Abstract

This paper briefly reviews recent research and developments of micropump designs with a particular emphasis on mechanical micropumps and summarizes their applications in biomedical fields. A comprehensive description of the actuation schemes, flow directing concepts and liquid chamber configurations for micro pumping is provided with illustrative diagrams. Then, a comparative study of current mechanical micropump designs highlighting their advantages and limitations for various applications is presented, based on performance criteria such as actuation voltage and power consumption, ranges of operating frequency and maximum flow rate and backpressure. This study compiles and provides some basic guidelines for selection of the actuation schemes and flow rate requirements in biomedical applications. Different micropumps in biomedical applications, such as blood transport and drug delivery also have been reviewed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Microfluidics deal with design and development of miniature devices which manipulate small amounts of fluids (10−9–10−18 l), using channels with dimensions of tens to hundreds of micrometers (White 2006). By miniaturizing the size, the scale of channels is in the range of a few micrometers, which significantly facilitates controlling and transferring of tiny volume of fluids. For example, Micro Total Analysis Systems (μTAS) which can be found in Auroux et al. (2002) and Reyes et al. (2002)—are designed to transport sample reagents to perform functions of delivery, mixing, reaction, analysis or detection of reagents. Applications of these microfluidic systems have demonstrated to be superior to their macro scale counterparts: greatly reduce the quantities of samples and reagents consumption, automate and improve the quality of experiments and shorten analysis times with less manual intervention, finally lower the costs of many standard processes. Except for μTAS devices in chemical and biological analysis and detection, other microfluidic systems, such as implantable drug delivery systems for high precision flow control (Maillefer et al. 1999), microchips integrated in computer to circulate coolant for cooling (Singhal and Garimella 2007), micro pumping systems in portable fuel cells (Zhang and Wang 2005), as well as impeller system for blood flow regulation and pressurization (Diaz et al. 2007), all need a fluid delivery unit to transfer the fluid from reservoir to the target place with accuracy and reliability.

As it says that the micropump is the beating heart of microfluidics (Brand 2006), micropump servers as the actuation source and has been the subject of a number of research projects since the early years of microelectromechanical systems (MEMS) development. The first MEMS based micropump dates back to 1980s, which was developed by Smits primarily for use in the controlled insulin delivery systems to maintain diabetic’s blood sugar level (Smits 1984). This peristaltic pump consisted of three active valves actuated by piezoelectric discs. This publication was first to demonstrate the feasibility of silicon-based micropump and inspire an extensive research on micropump from disposable biomedical microdevices to microelectronics cooling and portable fuel cells. Generally, micropumps can be classified into two categories: mechanical and non-mechanical, which is based on the principles whether converting external mechanical energy or non-mechanical energy directly into kinetic energy. Electrical, magnetic, thermal and optical as well as acoustic energies have been converting into mechanical energy in micropump applications. Under this system as shown in Table 1, mechanical pumps can be further divided into displacement pumps and dynamic pumps according to whether the mechanical energy is added periodically to increase pressure to move the fluid or continuously to increase the velocity of the fluid. On the other hand, many new fluid transport means, such as magnetohydrodynamic effect, electrohydrodynamics, and electrokinetic effect, acoustic streaming along with electroosmotic effects, which previously were neglected in macroscopic domain, also have attracted attentions in the microscale domain. A detailed description of this categorization and mechanism is available in the literature (Nguyen and Wereley 2002).

With the improvement of understanding of new fluid transport phenomena, other non-mechanical micropumps also have been developed: flexural planar wave pumps (Nguyen et al. 2000), capillary-force driven (Nilsson 2004), electrochemical micropumps (Suzuki and Yoneyama 2003), osmotic-type (Ehwald et al. 2006). One key feature of these two types of pumps is that most non-mechanical micropumps do not need actuation membranes to drive the fluid flow. The geometry in the design and fabrication process is comparatively simple. However, their operation and performance are influenced by the properties of the pumping fluids and surface material. For example, EHD pumps need a solution with the electrical properties (permittivity and conductivity), and electroosmotic pumps require a certain pH solution. In most cases non-mechanical micropumps cannot achieve high flow rates, driving pressures and fast response times. The typical operation flow rate of non-mechanical micropumps is less than 10 μl/min while it ranges from 10 μl/min to several milliliters per minute for mechanical micropumps (Nguyen and Wereley 2002). From this point of view, the small flow rates of non-mechanical micropumps are very suitable for small regulation and precise control in the μTAS.

Another frequently used system of categorization is set forth for traditional pumps (Krutzsch and Cooper 2001). Pumps fall into two major categories, positive displacement pumps and hydrodynamic pumps, according to the way the fluid is displaced (Krutzsch and Cooper 2001; Laser and Santiago 2004; Yamahata 2005). For the positive displacement pumps, energy is periodically added by applying a force to one or more movable boundaries of fluid-containing volumes. Volume changes resulting from this action produce a direct pressure increase up to the value required to overcome resistance of the channel and valve. On the other hand, hydrodynamic pumps increase the fluid velocities within the device by adding continuous energy. Because the aforementioned two categorization systems are not exactly same, to be consistent with the classification available in most papers published, the classification adapted in this research is using the mechanical and non-mechanical system.

Several excellent reviews on a number of reported micropumps compared qualitatively and quantitatively based on performance parameters (Nguyen et al. 2002; Laser and Santiago 2004; Woias 2005; Yun and Yoon 2006). Thus, in the work, the quantitative performance comparison tables and charts of micropumps are not repeated herein. Rather, the focus in this paper is more of a general view of currently mature mechanical micropump technologies, such as the choice of the pumping principles, selection criteria of fluid chamber configurations, and flow rate rectifiers based on the maximum flow rate, backpressure, excitation frequency, and size, as well as power consumption. Different micropumps for blood transport and drug delivery developed in both academia and industry are also outlined.

2 Design considerations

There are three basic components in the micropumps: a micro actuator, flow rectifiers and a fluid chamber. In mechanical micropumps, all the external energy is implemented by actuators which perform a variety of functions and carry out diverse tasks during operation, such as valve controlling and pumping, detectors positioning, and medications dispensing. Electrical, magnetic, thermal, optical and acoustic as well as chemical/biological energies, have been demonstrated successfully in converting into mechanical energy in micropumps (Tabib-Azar 1998). The flow rectifier is a device which regulates the flow of fluid by opening, closing or partially obstructing various micro channels and is connected to inlet port or outlet port.

2.1 Actuation schemes

Ideally, actuators are easy to construct and can provide large force, have large stroke, have fast response time, run under low power consumption, and have low thermal losses (Meng 2003). The choice of whether to use an integrated or an external actuator depends upon the specific requirements of the application. For example, to achieve large stroke for higher flow rates, the large force and displacement of external actuators is desirable. However, using an external actuator means sacrificing size at the same time. During the last decade according to the specific requirements, such as working liquid, maximum pumping rate or back pressure, and power consumption limitation a variety of micropumps have been designed and implemented. Thus, performances of these micropumps are presented herein by their actuation mechanisms.

2.1.1 Electrical actuation

Micropumps employing electrical actuation scheme include electrostatic, piezoelectric and electroactive polymer composite micropumps.

Electrostatic actuation depends on the columbic attraction of oppositely charged material bodies to induce displacement or exert force. The attraction force can be calculated from the stored energy in the electrostatic field of the device. When a voltage V is applied between two plates of area A separated by an air gap d, the electrostatic force can be described as follows:

where ɛ 0 is the permittivity of free space.

Electrostatic actuation is widely used in MEMS devices. Except for micropumps and microvalves in microfluidic applications, other examples also can be found in electrostatic micro motors (Trimmer and Gabriel 1987), electrostatic micro mirrors (Pacheco et al. 2000; Pu et al. 2004), and electrostatic micro switches and relays (Gretillat 1999).

Electrostatic micropumps typically have the parallel-plate actuator structure shown in Fig. 1. It depends on the electrostatic attraction force between two parallel plates, one of which is made to be a fixed electrode and the other one a movable electrode. The membrane of the electrostatic micropump can be actuated and displaced towards the fixed electrode by applying a voltage across the electrodes. When the actuation voltage is removed, the displaced membrane releases and returns to its original position. The alternate supplying and pumping operation therefore is achieved by periodically switching the applied voltage. The first electrostatic reciprocating micropump was reported in Judy et al. (1991). The authors designed and implemented a micropump by silicon surface micromachining processes which were compatible with standard IC processes. Zengerle et al. (1992) first reported the experimental results: it operated at a maximum flow rate of 70 μl/min and a backpressure of 2.5 kPa at an operation frequency of 25 Hz at 170 V. The structure was shown in Fig. 2. In 1995, pumping performance was improved by reducing the dimensions of the micropump. This design featured a maximum flow rate of 850 μl/min and backpressure of 29 kPa while operating at a frequency of 800 Hz with an actuation voltage of 200 V. Also, many theoretical analyses of the electrostatic micropumps have been presented in Francals et al. (1997) and Francais and Dufour (2000).

Electrostatic micropump (Zengerle et al. 1992)

Recent research on electrostatic micropumps can be found amongst many research groups (MacHauf et al. 2005; Lin et al. 2007). An improvement of an electrostatic micropump, which applied voltage across the liquid working fluid taking advantage of the high relative electric permittivity and low conductivity. Therefore, the higher the permittivity, the higher are the force and thus the pumping rate for the same input power. The flow rate achieved was 1 μl/min at 50 V actuation voltage across 63 μm gap. However, the micropump was limited to pump only conductive fluids.

The main advantages of electrostatic micropumps are low power consumption and fast response time. The deflection of the diaphragm can be easily controlled by applied voltage. One the other hand, a major limitation is the small membrane deflection, which is usually limited up to 5 μm with applied actuation voltages of around 200 V.

Piezoelectric mechanism is the most widely used in reciprocating micropumps and the piezoelectric micropump have grown to be the dominant in drug delivery and other biomedical applications. Piezoelectric actuation involves strain induced by an applied electric field on a piezoelectric crystal. The piezoelectric effect is related to the coupling that exists between mechanical deformation and electrical polarization.

where s E is the compliance tensor and σ is the stress, d the piezoelectric charge constant tensor and E is the electric field.

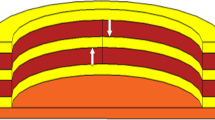

When used in micropumps, the basic idea is to convert the transverse piezoelectric strain to a large bending displacement in the perpendicular direction. In most implementations, strain in the piezoelectric layer is induced by either d31 or d33 piezoelectric coupling. In d31 mode, a transverse strain (perpendicular to the polarization axis) is caused by the d31 piezoelectric coupling while the d33 mode induces a strain parallel to the polarization. The voltage induced deflection of the membrane will cause the volume of liquid in the chamber to change. When AC voltage is applied, the membrane will move up and down alternately to complete expansion and contraction modes. The two different excitation modes, transverse strain and axial-strain, are illustrated in Figs. 3 and 4. In Fig. 3, the bottom surface of the piezoelectric actuator is directly bonded to the membrane of the micropump, while the top surface of it is unconstrained. During operation, an axial electric field is applied to the piezoelectric actuator. The pump membrane deflects in a radial direction under a bending moment causing the upward and downward movement. In Fig. 4, the piezoelectric actuator is positioned on the surface of the membrane and the top is constrained on a rigid frame. The pump diaphragm generates a large vertical force and consequently a large vertical displacement as a result of axial-strain of the piezoelectric actuator when voltage is applied. The first piezoelectric-actuated micropump was proposed in van Lintel et al. (1988). This piezoelectric micropump adopted the lateral-strain excitation mode working at an operation frequency of 1 Hz, 125 V. The maximum flow rate of 8 μl/min and the backpressure of 9.8 kPa were achieved. To obtain large displacements, a unique reciprocating micropump using an axial-strain configuration was reported in Esashi et al. (1989). This was a three-layer structure, two silicon layers and one intermediate sputtered glass layer. The bulk piezoelectric actuator was attached to the bossed silicon membrane. The maximum flow rate of this device was about 15 μl/min and the maximum back pressure of 6.4 kPa was achieved, respectively, at an operation frequency of 30 Hz, 90 V. A number of piezoelectric micropumps were designed and developed to improve the performance either by increasing the liquid chambers or number of piezoelectric actuators. A novel two-chamber piezoelectric micropump was successfully demonstrated by Olsson et al. (1995) as shown in Fig. 5.

Additionally, several papers on theoretical analyses to improve the performance and obtain optimized working parameters can be found in Ullmann (1998) and Morris and Forster (2000). These work may provide a tool for the design of piezoelectric micropump assembly and be able to predict the flow pressure characteristics for a given frequency, volume amplitude and nozzle loss coefficient. Especially, the author (Ullmann 1998) studied the relationship between the micropump performance and chamber configurations, such as series and parallel connections, which would benefit the designer of new micropump development. Meanwhile, a thin film piezoelectric material was explored as a passive membrane layer as shown in Fig. 6. For example, PZT is a piezoelectric material often used in many MEMS applications due to its high piezoelectric and electromechanical coupling coefficients. However, the fabrication techniques are complex and the material properties of thin film structures are quite different from the bulk piezoelectric disks (Cho et al. 2005).

Thick-film piezoelectric actuation micropump (Koch et al. 1997)

Piezoelectric micropumps have advantageous characteristics of high stress and fast response times. However, for specific cases of the reduced dimensions of the device, deposition of a thin film of piezoelectric material onto the silicon is required. This fabrication is complicated and time-consuming. Moreover, the required induced voltage has to be maintained to a certain level. The review of the literature suggests that most of the piezoelectric micropumps, either the transverse strain excitation mode or axial-strain excitation, require a high driving voltage, up to 100 V, to produce an effective deformation, however, the power consumption may be very low.

Similar to the other two electrical actuated approaches, the deflections of electroactive polymer composite are caused by the ionic movement due to electric field. The electroactive polymer material is newly emerging candidate for micropump application because of its large deformation (over 1% bending strain) (Lee and Kim 2006) in the presence of a low applied voltage and ability to work in aqueous environment. Ionic conductive polymer film (ICPF) or ionic polymer-metal composite (IPMC) is one of the most popular polymer composite. The IPMC is composed of a layer of perfluorosulfonic acid polymer or Nafion/silica with both sides chemically plated with high electrical conductive materials, such as gold or platinum, as electrodes. The electroactive polymer diaphragm can be easily controlled to bend bi-directionally when an alternating voltage is applied across the electrodes. Applications of IPMC in medical devices, microrobots and micromanipulators have been reported recently.

2.1.2 Magnetic actuation

Magnetic actuation mechanism generally can be classified as electromagnetic and magnetostrictive approaches. The magnetic force \( (\overrightarrow {F}_{\text{mag}} ) \) between a current carrying wire and a permanent magnet can be expressed as:

where l is the length of the wire, I is current through the wire and \( \overrightarrow {B} \) is the magnetic induction.

For an electromagnetic micropump, the movement results from the interaction between permanent magnets and the variable magnetic field generated by micro coils. Magnetic actuation forces can be either attractive or repulsive, thus bi-directional deflections of a flexible membrane can be easily realized by switching the phases of input currents. While the forces generated are large, electromagnetic actuation requires an external magnetic field usually present in the form of an external permanent magnet or a separated actuator. A typical schematic of electromagnetic actuation micropump consists of a fluid chamber, inlet/outlet and a flexible membrane, small permanent magnet and microcoils, shown in Fig. 7. The external drivers or permanent magnets directly bonded on the top of the membrane are convenient to provide magnetic field, however, the size is sacrificed at the same time. Therefore, recently many researchers have explored the integration of magnets, cores or the microcoils, to make the structure more compact and eventually reduce the entire size.

The first electromagnetically actuated micropump was investigated and reported (Zheng and Ahn 1996). A 7 μm thick Permalloy (Ni80Fe20) film was electroplated on a 17 μm thick, 8 × 8 mm2 silicon membrane as a magnetic core and the copper spiral micro coils were formed on a Pyrex glass wafer. Then these two parts were assembled together using low temperature polymer bonding techniques. When the driving current was applied to the micro coil, the membrane deflected upwards and downwards by the magnetic attraction force. The maximum deflection of membrane was achieved at 23 μm and the maximum flow rate was 20μL/min at 5 Hz when driven by integrated inductors operating at 300 mA and 3 V.

Due to relatively high stiffness, silicon membrane is not capable of generating large deflection. Polydimethylsiloxane (PDMS), a flexible elastomeric polymer, is widely used for fast prototyping microfluidic devices. Either the bulk permanent magnet or planar microcoils can be embedded in the PDMS membrane. Khoo (2000) developed a magnetic micropump with a 2 × 2 mm2, 40 μm PDMS membrane using the Permalloy (Ni80Fe20) flaps embedded in the membrane. A maximum displacement larger than 80 μm and a maximum flow rate of 1.2 μL/min were obtained in the presence of a 2.85 × 105 A/m external magnetic field for an actuation frequency of 2.9 Hz. The flow rate could be easily adjusted by the frequency. Yin et al. (2007) described the implementation of an electromagnetic membrane actuator with a semi-embedded coil for pumping applications. A permanent magnet was hold by an iron clamp on its top, while a flexible PDMS membrane with an embedded planer coil was connected with a silicon substrate frame to ensure the membrane moving bi-directionally. The whole fabrication process was based on the standard micromachining technologies, such as ICP, metal sputtering and electroforming and so on. Upon applying a current to the coil, electromagnetic fields generated by the microcoils created an attraction or repulsion between the permanent magnet and the membrane. For a Φ7 × 150 μm membrane, the maximum deflection reached 55 μm with an applied current of less than 500 mA. With good controllability and batch-process capability, this type of actuator with a valve-control microfluidic chip could be applied in portable biomedical analysis apparatus.

Pan et al. (2004) reported a magnetically driven peristaltic micropump for lab-on-a-chip and microfluidic system shown in Fig. 8 based on the soft molding and bonding of three 250 μm PDMS layers. The maximum pumping rate of this micropump was about 24 μL/min with a maximum backpressure of 330 Pa. In this study, the magnetic field was generated by three external permanent magnets mounted on the rotor shaft of a small DC motor (Φ6 × 15 mm) at different phase angles. The power consumption was 11 mW and the operating voltage was less than 1 V at this pumping rate. In his further study, the pumping performance was improved up to 774 μL/min for deionized water at the input power consumption of 13 mW (Pan and McDonald 2005). Alternatively, the variable magnetic field provided by a 10-turn planar microcoil fabricated on a PC board also studied and compared in this work. Although higher pumping rate of 1 mL/min for deionized water was obtained and the structure was more compact, much higher power consumption was required and heat dissipation also deserved consideration.

On the other hand, the flexible membrane also can be fabricated by mixing small size magnetic powders and polymers instead of bulk magnets directly embedded in the flexible membrane. Ferrite/polyimide, ferrite/PDMS, NdFeB/PDMS composite membranes were reported in the previous papers (Lagorce and Allen 1997; Wang et al. 2004). This kind of magnetic composite has several advantages: first, bulk permanent magnets or Permalloy pieces do not have to be positioned within the pre-polymer or integrated into the membrane. Hence, the membrane thickness is not limited by the dimensions of a bulk magnet and can be significantly reduced. Also, the relatively homogenous and isotropic material properties of the composite membrane will improve the performance of the micropump. Using the same technique, Yamahata et al. 2005b proposed the fabrication and characterization of a polymethylmethacrylate (PMMA) valveless micropump driven by a separated external solenoid actuator. The pump was composed of two diffuser elements and a PDMS membrane with an integrated composite magnet made of NdFeB magnetic powder. This composite membrane was fabricated using a two-step molding technique: first, synthesize isotropic magnetic powders and a PDMS to make a polymer magnet and then bond with another large PDMS membrane. A large-stroke membrane deflection (~200 μm) was obtained and the water flow rates up to 400 μl/min at the excitation frequency of 12 Hz were measured. Similar research conducted by the same author employed glass as the microchannel substrate with standard microfabrication techniques (Yamahata et al. 2005a). It consisted of three fusion-bonded glass plates and the same PDMS composite membrane. Higher water flow rates of up to 1 mL/min and a maximum backpressure of 50 mbar were obtained under a sinusoidal input current of 100 mA.

In summary, the major advantage of electromagnetic actuation is the large deflection and high tunable frequency capability. Also, electromagnetic fields arise and disappear rapidly, thus permitting devices with very fast operation speeds. However, electromagnetic micropump requires high power consumption and heat dissipation.

2.1.3 Thermal actuation

Thermal actuation mechanism includes thermal expansion and phase change types. Some popular thermally induced micropumps usually take the forms of thermopneumatic, shape memory alloys or bimetallic actuation methods. Representative thermal actuation micropumps, such as single gas expansion, liquid-gas phase change (vaporization and condensation) and two solid-phase change are briefly introduced herein.

Generally, a thermopneumatic actuator consists of a heater, diaphragm and a sealing cavity shown in Fig. 9. It is based on the thermally induced volume change or phase change of fluids sealed in a chamber. The periodical change in volume of the chamber results in a pressure change inside the cavity to actuate the flexible diaphragm. For the liquid, the pressure change is expressed as:

where ΔP is the pressure difference; E is the modulus of elasticity; β is the thermal expansion coefficient; ΔT the temperature increase and ΔV/V is the volume change percentage.

The first thermopneumatic micropump based on microfabrication techniques was proposed in Van De Pol et al. (1990). Essentially, it also could be classified as the reciprocating membrane micropump, which included the following components: the actuator, fluid chamber, silicon membrane and two silicon check valves. The actuator comprised of a cavity filled with air, a square silicon pump membrane and built in aluminum meander, which served as a resistive heater. As a voltage was applied to the heater, the temperature of the air inside the cavity was increased and thus caused a pressure increase in the chamber. When the voltage was switched off, air inside the cavity cooled down resulting in a pressure drop in the cavity and a related upward deflection of the pump membrane. The pressure difference by switching applied voltage resulted in opening and closing of the inlet and outlet valves, respectively. A maximum flow rate of 34 μl/min was reported at a voltage supply of 6 V and the temperature rise was around 30°. To have large membrane deflection and high flow rate, another representative thermopneumatic micropump (Jeong and Yang 2000) mentioned in several literatures was proposed shown in Fig. 10. The construction of the actuator involved a double side polished 450 μm thick n-type (1 0 0) corrugated silicon diaphragm and a microheater. The maximum flow rate of the micropump with corrugated diaphragm reached 14 μl/min at 4 Hz when the input voltage and duty ratio were 8 V and 40%, respectively. This flow rate was 3.3 times that with the flat membrane for the same input power.

Thermally induced expansion also occurs in the form of liquid-gas or gas-liquid phase change. A representative thermopneumatic micropump of this type (Cooney and Towe 2004) was designed by Cooney. The micropump consisted of a thin film heater, a microfluidic flow restrictor, and two solution reservoirs. These reservoirs were separated by a thin elastomeric membrane. The mechanism of this micropump relied on a two-phase liquid–vapor propellants, Perfluorocarbon mixture, to pressurize dispensing reservoirs with outlet flow restrictor. The micropump dispensed a flow rate of 1.4 μl/min for 4.5 h with an average power of 200 mW. This micropump could be designed to accommodate a wide range of sizes, shapes and flow rates for a variety of applications according to different power levels and temperature restrictions. The power levels required for this micropump could allow it to be battery operated, and thus potentially implemented into hand-held biomedical devices.

Although generates large induced pressure and deflections of the flexible membrane with low input voltage, thermopneumatic micropump requires high power consumption and shows slow response time (low actuation frequencies). The input driving power has to be constantly retained above a certain level. This type of micropump could be potentially implemented with lap-on-a-chip or other microfluidic system if the heat generation or temperature rise will not affect the performance of the working fluid and the operation environment.

For SMA materials, shape memory effect involves a reversible thermally induced two solid-phase transition: from the austenitic phase (at high temperature) to the martensitic phase (at low temperature). In SMA materials, the martensite is much more ductile than austenite and this low temperature state can suffer large deformation. When heated above the phase transformation temperature, the material starts to form single variant austenite. When mechanically constrained, the material exerts a large force while assuming its initial shape. This phase transition results in mechanical deformation that can be utilized as a driving force on membrane of a SMA pump shown in Fig. 11. High power to weight ratio, high damping capacity, good chemical resistance and biocompatibility make SMA materials promising in the field of MEMS applications (Fu et al. 2004). However, there is limited availability of special alloys, such as AuCu, InTi, and NiTi. The deformation of SMA cannot be accurately controlled and predicted due to its sensitivity to temperature. As other thermally induced actuations, high power consumption is required and SMA materials cannot cool sufficiently at high excitation frequencies.

TiNi plays an important role in the shape memory alloys because of its high energy storage capability leading to both high forces and high strains. The first thin film SMA micropump was proposed by Benard et al. (1998) and two different actuation configurations were designed. The polyimide spring-biased actuator isolates the TiNi in the actuator from the fluid both thermally and chemically, which removes the risk of thermal coupling and chemical reaction between the fluid and the TiNi.

In the complementary actuator pump, two TiNi actuators were bonded through intermediate spacers as illustrated in Fig. 12. Initially, both actuators were flat, but both were deflected due to the spacer placed between them during fabrication. When one TiNi actuator was heated, the resultant SMA caused the composite actuator to move and then deflect the other TiNi actuator. The heated TiNi actuator was then allowed to cool, and the second was heated, so the composite actuator moved in the other direction. Alternatively heating and cooling of the TiNi actuators caused the composite actuator to move up and down continuously. The complementary actuator pump achieved a maximum water flow rate of 50 μl/min and backpressure 0.53 kPa at a working frequency of 0.9 Hz and consumption of 0.63 W of power, while the polyimide-spring-biased actuator pump achieved a maximum water flow rate of 6 μl/min, as expected. Later, Xu et al. reported a TiNi actuation micropump, the dimension of which was 6 mm × 6 mm × 1.5 mm with the diaphragm size of 3 mm × 3 mm × 20 μm. The patterned SMA strips were heated by pulse currents as shown in Fig. 13, which caused the silicon diaphragm to move up and down. The maximum flow rate achieved was about 340 μl/min and the highest working frequency was up to 100 Hz.

NiTi/Si diaphragm micropump (Xu et al. 2001)

Bimetallic actuation is based on the difference in thermal expansion coefficients of two materials bonded together when subjected to temperature changes. Zhan et al. (1996) reported a bimetallic micropump consisting of a silicon membrane and a deposited aluminum layer. The overall size of the micropump was 6 × 6 × 1 mm3 and the maximum flow rate and the backpressure were 45 μl/min and 12 kPa, respectively, while 5.5 V driving voltage at a frequency of 0.5 Hz was applied. The forces generated are large and the implementation can be extremely simple. But the deflections achieved are small because usually the thermal expansion coefficients of materials involved are small. Despite bimetallic micropumps require relatively low voltages compared to other types of micropumps, they are not suitable to operate at high frequencies.

2.1.4 Optical actuation

“Light can be either directly or indirectly transformed into a mechanical deformation” (Tabib-Azar 1998). For example, an optical signal can directly excite silicon micro actuators by generating electrons to modify electrostatic pressure or by permittivity modulation of gas with light and through use of solar cells.

Terray et al. (2002) developed a particular type of light actuated rotary micropump, shown in Fig. 14, which utilized colloidal as the active flow control element. They demonstrated the actuation of colloidal silica microspheres optically trapped by a laser. Small, trapped pockets of fluid were directed through a specially designed cavity fabricated in a micro channel by rotating two colloidal lobes in opposite directions. Over repeated and rapid rotation, the accumulated effect of displacing these fluid pockets was sufficient to induce a net flow. Direction of the flow could be reversed by changing the direction of colloidal wave movement. The size of the silica sphere was about 3 μm in this investigation and the width of the micro channel was also very small, about 6 μm. Because of its biocompatibility and ability to be easily manipulated by external fields, these colloidal silica micropumps may show great potential for blood transport. Another representative micropump activated by light was reported in Mizoguchi et al. (1992). Light provided by a laser source was converted to heat. The heat vaporized the actuating fluid to pressurize the chamber and displace the membrane, just like the thermopneumatic actuation mechanism.

2.1.5 Mechanical actuation

Linear rotational conversion/amplification and acoustic actuation can be classified as mechanical actuation. In reviewing the literature aforementioned, it appears that most of the micropumps are displacement micropumps. High aspect ratio micro fabrication technology, such as LIGA and soft lithography, makes the micro structure with gears and joints in mechanical micro actuators possible. Dopper et al. (1997) presented a rotary gear pump fabricated with LIGA technology shown in Fig. 15. This rotary pump was actuated by an external miniaturized electromagnetic motor and was designed to pump highly viscous fluids. The two iron–nickel alloy micro gears had a diameter of 0.6 mm and the diameter of stainless steel shafts was 240 μm. At a rotational speed of 2,250 rpm, the gear micropump could pump a glycerin–water solution up to a maximum flow rate of 180 μL/min and maximum backpressure of 1,200 hPa whereas the maximum backpressure just could reach 70 hPa when water was used as working fluid.

2.1.6 Comparison of actuation schemes

The data in Table 2 and Fig. 16 are analyzed and summarized from previous reported work (Nguyen et al. 2002; Fu et al. 2004; Laser and Santiago 2004; Vishal et al. 2004; Tsai and Sue 2007). As a supplement to this review, one may refer to these papers, which proposed a comparison of a list of typical micropumps with different actuation mechanisms based on their performances. Here, the range of frequency, voltage, power consumption, and flow rate/outlet area as well as the backpressure of different actuation mechanisms is presented. This might provide other investigators a reference when they choose the actuation scheme according to the specific application requirements. But no matter which actuation approach is chosen during design of the micropump, obtaining a desired pumping flow rate and maintaining safe operation is a primary consideration. Also, numerical modeling and computer simulation of behavior of micropumps, in combination with experimental characterization efforts, will lead to the optimization of technical factors such as structural configuration, geometry and processing procedures and further improvement in the overall performance of the micropumps.

2.2 Flow directing elements

The flow directing elements are very important for the micropump operation and can significantly affect performance. Several different designs have been summarized in an extensive review of micro valves (Oh and Ahn 2006). In the earlier research, passive check valves have often been employed to induce unidirectional flow of pumping fluid. To make the micropumps work bi-directionally, active microvalves have been introduced.

2.2.1 Passive microvalve

Passive microvalves do not have any actuation means and the control functions of micro flow are dependent on a pressure difference buildup in a liquid chamber. Passive microvalves may only allow fluid to pass in one direction. The directional effect is a result from the motion of a mechanical opening/closing element, such as a cantilever (Koch et al. 1997, 1998), membrane (Nguyen and Truong 2004) or ball (Pan et al. 2005) or special flow directional geometry (nozzle/diffuser and Tesla).

Most of the previously-proposed micropumps need one or more check valves for their operation and therefore, moving mechanical components are involved. The significant problems are associated with check valve, such as high pressure losses, the sensitivity to solid particles, and the wear and fatigue of moving valves (Stemme and Stemme 1993). Thus, a micropump utilizing the difference of the flow resistance through the nozzle/diffuser elements, shown in Fig. 17 to direct the flow in a preferred direction was created. The original concept using nozzle-diffuser inlet and outlet channel structure geometries was first proposed by Van de Pol (1989). Later Stemme and Stemme (1993) developed this idea into a practical brass micropump. This type of micropump is also called “valveless micropump” which is able to avoid the problems encountered in check valves and suitable for drug delivery application.

The valveless micropump with nozzle/diffuser (Gerlach et al. 1995)

2.2.2 Active microvalve

An active valve is characterized by the opening and closing of active elements which are operated by an external actuator, not by the pressure buildup in the liquid chamber. All the actuation schemes aforementioned can be used as a mechanism of actuation for active microvalves. Most of the active valves reported have been designed as a separate component for regulating a flow in microfluidic systems or opening/closing channels. While active microvalves are easily controllable, they are much more complicated when integrated into micropumps.

2.3 Chamber configuration

Chamber configuration will influence the pressure characteristics, volume stroke, and nozzle-diffuser loss coefficients significantly. Most micropumps reported have a single liquid chamber. In order to improve the performance of a micropump, two and three-chamber configurations have been introduced in the investigation.

2.3.1 Two-chamber configuration

Shoji et al. (1990) developed piezoelectric micropumps with two pump chambers in series and in parallel. The two-chamber micropump design was reported to operate effectively at higher frequencies than a similar single chamber micropump. For the chambers arranged in a series configuration, the maximum flow rate and backpressure can be achieved at 18 μl/min and 10.7 kPa, respectively, when operated at 100 V with a frequency of 25 Hz. The micropump with parallel chambers configuration can pump water at 42 μl/min operating at a driving voltage of 100 V at 50 Hz. Olsson et al. (1995) presented a planar, double-chamber pump fabricated in brass. Later they developed the first nozzle-diffuser valveless micropump on a silicon substrate with two parallel chambers working in anti-phase as illustrated in Fig. 18 (Olsson 1998). The chamber dimension was about Φ6 × 200 μm. The maximum pump flow of 230 µl/min and pressure of 1.7 m H2O has been reached at 120 V driving voltage.

Anti-phase operation of the parallel arrangement of a double-chamber micropump (Olsson 1998)

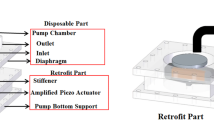

Ullmann (1998) extended the analysis of Olsson’s work on a nozzle-diffuser valveless micropump. To understand the best operational configuration, he developed a model for the performance of a single and double-chamber pump. Analysis and comparison of different combination modes also were presented, including a single chamber pump, a double-chamber pump, a single chamber with two times the stroke volume, a series connection of two single chamber pumps, a series connection of two single chamber pumps with a middle buffer and a parallel connection of two single pumps. Zordan and Amirouche (2007) recently developed a parallel-connected two-chamber valveless micropump that is shown in Fig. 19. The obvious characteristic is that the two individual superimposed chambers are separated by a specific membrane which bends to press the chamber alternately in expansion mode and contraction mode. The outer dimension of the micropump is 22 × 22 × 6 mm3. The maximum flow rate of 135 ml/min and maximum backpressure of 0.65 kPa were achieved when 3 W electric power was applied (see Fig. 20).

Separated two-chamber thermopneumatic microvalve for blood test system (Takao et al. 2005)

All of the above investigations suggest that the two-chamber micropump design is much more effective than the single chamber configuration when nozzle-diffuser elements are used in micropumps.

2.3.2 Three-chamber configuration

The three-chamber peristaltic micropump was also frequently reported in the literature. The pumping principle is based on the peristaltic motion of pump chambers, which squeezes the fluid in the desired direction. Each chamber is actuated by an individual actuator, which reduces the valve leakage problem and has no driven frequency limitation. Theoretically, the peristaltic pumps require three or more chambers consecutively arranged with reciprocating membranes. Most of the aforementioned actuation mechanisms have been applied to drive the peristaltic micropump. After the first piezoelectric peristaltic micropump was reported in 1990, electrostatic (Teymoori and Abbaspour-Sani 2002; Teymoori and Abbaspour-Sani 2005; Lin et al. 2007), magnetic (Pan et al. 2005), pneumatic (Wang and Lee 2006), and thermopneumatic (Grosjean and Tai 1999) peristaltic micropumps can be found in recently published literature. The main characteristic is that the structure is simple compared to the reciprocating pumps and shows promising applications in the biomedical field. One advantage is that the particles and living cells will not stick to the valves or become damaged since peristaltic micropumps do not require passive valves to rectify flow. Therefore, the risk of clogging in the channels is reduced. However, it also faces a major problem, the reverse leakage (see Fig. 21).

Piezoelectric peristaltic micropump (Cao et al. 2001)

2.4 Membrane selection

Except for micropumps, devices integrating oscillating membranes are extremely common in microsystems, including micro ultrasonic transducers (Jin et al. 1999), micromirrors (Maeda et al. 2005), as well as micro fluid density sensors (Crescini and Taroni 1998; Defa et al. 2002). For each of these systems, their performances are directly dependent upon properly controlling the resonant frequencies. For example, micropumps operating at resonant frequency can result in an increased displacement, higher flow rates and higher conversion efficiencies, thus reducing power requirements. Material property parameters influencing the vibration characteristic of a membrane include the density, residual stress, elastic modulus, and the Poisson’s ratio. Therefore, one important aspect of the micropump design is choosing the appropriate material for the actuation membrane. Flexible diaphragms with large deflection amplitudes are often self-priming and bubble-tolerant (Yamahata et al. 2005b).

A candidate material for the micropump application should be compatible with environmental and operating conditions. Also, mechanical fatigue resistance and fabrication means should be taken into account. Traditional MEMS materials, such as glass, silicon, silicon nitride and metals have been reported in the literature as the membrane materials with application in micropumps. In the last two decades, as MEMS technologies were applied to the biomedical industry, several known BioMEMS polymers (Parylene, Polyimide, PMMA and PDMS) widely employed in membrane actuation. Although the glass materials are attractive for the chemically inert and optically transparent, the stiffness is high and cannot generate large deflection. Among these polymers, PDMS and PMMA are commonly encountered in microfluidic devices. PDMS is a flexible and easily molded elastomeric polymer widely used for the rapid prototyping microfluidic devices. PDMS membrane is isotropic and homogenous in material property and the surface properties of PDMS can be easily changed by exposure of the surface in oxygen plasma. Thus it can bond with another PDMS layer or glass as well as other silicon-based materials. PMMA is an amorphous, highly transparent thermoplastic that may be used for analytical devices because of its high chemical and mechanical stability.

3 Micropump applications in biomedical fields

While much research and development continues, reduced dimensions, lower power consumption, fabrication process compatibility with other systems, and higher pumping flow rates, as well as lower backpressures, have made micropumps see a significant presence in a number of fields not only in academia but also in various commercial uses. Micropumps have been used for a number of years in ink jet printers, microelectronic cooling applications and most recently in the emerging fuel cell industry. However, until just recently, these micropumps have begun to appear in biomedical applications. One such example is that of wearable insulin pumps. The Insulet Corporation has designed and is now selling a disposable insulin micropump named Omnipod™. This micropump uses a shape-memory alloy, (Nitinol) for actuation. This pump is disposable, and therefore it offers many advantages to the diabetic patient over conventional insulin pumps on the market.

The importance of those features is dependent upon the individual system and application for which micropumps would be applied. Thus, determination of flow rate pumping and the specific operating environmental requirements is the first step in designing a micropump. For the application in micro total analysis systems (μTAS), micropumps are designed to transport sample reagents to perform many functions of delivery, mixing, reaction, analysis, or discharging of reagents (Auroux et al. 2002; Reyes et al. 2002; Vilkner et al. 2004). Accurate control of flow rate and maintaining reliability of the system are more important than the power consumption and operation voltage since the chips typically are integrated in macro control or interface systems (Yun and Yoon 2006). When micropumps are integrated in some microchips such as portable medical devices, hand-held analytical systems, both low voltage and power consumption are required in addition to accurate flow control. When it comes to implantable drug delivery and dosing systems, micropumps perform precise sampling and dispensing therapeutic agents into body. High concentration resolution and bio-compatibility are the main concerns in order to achieve desired therapeutic effects and to prevent infections (Tsai and Sue 2007). Meanwhile, the driving power is expected to remain low in electrical energy consumption. In the following section, we review the applications of micropumps and their specific requirements in blood transport and drug delivery.

3.1 Blood transport

Blood is a specialized biological fluid consisting of red blood cells, white cells and platelets suspended in a complex medium known as plasma, shown in Fig. 22. Blood plasma is the liquid component of blood, in which the blood cells are suspended. It makes up about 55% of total blood volume. It is the primary transport vehicle throughout the body and plays an important role in how our bodies function. The heart pumps blood through the arteries, capillaries and veins in order to provide oxygen and nutrients fight infections, and to help get rid of waste (Parents 2007; Wikipedia Available 2007). Therefore, blood is one of the most important indicators of human’s health and critical to make accurate diagnoses. Recently research on blood transport in blood test and analysis systems has drawn much attention of investigators. Micropumps are one of the primary devices used for transporting blood. Cardiac assist pump for circulatory support of failing hearts is designed for in vivo or clinical operation (Xia and Bai 2005). Also, a disposable pump is required for producing a maximum flow rate of 100 ml/min against a pressure head of 2 kPa in a blood cancer treatment device (Kilani et al. 2005). A micropump integrated into the microfluidic cassettes was employed to perform biological sample control and transport for genomic DNA blood processing (Taylor et al. 2003). Another pump currently in clinical trials, but approved for human investigational use, is the Debakey VAD® from Micromed Cardiovascular, Inc. They have developed a ventricle assist pump to improve blood flow through the heart using an implantable axial flow pump. It is able to provide continuous flow through the heart, which current implantable assisted devices are unable to provide.

Blood is a particle-laden viscous biological fluid. The viscosity of the blood is about 0.04 g/(cm s) and the density of blood is about 1.2 g/cm3 (Zordan and Amirouche 2007). The requirement for pumping viscous fluids in biological and medical applications leads to the exploration of viscous micropumps. For viscous fluids, rotary micropumps are generally more appropriate than other types of micropumps. This feasibility was first successfully demonstrated in Sen and Wajerski (1996). This viscous micropump used a rotating cylinder to generate flow between two fixed plates. Although displacement micropumps are capable of using a wide variety of fluids, their capability to handle particle-laden fluids is limited. The investigation of viscous micropumps has been motivated by the ability of generating significant pressure head in the viscosity dominated micro channels. Different viscous pumps for blood transport have been investigated recently (Zheng et al. 2002; Kilani et al. 2003a, b; Blanchard et al. 2005) and a number of analytical and numerical simulations have also been conducted on these micropumps and published in the literatures.

The application of screw type pump mechanism for blood transport was first successfully demonstrated by Wampler et al. (1988) and several new designs are being explored because of their compactness and simplicity (Zheng et al. 2002). A representative screw pump driven magnetically as shown in Fig. 23 consisted of a single screw that rotated inside a close fitting barrel. The overall outer dimension of the pumping device was 20 × 20 × 100 mm. The rotation of the screw moved the fluid forward in the channel between the screw core and the barrel due to its viscosity.

Compared to other rotary micropumps utilizing the centrifugal effect, Milani et al. presented several different spiral-channel micropumps which employ the drag effect resulting from moving a rigid element tangent to the flow field. This type of viscous micropump has some very attractive characteristics: the viscous forces are significant at very small scales which results in large pressure drops over small lengths for fluid flow through a channel; moreover, no valves are needed which allows for the handling of particle-laden fluids. The spiral-channel micropumps also can be made to be compatible with the lithographic patterning process of current micro fabrication technology (see Figs. 24).

Other serious issues also need to be considered in blood transport. First, minimizing the rate of the red blood cell damage produced by the micropump is an important issue, while simultaneously satisfying flow rate and pressure requirements. In screw type blood pumps, large shear stresses may contribute to the red blood cell damage, which is known as hemolysis (Leverett et al. 1972). Consequently, it is necessary to compare the shear stress with the threshold lytic shear stress for blood, which is defined as the maximum shear stress that a blood cell can withstand without rupture when exposed to for a period of time (Steinbach 1970).

3.2 Drug delivery

To achieve the desired therapeutic effect, drugs or chemical agents should remain at a certain level of concentration. Drug concentration below or above the designed limits might have some side-effects or even cause intoxication (Tsai and Sue 2007). As a consequence, the dose, frequency, duration, oscillatory behavior, toxicity, drug interaction and allergies must all be considered and customized for patients based on their illness and history. Research on new techniques for drug delivery seeks to develop micro devices capable of delivering precise quantities of a drug at the right time and as close to the treatment site as possible. These devices may incorporate silicon or polymer fabricated reservoirs. They also incorporate micropumps, controlled-release propellants or silicon micromachined needles for drug delivery, storage, and dispensing (Henry et al. 1998; McAllister et al. 2000). Here we present some representative micropumps for drug delivery. Readers that are interested in other delivery approaches may refer to these review papers (Dario et al. 2000; Tao and Desai 2003; Staples et al. 2006).

Micropumps are one of the MEMS devices, which play an important role in drug delivery applications. The micropump is the main part of a drug delivery system that transfers the drug from the drug reservoir to the target place with high performance, accuracy, and reliability. The small size and high precision of micropumps have made them useful for chemotherapy, insulin delivery for diabetic patients, and drug dosing for cancer patients (Smits 1990). A number of medical micropumps based on different actuation and pumping mechanisms have been successfully designed and fabricated. Shape memory alloys actuated active implantable devices for both solid and liquid drug delivery has been developed in Reynaerts et al. (1997). The operating principle of the liquid system was based on a precisely controlled discontinuous release from a pressurized reservoir. One dose could be controlled with an accuracy of up to 5 μl. Another interesting piezoelectric micropump for low flow rates (0–100 μl/h) controlling liquid drugs was integrated in an implantable drug delivery system. This system can be used, for example, for insulin infusion in diabetic patients (see Fig. 25).

Micropump for an implantable drug delivery system (Maillefer et al. 1999)

An electrostatically actuated micropump was based on the peristaltic mechanism, which was quite a suitable pumping mechanism for a drug delivery system shown in Fig. 26. The size of the micropump is 7 × 4 × 1 mm. Design and simulation were conducted, but there was no experiment validation of the proposed model. Recently, several companies are manufacturing and selling micropumps for drug delivery applications. Nektar® is manufacturing and selling a nebulizer that contains an ultrasonic micropump. This micropump is capable of delivering liquid and dry powder reagents to patients requiring inhalation therapies. Another company, Debiotech, has developed an insulin Nanopump™ based on SOI and Pyrex bonding and piezoelectric actuation. This Nanopump™ consists of two parts: a permanent part that contains the electronics and a disposable part with the reservoir. It has a total volume of 65 × 38 × 11 mm (27 ml) with an insulin reservoir capacity of 4–6 ml and the permanent part attached. Due to its low manufacturing costs the pump can be used as a disposable drug delivery system or for long term treatment. Other companies that have designed and marketed micropumps for the biomedical industry include Durect Corporation (Alzet® pump) and Steadymed, Ltd.

Electrostatic micromachined pump for drug delivery system (Teymoori and Abbaspour-Sani 2002)

Compared to traditional pumps used for intravenous medication administration, or more precise external pumps for analgesia and insulin administration, micropumps are designed for fine control of fluids (Saliterman 2006). The design criteria for an implantable micropump include small chip size, biocompatibility, having sufficient displacement to achieve desired flow rates, generating sufficient pressure to move a drug, safe operation for an extended period, stable flow rates and power consumption. In one word, micropumps are just beginning to impact the biomedical industry.

4 Conclusion

This paper provides a review of the current development of mechanical micropumps based on their actuation mechanisms. Current micropump designs are also compared to understand their advantages and limitations for different applications based on criteria such as power consumption, operational voltage, frequency range, working fluids, and maximum flow rate and backpressure in the literature. Depending on requirements of the working liquid and maximum pumping rate and backpressure in biomedical applications, different actuation mechanisms are reviewed and compared. Recommendations have been presented based on specific requirements. With current advancements in micro fabrication techniques, pursuing more compact dimensions and enhancing the pump performance while lowering power consumption, has become a main trend. New approaches can be realized in a simple implementation scheme either by using a new actuation mechanism, such as ionic conductive polymer film actuation, surface tension, and electrowetting, or using new materials such as PDMS, silicon rubber, plastic and parylene. However, reliability, bio-compatibility, power consumption and integration with other microfluidic system still deserve full consideration.

References

Wikipedia (Available 2007). http://en.wikipedia.org/wiki/Blood

Auroux PA, Iossifidis D, Reyes DR, Manz A (2002) Micro total analysis systems. 2. Analytical standard operations and applications. Anal Chem 74(12):2637–2652. doi:10.1021/ac020239t

Benard WL, Kahn H, Heuer AH, Huff MA (1998) Thin-film shape-memory alloy actuated micropumps. J Microelectromech Syst 7(2):245–251. doi:10.1109/84.679390

Blanchard D, Ligrani P, Gale B (2005) Single-disk and double-disk viscous micropumps. Sensor Actuator A Phys 122(1):149–158

Brand S (2006) Microdosing systems: micropumps the beating heart of microfluidics. http://www.mstonline.de/news/events/micropumps

Cao L, Mantell S, Polla D (2001) Design and simulation of an implantable medical drug delivery system using microelectromechanical systems technology. Sensor Actuator A Phys 94(1):117–125. doi:10.1016/S0924-4247(01)00680-X

Cho J, Anderson M, Richards R, Bahr D, Richards C (2005) Optimization of electromechanical coupling for a thin-film PZT membrane: II. Experiment. J Micromech Microeng 15:1804–1809. doi:10.1088/0960-1317/15/10/003

Cooney CG, Towe BC (2004) A thermopneumatic dispensing micropump. Sensor Actuator A Phys 116:519–524. doi:10.1016/j.sna.2004.05.015

Crescini DM, Taroni A (1998) Piezoelectric thick-film fluid density sensor based on resonant frequency vibration. In: Proceedings of the IEEE instrumentation and measurement technology conference

Dario P, Carrozza MC, Benvenuto A, Menciassi A (2000) Micro-systems in biomedical applications. J Micromech Microeng 10(2):235–244. doi:10.1088/0960-1317/10/2/322

Defa E, Millon C, Malhaire C, Barbier D (2002) PZT thin films integration for the realisation of a high sensitivity pressure microsensor based on a vibrating membrane. Sensor Actuators A Phys 99(1–2):64–67. doi:10.1016/S0924-4247(01)00883-4

Diaz J, Lopera JM, Pernia AM (2007) A micropump for pulmonary blood flow regulation. Ind Electron Mag IEEE 1:39–44. doi:10.1109/MIE.2007.357173

Dopper J, Clemens M, Ehrfeld W, Jung S, Kaemper KP, Lehr H (1997) Micro gear pumps for dosing of viscous fluids. J Micromech Microeng 7(3):230–232. doi:10.1088/0960-1317/7/3/040

Ehwald R, Woehlecke H, Adleff H, Ehwald M (2006) Method for control of the volume flux of a liquid in an osmotic micropump and osmotic micropump. Google Patents, USA

Esashi M, Shoji S, Nakano A (1989) Normally close microvalve and micropump fabricated on a siliconwafer. IEEE Micro Electro Mechanical Systems, Proceedings, ‘An Investigation of Micro Structures, Sensors, Actuators, Machines and Robots’: 29–34

Francais O, Dufour I (2000) Enhancement of elementary displaced volume with electrostatically actuated diaphragms: application to electrostatic micropumps. In: 10th Micromechanics Europe Workshop (MME’99). Gif sur Yvette, France, IOP Publishing. 10: 282–6

Francals O, Dufour I, Sarraute E (1997) Analytical static modelling and optimization of electrostatic micropumps. J Micromech Microeng 7:183–185. doi:10.1088/0960-1317/7/3/027

Fu Y, Du H, Huang W, Zhang S, Hu M (2004) TiNi-based thin films in MEMS applications: a review. Sensor Actuators A Phys 112(2–3):395–408. doi:10.1016/j.sna.2004.02.019

Gerlach T, Schuenemann M, Wurmus H (1995) A new micropump principle of the reciprocating type using pyramidic micro flowchannels as passive valves. J Micromech Microeng 5(12):199–201. doi:10.1088/0960-1317/5/2/039

Gretillat MA (1999) Micromechanical relay with electrostatic actuation and metallic contacts. J Micromech Microeng 9(4):324–331. doi:10.1088/0960-1317/9/4/307

Grosjean C, Tai YC (1999). A thermopneumatic peristaltic micropump. In: Proceeding on solid-state sensors and actuator (Transducers’99), Sendai, Japan

Henry S, McAllister DV, Allen MG, Prausnitz MR (1998) Microfabricated microneedles: a novel approach to transdermal drug delivery. J Pharm Sci 87(8):922–925. doi:10.1021/js980042+

Jeong OC, Yang SS (2000) Fabrication and test of a thermopneumatic micropump with a corrugated p diaphragm. Sensor Actuators 83:249–255. doi:10.1016/S0924-4247(99)00392-1

Jin X, Ladabaum I, Degertekin FL, Calmes S, Khuri-Yakub BT (1999) Fabrication and characterization of surface micromachinedcapacitive ultrasonic immersion transducers. Microelectromech Syst J 8(1):100–114

Judy JW, Tamagawa T, Polla DL (1991). Surface-machined micromechanical membrane pump. In: Proceedings of the 1991 IEEE micro electro mechanical systems. Nara, Japan, pp 182–186

Parents KHf (2007) http://www.kidshealth.org/parent/general/body_basics/blood.html

Khoo C (2000) A novel micromachined magnetic membrane microfluid pump. In: Proceedings of the 22nd annual international conference of the IEEE 3, Eng Med Biol Soc, pp 2394–2397

Kilani MI, Galambos PC, Haik YS, Chen CJ (2003a) Design and analysis of a surface micromachined spiral-channel viscous pump. J Fluids Eng 125:339–344. doi:10.1115/1.1524582

Kilani MI, Galambos PG, Haik Y, Chen CJ (2003) Surface micromachined viscous spiral pump. Technical proceedings of the 2003 nanotechnology conference and trade show

Kilani MI, Haik YS, Jaw SY, Chen CJ (2005) Numerical simulation of flow in a screw-type blood pump. J Visualization 8(1):33–40

Koch M, Harris N, Maas R, Evans AGR (1997) A novel micropump design with thick-film piezoelectric actuation. Meas Sci Technol 8(1):49–57. doi:10.1088/0957-0233/8/1/008

Koch M, Harris N, Evans AGR, White NM, Brunnschweiler A (1998) A novel micromachined pump based on thick-film piezoelectric actuation. Sensor Actuator A Phys A 70:98–103. doi:10.1016/S0924-4247(98)00120-4

Krutzsch WC, Cooper P (2001) Introduction: classification and selection of pumps. Pump Handbooks, McGraw-Hill

Lagorce LK, Allen MG (1997) Magnetic and mechanical properties of micromachined strontium ferrite/polyimide composites. J Microelectromech Syst 6(4):307–312. doi:10.1109/84.650127

Laser DJ, Santiago JG (2004) A review of micropumps. J Micromech Microeng 14(6):35–64. doi:10.1088/0960-1317/14/6/R01

Lee S, Kim K (2006) Design of IPMC actuator-driven valveless micropump and its flow rate estimation at low Reynolds numbers. Smart Mater Struct 15(4):1103–1109. doi:10.1088/0964-1726/15/4/024

Leverett LB, Hellums JD, Alfrey CP, Lynch EC (1972) Red blood cell damage by shear stress. Biophys J 2(3):257–273. doi:10.1016/S0006-3495(72)86085-5

Lin Q, Yang B, Xie J, Tai Y-C (2007) Dynamic simulation of a peristaltic micropump considering coupled fluid flow and structural motion. J Micromech Microeng 17(2):220–228. doi:10.1088/0960-1317/17/2/006

MacHauf A, Nemirovsky Y, Dinnar U (2005) A membrane micropump electrostatically actuated across the working fluid. J Micromech Microeng 15(12):2309–2316. doi:10.1088/0960-1317/15/12/013

Maeda R, Tsaur JJ, Lee SH, Ichiki M (2005) Microactuators based on thin films. Electroceramic-based MEMS: 19–35

Maillefer D, van Lintel H, Rey-Mermet G, Hirschi R (1999) A high-performance silicon micropump for an implantable drug delivery system. In: Proceedings of 12th international workshop on micro electro mechanical systems—MEMS. Orlando, FL, USA, IEEE: 541–546

McAllister DV, Allen MG, Prausnitz MR (2000) Microfabricated microneedles for gene and drug delivery. Ann Rev Biomed Eng 2:289–313. doi:10.1146/annurev.bioeng.2.1.289

Meng E (2003) MEMS technology and devices for a micro fluid dosing system. Pasadena, California Institute of Technology. Doctor of Philosophy: 150

Mizoguchi H, Ando M, Mizuno T, Takagi T, Nakajima N (1992) Design and fabrication of light driven micropump. In: Proceedings IEEE micro electro mechanical systems

Morris CJ, Forster FK (2000) Optimization of a circular piezoelectric bimorph for a micropump driver. J Micromech Microeng 10(3):459–465. doi:10.1088/0960-1317/10/3/323

Nguyen NT, Truong TQ (2004) A fully polymeric micropump with piezoelectric actuator. Sensor Actuator B Chem 97(1):137–143. doi:10.1016/S0925-4005(03)00521-5

Nguyen N-T, Wereley ST (2002) Microfluidics for internal flow control: micropumps. Fundam Appl Microfluidics, Artech House: 293–341

Nguyen NT, Meng AH, Black J, White RM (2000) Integrated flow sensor for in situ measurement and control of acoustic streaming in flexural plate wave micropumps. Sensor Actuator A Phys 79(2):115–121. doi:10.1016/S0924-4247(99)00279-4

Nguyen NT, Huang X, Chuan TK (2002) MEMS-micropumps: a review. J Fluids Eng 124(2):384–392. Transactions of the ASME. doi:10.1115/1.1459075

Nilsson J (2004) Autonomous protein sample processing on-chip using solid-phase microextraction, capillary force pumping, and microdispensing. Electrophoresis 25:3778–3787. doi:10.1002/elps.200406100

Oh KW, Ahn CH (2006) A review of microvalves. J Micromech Microeng 16:13–39. doi:10.1088/0960-1317/16/5/R01

Olsson A (1998) Valveless diffuser micropumps. Electrical Engineering. Stockholm, Royal Institute of Technology. Doctor of Philosophy

Olsson A, Stemme G, Stemme E (1995) A valve-less planar fluid pump with two pump chambers. Sensor Actuators A Phys 47(1):549–556. doi:10.1016/0924-4247(94)00960-P

Pacheco SP, Katehi LPB, Nguyen CTC (2000) Design of low actuation voltage RF MEMS switch. Microwave Symposium Digest., 2000 IEEE MTT-S international. Boston, USA. 1

Tingrui Pan, McDonald SJ (2005) A magnetically driven PDMS micropump with ball check-valves. J Micromech Microeng 15:1021–1026. doi:10.1088/0960-1317/15/5/018

Pan T, Kai E, Stay M, Barocas V, Ziaie B (2004) A magnetically driven PDMS peristaltic micropump. Engineering in Medicine and Biology Society, 2004. IEMBS 04. 26th annual international conference of the IEEE

Pan T, McDonald SJ, Kai EM, Ziaie B (2005) A magnetically driven PDMS micropump with ball check-valves. J Micromech Microeng 15(5):1021–1026. doi:10.1088/0960-1317/15/5/018

Pu C, Park S, Chu PB, Lee SS, Tsai M, Peale D, Bonadeo NH, Brener I (2004) Electrostatic actuation of three-dimensional MEMS mirrors using sidewall electrodes. J Sel Top Quantum Electron IEEE 10(3):472–477. doi:10.1109/JSTQE.2004.828480

Reyes DR, Iossifidis D, Auroux PA, Manz A (2002) Micro total analysis systems. 1. Introduction, theory, and technology. Anal Chem 74(12):2623–2636. doi:10.1021/ac0202435

Reynaerts D, Peirs J, Brussel HV (1997) An implantable drug-delivery system based on shape memory alloy micro-actuation. Sensor Actuator A Phys 61(1–3):455–462. doi:10.1016/S0924-4247(97)80305-6

Saliterman SS (2006) Microactuators and drug delivery. Fundamentals of BioMEMS and medical microdevices: 219–247

Sen M, Wajerski D (1996) Novel pump for MEMS applications. J Fluids Eng Trans ASME 118(3):624–627

Shoji S, Esashi M (1994) Microflow devices and systems. J Micromech Microeng 4(4):157–171. doi:10.1088/0960-1317/4/4/001

Shoji S, Nakagawa S, Esashi M (1990) Micropump and sample-injector for integrated chemical analyzing systems. Sensor Actuator A Phys 21(1):189–192

Singhal V, Garimella SV (2007) Induction electrohydrodynamics micropump for high heat flux cooling. Sensor Actuators A Phys 134(2):650–659. doi:10.1016/j.sna.2006.05.007

Smits JG (1984) Piezo-electrical micropump. E. patent. Netherlands. EP0134614

Smits JG (1990) Piezoelectric micropump with three valves working peristaltically. Sensor Actuators 21(1–3):203–206. doi:10.1016/0924-4247(90)85039-7

Mark Staples, Karen Daniel, Michael J. Cima, Langer R (2006) Application of micro- and nano-electromechanical devices to drug delivery. Pharm Res 23(5):847–863. doi:10.1007/s11095-006-9906-4

Steinbach J (1970) Hemolysis at tube walls. University of Minnesota, Minneapolis

Stemme E, Stemme G (1993) A valveless diffuser/nozzle-based fluid pump. Sensor Actuators A Phys 39(2):159–167. doi:10.1016/0924-4247(93)80213-Z

Suzuki H, Yoneyama R (2003) Integrated microfluidic system with electrochemically actuated on-chip pumps and valves. Sensor Actuator B Chem 96(1–2):38–45. doi:10.1016/S0925-4005(03)00482-9

Tabib-Azar M (1998) Microactuators: electrical, magnetic, thermal, optical, mechanical, chemical, & smart structures. Kluwer Academic Publishers, Boston

Takao H, Miyamura K, Ebi H, Ashiki M, Sawada K, Ishida M (2005) A MEMS microvalve with PDMS diaphragm and two-chamber configuration of thermo-pneumatic actuator for integrated blood test system on silicon. Sensor Actuators A Phys 119(2):468–475. doi:10.1016/j.sna.2004.10.023

Tao SL, Desai TA (2003) Microfabricated drug delivery systems: from particles to pores. Adv Drug Deliv Rev 55(3):315–328. doi:10.1016/S0169-409X(02)00227-2

Taylor MT, Nguyen P, Ching J, Petersen KE (2003) Simulation of microfluidic pumping in a genomic DNA blood-processing cassette. J Micromech Microeng 13(2):201–208. doi:10.1088/0960-1317/13/2/306

Terray A, Oakey J, Marr DWM (2002) Microfluidic control using colloidal devices. Science 296(5574):1841–1844. doi:10.1126/science.1072133

Teymoori MM, Abbaspour-Sani EA (2002) A novel electrostatic micromachined pump for drug delivery systems. Proc Semicond Electron 2002:105–109

Teymoori MM, Abbaspour-Sani E (2005) Design and simulation of a novel electrostatic peristaltic micromachined pump for drug delivery applications. Sensor Actuators A Phys 117(2):222–229. doi:10.1016/j.sna.2004.06.025

Trimmer WSN, Gabriel KM (1987) Design considerations for a practical electrostatic micro-motor. Sensor Actuators 11(2):189–206. doi:10.1016/0250-6874(87)80016-1

Tsai NC, Sue CY (2007) Review of MEMS-based drug delivery and dosing systems. Sensor Actuators A Phys 134(2):555–564. doi:10.1016/j.sna.2006.06.014

Ullmann A (1998) The piezoelectric valve-less pump performance enhancement analysis. Sensor Actuators A Phys 69(1):97–105. doi:10.1016/S0924-4247(98)00058-2

Van de Pol FCM (1989) A pump based on micro-engineering techniques, Universiteit Twente. Doctor of Philosophy

Van De Pol FCM, Van Lintel HTG, Elwenspoek M, Fluitman JHJ (1990) A thermopneumatic micropump based on microengineering techniques. Sensors Actuator A Phys 21:198–202

van Lintel HTG, van de Pol FCM, Bouwstra S (1988) A piezoelectric micropump based on micromachining of silicon. Sensor Actuators 15(2):153–168. doi:10.1016/0250-6874(88)87005-7

Vilkner T, Janasek D, Manz A (2004) Micro total analysis systems. Recent developments. Anal Chem 76(12):3373–3386. doi:10.1021/ac040063q

Vishal S, Garimella SV, Raman A (2004) Microscale pumping technologies for microchannel cooling systems. Appl Mech Rev 57(3):191–221. doi:10.1115/1.1695401

Wampler RK, Moise JC, Frazier OH, Olsen DB (1988) In vivo evaluation of a peripheral vascular access axial flow blood pump. Am Soc Artif Intern Organs Trans 34:450–454

Wang CH, Lee GB (2006) Pneumatically driven peristaltic micropumps utilizing serpentine-shape channels. J Micromech Microeng 16(2):341–348. doi:10.1088/0960-1317/16/2/019

Weisong Wang, Zhongmei Yao, Jackie C Chen, Fang J (2004) Composite elastic magnet films with hard magnetic feature. J Micromech Microeng 14(10):1321–1327. doi:10.1088/0960-1317/14/10/005

White NM (2006) The origins and the future of microfluidics. Nature 442(7101):368–373. doi:10.1038/nature05058

Woias P (2005) Micropumps—past, progress and future prospects. Sensor Actuator B 105(1):28–38. doi:10.1016/S0925-4005(04)00108-X

Xia DD, Bai J (2005) Simulation study and function analysis of micro-axial blood pumps. In: 27th annual international conference of the engineering in medicine and biology society, 2005. IEEE-EMBS 2005: 2971–2974

Xu D, Wang L, Ding G, Zhou Y, Yu A, Cai B (2001) Characteristics and fabrication of NiTi/Si diaphragm micropump. Sensor Actuators A Phys 93(1):87–92. doi:10.1016/S0924-4247(01)00628-8

Yamahata C (2005) Magnetically actuated micropumps. Lausanne, Swiss Federal Institute of Technology. Doctor of Philosophy

Yamahata C, Lacharme F, Gijs MAM (2005a) Glass valveless micropump using electromagnetic actuation. J Microelectron Eng 78:132–137. doi:10.1016/j.mee.2004.12.018

Yamahata C, Lotto C, Al-Assaf E, Gijs MAM (2005b) A PMMA valveless micropump using electromagnetic actuation. Microfluid Nanofluidics 1(3):197–207. doi:10.1007/s10404-004-0007-6

Yin HL, Huang YC, Fang W, Hsieh J (2007) A novel electromagnetic elastomer membrane actuator with a semi-embedded coil. Sens Actuators A Phys 139(1–2):194–202. doi:10.1016/j.sna.2007.01.003

Yun KS, Yoon E (2006) Micropumps for MEMS/NEMS and Microfluidic Systems. MEMS/NEMS Handbook Techniques and Applications. Springer 4:121–153

Zengerle R, Richter A, Sandmaier H (1992) A micro membrane pump with electrostatic actuation. Micro Electro Mechanical Systems, 1992, Proceedings. An Investigation of Micro Structures, Sensors, Actuators, Machines and Robot. IEEE. Travemunde, Germany: 19–24

Zhan C, Lo T, Liu L, Tsien P (1996) Silicon membrane micropump with integrated bimetallic actuator. Chin J Electron 5(2):29–35

Zhang T, Wang QM (2005) Valveless piezoelectric micropump for fuel delivery in direct methanol fuel cell (DMFC) devices. J Power Sources 140(1):72–80. doi:10.1016/j.jpowsour.2004.07.026

Zheng W, Ahn CH (1996) A bi-directional magnetic micropump on a silicon wafer. Technical Digest Solid-State Sensor and Actuator Workshop, Hilton Head Island, SC, USA

Zheng P, Haik Y, Kilani M, Chen CJ (2002) Force and torque characteristics for magnetically driven blood pump. J Magn Magn Mater 241(2–3):292–302. doi:10.1016/S0304-8853(01)01372-5

Zordan E, Amirouche F (2007) Design and analysis of a double superimposed chamber valveless MEMS micropump. Proc Inst Mech Eng [H] 221(2):143–151. doi:10.1243/09544119JEIM152

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Amirouche, F., Zhou, Y. & Johnson, T. Current micropump technologies and their biomedical applications. Microsyst Technol 15, 647–666 (2009). https://doi.org/10.1007/s00542-009-0804-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-009-0804-7