Abstract

The purpose of this study is the application of meta-heuristic algorithms and fuzzy logic in the optimization and clustering to predict the sawability of dimension stone. Survey and classification of dimension stones based on their physical and mechanical properties can be so impressive in the optimization of machine applications that are in this industry such as circular diamond saw block cutting machine. In this paper, physical and mechanical properties were obtained from laboratory testing on dimension stone block samples collected from 12 quarries located in Iran and their results were optimized and classified by one of the strongest meta-heuristic algorithms and fuzzy clustering technique. The clustering of dimension stone was determined by Lloyd’s algorithm (k-means clustering) based on imperialist competitive algorithm and fuzzy C-mean by MATLAB software. The hourly production rate of each studied dimension stones was considered as a criterion to evaluate the clustering efficacy. The results of this study showed that the Imperialist Competitive algorithm and fuzzy C-mean are very suitable for clustering with respect to the physical and mechanical properties of the dimension stone, and the results obtained showed the superiority of the ICA.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Nowadays, circular diamond saw blades are widely used to processing the dimension stone in stone processing plant and quarry. The performance and life of these tools represent a major factor in the cost of stone industry. Therefore, predicting the sawing performance for a particular stone is important. Sawing performance is affected by many factors. One of the most important factors that affect sawing performance is the physical and mechanical properties of stone. In this regard, many studies have been performed. Some of these studies are listed in Table 1.

This paper describes the application of meta-heuristic algorithm and fuzzy C-mean to predict the sawability of dimension stone based on some important physical and mechanical properties of rock. To achieve this goal, in the first step, four major properties of dimension stone including the uniaxial compressive strength, Schmiazek F-abrasivity, Mohs hardness and Young’s modulus were tested in rock mechanics laboratory. During the research process, two groups of dimension stones were selected and analyzed. The dimension stone block samples were collected from a number of Iranian quarries. In the second step, the studied dimension stones were classified by imperialist competitive algorithm. The objectives are to minimize distance among members of a cluster and to maximize the distance of cluster centers from each other. The ICT is an evolutionary algorithm to solve optimization complex problems. This method was created by the simulation of the sociopolitically processes, and fuzzy C-mean was considered as a flexible clustering method [24]. To show the efficiency of the proposed methods, the classification results were validated by test results. Finally, comparing the results of the proposed two methods with test results, it can be derived that the proposed methods can find an appropriate solution. Hence, the scope of this paper is the applications of ICA technique and fuzzy logic in mining engineering with focus on optimization of classification.

2 Imperialist competitive algorithm

Nowadays, meta-heuristic algorithms are widely used for optimization and solving engineering problems in engineering sciences. Several evolutionary algorithms are provided for optimization such that it can be noted to the genetic algorithm (GA) [25], particle swarm optimization algorithm (PSO) [26] and bat algorithm [27]. The imperialist competitive algorithm is one of the most effective methods to find optimal solution of different problems among meta-heuristic algorithms. This algorithm is for solving nonlinear integer programming such as dynamic programming (DP) [28]. This algorithm inspired from a sociopolitical phenomenon proposed by Atashpaz-Gargari and Lucas [29]. The ICA is a great algorithm in the field of evolutionary computation based on the sociopolitical evolution of humans. This algorithm has an application effective in various fields of sciences in optimization of complex issues. In general, the imperialist competitive algorithm can be used in any optimization problem without limitation. This matter has caused which this algorithm is used for solving lots of problems in the field of electrical engineering, mechanics engineering, industry, management, civil engineering and artificial intelligence, etc. [30–34]. The ICA established based on three main principles, which include assimilation policy, imperialistic competition and revolution. Assimilation policy is moving colonies toward their relevant imperialist in a randomly deviated direction. Imperialistic competition and revolution are competition of take possession of colonies from other empires and random changes in the characteristics of some countries, respectively. Finally, algorithm continues with these three main principles until a stop condition is satisfied.

Like other meta-heuristic algorithms, process begins with an initial population in this algorithm, each of them being called a country. The countries have two types: imperialists or colonies. In fact, the country is an array of variable values like to chromosome in GA terminology. Each empire gets and controls one or more of the colonies of the weakest imperialist based their capacity and ability. Some of them that have the lowest costs of the fitness function selected as imperialist and also remaining population considered are as a colony. At first, normalized cost is calculated for per empire by Eq. (1), where the C n is the normalized cost of empire, max{c i } is the highest cost among imperialists and c n is the cost of nth imperialist.

Then, with having cost of normalized, the normalized strength of each imperialist (P n) is calculated by Eq. (2) which based on this process, colonies divided among the empire:

Therefore, the number of initial colonies obtained by Eq. (3) in which NC n and N col are the initial number of colonies of nth imperialist and the number of total colonies, respectively:

Figure 1 shows moving colonies toward their relevant imperialist.

According to Fig. 1, the value of X is defined by Eq. (4) that (d) and (β) are distance between colony and imperialist and a parameter greater than one, respectively. The β > 1 causes to get closer to the imperialist from both sides. Also, for increasing search area around of the imperialist, this absorption occurs with a random amount of deviation in absorption direction of colony by empire. This deviation is shown with \(\theta\). This value is random number that selected randomly and uniform distribution according to Eq. (5).

γ is a parameter that controls the angle of deviation range and is considered equal to \(\frac{\pi }{4}\) (Rad). At the final step, time of empire competitive is among the imperialists. At this stage, each colony separated from the weakest empire and joins to a stronger colonial. Whatever colonial is stronger and it is more likely to be selected by colony. Finally, each empire that lost their colony becomes as a new colony. This process will continue to establish the stop condition in the algorithm [35].

3 Fuzzy C-mean

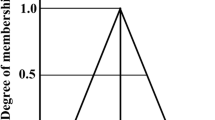

Fuzzy C-means clustering is an evolutionary model for creating the hard C-means clustering. In the meantime, application of the fuzzy sets theory in the clustering process is very effective and beneficial. In other words, the fuzzy clustering technique is one of the most effective methods in the determination of the set member’s membership degree. Fuzzy clustering is viewed as a flexible clustering method. This method was proposed by Bezdek et al. [36] in 4 steps based on the iteration optimization [37].

In the first step, the number of clusters represented by the symbol c is determined (2 ≤ c ≤ n) and a value is also determined for the weighting parameter of m′. This parameter plays a key role in the clustering process’s fuzziness. Then, a primary partitioning matrix of U(0) is calculated, which will be updated per iteration of the algorithm. Each algorithm’s iteration is determined with an r value where r = 0, 1, 2, 3 and …

In the next step, the centroid of clusters, {Vi(r)}, is calculated per iteration.

Using Eqs. (6)–(10), the partition matrix for the rth iteration will be updated as U (r). μ (r+1) ik is the degree of membership of the kth data in the ith cluster for the algorithm’s (r + 1) th iteration in the third step. dik represents the Euclidean distance between kth data and ith cluster center. In Eq. (6), φ indicates the equation hardness.

In the last step, the clustering’s precision level is controlled by Eq. (11), where ε L is the precision level, i.e., calculations have reached the desired precision level of ε L and clustering has led to a proper optimization, and therefore, the calculations end here. Otherwise, we should return to the second step and repeat the calculations. This loop is repeated until the desired precision level is obtained. Due to the complexity and heavy calculations and the risk of error in manual computations, a MATLAB code is used for calculations.

4 Studied quarries

Iran is among the countries that possess great potentials and capabilities in the production of dimension stones. There is a wide range of sedimentary, igneous and metamorphic dimension stone resources in Iran. Due to the high quality, beautiful color and texture of dimension stones of Iran, these resources are distinguished and superior as compared their compared to their counterparts from other parts of the word, and in some cases, they are one of a kind in market. Therefore, the dimension stones industry can be accounted as a strong point of mining sector from different aspects such as exploitation, domestic production, export and foreign exchange revenue. The exploitable dimension stone deposits of Iran can be summarized as travertine about 59 million tons, marble about 500 million tons and granite about 60 million tons [38]. In this paper, 12 quarries with famous dimension stones as follows: Red Granite (A1), Black Granite (A2), White Granite (A3), Chocolate Granite Khoramdeh (A4), Pearl Granite (A5), Cream Marble Harsin (A6), Pink Marble Anarak (A7), Red Travertine (A8), Travertine Hajiabad (A9), Travertine Darebokhari (A10), Marble Salsali (A11) and Pink Marble Haftoman (A12) are considered and studied. The location, geological and discontinuities of studied quarries are given in Fig. 2 and Table 2. The samples of stones which have been studied were collected from these mines and transferred to laboratory.

5 Laboratory studies

For laboratory tests, sample blocks were collected from the studied quarries. Standard tests were done to measure the four major of physical and mechanical properties of rock were chosen for assessing the sawability of dimension stone. These parameters are listed as follows:

-

(a)

Schmiazek abrasivity factor (SF-a)

-

(b)

Uniaxial compressive strength (UCS)

-

(c)

Mohs hardness (MH)

-

(d)

Young’s modulus (YM)

The reasons of the selections of these parameters are given below.

5.1 Schmiazek F-abrasivity factor (SF-a)

Abrasiveness influences the wear of sawing tools. Abrasiveness is mainly affected by various factors such as mineral composition, the hardness of mineral constituents and grain size, grain shape and grain angularity [39]. Schimazek’s F-abrasiveness factor is the most common factor for evaluation of rock abrasivity. It is depended on textural and mechanical properties. The Schimazek’s F-abrasiveness factor is defined as

where F is the Schimazek’s wear factor (N/mm), EQC is the equivalent quartz content percentage, Gs is the median grain size (mm) and BTS is the indirect Brazilian tensile strength.

The Schimazek’s F-abrasiveness factor was selected as an abrasiveness index of rock in clustering system. The results of laboratory studies to determine this index are given in Table 3.

5.2 Uniaxial compressive strength (UCS)

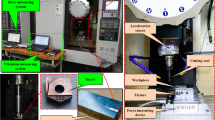

Uniaxial compressive strength is an important mechanical parameter to present the engineering property of rock. Rock material strength is used as an important parameter in many rock mass classification systems [40]. Uniaxial compressive strength test can be considered as characteristic of rock strength, density, weathering, texture and matrix type. Therefore, using this parameter in this study to predict the sawability of dimension stone is necessary. To determine the uniaxial compressive strength of studied dimension stones, the 5 standard NX core samples with a length-to-diameter ratio of 2.5:1 were taken using a diamond rotating drill from block sample. A circular diamond saw blade was used to cut the specimens to their final lengths. After that, the surfaces of specimens were grinded using a grinding machine to achieve a high-quality surface for the axial loading. The mechanical tests were carried out by a servo-controlled testing machine designed for rock test. The standard uniaxial compressive strength test of core samples was carried out under a loading rate of 1 MPa/s [41]. Finally, the average uniaxial compressive strength was calculated for each studied dimension stones. The results are given in Table 4.

5.3 Mohs hardness scale (MH)

Hardness can be defined as the rock’s resistance to fracture or plastic deformation due to scratching and cracking from circular diamond saw. The factors that affect rock hardness are the hardness of the constitutive minerals, cohesion forces, homogeneity and the water content of rock [42]. Hardness is a good index of all above given parameters of rock material. Mohs hardness scale is the common and useful index to evaluate the hardness of rock. It was selected as hardness index in the clustering system. The mean hardness of each dimension stone is calculated based on the hardness of contained minerals using the following equation:

where M i is mineral amount (%), Hi is Mohs hardness and n is the total number of minerals in the dimension stone. The mean Mohs hardness of each studied dimension stone is given in Table 4.

5.4 Young’s modulus (YM)

According to rock behavior during the fracture process, especially in sawing, the way that rocks reach the failure point has a great influence on sawability. The best scale for rock elasticity is Young’s modulus. Based on ISRM suggested methods [41], the tangent Young’s modulus at a stress level equal to 50 % of the ultimate uniaxial compressive strength is used in this clustering system. The results are given in Table 4.

Then, the pseudo-code must be written for the fitness function and the other parts of the algorithm in MATLAB. Afterward, for more evaluation and data analysis the samples are evaluated in 2, 3, 4 and 5 clusters. The results of classification were not agreeable with properties of the studied dimension stones for 2, 4 and 5 clusters. The lowest and the most appropriate cost function achieved for 3 clusters.

6 Application of imperialist competitive algorithm in dimension stone sawability prediction

One of the most impressive applications of ICA is data clustering of information. The objective function is one of the most significant parts in meta-heuristic algorithms. In fact, the fitness function of an optimization problem is to maximize the distance of cluster centers from each other and to minimize distance among members of a cluster. The Lloyd’s algorithm (k-means clustering) is the fitness function in imperialist competitive algorithm. It shows in Eq. (14):

In fact, for the optimization of data clustering, Lloyd’s algorithm (k-means clustering) is used based on the imperialist competitive algorithm in this research and the main results of optimization obtained from ICA.

6.1 Data clustering by 3 clusters

In data mining for the total sample dimension stones, the considered limits in the clustering are maximum iteration of 150, minimum acceptance precision of ε L = 0.0001 and 75 population as initial population for ICA. The Lloyd’s algorithm conducted an optimization as the fitness function and found to maximize the distance of cluster centers from each other and to minimize distance among samples of a cluster based on the considered limits of ICA and four important physical and mechanical properties of samples. The algorithm process stops after the calculations. For fuzzy C-mean, considered limits in the clustering are maximum iteration of 100, minimum acceptance precision of εL = 0.00001 and the weighting parameter of m′ = 2. Distance of clusters’ centers from criteria and classification of samples for each method are given in Tables 5 and 6, respectively.

Table 7 represents the difference between the results of step 120 and 121 in which it is less than the minimum acceptance precision of 0.0001 and this process is fixed from 121th to 150th iteration; therefore, the computing stops at the 200th iteration for ICA. Furthermore, as listed in Table 7, the difference between the results of stages 47 and 48 is less than the minimum acceptance precision of 0.00001; therefore, the calculations stop at the 17th iteration.

Figure 3 shows data clustering based on 3 clusters, and Fig. 4 shows minimum cost per iteration in which the 121th iteration is reached to the optimal point.

7 Validation of results

Validation of results is an important phase of search. For validation of the applied algorithm and its results, field studies were carried out. The production rate of each studied dimension stones was used as a criterion for evaluating and validating the results. For this purpose, some stone factories in Shamsabad located in Tehran were selected, and the performance of the diamond circular saw was measured in term of hourly production rates (P h). The production rate and sawability classification of the studied dimension stones are given in Table 8.

According to Table 5, the applied algorithm is almost able to classify the studied dimension stone into two geological groups based on physical and mechanical properties. The first group (Class 1) is hard dimension stone and the second group (Class 3) is soft dimension stone such as marble and travertine. In addition, the applied algorithm can be used to predict and classify the dimension stone sawability or the performance of circular diamond saw. The sawability of studied dimension stones was classified into two major groups. The first group (Class 1) has a poor sawability with a P h less than 6.5 m2/h, and the second group (Class 3) has a good sawability with a P h greater than 8.5 m2/h. The results show the capability of the imperialist competitive algorithm (ICA) and fuzzy clustering technique for solving optimal classification in stone industry.

8 Conclusion

The circular saw machine is one of the most important machines used in the stone processing factories. The performance prediction of circular diamond saw blade is very important in the cost estimation and the planning of the factories. In this paper, it was aim to evaluate and classify the dimension stone by imperialist competitive algorithm and fuzzy C-mean based on some important physical and mechanical properties of dimension stone. To achieve this goal, two groups of Iranian famous dimension stones were studied. The studied dimension stones were classified by applied algorithms, and the classification results were validated by the performance of the diamond circular saw was measured in term of hourly production rates (P h) at some stone factories in Shamsabad. According to the results of this study, the applied algorithms were almost able to classify the studied dimension stones into two geological groups such as hard dimension stone (Class 1) and soft dimension stone (Class 3). Moreover, the sawability results of studied dimension stones confirm the capability of applied algorithm. The first class has a poor sawability, and the third class 3 has a good sawability. The results of ICA algorithm showed that the identified samples are similar to that obtained from fuzzy C-mean. In addition, based on optimal and comparative results and prediction of the dimension stone sawability, ICA and fuzzy C-mean make it possible to evaluate the hurly production rate of circular diamond saw although ICA is superior to fuzzy C-mean based on the results of optimum partition. Finally, the results showed that the sawability of dimension stone can reliably be classified from some important physical and mechanical properties of dimension stone such as uniaxial compressive strength, Schmiazek F-abrasivity, Mohs hardness scale and Young’s modulus by using imperialist competitive algorithm and fuzzy clustering technique.

References

Buyuksagis IS, Goktan RM (2005) Investigation of marble machining performance using an instrumented block-cutter. J Mater Process Technol 169:258–262

Ersoy A, Buyuksagis S, Atici U (2005) Wear characteristics of circular diamond saws in the cutting of different hard and abrasive rocks. Wear 258:1422–1436

Delgado NS, Rodriguez R, Rio A, Sarria ID, Calleja L, Argandona VGR (2005) The influence of microhardness on the sawability of Pink Porrino granite (Spain). Int J Rock Mech Min Sci 42:161–166

Kahraman S, Altun H, Tezekici BS, Fener M (2005) Sawability prediction of carbonate rocks from shear strength parameters using artificial neural networks. Int J Rock Mech Min Sci 43(1):157–164

Fener M, Kahraman S, Ozder MO (2007) Performance prediction of circular diamond saws from mechanical rock properties in cutting carbonate rocks. Rock Mech Rock Eng 40(5):505–517

Kahraman S, Ulker U, Delibalta S (2007) A quality classification of building stones from P-wave velocity and its application to stone cutting with gang saws. J South Afr Inst Min Metal 107:427–430

Özçelik Y (2007) The effect of marble textural characteristics on the sawing efficiency of diamond segmented frame saws. Ind Diam Rev 2:65–70

Tutmez B, Kahraman S, Gunaydin O (2007) Multifactorial fuzzy approach to the sawability classification of building stones. Constr Build Mater 21:1672–1679

Buyuksagis IS (2007) Effect of cutting mode on the sawability of granites using segmented circular diamond sawblade. J Mater Process Technol 183:399–406

Mikaeil R, Ataei M, Hoseinie SH (2008) Predicting the production rate of diamond wire saws in carbonate rocks cutting. Ind Diam Rev 3:28–34

Mikaiel R, Ataei M, Yousefi R (2011) Application of a fuzzy analytical hierarchy process to the prediction of vibration during rock sawing. Min Sci Technol (China) 21:611–619

Mikaeil R, Yousefi R, Ataei M, Abbasian R (2011) Development of a new classification system for assessing of carbonate rock sawability. Arch Min Sci 56(1):57–68

Ataei M, Mikaiel R, Sereshki F, Ghaysari N (2011) Predicting the production rate of diamond wire saw using statistical analysis. Arab J Geosci 5:1289–1295

Mikaiel R, Ataei M, Yousefi R (2011) Correlation of production rate of dimension stone with rock brittleness indexes. Arab J Geosci 6:115–121

Mikaeil R, Yousefi R, Ataei M (2011) Sawability ranking of carbonate rock using fuzzy analytical hierarchy process and TOPSIS approaches. Sci Iran Trans B Mech Eng 18:1106–1115

Mikaeil R, Ataei M, Yousefi R (2011) Evaluating the power consumption in carbonate rock sawing process by using FDAHP and TOPSIS techniques, efficient decision support systems: practice and challenges—from current to future/Book 2, ISBN 978-953-307-441-2, p 478

Mikaeil R, Ozcelik Y, Ataei M, Yousefi R (2011) Correlation of specific ampere draw with rock brittleness indexes in rock sawing process. Arch Min Sci 56(4):741–752

Ataei M, Mikaeil R, Hoseinie SH, Hosseini SM (2012) Fuzzy analytical hierarchy process approach for ranking the sawability of carbonate rock. Int J Rock Mech Min Sci 50:83–93

Ghaysari N, Ataei M, Sereshki F, Mikaiel R (2012) Prediction of performance of diamond wire saw with respect to texture characterestic of rock. Arch Min Sci 57(4):887–900

Mikaeil R, Ozcelik Y, Ataei M, Yousefi R (2013) Ranking the sawability of dimension stone using Fuzzy Delphi and multi-criteria decision-making techniques. Int J Rock Mech Min Sci 58:118–126

Sadegheslam G, Mikaeil R, Rooki R, Ghadernejad S, Ataei M (2013) Predicting the production rate of diamond wire saws using multiple nonlinear regression analysis. Geosyst Eng 16(4):275–285

Mikaeil R, Ataei M, Ghadernejad S, Sadegheslam G (2014) Predicting the relationship between system vibration with rock brittleness indexes in rock sawing process. Arch Min Sci 59–1:139–153

Mikaeil R, Abdollahi Kamran M, Sadegheslam G, Ataei M (2015) Ranking sawability of dimension stone using PROMETHEE method. J Min Environ 6(2):263–271

Das SK, Basudhar PK (2009) Utilization of self-organizing map and fuzzy clustering for site characterization using piezocone data. Comput Geotech 36(1):241–248

Holland JH (1975) Adaptation in natural and artificial system: an introduction with application to biology, control and artificial intelligence. University of Michigan Press, Ann Arbor

Eberhart RC, Kennedy J (1995) A new optimizer using particle swarm theory. In: Proceedings of the sixth international symposium on micro machine and human science, vol 1, pp 39–43

Yang XS (2010) A new metaheuristic bat-inspired algorithm. In González JR, Pelta DA, Cruz C, Terrazas G, Krasnogor N (eds) Nature inspired cooperative strategies for optimization (NICSO 2010). Springer, Berlin, Heidelberg, pp 65–74. doi:10.1007/978-3-642-12538-6_63

Hammer PL, Rudeanu S (2012) Boolean methods in operations research and related areas, vol 7. Springer

Atashpaz-Gargari E, Lucas C (2007) Imperialist competitive algorithm: an algorithm for optimization inspired by imperialistic competition. In: IEEE congress on evolutionary computation, 2007. CEC 2007, pp 4661–4667

Xu S, Wang Y, Huang A (2014) Application of imperialist competitive algorithm on solving the traveling salesman problem. Algorithms 7(2):229–242

Shabani H, Vahidi B, Ebrahimpour M (2013) A robust PID controller based on imperialist competitive algorithm for load-frequency control of power systems. ISA Trans 52(1):88–95

Mokhtari G, Ghanizadeh AJ, Ebrahimi E (2012) Application of imperialist competitive algorithm to solve constrained economic dispatch. Int J Electr Eng Inf 4(4):553–562

Kaveh A, Talatahari S (2010) Imperialist competitive algorithm for engineering design problems. Asian J Civil Eng 11(6):675–697

Rad MY, Haghshenas SS, Haghshenas SS (2014) Mechanostratigraphy of cretaceous rocks by fuzzy logic in East Arak, Iran. In: Proceedings of 4th international workshop on computer science and engineering, Dubai, (Summer 2014), pp 45–51

Gargari A(2007)The development of optimization algorithm social and review of performance. Master thesis, Faculty of Electrical Engineering and by computer, Tehran University, Iran

Bezdek JC, Ehrlich R, Full W (1984) FCM: the fuzzy c-means clustering algorithm. Comput Geosci 10(2):191–203

Rad MY, Haghshenas SS, Kanafi PR, Haghshenas SS (2012) Analysis of protection of body slope in the rockfill reservoir dams on the basis of fuzzy logic. In IJCCI, pp 367–373

Ghorbani M (2013) the economic geology of Iran: mineral deposits and natural resources. Springer, London

Ersoy A, Waller MD (1995) Textural characterization of rocks. J Eng Geol 39(3–4):123–136

Bieniawski ZT (1989) Engineering rock mass classifications. Wiley, New York

Brown ET (1981) Rock characterization, testing & monitoring: ISRM suggested methods. Published for the Commission on Testing Methods, International Society for Rock Mechanics by Pergamon Press

Hoseinie SH, Ataei M, Osanloo M (2009) A new classification system for evaluating rock penetrability. Int J Rock Mech Min Sci 46:1329–1340

Acknowledgments

We would like to express our deepest thanks to Professor Mahdi Ghaem for his excellent advice. We are also grateful to anonymous reviewers for their advices and contributions to this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mikaeil, R., Haghshenas, S.S., Haghshenas, S.S. et al. Performance prediction of circular saw machine using imperialist competitive algorithm and fuzzy clustering technique. Neural Comput & Applic 29, 283–292 (2018). https://doi.org/10.1007/s00521-016-2557-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-016-2557-4