Abstract

The present work deals with a non-clinical scheme to develop a system-on-chip for the detection and identification of the malignant cells in a known volume of white blood cells (WBC) using MEMS capacitive sensor. In presence of cancerous cells, the sensor produces a change in the value of capacitance which reflects a significant variation of dielectric permittivity. For this purpose, a double shell electrical model of WBC is designed and analyzed in frequency range 20 kHz–10 MHz due to the polarization of cell membrane. The polarization is induced using electroporation process where the plasma membrane of the blood cell is polarized to a membrane potential of about 0.5–1 V with a supply of 1 V which makes cell membrane semi permeable for the exchange of ions, thus producing change in dielectric permittivity. In order to determine the change in dielectric permittivity, an electrostatic MEMS capacitive sensor is virtually fabricated with a pair of rectangular electrodes in which the second electrode is further divided into four sub-plates in same plane. This change in permittivity results in change of output capacitance, finally differentiate a malignant cell from a normal one.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Cancer is a deadly disease, which destroy the lifecycle of normal cell and allows it to divide randomly to invade other part of the body (http://www.cancer.gov/about-cancer/what-is-cancer, 9 Feb 2015). According to World Cancer Report in 2014, there are 14 million new cases with 8.2 million cancer caused deaths in 2012 (World cancer report 2014), therefore, early detection can drastically decrease the percentage of death due to cancer.

It has been observed in literature that in comparison to malignant cell a normal cell has higher value of dielectric permittivity therefore blood cancer can be detected on the basis of dielectric permittivity (Yang et al. 1999; Polevaya et al. 1999; Ermolina and Polevaya 2001; Ellappan and Sundararajan 2005). The standard process used in micro level for the detection of cancer depending upon dielectric property are (I) Electroporation, (II) Time Domain Dielectric Spectroscopy (TDDS) and (III) Electrorotation, while the most renowned method is electroporation. Electroporation process can detect the change in permittivity of cell membrane in frequency range of 20 kHz–10 MHz (called the β-dispersion) (Yang et al. 1999; Polevaya et al. 1999; Ermolina and Polevaya 2001). The characteristics of cell is described in three distinctive dispersion regions referred to as α, β and γ, where α region occurs in range of kHz frequency, β ranges from kHz to MHz and the range of frequency for γ region starts from MHz. In TDDS method, the dielectric permittivity of the cell is obtained by analyzing the response of sample according to the increasing pulse of applied voltage. The drawbacks of TDDS process is formation of electrical double layer and electrode polarization (Polevaya et al. 1999; Ermolina and Polevaya 2001) while the implementation of Electrorotation technique is expensive and complex. The present work deals with implicit fabrication of MEMS capacitive sensor and computation of electroporation process. In electroporation process, a transmembrane potential of about 0.5–1 V is induced in cell membrane with an external voltage of suitable magnitude and duration making it permeable for the exchange of electrons and ions, moreover changes the permittivity of the sample.

The paper introduces the electrical modeling of WBC in Sect. 2 followed by Sect. 3 gives the scheme of the proposed device. Section 4 describes the design of MEMS capacitive sensor. The mask design along with virtual fabrication details are described in Sects. 5 and 6 provides results and discussion. Finally Sect. 7 concludes with future scopes.

2 Electrical modelling of WBC

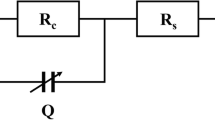

This section illustrates an electrically model of cell according to a double shell model of WBC, as the main attention is to discover the transmembrane potential of a cell. After receiving acceptable results (verified with Ellappan and Sundararajan 2005; Gupta and Kharat 2014), the excitation voltage is considered as the initial parameters for the design and fabrication of micro sensor. Figure 1 shows the electrical model of WBC. The double shell model of WBC consists of cytoplasm occupying 60% cell volume protected by an outer covering of cell membrane. In the electrical model, Cm1 and Cm2 denote cell membrane with Rcy as cytoplasm, Cnm1, Cnm2 and Rnc as respected nuclear membrane and nucleolus. The cell membrane consists of pores and act as a leaky dielectric due to the presence of lipid structure (Gupta and Kharat 2014). In electroporation process, cell membrane is polarized with an applied voltage of 1 V to induce a membrane potential of about 0.5 V (threshold voltage for electroporation to occur) so that the pores in the cell membrane temporarily opens up for the exchange of ions and electrons (Joshi and Schoenbach 2000; Lee 2010). The equivalent impedance (Z3) is represented by Eq. (3), where Z1 is the impedance of nuclear membrane and nucleolus (represented in Eq. 1) and Z2 is the corresponding impedance of cytoplasm and Z1 (represented in Eq. 2).

where Cm1 = Cm2 = Cm, Cnm1 = Cnm2 = Cnm,\({\text{C}}_{\text{M}} = \frac{{{\text{C}}_{\text{m}} }}{2}\) and \({\text{C}}_{\text{NM}} = \frac{{{\text{C}}_{\text{nm}} }}{2}\) and the cell natural frequency is

3 Scheme of the proposed device

The present work deals with blood cancer detection through WBC in a given sample of human blood. The proposed sensor output in term of capacitance is a function of dielectric permittivity of cell membrane. Figure 2 shows an overview of the overall system to be developed, where a 5 V DC source is converted to voltage of about 0.8–1.2 V AC in range of frequency of 20 kHz–10 MHz which is required for the polarization of blood cell. Further the micro sensor output is to be converted to voltage for significant realization and display, thus distinguishing a malignancy from the normal cell.

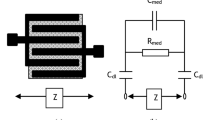

4 MEMS capacitive sensor design

MEMS capacitive sensor is virtually fabricated keeping cell thickness as 10 nm and radius as 3.5 µm. The sensor is designed as parallel plate geometry, where one plate is connected to 1 V supply while the other plate is grounded. Further the potential plate is subdivided to four smaller alike plates with parallel connection. The position of the plates, distance between them and the area of the plate is constant while the sensor output in terms of capacitance is obtained depending upon the dielectric permittivity in between due to the presence of WBC (Table 1). Equation (5) represents the standard equation for capacitive type sensor, in which C is the output capacitance, ε is dielectric permittivity of malignant cell, d is distance between two plates and A is plate area. In the present study the area of lower plate A1 and the upper plate A2 is different; therefore, the effective area A of Eq. (7) is a function of both A1 and A2. A formula has being developed based on the performance analysis of designed sensor which is shown in Eq. (6), where α is a variable which varies from 4.73 to 4.75. The material used for the fabrication of plates is polysilicon doped with boron. The property of polysilicon is presented in Table 2.

5 Virtual fabrication of MEMS sensor

The proposed sensor is virtually fabricated with base material silicon (Si) Czochralski 100, while the upper and lower plate is fabricated by conformal low pressure chemical vapor deposition (LPCVD) deposition and reactive ion etching (RIE) etching of SiO2, Si3N4 and PolySi whereas PolySi is implanted with boron. Photolithography is done to produce necessary pattern by depositing photoresist PR-SPR2 and allowing UV ray to pass through the mask. A three layer mask is designed which is shown in Fig. 3, where layers are marked as L1, L2 and L3 respectively. The plates are supported by a wall of SiO2 which is deposited on the side and on the middle of the sensor. The cavity between the plates is created using PSG material while copper and titanium is used for essential connection. Later the base material and the other unwanted materials are removed by the process of etching (partial etching or sacrifice). Thus, the stepwise virtual fabrication of MEMS capacitive sensor in a FEM based platform is sequentially shown in Fig. 4 stating step number 1 to step number 32.

6 Results and discussion

The simulation of electrical model of WBC is studied for specific range of dielectric permittivity between 7.119 and 12.814 F/m for a malignant cell membrane while the numerical value for the rest of the structural parts (cytoplasm and nucleus) of cell is kept constant. The simulation of electrical model of WBC cell is shown in Fig. 5. For a cell membrane electroporation process can occurs at low frequency as the entire external voltage applied to the cell is received by the cell membrane therefore inducing membrane voltage of about 0.5–1 V (Zimmermann and Neil 1996; Schoenbach et al. 2002). The electroporation method can take place in the interior parts of the cell at higher range of frequency which otherwise behave as an insulator (Zimmermann and Neil 1996; Schoenbach et al. 2002; Beebe et al. 2004). Figures 6 and 7 demonstrate the said phenomenon for the structural parts of the cell which depends upon the magnitude and duration of the external supply voltage. The MEMS capacitive sensor is non-invasive in nature; a given volume of WBC sample of unknown permittivity is placed inside the sensor and the resultant is in term of capacitance, shown by Table 3. The equivalent response of the senor output is represented in Fig. 8. From the output of micro sensor, quantitative analysis QC of blood cancer can be done (Eq. 8), where the output of micro sensor is denoted as Osensor, minimum sensor output below which WBC start transforming is denoted as ON, OC denotes the sensor output at which blood sample is totally malignant and scale is difference between ON and OC. Therefore quantitative analysis will help to find the amount Vaffected of blood sample infected with cancer (shown in Eq. 10).

where, \({\text{effective inner volume of sensor}} = V_{sample} = A \times h\), here h is the distance between two electrodes.

7 Conclusion

In view of the fact that this work is limited to simulation only, but all the simulated result and response is verified with other literatures (Yang et al. 1999; Polevaya et al. 1999; Ermolina and Polevaya 2001; Ellappan and Sundararajan 2005; Shin et al. 2015). Proper treatment and curability from cancer greatly depends on early detection and identification of cancer. Present work deals with blood cancer detection depending on the electrical properties of WBC instead of biological ones which enables early detection of blood cancer. Additional study of electrical model of a WBC cell shows that at higher frequency above 20 MHz, internal organelles can be electroporated (Ellappan and Sundararajan 2005; Sahu et al. 2015, 2016a, b). Further partial derivation of Eq. (3) will output to Cole–Cole impedance model which can provide additional physiological information (Pethig 1987). The proposed capacitive sensor is non-invasive non-clinical easy to adopt system-on-chip whose sensitivity depends on it geometry. The stray capacitance associated with the capacitive sensor is measured while doing electrical characterization of sensor on Probe station platform. Probe station not only helps in determining stray capacitance but also helps in C–V measurements. Moreover, the same electroporation technique with different working conditions can be performed on erythrocytes for the detection of other diseases such as thrombosis, malaria, jaundice, diabetes, cancer and mellitus.

References

Beebe SJ, Blackmore PF, White J, Joshi RP, Schoenbach KH (2004) Nanosecond pulsed electric fields modulate cell function through intracellular signal transduction mechanisms. Physiol Meas 25(4):1077–1093

Ellappan P, Sundararajan R (2005) A stimulation of the electrical model a biological cell. J Electrostat 63:297–307

Ermolina I, Polevaya Y (2001) Study of normal and malignant white blood cells by time domain dielectric spectroscopy. IEEE Trans Dielectr Electr Insulation 8(2):253–261

Gupta A, Kharat GU (2014) Research article modeling of dielectric properties of cancer cell and evaluation of cancer stages: a review. Int J Recent Sci Res 5(2):443–448

http://www.cancer.gov/about-cancer/what-is-cancer. Accessed 9 Feb 2015

Joshi R, Schoenbach K (2000) Electroporation dynamics in biological cells subjected to ultrafast electrical pulses: a numerical simulation study. Phys Rev E 62(1):1025–1033

Lee R, Kima PH et al (2010) Capacitance-based real time monitoring of receptor-mediated endocytosis. Biosens Bioelectron 25:1325–1332

Pethig R (1987) Dielectric properties of body tissues. Clin Phys Physiol Meas 8(Suppl A):5–12

Polevaya Y, Ermolina I, Schlesinger M, Ginzburg B-Z, Feldman Y (1999) Time domain dielectric spectroscopy study of human calls. II. Normal and malignant white blood cell. Biochem Biophys Acta (Elsevier) 1419:257–271

Sahu S, Chowdhury D, Chattopadhyay M (2015) Design of MEMS capacitive sensor for the identification of cancerous blood cell: a simulation study. In IEEE international conference on smart sensors and systems, Bangalore, book of abstract, p 47

Sahu S, Chowdhury D, Chattopadhyay M (2016) Determination of malignancy in leukocytes with micro capacitive sensor. In: International conference of biotechnology and biomedical science, p-ISSN 2454-4582, e-ISSN 2454-7808, vol 2(2), pp 130–133

Sahu S, Chowdhury D, Chattopadhyay M (2016) Design for analysis of blood cancer in white blood cell using MEMS capacitive sensor: a simulation study. In: International conference on recent trends in engineering and material sciences, ICEMS-2016, ISBN no. 978-93-5254-230-7

Schoenbach KH et al (2002) Bioelectrics, “new applications for pulsed power technology”. IEEE Trans Plasma Sci 30(1):293–300

Shin D-M et al (2015) Highly sensitive detection of epidermal growth factor receptor expression levels using a capacitive sensor. Sens Actuator B (Elsevier) 209:438–443

World cancer report (2014). http://www.who.int/mediacentre/factsheets/fs297/en/. Accessed 15 Feb 2015

Yang J et al (1999) Dielectric properties of human leukocyte subpopulations determined by electrorotation as a cell separation criterion. Biophys J 76:3307–3314

Zimmermann U, Neil GA (1996) Electromanipulation of cells. CRC Press, New York, pp 174–231

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chattopadhyay, M., Chowdhury, D. & Sahu, S. Study of dielectric properties of leukocytes for the determination of malignancy by capacitive type MEMS sensor. Microsyst Technol 25, 1613–1618 (2019). https://doi.org/10.1007/s00542-017-3542-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-017-3542-2