Abstract

The study of cells mechanical properties is of great interest both in medicine and biology to recognize and prevent some diseases causing alterations in cellular behaviour and resistance. Biological micro electro-mechanical systems allow the application of extremely small and precise forces increasing, as a consequence, the number of results possible per experiment and the number of experiments that can be performed simultaneously. The presented work deals with the analysis of an electro-thermally actuated microgripper for single-cell manipulation. Specifications and targets impose several limitations and difficulties in micro manipulators design and these obstacles are even more important when the target of microgripping are biological particles (e.g. living cells). The main parameters that have to be taken into account while designing a cell micromanipulator are, aside from its actuation principle, its kinematics, its fingertips shape, its releasing strategy and its material biocompatibility. More specifically in thermal actuation also thermal stability, insulation and high temperature in the device have to be considered to ensure the cell’s integrity during its micromanipulation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Cells are subjected to continuous stimulation inside the human body (e.g. bone cells are subjected to compression, endothelium cells to both stretching and shear stress, muscle cells to stretching, cardiac cells to both stretching and compression).

There is only little information about cellular mechanics and response to mechanical stimuli with respect to what is known about cellular structure.

Some diseases, such as many cardiovascular diseases, intracranial injury and hypertension, cause changes in cellular behaviour so the cellular resistance is modified in case of solicitations. In order to recognize and prevent some diseases, the quantification of the mechanical properties of cells becomes fundamental.

The problem of cell mechanics can be approached in two different ways: the study of cell populations and of single cells.

The dynamics of cell populations can be investigated using bioreactors. One criticism of cell population studies is that, despite the ability of such studies to provide information about the average mechanical properties of cells, the heterogeneity among cell responses is largely ignored so the response of a single cell to mechanical signals cannot be easily decoupled from the response of the entire population.

As concerns the single cell approach, the existing techniques can be subdivided into two separate branches: local probes [e.g. atomic force microscopy (AFM) and magnetic twisting cytometry (MTC) techniques], used to stimulate a portion of the cellular membrane, and mechanical stimulation of the entire cell performed mainly using optical tweezers or laser trap, micropipette aspiration, micro-plates or MEMS whose great flexibility, in terms of possible solicitation modes and of dimensions compatible with the characteristics of the single cell, make them the best solution for cell manipulation. Other MEMS important advantages are the possibility of applying forces in a wide range (pN–μN), of carrying out studies on the single cell both adherent to the substrate and in suspension in a liquid medium, of stimulating the entire cell and not only a local portion of its membrane, of moving individual groups of living cells or individual cell spheres within or out of a culture.

Cells are the smallest form of life (diameter in the range of 10–50 μm) and the functional and structural units of all living things. Human body contains trillions of cells, organized into more than 200 major types (e.g. skin cells, osteocytes, hepatocytes, neurons, glial cells, haemocytes) and different for shape, dimensions and function. Cells belonging to the same type work together in groups called tissues.

Cells carry out thousands of jobs essential for life and some of them also make the products our body needs, such as sweat, saliva, enzymes, hormones and antibodies.

2 Cell micromanipulation

During the last 20 years, the increased demand of microtechnical applications has led to the development of new assembling technologies which enable handling of very small microoptical, microelectronical or micromechanical elements in nano or micrometer range. Specifications and targets impose several limitations and difficulties in micro manipulators design especially when the target of microgripping are biological particles (e.g. living cells).

The actuation mechanism of cell microgrippers has to be suitable for operating in electrolytic aqueous media because of the ionic environment cells are immersed in; this fact limits the application of high voltage in piezo actuated grippers since bubble formation, caused by electrolysis, occurs at 1.5–2 V in water. Moreover, any exposure to magnetic or electrical fields may have some negative effects on biological cells limiting the application of electrostatic or electromagnetic actuated microgrippers. Shape memory alloy (SMA) actuators are not good microgrippers because of the lack of reliability for a high number of cycles. Electro-thermal actuators are widely studied for cell manipulation even though they show many difficulties when are used as the maximum allowed temperature for manipulation of human cells in many applications is around 37 °C.

Also gripper’s materials biocompatibility places some restrictions in the choice of the actuation method and of the fabrication process. A survey of the cells microgrippers state of art reveals that, whatever the actuation method is, there are many points that, from a system engineering point of view, must be taken into account in the preliminary design of a cell microgripper, such as:

-

Actuation principle

-

Kinematics

-

Fingertips shape

-

Force feedback

-

Releasing strategy.

2.1 Actuation principle

Talking about the actuation of a microgripper, two different strategies (internal and external) are possible. In case of internal actuation, it is possible to design a specific part of the gripper with piezoelectric (PZT) material in order to generate a localized force when an electric voltage is provided (Mohd et al. 2009; Nah and Zhong 2007). The electrostatic force (Beyeler et al. 2007; Chen et al. 2010; Volland et al. 2002) can be used as an actuation by applying a voltage difference on a capacitor with movable armature. The thermal actuation, widely used for both biological and non-biological manipulation, is based on the thermal expansion of the gripper arms due to the Joule effect in presence of electric currents (Andersen et al. 2008; Ivanova et al. 2006; Nguyen et al. 2004; Volland et al. 2007). A faster response of the arms can be achieved with shape memory alloys (Huang 2002; Kohl et al. 2002; Kohl and Skrobanek 1998) that are able to restore almost immediately the memorized shape when a threshold temperature is passed. The electromagnetic actuation (Giouroudi et al. 2008) is based on micro-coils and is able to generate weak confined magnetic fields. Hydraulic and pneumatic actuation can be used to manipulate bio-cells with micro-pipes integrated in small circuits including micro-pumps and valves.

Each internal actuation strategy has its own limits. PZT actuators have strong nonlinear output, high supply voltage, small motion range, low resistance to creep and mechanical fatigue phenomena, hysteresis and biocompatibility problems. The electrostatic actuators are generally disadvantaged by the small dimensions of the capacitors; very complicated shapes of the gripper having many comb drives are necessary to increase the force, but, as a consequence, the motion range is strongly reduced by the small gaps between the armatures and the applied voltage easily causes electrolysis of watered environments. Thermal actuators may induce high temperature in the region close to the cells so long grippers dissipating the heat produced by the actuators need to be used. SMA materials present low fatigue resistance that causes very limited cycle time, small strain capability, strong nonlinearity, hysteresis and a fabrication process that is usually very complicated at the microscale. The limitations of electromagnetic actuators are related to the small dimensions of electromagnetic micro-actuators that imply fast heating of the coil due to the Joule effect and low allowable currents; the resulting magnetic field is generally weak and subjected to relevant leakages, giving small power per unit volume. Hydraulic and pneumatic actuators are limited to pipe based devices; they are not suitable for precision operations involving more than one cell and the hydraulic solution only works in wet environments.

External actuators preserve the thermal insulation of the gripper and avoid contaminations or biocompatibility problems. Piezoelectric motors are the most promising solution for this application, due to their small size and high accuracy as they have very high response and wide speed range (from few micrometers/second to few millimeters/second); thermal heating is negligible in this kind of actuator, but there are problems related to the interface between the motor and the microgripper (Mousavi et al. 2011), where interferences and frictions must be considered. A particular kind of external actuation strategy is the manual one; in this case (Chan et al. 2012) the manual rotation of a micrometer head is used to open the tips of the tweezer structure, while the closing of the device is due to elastic deformation.

2.2 Kinematics

The kinematic solutions adopted and found in the literature are strongly related to the field of application of the gripper and to the actuation strategy used. Compliant structures belong to a particular class of grippers where the material elasticity is used to transfer the force from the actuator to the cell by amplifying its effect exploiting the geometrical characteristics of the device; this solution is very interesting because of its simplicity and the possibility to increase the gripping surface limiting the local pressure acting on the cell membrane.

Rotational and translational movement of the microgripper’s clamps are the two possible kinematic strategies. During the rotational gripping process, reaction forces act at the contact points between the gripping arms and the gripped object. In the case of microparts with curved or especially with circular surface, such as cells, the reaction forces act perpendicular to the object surface: the x-component of the reaction force holds the gripped object between the gripping arms, but the y-component of the reaction force acts parallel to the longitudinal axes of the microgripper and pushes the gripped object out of the gripping arms; this negative effect can be avoided if the gripping process is realised without y-component of the reaction force (clamps translation): this can be achieved by using a gripping mechanism with parallel movement of both gripping arms to guarantee a reliable gripping process (Keoschkerjan and Wurmus 2002).

2.3 Fingertips shape

The fingertips shape must be carefully designed according to the conformation of the grip site. The less elaborated kinematics of arms lead to gripping by only two points; in this case very high pressures may interest the gripping site so this solution is not indicated for the manipulation of bio-cells not to compromise their integrity. Cell microgrippers prefer rigid translating fingers instead of rotating fingers; the most diffused fingertips shapes can be divided in flat, angular carved and cylindrical carved fingertips.

2.4 Force feedback

The force feedback measurement is often crucial for biomanipulation, due to the small mechanical resistance of the cells. The most suitable strategy is the displacement control through optical detection which is contactless and very accurate also for the microgripper dealt with in this paper; other methods can be found in the literature, such as integrated piezoresistive transducers or micro capacitive sensors. These last two approaches are usually limited by the low biocompatibility of materials and by the possibility to induce electrolysis of water with related bubbles formation.

2.5 Releasing strategy

Cell releasing in microgripping is generally problematic because of the small effect of gravity force compared to the adhesion and the capillary ones.

The most common releasing strategies can be divided in passive and active strategies; the first ones exploit the features of the gripper surface (e.g. shape, material, coatings, etc.), while the last ones make use of external actions (e.g. forces, pressures, vibrations, etc.).

3 Electro-thermal actuation strategy

The dimensional scaling (Thielicke and Obermeier 2000; Ouyang et al. 2008) has consequences both for the mechanical design and for the actuation of microactuators; the choice of the actuation principle depends on the structural dimensions, the technology, the functioning and the purpose of the micro device.

External forces can be generated using different effects such as the thermopneumatic, the electrochemical, the electrostatic and the magnetic ones; internal forces exploit the intrinsic actuation capability of some special materials including piezoelectric, thermomechanical, shape memory and electrostatic effects.

The presented work deals with the electro-thermal actuation of a polymeric microgripper used to catch a single cell having a diameter in the 20 ÷ 40 μm range creating an insulating micro chamber around it to provide cell rheological analyses.

The polymer used as the base material of the microdevice is SU-8 having good mechanical and chemical properties (see Table 1), biocompatibility, ease of fabrication and low cost.

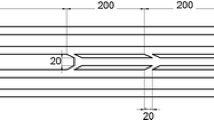

In Fig. 1 it is possible to see a computer aided drafting (CAD) drawing of the microgripper under examination (Iamoni and Somà 2013) with its main dimensions; Fig. 2 shows a thin gold layer deposited and patterned on the top of SU-8 for thermal actuation. A very thin Chromium layer is deposited between gold and SU-8 to facilitate gold adhesion on the polymeric substrate. Red parts are the electrical contact pads for power supply voltage.

Tables 2 summarises the gold material properties used to perform both the finite element method (FEM) simulations and the mathematical-physical analysis of the problem dealt with.

3.1 Mathematical-physical analysis

A current-carrying wire heats up because of Joule effect and its temperature changes from the initial reference value to the regime one. The gold layer deposited on the polymeric substrate was studied as a set of electrical resistances whose layout is shown in Figs. 3 and 4.

The geometrical parameters related to the gold layer arms and to the SU-8 substrate are reported in Table 3:

As it can be seen in Fig. 5, the central hot arm is in series (XZ) with the parallel of the series (ZY) of the other two lateral hot arms. The electrical resistances have a symmetrical configuration and the equivalent resistance (Re) can be calculated as it follows:

where

ρg is the gold electrical resistivity depending on the reference temperature (Tref = 20 °C) and on the maximum temperature gold can withstand without overcoming its melting point:

Looking at Eqs. (1a) and (1b) it is important to note that each gold arm was modeled as a wire whose electrical resistance is directly proportional to its length and indirectly proportional to its cross section.

Joule effect can be analyzed taking into account the energy balance between the heat produced by the passage of the current (I) due to the applied voltage (V), the heat stored in the cable and the heat lost to the surrounding environment.

The gold layer transfers heat to both the substrate and air. The gold layer-air (Sair) and the gold layer-substrate (Sint) thermal exchange surfaces were obtained using the following formulas:

The total thermal exchange surface (Stot) was calculated by means of these equations:

The electrical currents (I) flowing through the device are equal to:

As a consequence, the generated total thermal-electrical fluxes (Φ) can be written as:

The thermal-electrical fluxes at the layer-substrate interface that make the hot arms heat up for the microgripper actuation are given by the following equations:

The gold layer arms temperature variation (ΔT) depends on the exchanged thermal fluxes and on the conductive thermal resistance of gold arms:

Also for the thermal resistances calculus, the gold layers were taken into account as if they were electrical wires whose external diameter (D), obtained under the assumption that the cylindrically shaped wires have the same mass [mg—see Eq. (13)] of each gold arm, is reported below:

The thermal resistances (Rt) are:

The temperature (T) of the gold layer arms was then obtained as it follows:

To calculate the temperature of the SU-8 hot arms due to the Joule effect thermal flux, a thermal energy equilibrium condition was written so that all the heat exiting the gold layer and passing through the gold-SU-8 interface surface is absorbed by the polymeric substrate increasing its temperature from the reference to an equilibrium one (Tm):

The masses of the gold layer (mg) and of the SU-8 substrate (ms) are listed below:

3.2 FEM simulations and results

To perform the simulation it was necessary to put thermal constraints on the device as it can be seen in Fig. 6: the extreme cold arms of the gripper are at room temperature while the central hot arms are subjected to different temperatures depending on the voltage applied so on the current flowing through them. The applied hot temperatures are the equilibrium ones ™ described in the analysis of Sect. 3.1.

Figure 7 shows four opening zones considered in the gripping site; as it can be seen from the picture, “CD” and “GH” openings are the reference ones because a cell can enter without exiting the microgripper only if it has a diameter lower than “CD” distance and bigger than “GH” one.

In Fig. 8 the parabolic relationship between the four openings and the applied voltage is shown. Varying the applied voltage, single cells of different diameters can enter the microgripper to be incorporated and subsequently tested. For example, applying a voltage equal to 45 V a cell having a diameter lower than 37 μm and higher than 33 μm can be can be enclosed by the gripper.

The main problem related to thermal actuation of biological particles is the high temperature that could destroy or damage the cell, so it was necessary to study the temperature distribution (see Fig. 9) along the microgripper giving it a particular geometry so that the temperature of the gripping zone was not higher than the maximum temperature (37 °C) a cell can withstand without changing its biological/mechanical properties and behaviour. The temperature in the gripping zone (Tcell) is shown in Fig. 10; the highest value is about 30 °C, a safe result for cell’s integrity.

4 Conclusions and future purposes

In this paper an electro-thermally actuated microgripper is discussed by evaluating the system requirements. All the results were obtained by means of Ansys 11.0 FEM simulations; the real microgripper, having the same characteristics of the presented virtual design, is still under construction so no experimental activity has been done up to now and the simulations results were compared, in terms of orders of magnitude, to the ones found in the literature.

The cylindrical shape of the fingertips not to have high pressures acting on the cell external surface and the thermo-mechanical design and analysis of the gripper in order to have low temperatures in the cell gripping zone are all strengths that make the presented microdevice innovative, not conventional and especially suitable also in the bio-field and not only in the micro-mechanical one.

Some biological cells have a diameter up to 50 μm so the use of a microgripper having a gripping zone not bigger than 40 μm generates interference and compression forces between each one of these cells and the jaws of the device; our purpose is the creation of a FEM contact model to evaluate the pressure acting on the external surface of the cell by varying the gripping zone shape and/or the cell shape. The mechanical and the material properties of the cell have to be introduced in the FEM simulation as if the cell were a micro mechanical component subjected to an external load.

References

Andersen KN, Carlson K, Petersen DH, Mølhave K, Eichhorn V, Fatikow S, Bøggild P (2008) Electrothermal microgrippers for pick-and-place operations. Microelectron Eng 85:1128–1130

Beyeler F, Neild A, Oberti S, Bell DJ, Sun Y, Dual J, Nelson BJ (2007) Monolithically fabricated microgripper with integrated force sensor for manipulating microobjects and biological cells aligned in an ultrasonic field. J Microelectromech Syst 16(1):7–15

Chan B-D, Mateen F, Chang C-L, Icoz K, Savran CA (2012) A compact manually actuated micromanipulator. J Microelectromech Syst 21(1):7–9

Chen T, Sun L, Chen L, Rong W, Li X (2010) A hybrid-type electrostatically driven microgripper with an integrated vacuum tool. Sens Actuators A 158:320–327

Giouroudi I, Hötzendorfer H, Kosel J, Andrijasevic D, Brenner W (2008) Development of a microgripping system for handling of microcomponents. Precis Eng 32:148–152

Huang W (2002) On the selection of shape memory alloys for actuators. Mater Des 23:11–19

Iamoni S, Somà A (2013) Design of cell microgripper and actuation strategy. In: Proceedings of SPIE, vol 8765

Ivanova K, Ivanov T, Badar A, Volland BE, Rangelow IW, Andrijasevic D, Sümecz F, Fischer S, Spitzbart M, Brenner W, Kostic I (2006) Thermally driven microgripper as a tool for micro assembly. Microelectron Eng 83:1393–1395

Keoschkerjan R, Wurmus H (2002) A novel microgripper with parallel movement of gripping arms. In: Proceedings of 8th International Conference on New Actuators, pp 321–324

Kohl M, Skrobanek KD (1998) Linear microactuators based on the shape memory effect. Sens Actuators A 70:104–111

Kohl M, Brevet B, Just E (2002) SMA microgrypper system. Sens Actuators A 97–98:646–652

Mohd NMZ, Bijan S, Yanling T (2009) A new design of piezoelectric driven compliant-based microgripper for micromanipulation. Mech Mach Theory 44:2248–2264

Mousavi MMS, De Pasquale G, Somà A, Brusa E (2011) A novel SU-8 microgripper with external actuator for biological cells manipulation. In: Proceedings of DTIP, pp 356–361

Nah SK, Zhong ZW (2007) A microgripper using piezoelectric actuation for micro-object manipulation. Sens Actuators A 133:218–224

Nguyen N-T, Ho S-S, Low CLN (2004) A polymeric microgripper with integrated thermal actuators. J Micromech Microeng 14:969–974

Ouyang PR, Tjiptoprodjo RC, Zhang WJ, Yang GS (2008) Micro-motion devices technology: the state of arts review. Int J Adv Manuf Technol 38:463–478

Thielicke E, Obermeier E (2000) Microactuators and their technologies. Mechatronics 10:431–455

Volland BE, Heerlein H, Rangelow IW (2002) Electrostatically driven microgripper. Microelectron Eng 61–62:1015–1023

Volland BE, Ivanova K, TZV Ivanov, Sarov Y, Guliyev E, Persaud A, Zöllner JP, Klett S, Kostic I, Rangelow IW (2007) Duo-action electro thermal micro gripper. Microelectron Eng 84:1329–1332

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Iamoni, S., Somà, A. Design of an electro-thermally actuated cell microgripper. Microsyst Technol 20, 869–877 (2014). https://doi.org/10.1007/s00542-013-2065-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-013-2065-8