18:883–891

Babu RS, Prabhu P, Narayanan SS (2014) Enzyme-free selective determination of H2O2 and glucose using functionalized CuNP-modified graphite electrode in room temperature ionic liquid medium. RSC Adv 4:47497–47504

de Tacconi NR, Rajeshwar K, Lezna RO (2003) Metal hexacyanoferrates: electrosynthesis, in situ characterization, and applications. Chem Mater 15:3046–3062

Jayalakshmi M, Scholz F (2000) Charge–discharge characteristics of a solid-state Prussian blue secondary cell. J Power Sources 87:212–217

Narayanan SS, Scholz F (1999) A comparative study of the electrocatalytic activities of some metal hexacyanoferrates for the oxidation of hydrazine. Electroanalysis 11:465–469

Pauliukaite R, Florescu M, Brett CMA (2005) Characterization of cobalt- and copper hexacyanoferrate-modified carbon film electrodes for redox-mediated biosensors. J Solid State Electrochem 9:354–362

de Morais A, Pissetti FL, Lucho AMS, Gushikem Y (2010) Influence of copper hexacyanoferrate film thickness on the electrochemical properties of self-assembled 3-mercaptopropyl gold electrode and application as a hydrazine sensor. J Solid State Electrochem 14:1383–1390

Giorgetti M, Tonelli D, Berrettoni M, Aquilanti G, Minicucci M (2014) Copper hexacyanoferrate modified electrodes for hydrogen peroxide detection as studied by X-ray absorption spectroscopy. J Solid State Electrochem 18:965–973

Yang M, Yang Y, Qu F, Lu Y, Shen G, Yu R (2006) Attachment of nickel hexacyanoferrates nanoparticles on carbon nanotubes: preparation, characterization and bioapplication. Anal Chim Acta 571:211–217

Baioni AP, Vidotti M, Fiorito PA, Ponzio EA, de Torresi SIC (2007) Synthesis and characterization of copper hexacyanoferrate nanoparticles for building up long-term stability electrochromic electrodes. Langmuir 23:6796–6800

Rehman A, Zeng X (2012) Ionic liquids as green solvents and electrolytes for robust chemical sensor development. Acc Chem Res 45:1667–1677

Shiddiky MJA, Torriero AAJ (2011) Application of ionic liquids in electrochemical sensing systems. Biosens Bioelectron 26:1775–1787

Wei D, Ivaska A (2008) Applications of ionic liquids in electrochemical sensors. Anal Chim Acta 607:126–135

Kazemi SH, Karimi B, Fashi A, Behzadnia H, Vali H (2014) High-performance supercapacitors based on an ionic liquid-derived nanofibrillated mesoporous carbon. J Solid State Electrochem 18:2419–2424

Kuang Y, Wu B, Hu D, Zhang X, Chen J (2012) One-pot synthesis of highly dispersed palladium nanoparticles on acetylenic ionic liquid polymer functionalized carbon nanotubes for electrocatalytic oxidation of glucose. J Solid State Electrochem 16:759–766

Safavi A, Maleki N, Moradlou O, Tajabadi F (2006) Simultaneous determination of dopamine, ascorbic acid, and uric acid using carbon ionic liquid electrode. Anal Biochem 359:224–229

Maleki N, Safavi A, Farjami E, Tajabadi F (2008) Palladium nanoparticle decorated carbon ionic liquid electrode for highly efficient electrocatalytic oxidation and determination of hydrazine. Anal Chim Acta 611:151–155

Opallo M, Lesniewski A (2011) A review on electrodes modified with ionic liquids. J Electroanal Chem 656:2–16

Wang X, Cheng C, Dong R, Hao J (2012) Sensitive voltammetric determination of rutin at a carbon nanotubes-ionic liquid composite electrode. J Solid State Electrochem 16:2815–2821

Sun W, Duan Y, Li Y, Gao H, Jiao K (2009) Electrochemical behaviors of guanosine on carbon ionic liquid electrode and its determination. Talanta 78:695–699

Babu RS, Prabhu P, Narayanan SS (2011) Selective electrooxidation of uric acid in presence of ascorbic acid at a room temperature ionic liquid/nickel hexacyanoferarrate nanoparticles composite electrode. Colloids Surf B 88:755–763

Babu RS, Prabhu P, Narayanan SS (2012) Electrocatalytic oxidation of acetaminophen using 1-ethyl-3-methylimidazolium tetrafluoroborate-nickel hexacyanoferrate nanoparticles gel modified electrode. J Chem Pharm Res 4:3592–3600

de la Fuente C, Acuna JA, Vazquez MD, Tascon ML, Batanero PS (1999) Voltammetric determination of the phenolic antioxidants 3-tert-butyl-4-hydroxyanisole and tert-butylhydroquinone at a polypyrrole electrode modified with a nickel phthalocyanine complex. Talanta 49:441–452

Jayasri D, Narayanan SS (2006) Electrocatalytic oxidation and amperometric determination of BHA at graphite–wax composite electrode with silver hexacyanoferrate as electrocatalyst. Sensors Actuators B Chem 119:135–142

Kumar SS, Narayanan SS (2008) Mechanically immobilized nickel aquapentacyanoferrate modified electrode as an amperometric sensor for the determination of BHA. Talanta 76:54–59

Scholz F, Lange B (1992) Abrasive stripping voltammetry—an electrochemical solid state spectroscopy of wide applicability. Trends Anal Chem 11:359–367

Kong Q, Chen X, Yao J, Xue D (2005) Preparation of poly(N-vinyl-2-pyrrolidone)-stabilized transition metal (Fe, Co, Ni and Cu) hexacyanoferrate nanoparticles. Nanotechnol 16:164–168

Zakharchuk NF, Meyer B, Hennig H, Scholz F, Jaworksi A, Stojek Z (1995) A comparative study of Prussian blue-modified graphite paste electrodes and solid graphite electrodes with mechanically immobilized Prussian blue. J Electroanal Chem 398:23–35

Dussel H, Dostal A, Scholz F (1996) Hexacyanoferrate-based composite ion-selective electrodes for voltammetry. Fresenius J Anal Chem 355:21–28

Shankaran DR, Uehera N, Kato T (2003) A metal dispersed sol/gel biocomposite amperometric glucose biosensor. Biosens Bioelectron 18:721–728

Acknowledgments

The authors gratefully acknowledge the funding provided by the University Grants Commission (UGC), New Delhi, and the Department of Science and Technology, New Delhi, for the financial assistance through the “PURSE” program.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Babu, R.S., Prabhu, P. & Narayanan, S.S. Facile immobilization of potassium-copper hexacyanoferrate nanoparticles using a room-temperature ionic liquid as an ionic binder and its application towards BHA determination. J Solid State Electrochem 20, 1575–1583 (2016). https://doi.org/10.1007/s10008-016-3161-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-016-3161-3